Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

492results about How to "Eliminate unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

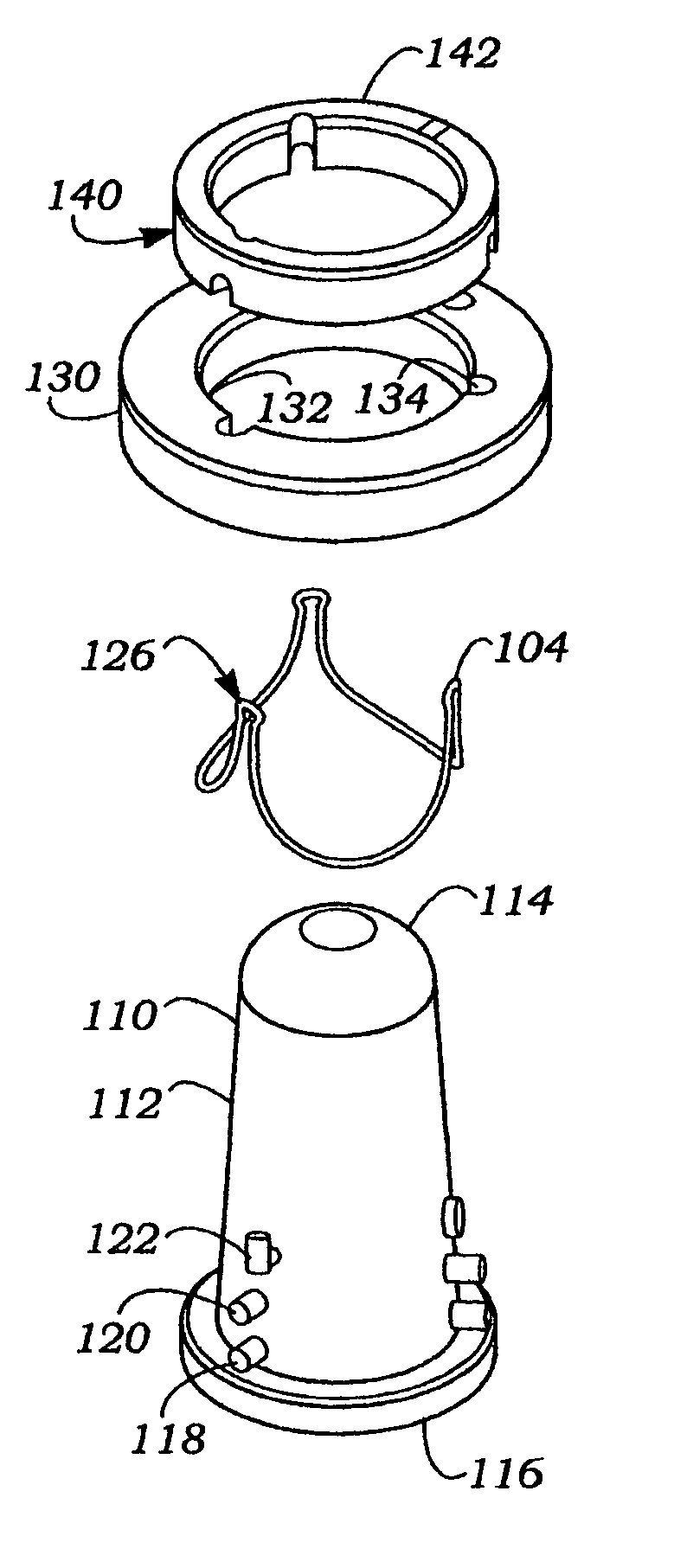

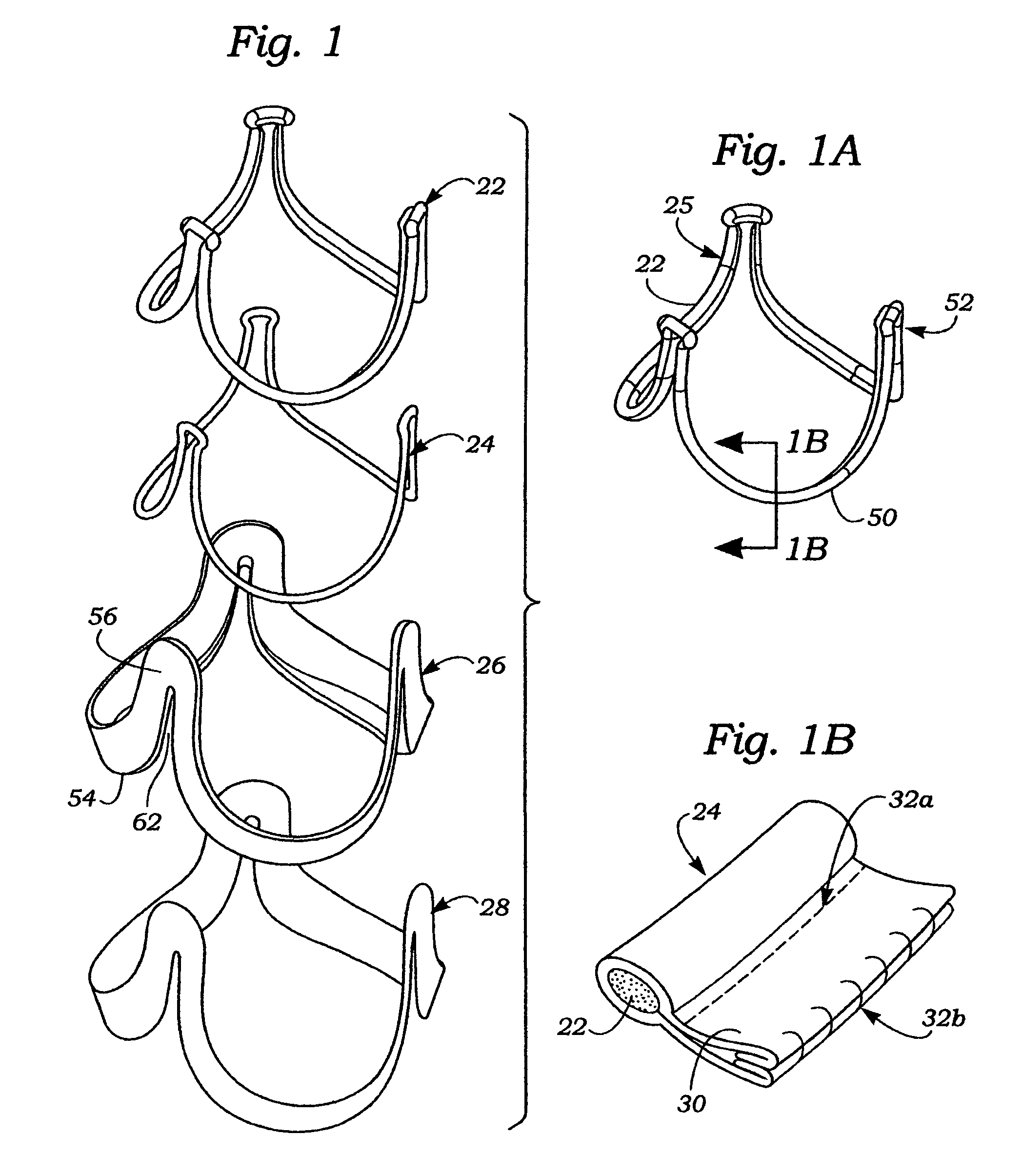

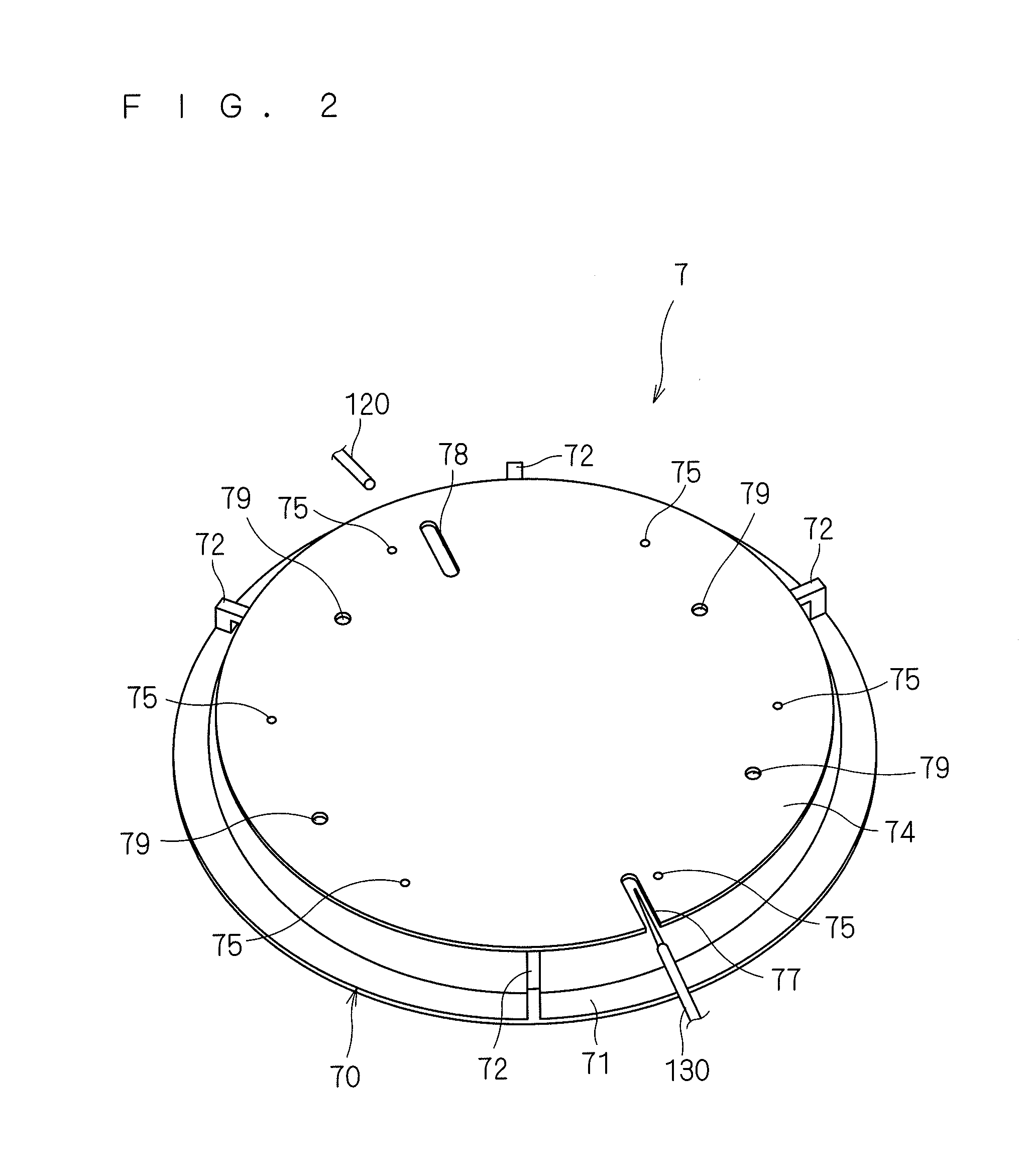

Continuous heart valve support frame and method of manufacture

InactiveUS7137184B2Eliminate unevennessIncrease flexibilityHeart valvesAssembly machinesElgiloyEngineering

Methods for forming a support frame for flexible leaflet heart valves from a starting blank include converting a two-dimensional starting blank into the three-dimensional support frame. The material may be superelastic, such as NITINOL, and the method may include bending the 2-D blank into the 3-D form and shape setting it. A merely elastic material such as ELGILOY may be used and plastically deformed in stages, possibly accompanied by annealing, to obtain the 3-D shape. Alternatively, a tubular blank could be formed to define a non-tubular shape, typically conical. A method for calculating the precise 2-D blank shape is also disclosed. A mandrel assembly includes a mandrel and ring elements for pressing the blank against the external surface of the mandrel prior to shape setting.

Owner:EDWARDS LIFESCIENCES CORP

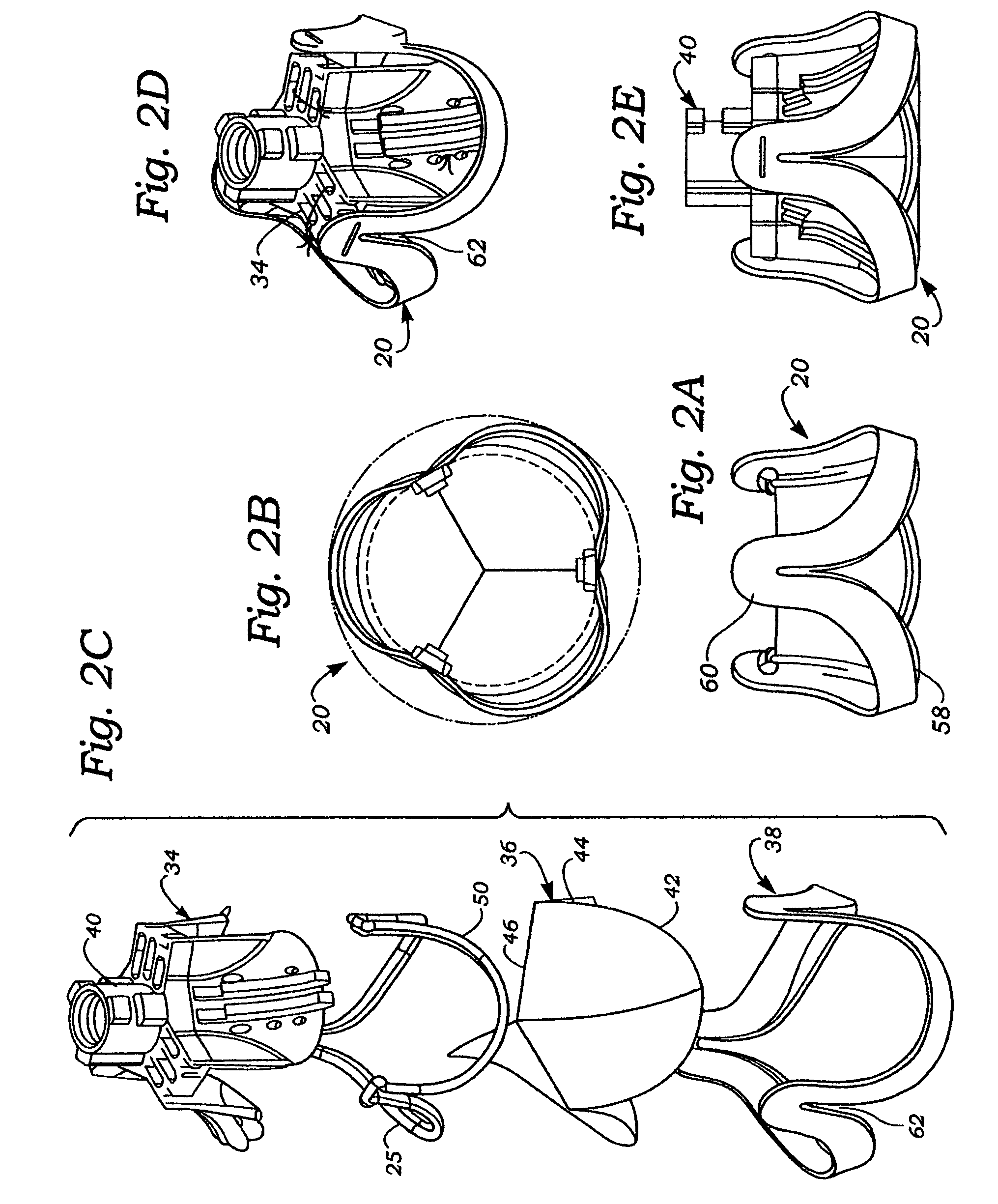

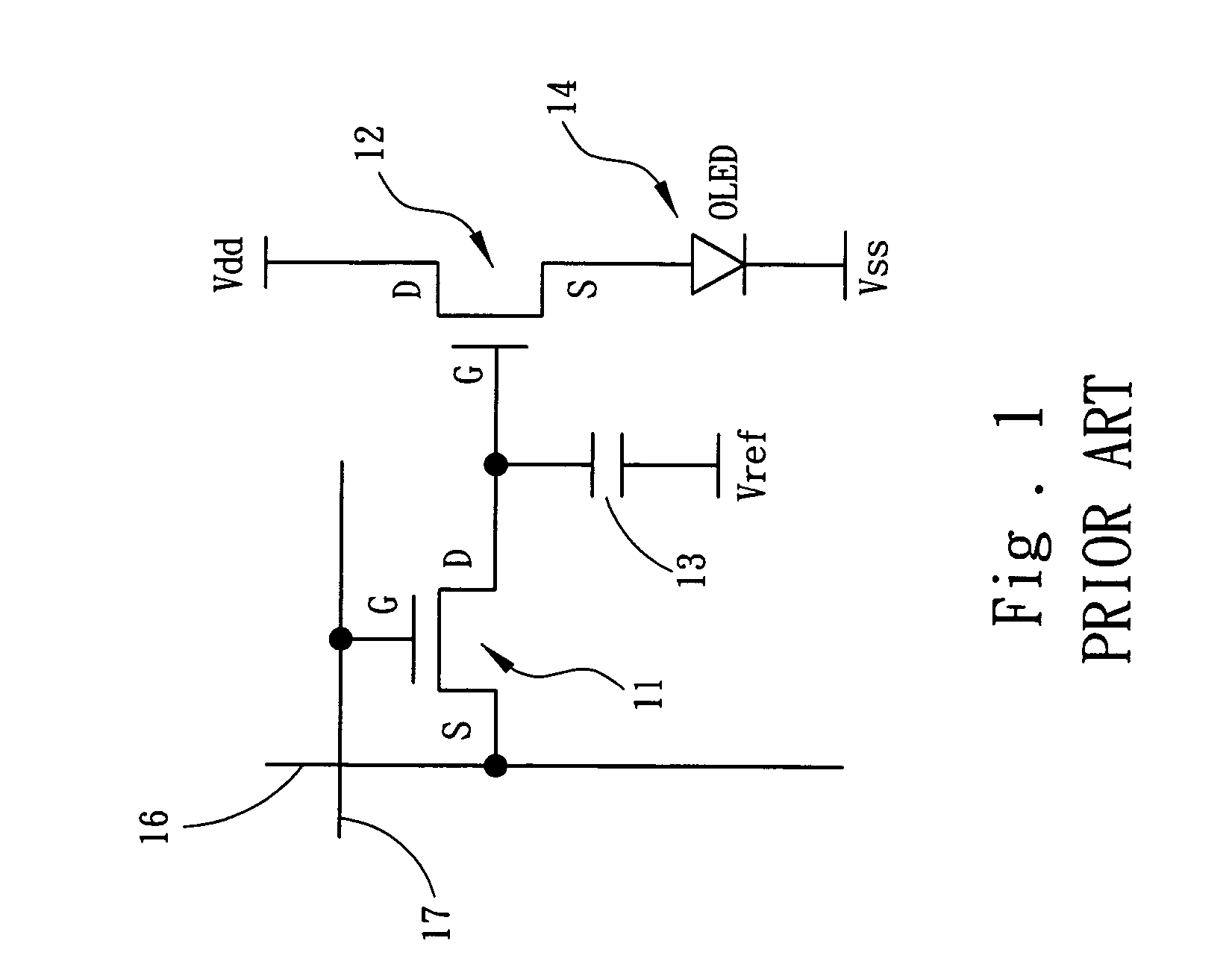

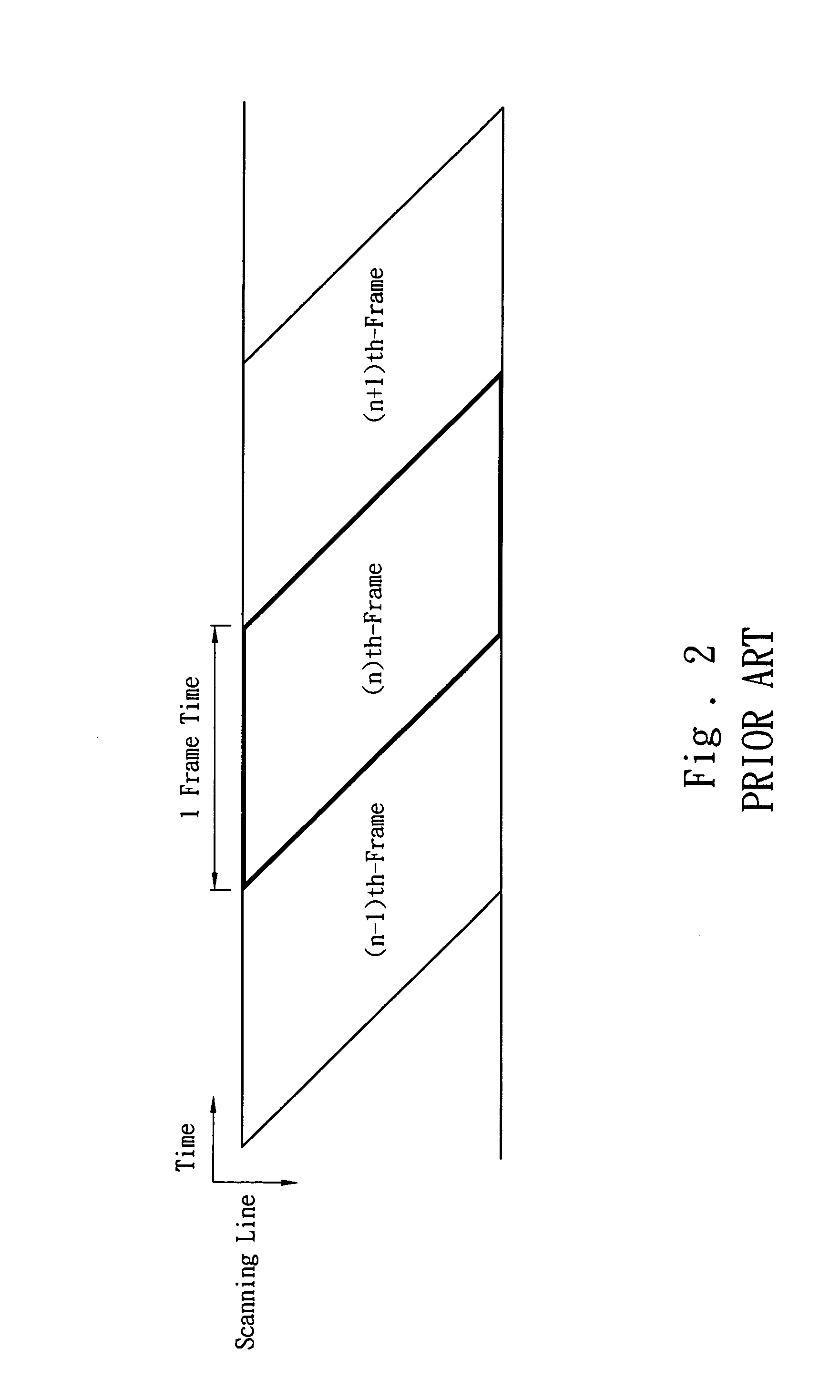

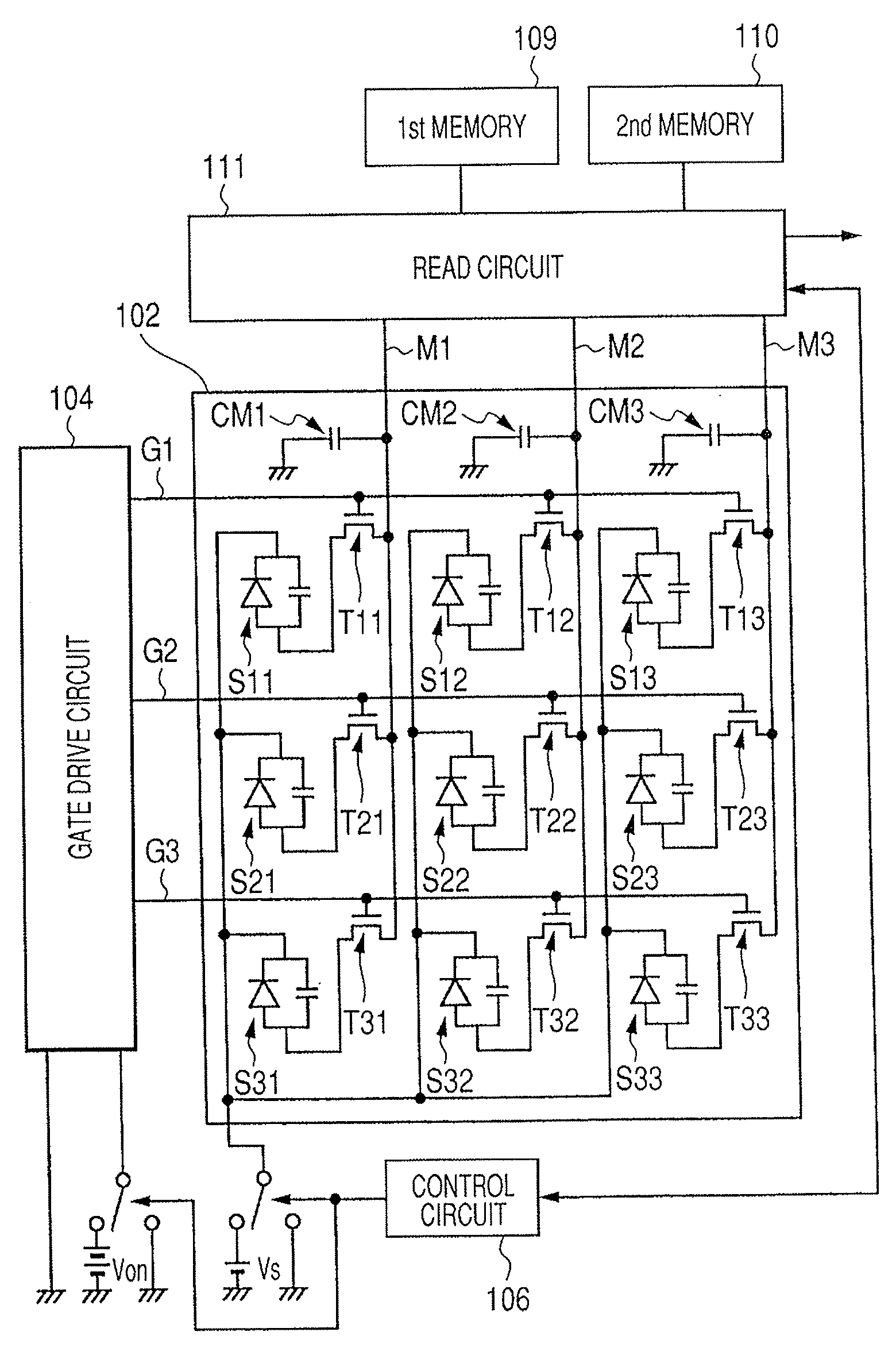

Method of improving the stability of active matrix OLED displays driven by amorphous silicon thin-film transistors

InactiveUS7116058B2Improve driving stabilityEliminate unevennessElectrical apparatusCathode-ray tube indicatorsCapacitanceDriver circuit

A method of improving the stability of organic light emitting diode (OLED) display devices driven by amorphous silicon thin-film transistors, in which the driving circuitry within each sub-pixel includes a driving transistor for driving organic light emitting diode (OLED), a scanning transistor and a storage capacitance. An end of the capacitance is connected to the signal resetting line, which a resetting time pulse of high potential and low potential are supplied. Since the resetting signals within the sub-pixels are synchronized, a single voltage of the resetting signal can control the positive and negative stresses for each transistor in the sub-pixels on the panel.

Owner:WINTEX

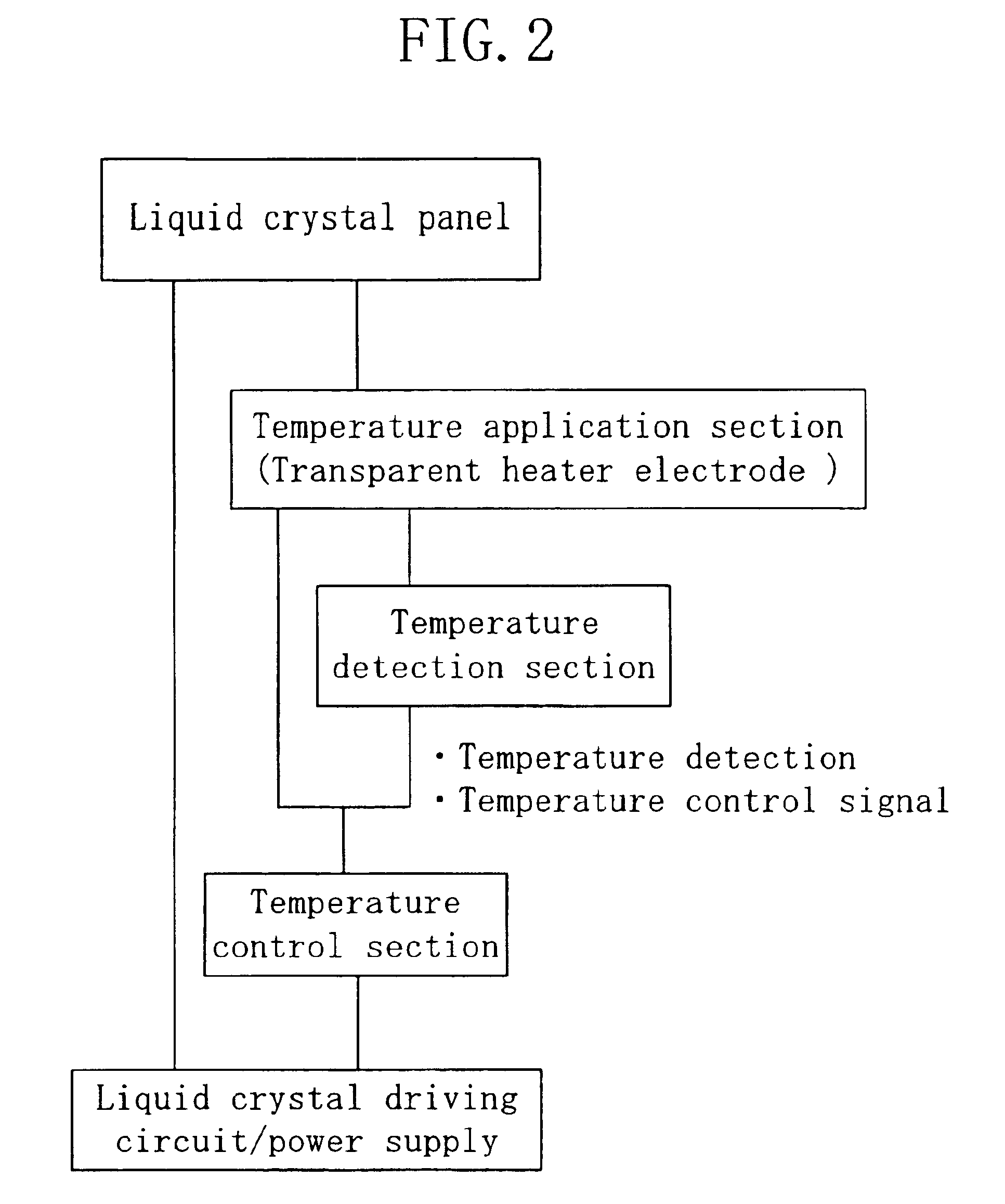

Liquid crystal display device, image shifting device, and image display apparatus

ActiveUS6885412B2Quality improvementQuick responseLiquid crystal compositionsTelevision system detailsLiquid-crystal displayEngineering

A liquid crystal display device includes a first substrate, a second substrate opposing the first substrate, a liquid crystal layer provided in a gap between the first substrate and the second substrate, and a temperature adjustment member formed on the first substrate and / or the second substrate. The panel temperature T (° C.) of the liquid crystal display device is controlled to be equal to or greater than TNI-65 and less than or equal to TNI-15, where TNI (° C.) is the nematic-isotropic phase transition temperature of the liquid crystal composition of the liquid crystal layer.

