Production method of anti-corrosion and high strength ultra-thick steel plates

A production method and high-strength technology, applied in the field of steelmaking, can solve the problems of high production cost, unreachable performance, high energy consumption, etc., and achieve the effect of low production cost, short process and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

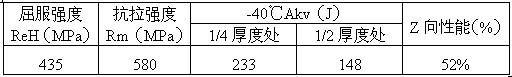

[0020] Example 1: Add molten iron and scrap steel during the converter smelting process, the ratio of molten iron and scrap steel is (85%~95%) / (5%~15%); copper plate, Cu95%~100%, impurity balance; then add ferroalloy Ferrosilicon, Si≥72.0%, Mn≤0.5%, S≤0.02%, P≤0.04%, C≤0.2%, Cr≤0.5%, Fe balance; Ferromanganese, Si≤1.5%, Mn≥78.0%, S≤0.03%, P≤0.20%, C≤1.5%, Fe balance; titanium ferro, 25.0%≤Ti≤35.0%, Al≤8.0%, Si≤4.50%, Mn≤2.50%, P≤0.05%, S≤0.03%, C≤0.10%, Cu≤0.40%, Fe balance; ferroniobium, C≤0.05%, Nb60~70%, Si≤2%, Al≤2.5%, Fe balance; nickel plate, Ni99 .9%~100%, impurity balance; the final addition ratio is Si≤2.0%, 30.0%≤Mn≤35.0%, S≤0.05%, P≤0.20%, C≤2.0%, 20.0%≤Al≤26.0% , Cu ≤ 0.5%, Fe balance composite deoxidized Al-Mn ferroalloy for smelting. After refining in LF furnace, the refining temperature is 1500~1650°C; the composition is fine-tuned, slag is deoxidized, the refining time is ≥35min, argon is blown and stirred throughout the process, and the basicity of the refin...

Embodiment 2

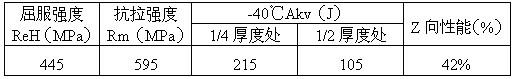

[0025]Embodiment 2: Add molten iron and steel scrap during converter smelting, the proportion of molten iron and steel scrap is (85%~95%) / (5%~15%); copper plate, Cu 95%~100%, impurity balance; then add Ferroalloy Ferrosilicon, Si≥72.0%, Mn≤0.5%, S≤0.02%, P≤0.04%, C≤0.2%, Cr≤0.5%, Fe balance; Ferromanganese, Si≤1.5%, Mn≥78.0% , S≤0.03%, P≤0.20%, C≤1.5%, Fe balance; ferro-titanium, 25.0%≤Ti≤35.0%, Al≤8.0%, Si≤4.50%, Mn≤2.50%, P≤0.05% , S≤0.03%, C≤0.10%, Cu≤0.40%, Fe balance; ferroniobium, C≤0.05%, Nb60~70%, SI≤2%, Al≤2.5%, Fe balance; nickel plate, Ni 99.9%~100%, impurity balance; the final addition ratio is Si≤2.0%, 30.0%≤Mn≤35.0%, S≤0.05%, P≤0.20%, C≤2.0%, 20.0%≤Al≤26.0% , Cu ≤ 0.5%, Fe balance composite deoxidized Al-Mn ferroalloy for smelting. After refining in LF furnace, the refining temperature is 1500~1650℃; the composition is fine-tuned, slag is deoxidized, the refining time is ≥35min, argon is blown and stirred throughout the process, and the basicity of the refined ...

Embodiment 3

[0030] Embodiment 3: Add molten iron and steel scrap during the converter smelting process, the proportion of molten iron and steel scrap is (85%~95%) / (5%~15%); copper plate, Cu 95%~100%, impurity balance; then add Ferroalloy ferrosilicon: Si≥72.0%, Mn≤0.5%, S≤0.02%, P≤0.04%, C≤0.2%, Cr≤0.5%, Fe balance; ferromanganese, Si≤1.5%, Mn≥78.0% , S≤0.03%, P≤0.20%, C≤1.5%, Fe balance; ferro-titanium, 25.0%≤Ti≤35.0%, Al≤8.0%, Si≤4.50%, Mn≤2.50%, P≤0.05% , S≤0.03%, C≤0.10%, Cu≤0.40%, Fe balance; ferroniobium, C≤0.05%, Nb 60~70%, Si≤2%, Al≤2.5%, Fe balance; nickel plate , Ni 99.9%~100%, impurity balance; the final addition ratio is Si≤2.0%, 30.0%≤Mn≤35.0%, S≤0.05%, P≤0.20%, C≤2.0%, 20.0%≤Al≤26.0 % , Cu ≤ 0.5%, the balance of Fe is smelted with composite deoxidized alloy Al-Mn-Fe. LF furnace refining, refining temperature, 1500~1650°C; composition fine-tuning, slagging deoxidation, refining time ≥ 35min, argon blowing and stirring throughout, refining slag alkalinity (CaO / SiO 2 ) = 5.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com