Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110 results about "Zinc chromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc chromate, ZnCrO₄, is a chemical compound containing the chromate anion, appearing as odorless yellow powder or yellow-green crystals, but, when used for coatings, pigments are often added. It is used industrially in chromate conversion coatings, having been developed by the Ford Motor Company in the 1920s.

Surface treated copper film

InactiveUS7651783B2Improve acid resistanceHigh bonding strengthInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentElectrolysisHeat resistance

A surface treated copper foil with improved adhesion to the insulating resin of a copper-clad laminate for higher frequency applications contains a copper foil provided with a heat-resistant layer and an olefin-based silane coupling agent layer sequentially on at least one side thereof. An anticorrosive treatment may be performed after the heat resistance treatment. The copper foil is preferably an electrolytic copper foil, and these layers can be provided on the S side and / or the M side thereof. The copper foil has an adequate adhesive strength, even without the roughening treatment that has been performed in the past. A film of zinc, zinc-tin, zinc-nickel, zinc-cobalt, copper-zinc, copper-nickel-cobalt, or nickel-cobalt can be used favorably as the heat-resistant layer, and a film that has undergone a zinc-chromate or a chromate treatment can be used favorably as the anticorrosive layer.

Owner:JX NIPPON MINING& METALS CORP

Corrosion-Resistant Epoxy Nanocomposite Coatings containing Submicron Emeraldine-Base Polyaniline and Organomodified Montmorrilonite

InactiveUS20100010119A1Good dispersionImprove barrier propertiesMaterial nanotechnologyLayered productsEpoxySalt spray test

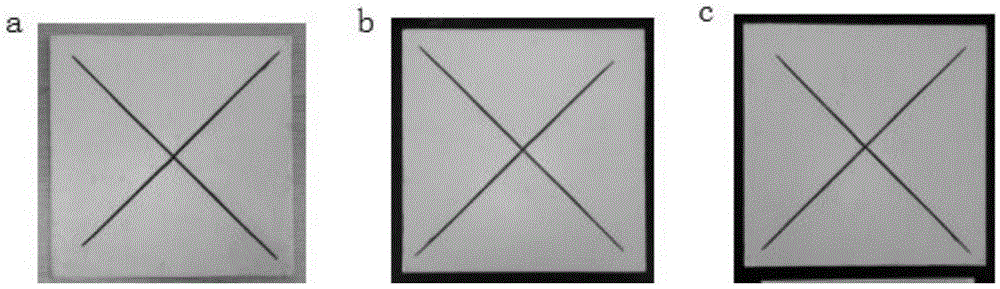

Disclosed is a method of preparation of corrosion-resistant epoxy coatings. The coating composition contains two main corrosion resistant factors: The first one was Eemeraldine-Base polyaniline (EB-PANi), dissolved in the aminic hardener of epoxy. The other one was montmorrilonite clay, dispersed or exfoliated in the base component of epoxy resin. The hardener composition was prepared via dissolution of EB-PANi in functional amines like 3-(aminomethyl)-3,5,5-trimethylcyclohexan-1-amine adopting sonication and nanoscale filtering methods. The base component was prepared via gradual charging of MMT clay in epoxy resin via high-shear mixing plus sonication method. The morphology of the coatings during different stages of preparation was studied by optical microscopy and scanning electron microscopy and TEM. The corrosion-protective performance of the resultant coatings was evaluated by electrochemical impedance spectroscopy and salt spray tests. The results were compared with those of conventional epoxy zinc-chromate and neat resin coatings. Superior corrosion resistance was achieved via dissolution of 0.5-2.5 wt % of EB-PANi in the aminic hardener and 2-4 WT % of organomodified MMT in base component of coating.

Owner:ZAAREI DAVOOD +4

Graphene anti-corrosion paint

ActiveCN106479313AImprove stabilityMaximum corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

The invention discloses a graphene anti-corrosion paint. The paint comprises, by weight, 76-87 parts of DER671 type Dow solid epoxy resin, 22-25 parts of 582 type melamine formaldehyde resin, 27-28 parts of stearalkonium hectorite, 6-7 parts of hydroxy-1-propenylboronic acid pinacol ester, 0.5-0.7 part of oxidative modified graphene precursor, 1-3 parts of gamma-amino propyl triethoxy silane, 5-7 parts of nanoscale titanium dioxide, 3-5 parts of Y-311SN type blocked isocyanate curing agent, 12-15 parts of calcined kaolin, 2-3 parts of zinc chromate, 32-35 parts of solvent, and 0.2-0.4 part of paraformaldehyde. The method uses the second time oxidative modification of the graphene to increase the graphene stability, thus benefiting the maximum exertion of the inherent anti-corrosion performance of the graphene, making the prepared paint have excellent adhesive force, hardness, anti-wear ability and resistance to the corrosion caused by neutral salt mist.

