Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Reduce macro segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

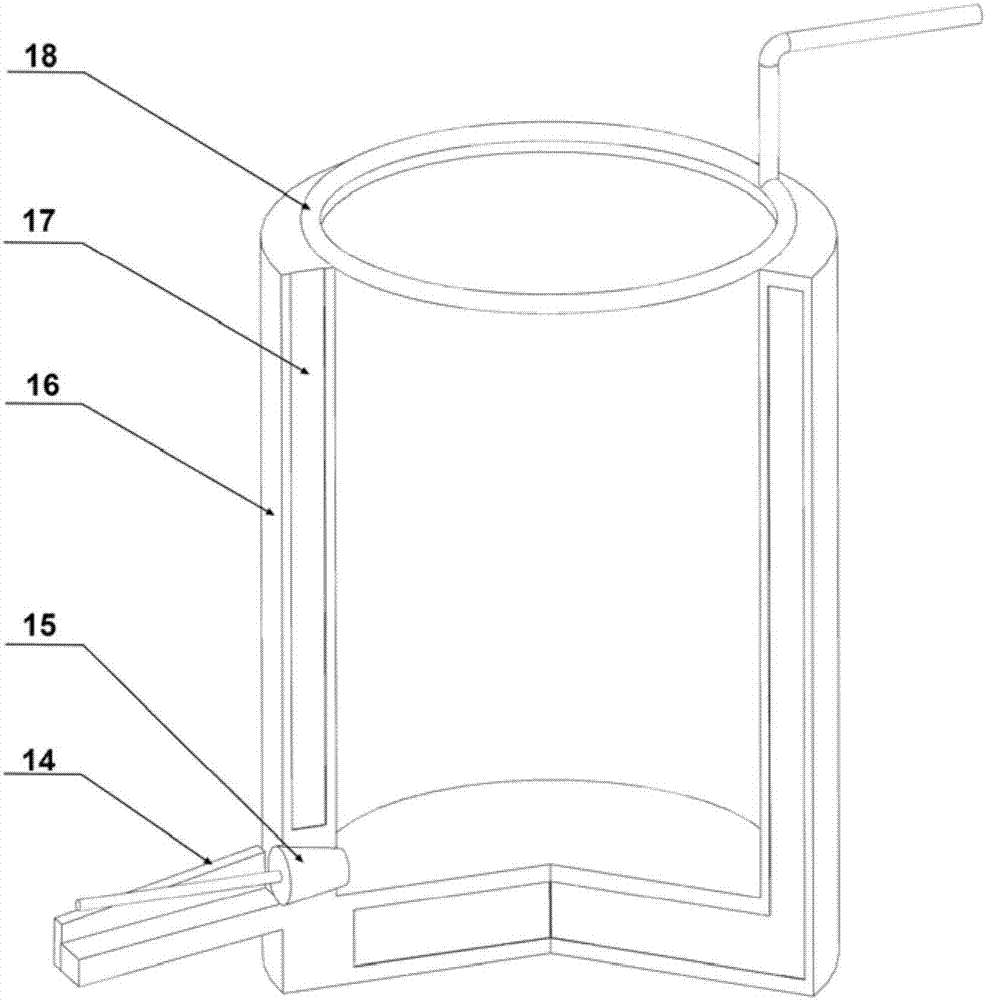

Electromagnetic semicontinuous casting device and casting method thereof

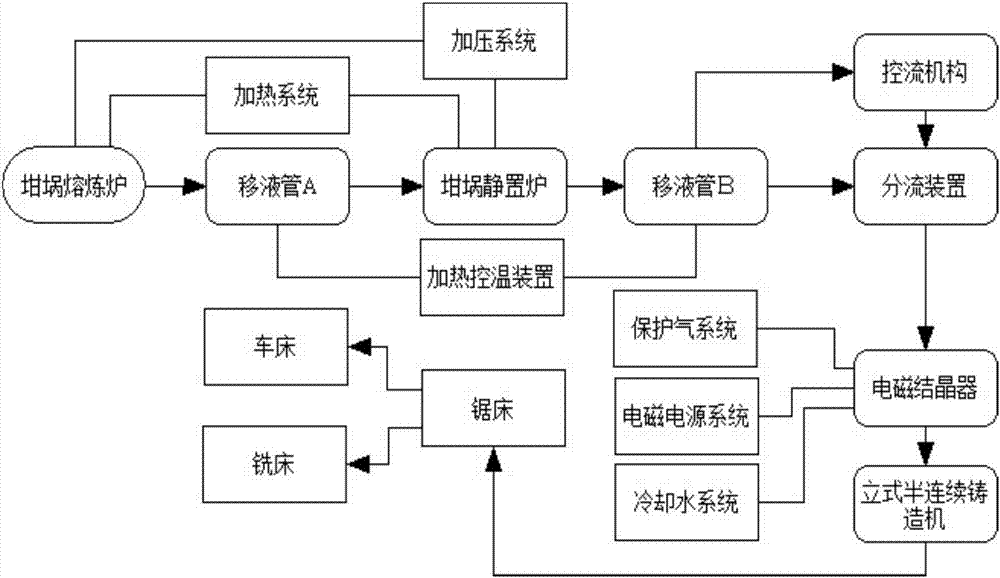

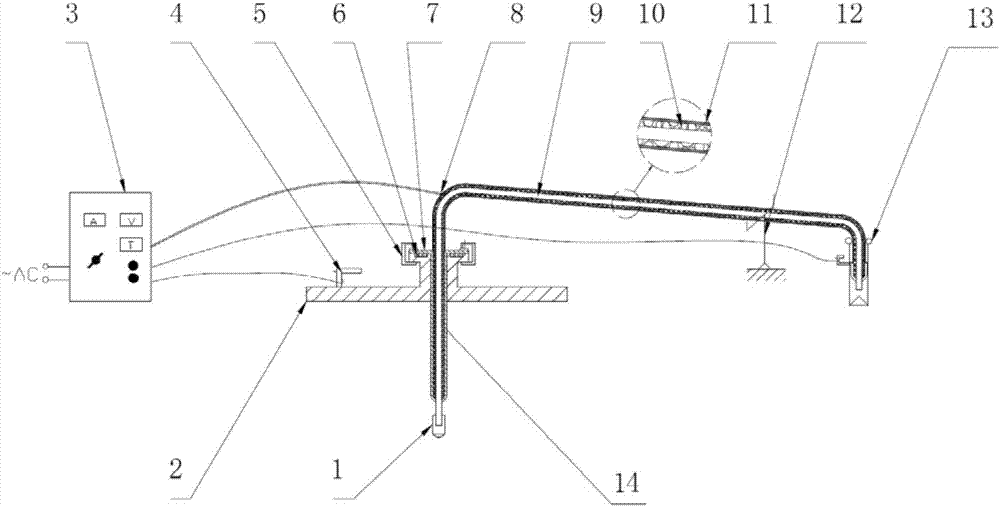

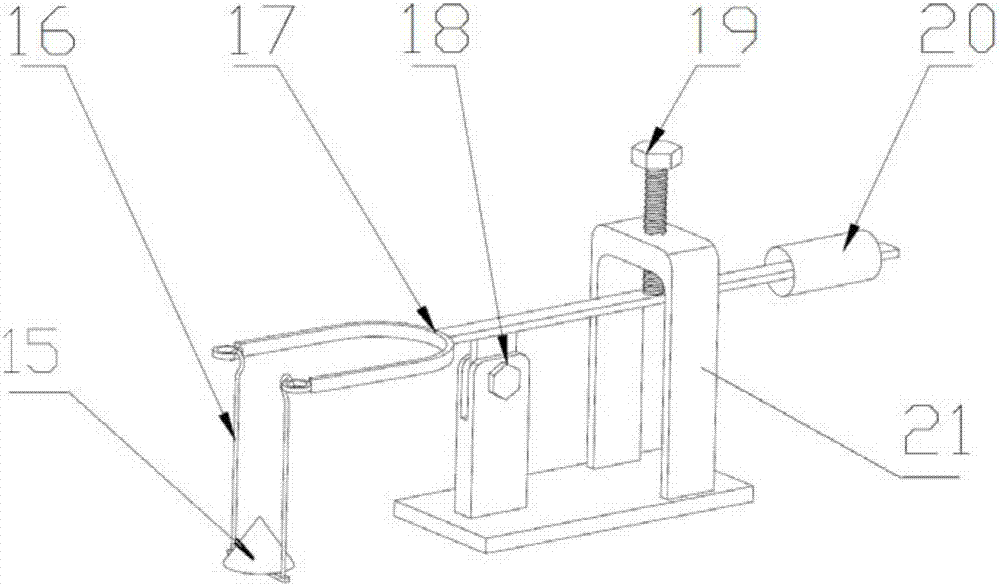

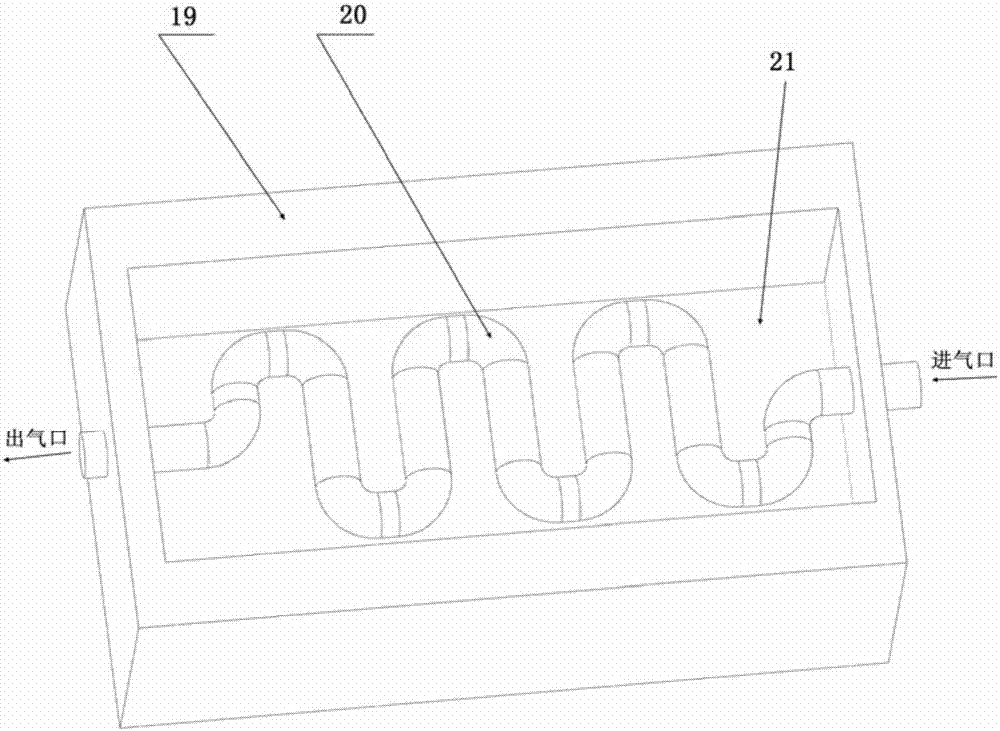

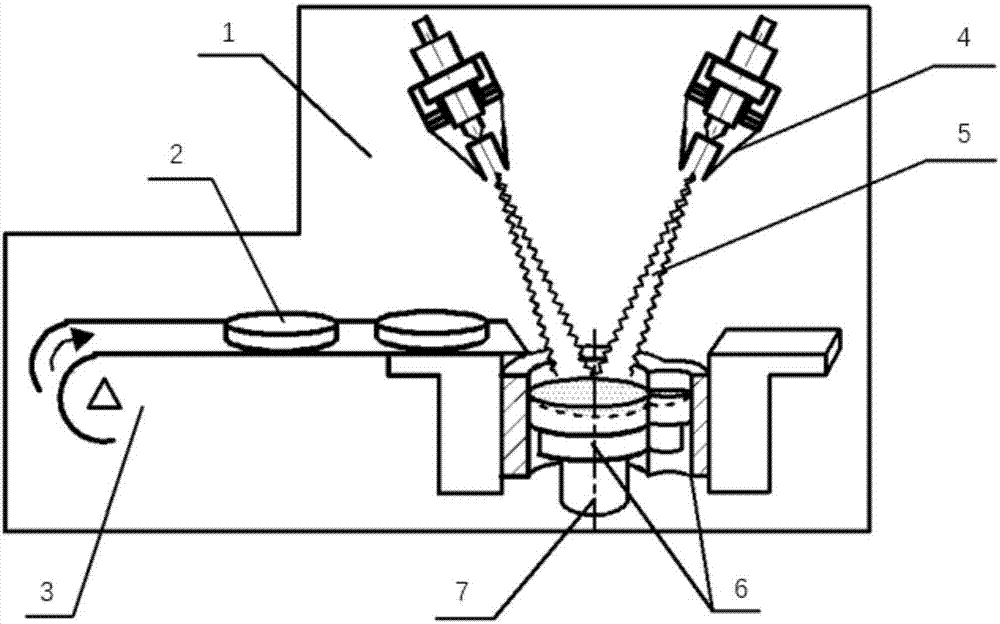

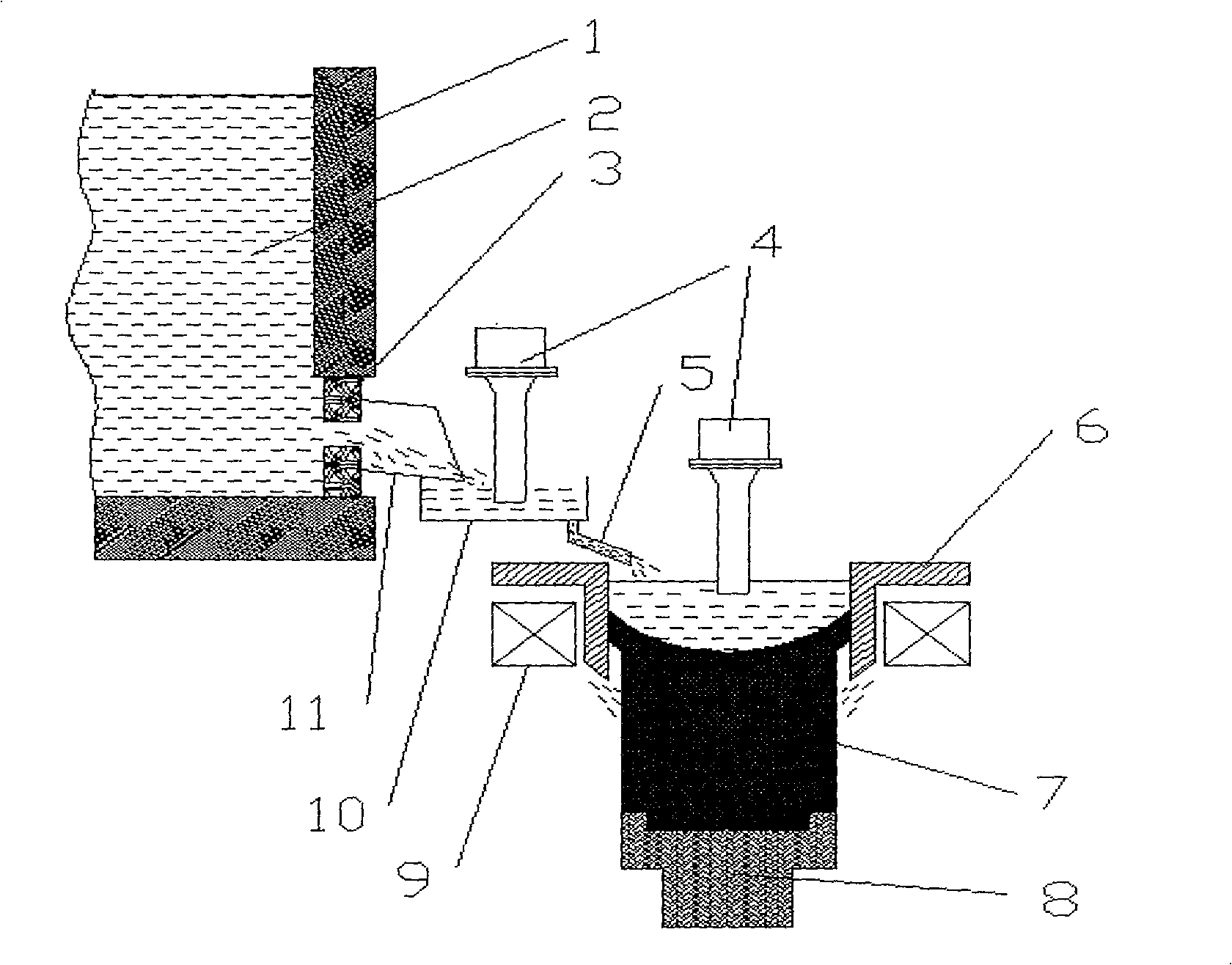

The invention discloses an electromagnetic semicontinuous casting device and a casting method thereof. The electromagnetic semicontinuous casting device comprises a crucible smelting furnace, a crucible standing furnace, a flow control mechanism, a split-flow device, an electromagnetic crystallizer system and a vertical semicontinuous casting machine, wherein the electromagnetic crystallizer system is a metal inner sleeve crystallizer system in which a group of build-in excitation coil is fixed, and comprises a metal inner sleeve, a cooling water cavity, the excitation coil, an oil supply system, an oil distribution system and a protective gas ring. According to the electromagnetic semicontinuous casting device disclosed by the invention, through a method of adjusting the frequency of electrical current, duty ratio and average current strength, the electrical current in a unique wave shape is formed in the single excitation coil placed in the cooling cavity of a crystallizer, so that desired forced convection or shaking effect is formed in the crystallizer with low current intensity; the grain of ingot blank is significantly refined; and columnar crystals are significantly reduced or eliminated to lower macroscopic segregation and realize the technical effect of low-stress casting. Under the condition of similar functional effects, the size of the electromagnetic crystallizer system is one third to one half of that of an original electromagnetic crystallizer system.

