Device for refining grain structure and application method

A technology for refining grains and structures, applied in the field of metallurgy, can solve the problems of aggravating the severity of central porosity and shrinkage defects, affecting the structure and properties of steel ingots, prone to segregation, shrinkage and shrinkage, etc., to ensure the crystal shape. The effect of nucleation rate, suppression of grain growth, optimization of production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is described in further detail:

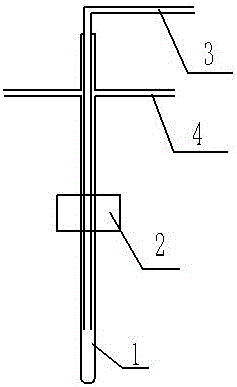

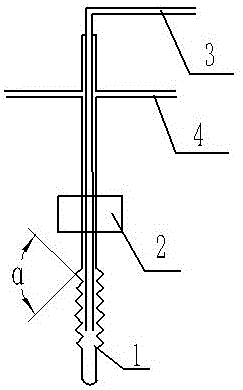

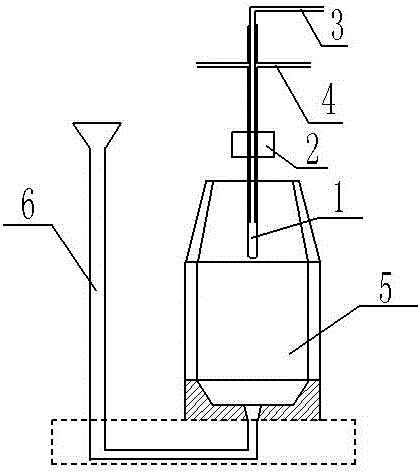

[0029] like figure 1 , image 3 As shown, a device for refining the grain structure includes a vibrating device inserted into the steel ingot mold 5, the vibrating device includes a vibrating rod 1 in direct contact with molten steel, a vibrating rod connected to the vibrating rod for driving the vibrating rod to move Generating source 2, wherein the center of the vibrating rod is provided with an inlet pipe 3 for cooling medium circulation and both sides of the upper end of the vibrating rod are provided with discharge pipes 4 for cooling medium circulation, wherein the vibration generating source 2 is a dual-frequency vibrator, which can be intelligently Set the frequency of the vibrator. When the molten metal nucleates rapidly on the surface of the vibrating rod, these primary crystal nuclei are ejected into the molten metal in large numbers and continuously under the action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com