Owner:常州市大使涂料有限公司

Polyaniline/attapulgite nano-material antirust primer and preparation method thereof

ActiveCN102816496AImprove rust resistanceEliminate hazardsAnti-corrosive paintsEpoxy resin coatingsEpoxyHazardous substance

The invention discloses a polyaniline / attapulgite nano-material antirust primer and a preparation method thereof. The polyaniline / attapulgite nano-material antirust primer comprises component A and component B, wherein the component A is composed of a modified epoxy resin, low molecular modified amine, a polyaniline / attapulgite nano-material, a pigment, a filling material, a coupling agent and a viscosity modifier, and the component B is a modified epoxy resin. The preparation method comprises the following steps: (1) preparation of the component A; (2) preparation of the component B; and (3) uniform mixing of the component A and the component B according to a certain weight ratio. According to the invention, the polyaniline / attapulgite nano-material, a novel organic antirust pigment, is used to replace heavy metal-containing antirust pigments like red lead powder and zinc chromate, and low molecular modified amine and a proper amount of the modified epoxy resin are combinedly used to produce a low molecular modified amine adduct; thus, the antirust primer prepared in the invention does not contain poisonous and harmful substances like heavy metals and volatile organic compounds and has the characteristics of no toxicity, environmental protection and excellent antirust performance.

Owner:CHANGZHOU GUANGHUI CHEM

Functional composite coating and preparing method thereof

ActiveCN105623341AOn-site construction is simpleImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyFluoropolymer

Owner:CHANGCHUN A&Z SCI CO LTD

Degradable plastic and method for preparing same

The invention discloses a degradable plastic. The degradable plastic is made of, by weight, 60-65 parts of starch, 50-55 parts of polycaprolactone, 70-75 parts of poly butylenes succinate, 75-80 parts of polyhydroxyalkanoate, 20-30 parts of polyvinyl alcohol, 4-6 parts of chitin, 7-15 parts of polyaspartate acid, 15-20 parts of celluloses, 10-15 parts of polypropylene, 13-16 parts of phenolic resin, 2-4 parts of diatomaceous earth, 20-30 parts of asbestos, 15-20 parts of carbon black, 8-10 parts of phthalate, 35-40 parts of silicone rubber, 12-14 parts of diisononyl phthalate, 5-8 parts of zinc chromate and 12-16 parts of organic tin. The degradable plastic has the advantages that the degradable plastic is good in thermoplastic property and can be sufficiently degraded, and good anti-aging effects can be realized.

Owner:WUHU TIANXIONG NEW MATERIAL TECH

Mildew-proof wear-resistant asphalt paint and preparation method thereof

InactiveCN104293069AGood weather resistanceImprove wear resistanceAntifouling/underwater paintsPaints with biocidesXylyleneTitanium isopropoxide

The invention discloses mildew-proof wear-resistant asphalt paint which is characterized by being prepared from the following raw materials in parts by weight: 17-23 parts of E-22 epoxy resins, 6-9 parts of benzyl transparent silicon resins, 8-11 parts of polyether acrylate, 4-7 parts of tetraethylenepentamine, 3-5 parts of tricresyl phosphate, 1-3 parts of nano bamboo fibers, 2-4 parts of zinc chromate, 37-43 parts of modified asphalt, 5-7 parts of modified waste resin sand, 1-2 parts of ammonium bromide, 2-4 parts of fungacetin, 3-4 parts of catechinic acid, 4-6 parts of epoxy linseed oil, 8-11 parts of amyl acetate, 6-9 parts of xylene, 5-7 parts of glycol, 1-2 parts of tri(dioctylphosphoryloxy) titanium isopropoxide and 2-4 parts of powdered aluminum. The mildew-proof wear-resistant asphalt paint is prepared by adding the epoxy resins on the basis of the modified asphalt, so that the characteristics of high corrosion resistance, weather fastness, waterproofness and thermal stability of the pain are ensured; the added tricresyl phosphate has the characteristics of favorable wear resistance, weather fastness, mildew resistance and radiation resistance; and the added modified waste resin sand has favorable fire resistance, antifouling property and anti-ageing property, so that the quality of the paint is improved and the waste is recycled to solve the problem of environment pollution.

Owner:TIANCHANG YINHU PAINT

High-performance alloy-matrix anticorrosive paint and preparation method thereof

ActiveCN105176328ADesign scienceReasonable combinationAnti-corrosive paintsEpoxy resin coatingsPolyvinyl alcoholKaolin clay

The invention belongs to the anticorrosive technical field, and particularly relates to high-performance alloy-matrix anticorrosive paint and a preparation method thereof. The high-performance alloy-matrix anticorrosive paint is prepared from, by weight, 10-20 parts of modified attapulgite, 15-25 parts of China wood oil, 5-8 parts of modified bentonite, 9-12 parts of modified zeolite powder, 6-15 parts of metakaolin, 2-4 parts of quick lime, 8-12 parts of pumice sand, 20-30 parts of epoxy acrylate, 3-5 parts of polyisobutene, 1-3 parts of polyvinyl alcohol, 9-15 parts of modified nano-active carbon and 2-4 parts of zinc chromate. The high-performance alloy-matrix anticorrosive paint is excellent in performance and long in valid period and can be applied to equipment corrosion prevention on the aerial, marine and other extremely severe environment conditions.

