Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Eliminate holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

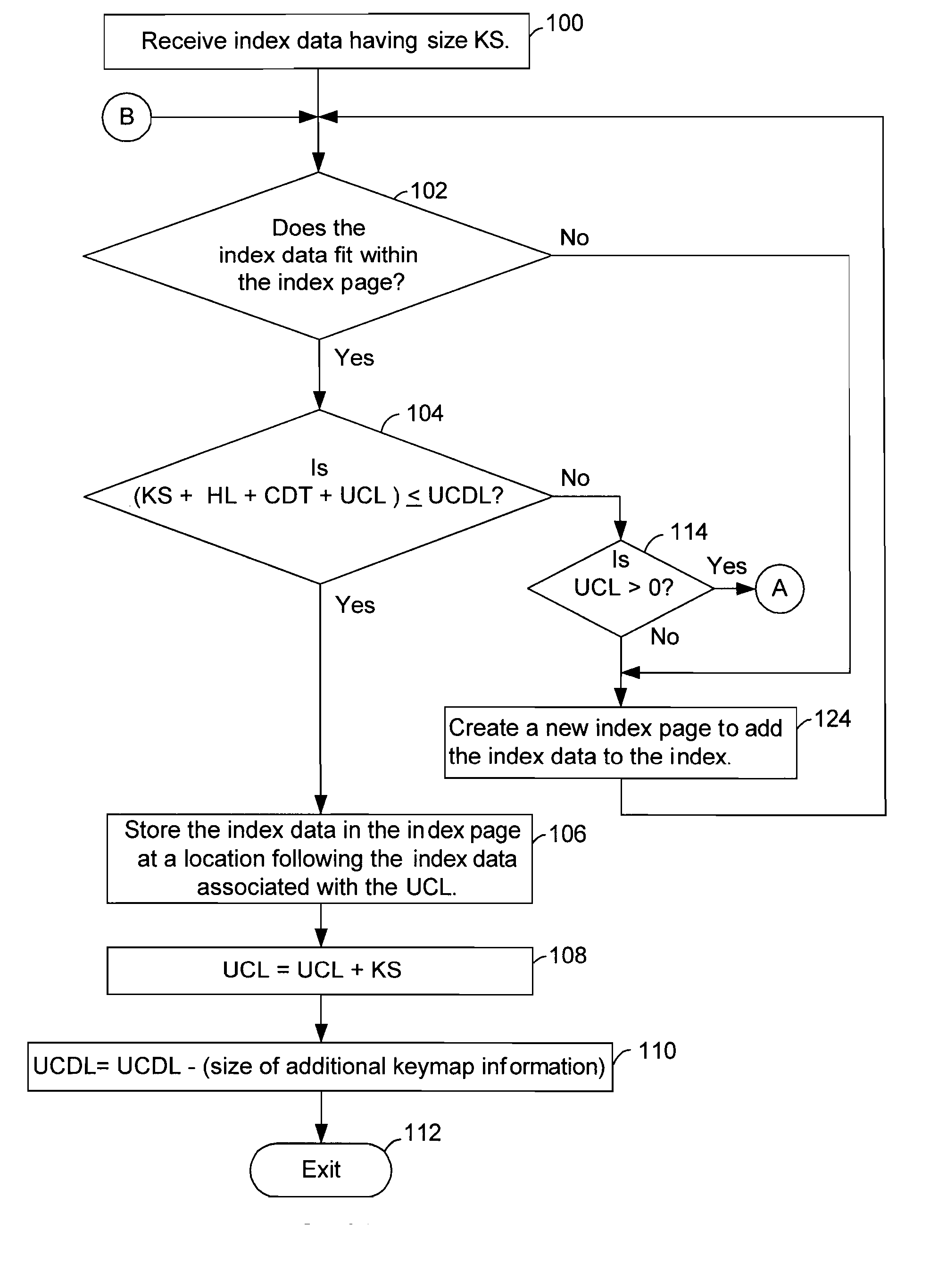

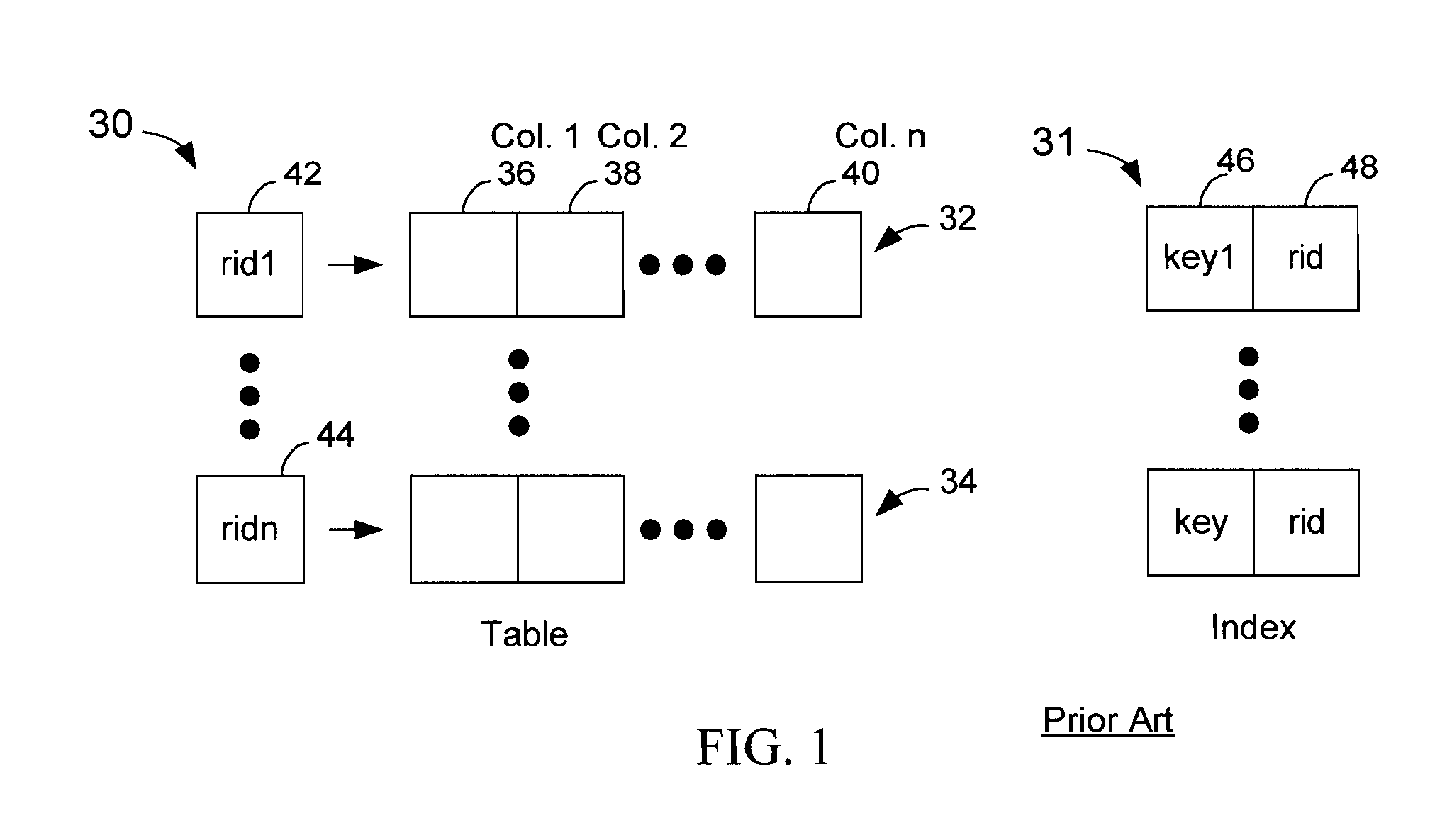

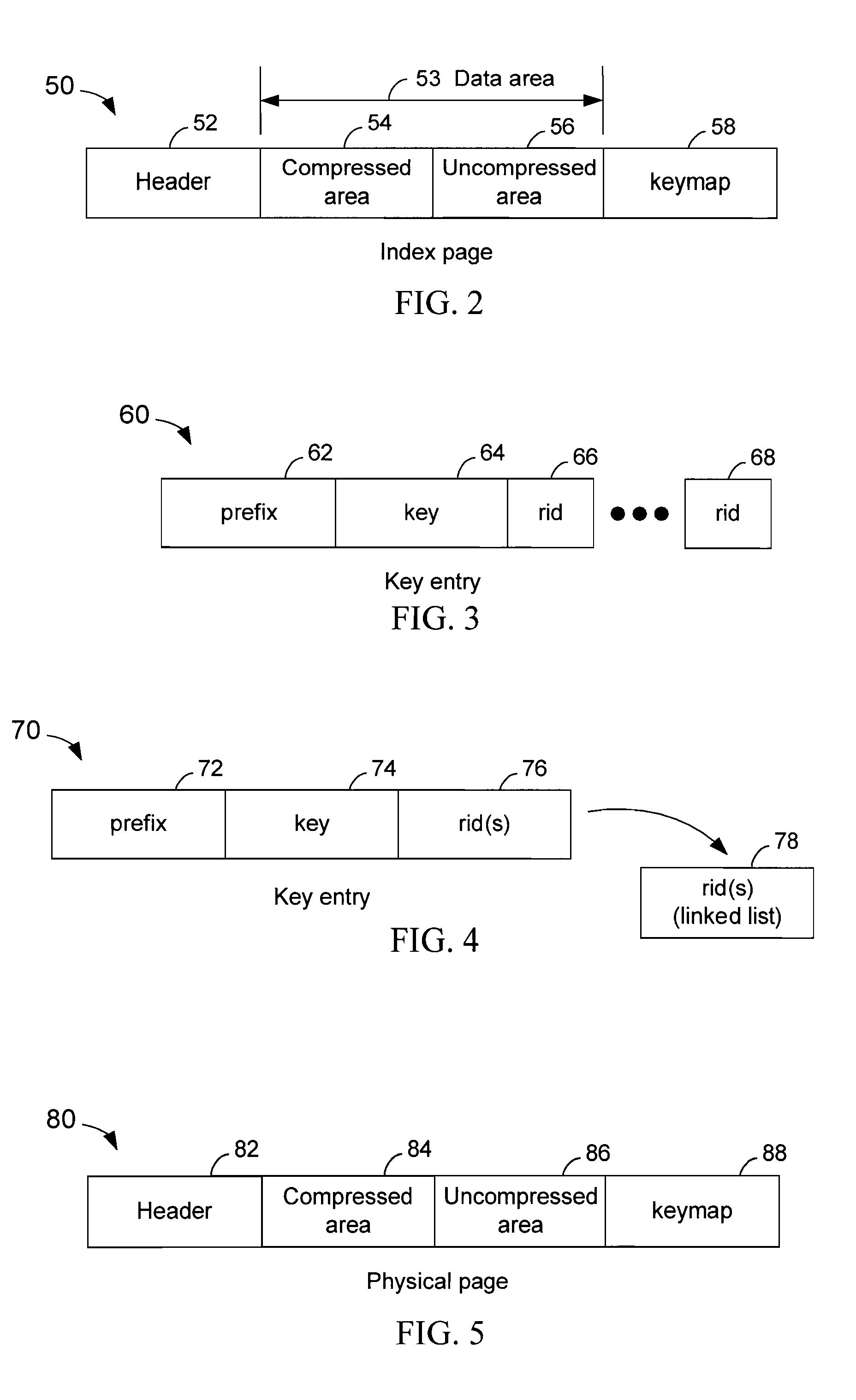

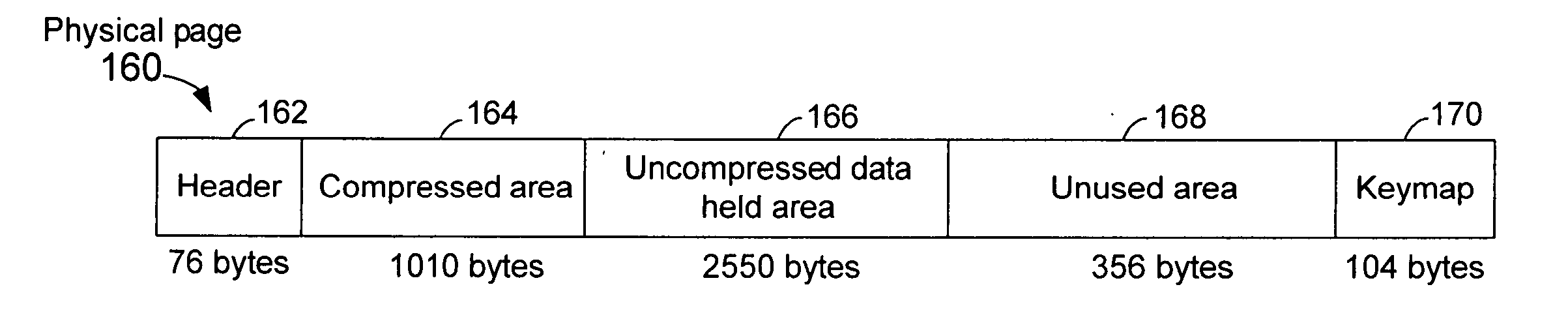

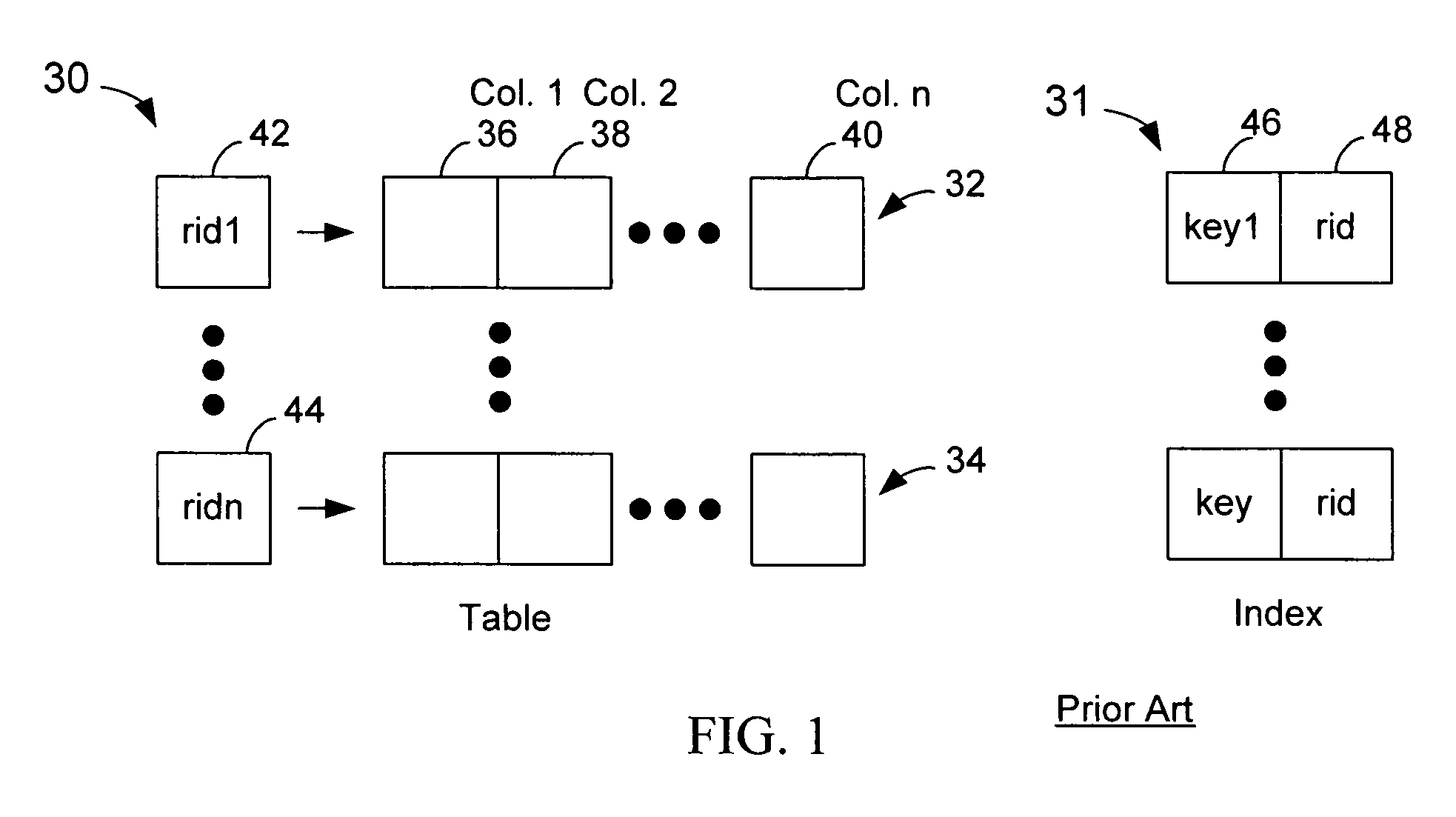

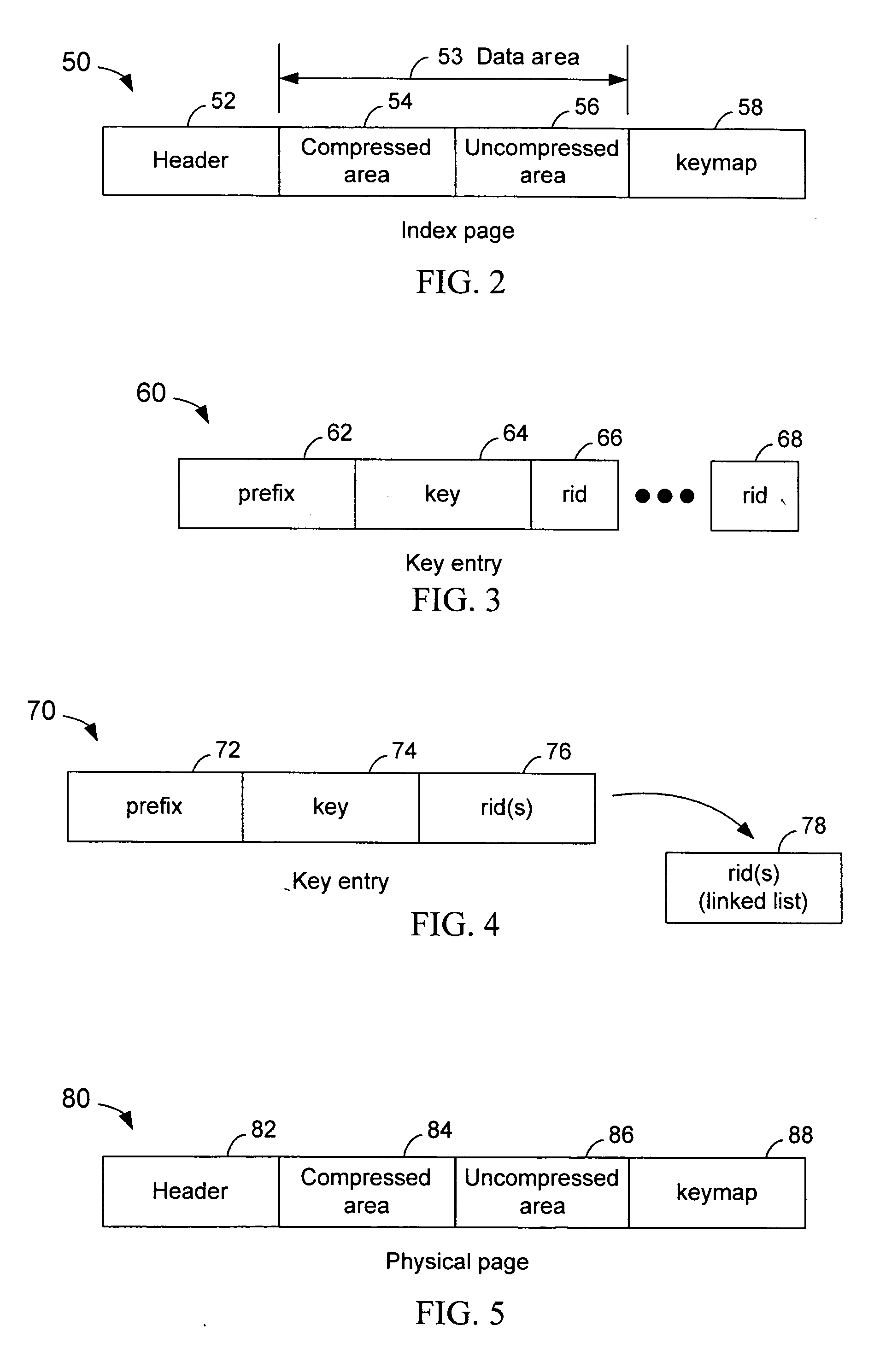

Keymap order compression

InactiveUS20070106876A1Reduce the amount requiredAvoid performanceDigital data information retrievalDigital data processing detailsDatabaseComputer program

Owner:IBM CORP

Compressibility checking avoidance

InactiveUS20070061546A1Reduce the amount requiredAvoid performanceDigital data information retrievalCode conversionCompressibilityDatabase

Various embodiments of a computer-implemented method, system and article of manufacture maintain a logical page having a predetermined size. Data is added to an uncompressed area of the logical page. The uncompressed area of the logical page is associated with an uncompressed area of a physical page. The logical page also has a compressed area associated with a compressed area of a physical page. In response to exhausting the uncompressed area, data in the uncompressed area is included in the compressed area. The uncompressed area is adjusted.