Owner:SHARP KK

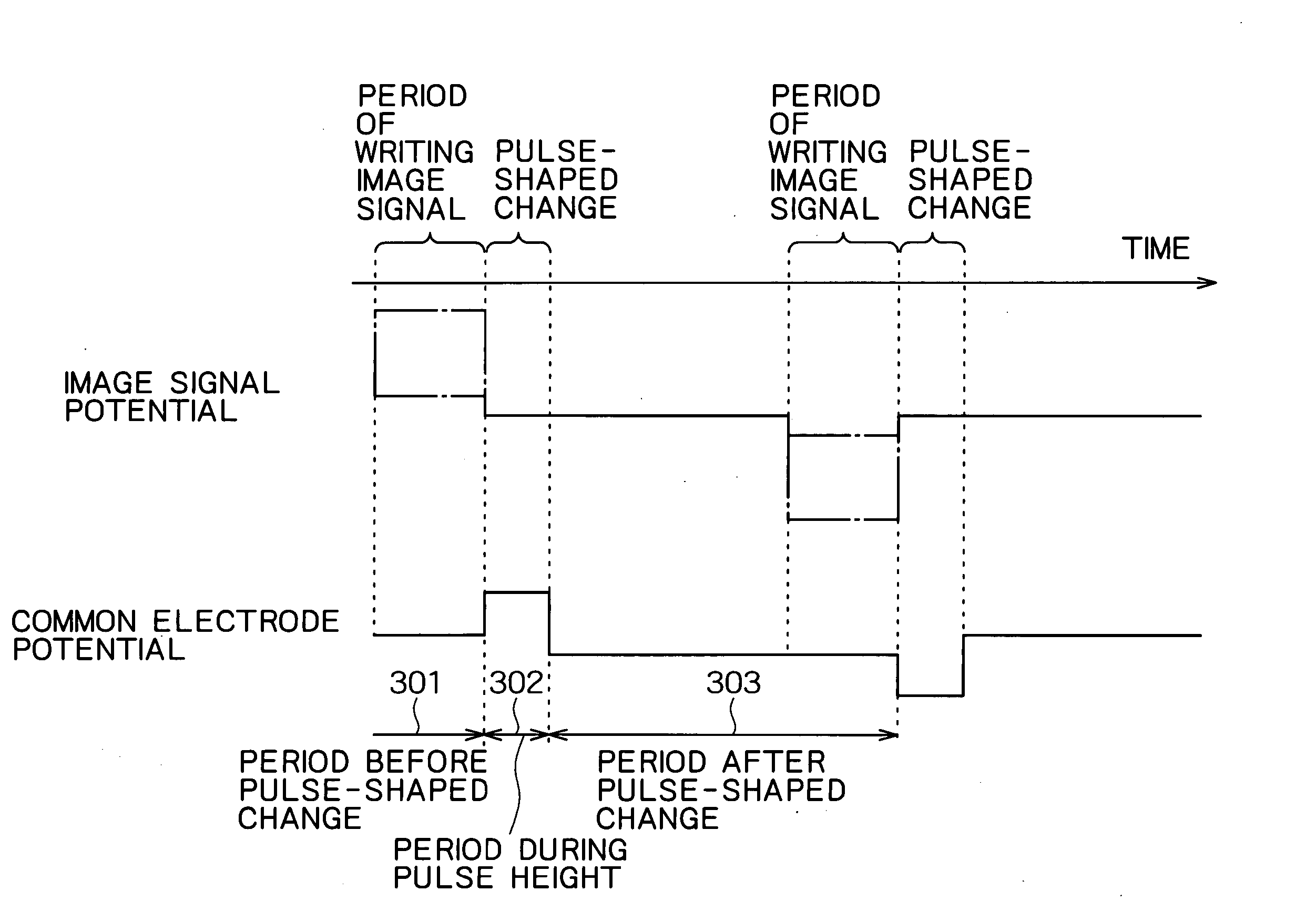

Liquid crystal display device, and method and circuit for driving liquid crystal display device

InactiveUS20050140634A1High light use efficiencyLow electric power consumptionStatic indicating devicesLiquid-crystal displayEngineering

Owner:NEC LCD TECH CORP

Compact foamy thyrite in high intensity and preparation method

The invention provides a high strength compact foam silicon carbide ceramics material and the prodn method. Counting on weight percentage, the material is composed by silicon carbide 90-98 and silicon 10-2, silicon carbide powder and resin with high carbon-producing ration are mixed to slurry, expanded plastice is cut and soaked in the slurry, which is taken out, removing unnecessary slurry, then is treated by semisolidifying, high-temp, high-pressure solidifying, the solidified foam body is pyrolized to obtain foam carbon frame with same shape as original foam shape composed by silicon carbide and pylolized carbon, to open a centre hole on carbon frame by grinding, the silicon slurry is injected into the centre hole until filling by press injection, then is pylolized, by silicizing process, carbon in the carbon frame and gas or liquid phase silicen are reacted to generate silicon carbide and combined with original silicon carbide particles in carbon frame, thus to obtain high strength compact silicon carbide foam ceramics.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

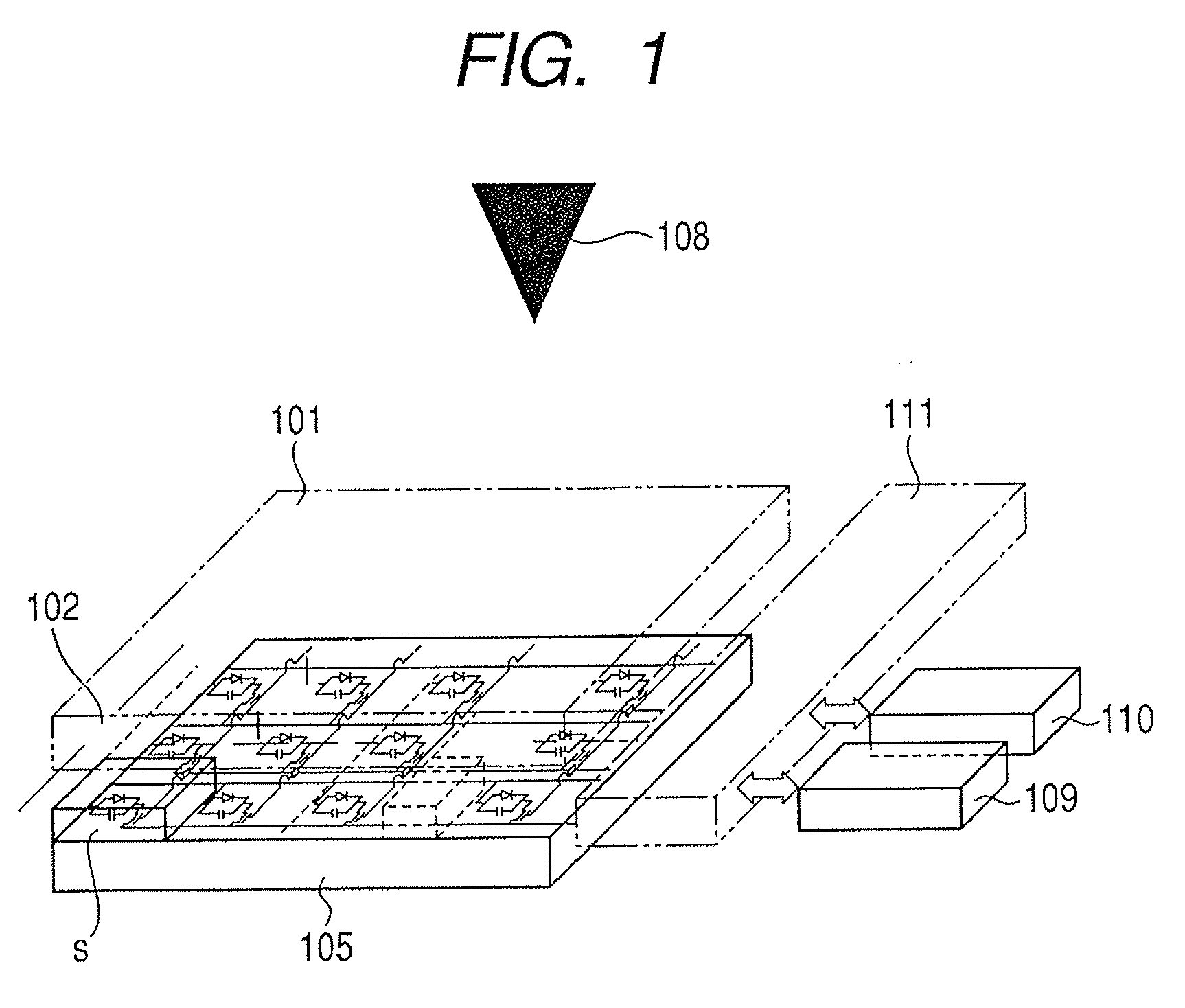

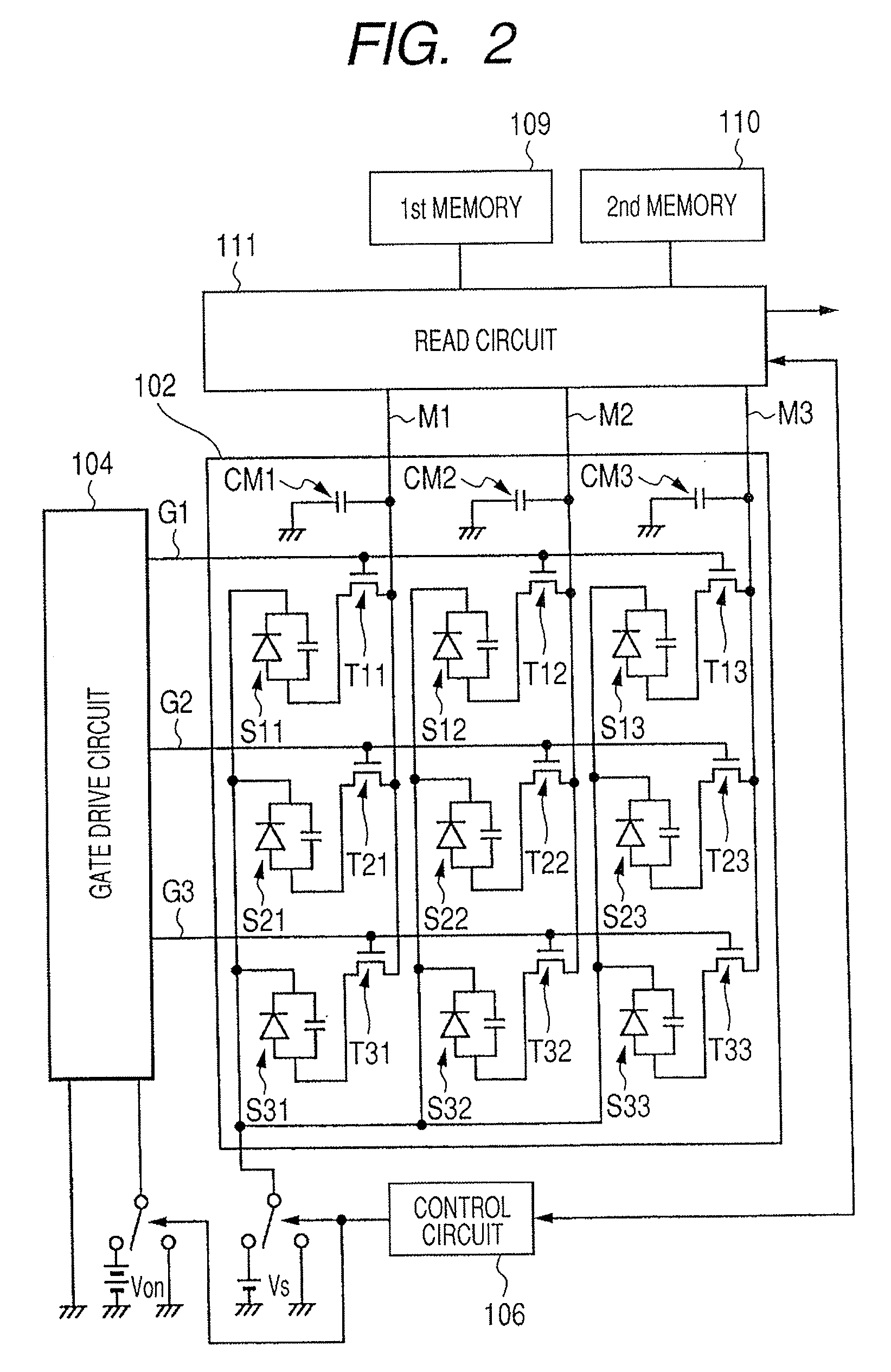

Radiation imaging apparatus, radiation imaging system, and correction method

ActiveUS20070131843A1Accurate signalEliminate the effects ofTelevision system detailsPhotometry using reference valueRadiation imagingRadiography

The invention intends to be able to adequately perform a gain correction. Hence, at the time of radiographing an object, a gain correction of the object image is performed based on a gain correction image (XRc1) derived by performing a light reset. On the other hand, at the time of radiographing an object, when a light reset is not performed, a gain correction of the object image is performed based on a gain correction image (XRc2) derived without performing the light reset.

Owner:CANON KK

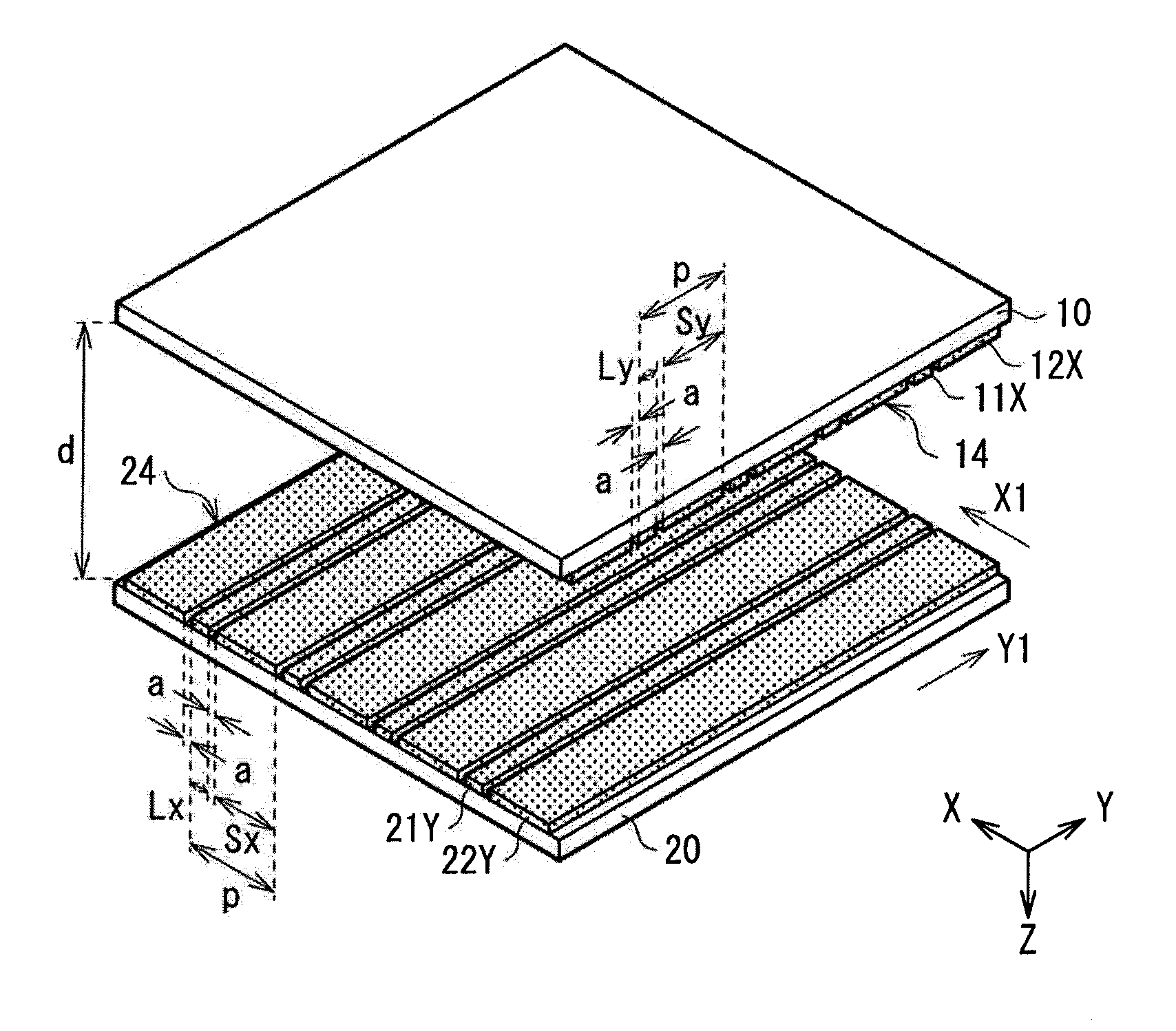

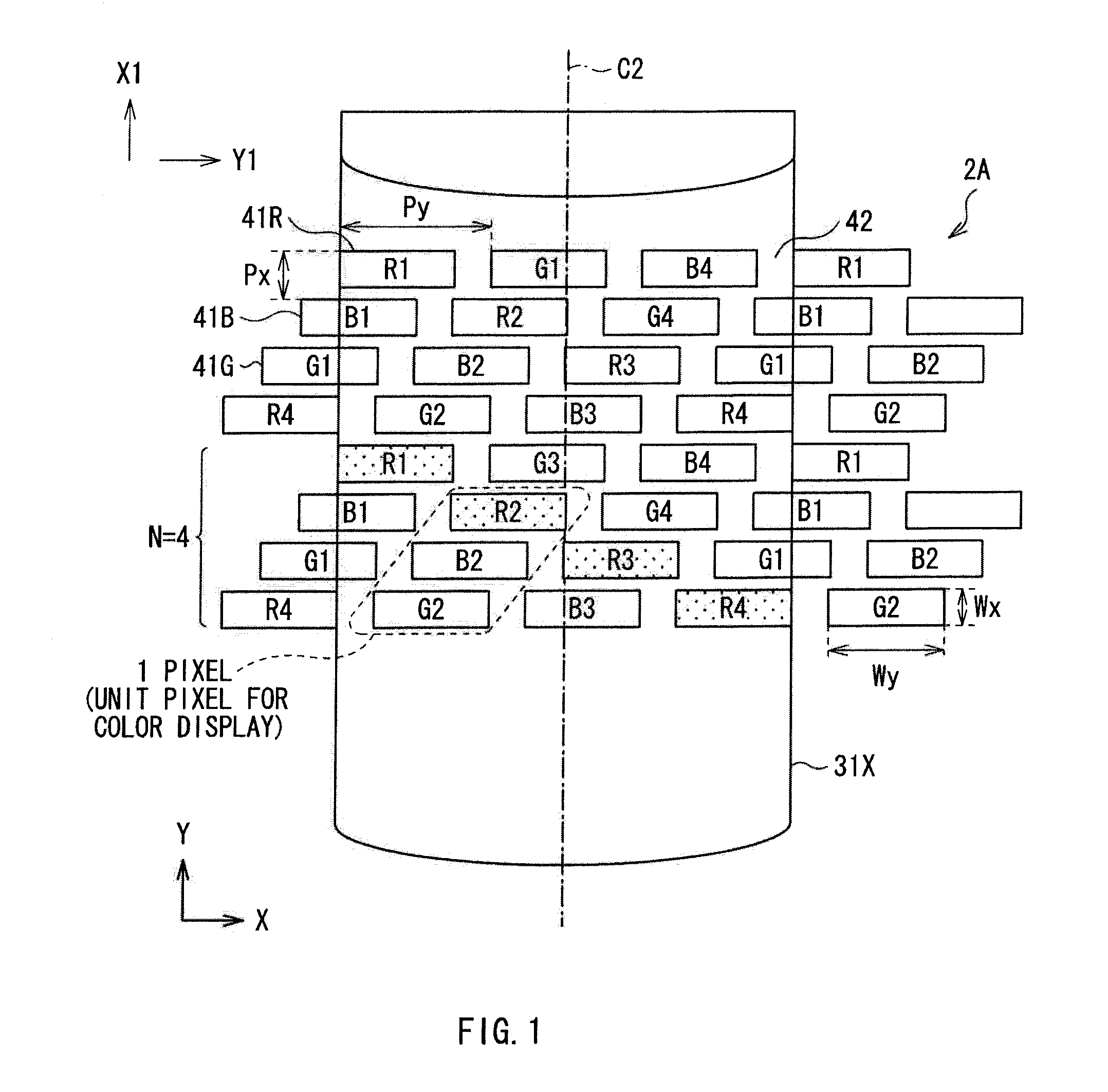

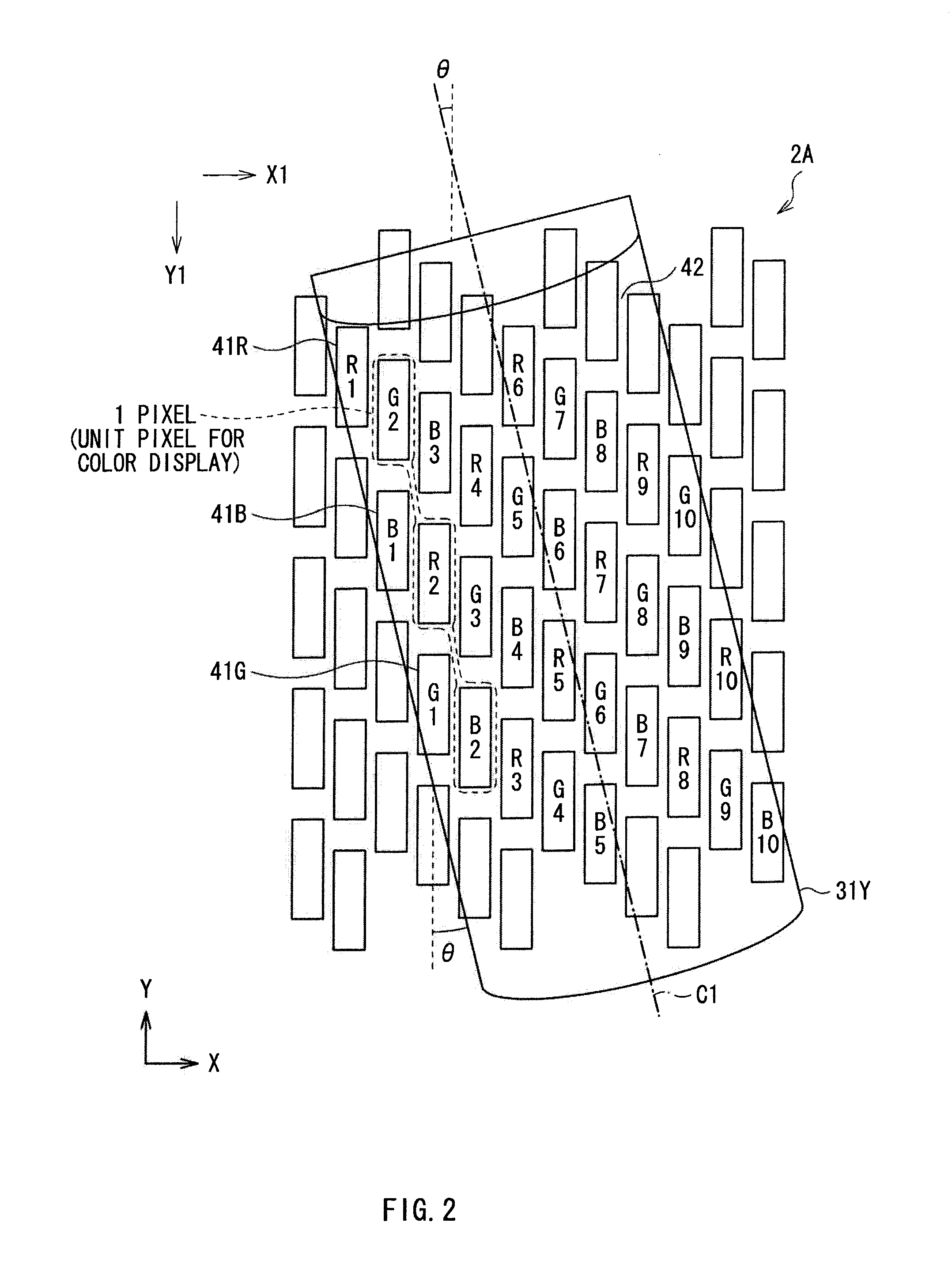

Stereoscopic display

InactiveUS20100259697A1Good stereo visionReduce brightness unevennessSteroscopic systemsNon-linear opticsComputer scienceLens effect

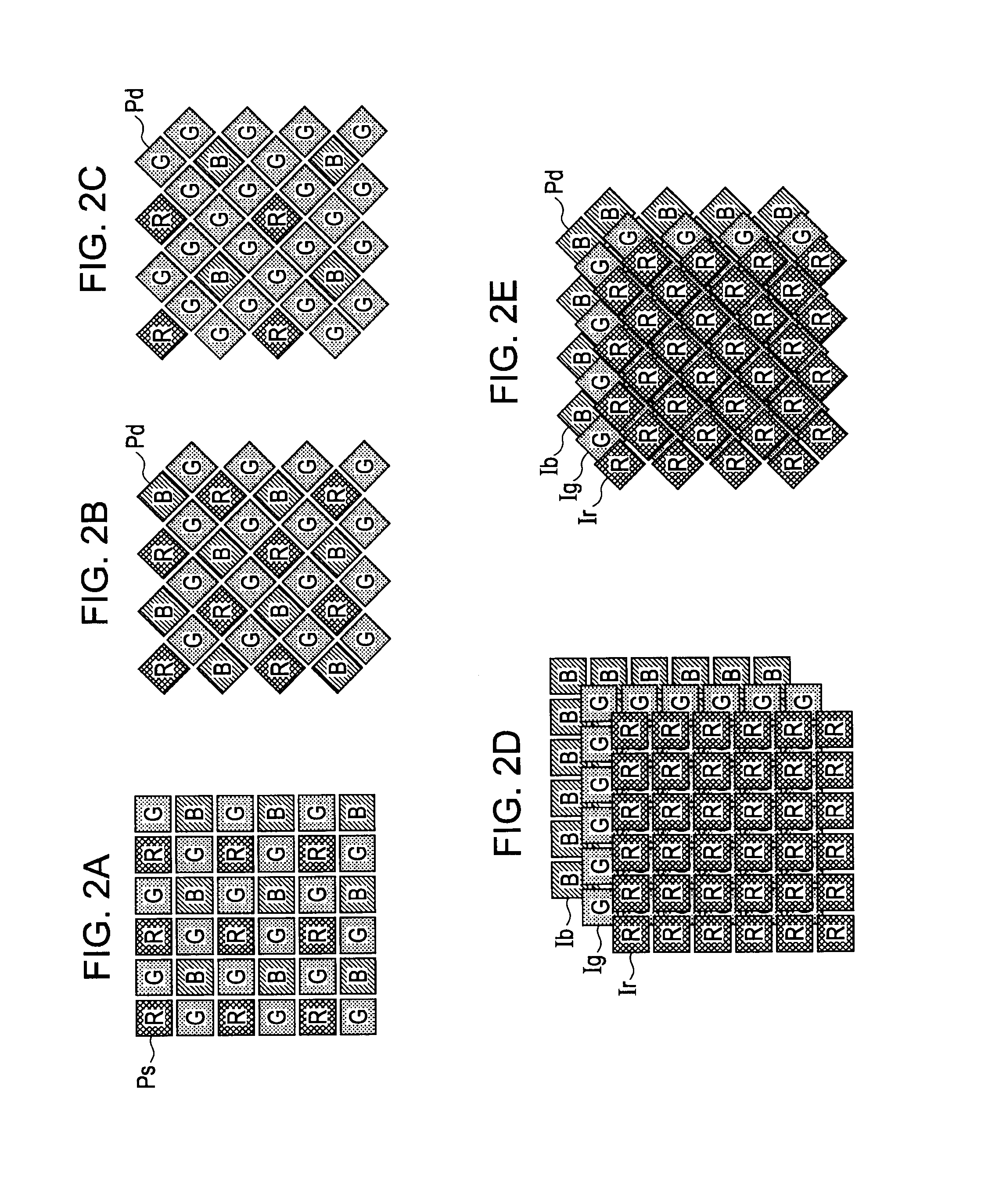

A stereoscopic display includes: a display panel configured to display an image in either one of two or more arrangement states including a first arrangement state and a second arrangement state which are switchable with each other; and a lens array device arranged to face a display surface of the display panel. The lens array device produces a lens effect in a direction, the direction of effect being changed between in the first arrangement state and in the second arrangement state. The display panel includes an array of a plurality of sub-pixels, and a combination of sub-pixels used as a unit pixel is changed between in the first arrangement state and in the second arrangement state.

Owner:SONY CORP

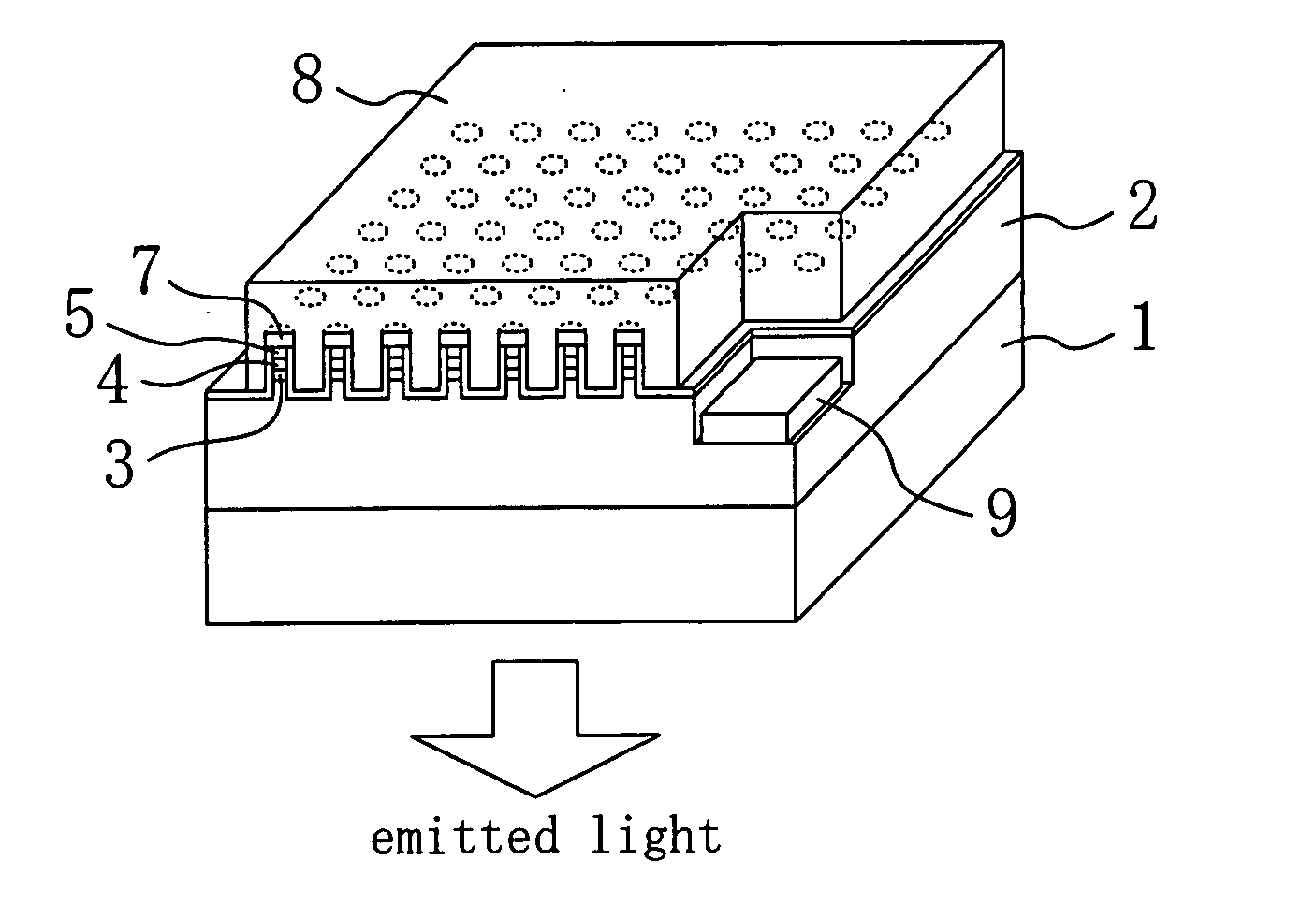

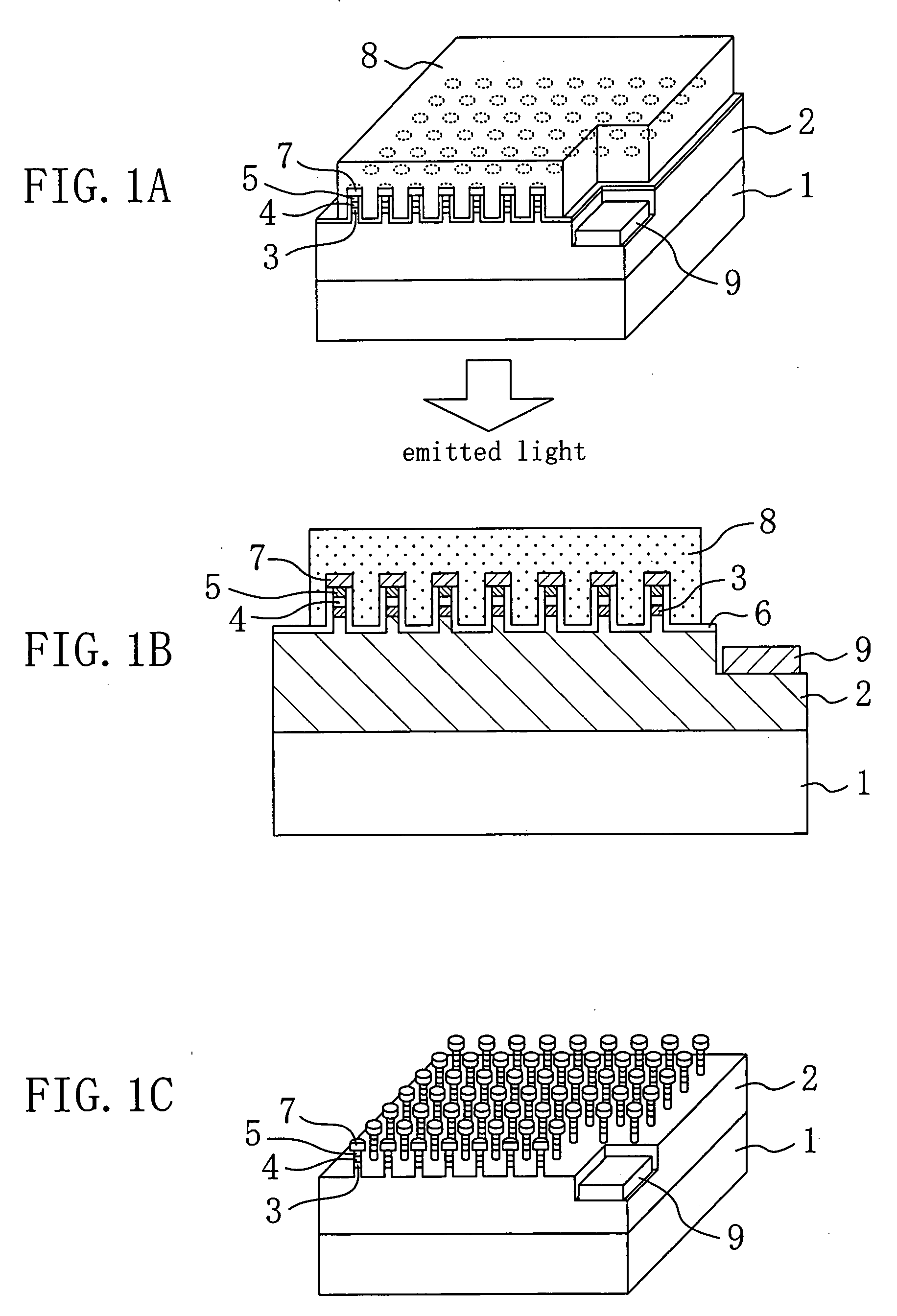

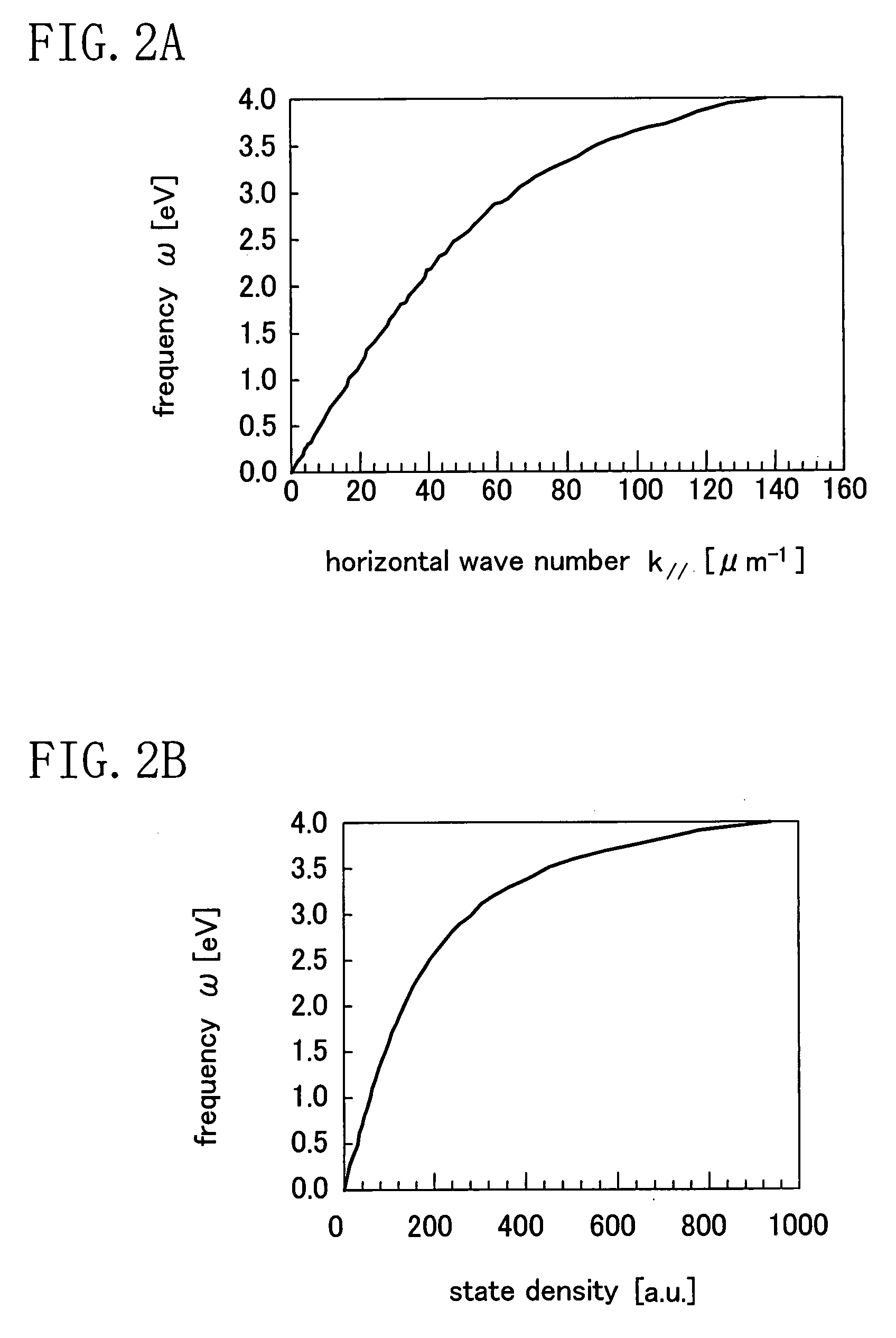

Semiconductor light emitting device and method for manufacturing the same

InactiveUS20070181889A1Less ability to dissipate heatImprove abilitiesSolid-state devicesSemiconductor devicesLength waveActive layer

A semiconductor light emitting device comprises a semiconductor multilayer film including an active layer for generating light, a p electrode formed on the semiconductor multilayer film, and a plasmon generating layer, which are provided on a substrate. A portion of the semiconductor multilayer film including at least the active layer forms a plurality of rods. The plasmon generating layer (8) fills between each rod. The plasmon generating layer (8) is formed of a material having a negative dielectric constant at the wavelength of emitted light. The rods are arranged in a periodic manner.