Owner:烟台鲁迈防水防腐材料有限公司

High-performance anticorrosive paint and preparation method thereof

InactiveCN105153936ADesign scienceReasonable combinationAnti-corrosive paintsActivated carbonPolyvinyl alcohol

The invention belongs to the field of paint, and particularly relates to a high-performance anticorrosive paint and a preparation method thereof. The anticorrosive paint is prepared from, by weight, 25-32 parts of modified nanometer activated carbon, 18-25 parts of white oil, 15-21 parts of modified zeolite powder, 1-2 parts of hydrogenated castor oil, 6-10 parts of modified attapulgite, 5-8 parts of pumice sand, 2-4 parts of polyisobutene, 4-6 parts of modified bentonite, 3-5 parts of polyvinyl alcohol and 3-4 parts of zinc chromate. The high-performance anticorrosive paint is excellent in anticorrosion performance and long in valid period and can be applied to device anticorrosion in aviation, marine and other extremely severe environments.

Owner:江西省高精科技有限公司

Anticorrosive paint containing acrylic emulsion

The invention discloses anticorrosive paint containing an acrylic emulsion. The anticorrosive paint comprises components in parts by mass as follows: 650 parts of the acrylic emulsion, 12 parts of butyl acrylate, 58 parts of tetrabasic zinc chromate, 32 parts of iron oxide red, 30 parts of talcum powder, 42 parts of calcium phosphate, 0.1 part of an emulsifier, 0.1 part of an organic silicon defoamer, 62 parts of deionized water, 10 parts of a 4% carboxymethyl cellulose solution, 5 parts of glycol butyraldehyde, 11 parts of potassium tripolyphosphate and 0.2 part of a sodium nitrite compound corrosion inhibitor. The anticorrosive paint has high salt water resistance and corrosion resistance, and a paint film has strong adhesive force and is tough and firm; the raw materials are easy to obtain, the production is simple, and the cost is low; the paint can be matched with various finishing coats, takes water as a solvent, is nontoxic, incombustible and explosion-proof, has little environmental pollution and can be produced widely and replace conventional materials; and the paint is convenient to store and transport and facilitates construction and coating, and is safe and reliable.

Owner:JIANGSU PACIFIC HYDRAULIC MACHINERY MFGCO

Anticorrosive paint for stainless steel decorating plate and preparation method of anticorrosive paint

InactiveCN104877483AImprove protectionImprove rust resistanceCoatingsPolyvinyl alcoholDiethyltoluene diamine

The invention relates to anticorrosive paint for a stainless steel decorating plate and a preparation method of the anticorrosive paint. The anticorrosive paint comprises the following components in parts by mass: 33-34 parts of white latex, 2-10 parts of iron oxide red, 1-4 parts of chromium oxide green, 0.3-1.5 parts of mica magnesium oxide, 5-15 parts of aluminum triphosphate, 2-8 parts of zinc chromate, 1-7 parts of polyvinyl acetal, 0.8-4 parts of zinc oxide, 6-18 parts of zirconia, 1-5 parts of cobalt naphthenate, 0.5-1.8 parts of polyvinyl siloxane, 0.7-2.2 parts of tripropylene glycol diacrylate, 0.1-0.6 part of diethyl methyl benzene diamine, 1-5 parts of sodium nitrite, 0.3-1.6 parts of phenolic resin and 12-24 parts of purified water. The anticorrosive paint has not only an excellent anticorrosive function, but also the properties of relatively high impact resistance, flexibility, hardness, water resistance and the like.

Owner:SUZHOU DEXIANG DECORATION ENG

Anti-corrosion coating glue

The invention discloses anti-corrosion coating glue which includes, by weight, 50 parts of polyvinyl acetate, 65 parts of zinc chromate, 6 parts of ferric yellow, 90 parts of butyl acrylate, 15 parts of dimethyl phthalate, 8 parts of acetic acid, 2 parts of sodium acetate, 12 parts of trisodium phosphate, 3 parts of methyl methacrylate, 10 parts of ammonium acrylate, 9 parts of isopropyl acrylate, 14 parts of butyl acetate, 6 parts of ammonium persulfate, 3 parts of glycerol, and 5 parts of urea. The anti-corrosion coating glue is easy to prepare, is not toxic and harmful by means of the raw materials, has good use effects, is environment-friendly and is good in use effects of a coated glue layer.