Owner:IBM CORP

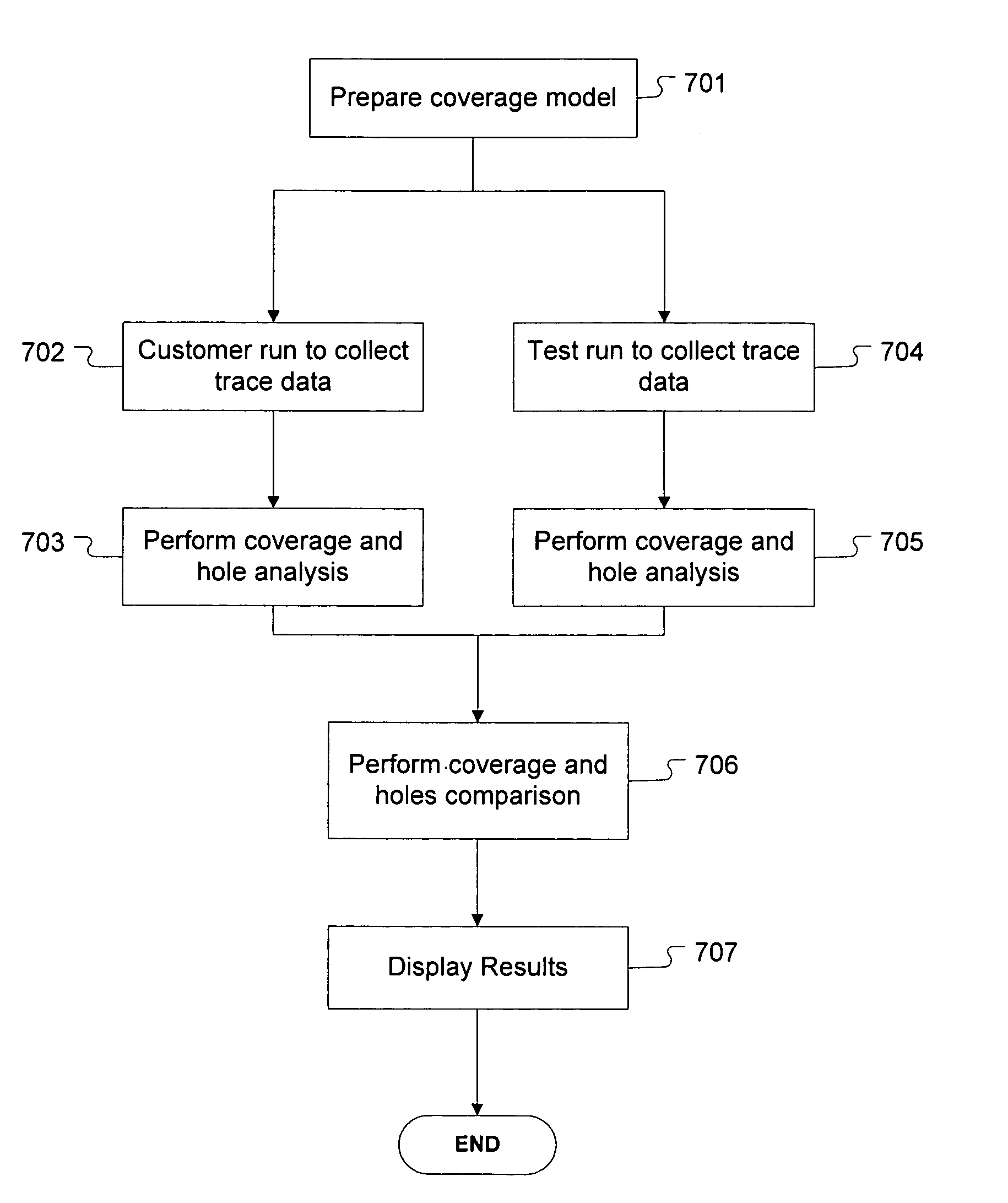

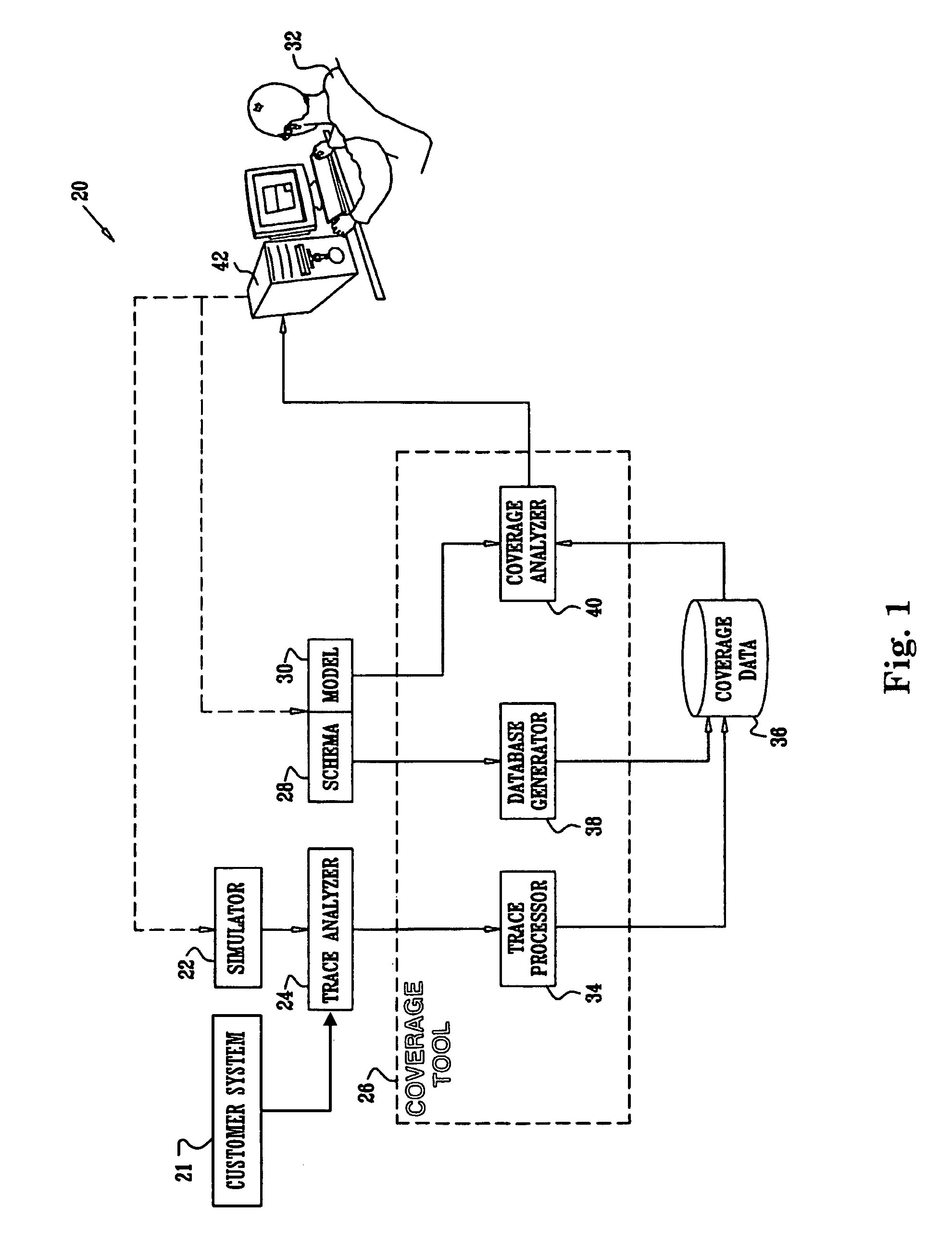

Method for comparing customer and test load data with comparative functional coverage hole analysis

InactiveUS7636871B1Easy to useReduce needError detection/correctionAnalogue computers for electric apparatusData sourceParallel computing

One aspect of the present invention includes performance of a comparative functional coverage technique for comparing analysis of actual operational load data, such as customer data, with test operational load data. In one embodiment, coverage and holes analysis operations are performed on each of actual trace data produced by the operation of actual activities, and test trace data produced by the operation of a simulation within a test execution. The functional coverage and hole analysis results produced for each of the actual data source and the test data source are then compared to discover the most important functional holes relevant to testing, namely holes which appear only in the test but not within the actual operation. The results of the holes comparison detailing which holes exist within the test are then presented and ultimately utilized to improve the test.