Owner:PANASONIC CORP

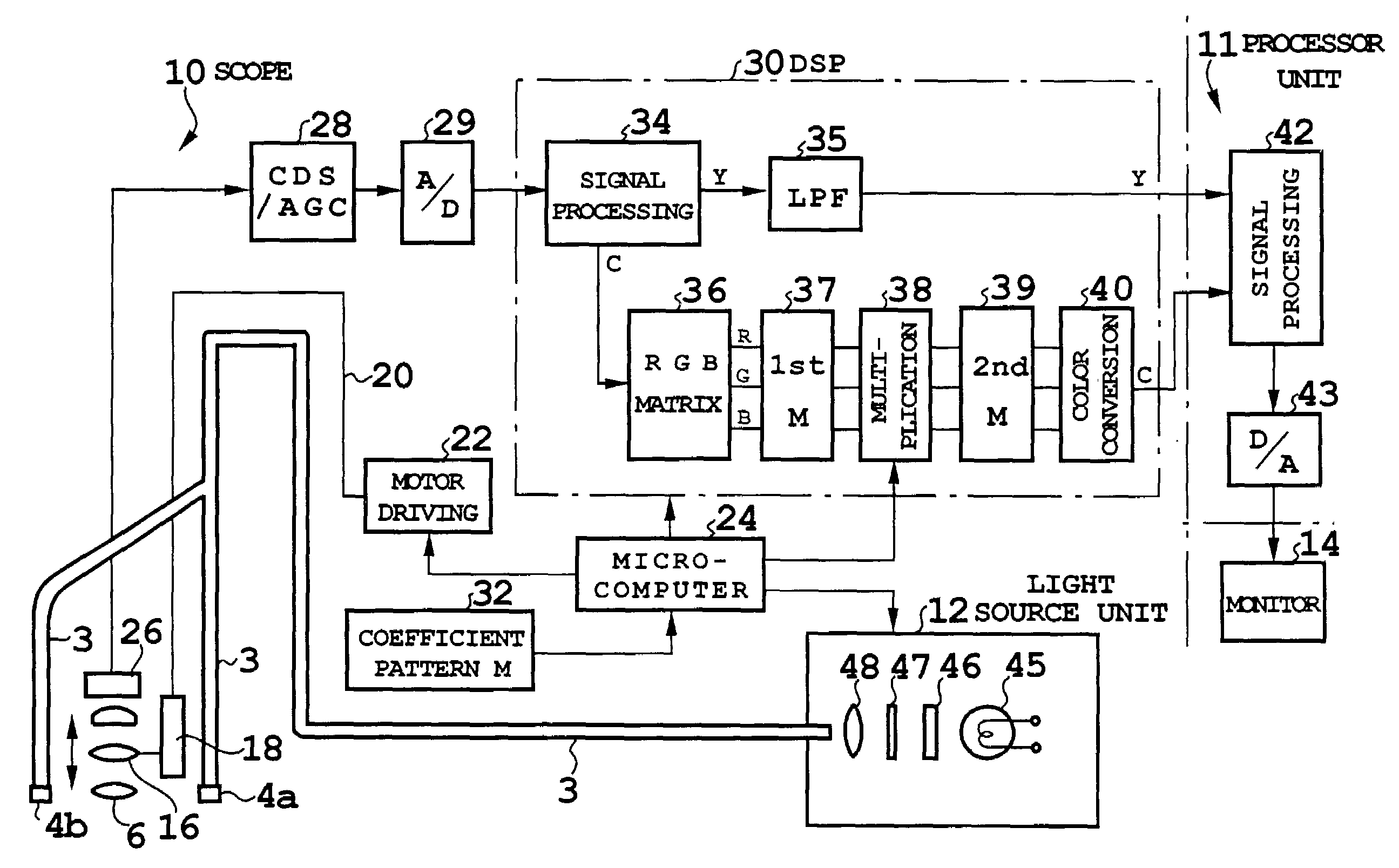

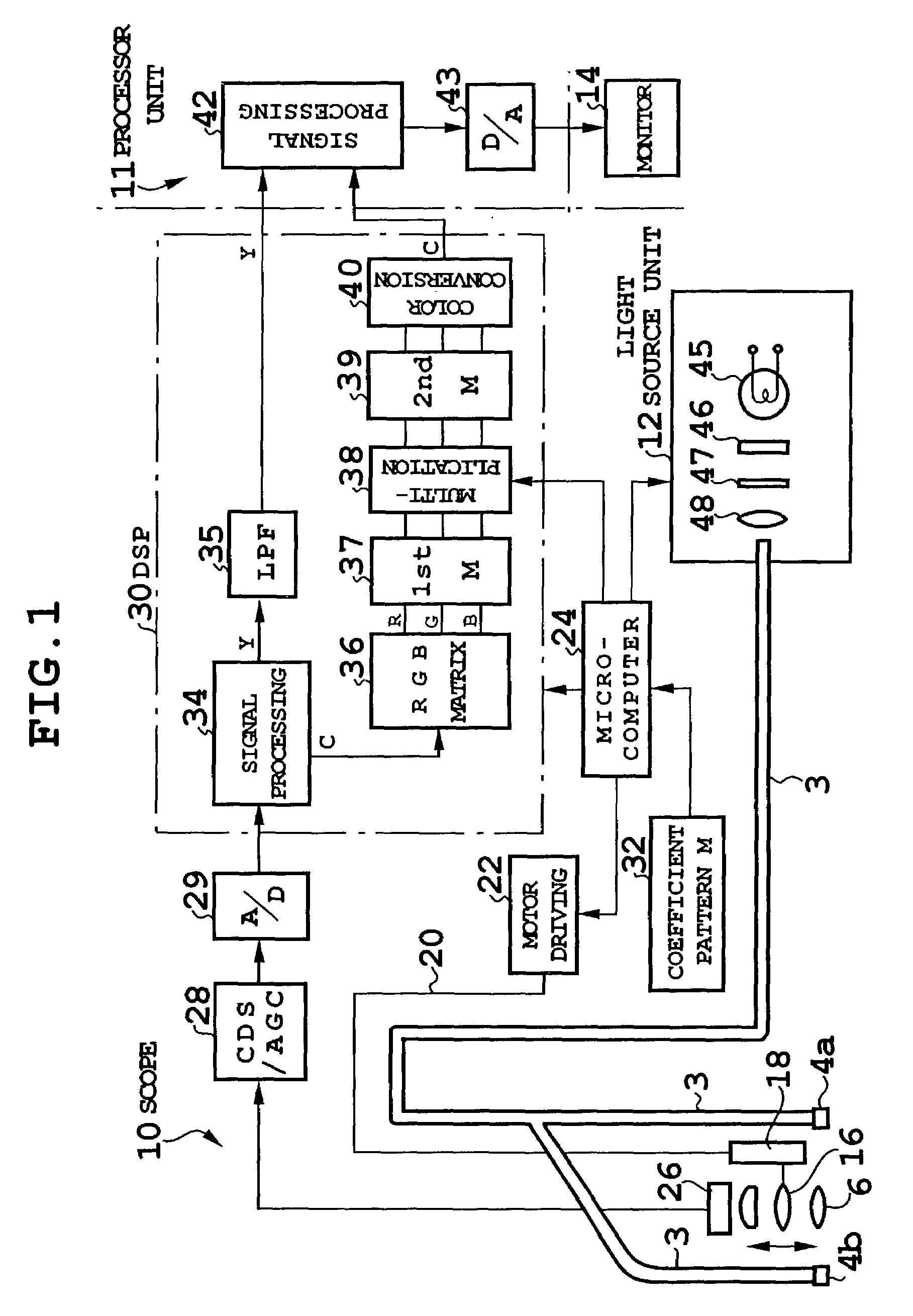

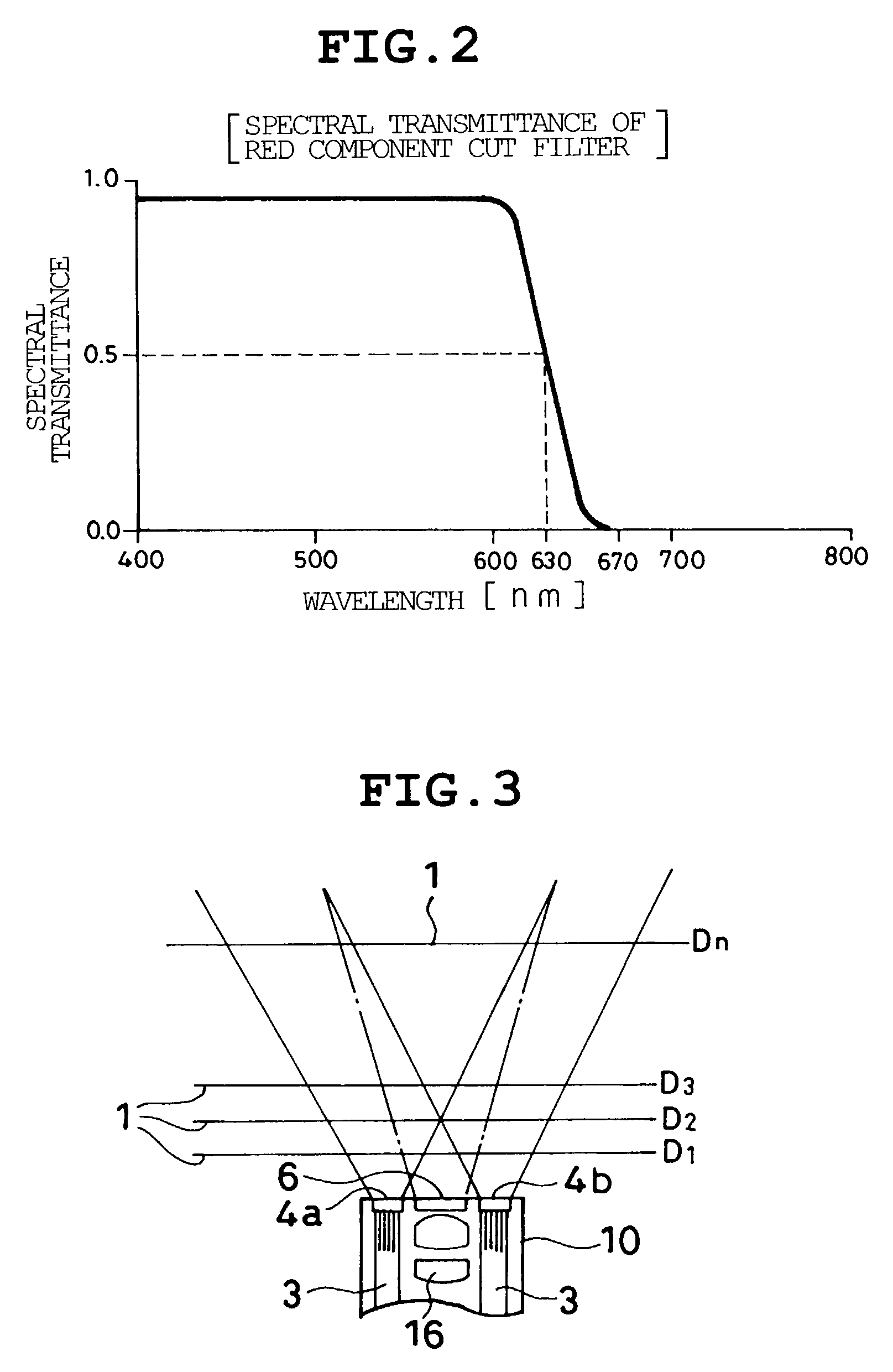

Electronic endoscope eliminating influence of light distribution in optical zooming

InactiveUS7123288B2Reduce signalingEnhance the imageDiagnostics using lightSurgeryComputational physicsColor signal

The invention provides an endoscope having a scope that takes an image enlarged by driving a movable lens of an optical zoom mechanism by a CCD and displays an image of an object to be observed, wherein a multiplier multiplies RGB color signals by a coefficient set in view of light distribution of illumination light depending on focusing distances of the movable lens, thus eliminating uneven brightness resulting from varying light distribution depending on the focusing distances in enlargement photography. A red component cut filter for cutting a long wavelength side in a red band of the illumination light is provided in a light source unit to improve redness. Further, a coefficient for averaging a brightness signal for a predetermined number of pixels for each horizontal line is calculated, and this coefficient calculation may eliminate unevenness.

Owner:FUJI PHOTO OPTICAL CO LTD

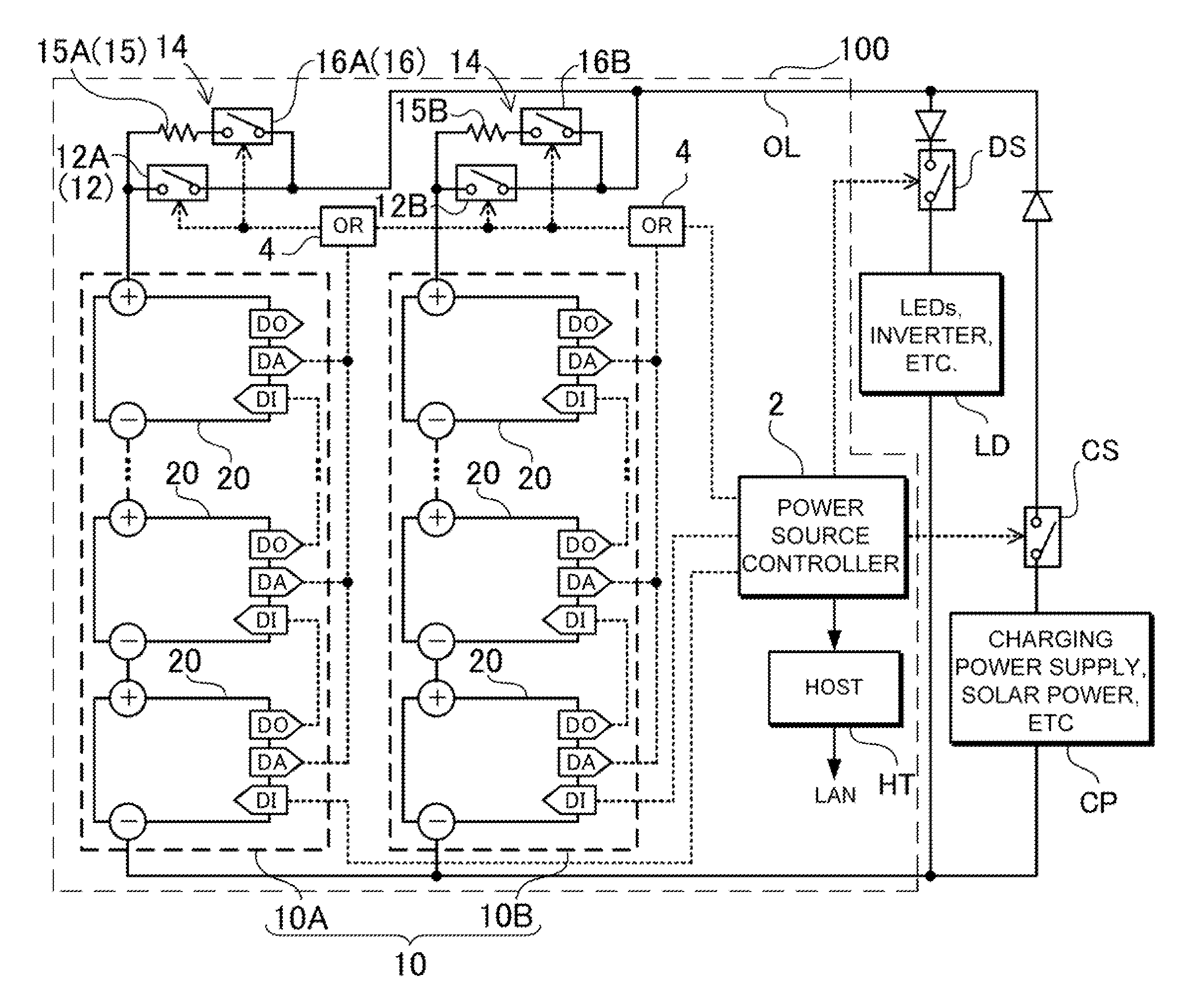

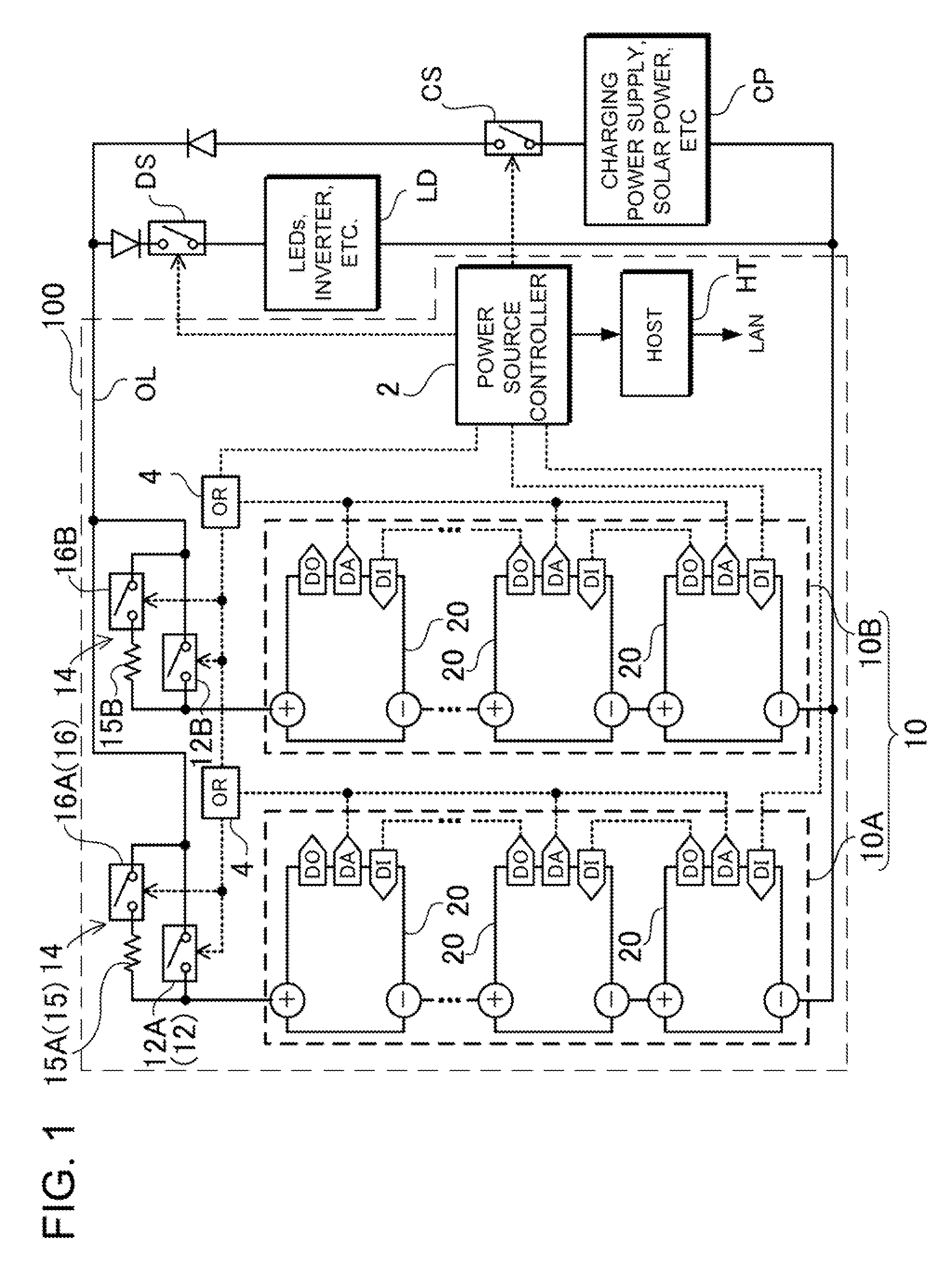

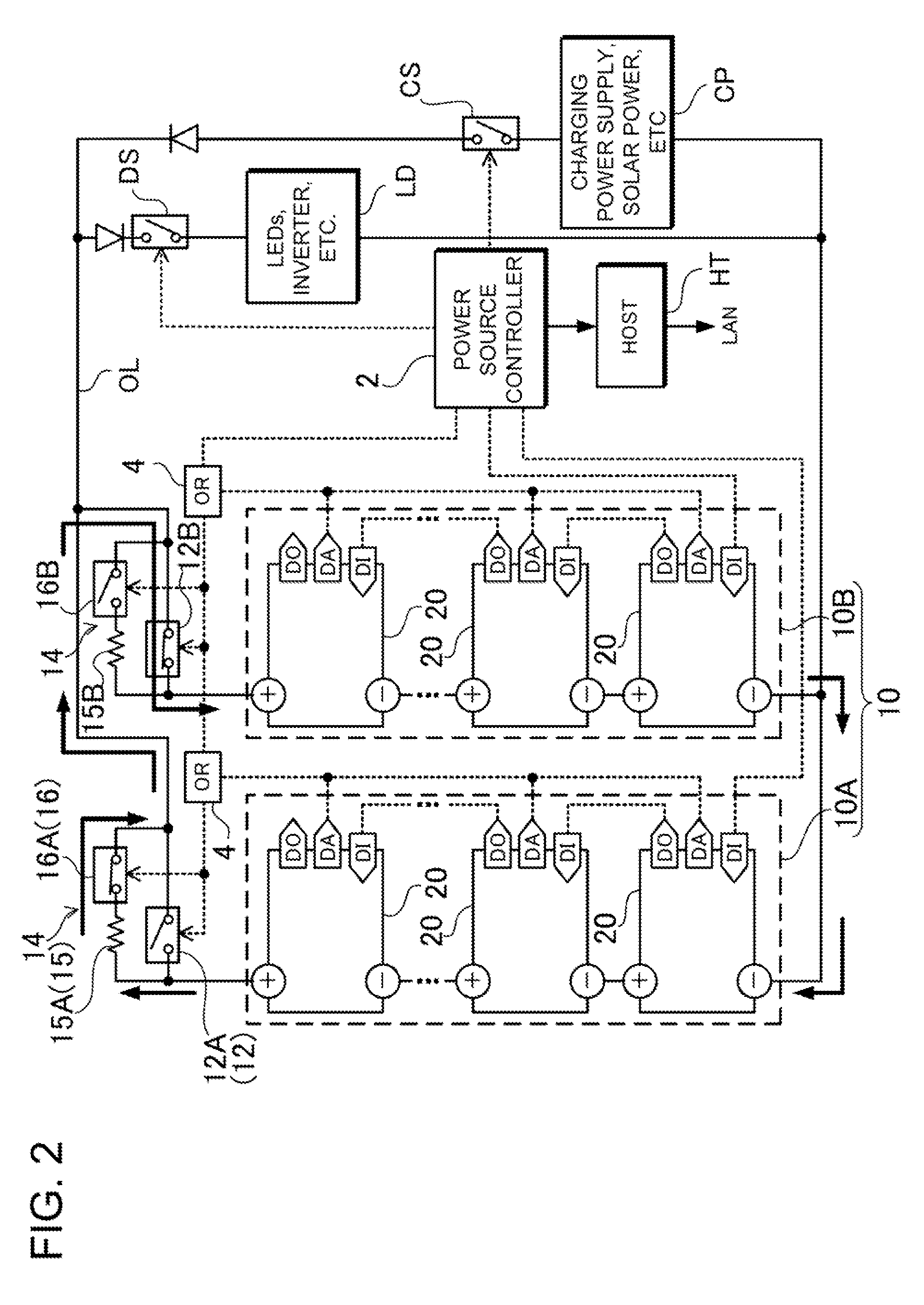

Power source apparatus

ActiveUS20120313439A1Maintain balanceEliminate unevennessDc network circuit arrangementsCharge equalisation circuitEngineeringBattery pack

The power source apparatus configuration can be changed to adapt to the installation site and environment. The power source apparatus is provided with first equalizing circuits 14 to control remaining charge capacity variation among a plurality of battery units 10, and second equalizing circuits 24 to control remaining charge capacity variation among all the series-connected battery packs 20 that make up each battery unit 10. A first equalizing circuit 14 connects each battery unit 10 with an output line OL through a first series circuit made up of a first limiting resistor 15 and first equalizing switch 16. Remaining charge capacity variation is equalized among all the battery units 10 by the first equalizing circuits 14, and remaining charge capacity variation between battery packs 20 in each battery unit 10 is controlled by the second equalizing circuits 24. (Cell balancing is performed quickly and efficiently.)