Owner:张娟

Spraying coating process for preventing interphase short circuit of reactor

ActiveCN101814365AAvoid short circuitRealize full insulationPretreated surfacesInductances/transformers/magnets manufactureTransformerSpray coating

The invention discloses a spraying coating process for preventing the interphase short circuit of a reactor. The invention has the technical scheme that the process comprises the following steps: firstly, carrying out conventional trimming work procedure on the reactor; spraying zinc chromate primer and polyurethane ash paint; then, carrying out grinding and cleaning; completely covering a coil and a wiring teminal of the reactor; using a special spray gun for carrying out spraying coating on the exposed metal part of the reactor under the condition of the pressure of 0.6 + / - 0.1 MPa; carrying out secondary spraying coating after the primary spraying coating is completed and the glue liquid surface is vulcanized; and carrying out repeated spraying coating until the coating layer thickness reaches 2.5 + / - 0.5 mm. At the same time, brushing coating enhancing treatment is carried out at corner angles and turning corners with relatively thin spraying coating thickness. The reactor carrying out the spraying coating by the process can effectively avoid the interphase short circuit accidents caused by bird and beast climbing. The invention can be used for the production of the reactor, and can also be used for reforming the reactors operating in a transformer station, the reformation can be completed without large-scale equipment such as a crane and the like, in addition, the operation is convenient, and the implementation is easy.

Owner:陕西合容电力设备有限公司 +1

Paint for aircraft stealth and preparation method thereof

InactiveCN106700880AStrong adhesionGood electromagnetic parametersAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedIsophorone diisocyanate

The invention discloses paint for aircraft stealth and a preparation method thereof. The paint is prepared from the following raw materials: hydroxylated acrylic resin, polyurethane, water-based acrylic resin, nickel powder, isophorone diisocyanate, zinc powder, triethanolamine, zinc chromate, triethylamine, ammonia water, zinc oxide, zirconium oxide, iron oxide red and a thickening agent; the paint can be used for resisting ultrahigh-frequency and high-strength radar detection and has good electromagnetic parameters; the density of a coating is 0.1g / cm<3>-0.5g / m<3>; the electric conductivity is 0.01W / m.k-0.016W / m.k, and the heat insulation performance is good; the surface is dried at 25 DEG C after 10min-50min, and the paint is completely dried after 4h-8h; a coated film is flat and smooth and has the effects of resisting humidity, atmosphere, acid rain, seawater and salt-fog corrosion; the rigidity is 6H-10H; and the paint has high adhesion force, impact resistance and good abrasion, can be widely produced and can continuously replace an existing material.

Owner:江苏悠谷未来科技有限公司

Aluminum and aluminum alloy passivation solution, preparation method and using method thereof

ActiveCN104451634AAvoid the problem of poor corrosion resistanceQuality improvementMetallic material coating processesChromate saltSodium fluoride

The invention provides an aluminum and aluminum alloy passivation solution, preparation method and using method thereof; the raw material ratios of the passivation solution are as follows: 3-5g / L of zinc chromate, 0.5-1g / L of cobaltous sulfate, 2-3g / L of zirconium sulfate, 0.5-1.5g / L of sodium fluoride, 2-4g / L of nitric acid, 1-2g / L of citric acid, and the rest amount is water. A passivation working solution (bath solution) which is prepared by diluting the passivation solution is stable, low concentration, fast in passivation speed, low void ratio of the obtained passivation film, is able to form a yellow chromate film layer on surface of the aluminum product, has an excellent anti-corrosion property, and is able to greatly increase the paint or coating layer adhesive force on the work piece. The property of the formed passivation film for resisting neutral salt mist is more than 120 hours.

Owner:HUNAN JINYU CHEM

Heat-resisting modified wire enamel and preparation method thereof

InactiveCN107177306AHigh solidsLow viscosityFireproof paintsInsulatorsToluene diisocyanateFirming agent

The invention discloses heat-resisting modified wire enamel and a preparation method thereof. The wire enamel comprises the following raw materials in parts by weight: 80-120 parts of poly-methyl phenyl organic silicon resin, 20-40 parts of phenolic resin, 5-15 parts of tetrabasic zinc chromate, 3-8 parts of diethanol amine, 5-10 parts of toluene diisocynate, 2-10 parts of a thermal stabilizer, 3-8 parts of a dryer, 5-12 parts of a curing agent, 3-6 parts of a colorant, 10-20 parts of acetonitrile and 40-60 parts of alcohol solvents. The preparation method comprises the steps of modifying, mixing, reacting and curing. The wire enamel disclosed by the invention is heat-resisting and anti-flaming, has the characteristics of high solid content and low viscosity, and is capable of reducing the dosage of the solvents and reducing the pollution. According to the preparation method, the energy consumption is saved and the cost is lowered.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

Preparation process of insulating resin for completely sealed bus duct

The invention discloses a preparation process of insulating resin for a completely sealed bus duct. The process comprises the following steps: (1) putting 5-15 parts of acrylic resin into a container, adding 10-20 parts of a mixed solvent, and stirring and dispersing for 30-40 minutes at the rotation speed of 4000-6000r / minute, thereby obtaining primary emulsion; (2) adding 2-8 parts of zinc chromate, 1-5 parts of zinc chloride, 2-6 parts of mica powder and 1-5 parts of pigment into the primary emulsion, and stirring and dispersing for 20-30 minutes at the rotation speed of 3600-4200r / minute, thereby obtaining a sizing agent; (3) mixing epoxy powder with benzophenone tricarboxylic acid anhydride, further adding 10-20 parts of the mixed solvent to mix with first inorganic packing, second inorganic packing, third inorganic packing and the sizing agent, and stirring and dispersing for 10-20 minutes at the rotation speed of 0-1200r / minute; and (4) adding 5-10 parts of organosilicone polyether polyol, 1-5 parts of ethylidene bioctadecanamide, 5-10 parts of crylic acid resin and 10-15 parts of polyamide resin into the mixed liquid, and stirring and dispersing for 10-20 minutes at the rotation speed of 600-1100r / minute, thereby obtaining the insulating resin for the completely sealed bus duct.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