Owner:IBM CORP

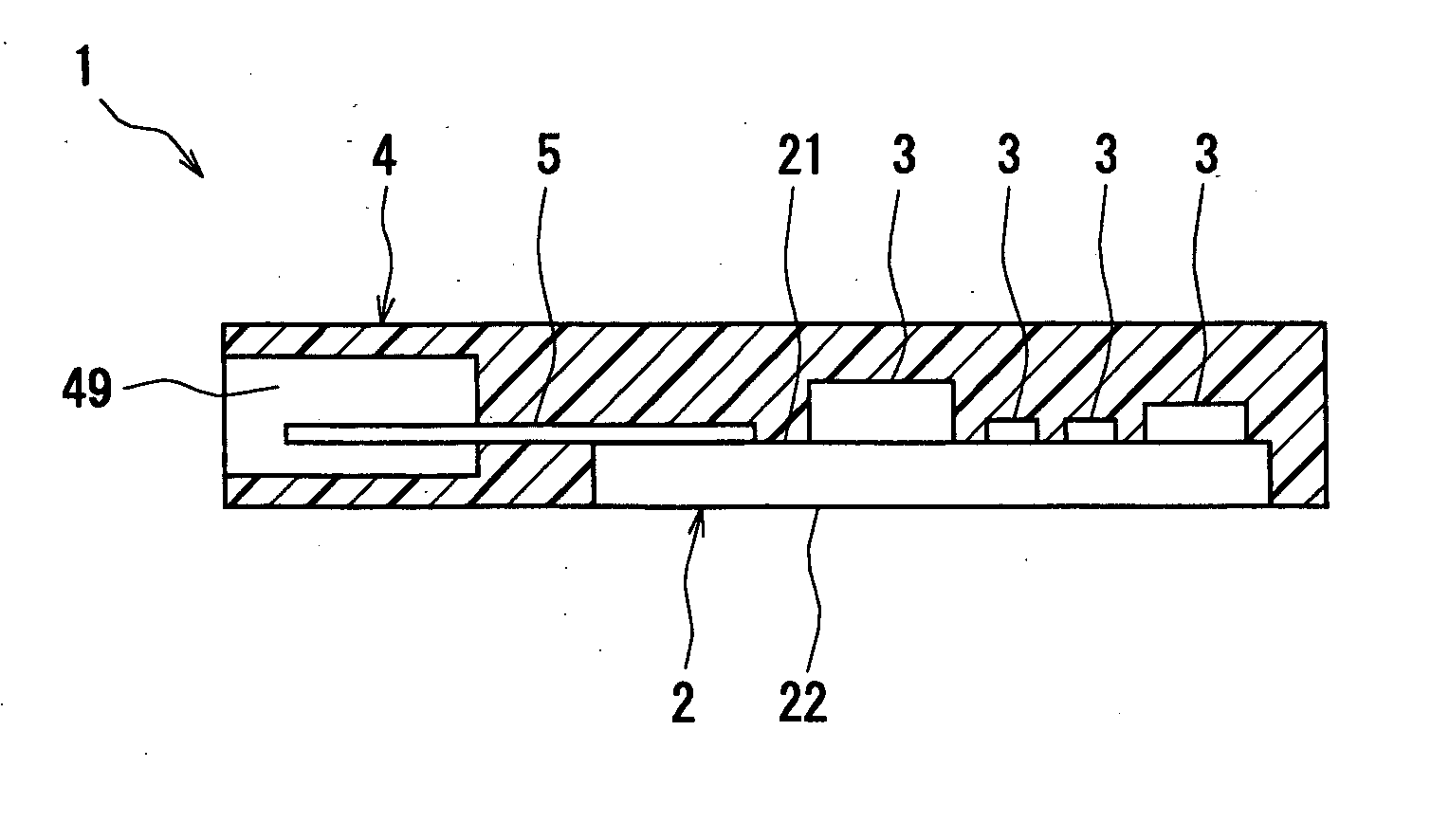

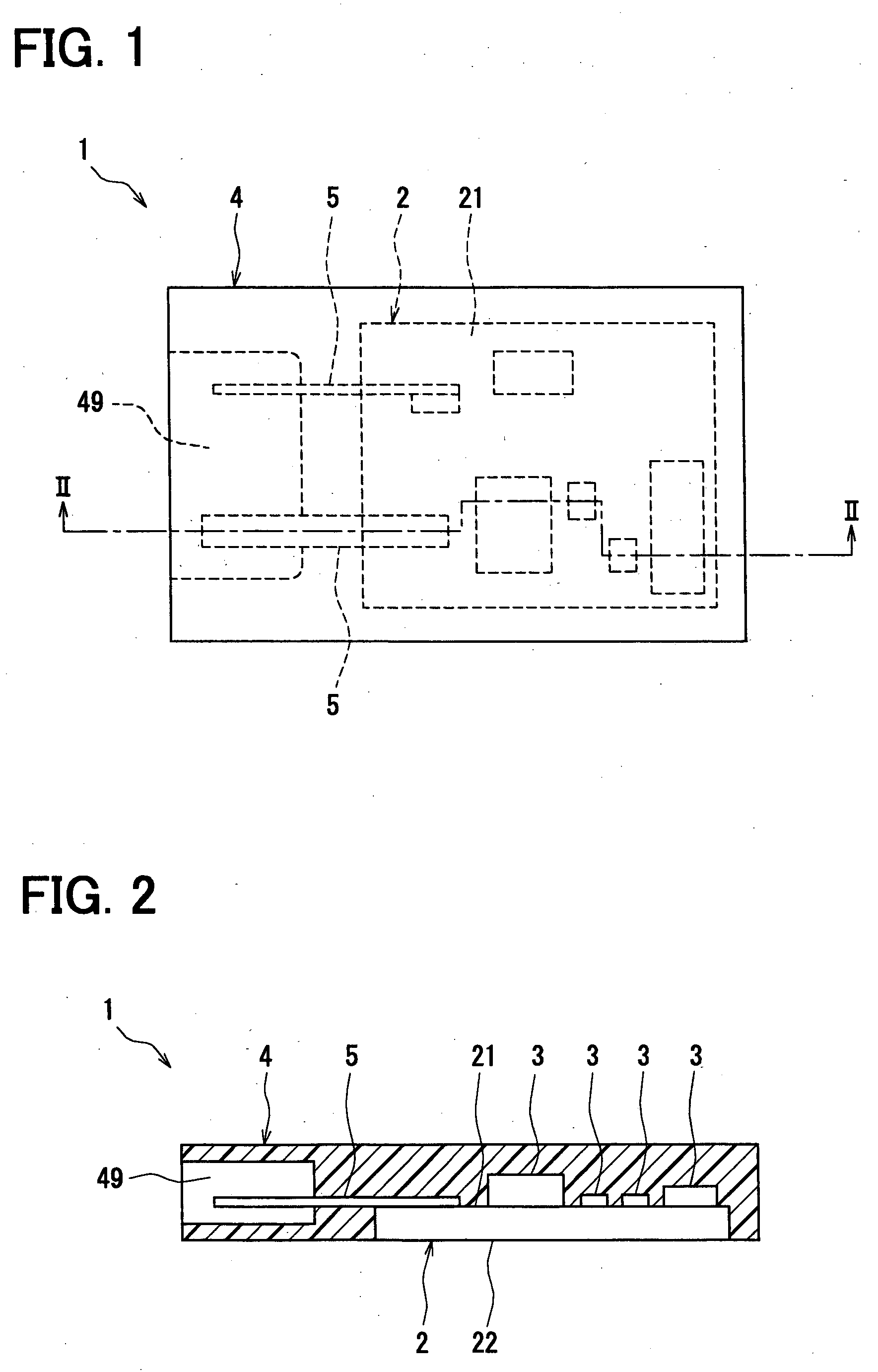

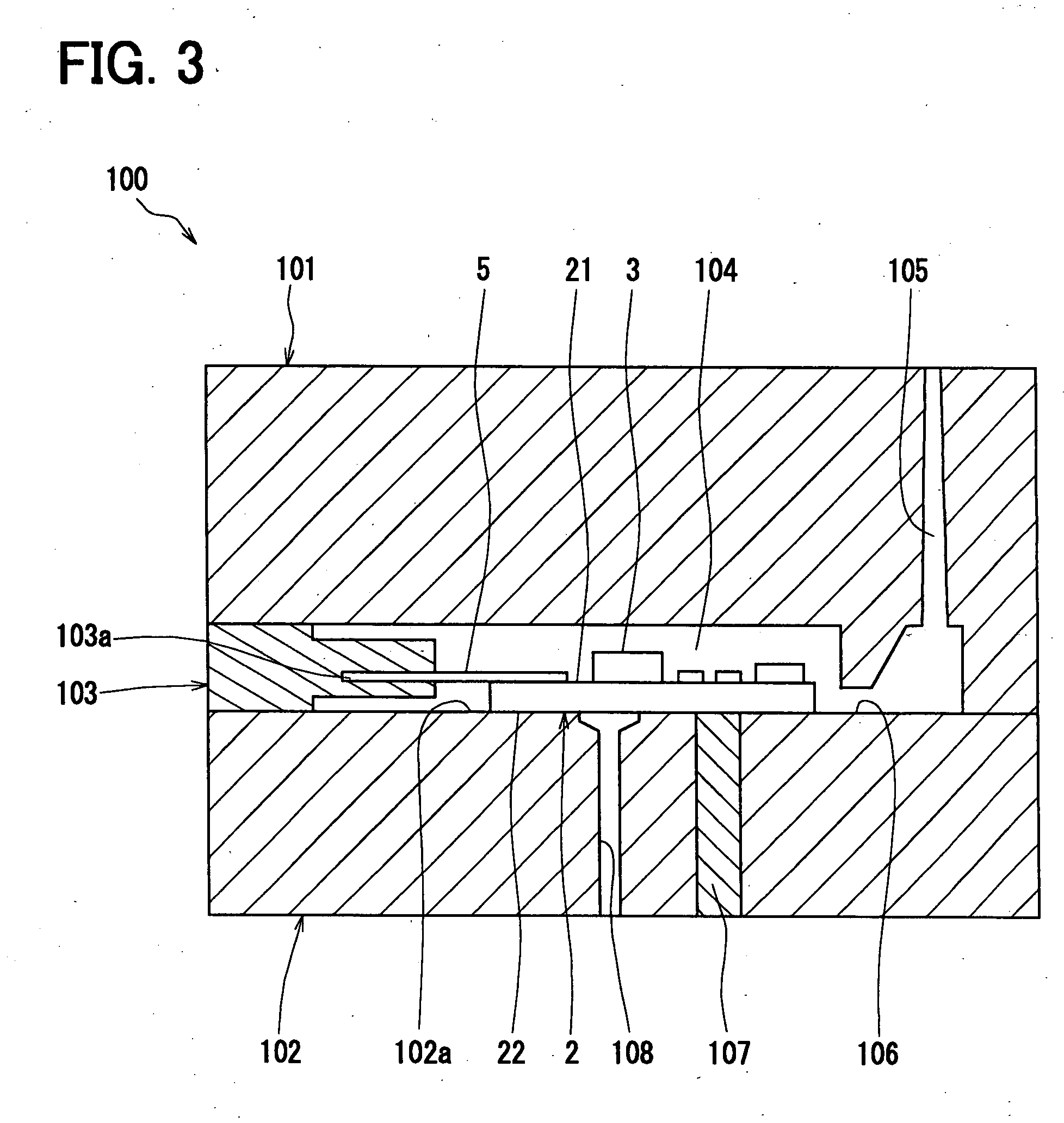

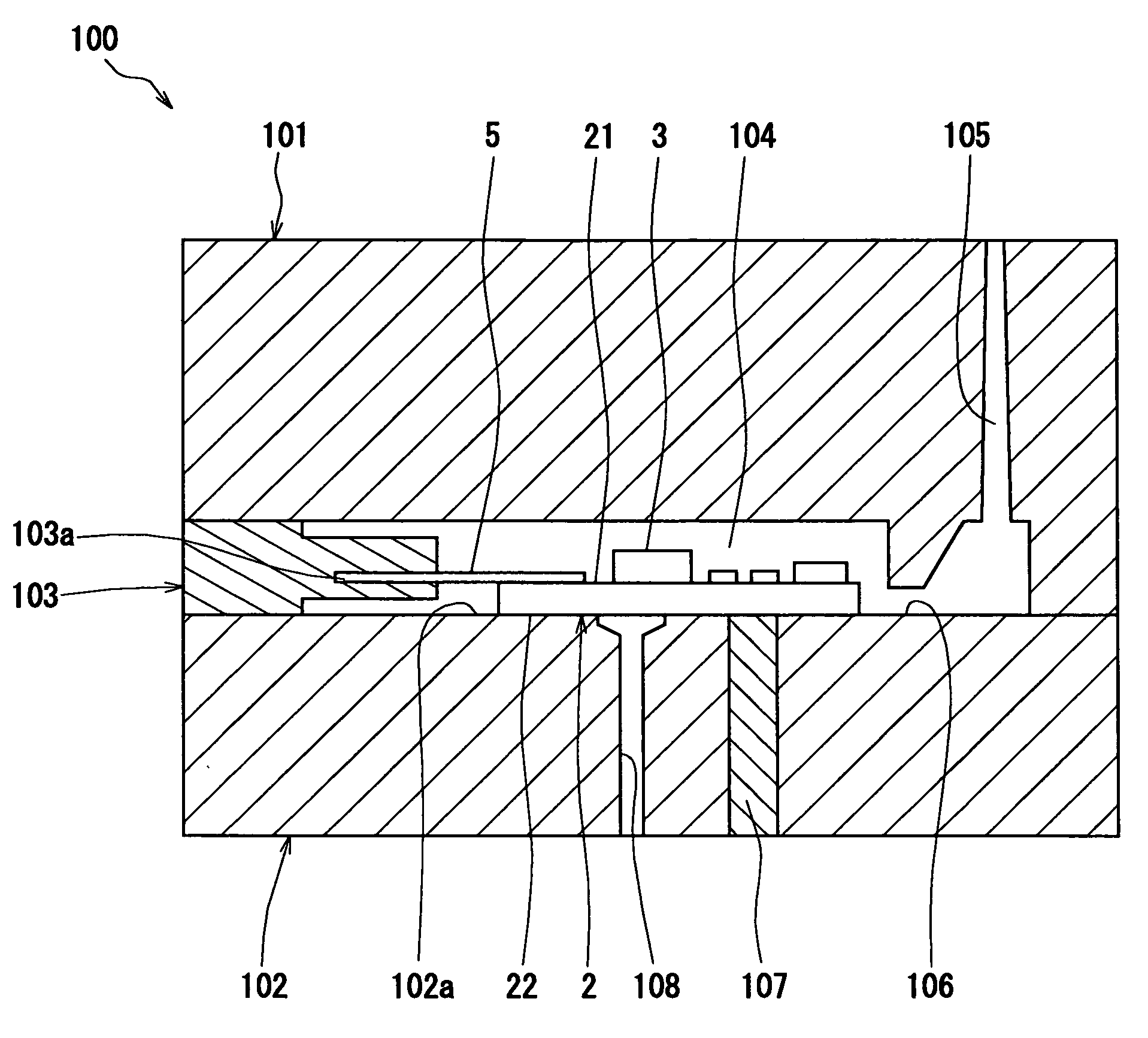

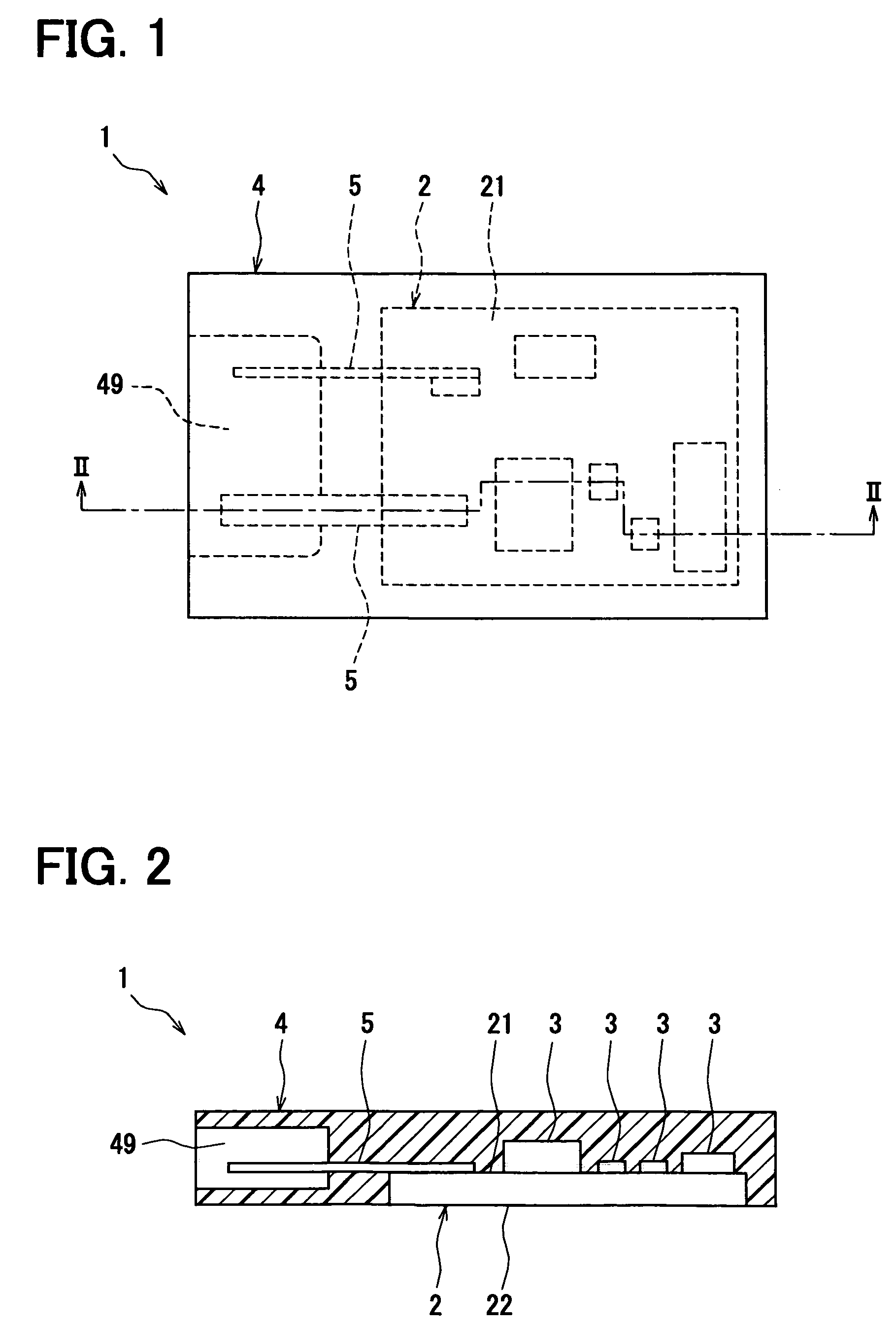

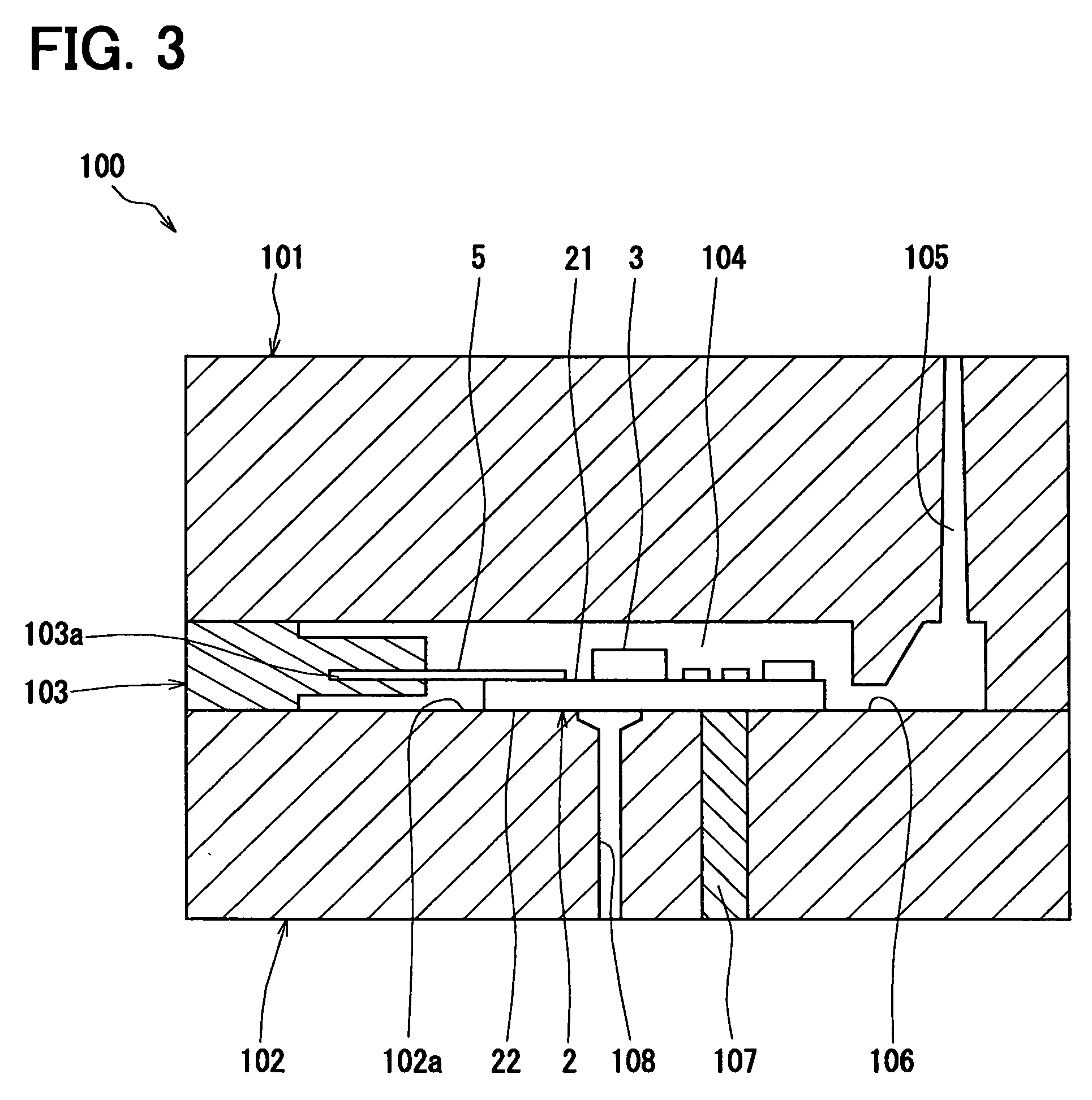

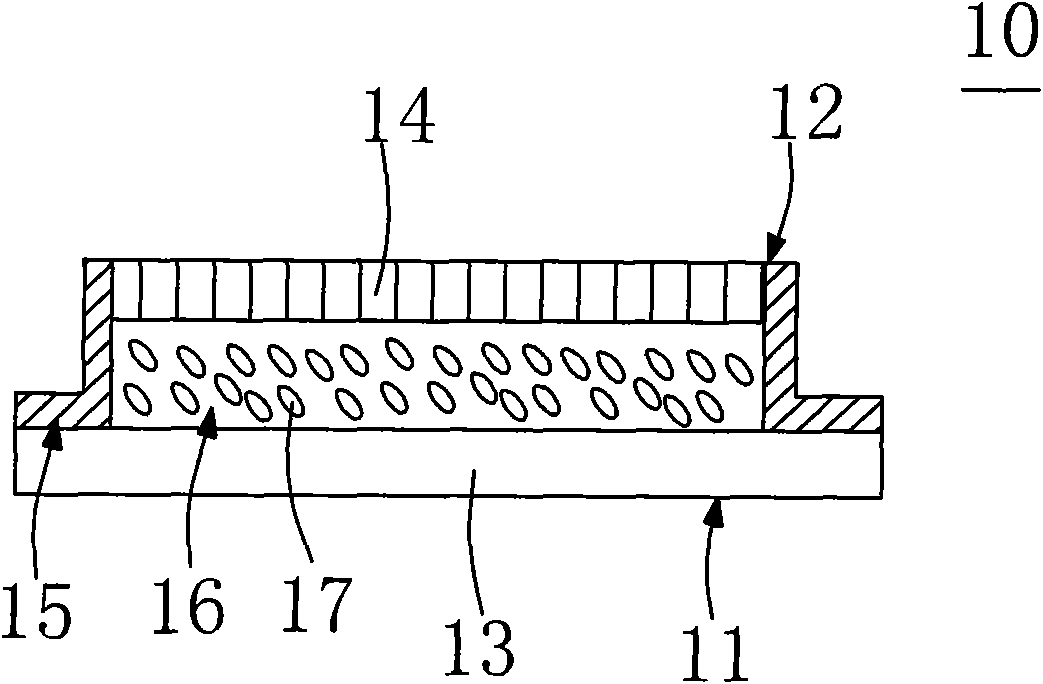

Electronic circuit device and manufacturing method of the same

ActiveUS20070161269A1Avoid deformationGood lookingDischarging arrangementMouldsEngineeringElectronic circuit

Owner:DENSO CORP

Electronic circuit device and manufacturing method of the same

ActiveUS20060252384A1Save mold costImprove molding appearanceCoupling device detailsPrinted circuit aspectsElectronic circuitEngineering

Owner:DENSO CORP

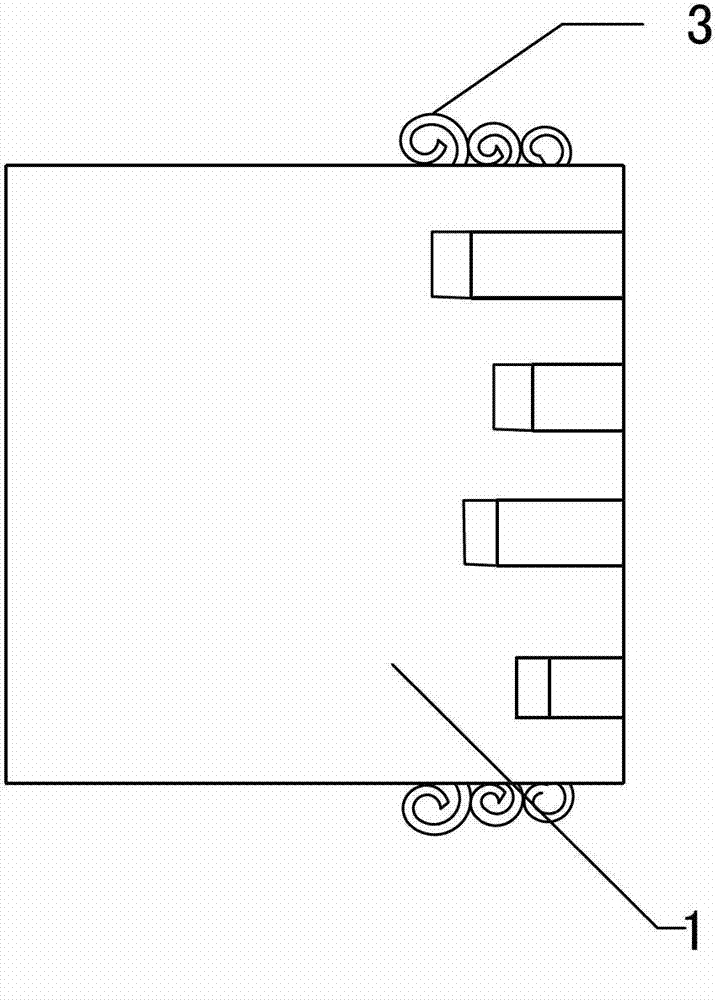

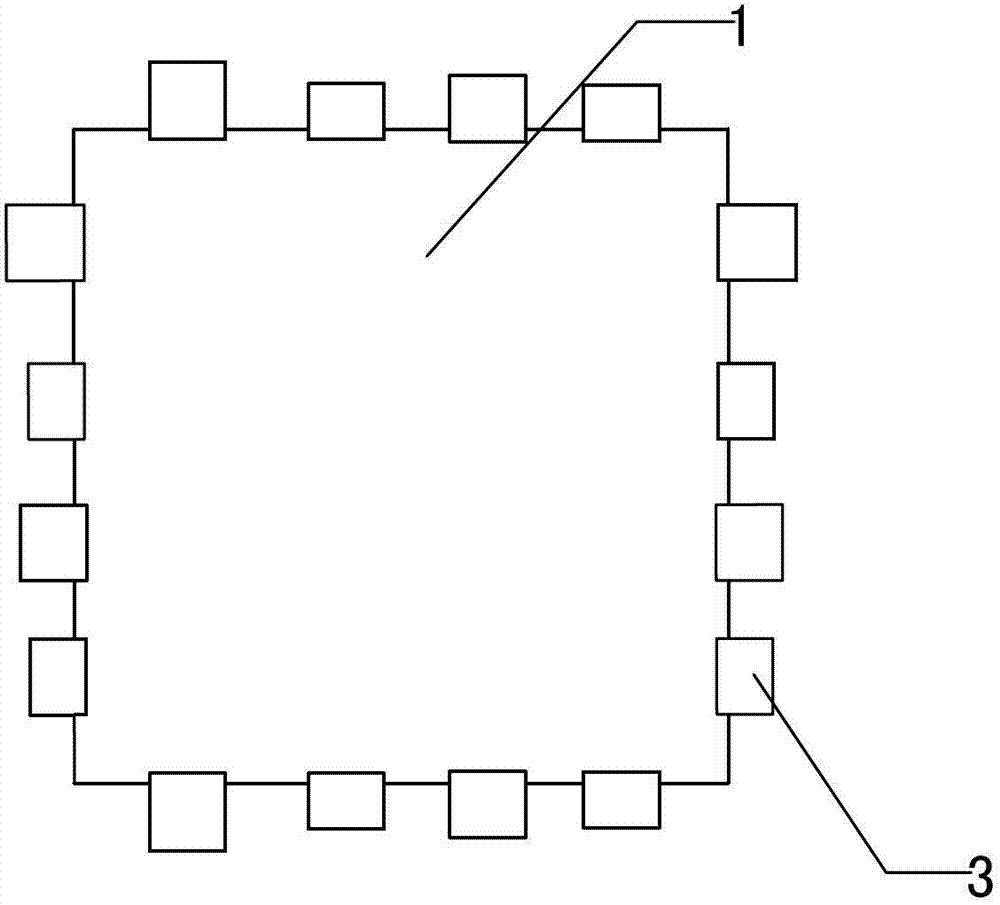

Strip seeding production line for raising hybrid rice seedlings

InactiveCN104221551AReduce pollutionOrderly rowsWatering devicesFertiliser distributersProduction lineSprouted Seeds

The invention discloses a strip seeding production line for raising hybrid rice seedlings. The production line is composed of a front part, a rear part and various mechanisms, wherein a driving motor, a drive device, a fertilizer applying mechanism, a subsoil mechanism, a brushing and flattening mechanism and a groove rolling mechanism are arranged on a front rack; a driving motor, a drive device, a seeding mechanism, a water spraying mechanism and a soil covering mechanism are arranged on a rear rack; and all the mechanisms are driven in a stepless synchronization manner and are respectively provided with a regulating device, so that the capacity of each mechanism can be regulated according to different needs. After an empty seedling disk passes an inlet, the drive devices convey the seedling disk into the production line, and thus the seedling disk can be driven at the bottom of each mechanism, wherein the fertilizer applying mechanism applies a thin layer of seedling strengthening agent fertilizers at the bottom of the seedling disk; the subsoil mechanism spreads subsoil on the fertilizers distributed in the seedling disk; the brushing and flattening mechanism brushes the subsoil on the surface of the seedling disk so as to flatten the subsoil; the groove rolling mechanism rolls 18 trapezoidal grooves in the subsoil on the seedling disk; the strip seeding mechanism quantificationally sows sprout seeds into the grooves in time by virtue of a strip seeding device; the water spraying mechanism firstly sprays atomized water to position the seeds in the grooves and then sprinkles water for the secondary time so as to ensure that the water is completely permeated into the subsoil; and the soil covering mechanism overlays a thin layer of fine soil on the seeds to prevent the exposure of the seeds so as to ensure that the seeds are not influenced, so that the one-time seeding is finished by the production line. The production line provided by the invention is suitable for strip seeding in the raising of the hybrid rice seedlings.