Owner:PANASONIC ENERGY CO LTD

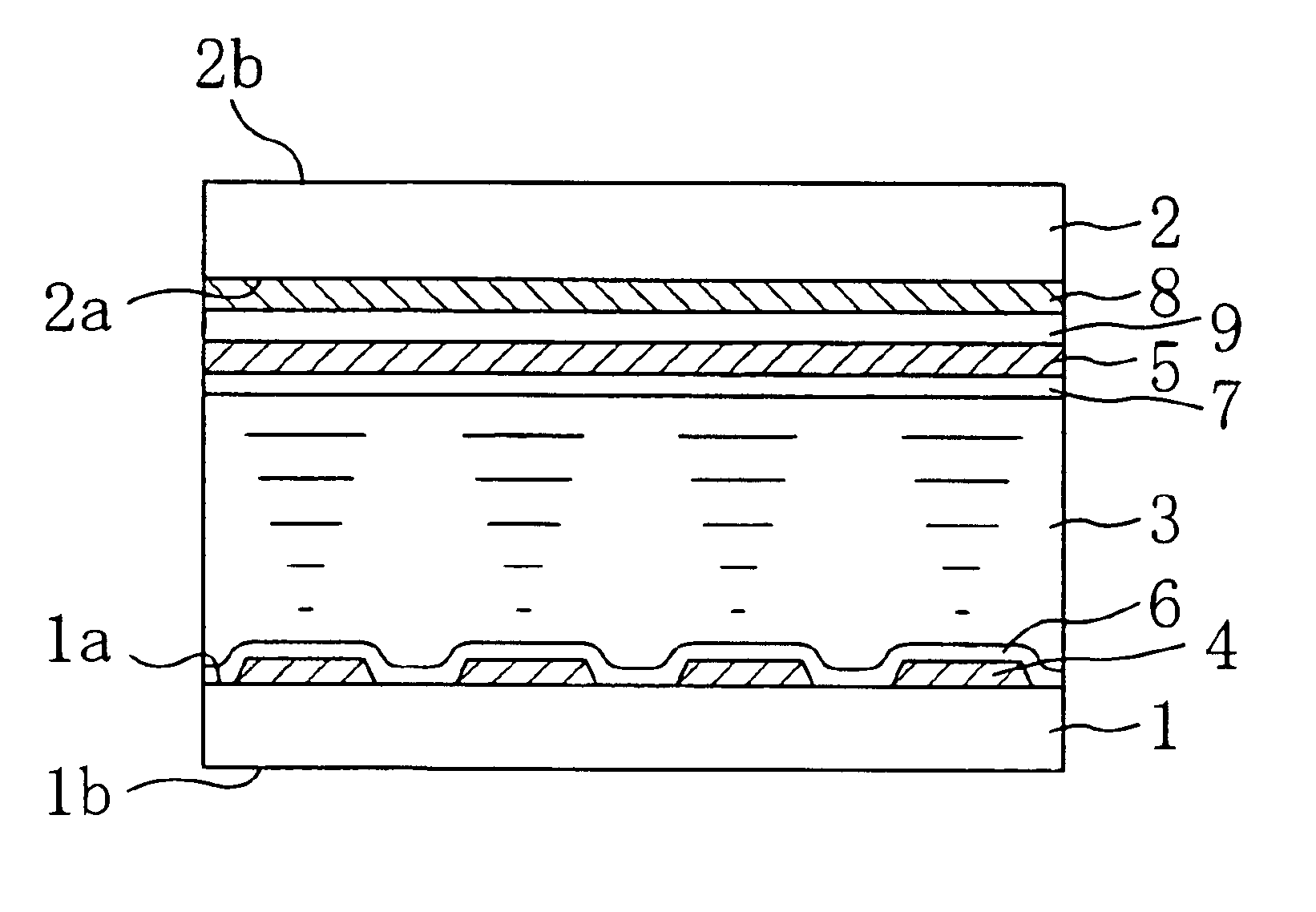

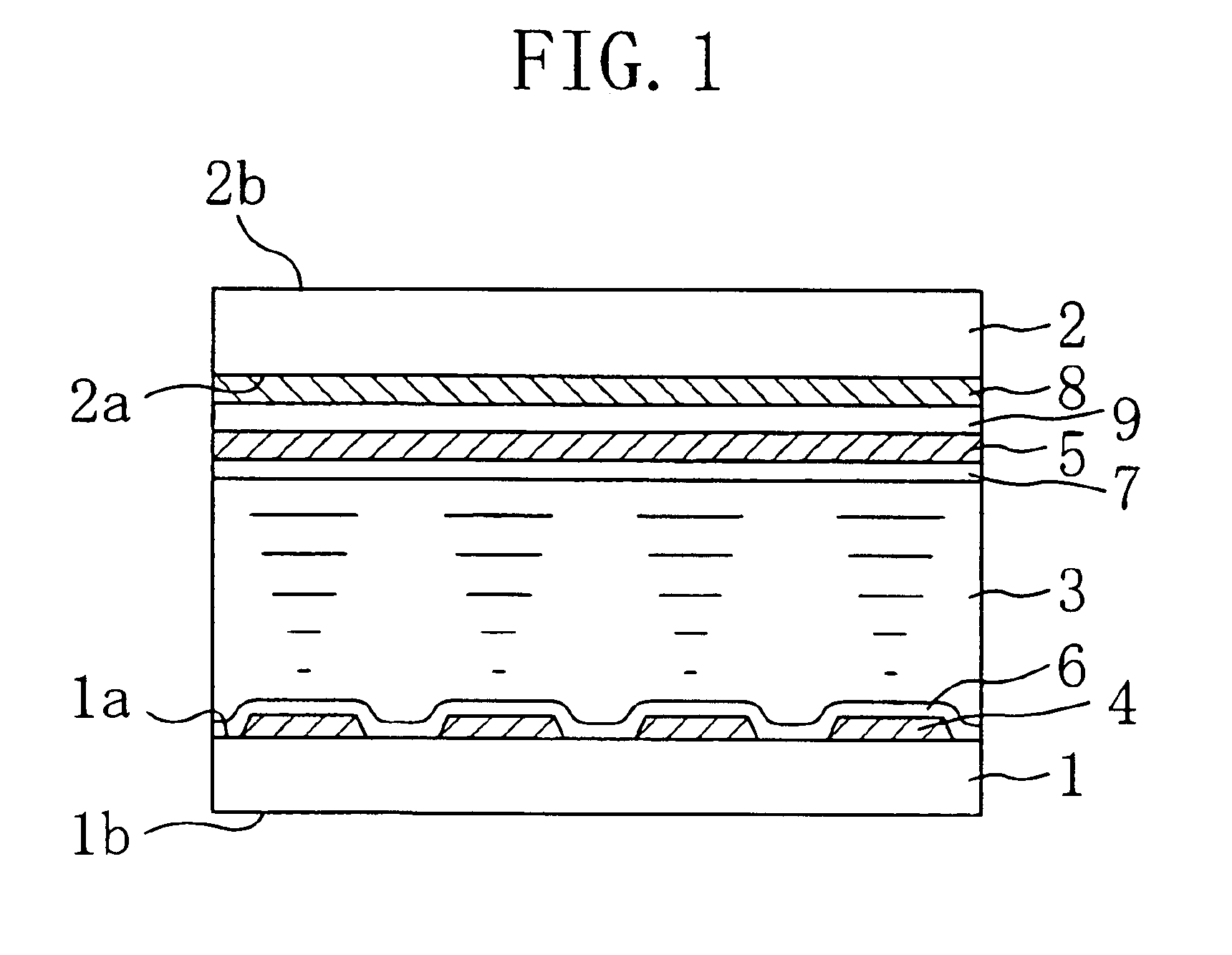

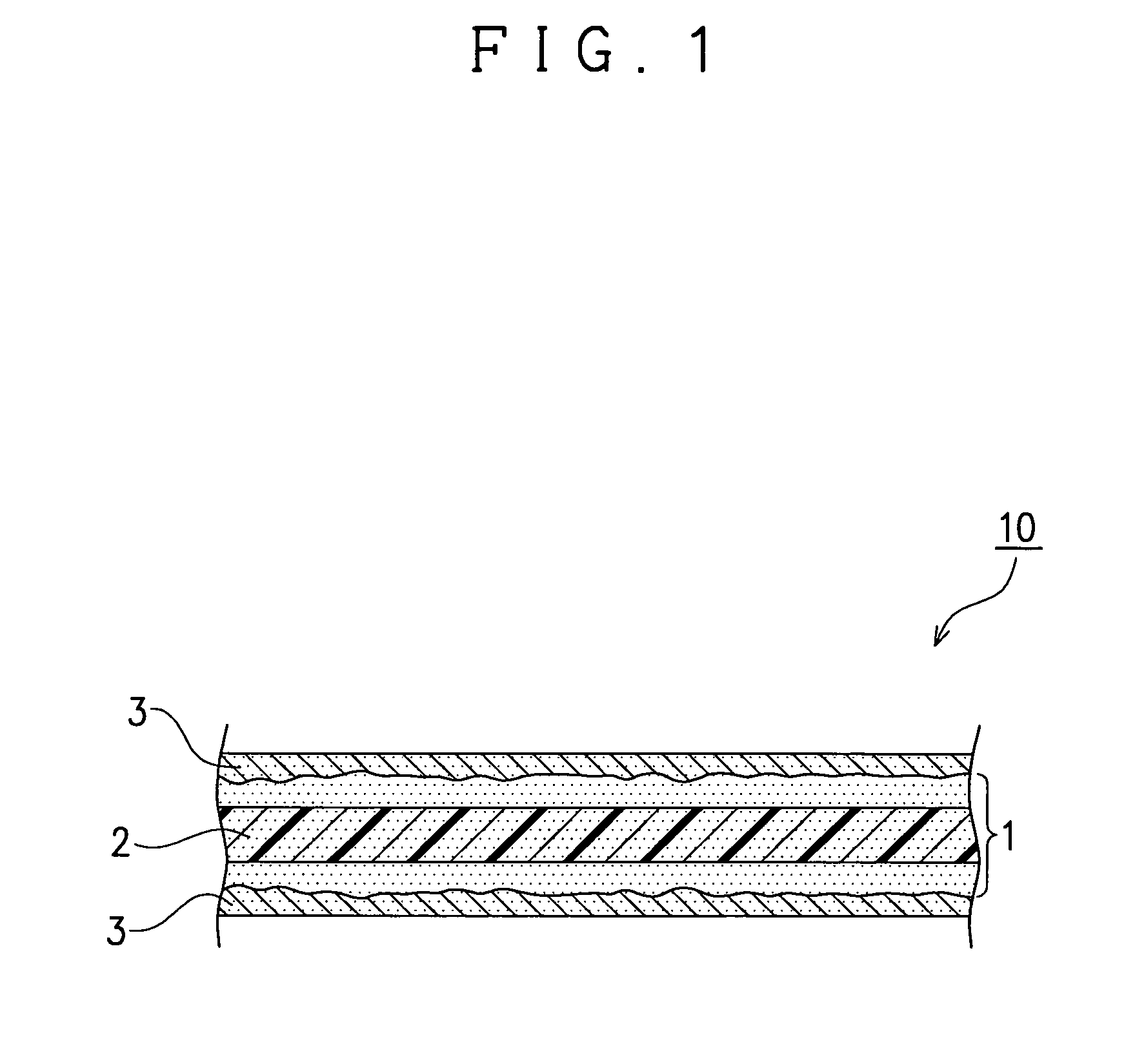

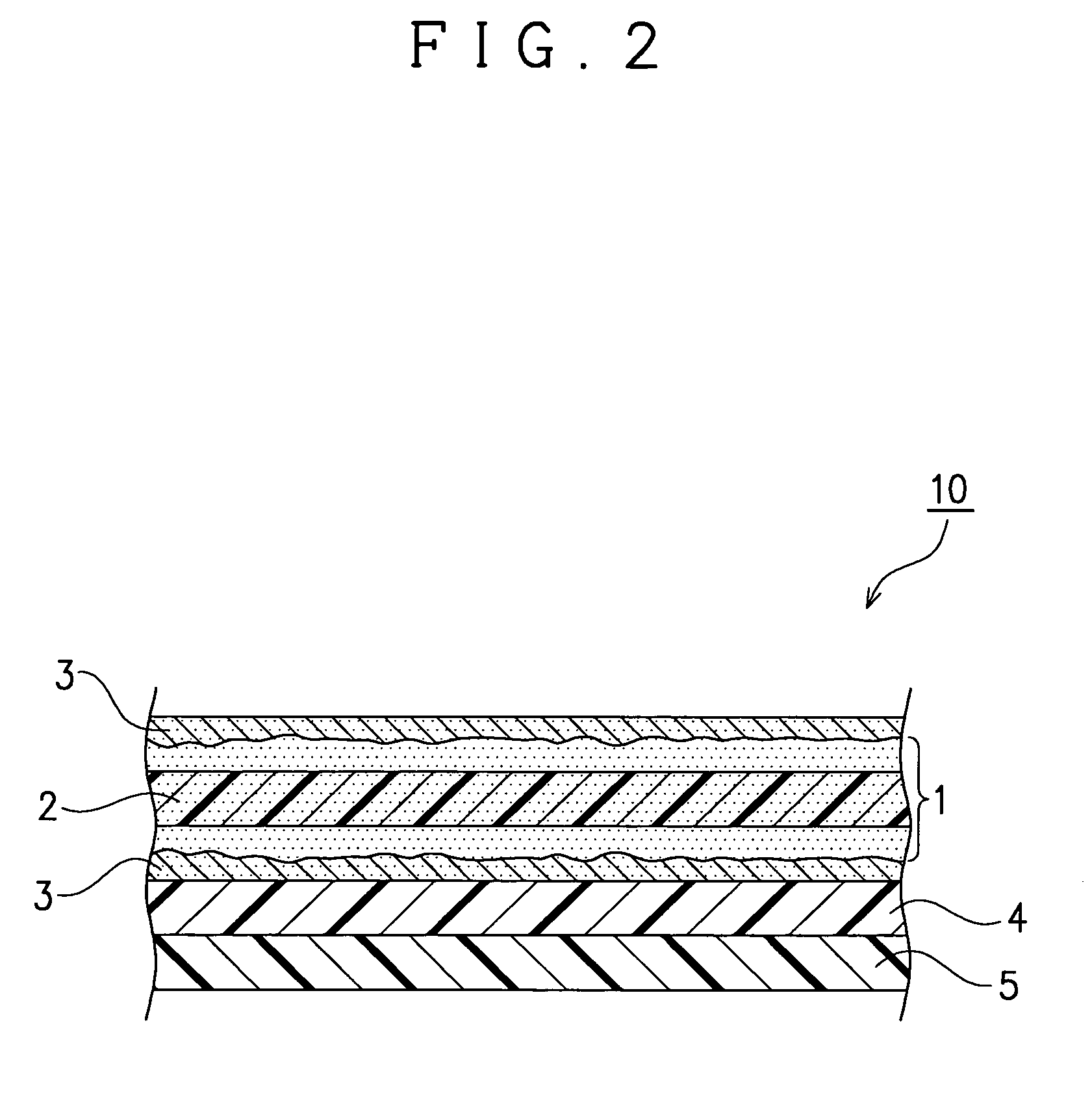

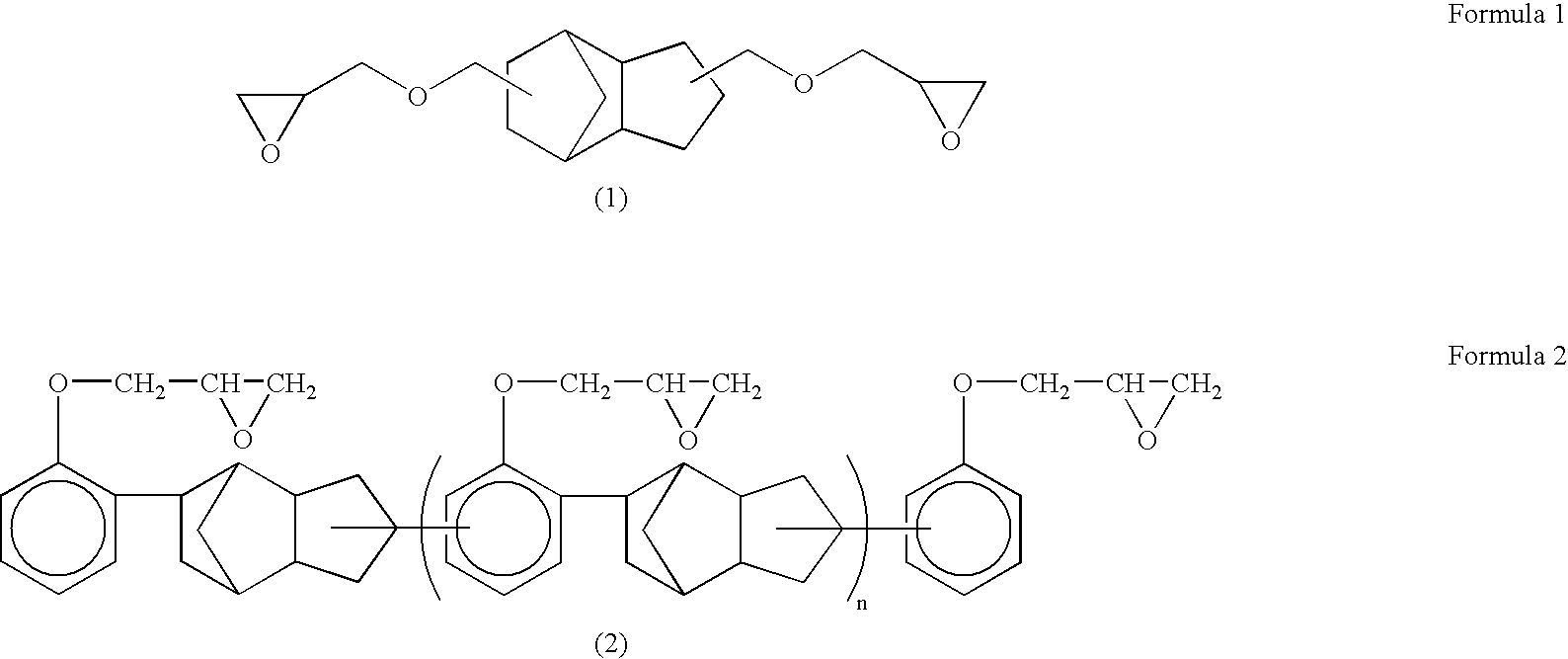

Resin sheet, liquid crystal cell substrate, liquid crystal display device, substrate for an electroluminescence display device, electroluminescence display device, and a substrate for a solar cell

InactiveUS20070042168A1Avoid misalignmentImprove impact resistanceLiquid crystal compositionsSolid-state devicesGlass fiberDisplay device

There is provided a resin sheet that achieves improvement in lightweight, low-profile and high impact characteristics, suppresses thermal shrinkage and expansion and is excellent in light transparency so as to prevent the display quality or the like of a display device from being deteriorated, as well as a substrate for a display device, a display device and a substrate for a solar cell, each having the aforesaid resin sheet. A resin sheet includes a cured resin layer containing a glass fiber cloth-like material and an overcoat layer laminated on the cured resin layer to have a surface roughness Rt of 200 nm or less, and is structured to have a haze value of 10% or lower.

Owner:NITTO DENKO CORP

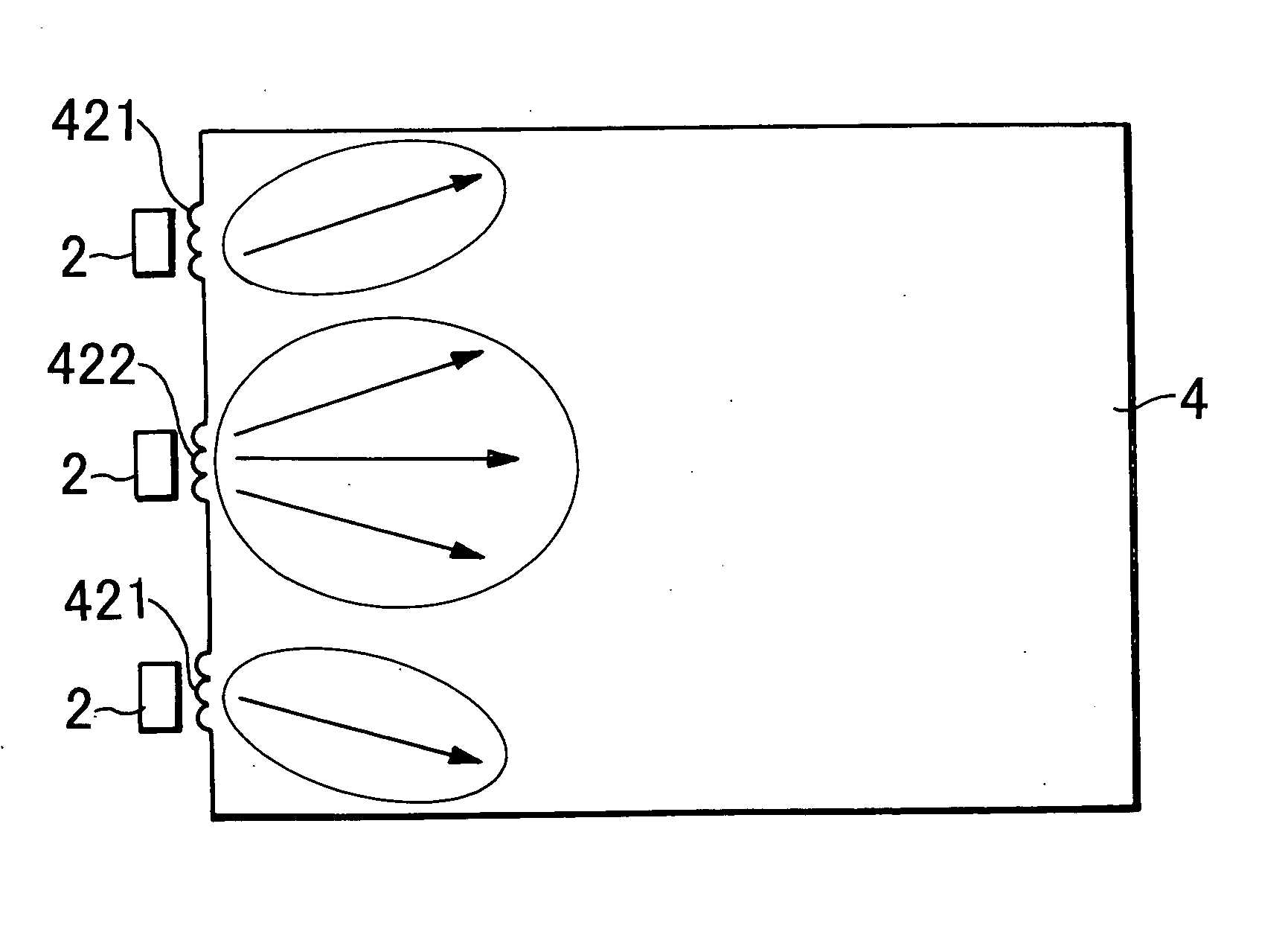

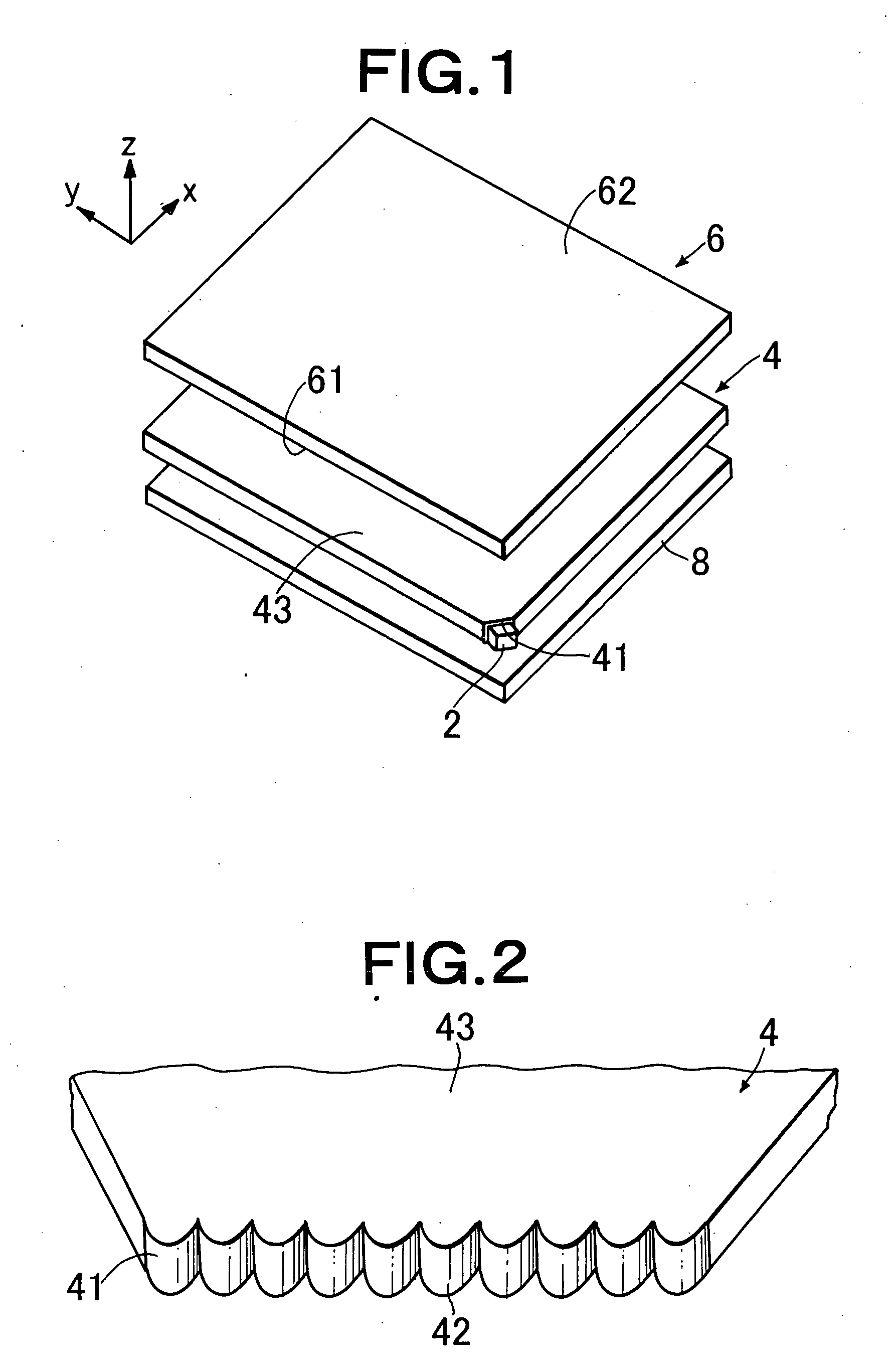

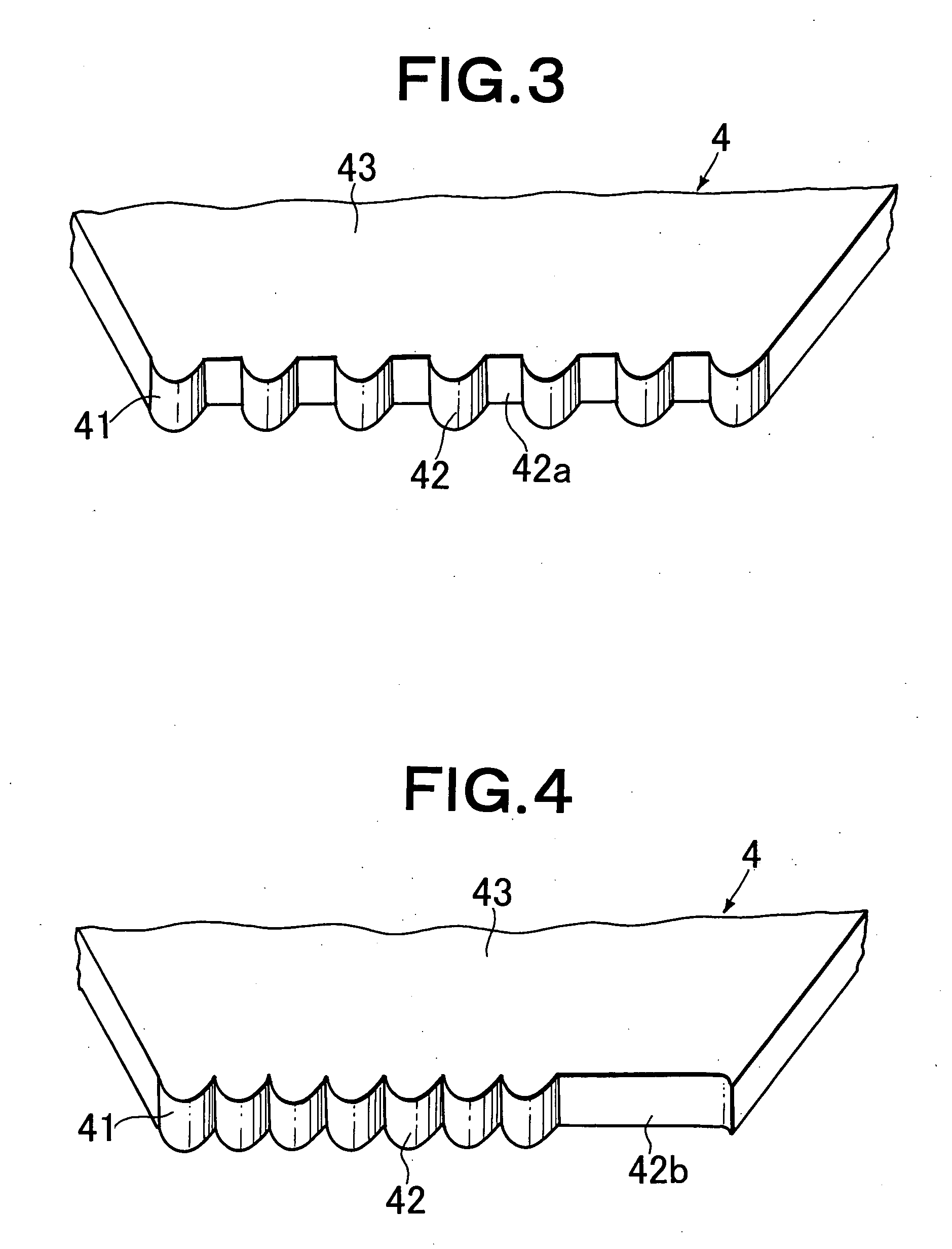

Planar light source and light guide for use therein

InactiveUS20050254771A1Improve uniformityEliminate unevennessMechanical apparatusPlanar/plate-like light guidesLight guideOptoelectronics

A planar light guide (4) having a light entrance end face (41) receiving light from a spot-like primary light source and a light exit face (43) outputting the entered light, wherein a plurality of lens arrays (42) are formed, at at least a part of the light entrance end face, to extend from the light exit face toward the opposite face substantially in parallel with each other. The lens array (42) has an asymmetric cross-sectional shape defined by a combination of at least two different curves. When the light guide (4) is combined with a primary light source disposed oppositely to the light entrance end face (41) and a light deflecting element disposed oppositely to the-light exit face (43), a high quality planar light source having a high uniformity and no variation in luminance is provided even when a relative small number of spot-like light sources are used as the primary light source.

Owner:MITSUBISHI CHEM CORP

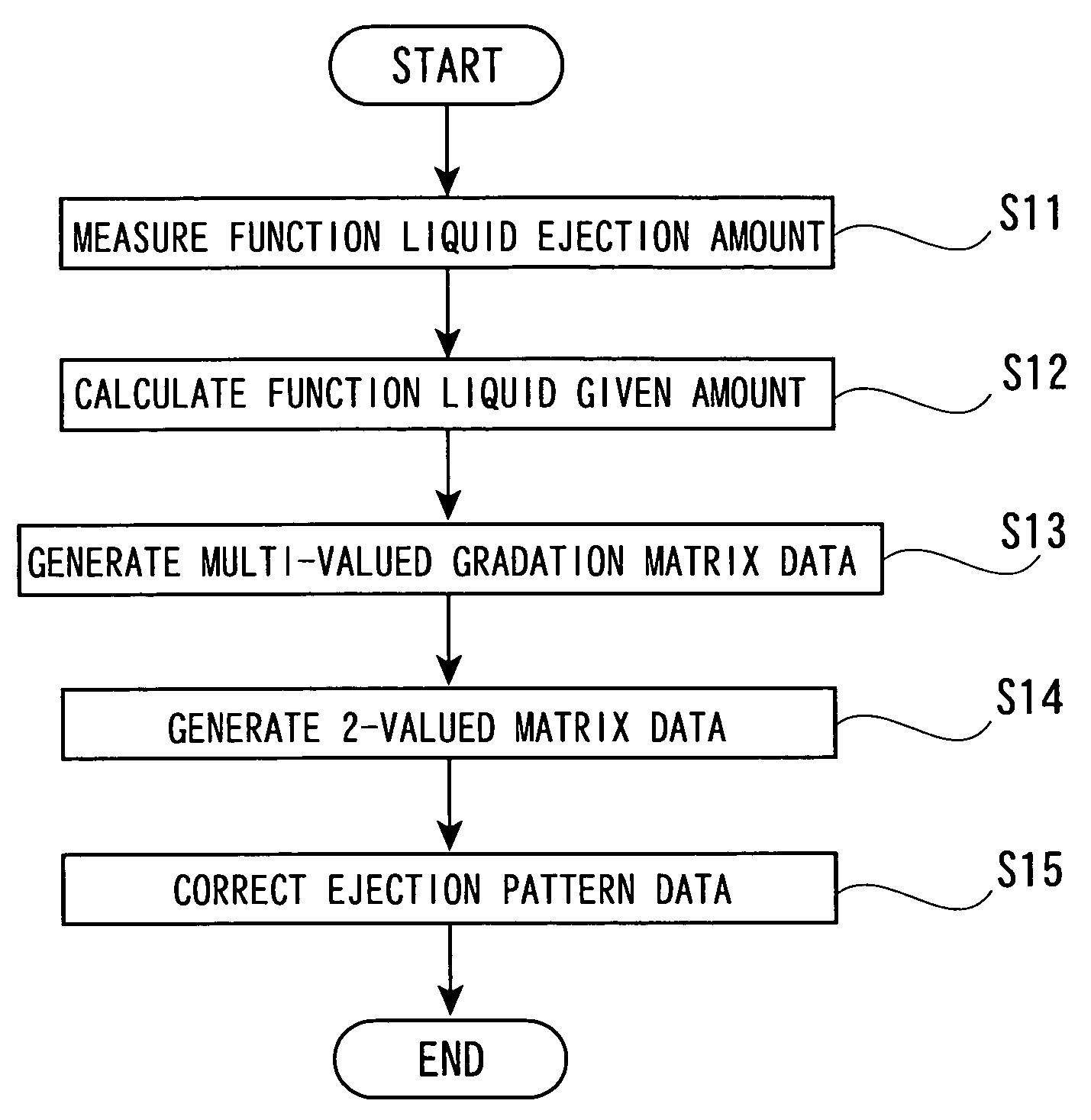

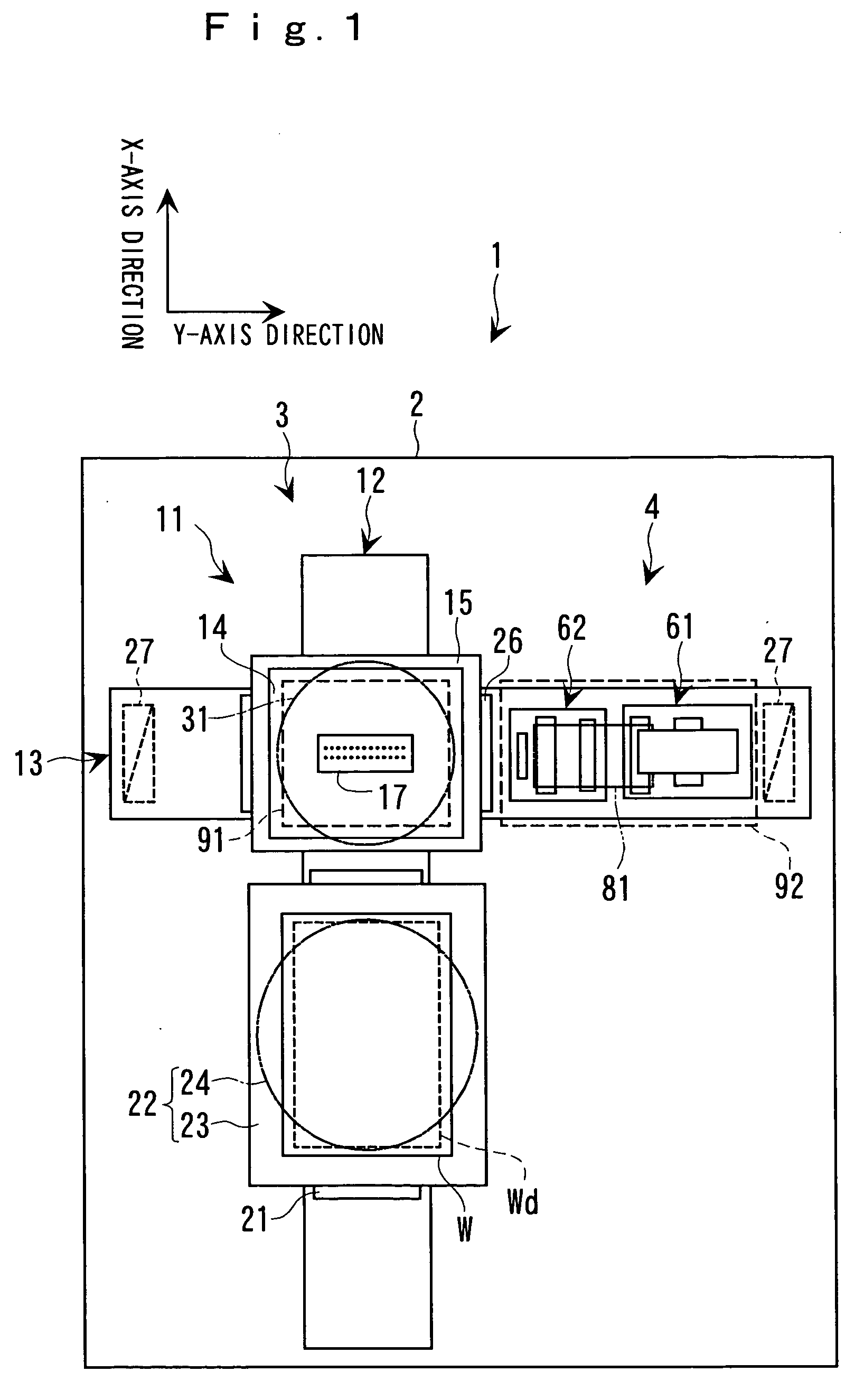

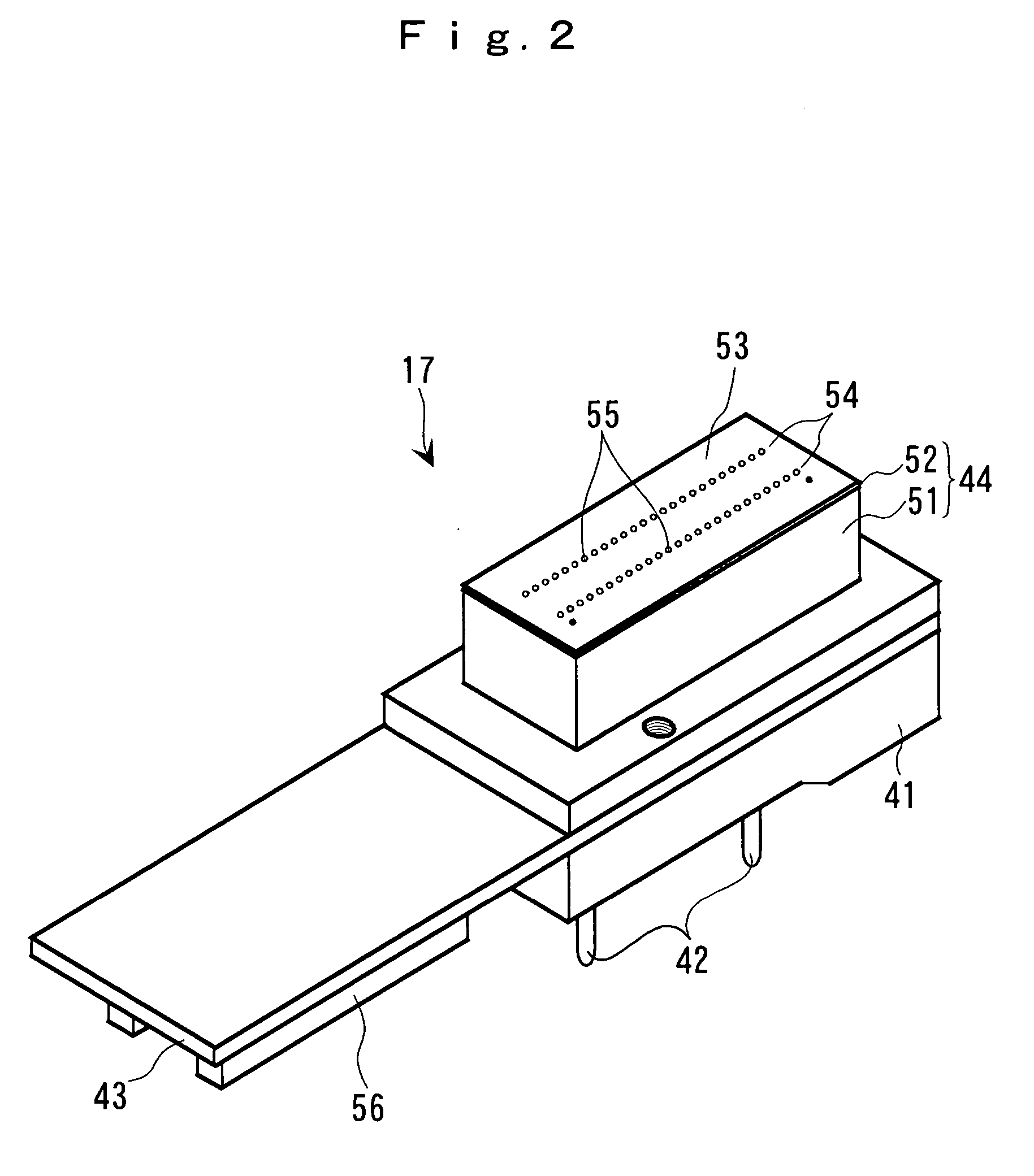

Method of correcting ejection pattern data, apparatus for correcting ejection pattern data, liquid droplet ejection apparatus, method of manufacturing electro-optic device, electro-optic device, and electronic device

InactiveUS20070109606A1Not easy to realizeEliminate drawing unevennessImage enhancementDigitally marking record carriersEngineeringElectron

In drawing processing, a function liquid droplet ejection head is moved relative to a workpiece to selectively eject function liquid droplets from a plurality of nozzles of the function liquid droplet ejection head according to ejection pattern data. Calculation is made of an amount given to each of a plurality of imaginary divided portions obtained by partitioning in matrix a drawing region on the workpiece. Matrix data representing in multi-valued gradation the amount of function liquid given to the plurality of imaginary divided portions is generated. N-valued matrix data is generated by converting the matrix data into n-valued data (n≧2). The ejection pattern data is corrected to decrease and / or increase the amount of function liquid given to the imaginary divided portions.

