Manufacture method of novel marine corrosion resistance stainless steel and steel cable thereof

A technology of stainless steel and seawater resistance, which is applied in the manufacture of stainless steel and its steel wire rope, and the manufacture of seawater corrosion-resistant stainless steel and its steel wire rope. It can solve the problems of shortened service life, short life, and not strict control of inclusions such as MnS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

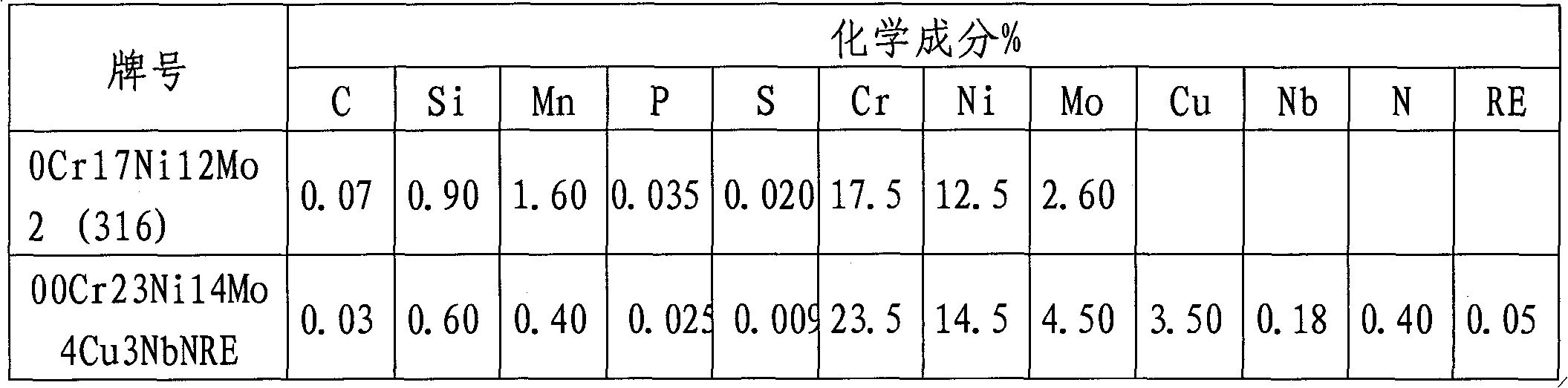

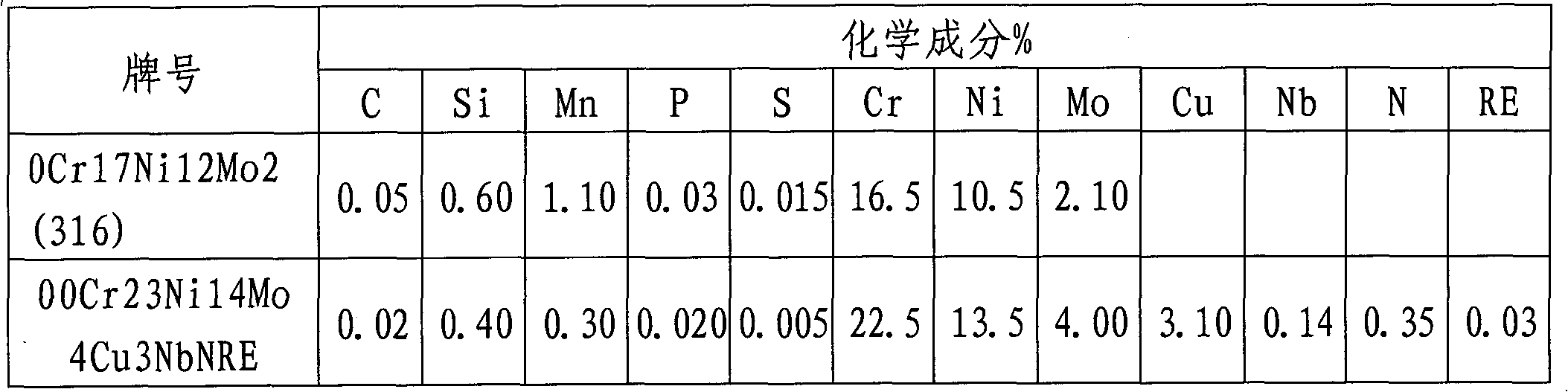

[0047] 00Cr23Ni14Mo4Cu3NbNRE stainless steel smelting and rolling manufacturing process