Owner:ZHUJI LEYE AGRI MACHINERY

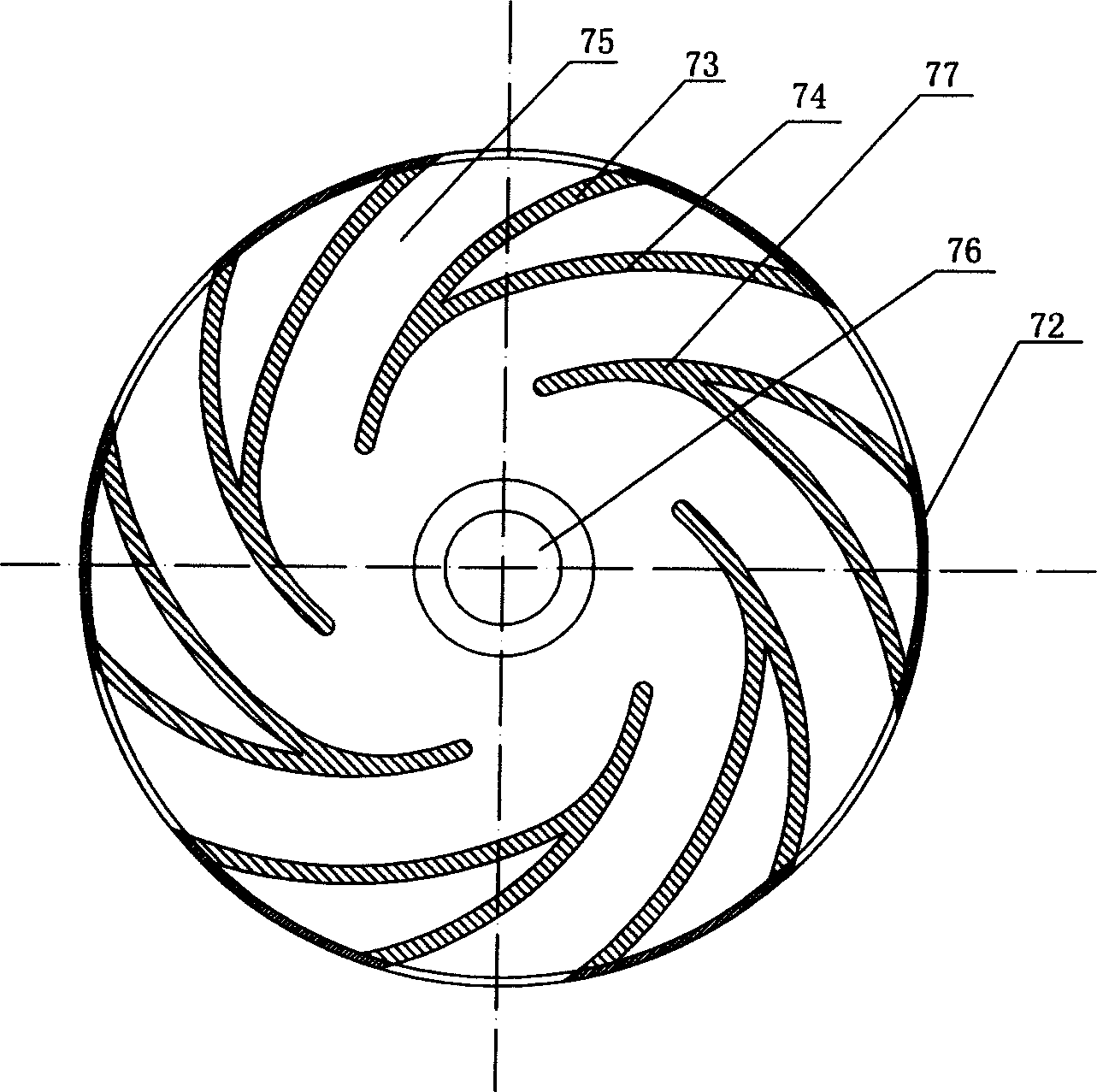

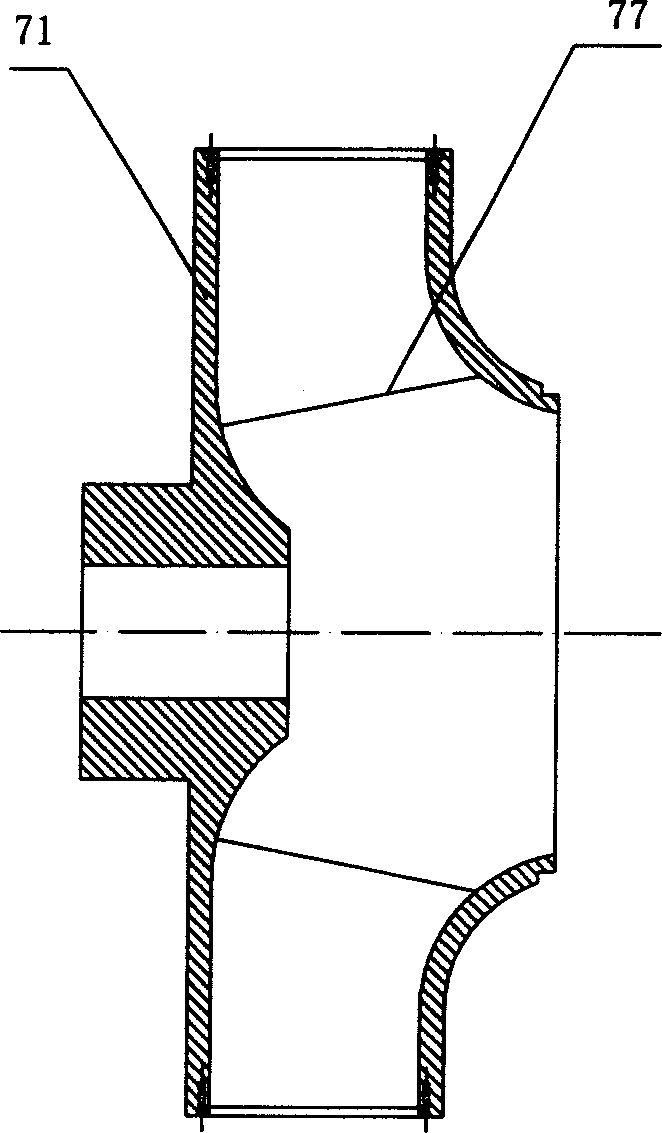

Impellor used for centrifugal pump and centrifugal type fan

A blade wheel for centrifugal pump (or blower) is composed of hub, webs and two or more blades consisting of the primary and secondary blades, which are overlapped at the small radium position and connected by a sealing plate at the maximal radium position. Its advantages are high efficiency and low energy consumption.

Owner:陈瑜

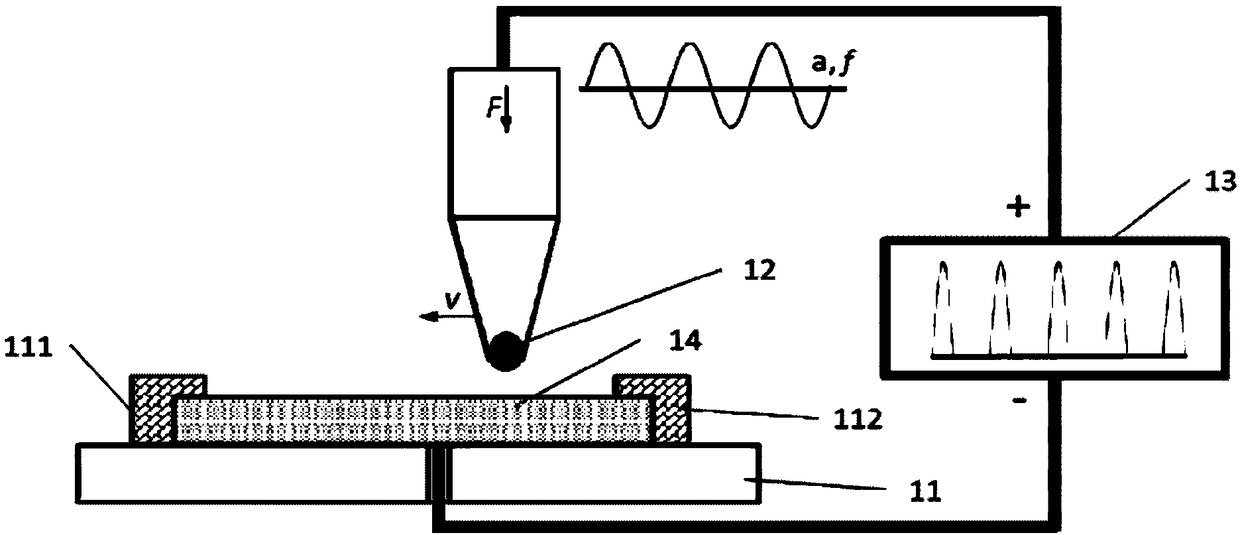

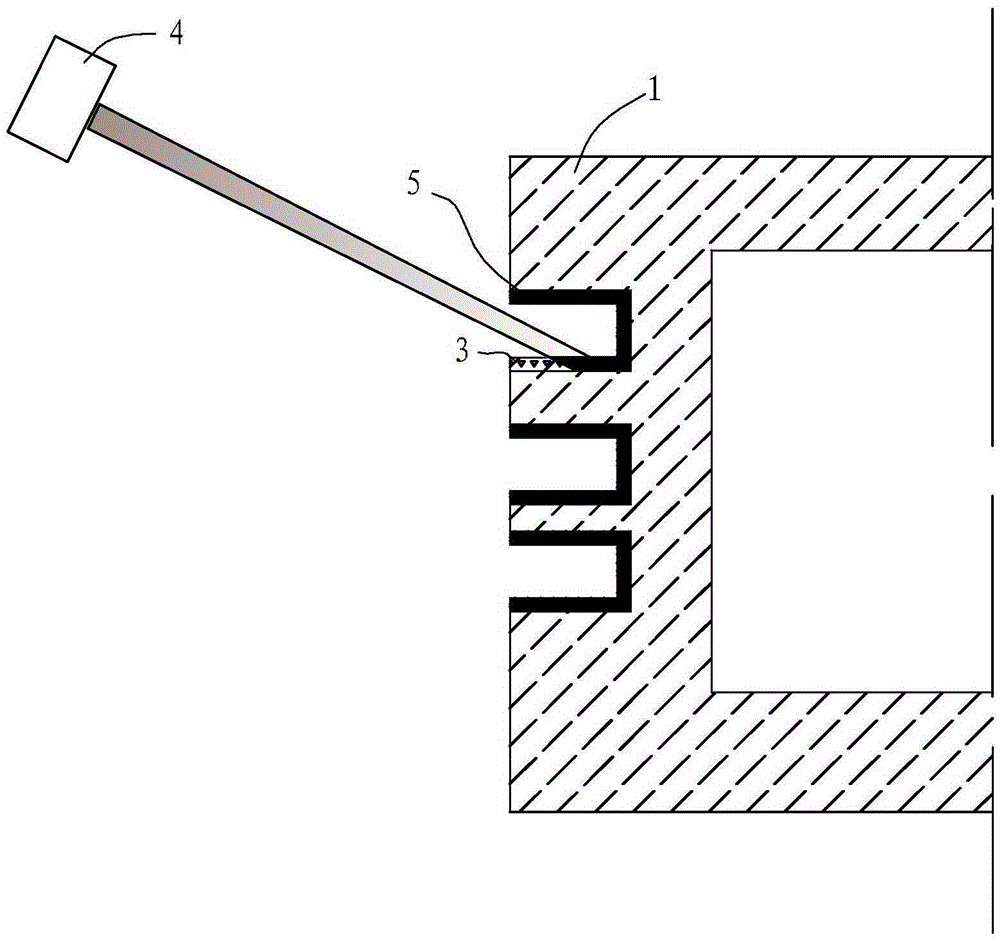

Metal component optimization method based on additive process forming and forming equipment with same

InactiveCN109158829AHigh densityExcellent surface hardnessAdditive manufacturing apparatusManufacturing technologyStressed state

The invention relates to the technical field of metal component additive manufacturing, and discloses a metal component optimization method based on additive process forming and forming equipment withthe same. The metal component optimization method comprises the following steps that a metal component prepared by an additive process is arranged, and a cladding layer is arranged on the metal component; ultrasonic rolling treatment is performed on the cladding layer; and a pulse current is applied to the metal component. According to the method and the equipment, an internal structure of the metal component can be regulated, the defects of holes, microcracks and the like can be reduced, the compactness of a base body can be improved, the stress state of the component is regulated, the surface quality, the precision and the stability of the metal component are improved, the comprehensive service performance of the metal component, such as the surface hardness, the wear resistance, the fatigue resistance and the corrosion resistance, can further be improved, extra heat treatment is not needed, and the metal component optimization method based on the additive process forming and the forming equipment with the same have the advantages of being efficient, stable in the process, safe, reliable, friendly in working environment, energy-saving, environmentally friendly, green and pollution-free and the like.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

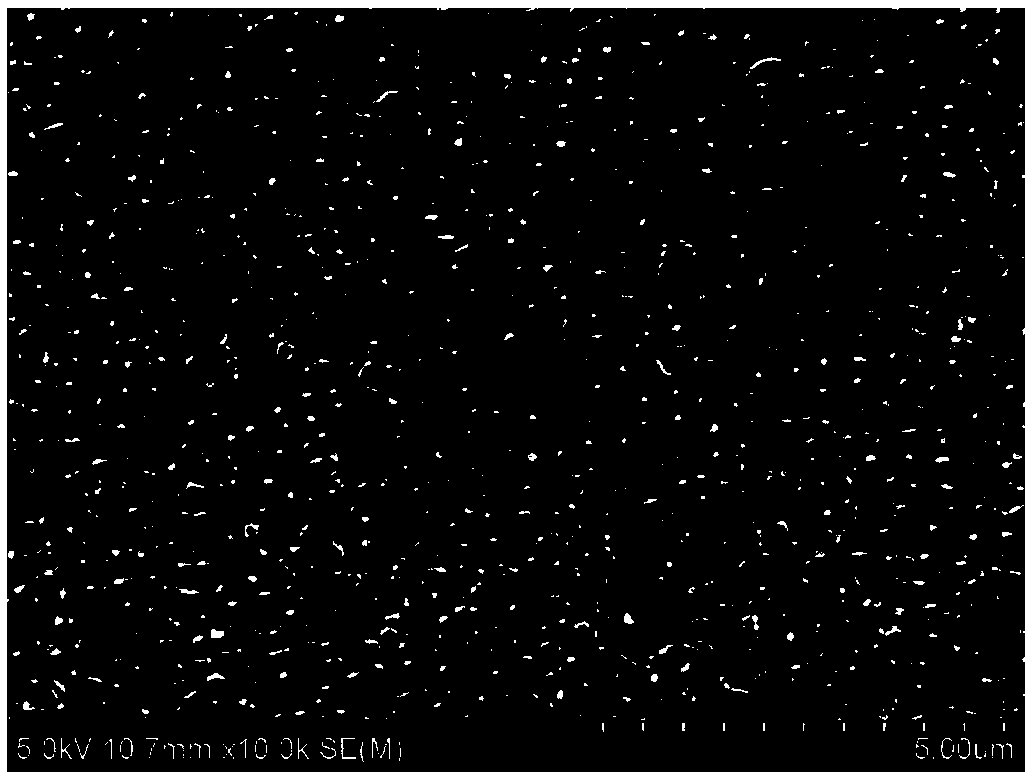

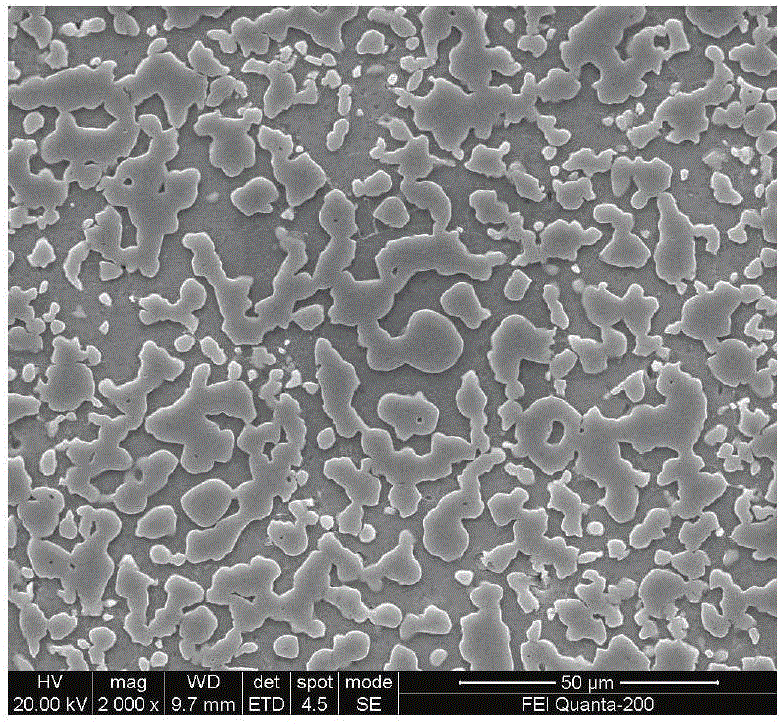

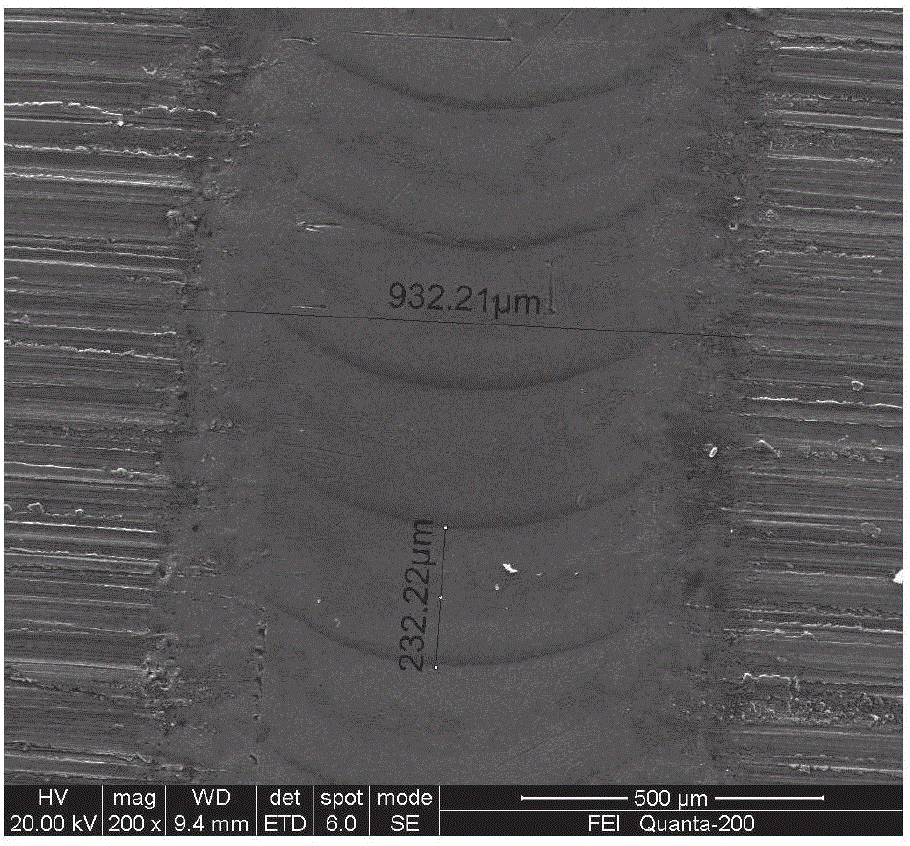

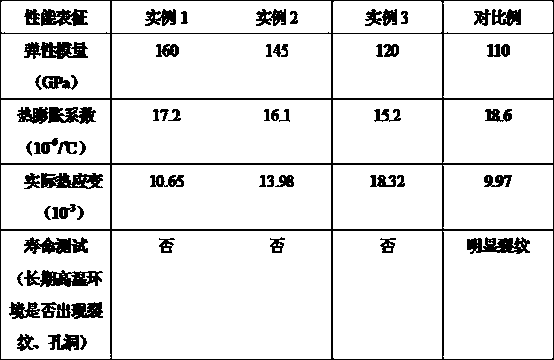

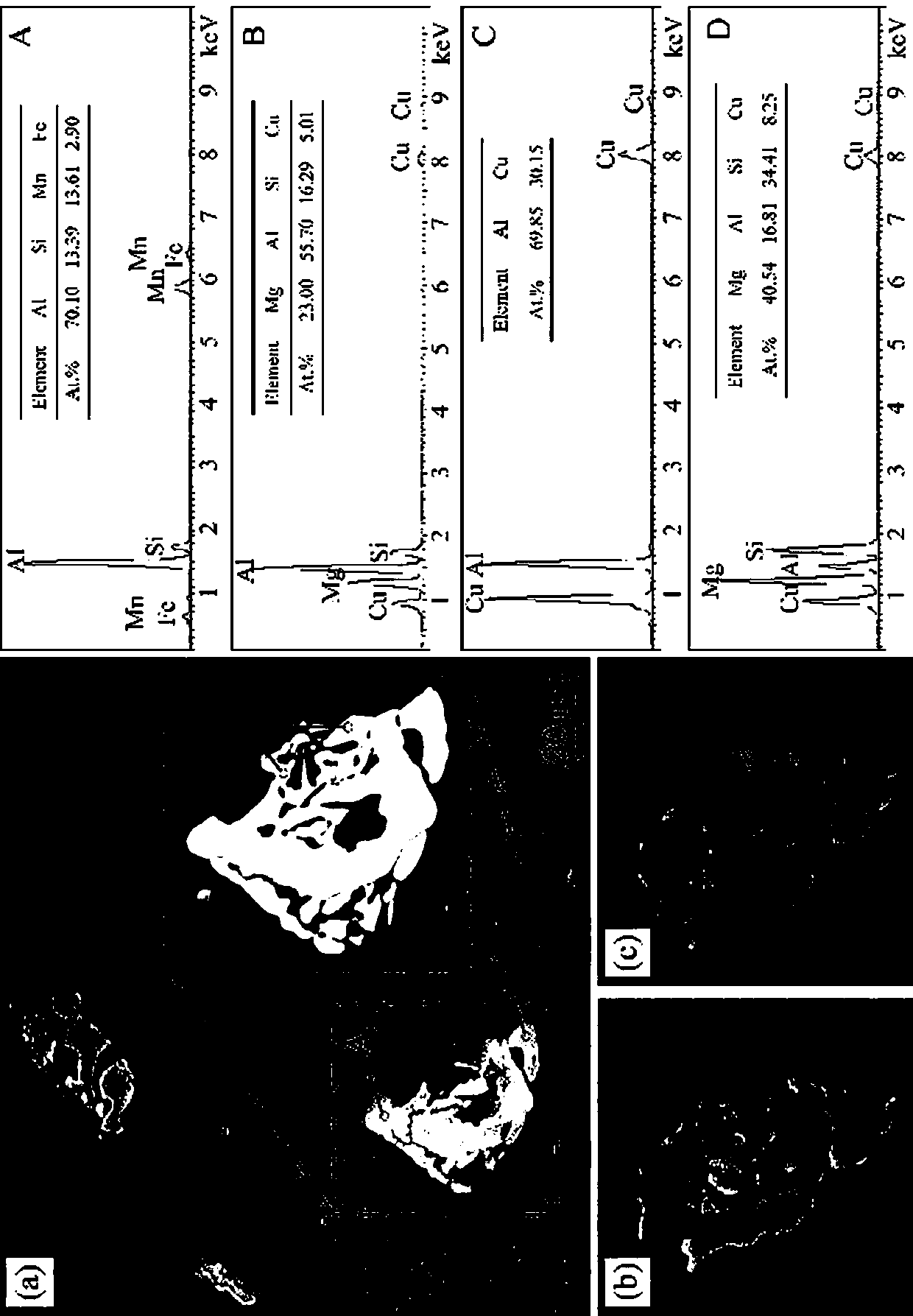

Alloying-element-strengthened high-silicon aluminum composite and preparation method thereof

The invention provides a preparation method of an alloying-element-strengthened high-silicon aluminum composite and belongs to the technical field of material preparation. The preparation method is particularly suitable for preparation of electronic packaging material. The designed alloying-element-strengthened high-silicon aluminum composite comprises, by mass percent, 48.0%-52.0% of silicon, 0.5%-4.0% of X and the balance aluminum. The X is copper and / or magnesium. The preparation method of the alloying-element-strengthened high-silicon aluminum composite comprises the steps that a silicon source, an aluminum source and an X source are prepared according to the designed components, the prepared silicon source, the prepared aluminum source and the prepared X source are smelted, and then a melt is obtained; and atomized spray deposition is conducted on the obtained melt, so that a deposition preform is obtained, hot isostatic pressing treatment is conducted on the deposition preform, and then a finished product is obtained, wherein during hot pressing pressure treatment, the temperature is controlled to be 520-600 DEG C, and the pressure is controlled to be 150-200 MPa. The designed composite has the advantages of being excellent in comprehensive performance, outstanding in mechanical property, low in preparation cost and the like and is suitable for large-scale industrial production.