Cooling coating special for lost foam casting and preparation method of cooling coating

ActiveCN105234344ADesign scienceReasonable combinationFoundry mouldsFoundry coresPolyvinyl alcoholKaolin clay

The invention belongs to the technical field of casting, and particularly relates to a cooling coating special for lost foam casting and a preparing method of the cooling coating. The cooling coating is prepared from, by weight, 20-30 parts of modified zircon powder, 9-12 parts of modified zeolite powder, 12-15 parts of modified attapulgite, 2-4 parts of modified bentonite, 18-21 parts of white oil, 7-15 parts of pumice sand, 6-8 parts of metakaolin, 2-4 parts of quick lime, 1-3 parts of polyisobutene, 1-3 parts of polyving akohol and 2-4 parts of zinc chromate. The cooling coating is good in invasion and painting performance and moderate in high-temperature permeability, especially, the heat transferring speed is high, the outer surface of the part, with slow cooling, of a lost foam body is coated with the cooling coating so that the cooling speed of molten metal in the remaining position can be increased, the temperature of a casting is reduced in a uniform manner, and the reject ratio of products is reduced obviously.

Owner:GAOYAO HONGXING PRECISION CASTING

Phosphating solution for aluminum product surface treatment

InactiveCN104357824AImprove adsorption capacityImprove the lubrication effectMetallic material coating processesPhosphateWater insoluble

The invention discloses a phosphating solution for aluminum product surface treatment. The phosphating solution is prepared from the following raw materials in parts by weight: 32-36 parts of 60-65% phosphoric acid, 10-12 parts of oxalic acid, 5-8 parts of crylic acid, 2-9 parts of hydrofluoric acid, 4-8 parts of zinc dihydrogen phosphate, 1.2-3.2 parts of ammonium molybdate, 2.5-3.5 parts of chromium sulfate, 0.2-1.4 parts of nickel nitrate, 0.6-1.2 parts of cobalt naphthenate, 1.5-2.8 parts of tetrabasic zinc chromate, 4.5-6.5 parts of an antifoaming agent, 0.5-1.2 parts of a dispersing agent and 35-40 parts of distilled water. The phosphating solution is simple and practical in formula. A metal workpiece is immersed in the phosphating solution, and a water-insoluble crystalline phosphate conversion coating can be deposited and formed on the surface of the metal workpiece at normal temperature. The coating layer is of a micropore structure, is firmly combined with a substrate, has good adsorbability, lubricity and corrosion resistance and high electrical insulating property, and does not stick molten metal.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Decorative PVC (Polyvinyl Chloride) film

The invention discloses a decorative PVC (Polyvinyl Chloride) film. The decorative PVC film is prepared from the following raw materials in parts by weight: PVC440 resin powder, nano-tic, chitosan-grafted polyacrylic acid, polyoxyethylene sorbitan monostearate, tetrabutyl titanate, ethyl stearate, stearyl clcohol, titanium bis(triethanolamine)diisopropoxide, saturated fatty alcohol multiple carboxylic ester, sodium antimonate, zinc chromate, plasticizer, stabilizer and antioxidant. Through reasonable combination in a formula, the obtained decorative PVC film has the advantages of aging resistance, high toughness, good thermal stability and high flame resistance. Meanwhile, the decorative PVC film further has the characteristic of acid and alkali resistance.

Owner:黄山豪泰塑胶有限公司

Water-based antirust paint and preparation method thereof

InactiveCN104073139AResolutionSolve the problem of brittle paint filmAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

The invention relates to water-based antirust paint and a preparation method thereof and belongs to the technical field of high polymer materials. The water-based antirust paint comprises the following raw materials in parts by weight: 10-20 parts of acrylic based emulsion, 20-30 parts of waterborne polyurethane resin, 5-10 parts of polyisocyanates, 2-10 parts of tetrabasic zinc chromate, 2-9 parts of alcohol soluble phenolic resin, 5-15 parts of mica iron oxide, 0.5-1.5 parts of defoaming agent, 0.5-1.0 part of antifoaming agent, 1.0-2.0 parts of dispersing agent, 1.0-2.0 parts of thickening agent, 21-29 parts of pigment, 30-50 parts of filler and 100-180 parts of water. The waterborne polyurethane resin and polyisocyanate curing agent are taken as raw materials, the water-based double-component polyurethane antirust paint is prepared, and the antirust paint has the advantages of low film-forming temperature, high gloss, high adhesive force and the like, is energy-saving, environment-friendly, safe and reliable and is widely applied to coating in the fields of automobiles and steel structures.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Novel oil-resistant sealing pad material and preparation method thereof