Owner:NORTHEASTERN UNIV

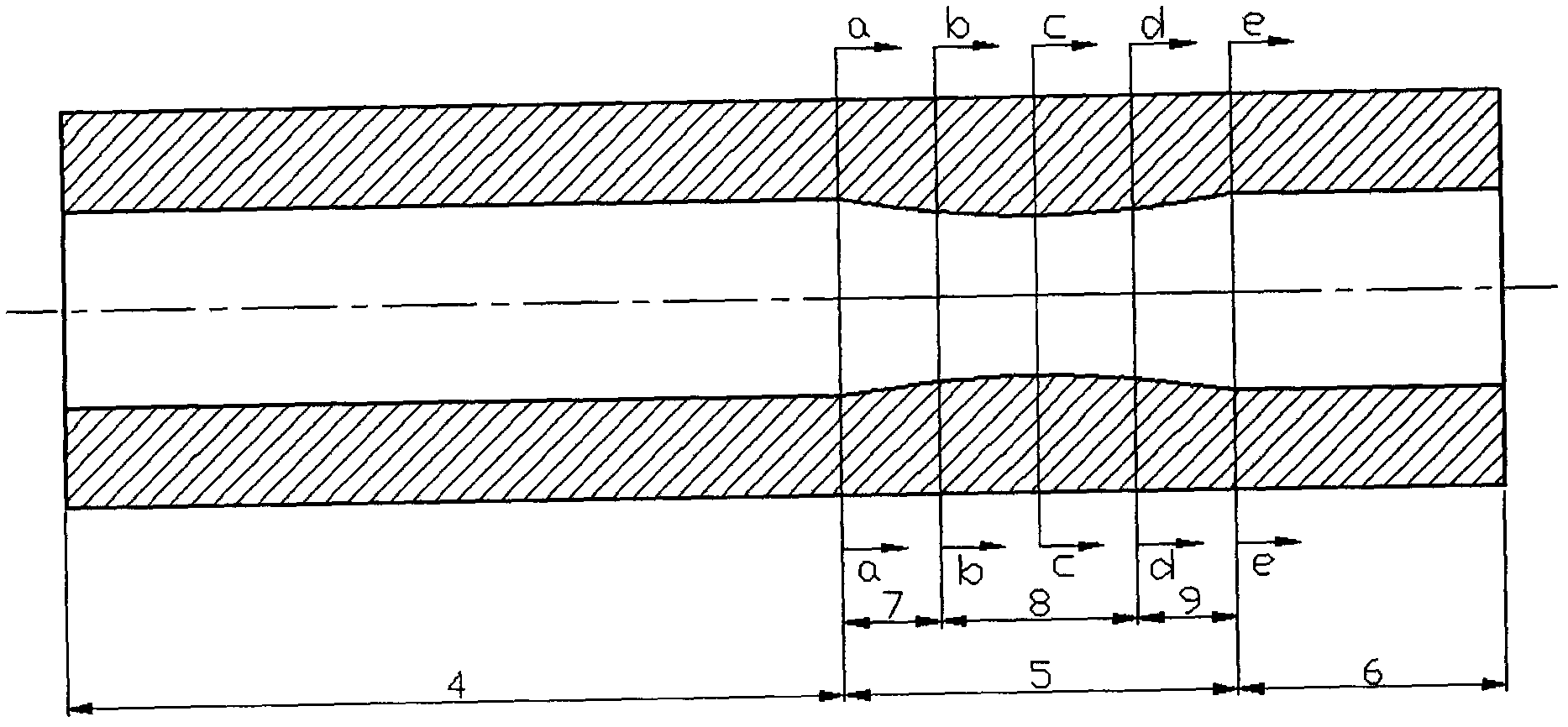

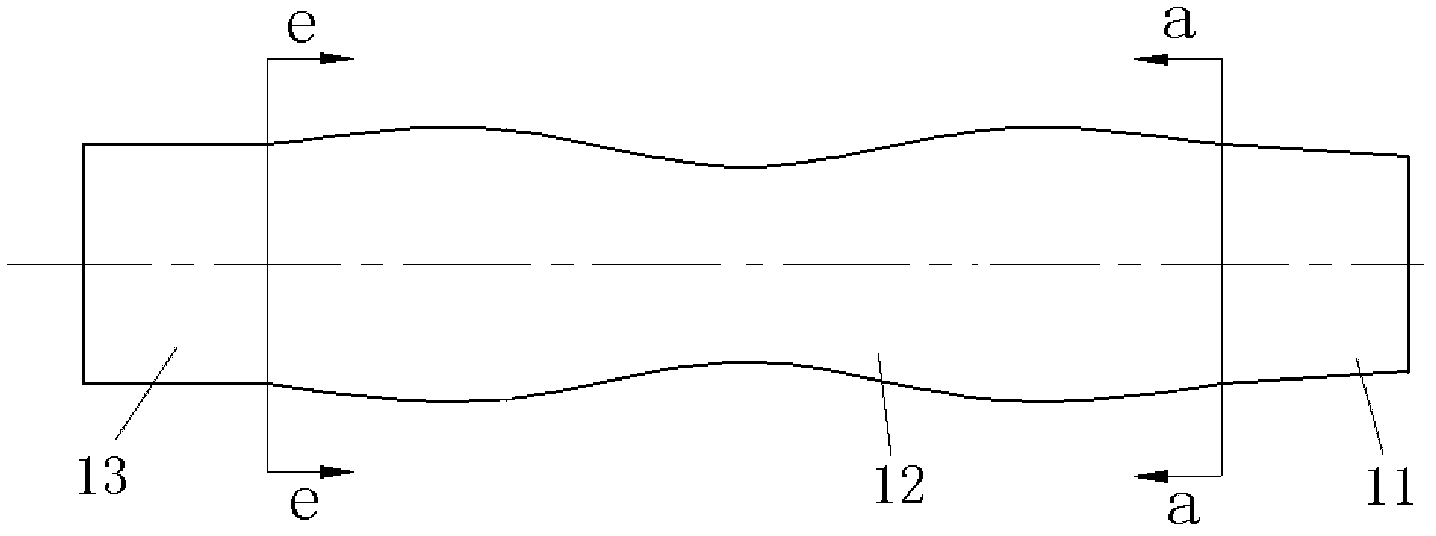

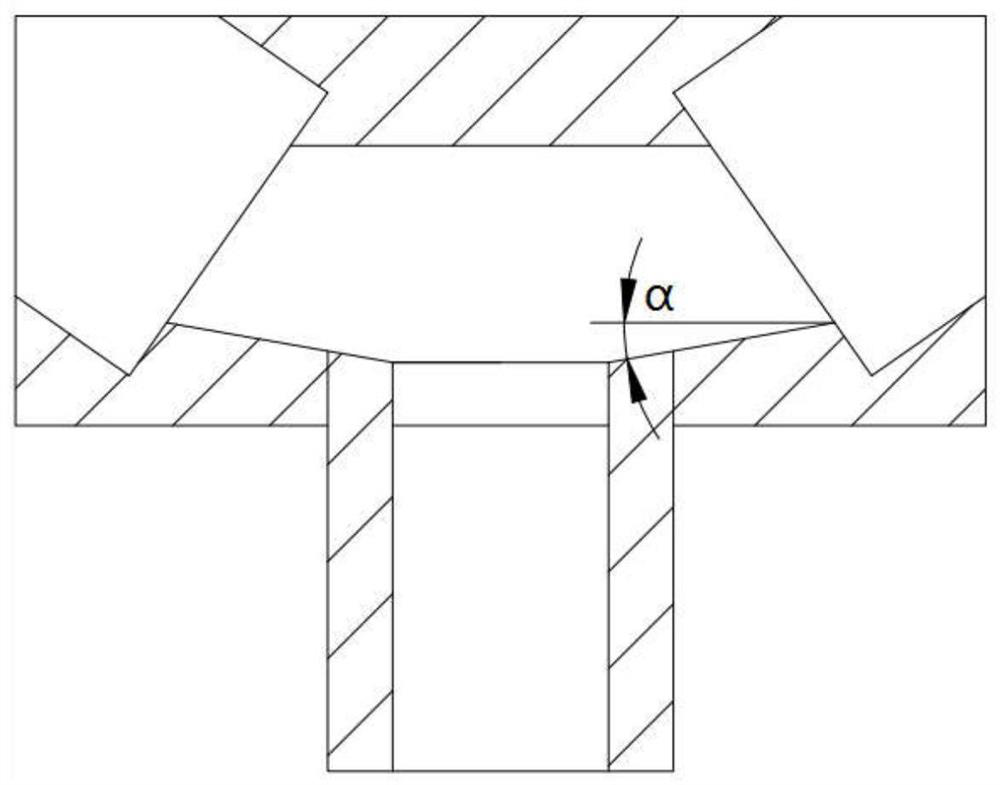

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

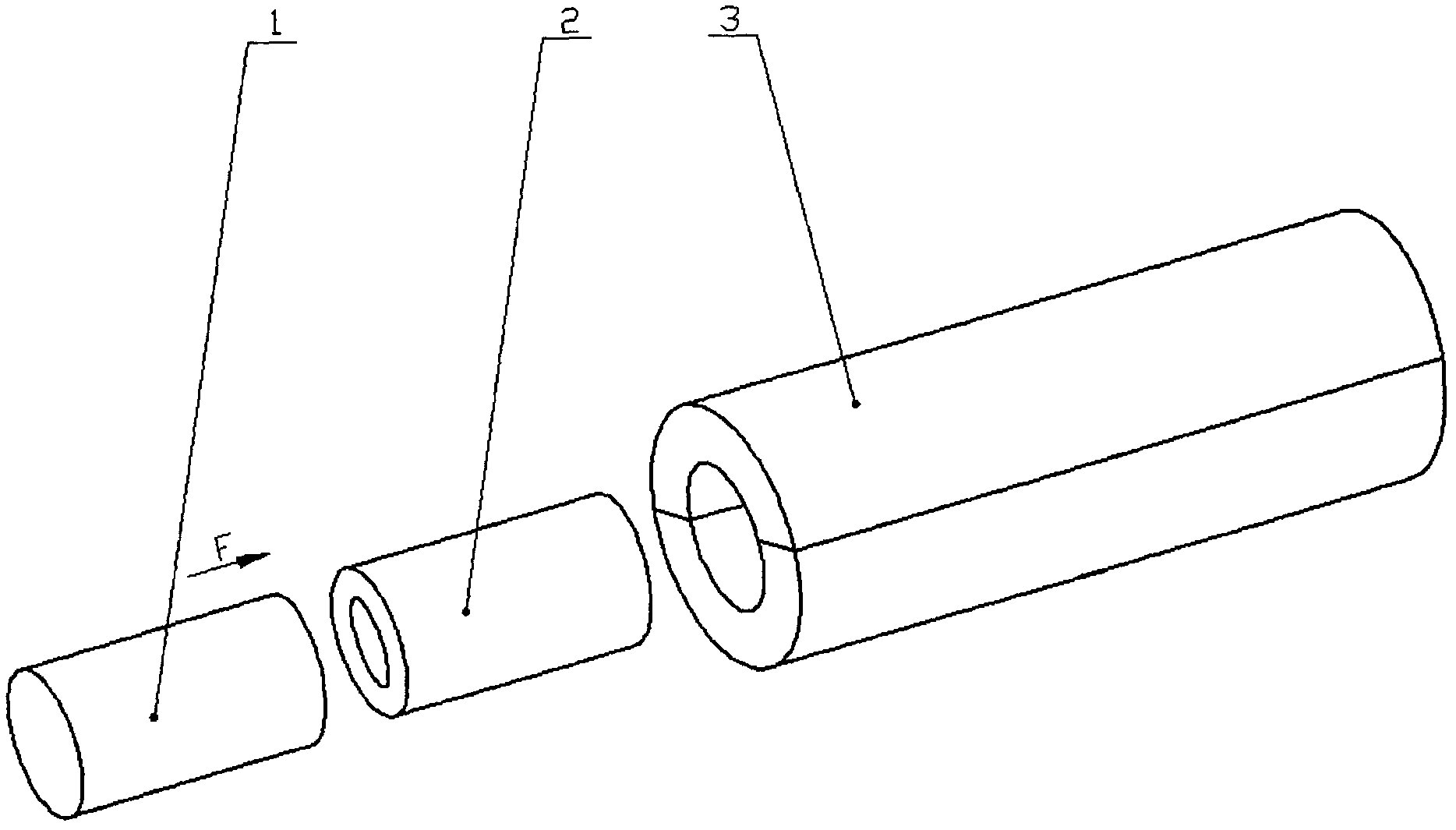

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

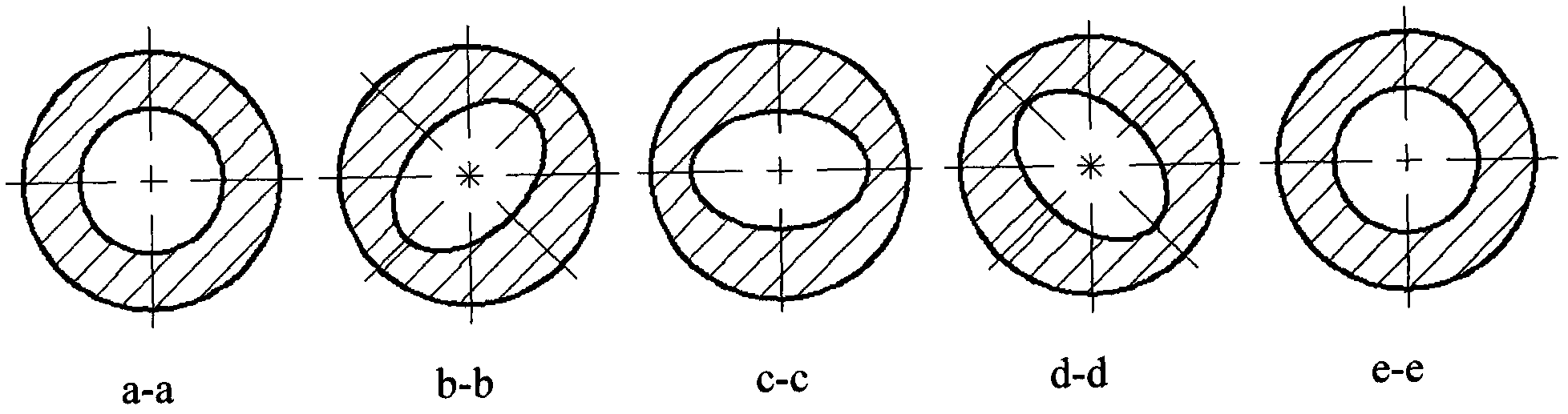

Full-path full-valence separation method for multifarious metal

ActiveCN105695744AInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementAntimonyRaw material

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

Method for restraining macrosegregation of large steel ingot

The invention relates to a method for restraining macrosegregation of a large steel ingot. The method for restraining macrosegregation of the large steel ingot comprises the following steps that (1) a steel ingot mould is placed in a vacuum tank and is located on a base plate, and an exothermic riser is arranged on the inner side of a steel ingot mould riser; (2) the steel ingot mould is preheated, wherein the preheating temperature ranges from 100 DEG C to 200 DEG C; (3) after the steel ingot mould reaches the preheating temperature, steel ingot pouring is conducted according to the multi-ladle continuous vacuum pouring technology, the time interval between every two adjacent ladles is zero second, molten steel in the first ladle is high in carbon content, and the carbon contents of molten steel in other ladles become lower in sequence, so that a normal segregation area at the position of the large steel ingot riser is restrained; (4) when pouring of molten steel is completed, the vacuum tank is opened, and an exothermal agent and a heat preservation and covering agent are placed in the exothermic riser in the top of the steel ingot; (5) the exothermic riser is started for heating after the exothermal agent and the heat preservation and covering agent are added till the steel ingot is solidified completely and demolding is conducted. According to the method for restraining macrosegregation of the large steel ingot, macrosegregation of the large steel ingot can be reduced, tissue is improved, primary shrinkage of the riser is reduced greatly, and the method is suitable for production of large steel ingots made of various materials.

Owner:TSINGHUA UNIV

Method and apparatus for reducing segregation in metallic ingots

The present disclosure relates to electroslag remelting methods and apparatus for producing metallic ingots, as well as to articles of manufacture made from materials processed according to the methods and / or using the apparatus. One such method includes disposing slag within a withdrawal mold comprising a mold wall and an electrically conductive member disposed through the mold wall, contacting the slag with a consumable electrode, and heating the slag by conducting an electrical current through the consumable electrode into the slag, thereby melting at least a portion of the consumable electrode in contact with the slag. At least a fraction of the melted portion of the consumable electrode is collected in the withdrawal mold to form the ingot. At least a portion of the electrical current is conducted form the slag through the electrically conductive member.