[0048] Charge (scrap steel)——EAF (electric furnace)——VOD (refining furnace)——continuous casting of 180mm billet——skinning—flaw detection—heating—hot continuous rolling (rough, medium, and finish rolling) ф5.5- 16mm wire—coiling—heat treatment (solution)—pickling—inspection—packaging and storage.

Embodiment 2

[0050] 00Cr23Ni14Mo4Cu3NbNRE stainless steel wire rope manufacturing process

[0051] ф5.5mm wire—film treatment—drying—rough drawing (6-7 passes) ф2.5mm—cleaning surface—drying—solution heat treatment—medium drawing (9-11 passes) ф1.2mm——Bright annealing——Water tank drawing (19 molds) ф0.6mm——Electrolytic polishing——Twisting strands (1×7)——Combined rope (6×7) Rope diameter 5.8mm——Take-up— Inspection - packing - storage.

[0052] Above-mentioned embodiment 1 and 2 conventional process manufacturing technical means, do not describe in detail here, the key manufacturing technology involved in the present invention is as follows:

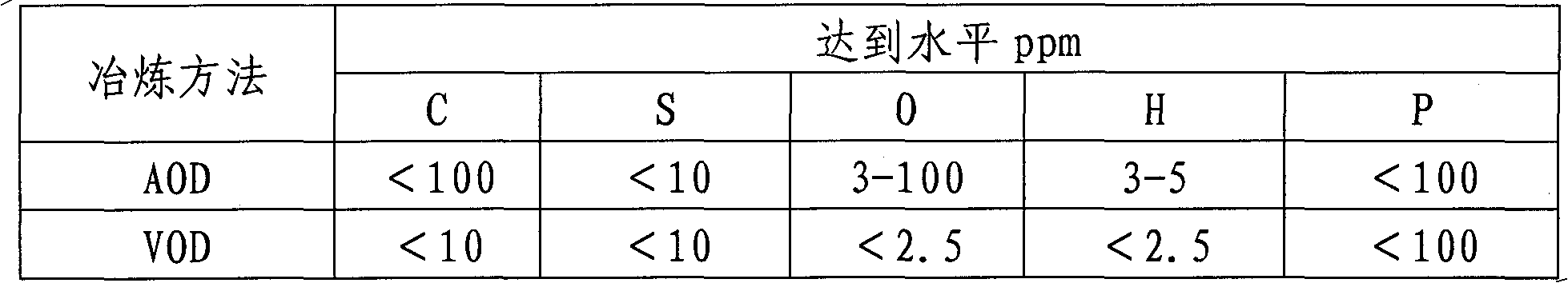

[0053] 1) The SS-VOD method is used for refining outside the furnace, that is, blowing argon or nitrogen with more than 2 air-permeable bricks or 3-6 (ф2-4mm) stainless steel heat-resistant steel pipes to strongly stir the molten steel and increase the N alloy It can produce ultra-low carbon (C<0.03%) and ultra-low sulfur (S<0.01%) stainless steel. ...

Embodiment 3

[0060] After the water tank is drawn, the steel wire is electrolytically polished, and then twisted and closed, which is the most important technological innovation point of the present invention. The surface of electropolished stainless steel wire and steel rope has the best corrosion resistance. The reason is that electropolishing can remove dirt and impurities, chromium-poor layer and non-metallic inclusions on the surface of stainless steel, and reduce the surface roughness of steel wire by 50%. The surface of the steel wire is not only bright, smooth and clean, but also has high passivation state stability, so it has high corrosion resistance. This can also be seen from the test results. The following are the comparison results of different surface treatments of 0Cr17Ni12Mo2 (316) for corrosion resistance in natural seawater. (at room temperature)

[0061] code name

surface treatment

Corrosion area (%)

Maximum corrosion depth (mm)

A

cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com