Owner:SEIKO EPSON CORP

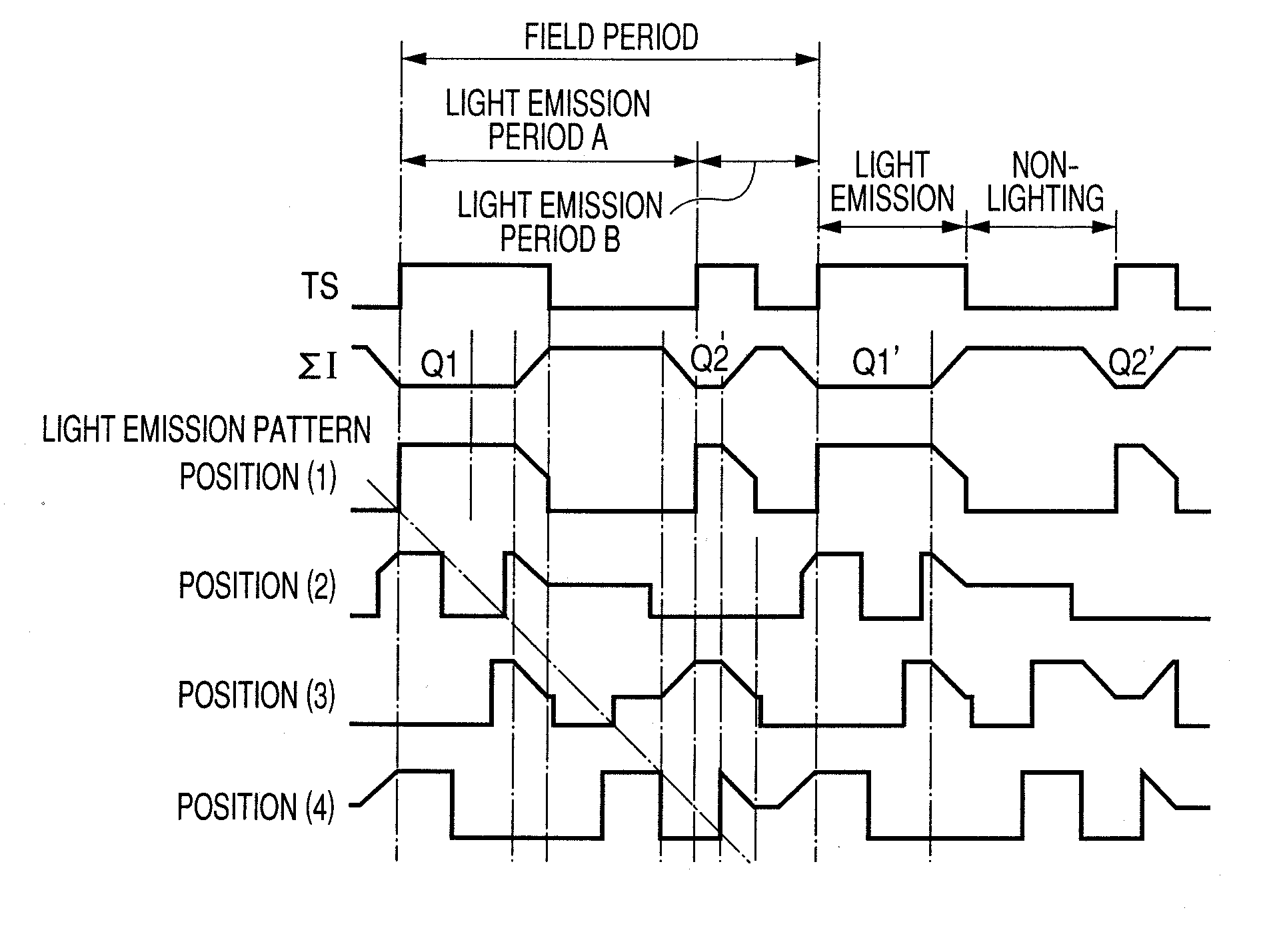

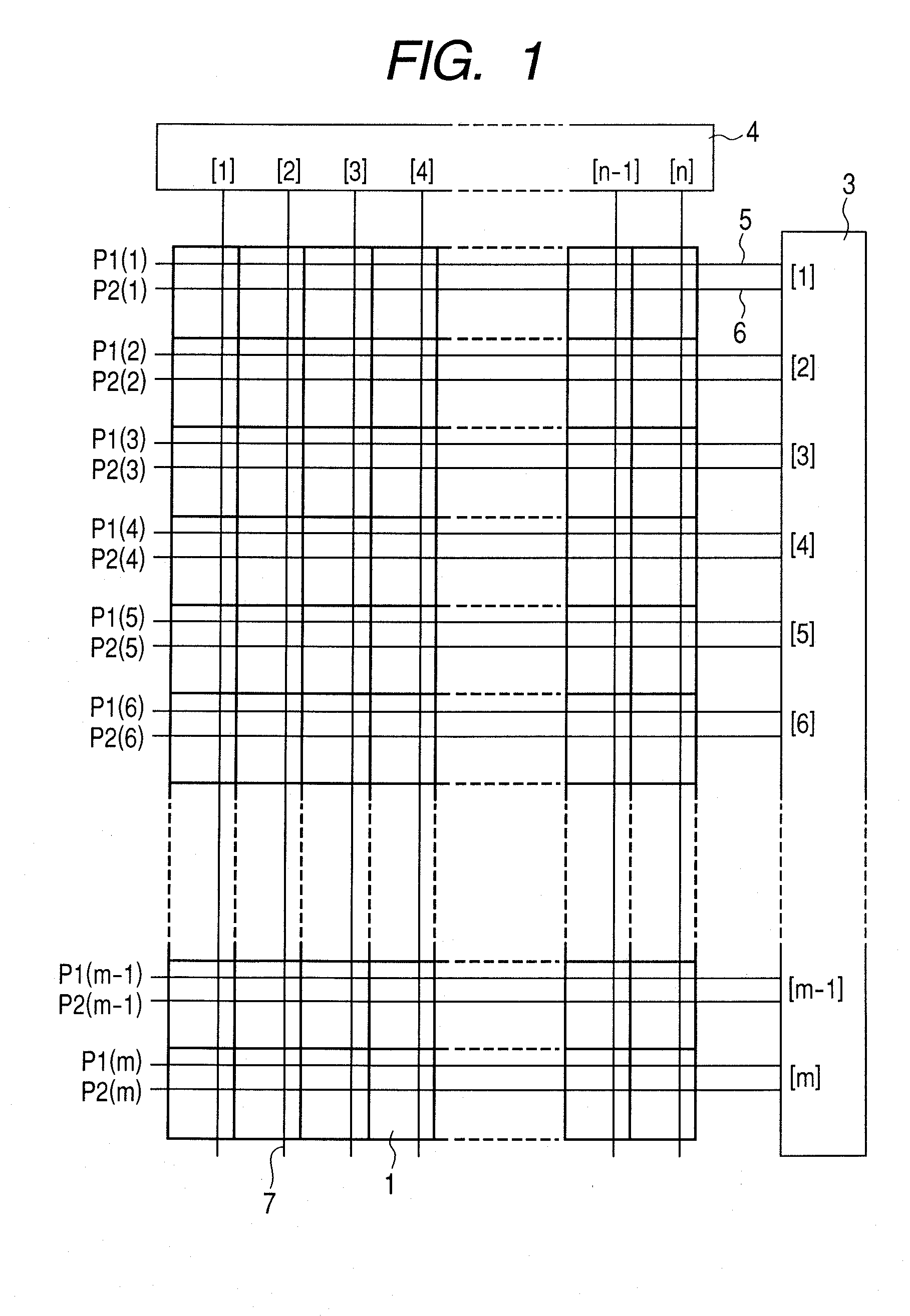

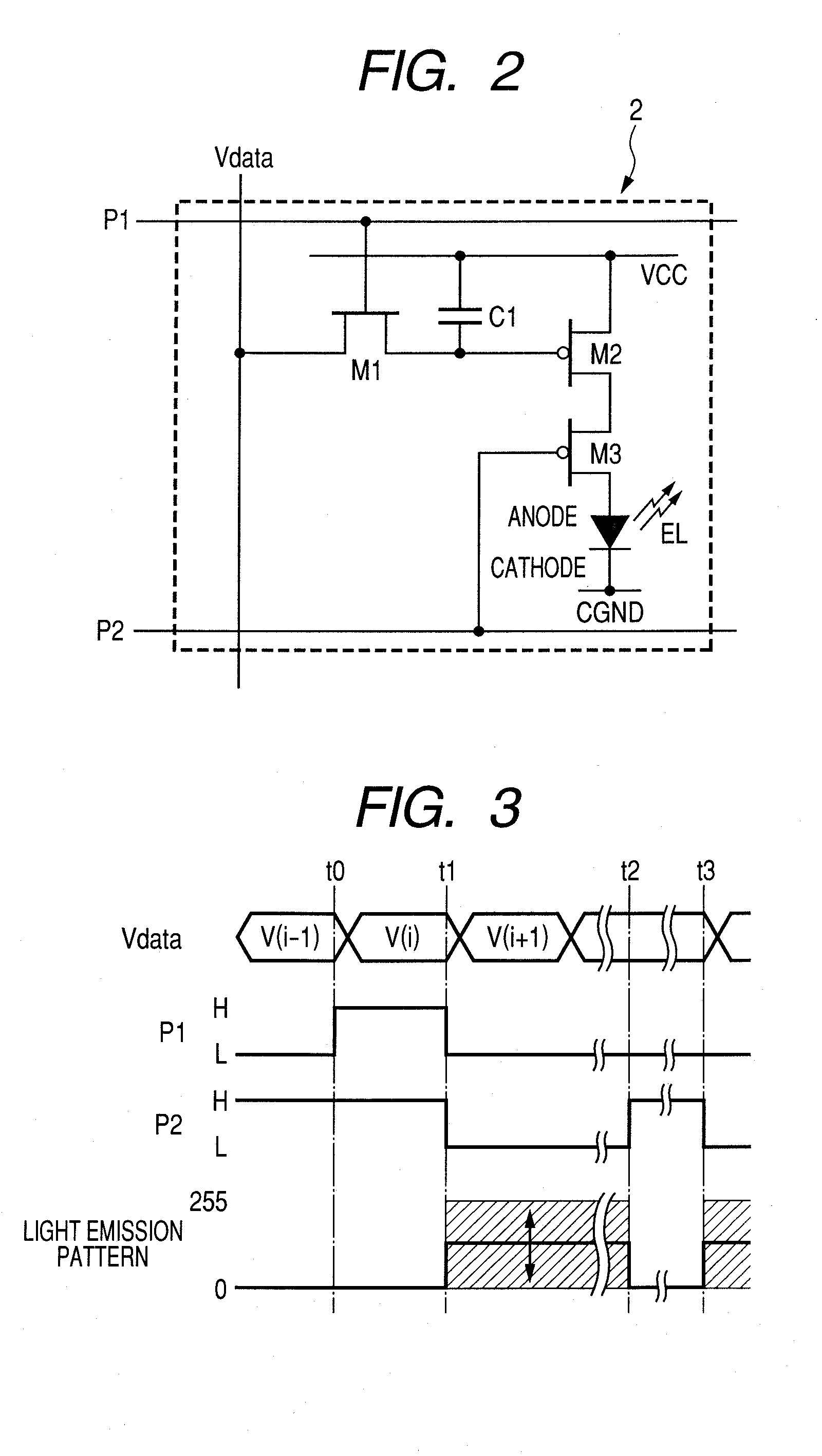

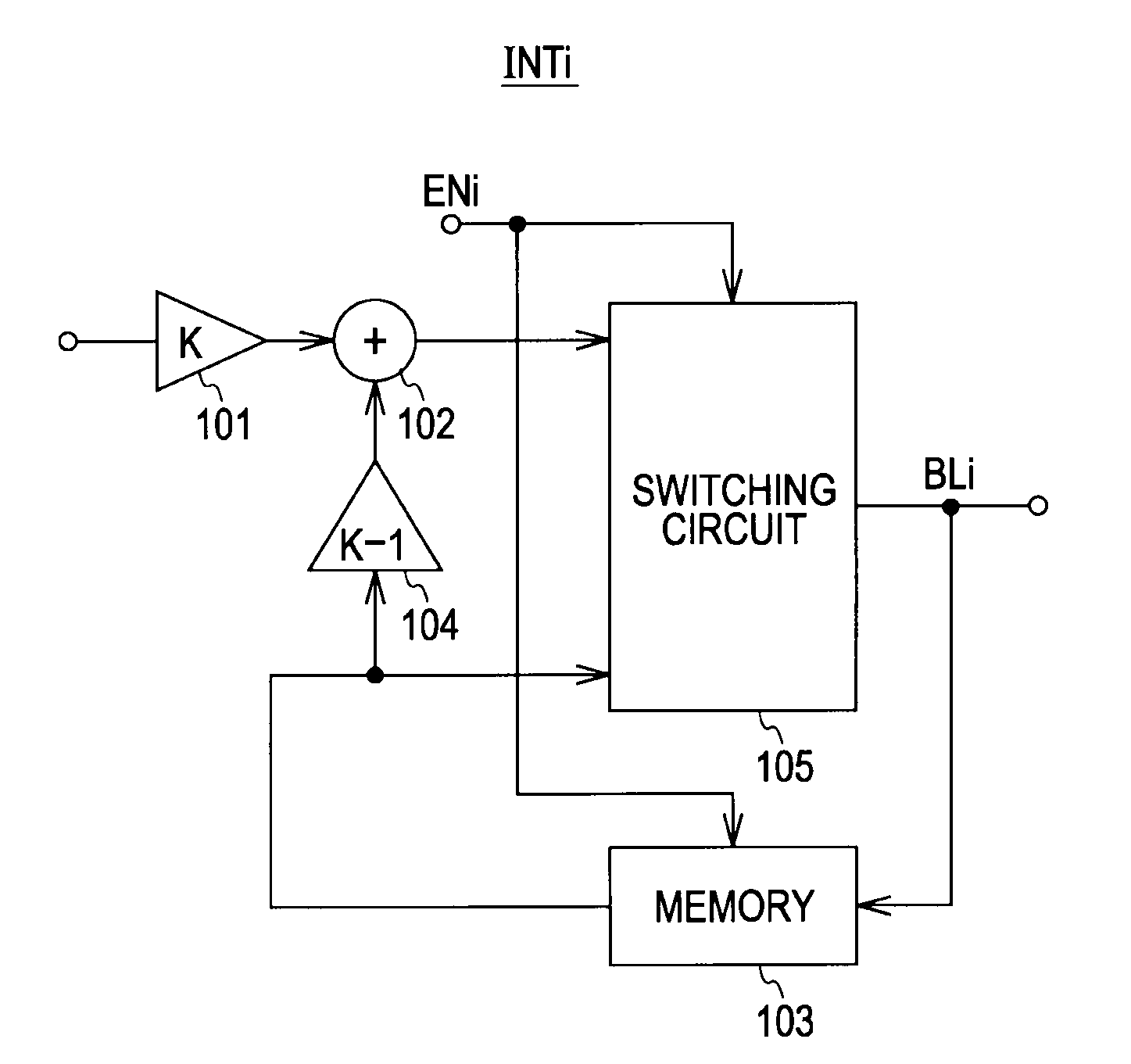

Display apparatus and drive method thereof

InactiveUS20090289966A1Easy to displaySuppresses image quality degradationCathode ray tubes/electron beam tubesCathode-ray tube indicatorsLuminous intensityLight emission

A display apparatus for driving light emitting elements to emit light at a timing shifted according to the order of scanning lines, is arranged to control the light emission intensity of the light emitting element in accordance with an image signal and include a drive unit for driving the light emitting elements of the respective scanning lines in a light emission pattern including a first impulse operation period light emission pattern and a second impulse operation period light emission pattern.

Owner:CANON KK

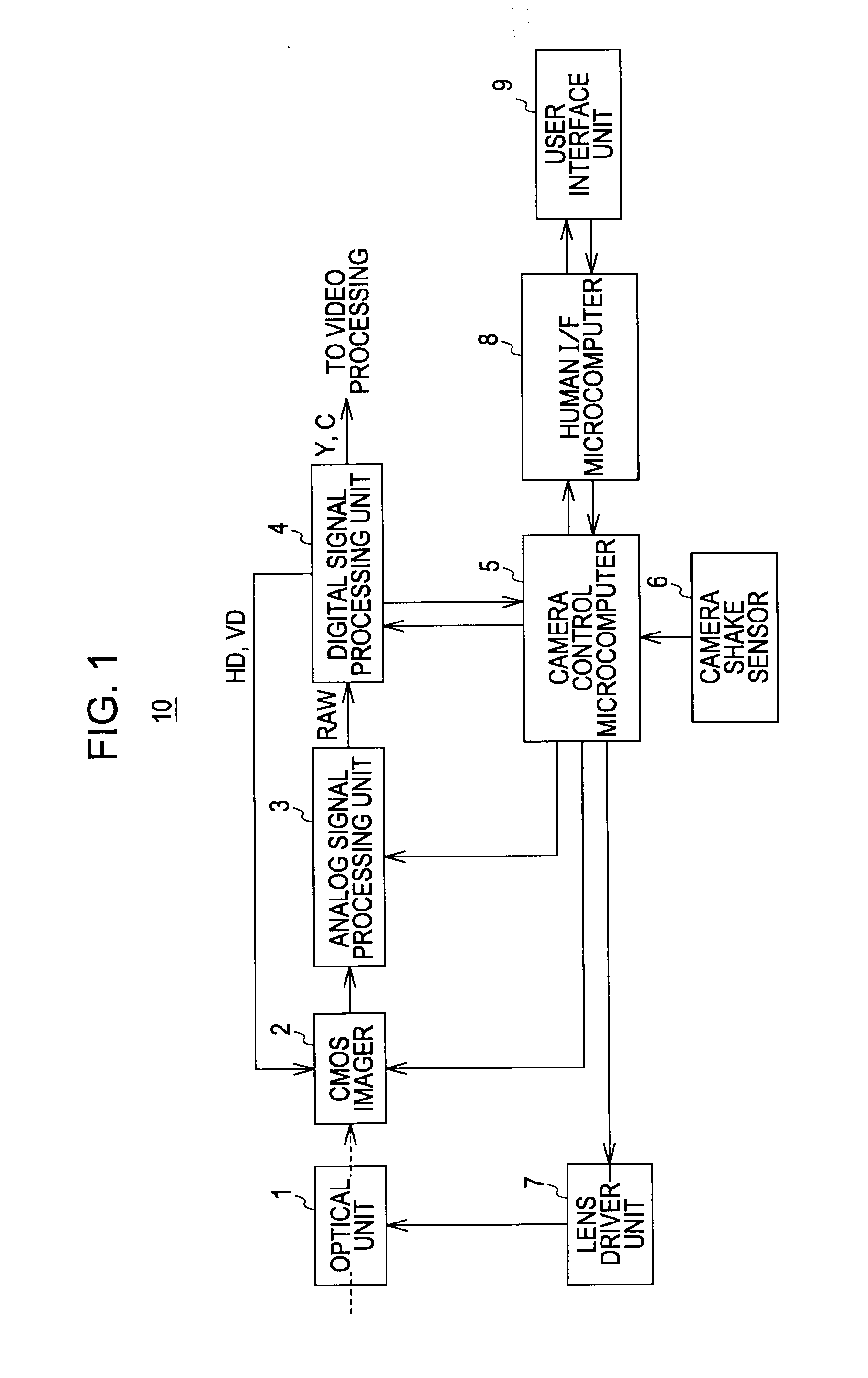

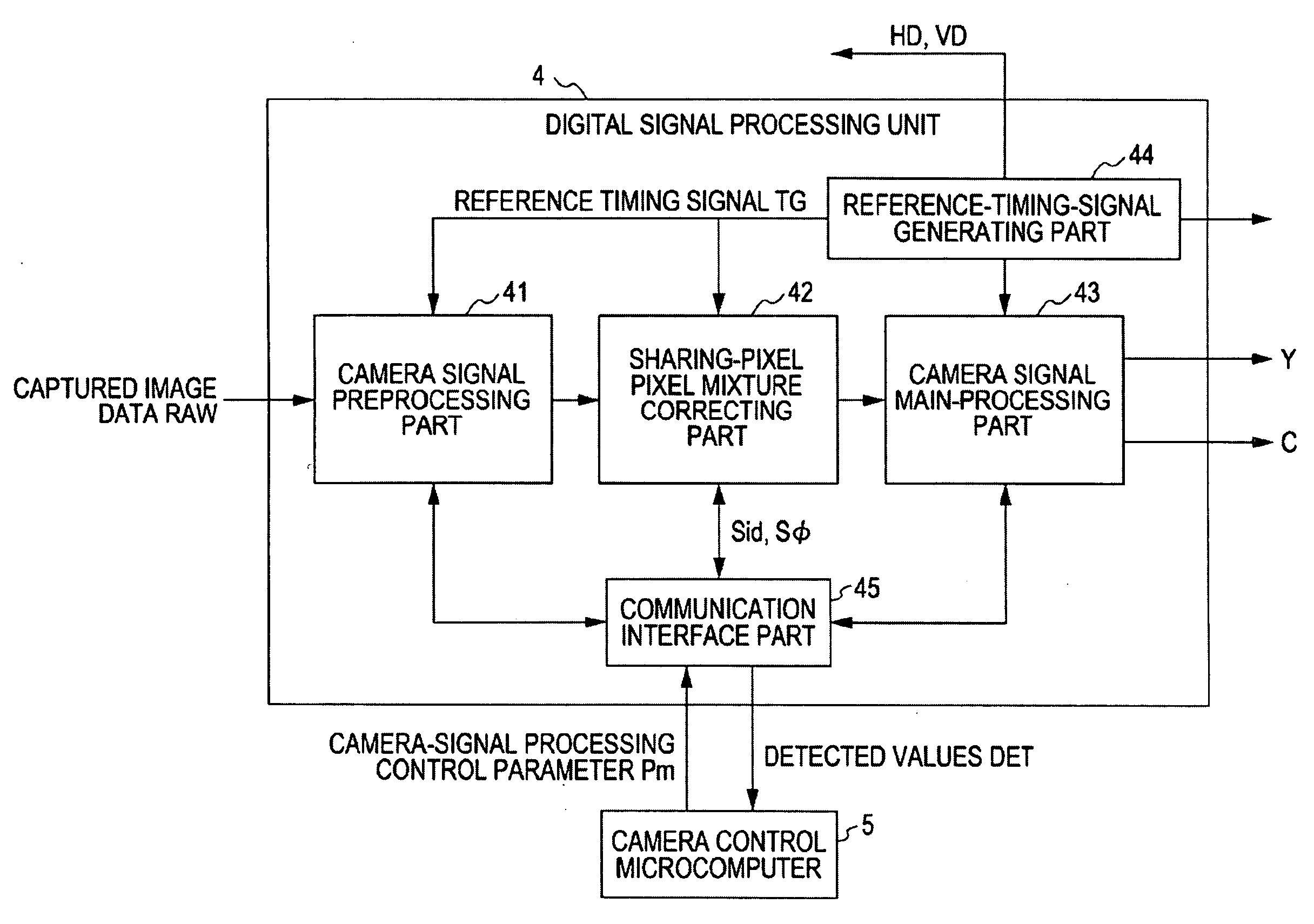

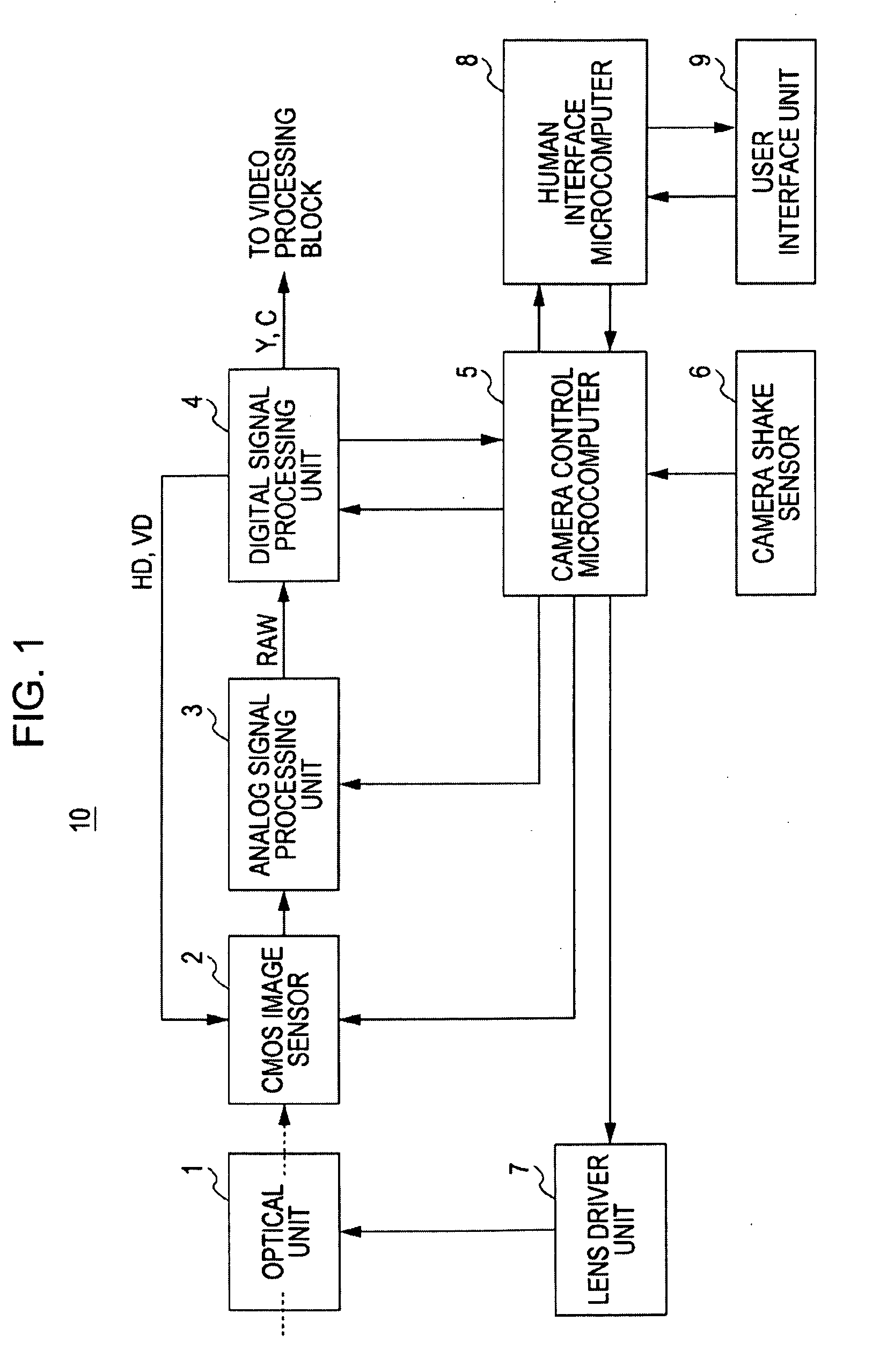

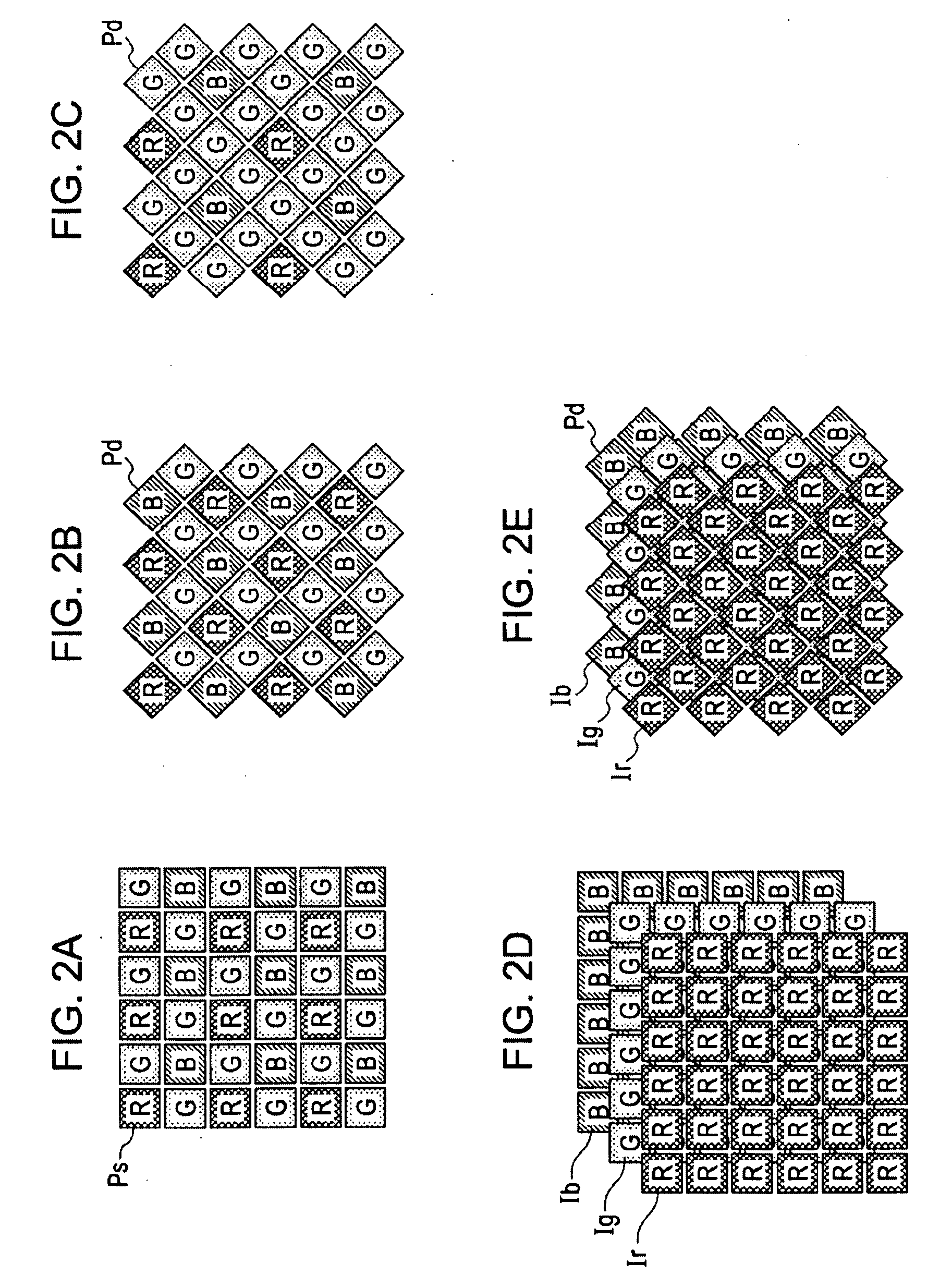

Image pickup apparatus and method of correcting captured image data

InactiveUS20080284889A1Corrects nonuniformityReduce unevennessTelevision system detailsColor signal processing circuitsComputer visionImaging data

An image pickup apparatus includes a solid-state image pickup device including a plurality of pixels arranged in a two-dimensional array, a circuit necessary for the pixel structure being shared between the pixels of a predetermined number having the same arrangement pattern; correction value generating means for generating a correction value for the pixel data read out from the pixel position of each pixel having the same arrangement pattern, the correction value being used for correcting the nonuniformity in pixel characteristics caused by a difference in position between the pixels in the arrangement pattern; and correcting means for correcting each pixel data read out from the solid-state image pickup device on the basis of the correction value for the corresponding pixel data, generated by the correction value generating means.