Owner:ATI PROPERTIES

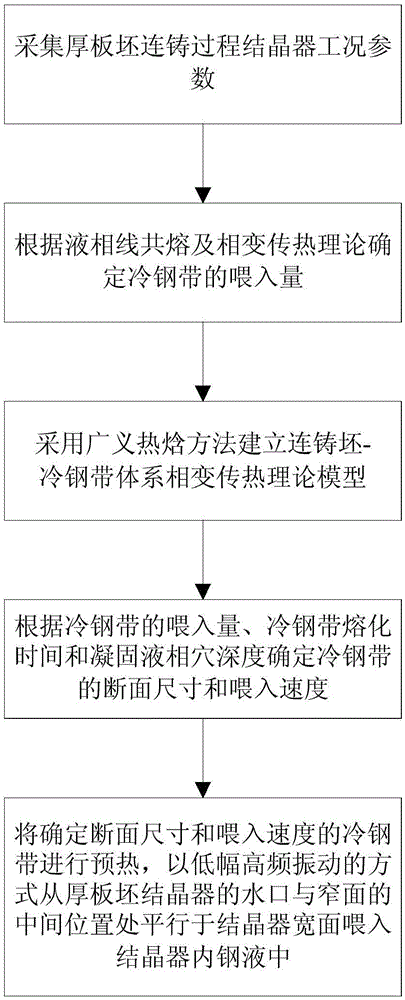

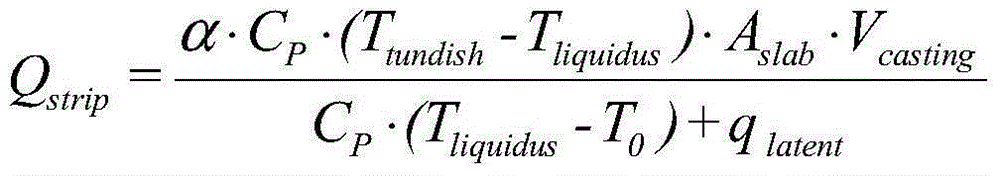

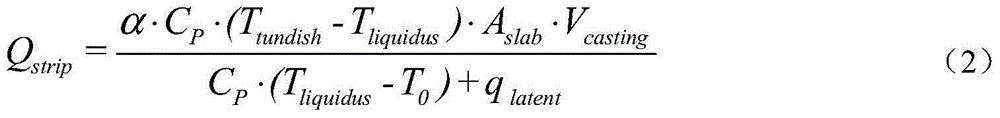

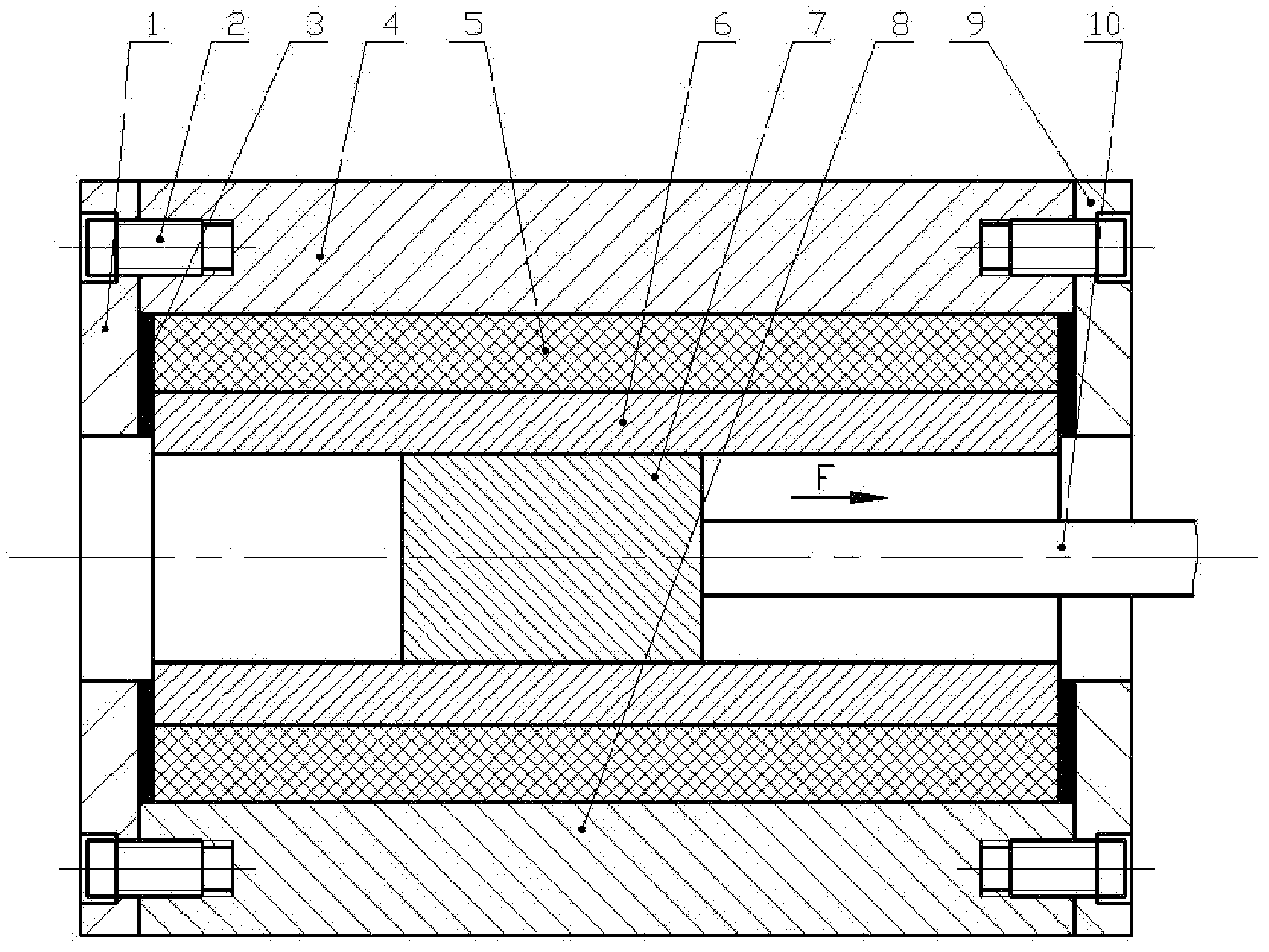

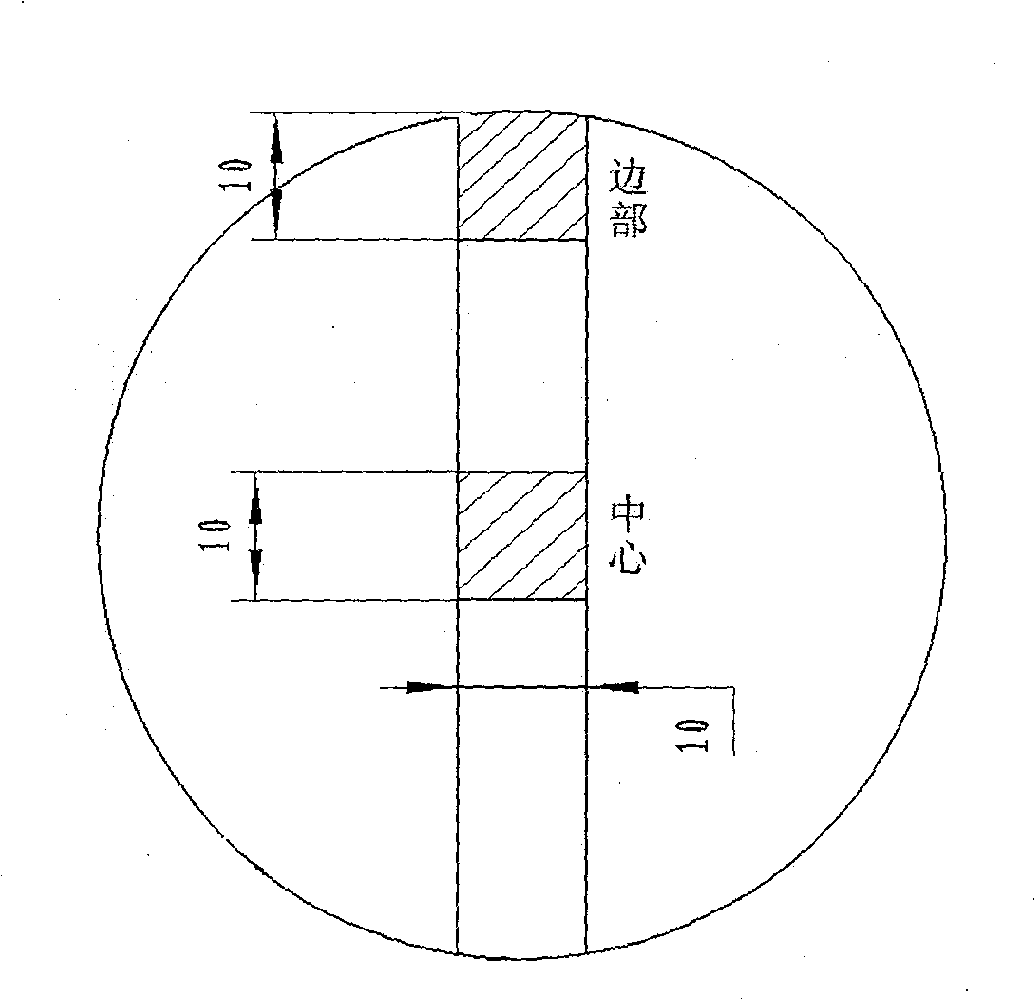

Method for determining steel belt feeding process parameter of crystallizer in thick slab continuous casting process

ActiveCN105033216AReduce macro segregationIncrease equiaxed crystal ratioLiquid coreCongruent melting

The invention relates to a method for determining the steel belt feeding process parameter of a crystallizer in the thick slab continuous casting process. The method comprises the steps the work condition parameter of the crystallizer in the thick slab continuous casting process is collected, and the feeding quantity of a cold steel belt is determined through the work condition parameter of the crystallizer in the thick slab continuous casting process based on the liquidus congruent melting and phase change heat transfer theory; a continuous casting slab-cold steel belt system phase change heat transfer theoretical model is built through a generalized enthalpy method, namely, a relation model among the melting time and feeding thickness of the cold steel belt, the superheat degree of casting molten steel and the initial temperature of the cold steel belt; the section size and feeding speed of the cold steel belt are determined through the continuous casting slab-cold steel belt system phase change heat transfer theoretical model according to the feeding quantity and melting time of the cold steel belt and the depth of a solidified liquid core; and the cold steel belt with the determined section size and feeding speed is preheated and fed into molten steel in the crystallizer through the position between a water opening and a narrow face of the thick slab crystallizer parallel to the wide face of the crystallizer in a low-amplitude high-vibration manner.

Owner:NORTHEASTERN UNIV

Preparation method of TiCu50 master alloy material by vacuum consumable arc melting

The invention discloses a preparation method of a TiCu50 master alloy material by vacuum consumable arc melting, which mainly comprises the following steps: (1) mixing raw materials: according to theweight percentage content, the percentage contents of raw material are: Cu 50%, and TiO 50%, the required raw materials are weighted according to the proportion, and the raw materials are mixed in a mixer; (2) pressing: the mixed powder is loaded into a rubber sleeve and is subjected to mechanical vibration, rolling and reverse material mounding, and then the cold isostatic pressing method is adopted to press the mixed powder, and then the pressure-keeping treatment is carried out; (3) sintering: the pressed consumable electrode is loaded into a vacuum sintering furnace for sintering, and thesintering temperature, the holding time and the vacuum degree are controlled; Step (4) smelting: the sintered consumable electrode is charged into a vacuum consumable arc smelting furnace for smelting. The TiCu50 master alloy material prepared by the invention has low gas content and less impurities, and is uniform in composition, and has no macroscopic and microscopic defects such as enrichment of Cu and Ti.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

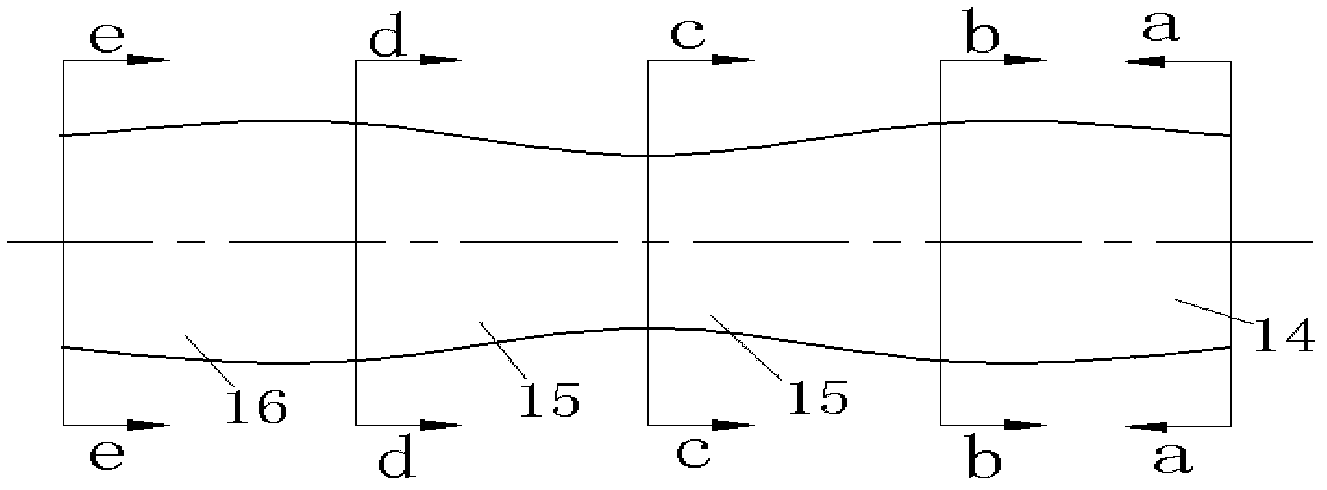

Tube drawing forming method and forming mould

InactiveCN102423770AImproved strain distributionIncrease stressDrawing diesStress distributionShear stress