The invention discloses a novel oil-resistant sealing pad material. The novel oil-resistant sealing pad material is prepared from the following material in parts by weight: 45-50 parts of fluororubber, 20-25 parts of nitrile rubber, 20-25 parts of SG-5 type PVC (Polyvinyl Chloride) resin, 5-8 parts of acetyl triethyl citrate, 2-3 parts of zinc oxide, 1-2 parts of phthalic anhydride, 2-3 parts of zinc chromate, 1-2 parts of sulfur, 2-3 parts of magnesium oxide, 1-2 parts of an accelerant DTDM (Dithiodimorpholine), 1-2 parts of di-n-octyl tin dimercaptoiso-octyl acetate, 1-2 parts of a cross-linking agent TAIC (Triallyl Isocyanurate), 1-2 parts of zinc stearate, 30-35 parts of semi-reinforcing carbon black and 10-12 parts of modified attapulgite clay. According to the invention, the modified attapulgite clay is added, so that process performances of the rubber material are improved; and an environment-friendly compounding agent is used, so that toxic or side effect and pollution to environment are reduced. According to the novel oil-resistant sealing pad material and the preparation method disclosed by the invention, formula is reasonable, cost is lowered, process is simple, and oil resistance and insulativity are good.

Owner:TONGLING SIDE TECH

Antirust coating for metal pipeline

InactiveCN103666188ANo pollutionImprove adhesionAnti-corrosive paintsEpoxy resin coatingsPolyesterOrganic solvent

The invention discloses an antirust coating for a metal pipeline. The antirust coating comprises the following ingredients in parts by weight: 30-50 parts of dicyanodiamide modified phenol-formaldehyde resin, 20-25 parts of epoxy acrylate, 5-12 parts of talcum powder, 10-20 parts of stearic acid, 6-8 parts of butanediol, 5-9 parts of glass powder, 3-6 parts of zinc chromate, 10-15 parts of macromolecular polymer. Through mixing and curing of the antirust coating and epoxy acrylate, the product has better adhesive power and antirust property, and is faster in curing speed, and the production efficiency can be effectively improved; the product does not contain any organic solvent, has no emission of volatile organic compounds (VOC), does not contain elements of Pb, Cr, Zn and the like, and has no environmental pollution in the production and use process, thus being a high-efficiency and green and environment-friendly coating.

Owner:QINGDAO HUIERTONG TRADING

Waterproof coating material resistant to acid rain scouring

ActiveCN103602257AReduce pollutionWon't peel offPolyurea/polyurethane coatingsAcrylate esterUrethane acrylate

The invention discloses a waterproof coating material resistant to acid rain scouring. The waterproof coating material is prepared from the following raw materials in parts by weight: 5-10 parts of polyurethane acrylate resin, 2.3-4.4 parts of silane coupling agent, 3-7 parts of polyethersulfone, 2.3-3.6 parts of tourmaline powder, 1.1-2.3 parts of zinc chromate, 1.5-2.8 parts of sodium pentachlorophenate, 2.3-3.6 parts of N-alkyl sarcosinate and 0.9-1.8 parts of fatty-acid polyoxyethylene ester. Compared with the existing waterproof coating materials, the waterproof coating material has the advantages that the water resistance and waterproofing performance are higher, the tensile strength is high, the waterproof coating material is healthy and environmental-friendly, the environmental pollution is reduced, and wall body flaking caused by rainwater scouring can not occur during long-time use; the waterproof coating material can prevent acid rain scouring, and a coated film can not flake off after the coated film is subjected to rainwater scouring, so that the probability that loss is caused due to the fact that rainwater penetrates into wall faces and corrodes the wall faces is reduced.

Owner:中山市粤马科技有限公司

Novel aqueous alkyd rust-resisting paint

InactiveCN105623485AReduce curing costsLow VOC contentAnti-corrosive paintsPolyester coatingsPhosphateHuman health

The invention relates to a novel aqueous alkyd rust-resisting paint. The novel aqueous aqueous alkyd rust-resisting paint has the advantages of no toxicity, no odour, no pollution, no harm on human health, and environmental protection. The novel aqueous aqueous alkyd rust-resisting paint comprises the following components by mass fraction: 15-25 parts of deionized water, 30-40 parts of water-soluble alkyd resin, 10-15 parts of iron oxide red, 4-5 parts of sericite powder, 3-4 parts of zinc oxide, 6-8 parts of barium sulfate, 8-10 parts of aluminium triphosphate, 6-10 parts of zinc chromate phosphate, 4-6 parts of ethylene glycol monobutyl ether, 0.1-0.3 parts of an X-405 wetting agent, 0.6-1.2 parts of a GA40 dispersant, 0.1-0.3 parts of a 1488 antifoaming agent, 0.3-0.6 parts of a DWB-95 multifunctional auxiliary agent, and 0.5-1 part of an ASE-60 thickening agent.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Glass antifogging detergent