Owner:SONY CORP

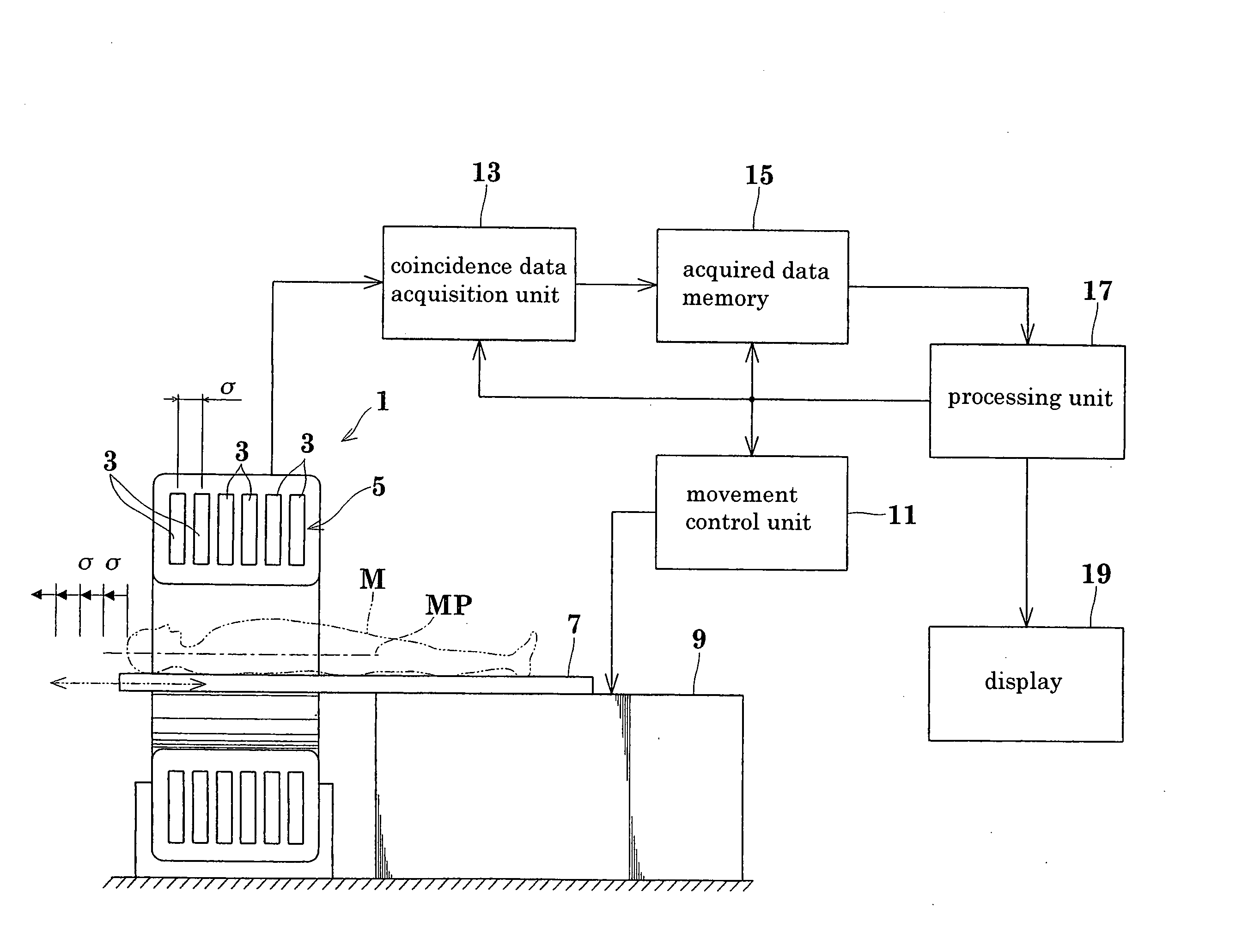

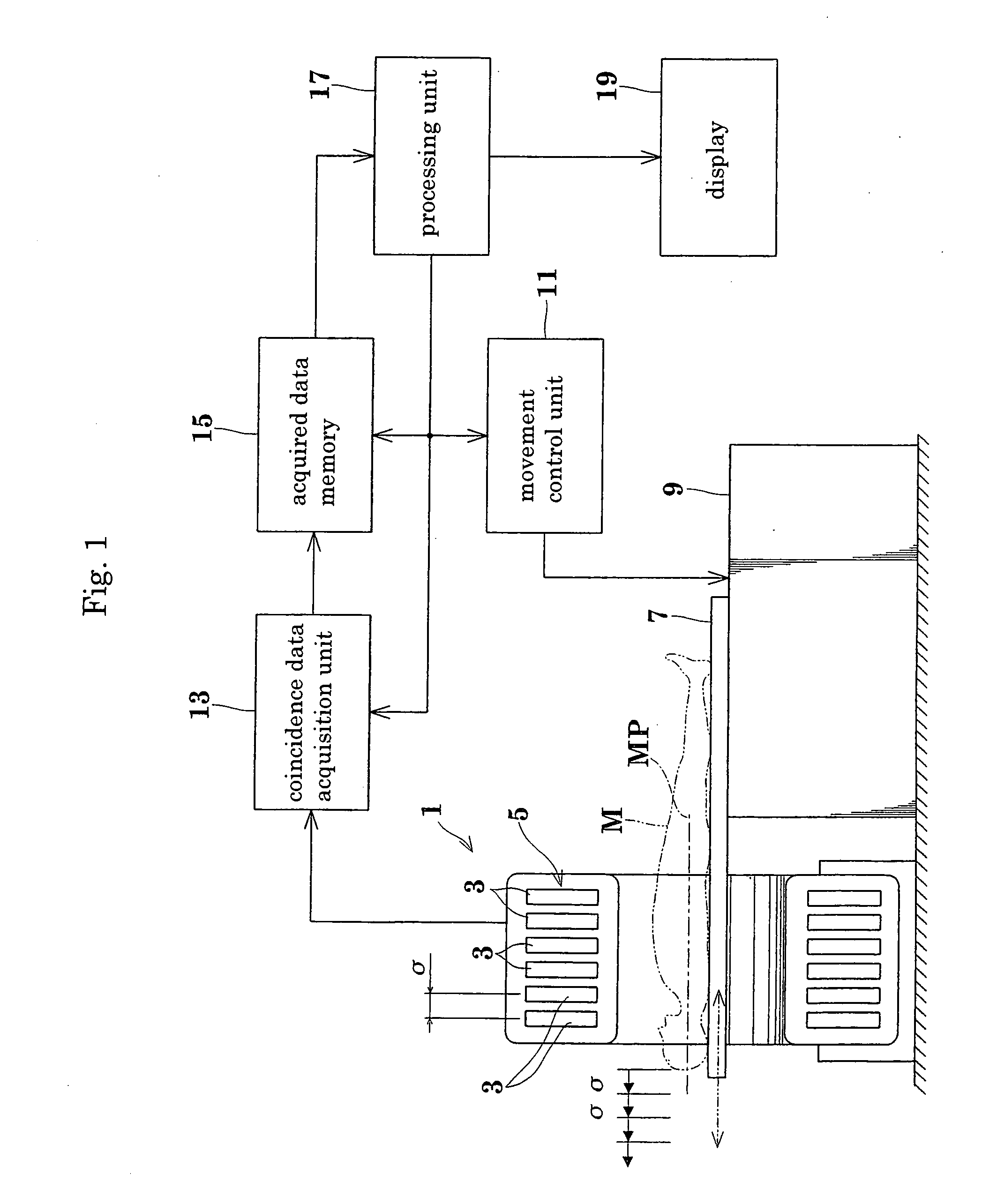

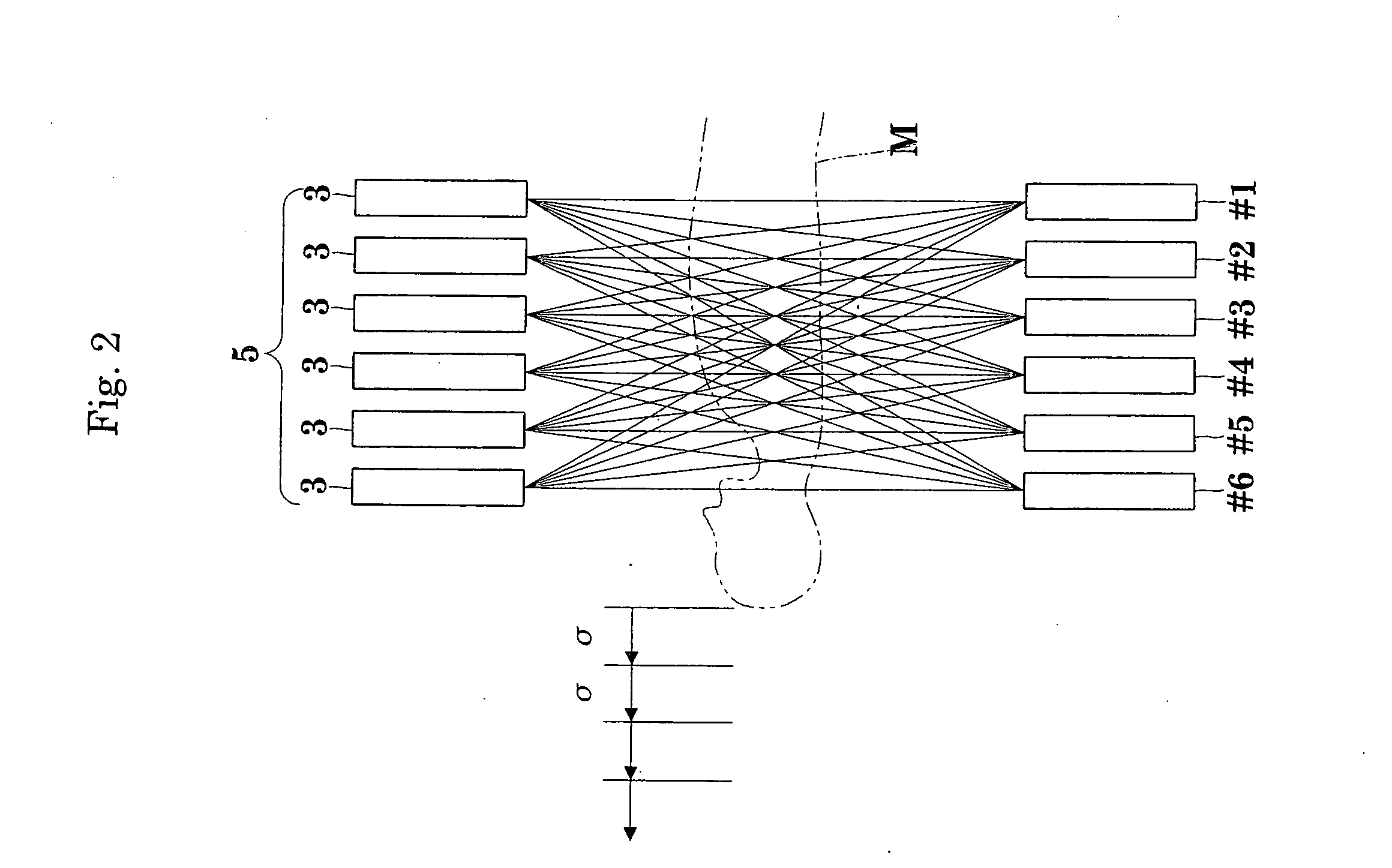

3D image reconstructing method for a positron CT apparatus, and positron CT apparatus

InactiveUS20070018108A1Eliminate unevennessReduce image qualityMaterial analysis by optical meansX/gamma/cosmic radiation measurmentUltrasound attenuation3d image

Image quality deterioration due to a drop in resolution or lowering of S / N ratio while reducing the amount of data stored during a 3D data acquisition process, and shortening the time from the start of an examination to the end of imaging. The method and apparatus of this invention perform, in parallel with the 3D data acquisition process, addition of sinograms, reading of subsets of the sinograms having been added, and image reconstruction. Consequently, the amount of data stored is reduced, and the time from the start of an examination to the end of imaging is shortened. At the same time, since 3D iterative reconstruction is not accompanied by conversion from 3D data to 2D data, a drop in resolution due to errors occurring with the conversion from 3D data to 2D data is avoided. The 3D iterative reconstruction can directly incorporate processes such as an attenuation correction process. It is thus possible to avoid also a lowering of S / N ratio resulting from an indirect incorporation of such processes.

Owner:SHIMADZU CORP

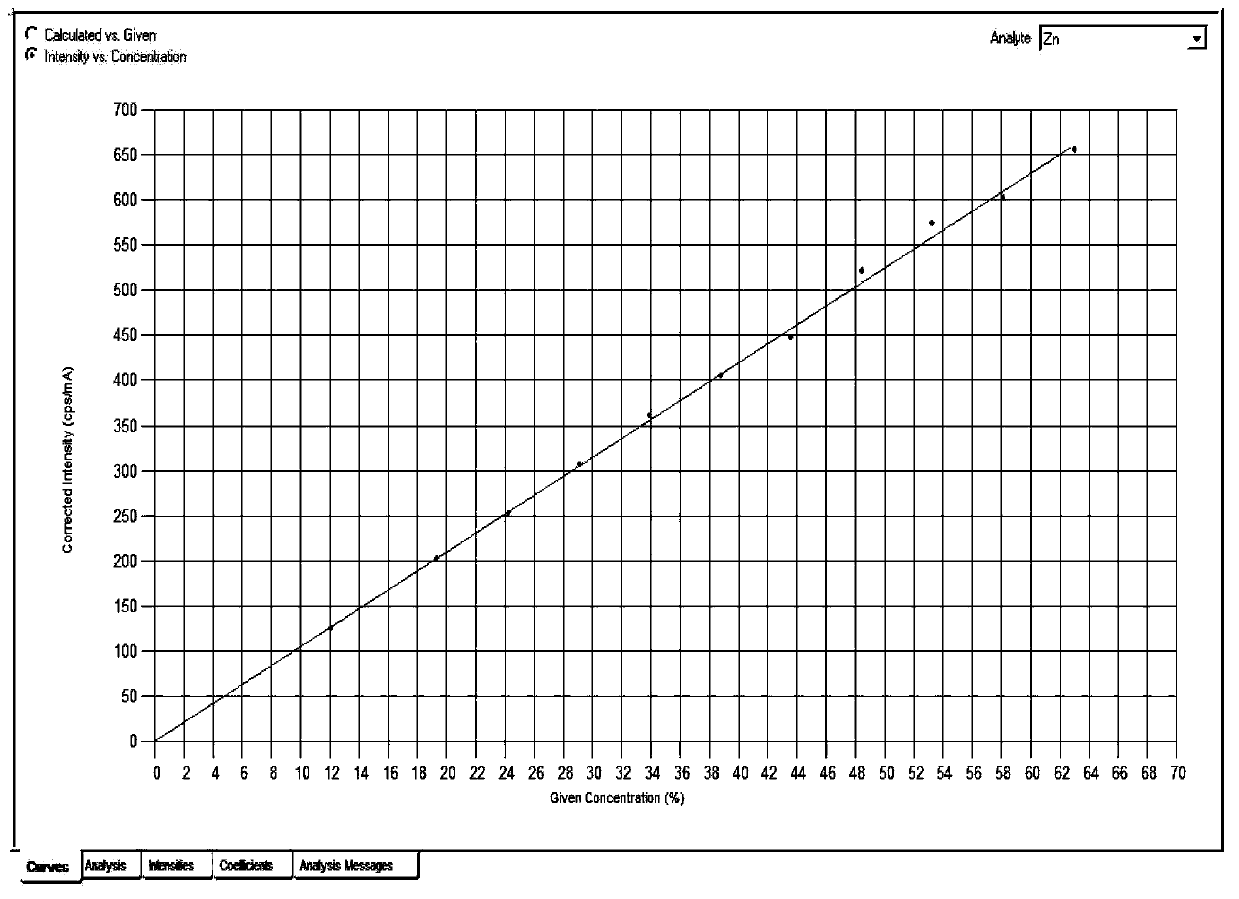

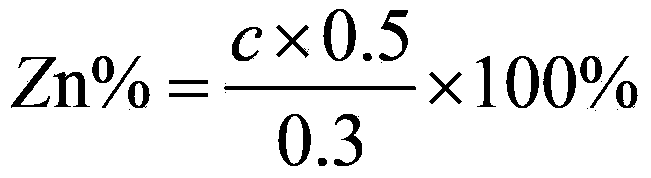

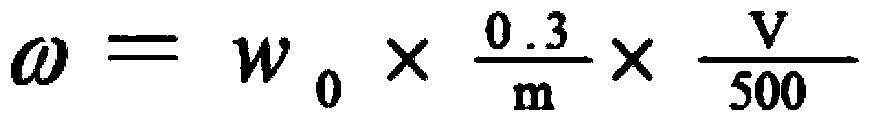

Method for determining content of zinc in zinc concentrate through energy-dispersive X-ray fluorescence spectrometry

ActiveCN103364426AEliminate unevennessElimination of physico-chemical effectsMaterial analysis using wave/particle radiationX-rayFluorescence spectrometer

The invention discloses a method for determining the content of zinc in the zinc concentrate through energy-dispersive X-ray fluorescence spectrometry. The method comprises the following steps: 1, preparing a plurality of zinc-iron working liquids, converting the mass concentrations of Zn in the operating liquids to Zn mass percentage concentrations, detecting the Zn mass percentage concentrations with an energy-dispersive X-ray fluorescence spectrometer as a detector, recording the fluorescence intensity during each time injection of a sample, and making a working curve; and 2, processing the zinc concentrate as a sample to prepare a sample solution, injecting the sample solution under detection conditions for making the working curve, recording the fluorescence intensity displayed on the detector, reading out the Zn mass percentage concentration corresponded to the fluorescence intensity according to the determined working curve, and calculating according to a specific formula to obtain the mass percentage concentration of simple substance zinc in the sample. The method utilizes a solution process to eliminate or basically eliminate the matrix effect, so the zinc content can be accurately determined; and the method has the advantages of simple operation, short detection period, good detection result accuracy and high precision.

Owner:广西出入境检验检疫局危险品检测技术中心

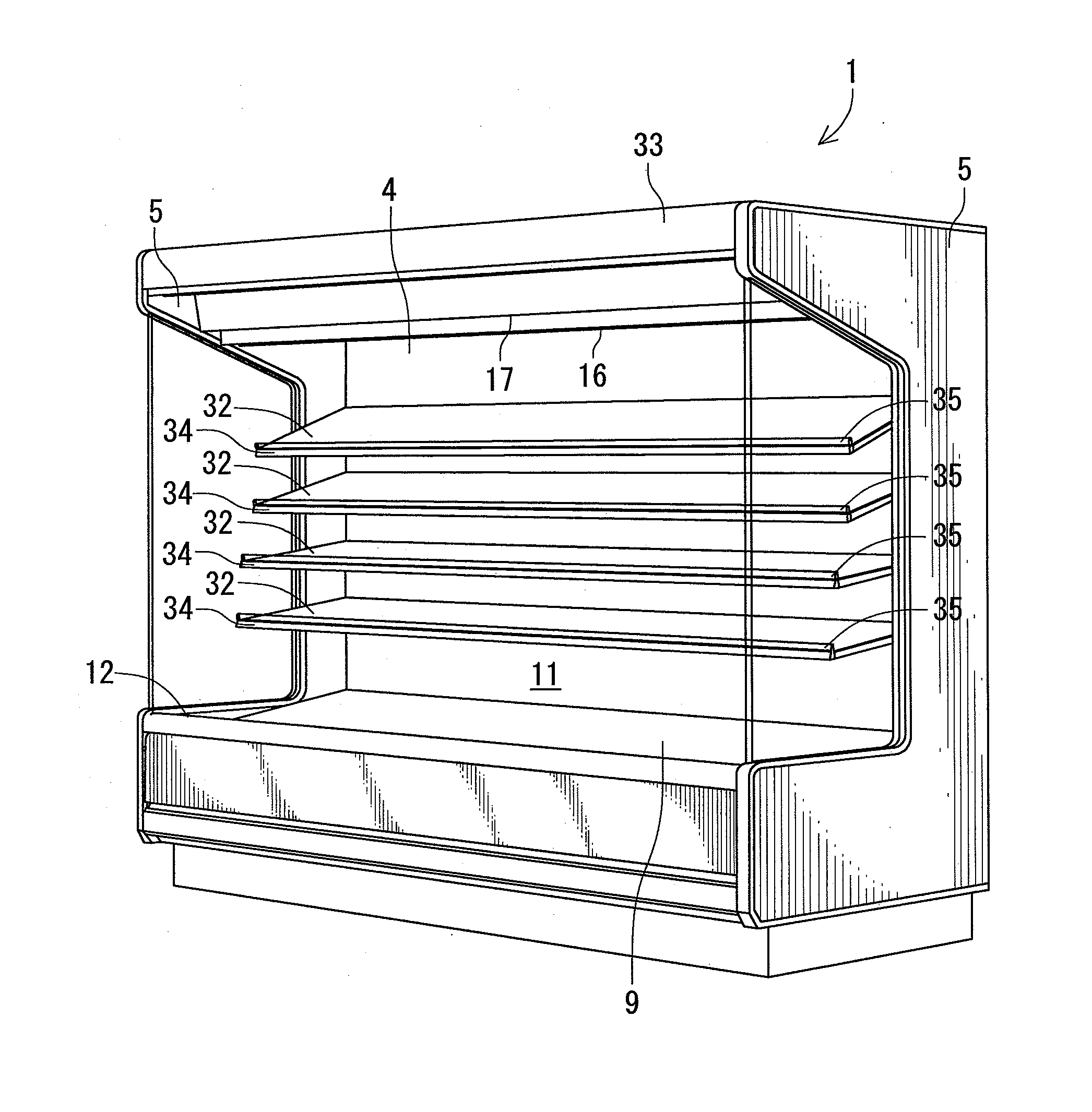

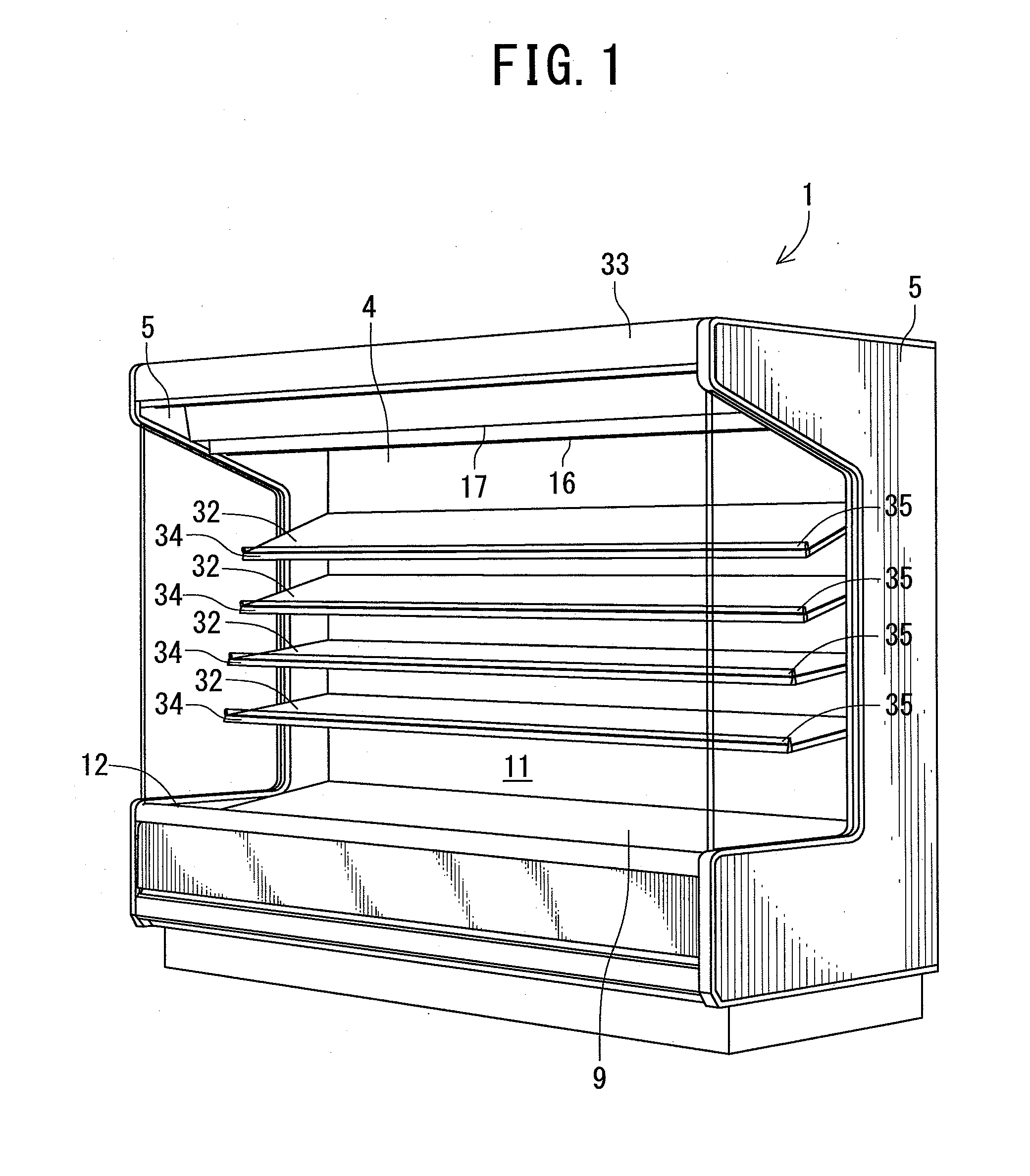

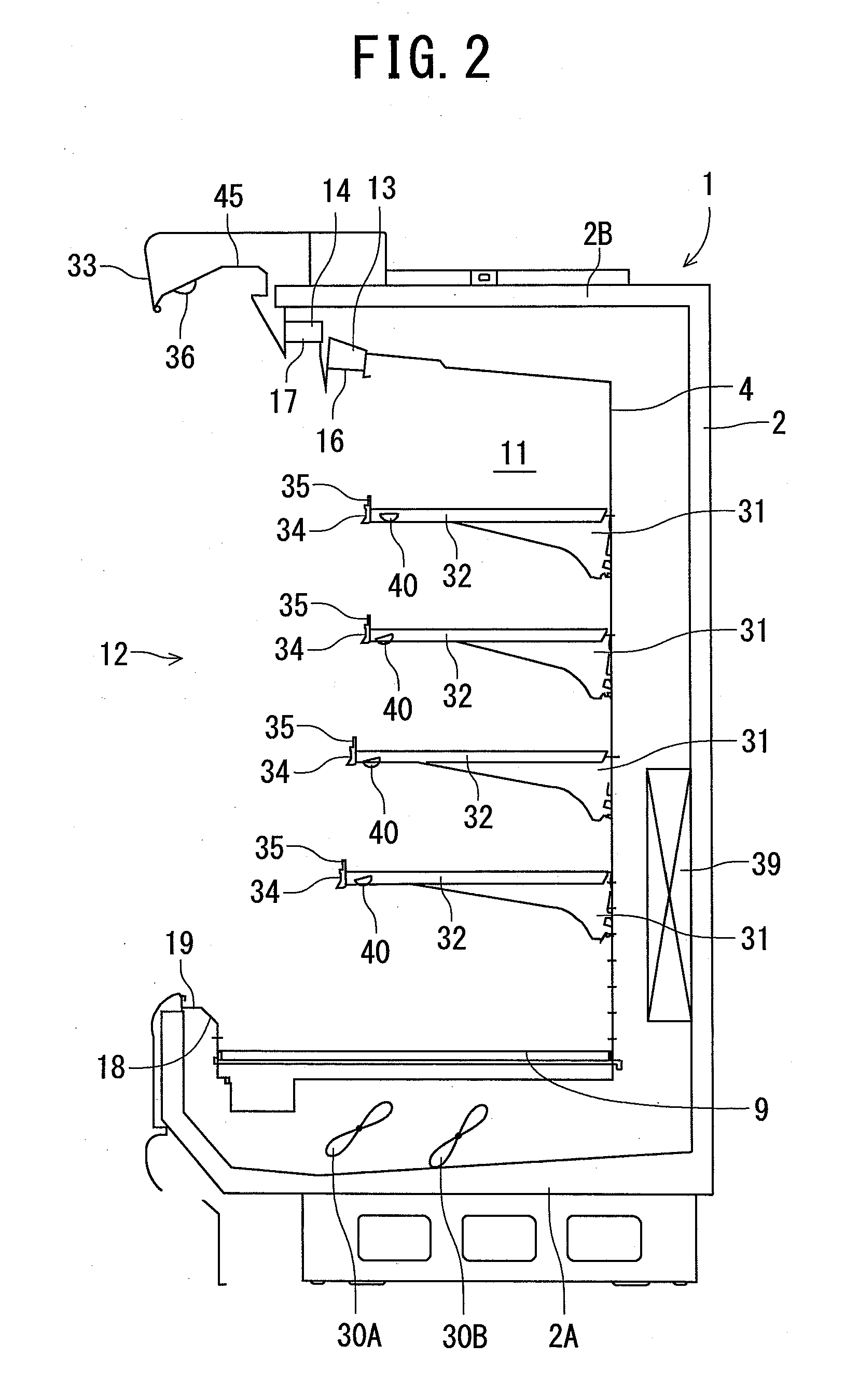

Showcase

InactiveUS20100195317A1Present inventionSatisfactory propertyMechanical apparatusLighting support devicesAcute angleEngineering

There is disclosed a showcase comprising an illumination apparatus which can stably be held by a simple structure and which can illuminate the inside of a display chamber effectively without any unevenness. The illumination apparatus provided in the showcase comprises a shade member constituted of a light-transmitting front wall positioned on the side of the light emitting surfaces of LED elements, and a back wall positioned on the side of a substrate provided with the LED elements, the front wall comprising a curved portion having an arc-like section and a pair of flat portions extended continuously from both ends of the curved portion to intersect with the back wall at an acute angle, corner portions where the flat portions intersect with the back wall being a pair of engaging portions; and a holder provided with a plurality of engagement portions and the like with which the engaging portions are disengageably engaged.

Owner:SANYO ELECTRIC CO LTD

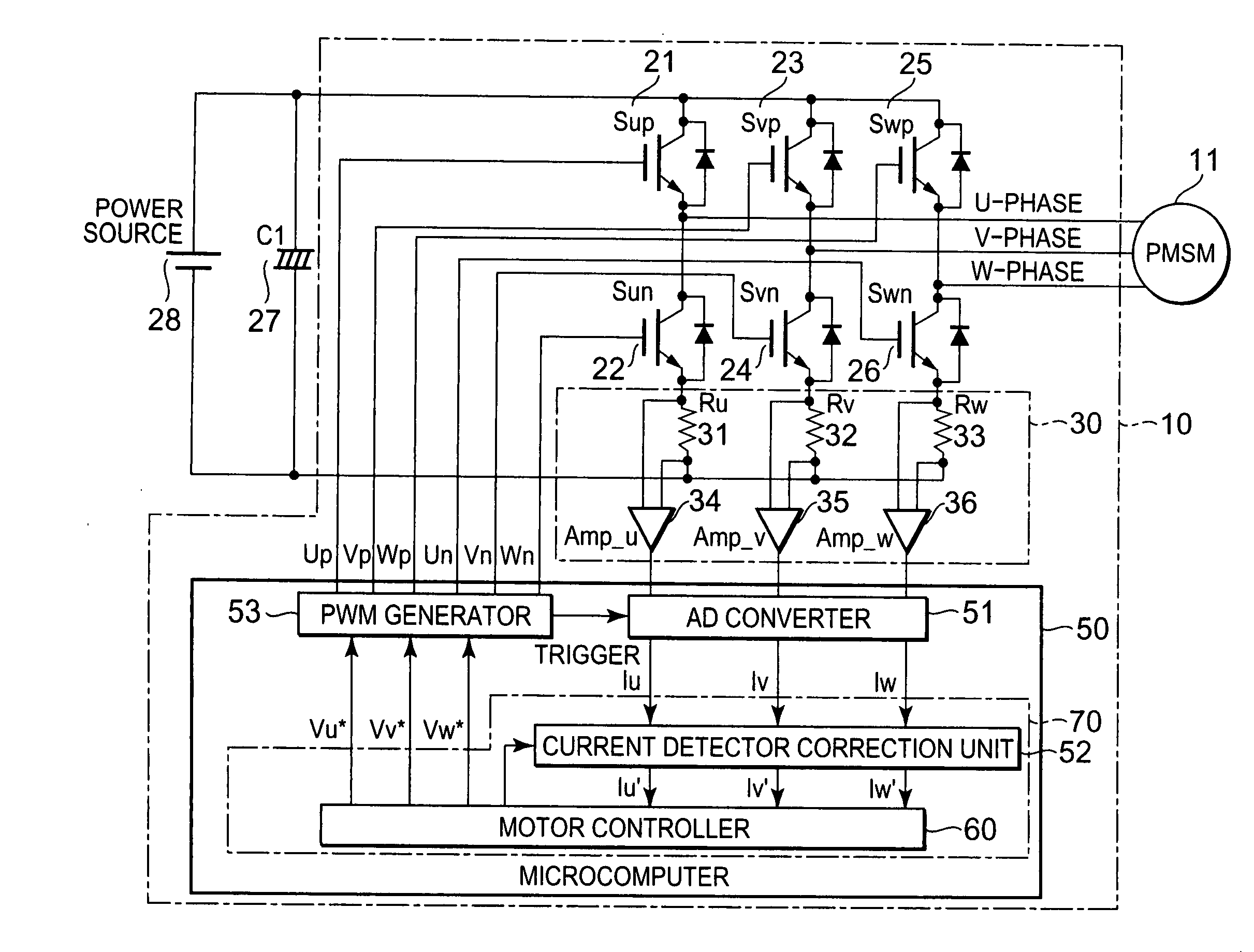

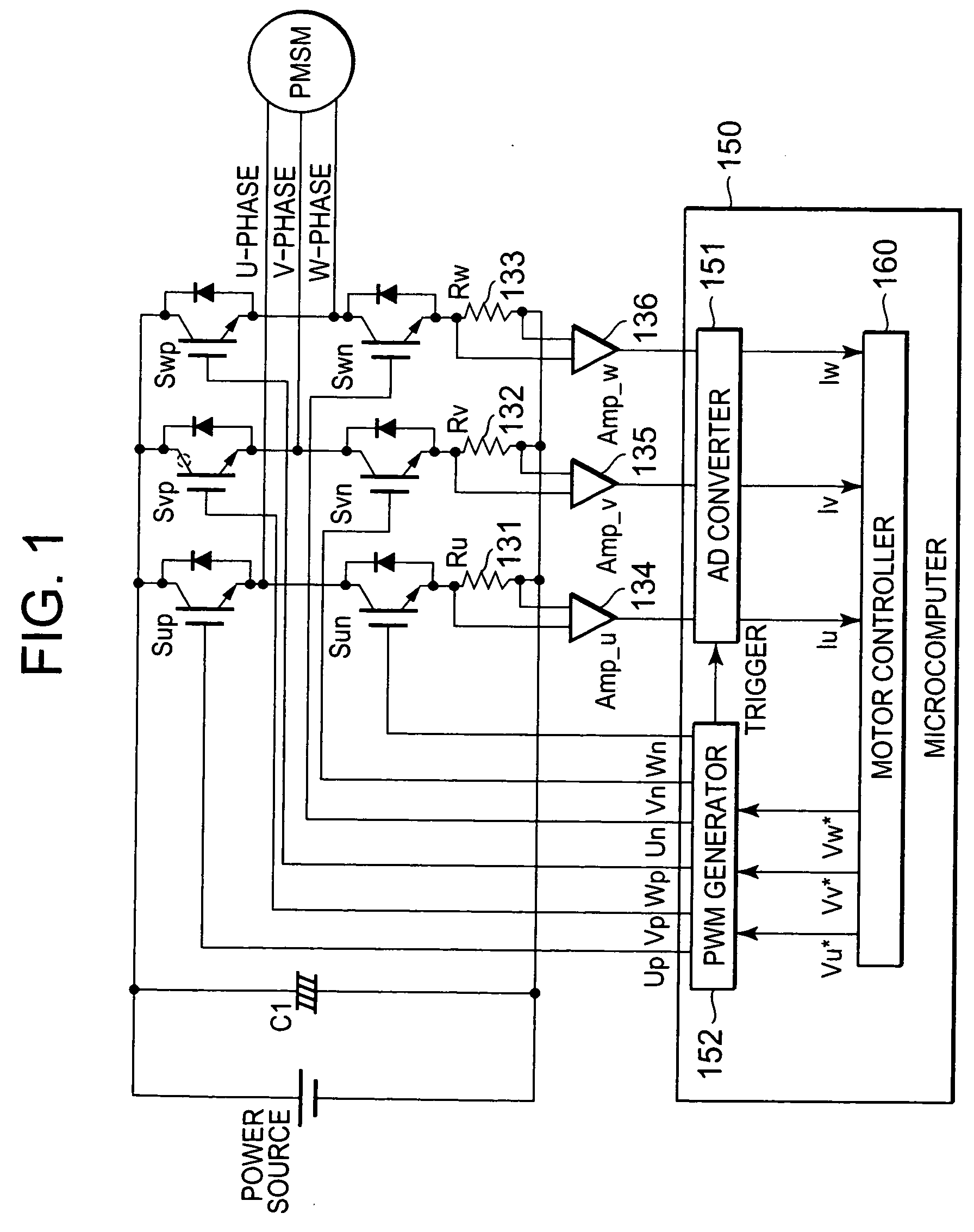

Inverter apparatus and a semiconductor device used for the same

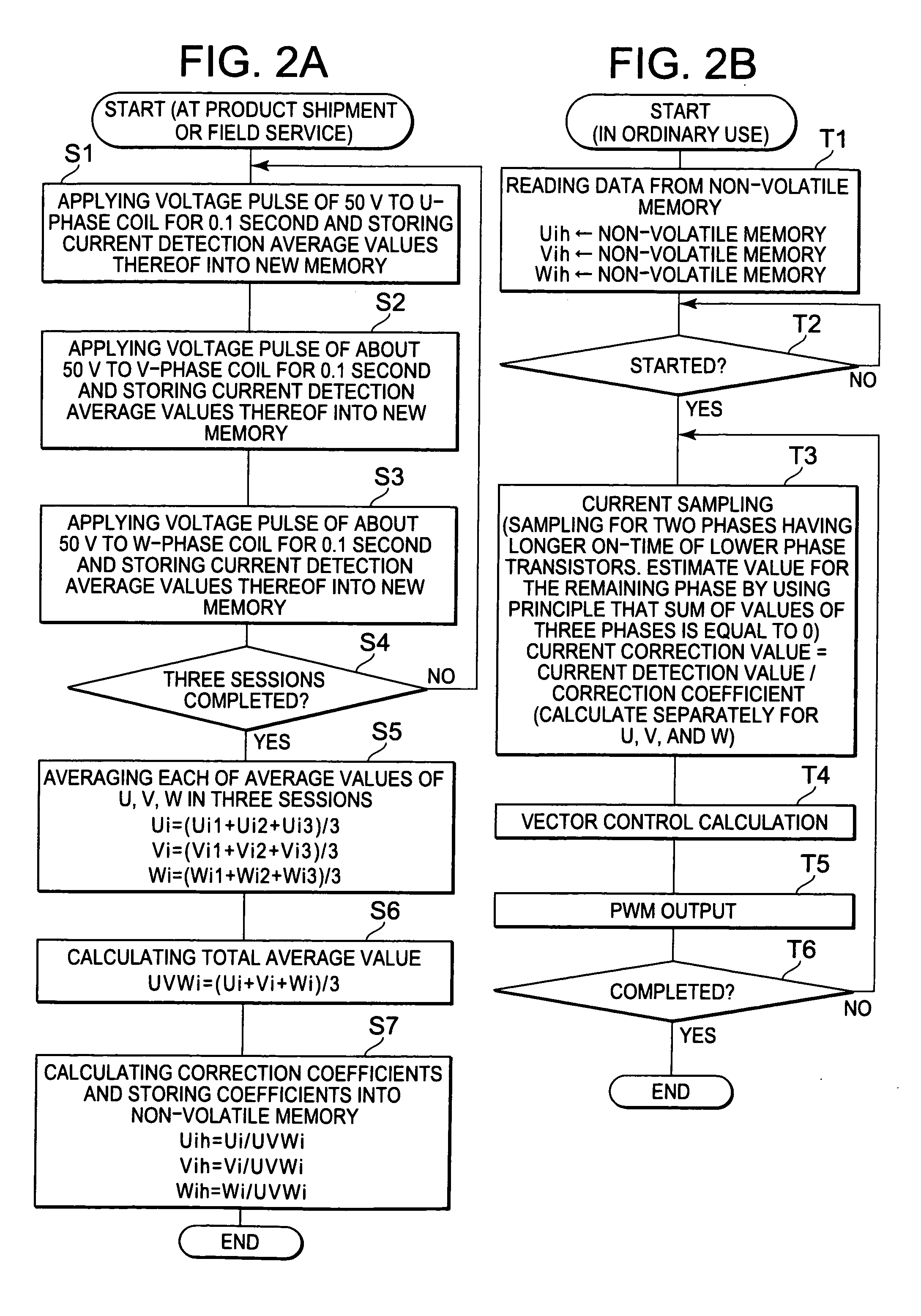

ActiveUS20080265829A1Low costIncrease torqueSingle-phase induction motor startersDC motor speed/torque controlThree-phaseSemiconductor

FIGS. 4A and 4B are principle diagrams for correcting deviations among current detectors of a three-phase motor 19 in an inverter apparatus of the present invention, which includes bidirectional switching elements 13 to 18. FIG. 4C shows on and off states of switches in the cases of FIGS. 4A and 4B, in which 1 and 0 mean on- and off-states, respectively. The states shown in FIGS. 4A and 4B are alternately repeated by controlling the switches, and measurement for correcting the deviations among the current detectors are obtained in the state shown in FIG. 4B. Specifically, in FIG. 4B, currents having the same amplitude flow on a U phase and a V phase. Accordingly, a difference in the measured data represents a difference in performances of the current detectors. In the state of normal use, the inverter apparatus is operated by correcting detected current values based on the measurement data.