The invention discloses a tube drawing forming method and forming mould. In the forming method, extrusion-bulging deformation is performed on a tube by using a drawing torsion variable-section core to realize combination of various deformation modes in a primary forming process. The tube wall of the formed tube is subjected to the extrusion-bulging of the core and is in a strong three-way compressive stress state due to the limitation of a polyurethane filling layer; at a deformation stage of circular-elliptical-circular and elliptical torsion change, the tube enters a torsion shearing deformation zone of a metal transition region; under the action of shearing stress, the internal organization of the material is subjected to rotation and shear strain to cause the orientation of a materialorganization structure, namely a new texture is formed, thereby improving deformation texture under the equivalent deformation degree. The drawing variable-section core extrusion-bulging tube deformsto achieve larger deformation degree compared with that of the conventional forming process, so that strain distribution and stress distribution in the tube are improved, the casting organization remained in the broken tube is facilitated, the form and the distribution of inclusion are changed, and the defects of the internal organization of the tube are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

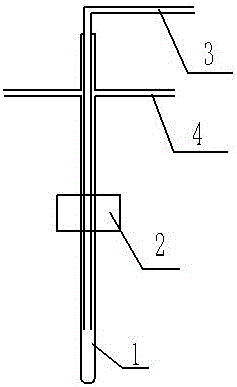

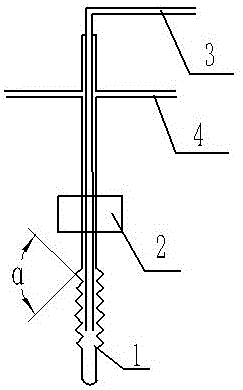

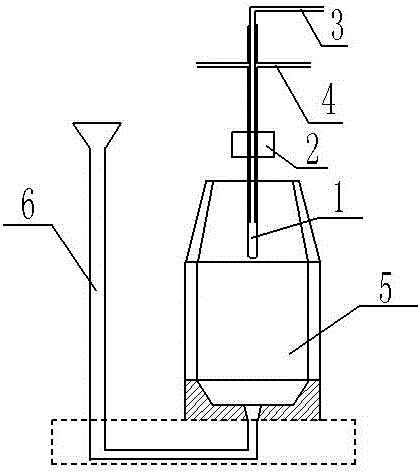

Variable frequency ultrasonic semi-continuous casting method for magnesium alloy

The invention belongs to the field of light alloy machining, and particularly relates to a variable frequency ultrasonic semi-continuous casting method for magnesium alloy. The method comprises the steps of alloy smelting, melt delivery and consolidation forming under ultrasonic treatment. Magnesium alloy melt is treated in a real-time variable frequency ultrasonic field introduced in the semi-continuous casting process, and the quasi real-time tracking of the resonant frequency of metal melt is achieved; and liquid cave melt is subjected to the ultrasonic resonance treatment continuously in the whole semi-continuous casting process, so that the continuous ultrasonic high-efficiency treatment of the magnesium alloy melt is achieved in the solidification process. In the method provided by the invention, an ultrasonic radiation rod is extended into the magnesium alloy melt in the magnesium alloy semi-continuous casting process, so that the cavitation effect and acoustic streaming effect produced by the variable frequency ultrasonic field directly act on the magnesium alloy melt solidifying. With the method provided by the invention, the magnesium alloy solidification behavior can be changed obviously, the structure is refined, and the uniformity of the billet solidification structure as well as the mechanical property of magnesium alloy billets are improved; and the billet casting defects are reduced obviously, and the quality of the magnesium alloy billets is improved greatly.

Owner:NORTHEASTERN UNIV +1

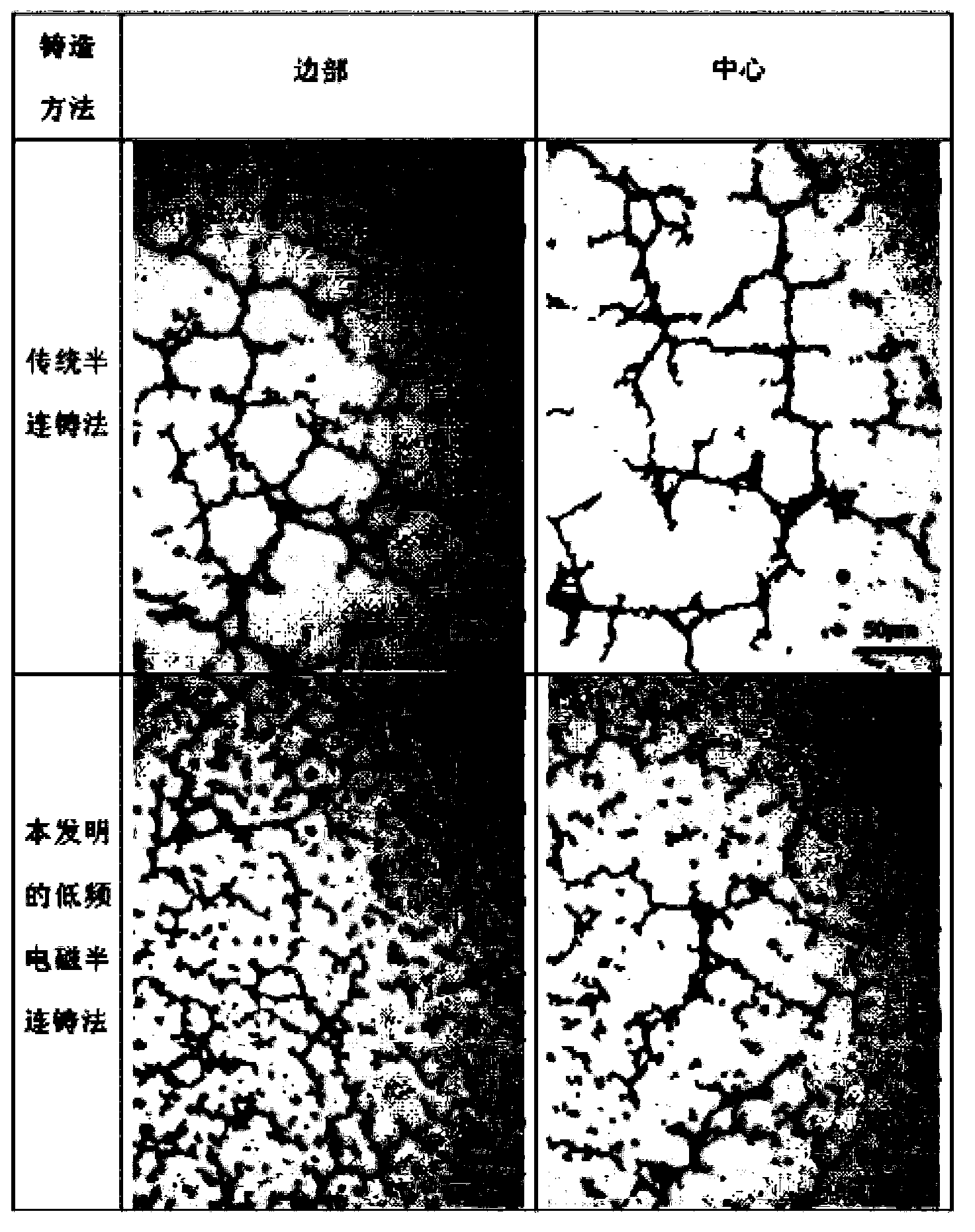

Electromagnetic semi-continuous casting method for preparing high-strength heat-resistant rare-earth magnesium alloy ingot blank

The invention discloses an electromagnetic semi-continuous casting method for preparing a high-strength heat-resistant rare-earth magnesium alloy ingot blank. The method is characterized by comprising the following steps: batching, smelting and casting molding, namely by adopting a mold provided with an excitation coil, allowing melt to flow into the mold, and applying a low-frequency electromagnetic field of specified frequency and strength; starting a casting machine and performing throwing casting when the metal liquid level in the mold reaches the liquid level height which is 30-40mm away from the horizontal position on the top of the mold, wherein the casting speed is 50-90mm / min, the casting temperature is 740-750DEG C; and the applied low-frequency electromagnetic frequency ranges from 1 to 90Hz, and the strength is 2000-4000AT. According to the method, the transverse temperature gradient in the process of solidifying the casting blank can be greatly reduced, the liquid pool shape is changed, the solidification uniformity of the casting blank is improved, the size effect of the casting blank casting defects is reduced, the internal metallurgical quality and surface quality of a large vertical semi-continuous casting rare-earth magnesium alloy ingot blank are improved, and a high-quality rare-earth magnesium alloy ingot blank which does not have cracks and is even and smooth in surface, stable in components, obviously low in macrosegregation and fine and uniform in texture can be obtained.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

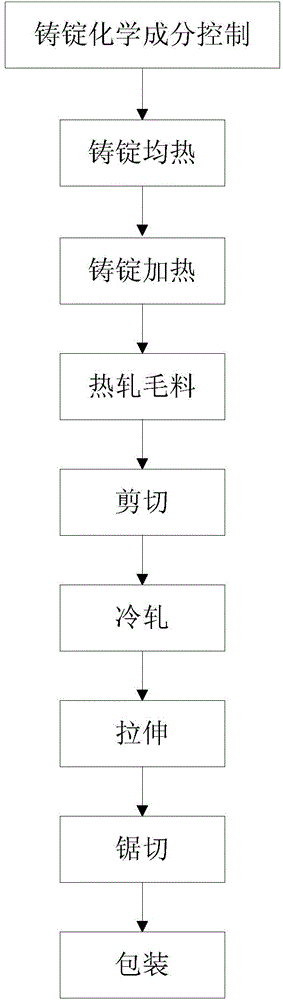

Production process of aluminum alloy plate for notebook computer

The invention discloses a production process of an aluminum alloy plate for a notebook computer. The production process comprises the following steps: controlling the chemical components of a cast ingot; uniformly heating the cast ingot, heating the cast ingot to 470-500 DEG C, and keeping the temperature for 10-50 hours; heating the cast ingot; hotly rolling raw materials; cutting; coldly rolling; straightening; sawing; and packing. The control of the chemical components of the cast ingot comprises the steps of controlling the Mg content in aluminum alloy to be 2.2-2.4%, the Cr content to be 0.15-0.20% and the use amount of a waste material in the aluminum alloy to be less than 35%, and adding a grain refiner in a casting process of the cast ingot. Compared with an existing production process, the production process has the advantages that the internal organization macro-segregation of the cast ingot is reduced, the content of impurities is effectively controlled, the production amount and size of a difficultly soluble interphase of the casting process are reduced, and the good effects in refining grains and controlling coarse compounds are achieved. The production process realizes the uniform control of large-scale cast ingot components and solves the problem that the internal organization of the aluminum alloy plate is non-uniform.

Owner:SOUTHWEST ALUMINUM GRP

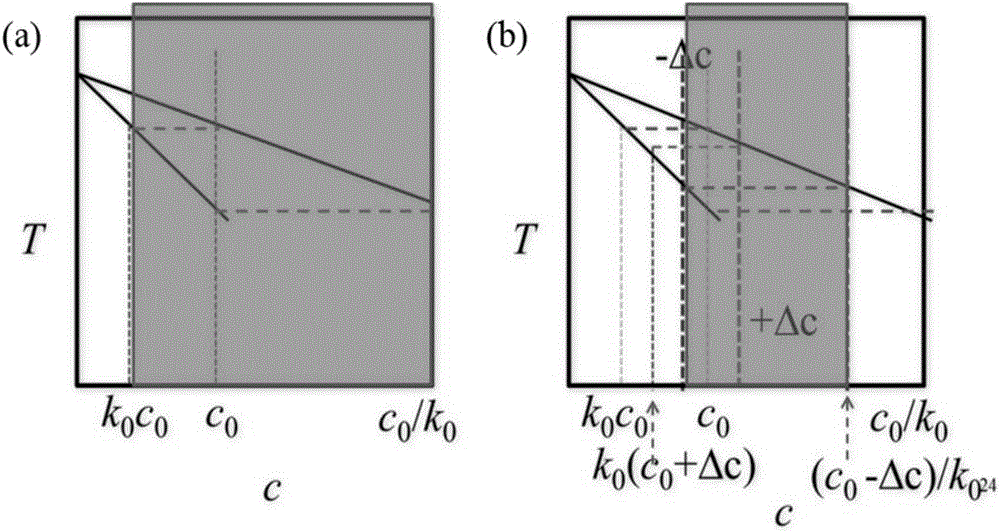

Dispersion additive casting method for preparing homogenized ingot by use of variable components

ActiveCN105945246ASmall solidification fluidityReduce macro segregationIngot castingMaterials science

The invention provides a dispersion additive casting method for preparing homogenized ingot by use of variable components. The method comprises the steps of dividing the ingot into N casting ladles for dispersion casting, wherein the casting component of a first casting ladle is decided by a target alloy component; the casting component of each casting ladle thereafter is decided by a target alloy component, a solidified segregation morphology of the last casting ladle, and the solute content of residual metallic liquid of the last casting ladle. According to the variation dispersed material additive casting method for preparing the homogenized ingot casting provided by the invention, according to the quality, a window is required to adjust the casting metallic liquid, so that the homogenization of an ingot solute is realized, and the macrosegregation of the whole ingot is greatly reduced.