Owner:CENT SOUTH UNIV

Super-thick steel plate and production technology thereof

The invention belongs to the technical field of steel rolling and particularly relates to a super-thick steel plate and a production technology thereof. The super-thick steel plate includes, by weight, 0.31%-0.37% of C, 0.41%-0.59% of Si, 1.42%-1.59% of Mn, less than or equal to 0.007% of P, less than or equal to 0.004% of S, 1.91%-2.16% of Cr, 0.51%-0.63% of Mo, 0.17%-0.29% of Ni, and the balance Fe and inevitable impurities. The production technology includes the technical processes of electric furnace smelting, ladle furnace (LF) refining, vacuum degassing (VD), constant-speed die casting under argon shield, high-temperature demoulding, liquid core rolling, slow cooling, heating, rolling, online quenching and tempering. The Brinell hardness of the steel plate ranges from 291 HB to 329 HB, the value of difference between the surface hardness and the core hardness of the steel plate is smaller than 15 HB, the maximum thickness of the steel plate can reach 430 mm, and the steel plate can meet the I-class flaw detection requirement of the test standard of JB / T4730.3-2005 forge pieces and the requirement for high-quality interiors of high-class super-thick steel plates.

Owner:SHANDONG IRON & STEEL CO LTD

Thermal barrier coating and preparation method thereof

InactiveCN107937858AImprove the interface binding forceImprove anti-circulatory oxidation capacityMolten spray coatingCeramic compositeRare earth

The invention relates to a thermal barrier coating and a preparation method thereof, and belongs to the technical field of ceramic composite materials. The preparation method of the thermal barrier coating includes the steps that a layer of Dy-doped NiCoCrAlYTa is sprayed to a substrate surface with a low pressure plasma spraying technology, the interface bonding force of a oxidation film is improved through Dy doping, holes of the oxidation film / a coating interface are effectively removed, and grains are refined; distributing conditions of different phases in the coating are changed, the function of cyclic oxidation resistance of the coating is significantly improved, and tack coat is polished to mirror surface simultaneously to be capable of lowering growth rate of oxide; and the polishing treatment to the tack coat can still prevent producing and extending of microcracks of a ceramic layer / the oxide / tack coat and the interior of the ceramic layer, the ceramic layer is made of thermal barrier ceramic powder doped with rare earth oxide in a spraying mode, the heat conductivity of the coating is drastically reduced, and the service life in the heat cycle is prolonged.

Owner:江苏华友装饰工程有限公司

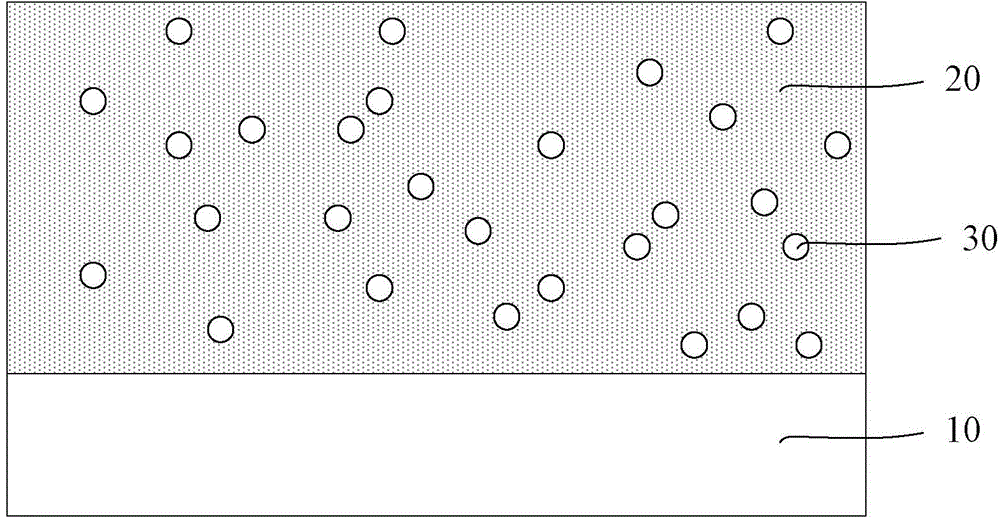

Perovskite solar cell and preparation method thereof

ActiveCN105514280AImprove densification performanceImprove high-quality film formation rateFinal product manufactureOrganic semiconductors manufacture/treatmentSputteringPerovskite solar cell

The invention provides a perovskite solar cell and a preparation method thereof and relates to a solar cell. The perovskite solar cell is of a laminated structure and is sequentially provided with a substrate, a transparent electrode, a compact electron transfer layer, a mesopore layer, a perovskite light absorption layer, a hole transporting layer and a counter electrode from bottom to top. The preparation method comprises the steps of performing evaporation or sputtering of the transparent electrode on the substrate; coating the transparent electrode with dispersion liquid, and after sintering, preparing the electron transfer layer; coating the electron transfer layer with dispersion liquid, and after sintering, preparing the mesopore layer; coating the mesopore layer with a one-step method perovskite alkaline solution, and after annealing, preparing a perovskite crystal film; preparing the counter electrode on the perovskite crystal film, and obtaining the perovskite solar cell. Prepared perovskite film crystal is high in thickness and compact, holes and needle holes and the like are eliminated completely, the high quality film-forming reproducibility of perovskite is very good, and the stability and photoelectric conversion efficiency of the perovskite solar cell are greatly improved.

Owner:SUZHOU GCL NANO TECH CO LTD

Surface alloy strengthening method of aluminum-based piston ring grooves

ActiveCN105296878AEliminate holesElimination of defects such as unmelted powderMolten spray coatingPiston ringUltimate tensile strength

A surface alloy strengthening method of aluminum-based piston ring grooves is characterized in that the method includes the following steps that firstly, matching is conducted on iron-based alloy powder; secondly, plasma spraying is conducted on the aluminum-based piston ring grooves; fourthly, remelting treatment is conducted on coatings and substrates through electronic beams; and fifthly, turning finishing is conducted on the aluminum-based piston ring grooves. According to the method, the plasma spraying technology and the electronic beam remelting reinforcing technology are combined, and the defects of holes and unmelted powder in the coatings and the like can be eliminated, so that reinforcing layers and the ring groove substrates can form stable and reliable metallurgical bonding, and bonding strength is high; and the overall process is easy to operate, low in cost and free of polluting the environment.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

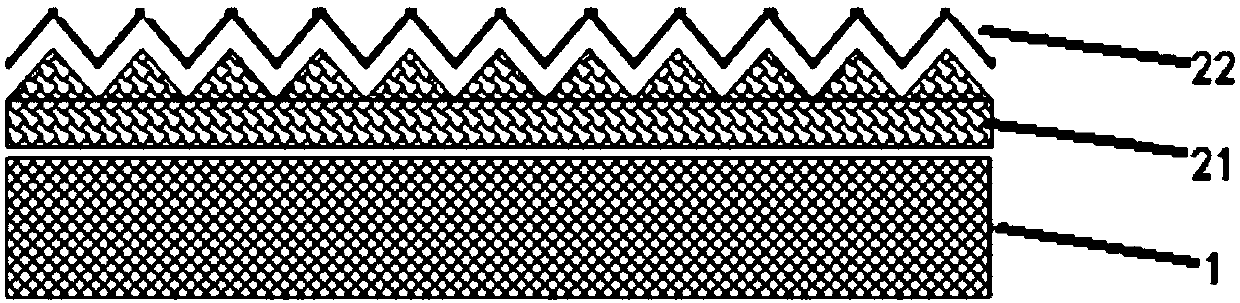

Graphene-based high-emissivity infrared emission film and preparation method thereof

ActiveCN109618428AHigh emissivityIncrease the areaOhmic-resistance electrodesGrapheneEmissivityAdhesive

The invention discloses a graphene-based high-emissivity infrared emission film and a preparation method thereof. The graphene-based high-emissivity infrared emission film comprises a transparent substrate, a roughened graphene composite layer, an electrode layer and a packaging layer which are sequentially stacked from bottom to top, wherein the graphene composite layer is a composite layer formed by an adhesive layer formed by curing a liquid adhesive and a graphene thin film when the graphene thin film which grows on a rough processed catalytic substrate is transferred to the transparent substrate through the liquid adhesive; the adhesive layer completely copies rough lines on the catalytic substrate; and the roughness of the graphene composite layer is 0.5-40 [mu]m. The graphene composite layer is formed when the graphene thin film which grows on the rough processed catalytic substrate is transferred to the transparent substrate by the liquid adhesive, so that the specific surfacearea and the surface roughness of the graphene composite layer are obviously improved, thereby improving the emissivity of the infrared emission film.

Owner:CHONGQING GRAPHENE TECH

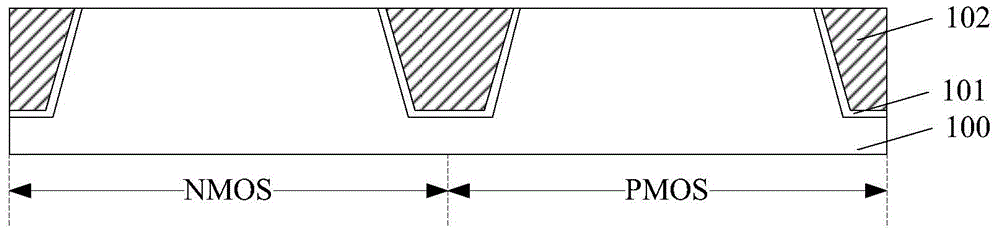

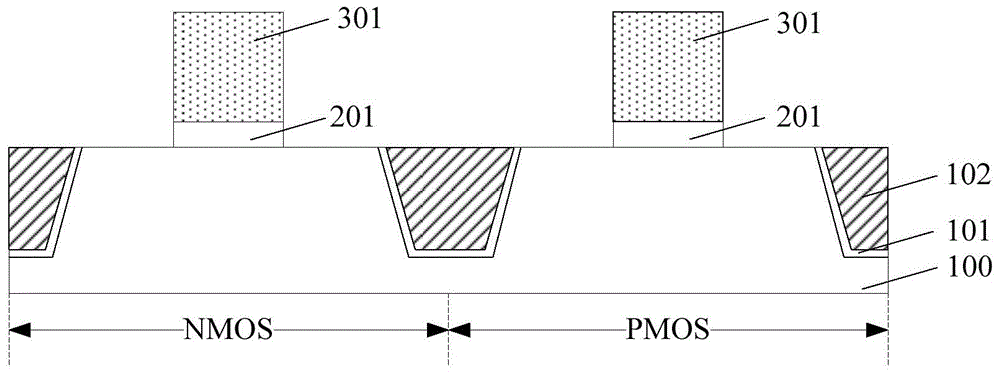

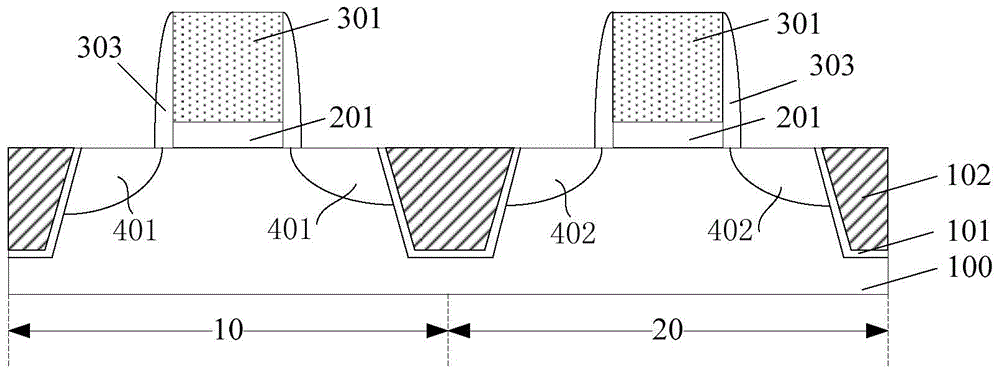

Forming method of CMOS (complementary metal-oxide-semiconductor) transistor

InactiveCN104681490AImprove performancePerformance impactSemiconductor/solid-state device manufacturingCMOSEngineering

The invention provides a forming method of a CMOS (complementary metal-oxide-semiconductor) transistor. The forming method comprises the following steps that a semiconductor substrate is provided, the semiconductor substrate comprises an NMOS (N-channel metal oxide semiconductor) region and a PMOS (P-channel metal oxide semiconductor) region, and a shallow groove isolation structure is also formed in the semiconductor substrate; a pseudo grid structure is respectively formed on the surfaces of the NMOS region and the PMOS region; a dielectric layer is respectively formed on the semiconductor substrate and the surface of the shallow groove isolation region; the pseudo grid structure is removed, a first groove is formed in the surface of the NMOS region, and a second groove is formed in the surface of the PMOS region; a high-K grid dielectric material layer is formed, and displacement ions are doped in the high-K grid dielectric material layer, and can overcome defects in the high-K grid dielectric material layer; the high-K grid dielectric material layer is subjected to annealing processing, and the defects in the high-K grid dielectric material layer are further eliminated; a first grid electrode and a second grid electrode are formed. The forming method of the CMOS transistor has the advantage that the quality of the high-K grid dielectric material layer can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Five-in-one low-temperature quickly-smelting agent

InactiveCN101418514AGood whitenessImprove gross effectFibre treatmentDry-cleaning apparatus for textilesSodium silicateAlkyl phosphate

The invention discloses a five-into-one low temperature rapid scouring agent, which belongs to the technical field of fabric dyeing and finishing. The rapid scouring agent is characterized in that the rapid scouring agent is prepared by the following raw materials in weight portion: 18 to 20 portions of alkyl phosphate, 10 to 18 portions of alkyl polyether phosphate ester, 8 to 19 portions of alkyl polyethenoxy ether, 15 to 16 portions of calcined soda, and 40 to 45 portions of sodium silicate. The product is used for the desizing, the scouring and the bleaching of cellulose fiber, has excellent osmosis, dispersivity, hydrogen peroxide stability and scouring effect, replaces the prior osmotic agent, dispersion chelator, hydrogen peroxide stabilizer, caustic soda and scouring agent, is time-saving and labor-saving, and has good scouring effect and high whiteness.

Owner:SHANDONG JINLU CHEM

Method for preparing high-density concrete with uniform aggregate and aggregate thereof

ActiveCN102733607AThe construction process parameters are clearImprove efficiencyBuilding material handlingHigh densitySlurry

The invention discloses a method for preparing high-density concrete with a uniform aggregate and an aggregate thereof, and particularly relates to a method for preparing high-density concrete, belonging to the technical field of concrete preparation. The method is characterized in that the disturbance area of a slurry caused by subsidence trend of an iron aggregate or a lead aggregate is larger than or equal to the equivalent area of the aggregate; a mixture hand sample is produced on an experiment table according to the calculated mix proportion before the mixture is tried; the subsidence condition of the iron aggregate or the lead aggregate is detected, and the detection data is recorded; and the concrete is poured in a split level when being poured in a layered mode. By adopting the method and the aggregate, the uniform distribution rate of the aggregates is improved, and the ray-preventing capability of projects is more uniform.

Owner:山东起凤建工股份有限公司 +1

Corrosion-resistant casting cobalt alloy for solar thermal power generation molten salt system and process thereof

The invention discloses a corrosion-resistant casting cobalt alloy for solar thermal power generation molten salt system and a process thereof. The alloy consists of the following components in percentage by weight: 2.0-3.0wt% of Sn, 1.5-1.8wt% of In, 0.4-0.6wt% of Ag, 3.0-3.5wt% of Cr, 4.0-5.0wt% of Al, 0.4-0.6wt% of Mn, 1.0-1.4wt% of Ge, 2.0-3.0wt% of Cu and the balance of cobalt. The material provides a novel materials science scheme for a corrosion-resistant cobalt alloy used under a marine environment, and also provides the cobalt alloy with excellent casting property. The alloy is implemented and industrialized, so that commercial upgrading needs, on the high-end cobalt alloy material, of heat dissipation tubes and heat storage tubes in the solar thermal power generation field in China are greatly promoted.

Owner:GUANGZHOU YUZHI TECH CO LTD

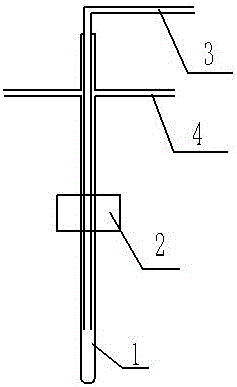

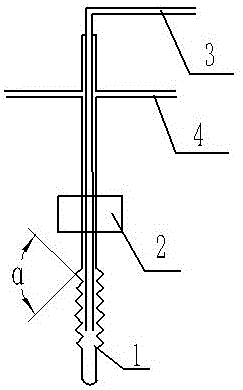

Device for refining grain structure and application method

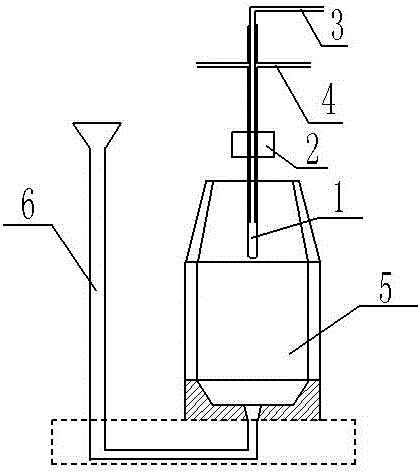

The invention discloses a device for refining grain structure and an application method, and belongs to the technical field of metallurgy. The device comprises a vibration device inserted in a steel ingot mold; the vibration device includes a vibration rod making direct contact with molten steel; the vibration rod is provided with a vibration generation source for driving the vibration rod to move; an introduction pipe for circulating a cooling medium is arranged in the center of the vibration rod; and discharge pipes for circulating the cooking medium are arranged on two sides of the upper end of the vibration rod. A steel ingot is vibrated in the solidification process to urge fusing and breakage of dendrites; and the number of free cold crystals is increased to inhibit growth of columnar crystals, so that the isometric crystal rate is increased, the solidification structure is refined, and the purpose of relieving segregation is achieved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