InactiveCN104479895AQuick cleanEasy to cleanInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsO-Phosphoric AcidSodium sulfate

The invention relates to a glass antifogging detergent, belonging to the technical field of fine chemical engineering. The glass antifogging detergent is prepared from the following raw materials in parts by weight: 10-30 parts of sorbitan monolaurate, 15-25 parts of orthophosphoric acid, 9-18 parts of zinc chromate, 5-18 parts of sulfated castor oil, 5-18 parts of polypropoxybutyl ether sodium sulfate, 2-12 parts of quick-drying agent and 60-90 parts of water. By reasonably combining the sorbitan monolaurate and other raw materials, the detergent can quickly and effectively clean the glass, can be quickly dried, and can form an antifogging film on the glass surface to perform the antifogging function; and the antifogging efficacy time can reach one week and even longer.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

Anticorrosive primer for copper

InactiveCN103665980AImprove bindingImprove corrosion resistanceAnti-corrosive paintsPolymer scienceOrganosolv

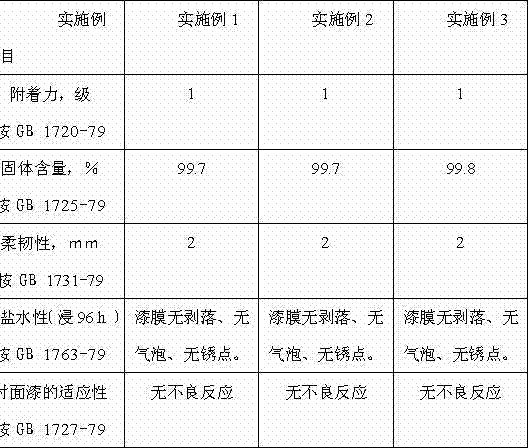

An anticorrosive primer for copper comprises the components in parts by mass as follows: 100 parts of isopropyl alcohol, 25-30 parts of phenolic novolac resin, 15-30 parts of butyl alcohol, 15-25 parts of polyvinyl acetate, 15-20 parts of zinc chromate, 50-60 parts of toluene, 10-15 parts of a corrosion inhibitor, 10-20 parts of alkyd resin, 3-15 parts of iron oxide red, 3-10 parts of chlorinated paraffin, 15-20 parts of carbon black, 10-15 parts of a dispersant and 5-10 parts of talc powder. The binding force of the primer to the copper is good, the adhesive force reaches grade 1, the shock strength is larger than 500 MPa, the flexibility is smaller than 1 mm, and the hardness is larger than 2 H; and the primer is good in corrosion resistance, convenient to construct, simple in process, free of organic solvents and capable of being widely produced and replacing existing materials.

Owner:JIANGSU PAQINI COPPER IND

Anti-corrosion aluminum coating for titanium alloy connecting part for aluminum alloy composite structure

InactiveCN110684423APrevent Galvanic CorrosionImprove high temperature resistanceFireproof paintsAnti-corrosive paintsPolyamideEthylic acid

The invention relates to an anti-corrosion aluminum coating for a titanium alloy connecting part for an aluminum alloy composite structure. The coating comprises the following material components in parts by weight: 300-600 parts of aluminum slurry, 400-1000 parts of strontium chromate, 0-300 parts of zinc chromate. 0-260 parts of molybdenum disulfide, 1000-4000 parts of thermal-resistant phenolicresin, 1000-8000 parts of ethylene glycol monoethyl ether acetate, 50-200 parts of polytetrafluoroethylene, 20-60 parts of bentonite, 60-120 parts of a polyamide wax liquid variation aid and 10-20 parts of a leveling agent. The coating is applicable to surface coating to a titanium alloy fastener, a titanium alloy pivot, and the like, is capable of preventing dissimilar metal galvanic corrosion of other metals such as an aluminum alloy with titanium alloy connecting parts, in addition, has very good high temperature resistance, paint peeling agent resistance and self lubrication performance.