Owner:SHANGHAI JIAO TONG UNIV

Brass alloy smelting device and brass alloy smelting method

InactiveCN105603225AReduce macro segregationImprove ingot qualityMolten stateElectromagnetic generator

The invention discloses a brass alloy smelting device and a brass alloy smelting method. The technical problem of poor quality of brass alloy cast ingots produced by adopting a brass alloy smelting device and a brass alloy smelting method in the prior art is solved. The brass alloy smelting device comprises a smelting furnace and an electromagnetic generator installed on the smelting furnace, wherein the electromagnetic generator is used for exerting electromagnetic disturbance on the smelting furnace, and an alloy melt in the smelting furnace is forced to produce convection under the effect of the electromagnetic disturbance. The brass alloy smelting method comprises the steps of firstly calculating the weights of brass alloy returns, pure copper and pure zinc required during brass alloy smelting, then adding the brass alloy returns, the pure copper and a composite covering agent to the smelting furnace to form the alloy melt, heating the alloy melt to be in a molten state, then adding the pure zinc to the smelting furnace for several times, exerting the electromagnetic disturbance on the alloy melt through the electromagnetic generator and finally starting to perform horizontal continuous casting when the temperature in the smelting furnace reaches discharging temperature.

Owner:ZHEJIANG HAILIANG +1

Method for high purification preparation for nickel-base superalloy through electron beam coating induced solidification technology

The invention discloses a method for high purification preparation for nickel-base superalloy through an electron beam coating induced solidification technology. The method comprises the following steps of 1, raw material preparing, 2, preparing before smelting, and 3, electron beam coating smelting. Nickel-base superalloy cast ingots are prepared by adopting the method, and macrosegregation of the cast ingots is reduced; under the electron beam induced solidification technology, the degree of purity and the metallurgical quality of the cast ingots are improved by a large margin; and engineering preparation of the large-scale cast ingots can be achieved, and the yield of primary product is improved from being less than 70% of a traditional technology to being above 85%.

Owner:DALIAN UNIV OF TECH

Method for preparing single crystal blades based on double-induction directional recrystallization of ultrafine nickel powder area

ActiveCN107159896ALower crystallization temperatureGrain refinementTurbinesZone meltingSingle crystal

The invention relates to a method for preparing single crystal blades based on double-induction directional recrystallization of an ultrafine nickel powder area. Ultrafine single crystal nickel powder serves as a main raw material; other ultrafine metal powder is added according to the high-temperature alloy material prescription requirement; and the nickel-based high-temperature alloy single crystal turbine blades of an airplane engine are prepared through the method of smelting, directional solidification and recrystallization of the double-constraint induction area of an electromagnetic field after forming. Compared with the prior art, the method for preparing the single crystal blades based on double-induction directional recrystallization of the ultrafine nickel powder area has the advantages that alloying and recrystallization are completed at a time, the recrystallization process is easy to control, the single crystal finished product rate is high, mechanical performance of products is high, the production cost is high, a mould shell and a mold core are not needed, and waste is not generated in crystal guiding and selecting sections.

Owner:SHANGHAI JIAO TONG UNIV

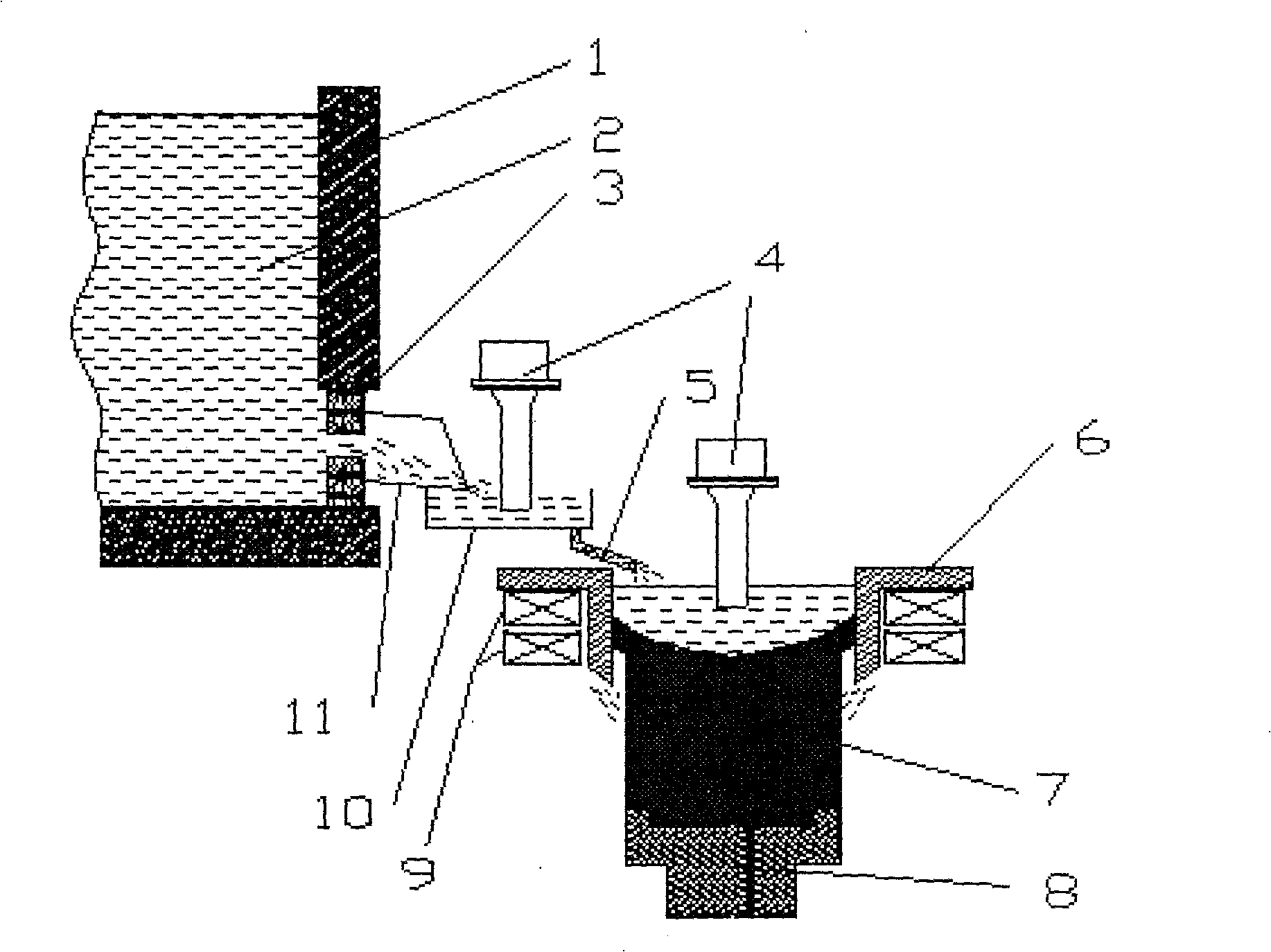

Method and device for homogenizing large ingot solidification structure by combining static magnetic field with rotating magnetic field

The invention discloses a method and device for homogenizing a large ingot solidification structure by combining a static magnetic field with a rotating magnetic field. Through the electromagnetic oscillation effect generated by a combined magnetic field and the rotational flow induction stirring effect of the rotating magnetic field, nucleation is promoted, dendritic crystal tips are crushed, crystal grains are refined, the solidification structure is homogenized, macroscopic segregation is reduced, and therefore the method and the device are used for the large ingot casting process. When metal melt is solidified, the static magnetic field and the rotating magnetic field are exerted to a heat preservation riser in a combined mode according to the characteristics that metal liquid at an ingot mould riser is solidified lastly, the riser wall and the metal liquid surface are easy to nucleate first, and the rotating magnetic field and the static magnetic field can easily permeate a riser material, the metal liquid in the heat preservation riser is effectively oscillated and stirred, and the metal liquid in the riser is delivered into the metal liquid at the center of an ingot mould through oscillating and rotational flow stirring; the dendritic crystal tips are crushed, the crystal grains are refined, the solidification structure is homogenized, macroscopic segregation is reduced, a compact, homogenized and crystal grain-refined large ingot is obtained, and therefore the subsequent machining performance and service performance of the large ingot are improved.

Owner:SHANGHAI UNIV

Multi-alloy vertical semi-continuous casting method

The invention relates to a method for the vertical semi-continuous direct chill casting of composite billets or plates comprising at least two layers of aluminum alloys, using a separator which is in contact with the solidification front and which provides a seal between the two alloys during casting, said separator being vibrated while it is in contact with the solidification front, so that the separator is not frozen in and entrained by the solid metal. The invention also relates to a device that can be used to carry out said method.

Owner:CONSTELLIUM ISSOIRE

Discrete casting method for preparing homogenized cast ingot

The invention discloses a discrete casting method for preparing a homogenized ingot, which comprises the following steps: step 1, numerically simulating the discrete pouring process, obtaining the relationship between the solid phase ratio and solidification time in the solidification process as the numerical simulation result; step 2, After smelting, degassing, and slag removal of the molten metal, the alloy liquid is obtained and ready for casting; step 3, adopt the top pouring casting method, use the alloy liquid to cast to a predetermined thickness, and stop pouring; step 4, track and measure the temperature in real time, refer to step 1 According to the numerical simulation results, when the solid phase ratio of the poured metal liquid reaches 70%-80%, the next casting is carried out; step 5, repeat steps 3 and 4 until the casting and solidification of the ingot is completed; step 6, heat treat the ingot To eliminate casting stress. Compared with the ordinary casting process, in the discrete casting method of the present invention, more metal surfaces are in contact with the environment, and the cooling rate is faster, which is helpful for grain refinement.

Owner:SHANGHAI JIAO TONG UNIV

Method of applying electric field energy on molten steel to improve quality of silicon steel billet

The method of applying electric field energy on molten steel to improve quality of silicon steel billet is to introduce electric field energy with the electric field energy generator and the electrodes into molten steel, the electric field energy waveform is duty ratio variable square wave of energy 1000 J-180 MJ, voltage 100-1800V, current 100A-8KA, frequency not higher than 25 Hz and duty ratio of 5-90 %. The electric field energy generator is suitable for use in industrial production and controllable in electric field energy parameters. The treated molten steel results in refined billet structure with obviously increased global crystal, less defaults and high quality.