Owner:RENESAS ELECTRONICS CORP

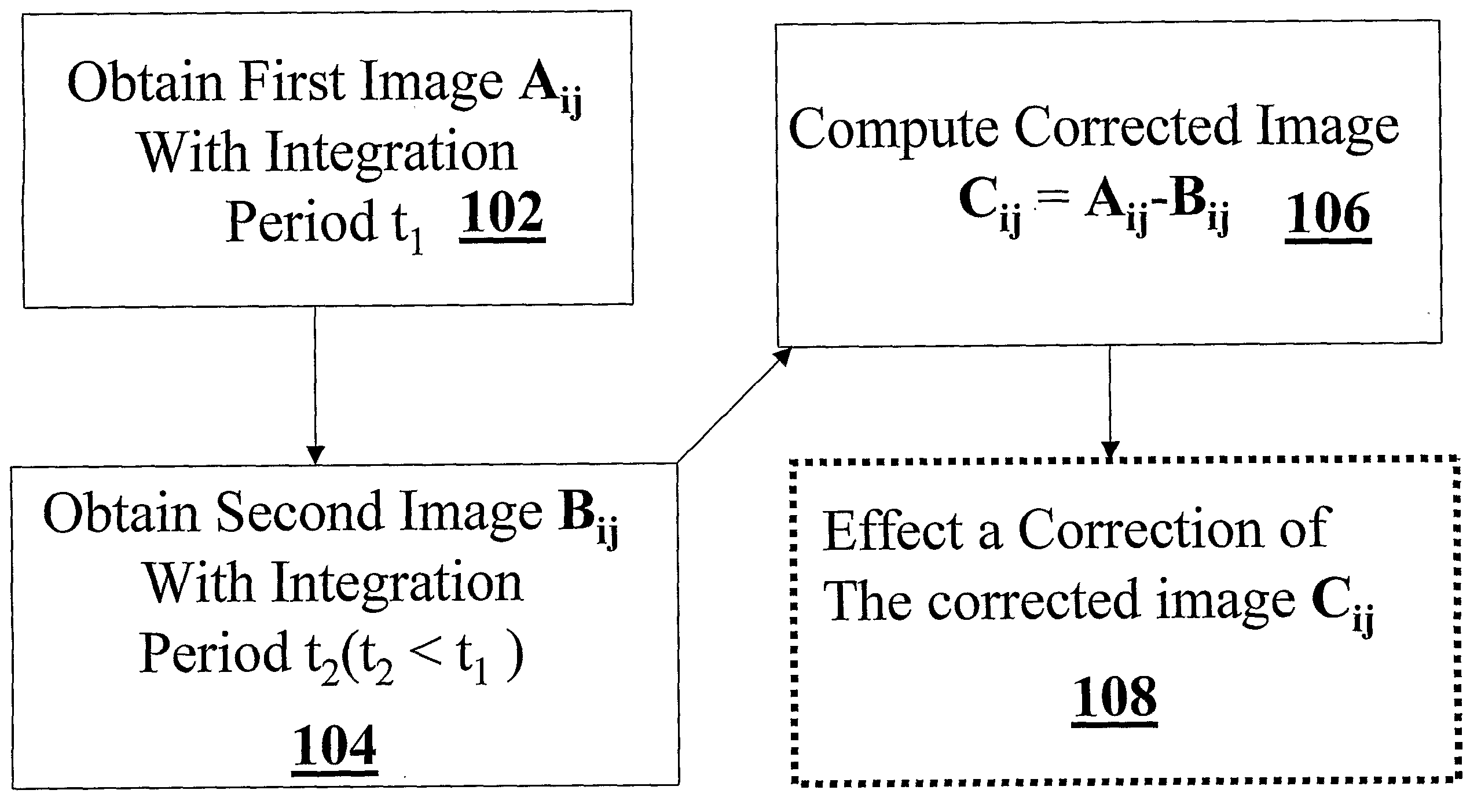

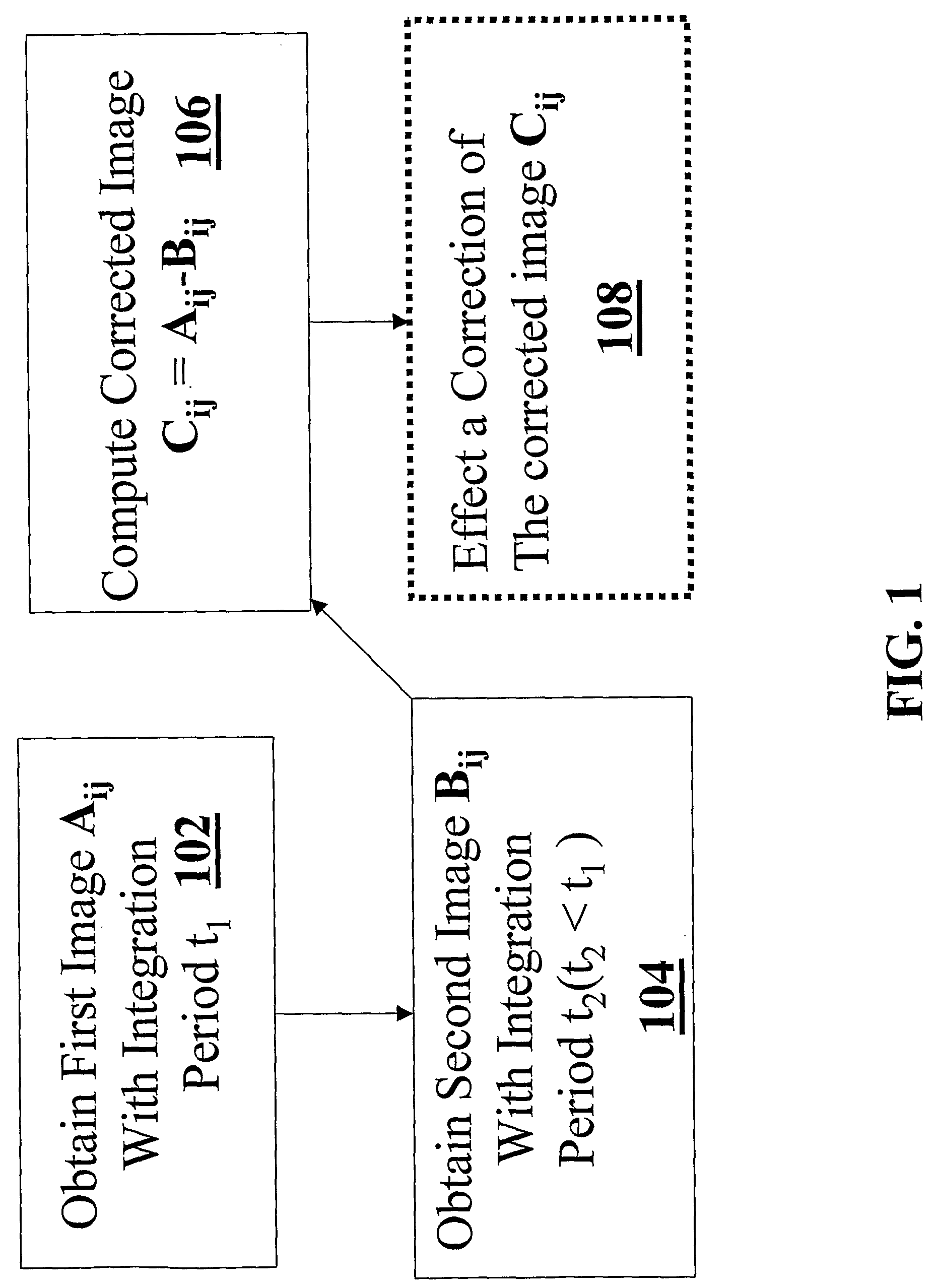

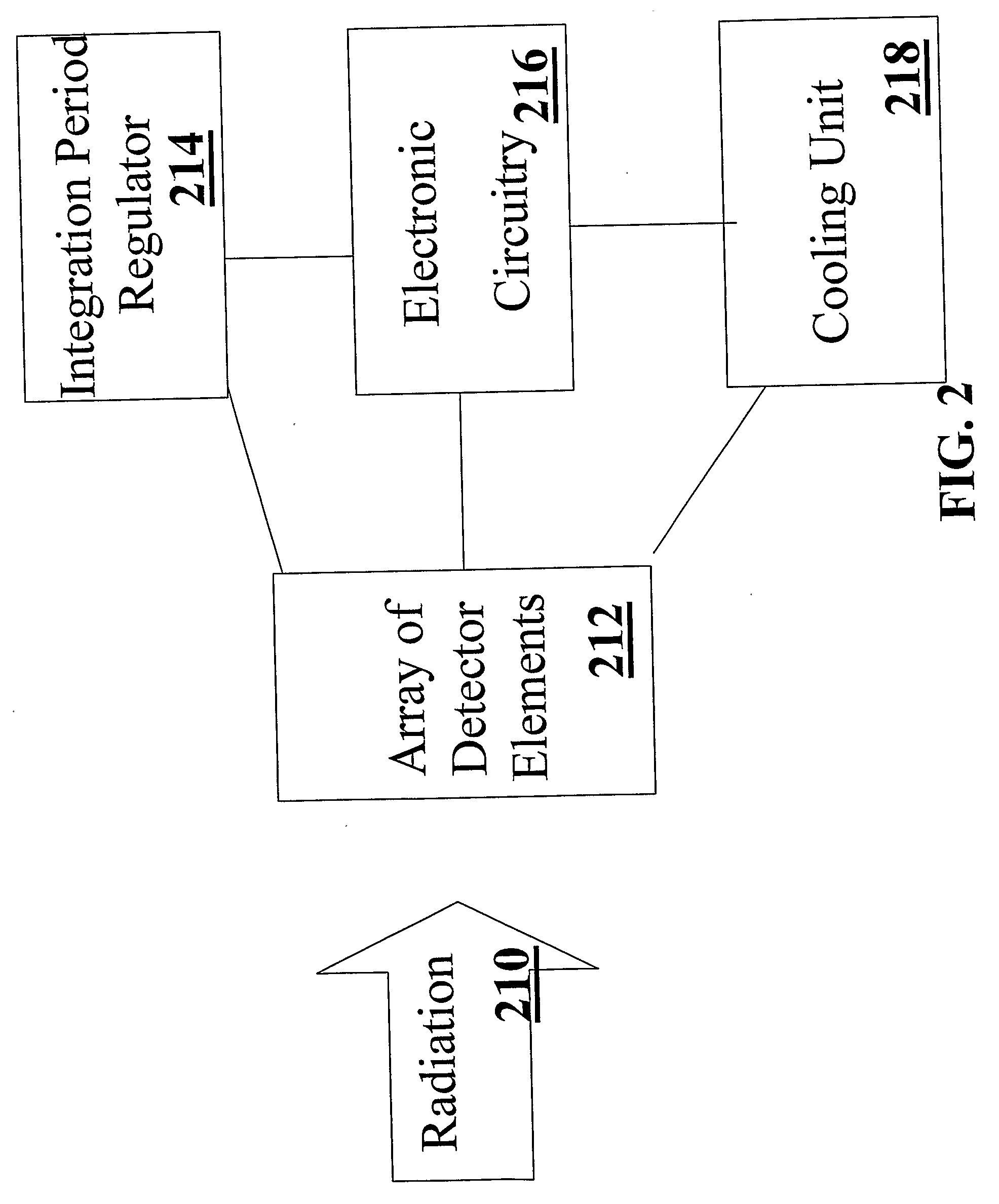

Non-uniformity correction of images generated by focal plane arrays of photodetectors

ActiveUS20090079854A1Reduce residual non-uniformityEliminate unevennessImage enhancementTelevision system detailsPhotovoltaic detectorsPhotodetector

Methods and apparatus for effecting a non-uniformity correction of images of a scene obtained with an array of detector elements are disclosed. A first image of the scene having a first integration period is acquired using the array of detector elements. A second image of the scene having a different integration period is acquired, and a corrected image of the scene is generated by computing a difference of the images. In some embodiments, the first and second images are images of substantially identical scenes. According to some embodiments, the images are infrared images. Optionally, the corrected image is subjected to further correction using pixel dependent correction coefficients, such as gain coefficients. Exemplary image detection elements include but are not limited to InSb detector elements and ternary detector elements, such as InAlSb, MCT (Mercury Cadmium Telluride), and QWIP technology (Quantum Well Infrared Photodiodes). In some embodiments, the detector elements are cooled to a temperature substantially equal to an atmospheric boiling point of liquid nitrogen. Alternatively, the detector elements are cooled to a temperature below an atmospheric boiling point of liquid nitrogen, or any other operating temperature.

Owner:RAFAEL ADVANCED DEFENSE SYSTEMS

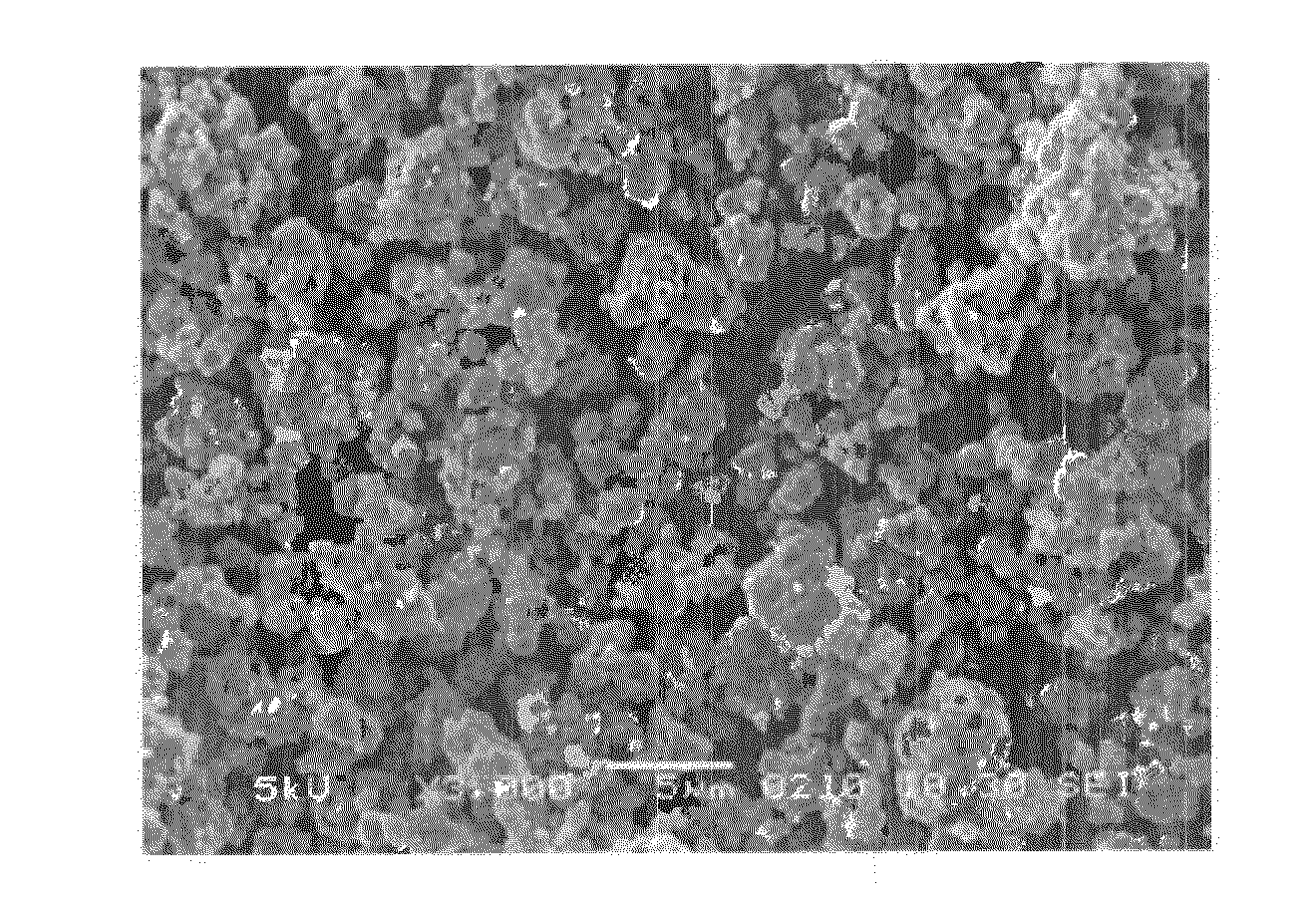

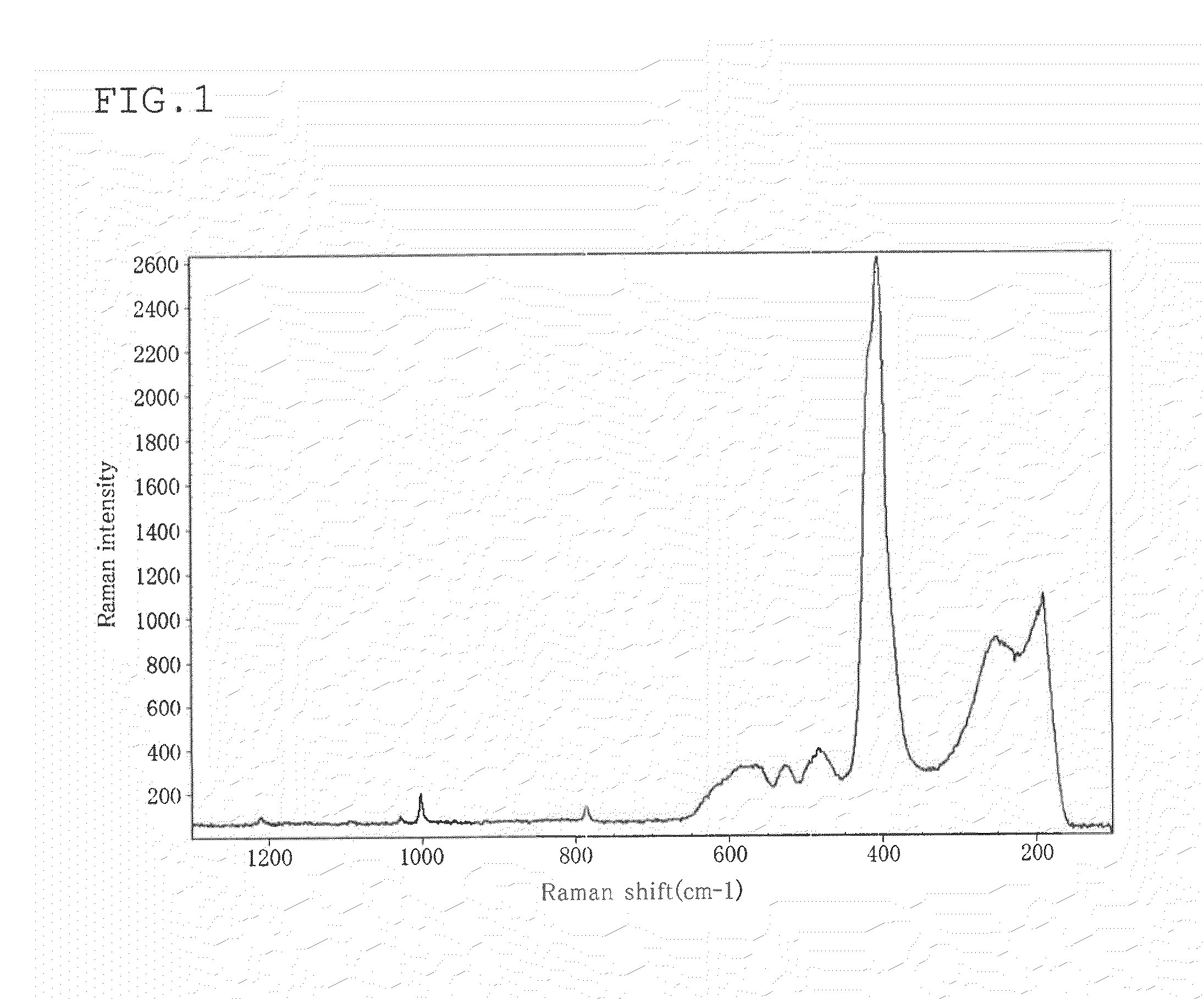

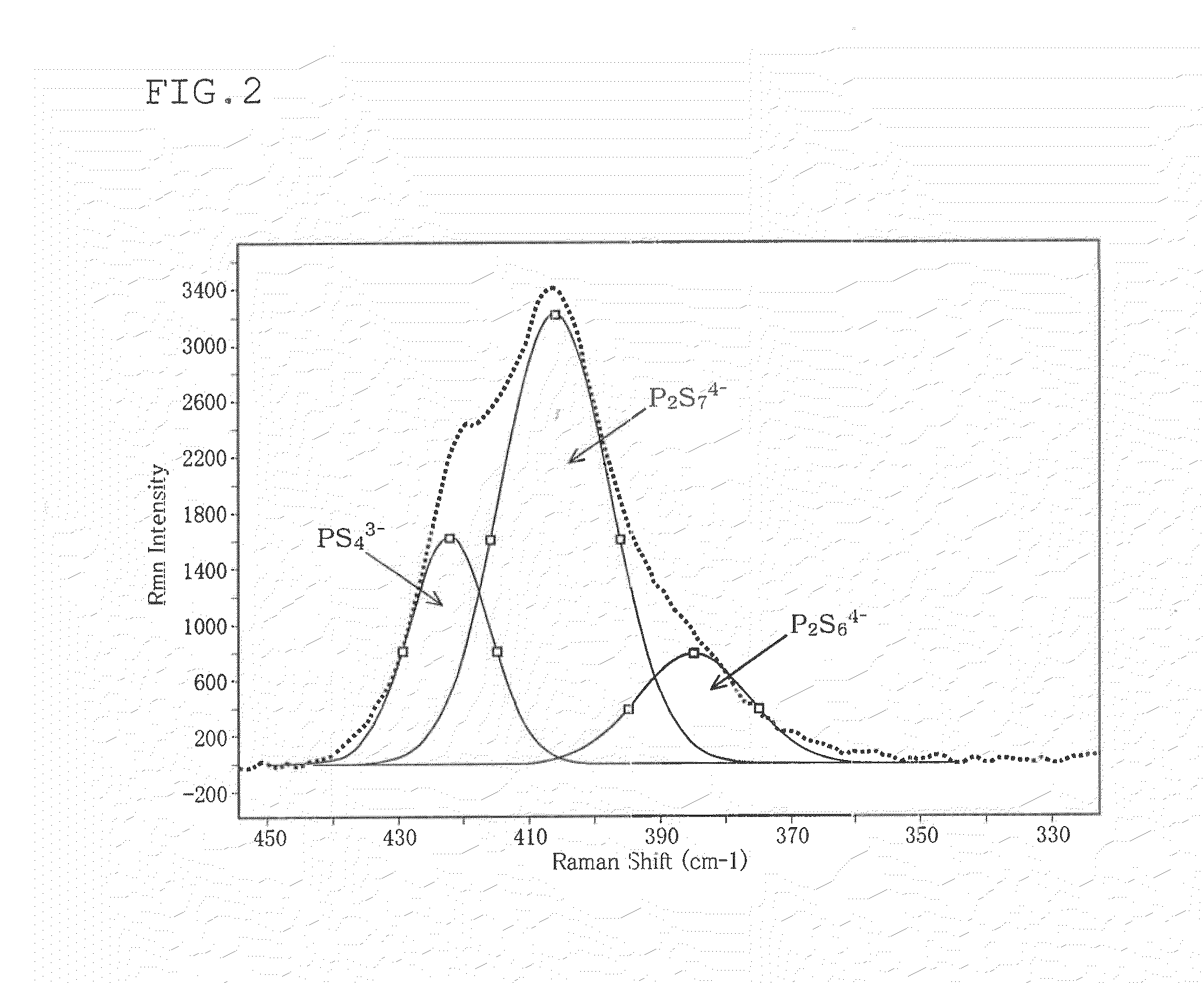

Glass comprising solid electrolyte particles and lithium battery

ActiveUS20120009484A1Deterioration of battery performanceStabilize battery performanceSolid electrolytesFinal product manufactureElectrolyteMaterials science

Glass includes an aggregate of solid electrolyte particles including Li, P, and S, wherein when a Raman spectrum of the glass is repeatedly measured and a peak at 330 to 450 cm−1 in each Raman spectrum is separated to waveforms of individual components, a standard deviation of a waveform area ratio of each component is less than 4.0.

Owner:IDEMITSU KOSAN CO LTD

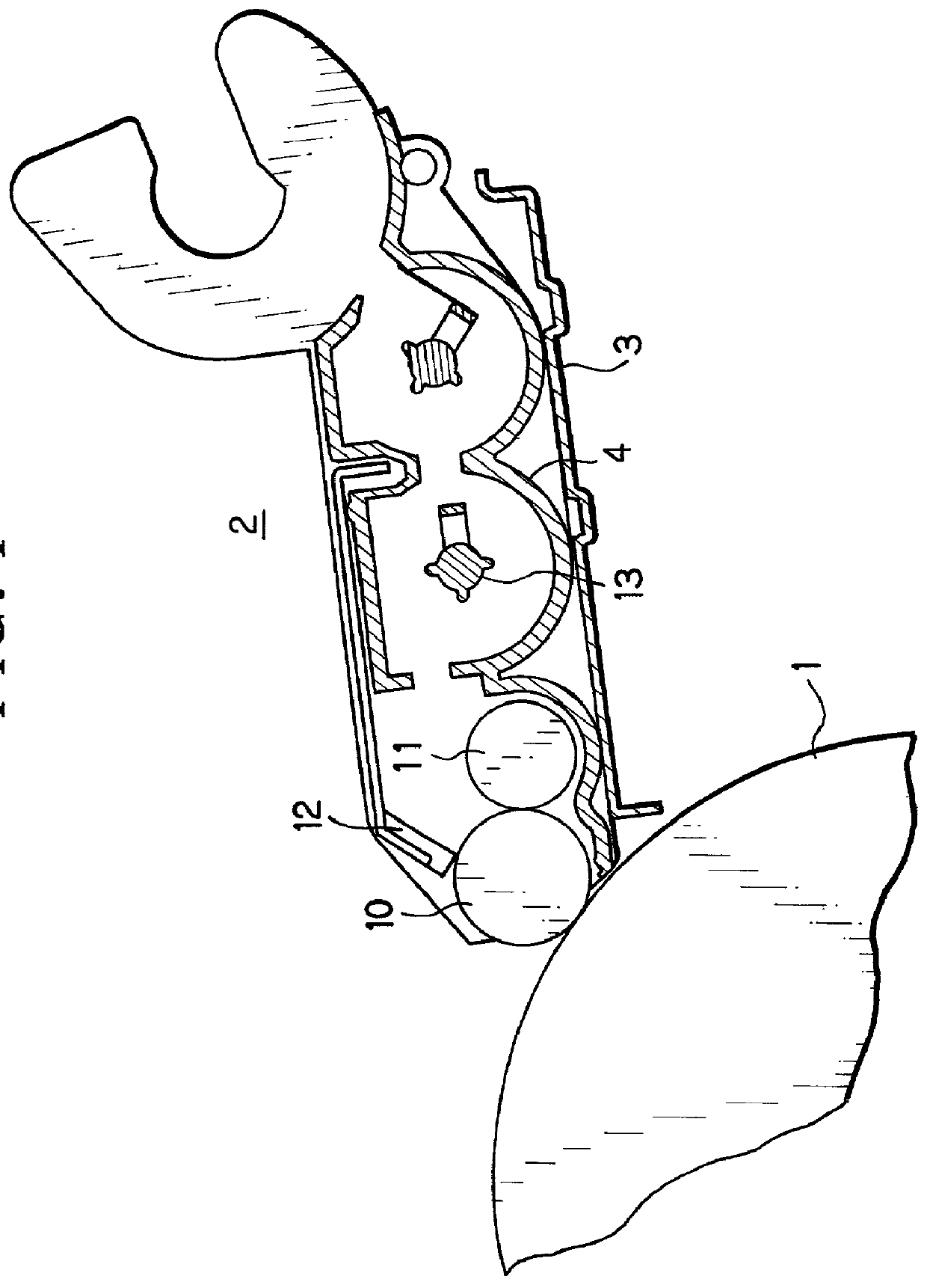

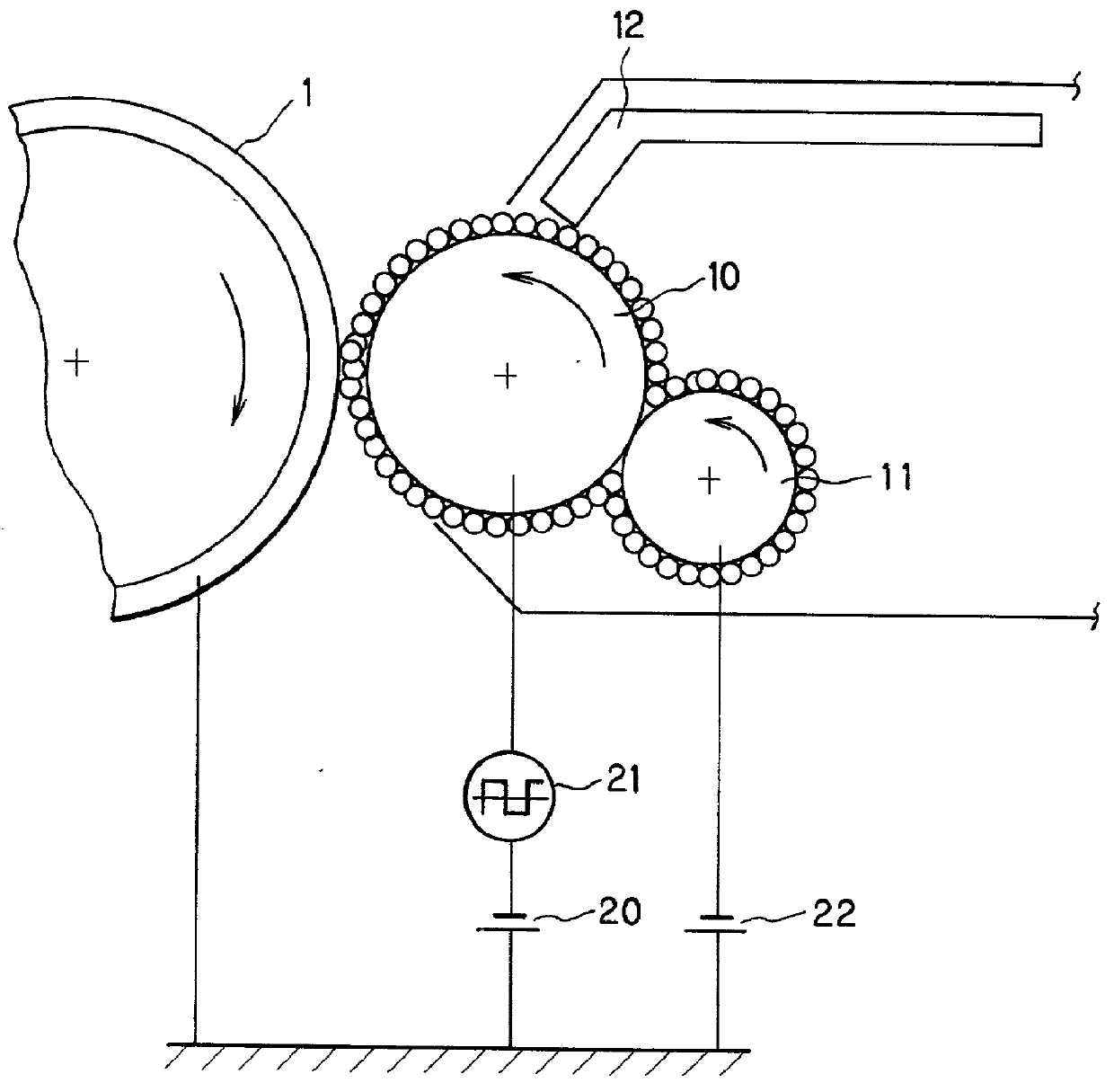

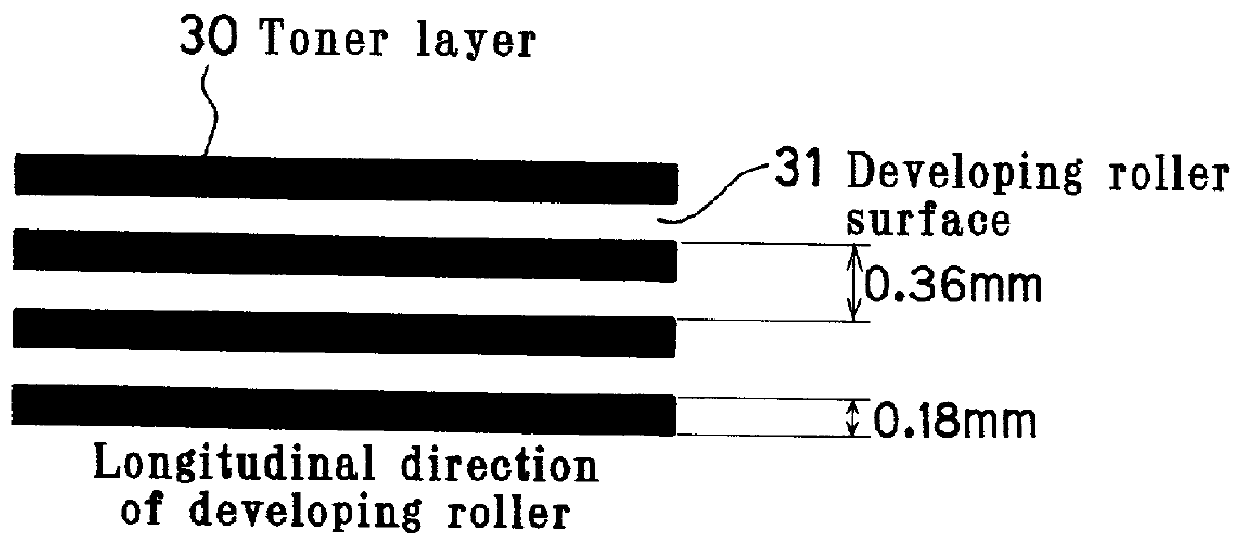

Image forming apparatus

InactiveUS20010055503A1Reduce impactMinimize packagingElectrographic process apparatusEngineeringVoltage

An image forming apparatus has a latent image carrier on which a latent image is formed. A developer carrier conveys a one-component non-magnetic developer and develops the latent image either in close proximity to or in contact with the latent image carrier. A voltage application unit applies an AC-superimposed bias voltage to the developer carrier. A regulating member abuts against the developer carrier to regulate the thickness of the developer layer on the developer carrier. The regulating member has a semiconductive member provided at the distal end thereof to produce an electric potential difference between the semiconductive member and the developer carrier, to which the AC-superimposed bias voltage is applied, when regulating the thickness of the developer layer on the developer carrier, thereby forming a line-shaped uneven conveying surface. Thus, the occurrence of banding and longitudinal unevenness and stripes is prevented, and fogging and scattering are also prevented. Further, the occurrence of filming is prevented, thereby allowing formation of a uniform image free from density unevenness.