Owner:沈阳市航达科技有限责任公司

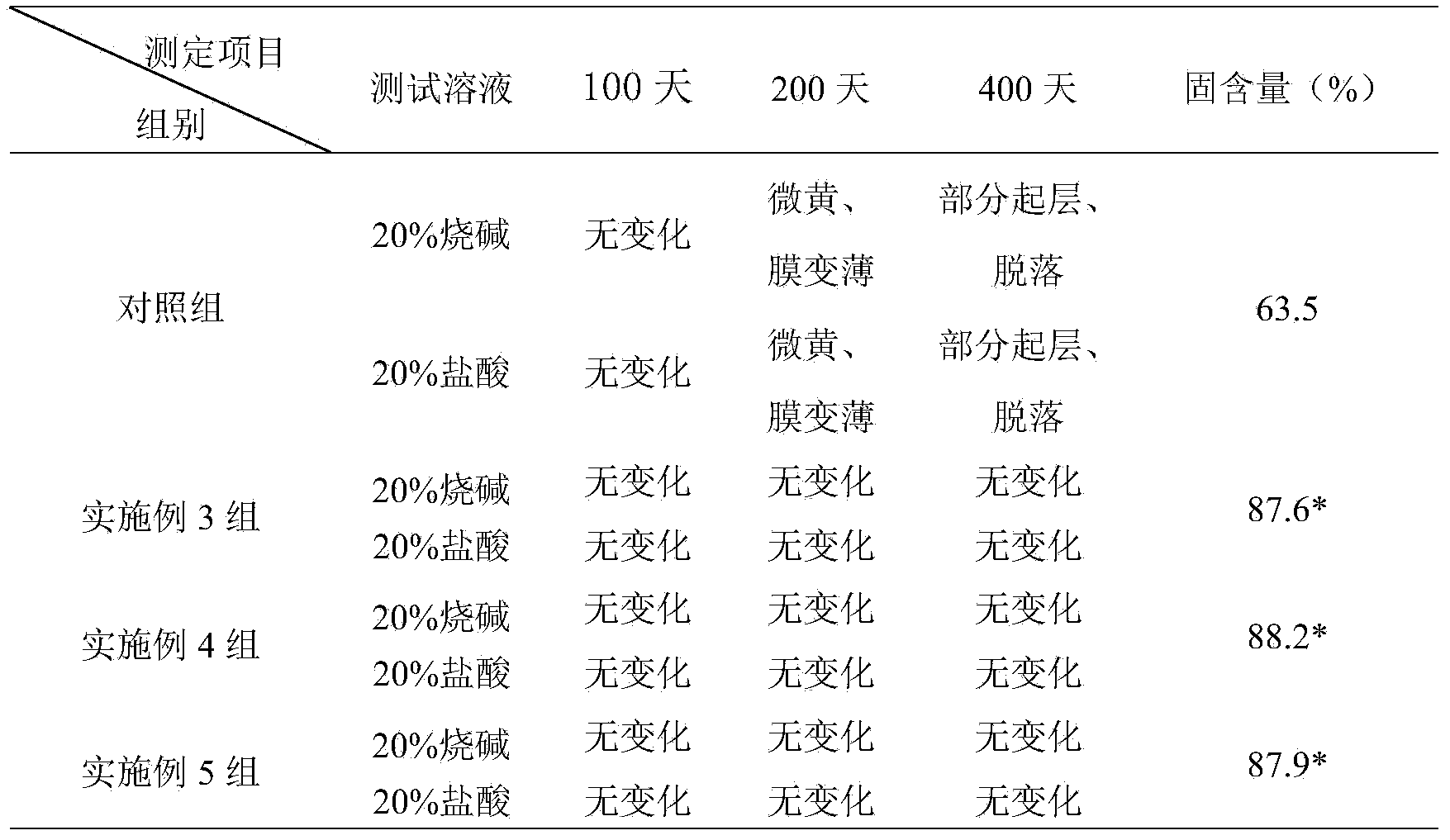

Anti-corrosion resin coating and preparation method thereof

InactiveCN104231853ALow costSimple processAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyResin coating

The invention discloses an anti-corrosion resin coating which is mainly prepared from the following raw materials in parts by weight: 20 parts of bisphenol F type epoxy resin, 10-20 parts of polyamide resin, 2-10 parts of polyurethane, 2-8 parts of zinc chromate, 1-5 parts of zinc chloride, 2-6 parts of mica powder, 1-5 parts of pigment, 2-8 parts of inorganic packing and 20-40 parts of a mixed solvent. The invention further provides a preparation method of the anti-corrosion resin coating. Compared with the prior art, the anti-corrosion resin coating disclosed by the invention is low in cost, simple in process, corrosion resistant, long in service life and high in solid content, and can effectively reduce environment pollution.

Owner:南京市荣达树脂有限公司

Fastener surface treatment method

InactiveCN108187992ABright appearanceImprove bindingPretreated surfacesCoatingsCollision resistanceDip-coating

The invention discloses a fastener surface treatment method. The method comprises the following steps of S1, shot blasting, wherein shot blasting is carried out on a fastener in a shot blasting machine, and rusting is removed; S2, dip-coating, wherein the fastener subjected to shot blasting is put into a coating solution containing zinc chromate for immersion coating; S3, centrifuging, wherein thepower is 35-40 Hz, the time is 50 + / - 10 seconds; S4, baking, wherein baking and curing are carried out by adopting a mesh belt type gas stove; S5, discharging, wherein the baked fastener is taken out and placed well; S6, secondary immersion coating, wherein the fastener which is baked and discharged is put into the coating solution containing zinc chromate for immersion coating; S7, secondary centrifuging, wherein power is 35-40 Hz, and the time is 50 + / -10 seconds; S8, secondary baking, wherein the baking and curing are carried out by adopting the mesh belt type gas stove; and S9, discharging, wherein the fastener after secondary baking is taken out, and then baking and curing are carried out after the surface of the fastener is coated with the organic resin (repeated twice). Accordingto the fastener surface treatment method, the product can be bright in appearance, uniform in color and luster, high in collision resistance and good in anti-corrosion performance.

Owner:GEM YEAR IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com