Owner:ANGANG STEEL CO LTD

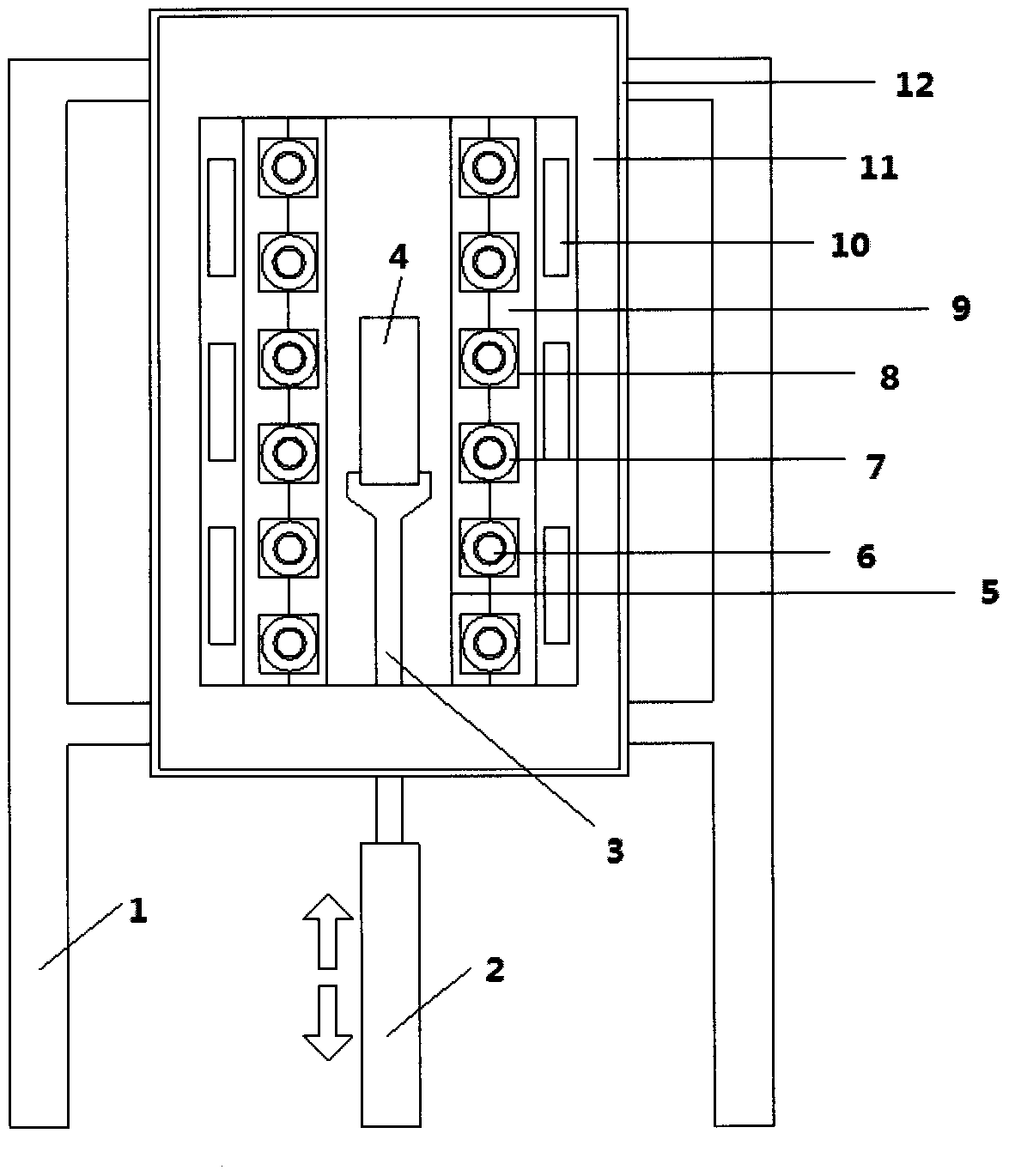

Device for refining grain structure and application method

The invention discloses a device for refining grain structure and an application method, and belongs to the technical field of metallurgy. The device comprises a vibration device inserted in a steel ingot mold; the vibration device includes a vibration rod making direct contact with molten steel; the vibration rod is provided with a vibration generation source for driving the vibration rod to move; an introduction pipe for circulating a cooling medium is arranged in the center of the vibration rod; and discharge pipes for circulating the cooking medium are arranged on two sides of the upper end of the vibration rod. A steel ingot is vibrated in the solidification process to urge fusing and breakage of dendrites; and the number of free cold crystals is increased to inhibit growth of columnar crystals, so that the isometric crystal rate is increased, the solidification structure is refined, and the purpose of relieving segregation is achieved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Aluminum alloy laminar flow distribution plane solidification casting device and casting method thereof

ActiveCN106238716AAchieve laminar distributionAvoid local overheatingMolten metal pouring equipmentsIngot castingWater spray

The invention discloses an aluminum alloy laminar flow distribution plane solidification casting device and a casting method thereof, and belongs to the technical field of aluminum alloy ingot blank casting. The device comprises a support. A translation flow distribution mechanism capable of moving horizontally is arranged on the upper portion of the support. A flow control mechanism is arranged at an outlet of the translation flow distribution mechanism. A casting tank is arranged below the translation flow distribution mechanism. A water spraying system and a cooling plate system are arranged below the casting tank. The method includes the steps that the cooling plate system rises into the casting tank, and molten aluminum alloy enters a flow distribution groove and then enters a guide rod sleeve; a second motor is started to control flow of the molten aluminum alloy; a first motor is started, a movable plate drives the flow distribution groove to move horizontally, and the molten aluminum alloy flows to a cooling plate upper plate body in a laminar mode; when an aluminum alloy solidification layer can be supported, a cooling plate oil cylinder is started, and thus the cooling plate system descends; then the water spraying system is pushed in, and sprayed water is cooled; the descending speed of a main oil cylinder is controlled until casting reaches a preset thickness; and after all the cooling is completed, water spraying is stopped, the water spraying system is extracted, ingot castings are taken out, and accordingly casting is completed.

Owner:NORTHEASTERN UNIV

Cast-rolling mechanism for aluminum alloy plates

The embodiment of the invention discloses a cast-rolling mechanism for aluminum alloy plates. The cast-rolling mechanism comprises a front box, a cast-rolling mouth, casting rollers and a pulse loop, wherein the front box is used for bearing aluminum alloy flux, the cast-rolling mouth is connected to a sluice in the lower part of the front box, the casting rollers are symmetrically arranged on and under the front end of the cast-rolling mouth, the aluminum alloy flux is cast and rolled for forming the aluminum alloy plates through the casting rollers, one electrode of the pulse loop is connected to the aluminum alloy flux, and the other electrode of the pulse loop is connected to the aluminum alloy plates. According to the cast-rolling mechanism for the aluminum alloy plates, low-temperature casting is adopted, and therefore more crystal nucleuses can be formed at the solidification front of a cast-rolling area, and grains can be refined; the pulse loop with one electrode connected to the aluminum alloy flux and the other electrode connected to the aluminum alloy plates is arranged additionally, and therefore the flux of aluminum alloy 7075 can be always subjected to the effect of pulsed magnetic force, the phenomenon that the flowing property is lowered because the crystal nucleuses grow up and get bridged can be prevented, the roundness degree of the crystal nucleuses can be improved, and the uniformity of alloy elements can be improved.