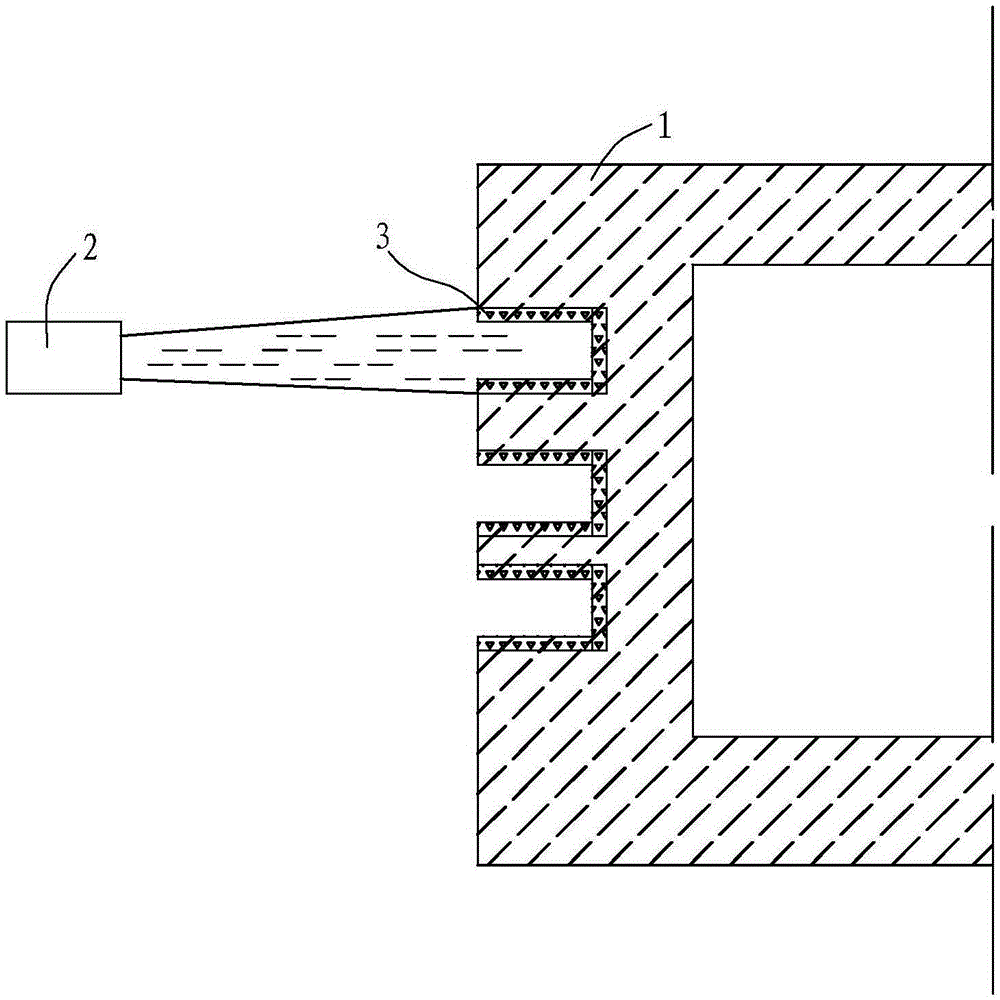

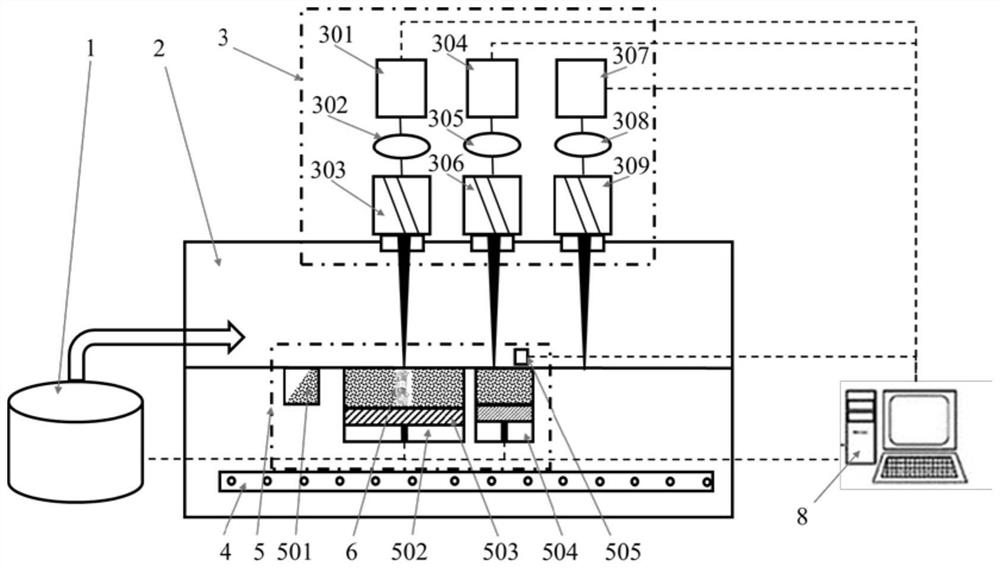

Device conducting composite manufacturing on basis of laser technology

PendingCN111992712AImprove mechanical propertiesImprove the finishAdditive manufacturing apparatusIncreasing energy efficiencyLaser technologyEngineering

The invention discloses a device conducting composite manufacturing on the basis of a laser technology. The device comprises a sealed forming chamber, an inert protective gas source and a machining forming platform. The inert protective gas source is connected with the sealed forming chamber. The machining forming platform is arranged in the sealed forming chamber, and a light path selection system is arranged over the machining forming platform. A machining station is arranged on the machining forming platform, and the machining forming platform is arranged on a guide rail and can slide forwards and backwards through the guide rail. The light path selection system comprises a shock reinforcing independent laser light path, an additive independent laser light path and a subtractive independent laser light path. The light paths are arranged in the direction of the guide rail, and all the independent laser light paths do not share equipment and are arranged over the machining forming platform. According to the device, the laser shock reinforcing technology and the laser additive and subtractive technology are integrated, the forming precision, the surface quality, the organization performance and the residual stress state of a complex fine additive workpiece are improved, and one-stop high-efficiency high-precision and high-performance additive workpiece preparation is achieved.

Owner:SHANGHAI UNIV OF ENG SCI

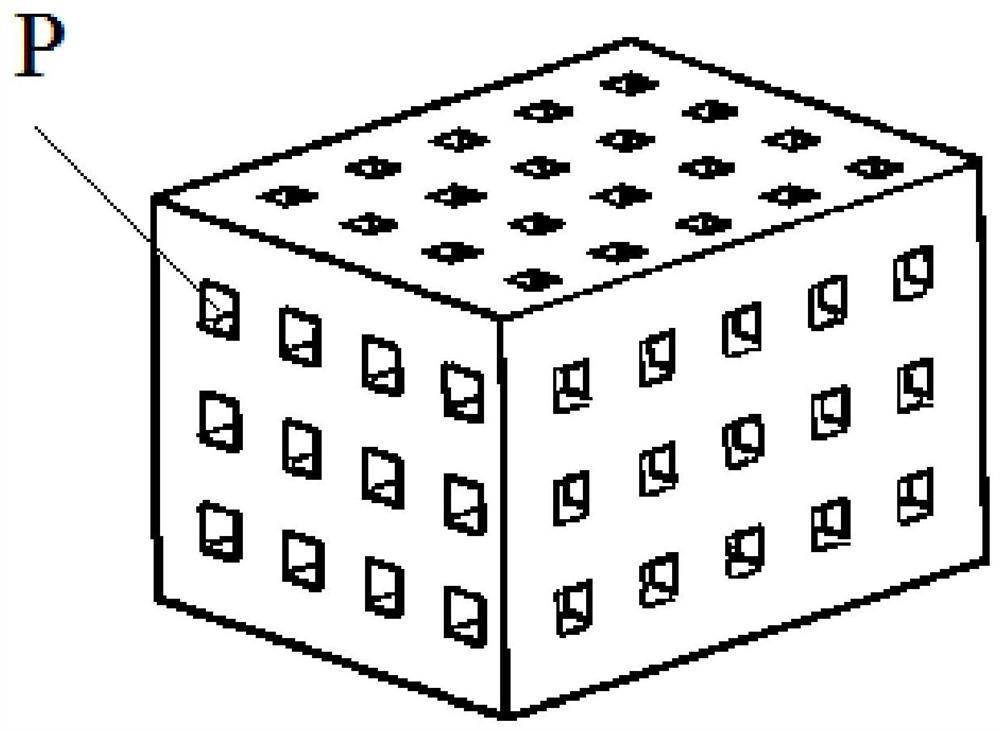

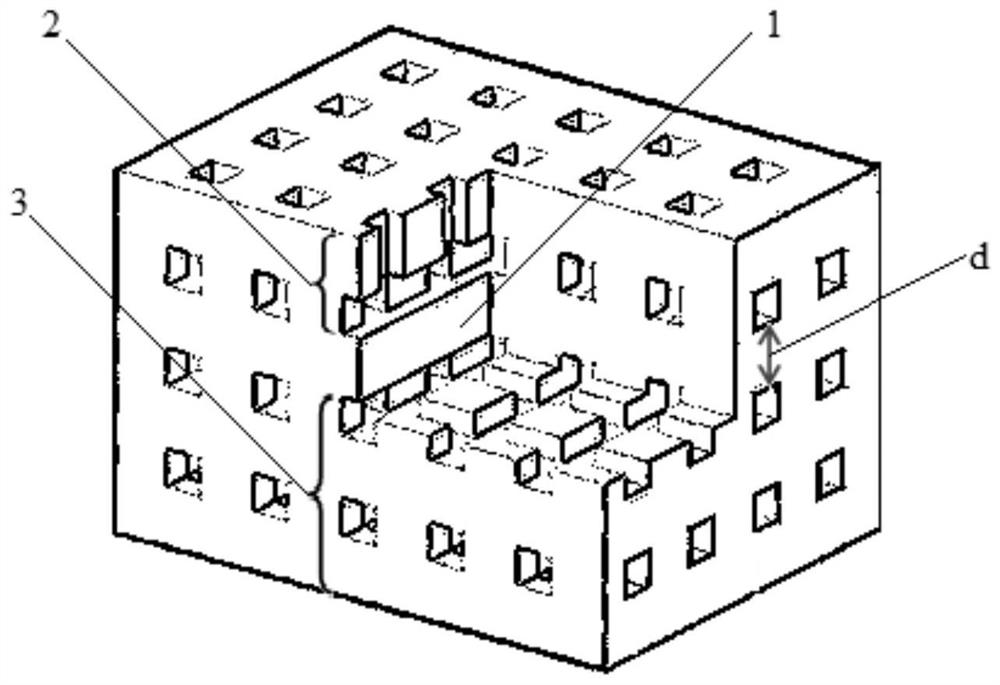

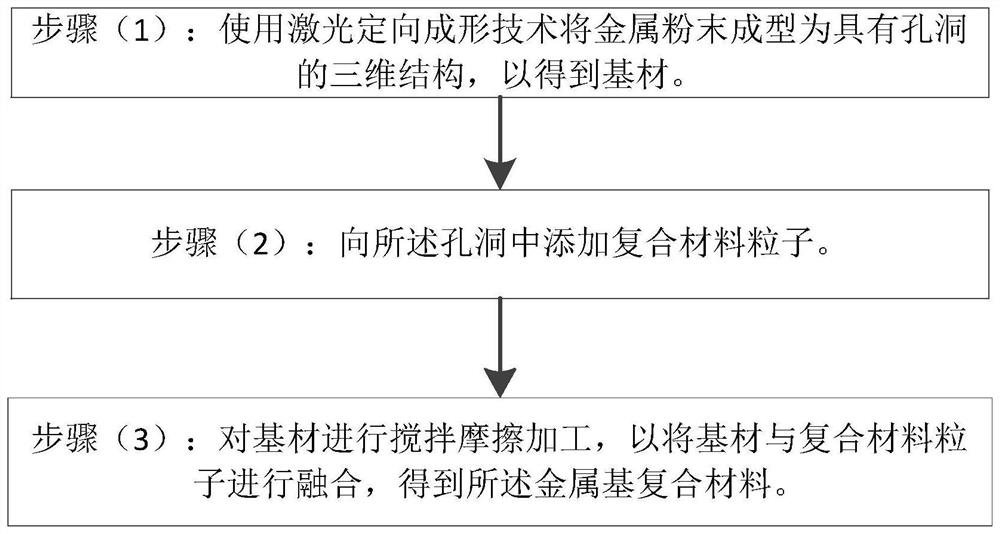

Metal-based composite material and preparation method thereof

InactiveCN113084326AImprove utilization efficiencyPrecisely control the area of particle distributionNon-electric welding apparatusMetal matrix compositeMetal powder

The invention discloses a preparation method of a metal-based composite material. The preparation method comprises the following steps: (1) forming metal powder into a base material with holes by using a laser directional forming technology; (2) adding composite material particles into the holes; and (3) carrying out stirring friction machining on the base material so as to fuse the base material and the composite material particles, and obtaining the metal-based composite material. In addition, the invention further discloses the metal-based composite material which is prepared by adopting the preparation method.