Owner:FOSHAN JINLAN NON FERROUS METAL PROD CO LTD

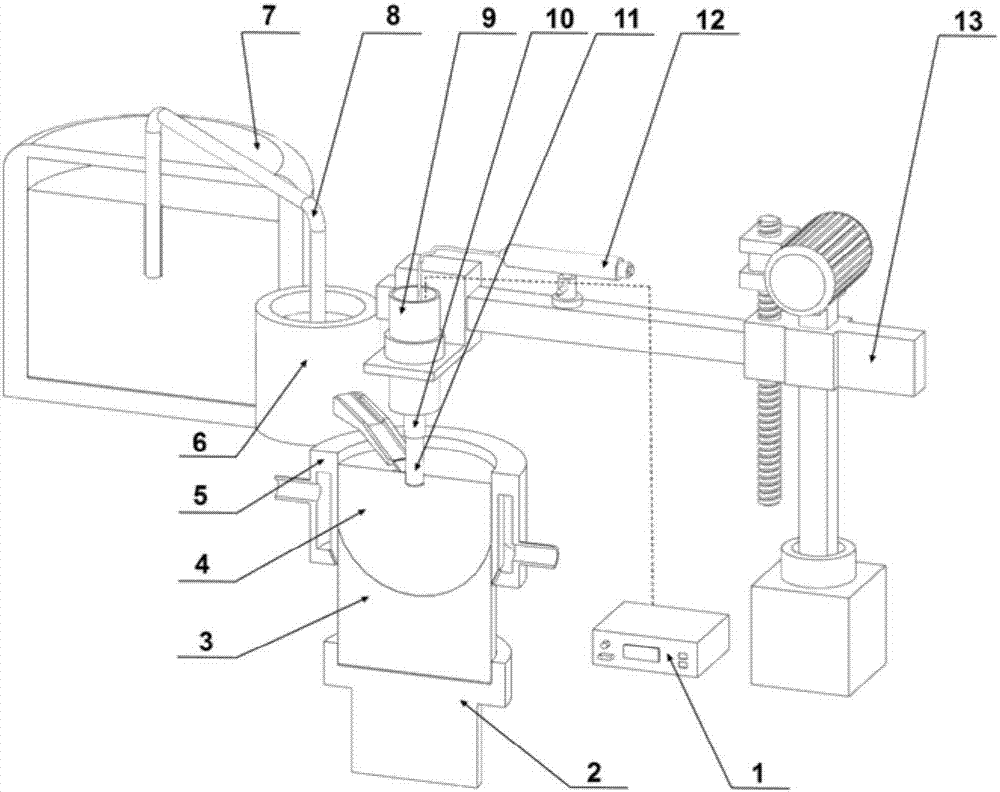

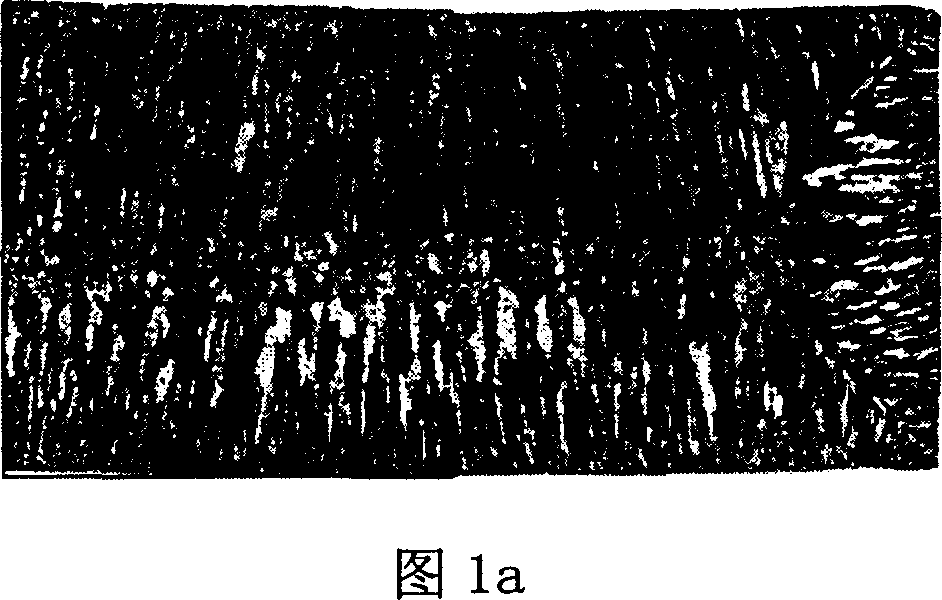

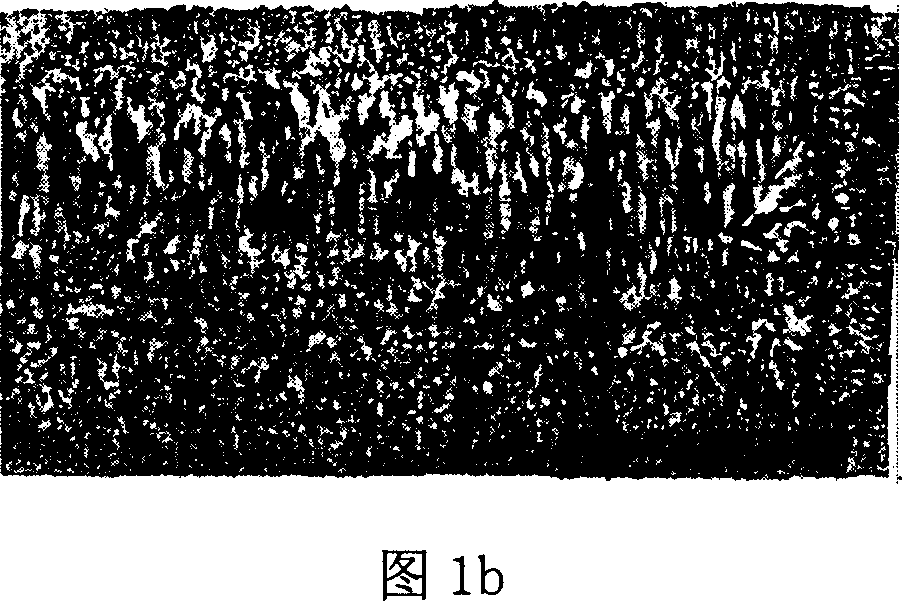

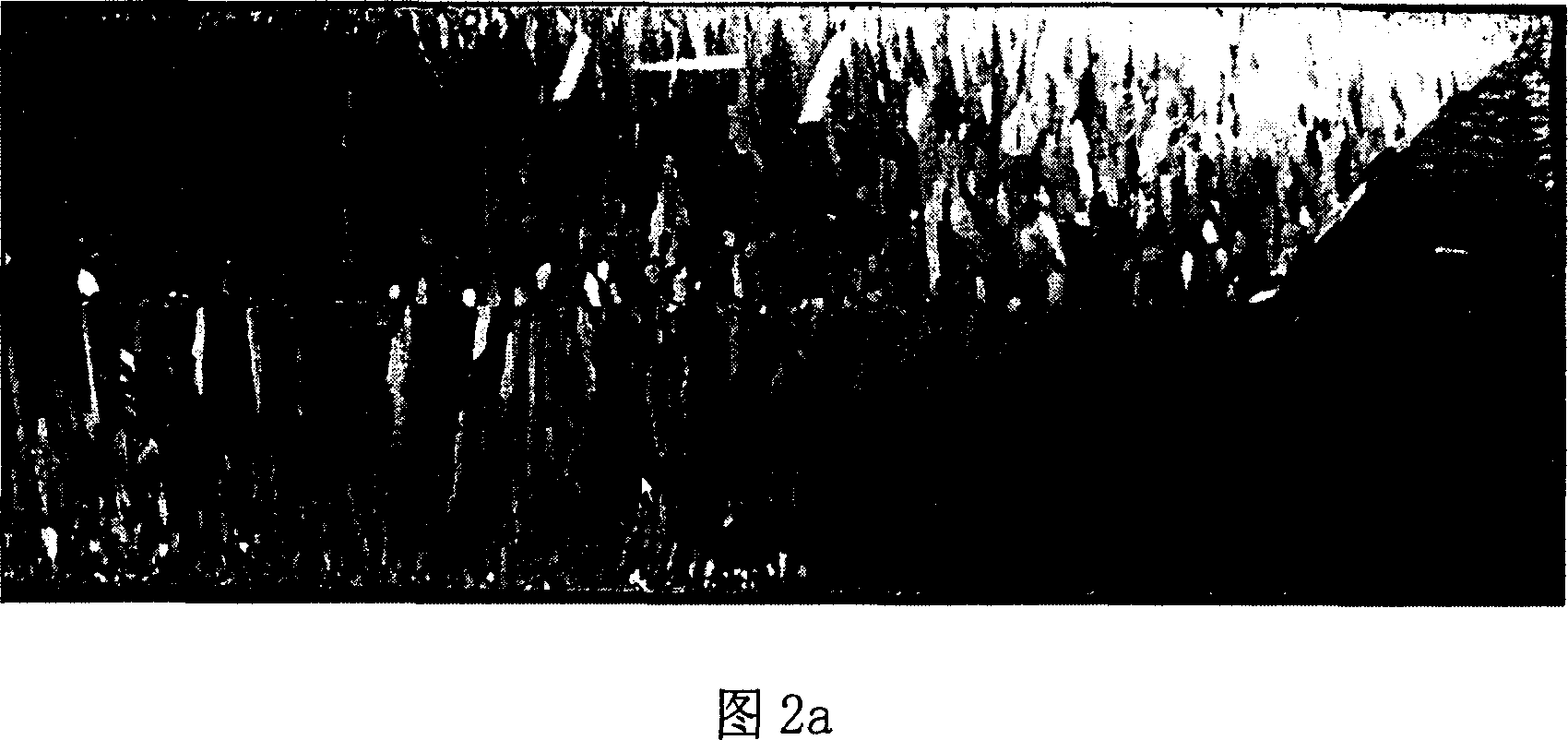

Vertical semi-continuous light alloy ingot casting process and apparatus with cooperation of power ultrasound wave and low frequency electromagnetic wave

InactiveCN100534669CImprove uniformityReduced lateral temperature gradientContinuous lightShape change

A method and equipment for vertical semi-continuous casting of light alloy large-size ingots with synergistic effects of power ultrasound and low-frequency electromagnetics, which adopts vertical semi-continuous casting of light alloy large-size ingots that can be applied with the synergy of two external fields, power ultrasound and low-frequency electromagnetics Equipment, apply low-frequency electromagnetic field and power ultrasonic field or low-frequency electromagnetic oscillation field and power ultrasonic field at the same time during the casting process, the power ultrasonic field acts on the axis of the crystallizer, and the electromagnetic field acts near the surface of the metal melt, through the adjustment of the two external field parameters Realize the synergistic effect, so that the whole volume of the external field can be cast during the solidification process of the crystallizer melt; The size effect of ingot casting defects, greatly improving the internal and surface quality of vertical semi-continuous casting light alloy large ingots.

Owner:NORTHEASTERN UNIV LIAONING

Indium gallium antimonide crystal growing furnace with traveling wave magnetic field

PendingCN108193279AReduce dislocationEvenly distributedPolycrystalline material growthSingle crystal growth detailsMelting tankIndium

The invention provides an indium gallium antimonide crystal growing furnace with a traveling wave magnetic field. The indium gallium antimonide crystal growing furnace comprises a magnetic field generation mechanism, a vertical lifting mechanism and a furnace body supporting mechanism. The magnetic field generation mechanism is composed of an iron core, a three-phase conduction insulated wire, andan insulated protective shell; the three-phase conduction insulated wire is connected to a power supply; the power supply generates electric current, and the electric current generates a travelling wave magnetic field in a horizontal coil. By applying a travelling wave magnetic field in the crystal growing furnace, when the direction of the lorentz force caused by the travelling wave magnetic field is downward, the melted material of indium gallium antimonide in a crucible is conveyed under the action of the lorentz force so that the convection process of the melted material can be accelerated and cold and hot area distribution in a furnace hearth can be more uniform. Meanwhile, a rectangular wave current generator is used for periodically controlling phase displacement signals of the three-phase current in the coil, so that uniform distribution of the melted material is facilitated, macrosegregation is obviously weakened, and indium gallium antimonide crystal ingots with lower dislocation and better crystal quality are obtained.

Owner:TIANJIN POLYTECHNIC UNIV

Device and method for preparing large cast ingot through slag protection based multi-layer casting magnetic field current compound treatment

ActiveCN110369682ASpeed up the flowHigh degree of homogenizationIngot casting plantsPorosityMelting tank

The invention discloses a device and method for preparing large cast ingot through slag protection based multi-layer casting magnetic field current compound treatment. The device comprises a steel ingot mould, a dead head, a slag ladle and a tundish, wherein movable type parallel electrodes and a movable type magnetic field coil are further separately arranged on the upper part of the steel ingotmould; during casting, amount of needed molten steel is firstly determined according to the specification of the large cast ingot, and the amount of the molten steel is divided into a plurality of parts according to the property of easily segregating elements in the molten steel; content of elements which are easily segregated in each part is regulated, so that casting powder is added before the first part of the molten steel is cast, tapping in a slag layer is guaranteed, and impurities are adsorbed; under action of magnetic fields and / or current, the next part of the molten steel is added while the first part of the molten steel is gradually solidified till a molten pool is relatively small, and protective slag is supplemented till all of the molten steel is cast to prepare the cast ingot. The casting method disclosed by the invention can purify the molten steel, relieves and even eliminates gross segregation, and alleviates shrinkage cavity and porosity.

Owner:SHANGHAI UNIV

Magnesium alloy electromagnetic low-temperature semicontinuous casting method

The magnesium alloy electromagnetic low-temp. semicontinuous casting method includes the steps of melting magnesium, adding compound fire-resisting elements, adding alloy elements, heat-insulating, standing still and semicontinuous casting under the electromagnetic field. It utilizes the addition of compound fire-resisting elements to implement smelting of magnesium alloy free from coverage or protection so as to shorten technological process and raise melt quality, and utilizes the application of electromagnetic field and optimization of crystallizer structure to implement the low-temp. and high-speed semicontinuous casting of magnesium alloy.

Owner:NORTHEASTERN UNIV LIAONING

A kind of cu-fe composite material double-melt mixed casting equipment and technology

The invention discloses a Cu-Fe composite double-melt mixed casting equipment and process, comprising a first melting furnace for heating and melting pure Cu; a second melting furnace for heating and melting Cu-Fe alloy; a mixing chamber, The flow guide tube communicates with the liquid outlets of the first melting furnace and the second melting furnace to mix the heated and melted pure Cu and Cu-Fe alloy; The body is heated and electromagnetically stirred; the crystallizer is docked with the liquid outlet of the mixing chamber; the stopper mechanism is used to control the opening and closing of the liquid outlet and the melt flow of the first melting furnace and the second melting furnace; An air pressure regulating mechanism for adjusting the air pressure in the first melting furnace and the second melting furnace. The casting equipment and process not only solve the problem of inhomogeneous composition and structure of Cu-Fe composite materials in the casting process, but also can significantly improve production efficiency and reduce production costs, and are suitable for industrial scale production.

Owner:CENT SOUTH UNIV

Method for preparing copper stainless steel in-situ composite material by adopting vacuum consumable arc melting

ActiveCN114686747AReduce bring inImprove degassing effectPhotography auxillary processesIncreasing energy efficiencyArc meltingRaw material

The invention discloses a method for preparing a copper and stainless steel in-situ composite material through vacuum consumable arc melting. The method comprises the following steps that S1, raw materials are prepared, wherein 2 wt%-98 wt% of electrolytic copper powder and 98 wt%-2 wt% of gas atomization stainless steel powder are prepared; s2, raw material mixing, wherein the electrolytic copper powder and the gas atomization stainless steel powder are weighed according to the proportion and stirred and mixed in a mixer; s3, heading powder: filling the mixture into a rubber sleeve for heading powder; s4, pressing is conducted, specifically, the rubber sleeve subjected to powder upsetting is put into a cold isostatic press to be pressed into a blank; s5, sintering: putting the pressed green body into a vacuum sintering furnace for sintering; and S6, smelting is conducted, specifically, the sintered blank serves as a consumable electrode and is put into a vacuum consumable arc smelting furnace to be smelted. The copper stainless steel in-situ composite material prepared through the method is uniform in element distribution, less in macrosegregation, free of macroscopic and microcosmic defects such as element enrichment and good in structure uniformity.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Method and device for homogenizing the solidified structure of a large ingot with a static magnetic field combined with a rotating magnetic field

The invention discloses a method and device for homogenizing a large ingot solidification structure by combining a static magnetic field with a rotating magnetic field. Through the electromagnetic oscillation effect generated by a combined magnetic field and the rotational flow induction stirring effect of the rotating magnetic field, nucleation is promoted, dendritic crystal tips are crushed, crystal grains are refined, the solidification structure is homogenized, macroscopic segregation is reduced, and therefore the method and the device are used for the large ingot casting process. When metal melt is solidified, the static magnetic field and the rotating magnetic field are exerted to a heat preservation riser in a combined mode according to the characteristics that metal liquid at an ingot mould riser is solidified lastly, the riser wall and the metal liquid surface are easy to nucleate first, and the rotating magnetic field and the static magnetic field can easily permeate a riser material, the metal liquid in the heat preservation riser is effectively oscillated and stirred, and the metal liquid in the riser is delivered into the metal liquid at the center of an ingot mould through oscillating and rotational flow stirring; the dendritic crystal tips are crushed, the crystal grains are refined, the solidification structure is homogenized, macroscopic segregation is reduced, a compact, homogenized and crystal grain-refined large ingot is obtained, and therefore the subsequent machining performance and service performance of the large ingot are improved.

Owner:SHANGHAI UNIV

Homogenized copper-nickel-tin alloy rod and preparation method thereof

The invention relates to a homogenized copper-nickel-tin alloy rod and a preparation method thereof. The formula is as follows in terms of mass percentage: Zn is 0.01%-0.026%, Sn is 7.9%-8.2%, Nb is 0.02%-0.05%, Ni+Co is 14.0%‑16.0%, Fe is 0.01%‑0.02%, Mg is 0.01%‑0.15%, the rest is Cu, and Co accounts for 0%‑5.0% of the total mass of Ni+Co. The preparation method includes batching, smelting, homogenization treatment, forging, aging treatment and grinding steps. The hardness of the bar of the present invention is HRC≥35, and the tensile strength σ b ≥998Mpa, yield strength σ 0.2 ≥950Mpa, elongation δ≥6%, good uniformity of chemical composition of the bar, short production process and low manufacturing cost.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com