Owner:BAOSHAN IRON & STEEL CO LTD

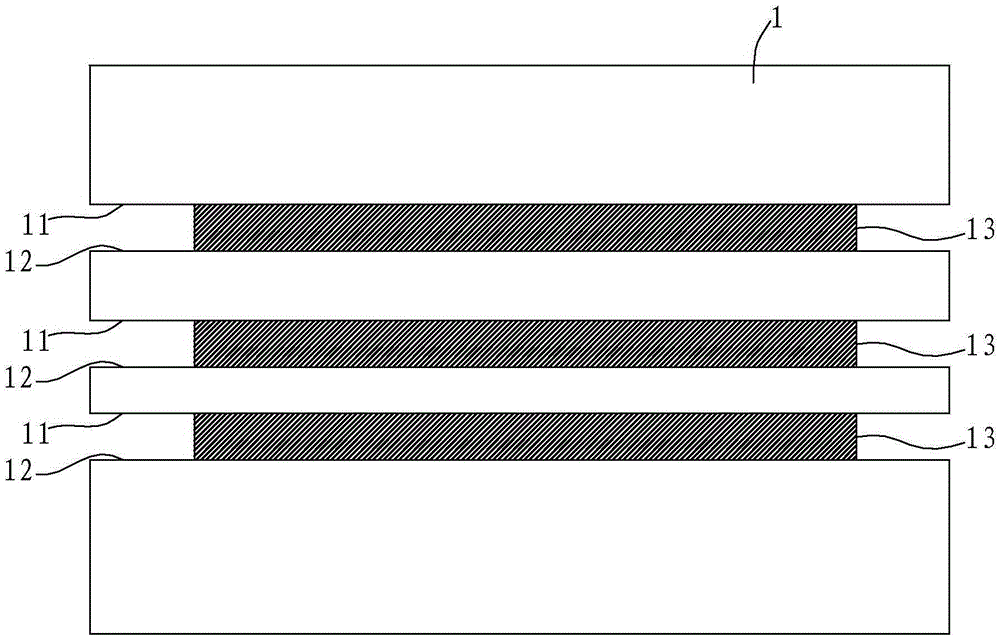

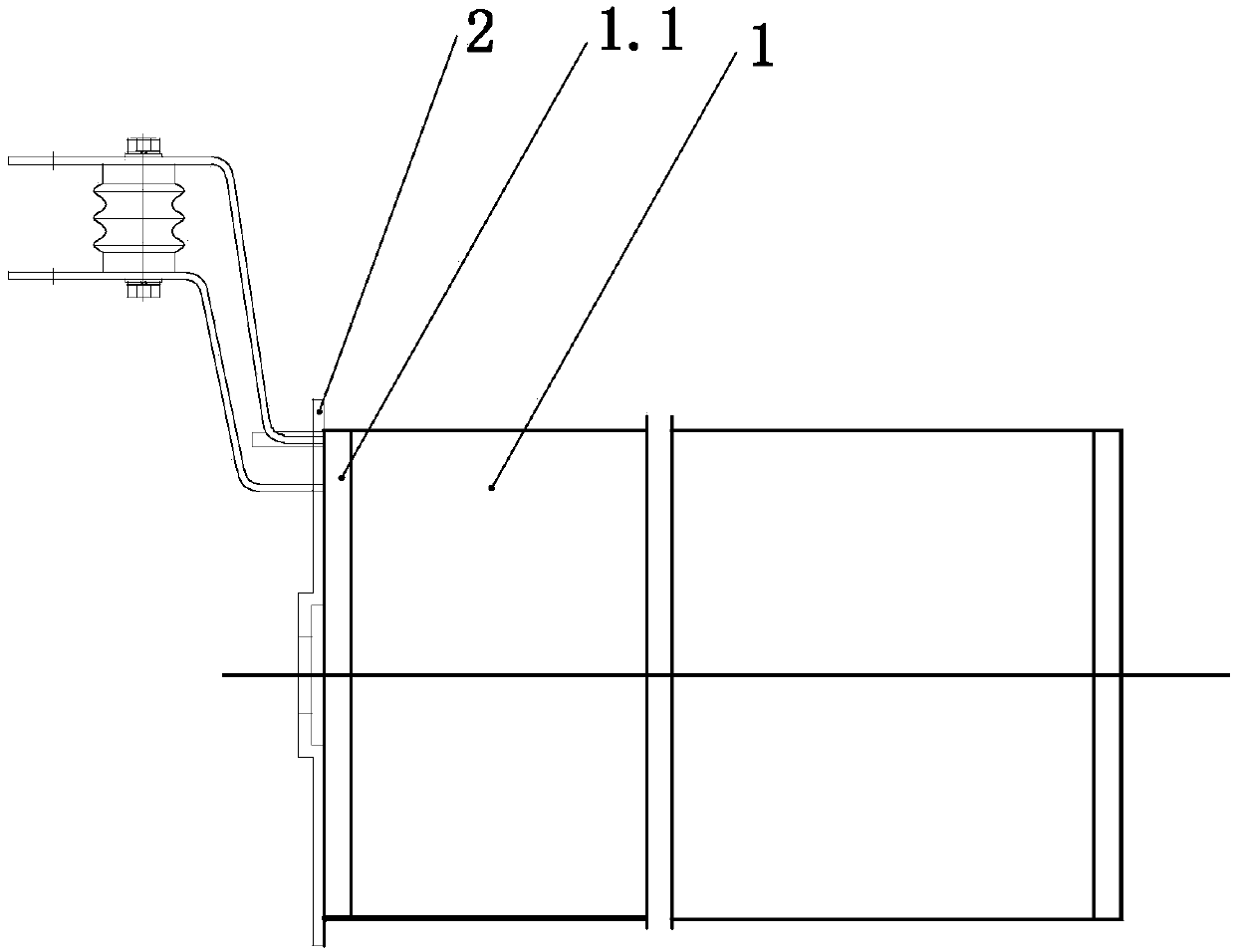

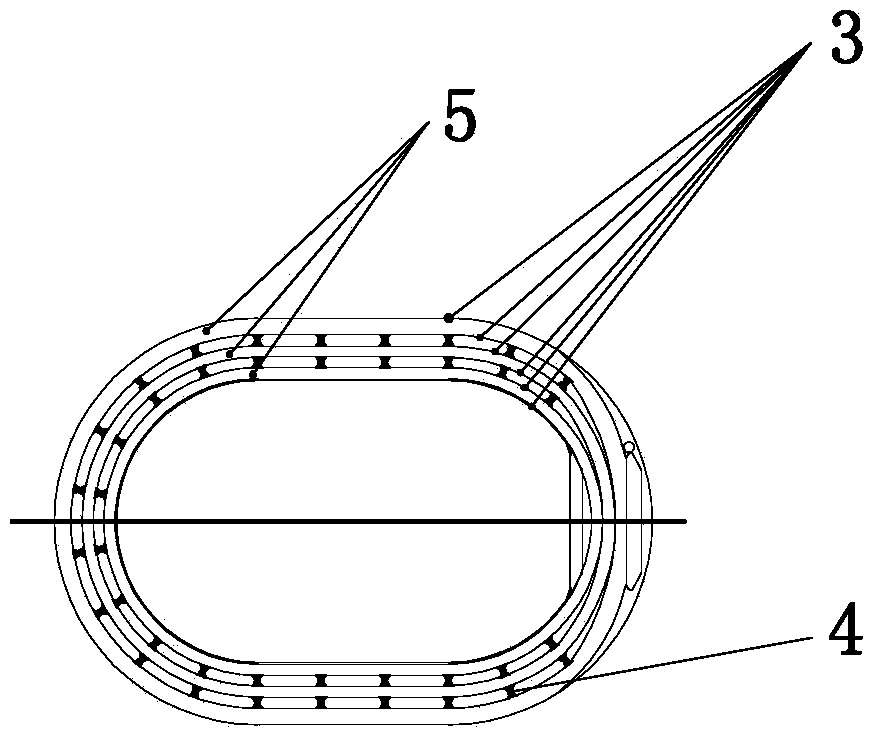

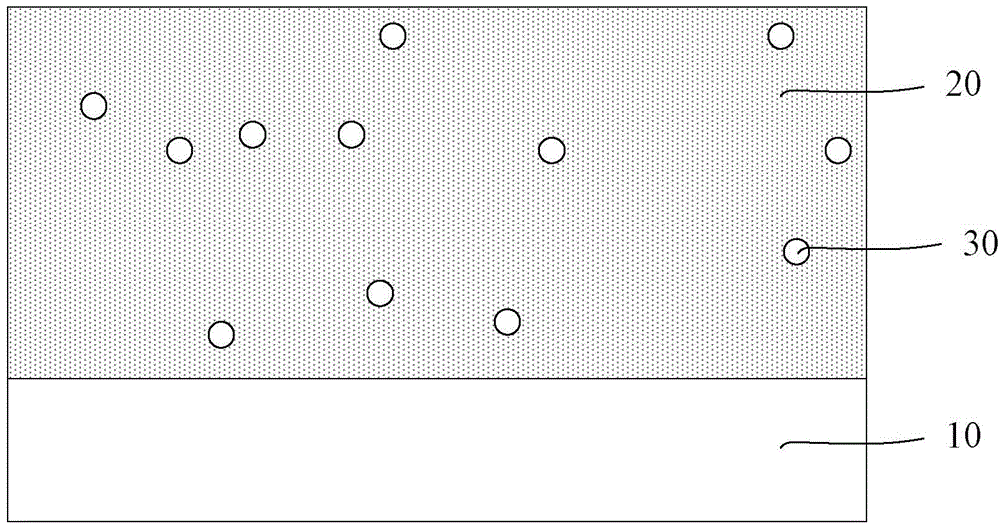

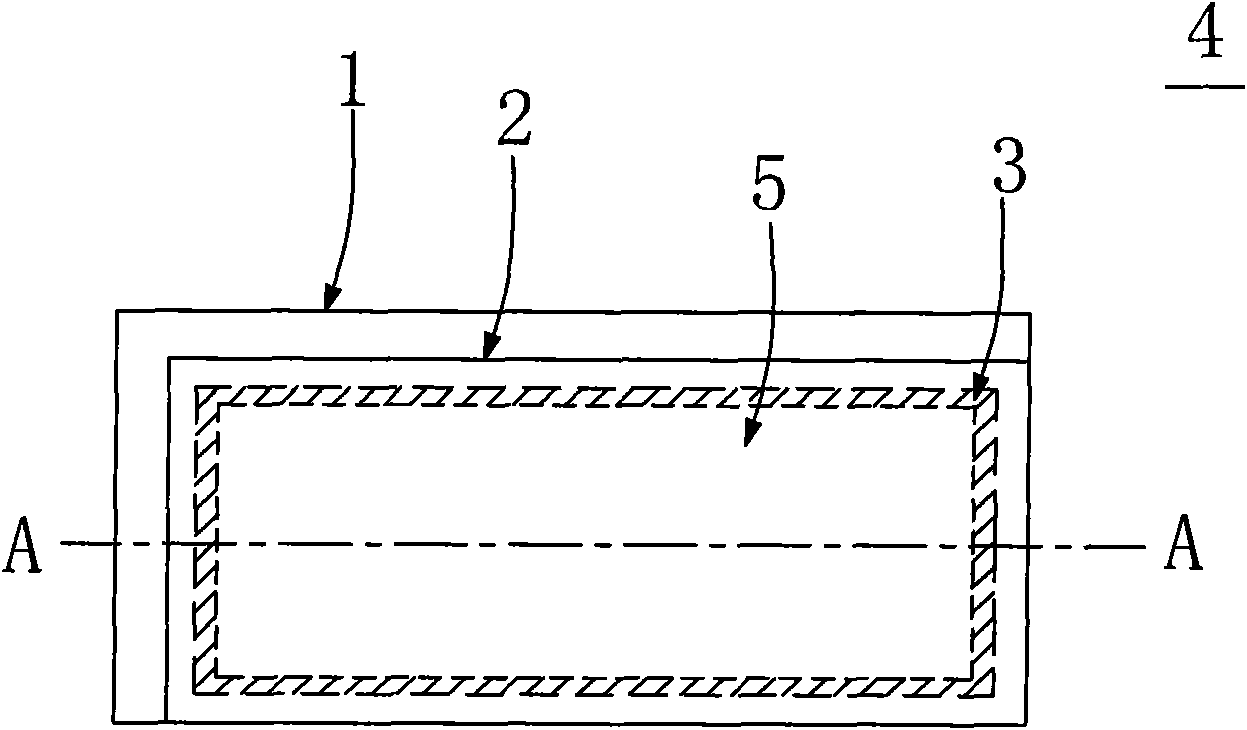

End sealing method for low-voltage foil type coil of dry type transformer

The invention discloses an end sealing method for a low-voltage foil type coil of a dry type transformer. The end sealing method comprises the following specific steps of (1) forming a pouring groove (5) when a low-voltage coil (1) is wound; (2) solidifying and demolding; (3) painting glass cement or filling alkali-free glass tape; (4) preheating; (5) preparing high-temperature-resisting normal temperature resin; (6) carrying out degasification processing; (7) fully solidifying the high-temperature-resisting normal temperature resin; (8) polishing the low-voltage coil to be in a drawing size; (9) painting mixture of putty and a curing agent in the position of a bubble generated by resin reaction, and smoothing the bubble; (10) cleaning the low-voltage coil (1). According to the end sealing method disclosed by the invention, an uneven surface, a hole and a gap of the low-voltage coil are successfully removed, the upper end surface of the produced low-voltage coil is bright in color and clear in corner angle, the end sealing is not subjected to warping and cracking at 155 DEG C, and the appearance quality and the electrical performance of the low-voltage coil are greatly increased.

Owner:NINGBO AUX HIGH TECH

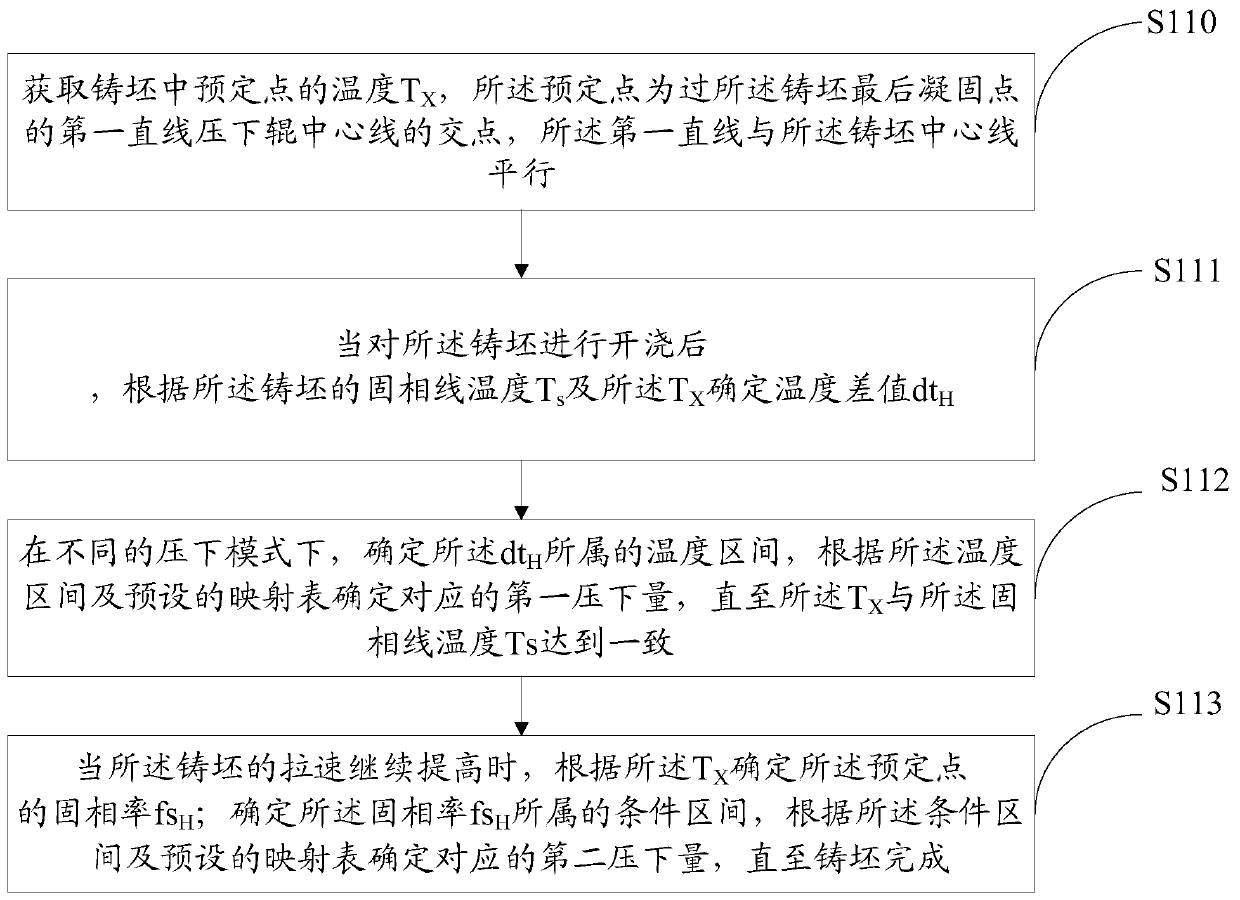

Reduction method and device

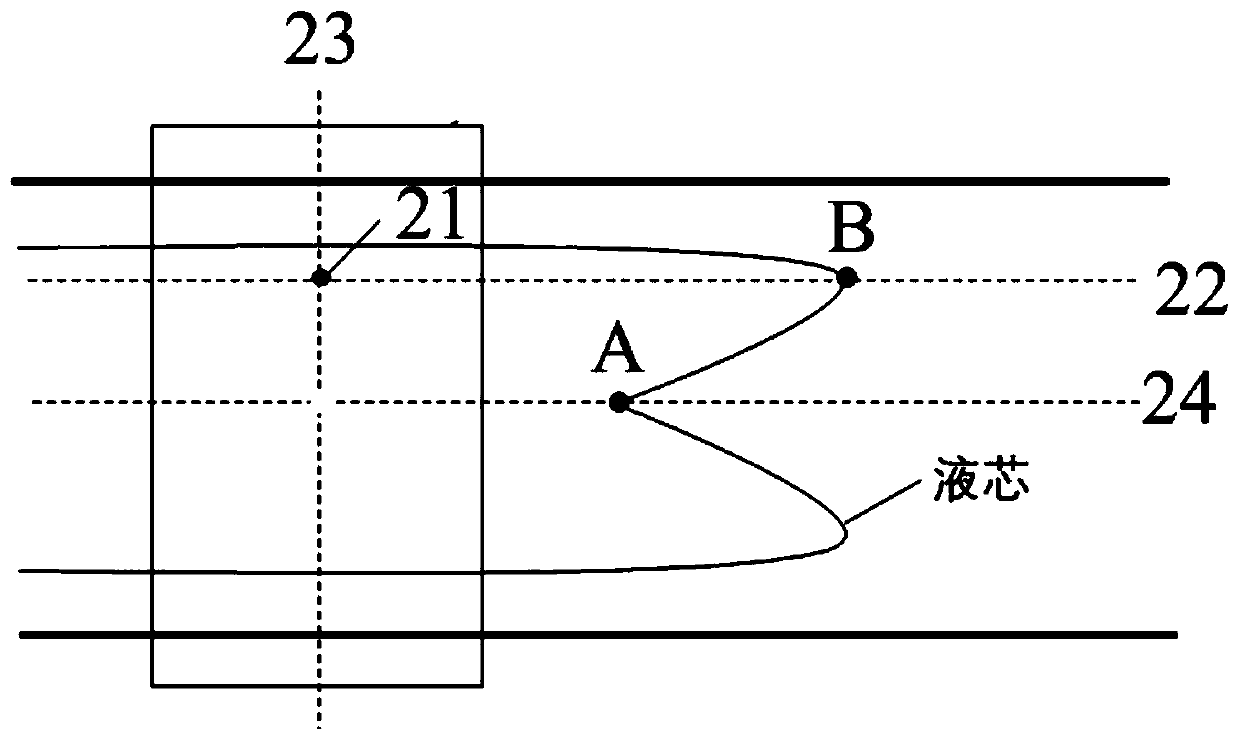

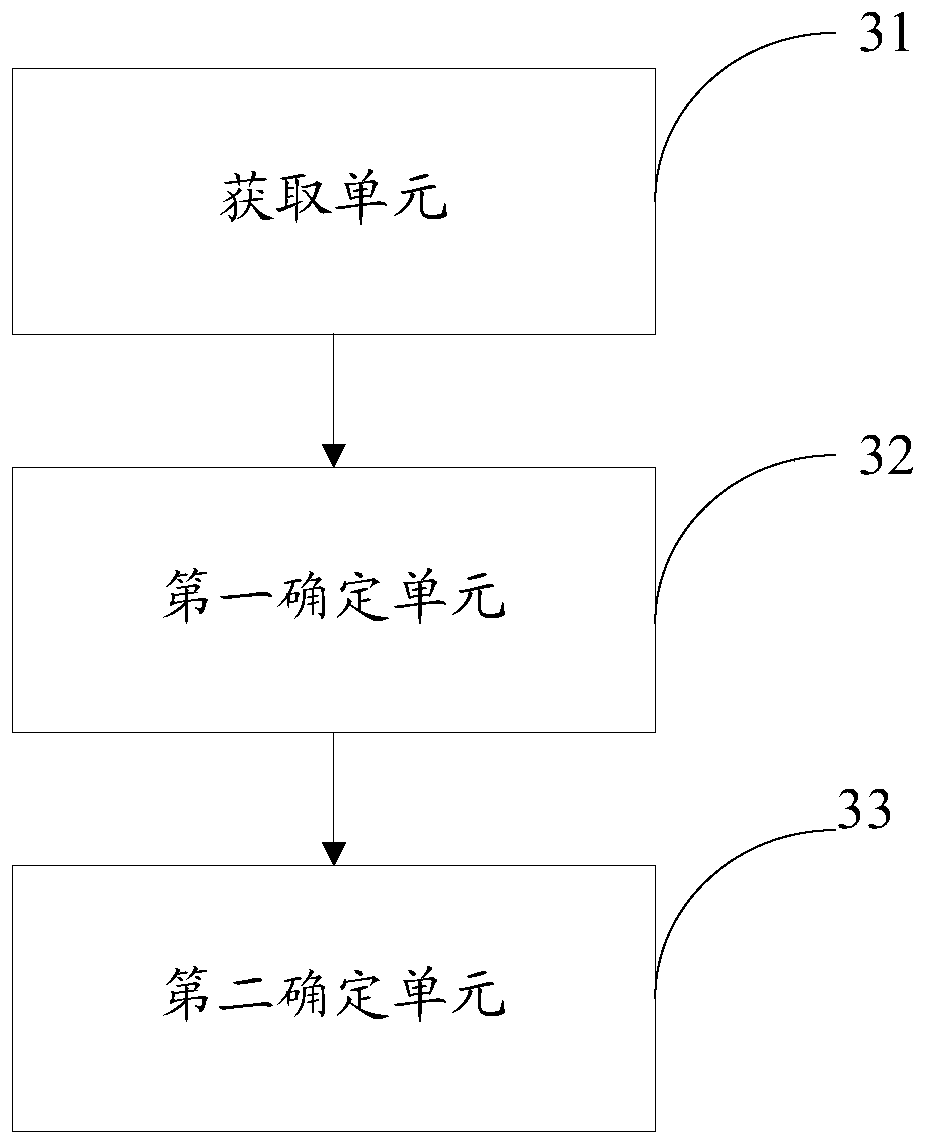

The embodiment of the invention provides a reduction method and device. The method includes the steps that the temperature TX of a predetermined point in a casting blank is obtained; the difference value dtH is determined according to the solidus temperature Ts and TX of the casting blank after casting of the casting blank; in different reduction modes, a temperature interval to which the dtH belongs is determined, and a corresponding first reduction amount is determined according to the temperature interval and a preset mapping table until the TX and the solidus temperature Ts are consistent;the mapping table is used for characterizing the corresponding relationship between the temperature interval and the first reduction amount, and the first reduction amount is 0 to 15 mm; when the drawing speed of the casting blank is continuously increased, the solid fraction fsH of the predetermined point is determined according to the TX; the condition interval to which the solid fraction fsH belongs is determined, a corresponding second reduction amount is determined according to the condition interval and the mapping table until the casting blank is completed; and the mapping table is also used for characterizing the corresponding relationship between the condition interval and the second reduction amount, and the second reduction amount is 0-20 mm.

Owner:SHOUGANG CORPORATION

Doped sulfide composite film, preparing method of doped sulfide composite film and workpiece comprising doped sulfide composite film

ActiveCN110578115AImprove mechanical propertiesImprove wear resistanceVacuum evaporation coatingSputtering coatingComposite filmHardness

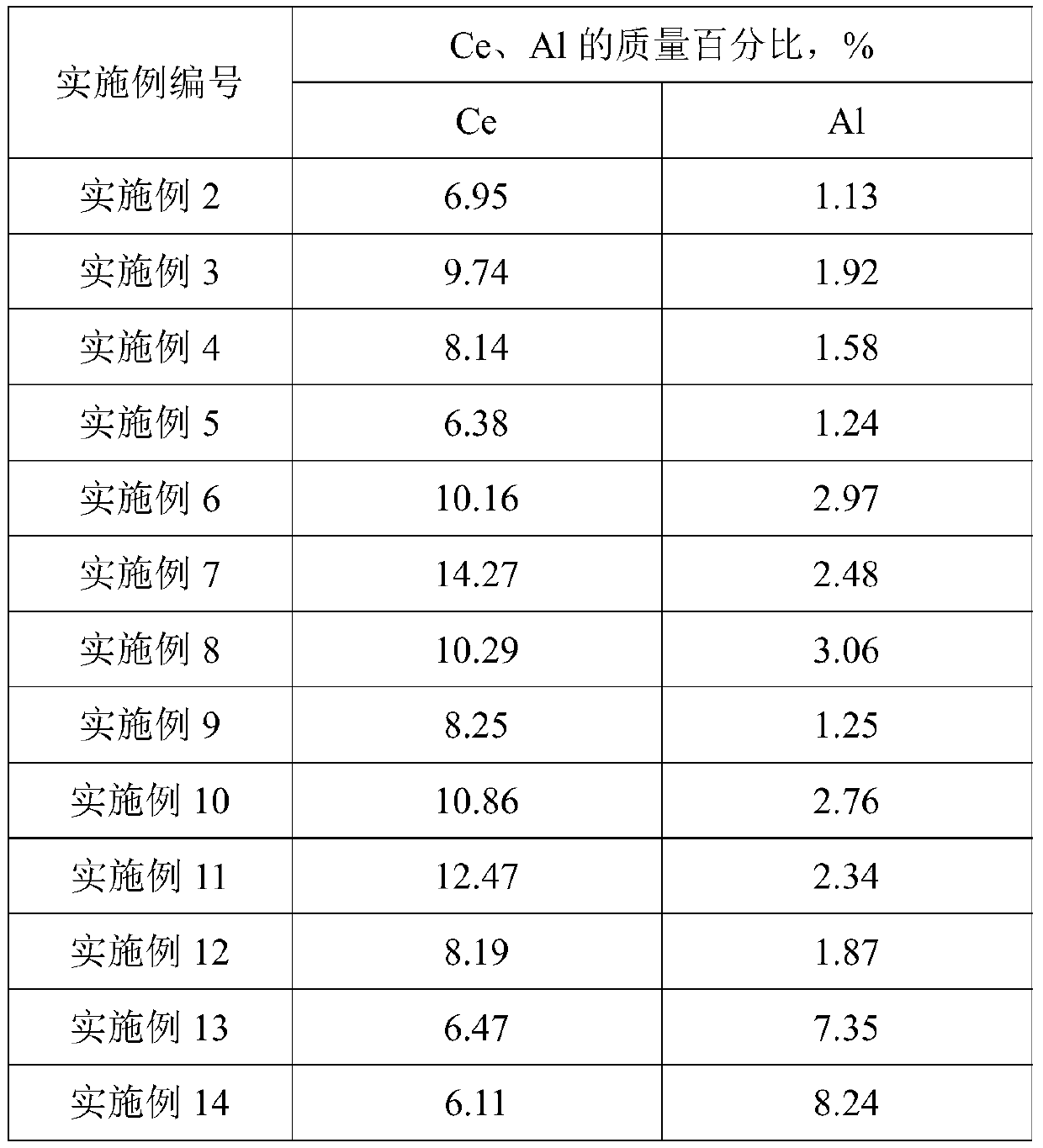

The invention relates to a doped sulfide composite film, a preparing method of the doped sulfide composite film and a workpiece comprising the doped sulfide composite film. The doped sulfide compositefilm is composed of doped elements and sulfide, wherein the doped elements are Ce and Al, and the sulfide is WS2 or MoS2; and the doped sulfide composite film includes, by mass, 6.11%-14.27% of Ce, 1.13%-10.26% of Al and the balance sulfide. The mechanical performance of the doped sulfide composite film is improved, and therefore good wear-resisting performance can be shown; and the crystal strength of the Ce and Al co-doped sulfide base composite film is high, and the elasticity and elasticity modulus are improved by 300% or higher.

Owner:HENAN UNIV OF SCI & TECH

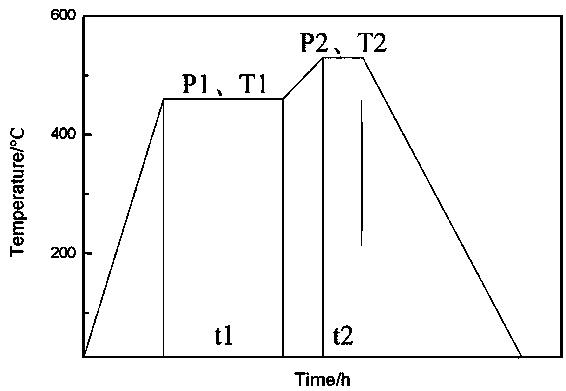

Multi-stage hot isostatic pressing method of Cu-containing cast Al-Si-Mg aluminum alloy castings

The invention relates to a multi-stage hot isostatic pressing method of Cu-containing cast Al-Si-Mg aluminum alloy castings, and belongs to the technical field of machining of aluminum alloy castings.Specifically, hot isostatic pressing treatment is performed after pouring of the Cu-containing cast Al-Si-Mg aluminum alloy castings is completed, the hot isostatic pressing treatment is divided intotwo stages, at the first stage, pressure is P1, a temperature T1 is lower than or equal to a melting temperature of a low-melting-point Cu-containing phase, at the second stage, pressure is P2, a temperature T2 is higher than the melting temperature of the low-melting-point Cu-containing phase and lower than a line temperature of an alloy solid phase, and P2 is larger than or equal to P1. The temperature at the first stage is controlled to be lower than the melting temperature of the copper-rich phase, the temperature is then raised at the second stage, defects of the castings are eliminated,meanwhile the copper-rich phase is prevented from overburning under the conditions of high temperature and high pressure, and the compactness, mechanical property and elongation of the Cu-containingcast Al-Si-Mg aluminum alloy castings subjected to hot isostatic pressing are all effectively improved compared with those of castings not subjected to hot isostatic pressing.

Owner:ZHONGBEI UNIV

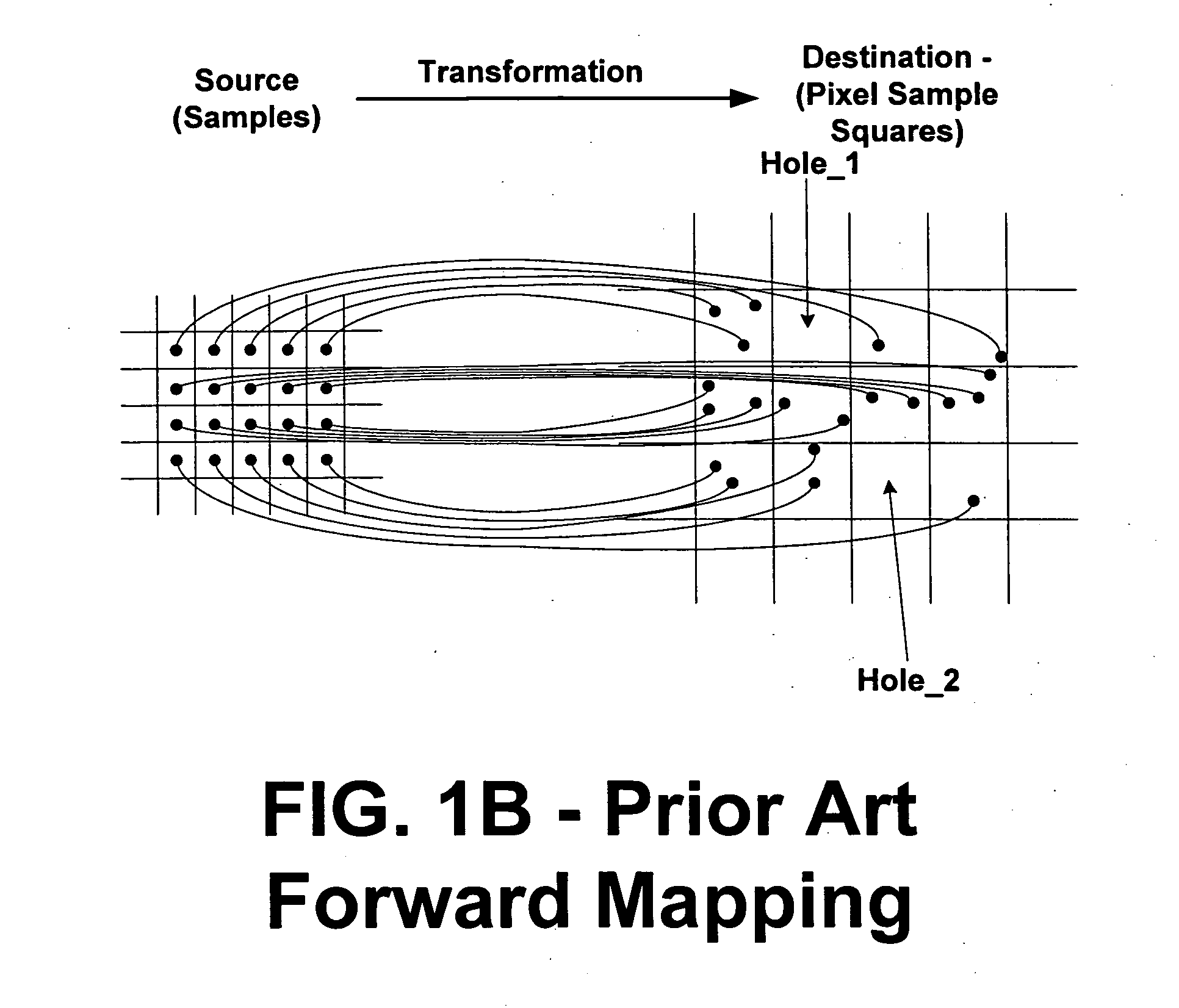

Systems and methods for providing image rendering using variable rate source sampling

InactiveUS20050035973A1Eliminate gapsEliminate holesCharacter and pattern recognitionCathode-ray tube indicatorsGraphicsHigh rate

Systems and methods are provided for variable source rate sampling in connection with image rendering, which accumulate and resolve over all samples forward mapped to each pixel bin. In accordance with the invention, the textured surface to be rendered is sampled, or oversampled, at a variable rate that reflects variations in frequency among different regions, taking into account any transformation that will be applied to the surface prior to rendering and the view parameters of the display device, thus ensuring that each bin of the rendering process receives at least a predetermined minimum number of samples. In one embodiment, the sampling rate is variably set such that each bin is assured to have at least one sample point. In another embodiment, a tiling approach to division of the surface is utilized. In accordance with the architecture provided, the sample points of the surface are forward mapped to sample squares, other regions, of a rendering device, taking into account any transformations applied to the surface and the view parameters of the rendering device, such that each bin receives at least the predetermined minimum number of samples. A filter determines the value(s) to assign to each pixel based upon accumulation and resolution of all of the sample points that fall within the pixel bin(s), rather than assigning a value by selecting only the point sample that corresponds to the center of the pixel. Gaps or holes left by conventional forward-mapping techniques are eliminated by oversampling the source(s), and interpolated points are generated at a higher rate than the original source signal(s) to adequately cover the destination bins. A pixel, or sub-pixel, binning approach is used that accumulates and resolves over all samples, and performs particularly well compared to prior architectures in areas that have higher frequency content, solving the minification antialiasing problem and producing a high quality result. Anisotropic filtering is handled simply with the forward mapping approach by filtering over all samples that naturally accumulate after the forward map, and via variable control of the number of samples forward mapped to the bins. A variety of image processing applications are contemplated wherein variable rate source sampling, and accumulation and resolution of forward mapped point samples can be applied, ranging from 3-D graphics applications to applications wherein images recorded in a recording / storage environment are mapped to the arbitrary requirements of a display environment.

Owner:MICROSOFT TECH LICENSING LLC

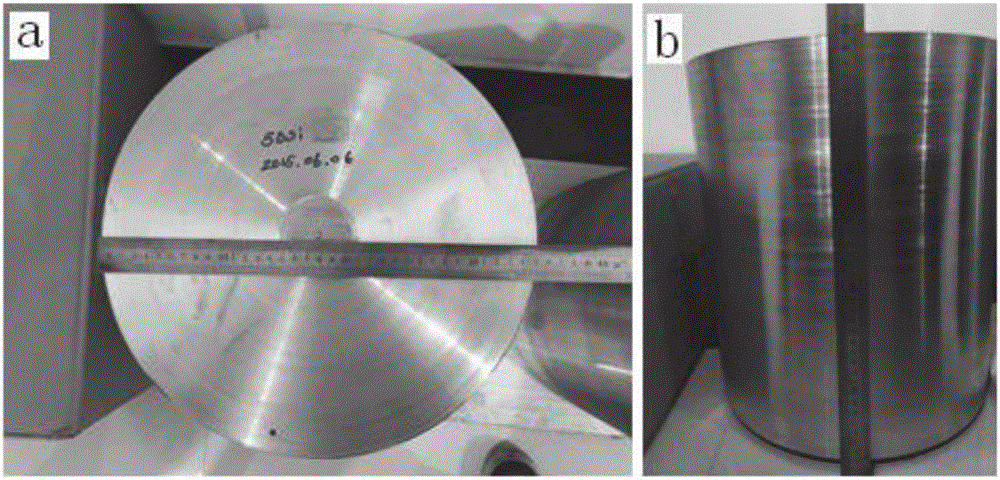

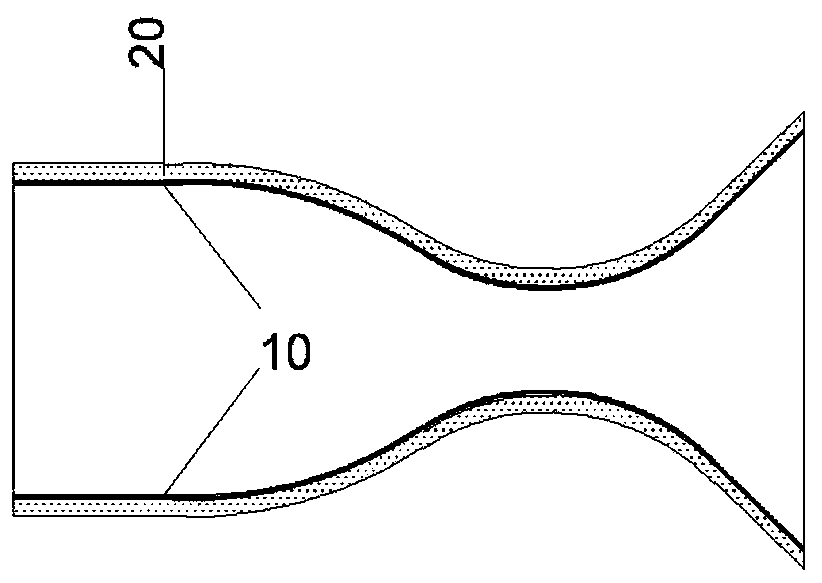

Anti-oxidation coating for rhenium spray pipe, preparation method of anti-oxidation coating and rhenium-anti-oxidation coating spray pipe

ActiveCN111411251AImprove compactnessImprove densification performanceChemical vapor deposition coatingRheniumMetallic materials

The invention provides an anti-oxidation coating for a rhenium spray pipe, a preparation method of the anti-oxidation coating and a rhenium-anti-oxidation coating spray pipe, and belongs to the technical field of coating preparation. The anti-oxidation coating has high compactness and component uniformity. Smelting is a traditional method commonly adopted for preparing precious metal materials andhas the advantages of being high in preparation speed, mature in process and simple in equipment. According to the anti-oxidation coating for the rhenium spray pipe, the preparation method of the anti-oxidation coating and the rhenium-anti-oxidation coating spray pipe, through smelting pre-alloying, homogenizing heat treatment, hot forging and hot isostatic pressing, materials are further homogenized and densified, and the high-density coating materials with the relative density exceeding 99.9% can be obtained; and the coating is prepared through machining, machining the thickness and the machining precision of the coating completely according to drawing design requirements is carried out, so that the thickness uniformity is controllable, and the size precision can reach + / -10 microns.

Owner:SINO PLATINUM METALS CO LTD

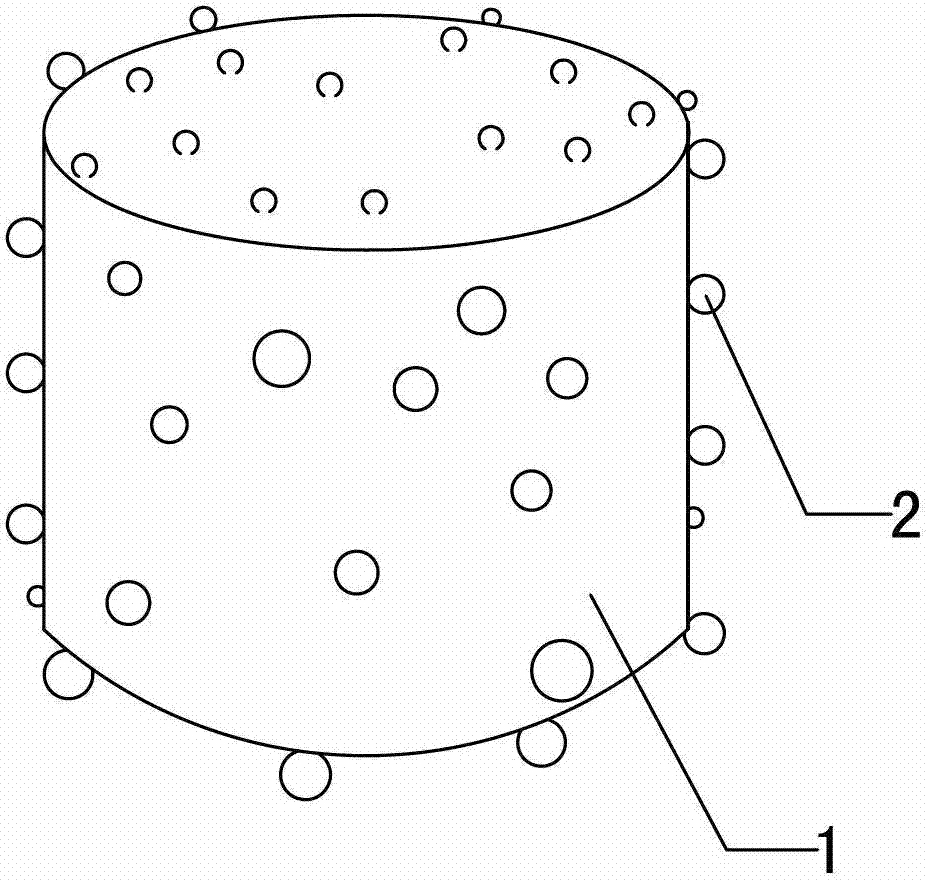

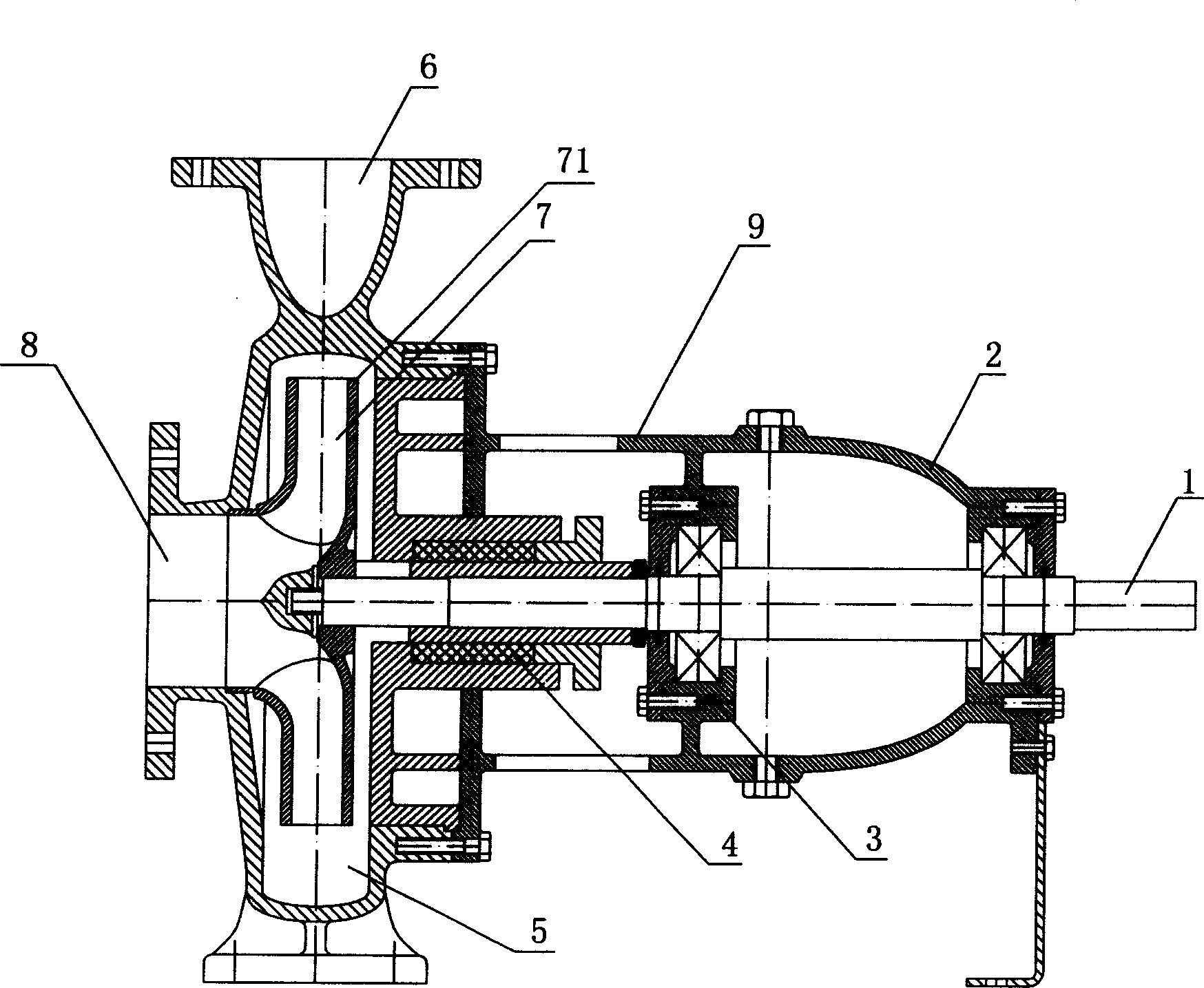

Centrifugal pump

InactiveCN1757931AEliminate negative pressureEliminate holesPump componentsPumpsEngineeringEnergy consumption

A centrifugal pump is composed of a main body with a volute cavity at its one end, a mainshaft installed at another end of main body, and a blade wheel installed on said mainshaft and contained in said volute cavity. Said blade wheel consists of hub, webs and two or more blades installed to webs and composed of primary and secondary blades linked by a sealing plate. Its advantages are high efficiency and low energy consumption.

Owner:陈瑜

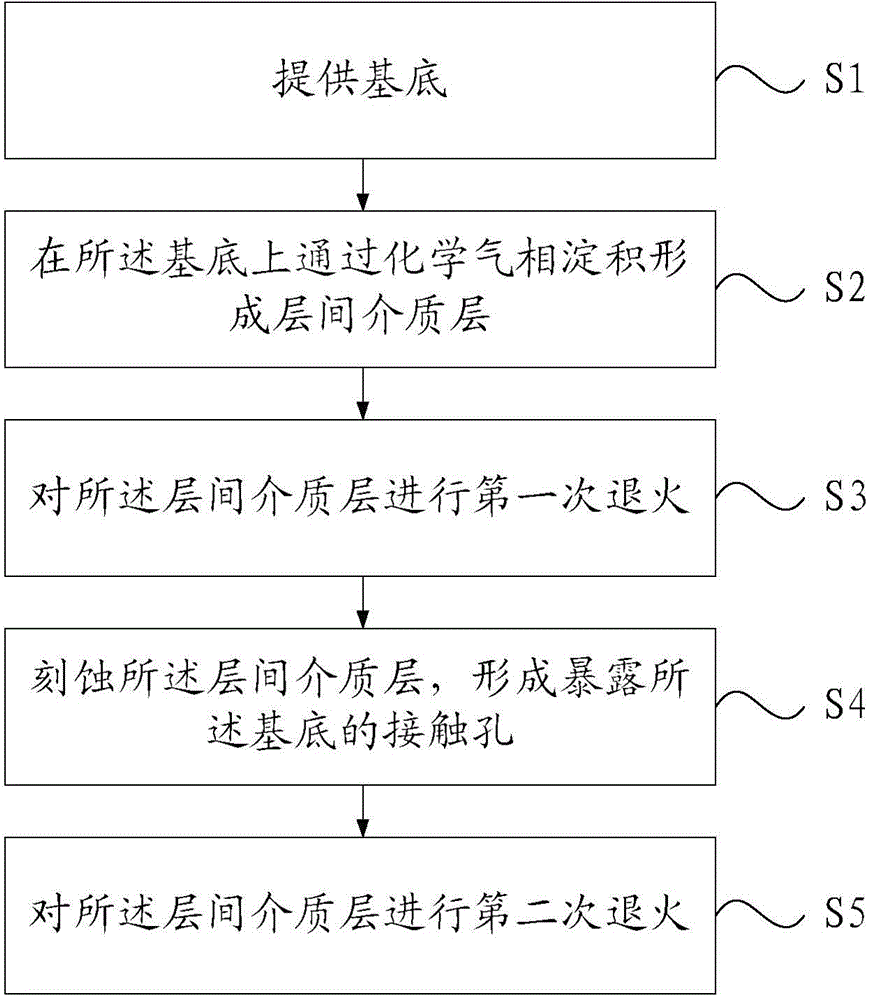

Interlayer dielectric layer forming method and semiconductor device forming method

InactiveCN105845619AIncrease surface areaEliminate holesSemiconductor/solid-state device manufacturingGas phaseChemical vapor deposition

In the method for forming an interlayer dielectric layer provided by the present invention, after the interlayer dielectric layer is formed by chemical vapor deposition, the interlayer dielectric layer is annealed for the first time, and then etched to form a contact hole. After the contact hole is formed, use the contact hole to increase the surface area of the interlayer dielectric layer, and then perform the second annealing to completely eliminate the holes in the interlayer dielectric layer and improve the quality of the interlayer dielectric layer. When the thickness of the interlayer dielectric layer is relatively large, a better quality interlayer dielectric layer can also be obtained through this method. The present invention also provides a method for forming a semiconductor device. A device structure is previously formed in the substrate. After the second annealing, a wiring structure is formed through the contact hole to electrically connect the device structure. This method can simplify the process steps.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Liquid crystal display panel and manufacturing method thereof

InactiveCN101975999AControl adhesionSave processNon-linear opticsLiquid-crystal displayPlastic materials

The invention discloses a liquid crystal display (LCD) panel and a manufacture method thereof. The LCD panel comprises a first substrate, a second substrate and a liquid crystal layer, wherein the first substrate is provided with a first insulating substrate; the second substrate is provided with a second insulating substrate prepared by a plastic material; an adsorption region is arranged on the periphery of the second insulating substrate, and is adhered to the first insulating substrate to ensure that the first substrate and the second substrate are combined and fixed to form an accommodating region; and the liquid crystal layer is accommodated in the accommodating region. The LCD panel and the manufacture method thereof can save the procedure of frame glue coating, and eliminate pollution, pores and other related adverse influences generated by using a frame coating.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com