Owner:SEIKO EPSON CORP

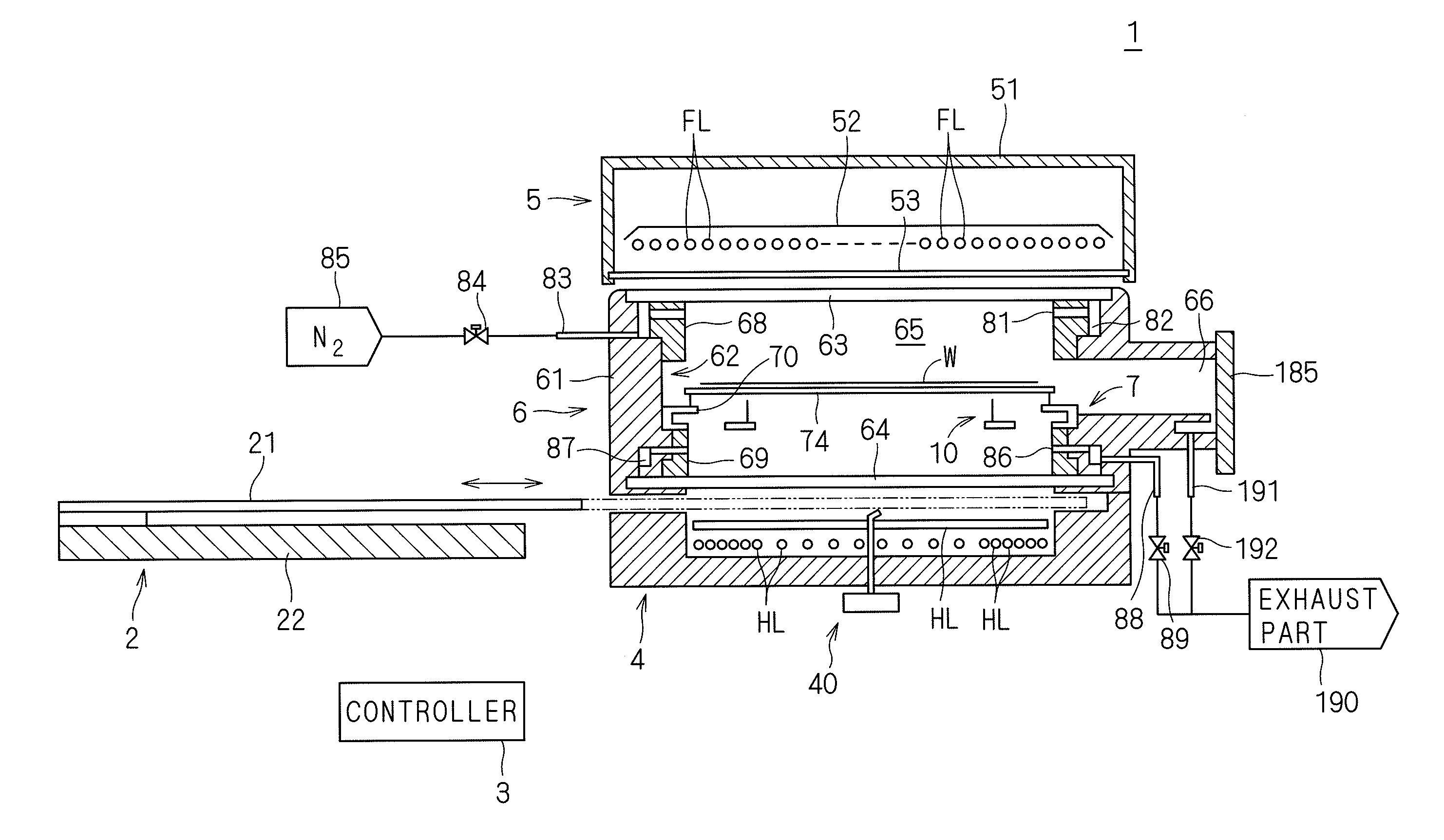

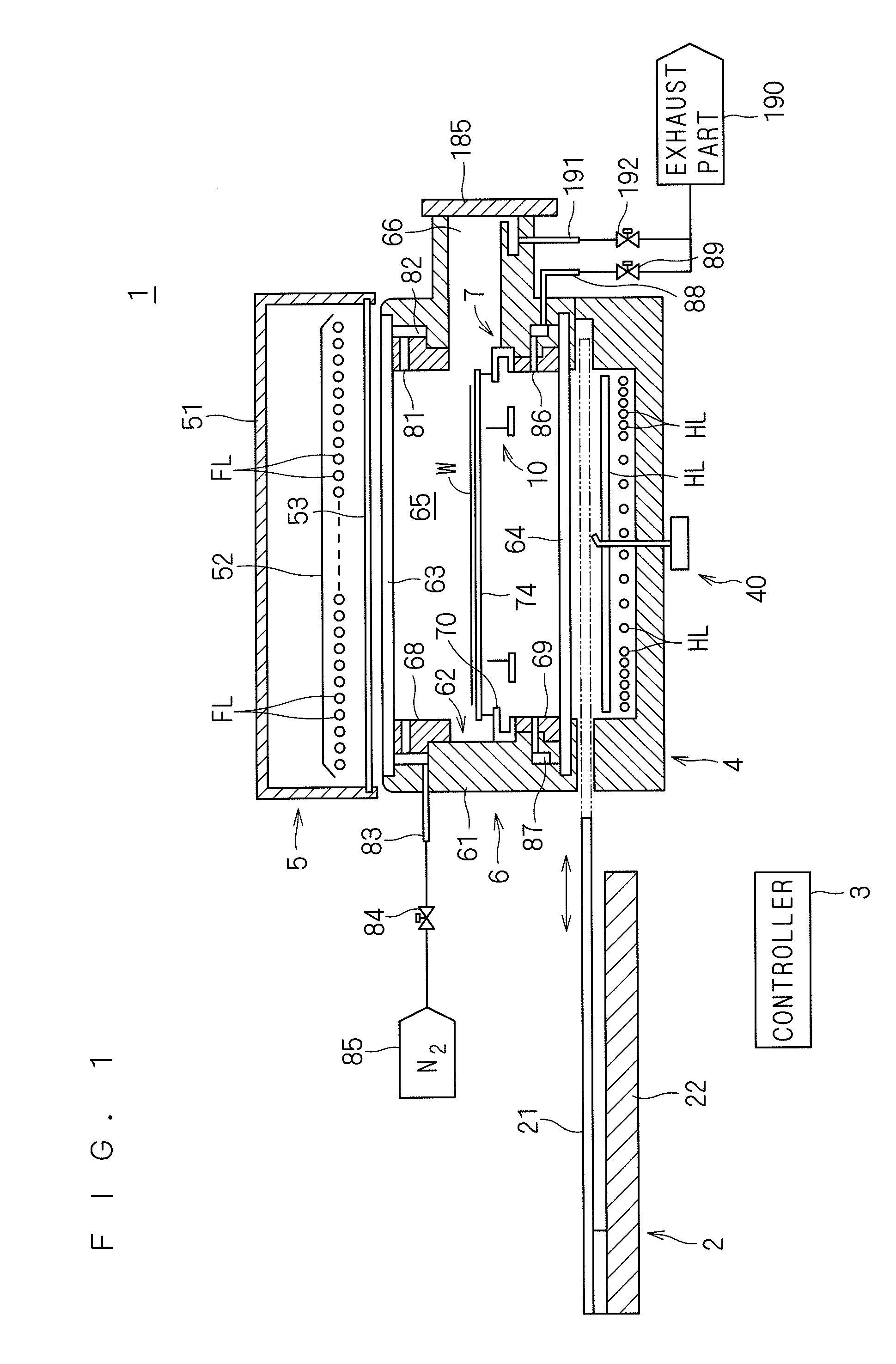

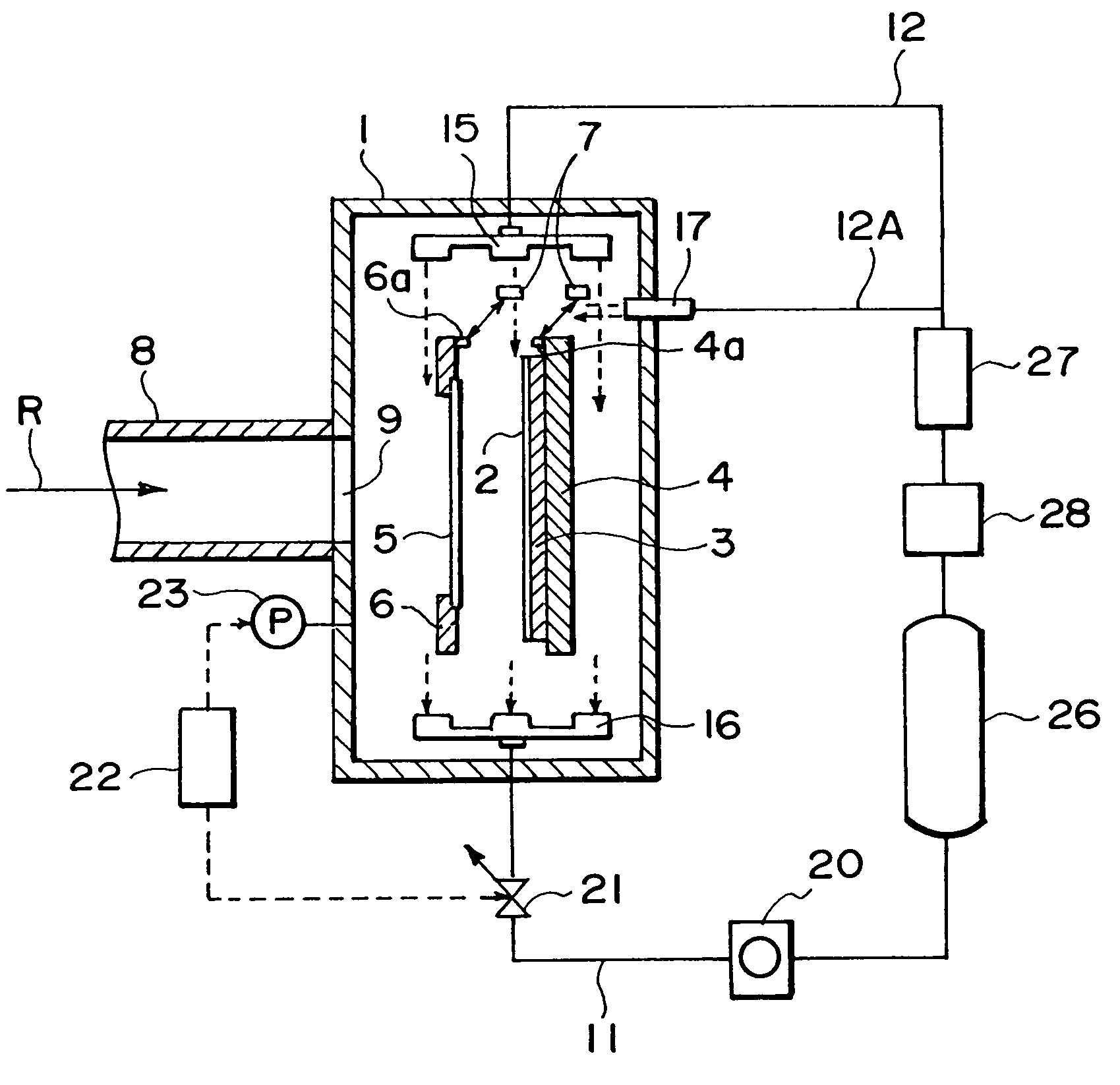

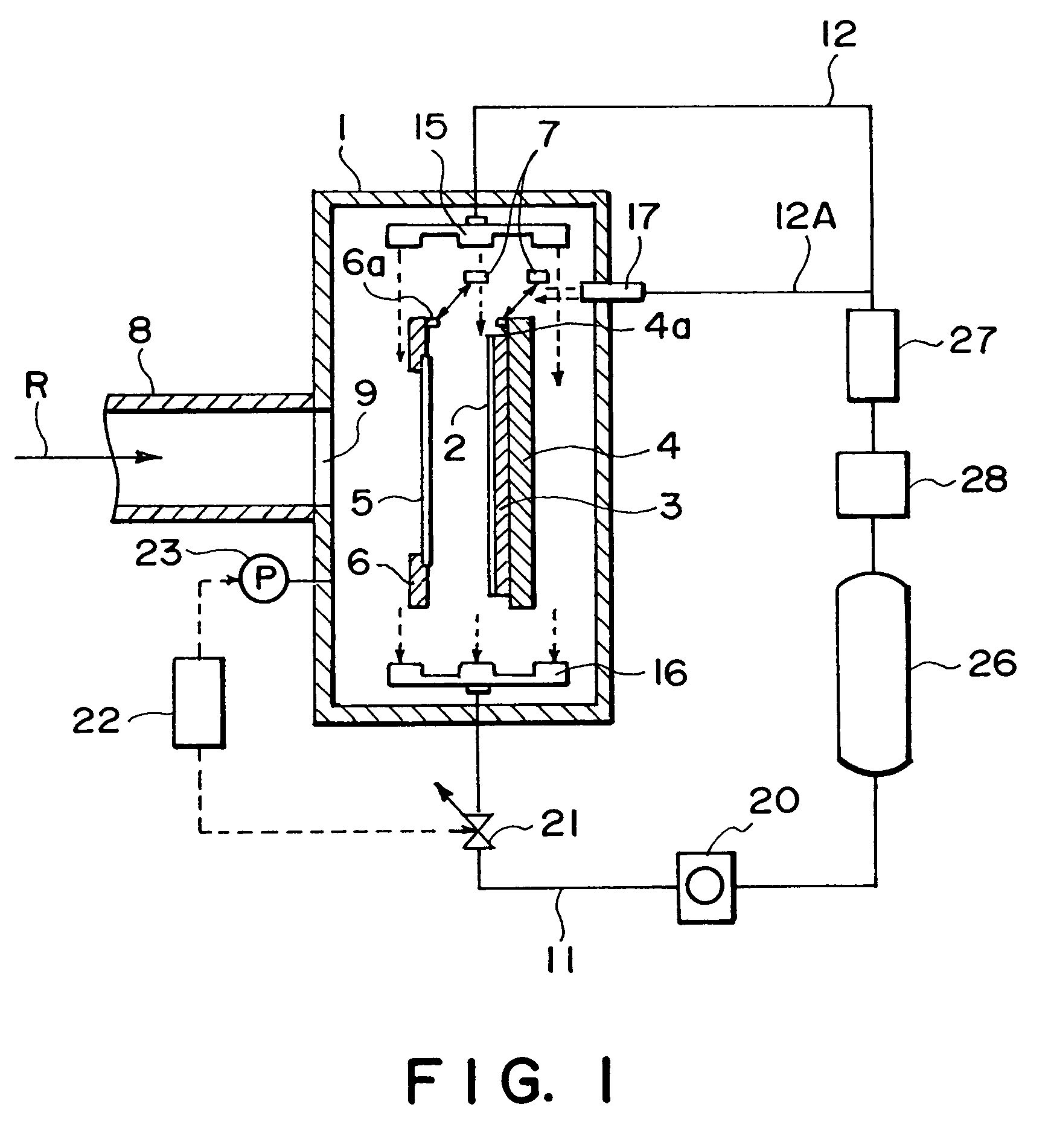

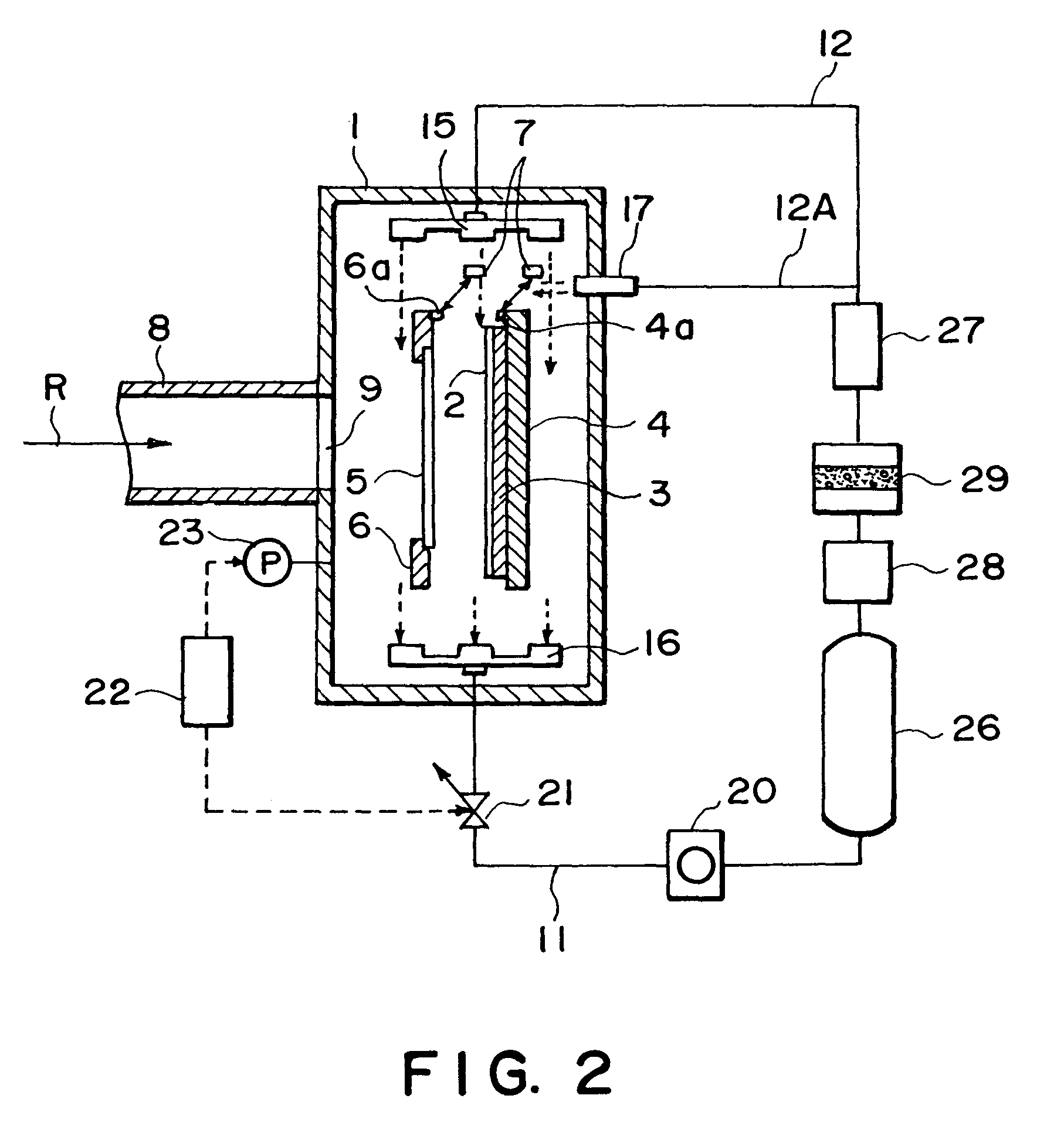

Heat treatment apparatus for heating substrate by irradiating substrate with flashes of light

ActiveUS20120067864A1Eliminate unevennessUniform temperature distributionElectric heatingSemiconductor/solid-state device manufacturingIn planeHalogen

When a semiconductor wafer is preheated by halogen lamps, the temperature of a peripheral portion of the semiconductor wafer is lower than that of a central portion thereof. A laser light emitting part disposed immediately under the center of the semiconductor wafer is rotated about the center line of the semiconductor wafer, while laser light is directed from the laser light emitting part toward the peripheral portion of the semiconductor wafer. Thus, the irradiation spot of the laser light exiting the laser light emitting part swirls around along the peripheral portion of the back surface of the semiconductor wafer so as to draw a circular trajectory. As a result, the entire peripheral portion of the semiconductor wafer at a relatively low temperature is uniformly heated. This achieves a uniform in-plane temperature distribution of the semiconductor wafer.

Owner:DAINIPPON SCREEN MTG CO LTD

Processing apparatus, measuring apparatus, and device manufacturing method

InactiveUS6984362B2Eliminate unevennessStable atmosphereExhaust apparatusTemperatue controlInternal pressureControl system

A processing apparatus includes a sealed vacuum chamber which contains a processing portion; a pressure controlling system which keeps the internal pressure of the sealed vacuum chamber constant at a predetermined level by exhausting the ambient gas in the sealed vacuum chamber; and an ambient gas recirculating system which recirculates the ambient gas exhausted from the sealed vacuum chamber back into the sealed vacuum chamber; wherein the ambient as recirculated by the ambient gas recirculating system is blown into the sealed vacuum chamber so that a gas flow is generated in a predetermined direction along the processing portion.

Owner:CANON KK

Image Pickup Apparatus, Method of Correcting Captured Image Data, and Program

InactiveUS20090122165A1Reduce the impactReduce unevennessTelevision system detailsColor signal processing circuitsComputer visionImaging data

An image pickup apparatus includes a solid-state image pickup device sharing a circuit necessary for a pixel structure between multiple pixels composing each set including a certain number of pixels having the same arrangement pattern; a pixel mixture correcting unit correcting leakage of light that should be incident on each pixel of the solid-state image pickup device from the pixel into adjacent pixels and / or leakage of light that should be incident on the adjacent pixels into the pixel in accordance with a correction parameter; a correction parameter generating unit generating multiple correction parameters corresponding to the multiple pixels composing the set; and a correction parameter selecting unit selecting the correction parameter from the multiple correction parameters in accordance with which pixel in the multiple pixels composing the set a pixel to be corrected corresponds to and supplying the selected correction parameter to the pixel mixture correcting unit.

Owner:SONY CORP

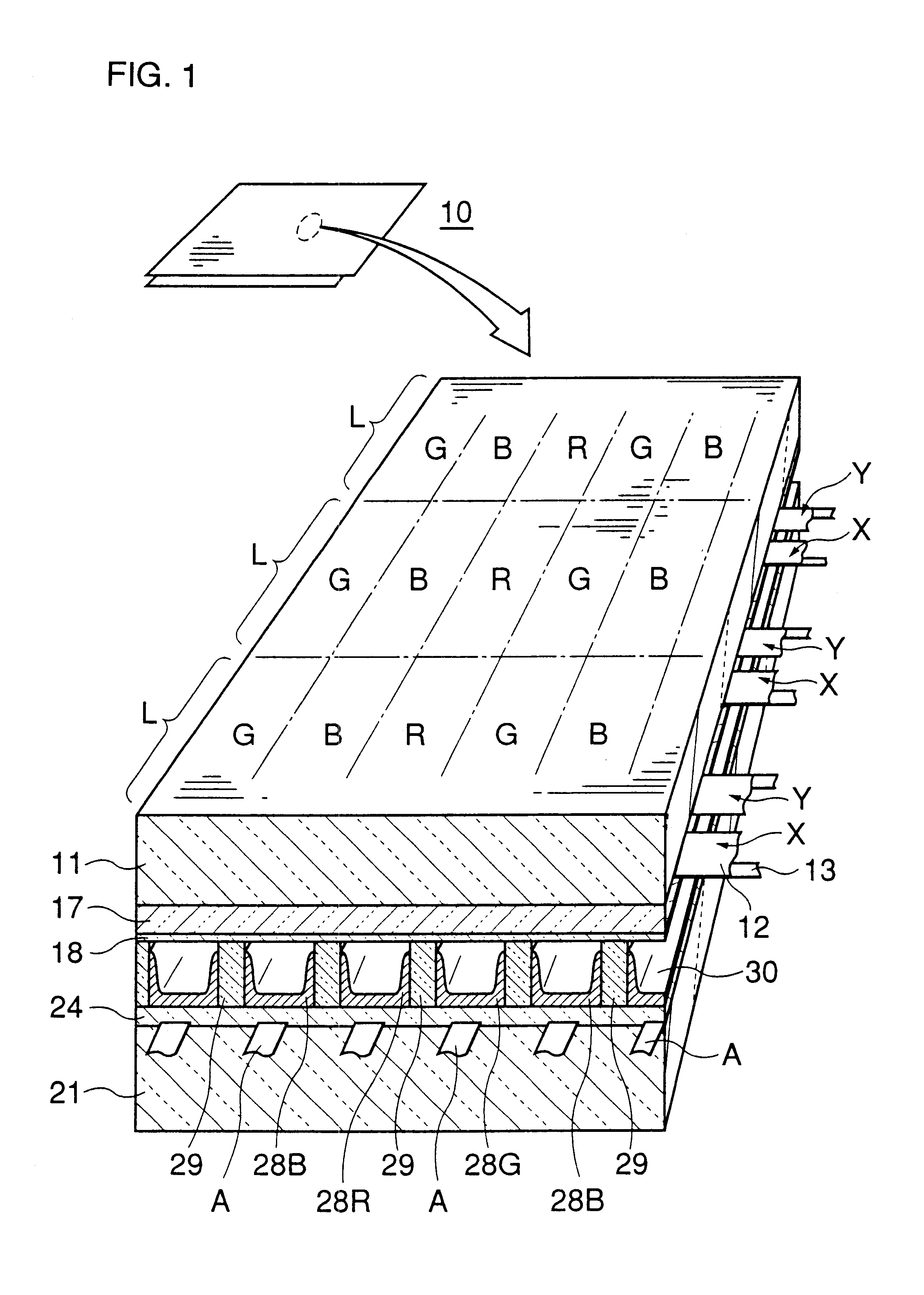

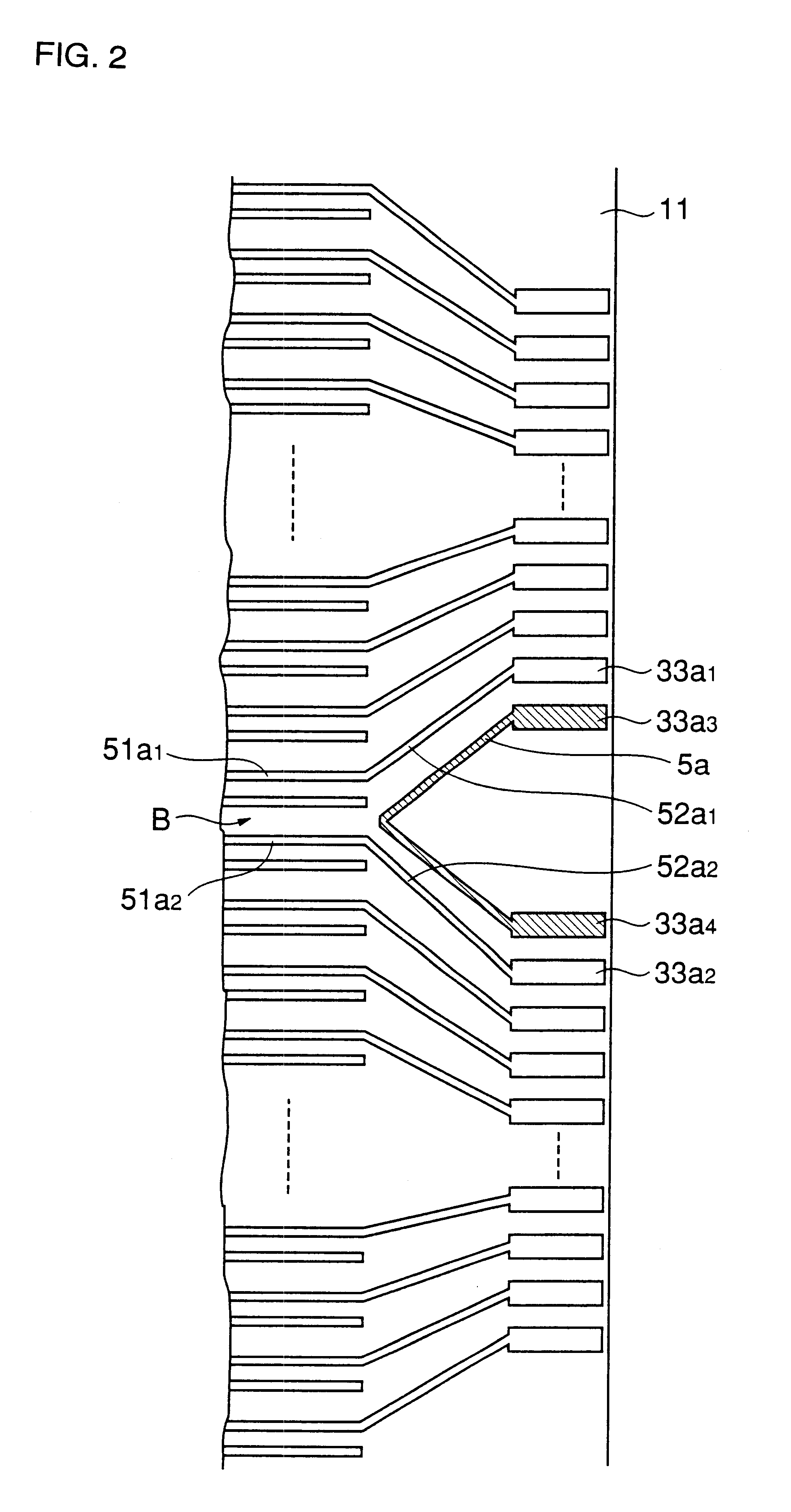

Electrode structure of display panel and electrode forming method using dummy electrode

InactiveUS6680759B2Eliminate unevennessControl flowAddress electrodesSustain/scan electrodesEngineeringLead electrode

An electrode structure of a display panel includes a plurality of electrodes formed on a substrate constituting the display panel, the electrodes including display electrode portions provided in almost parallel in a central part of the substrate and oblique lead electrode portions converged in a predetermined number for each block from the display electrode portions to reach terminal portions at an end of the substrate, and a dummy electrode provided between two oblique lead electrode portions extending in different directions in a block boundary portion for limiting a flow of an etching solvent into the block boundary portion during etching when the electrodes are formed.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

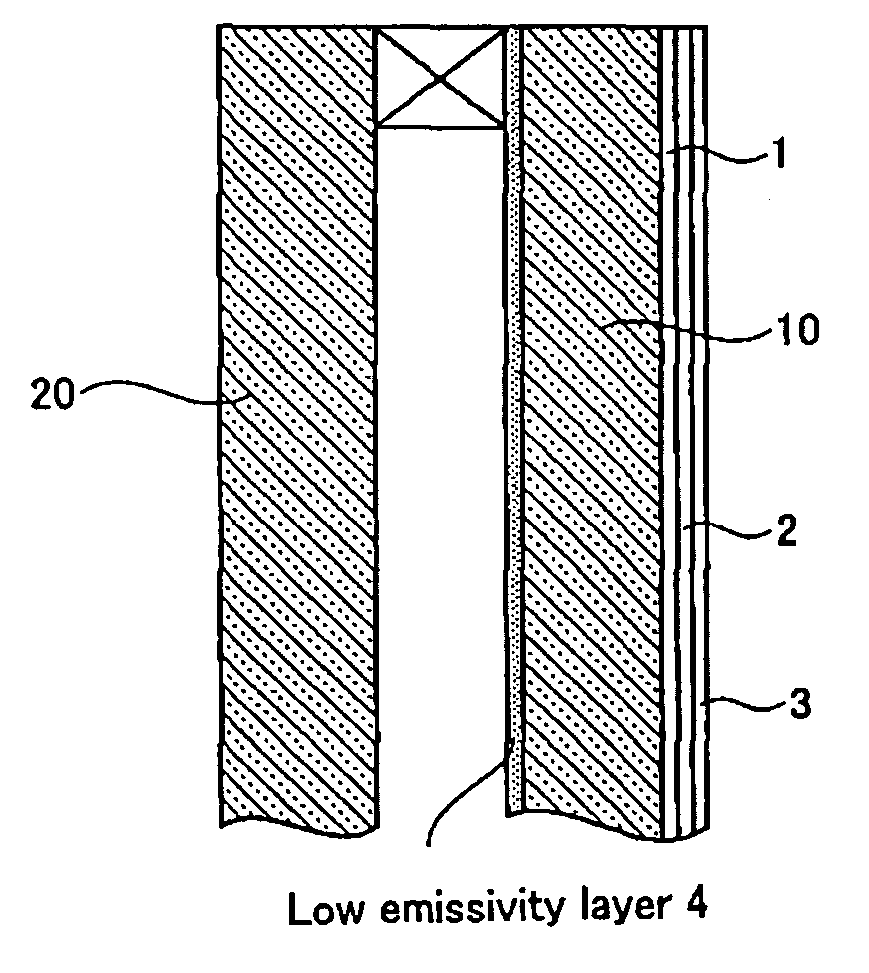

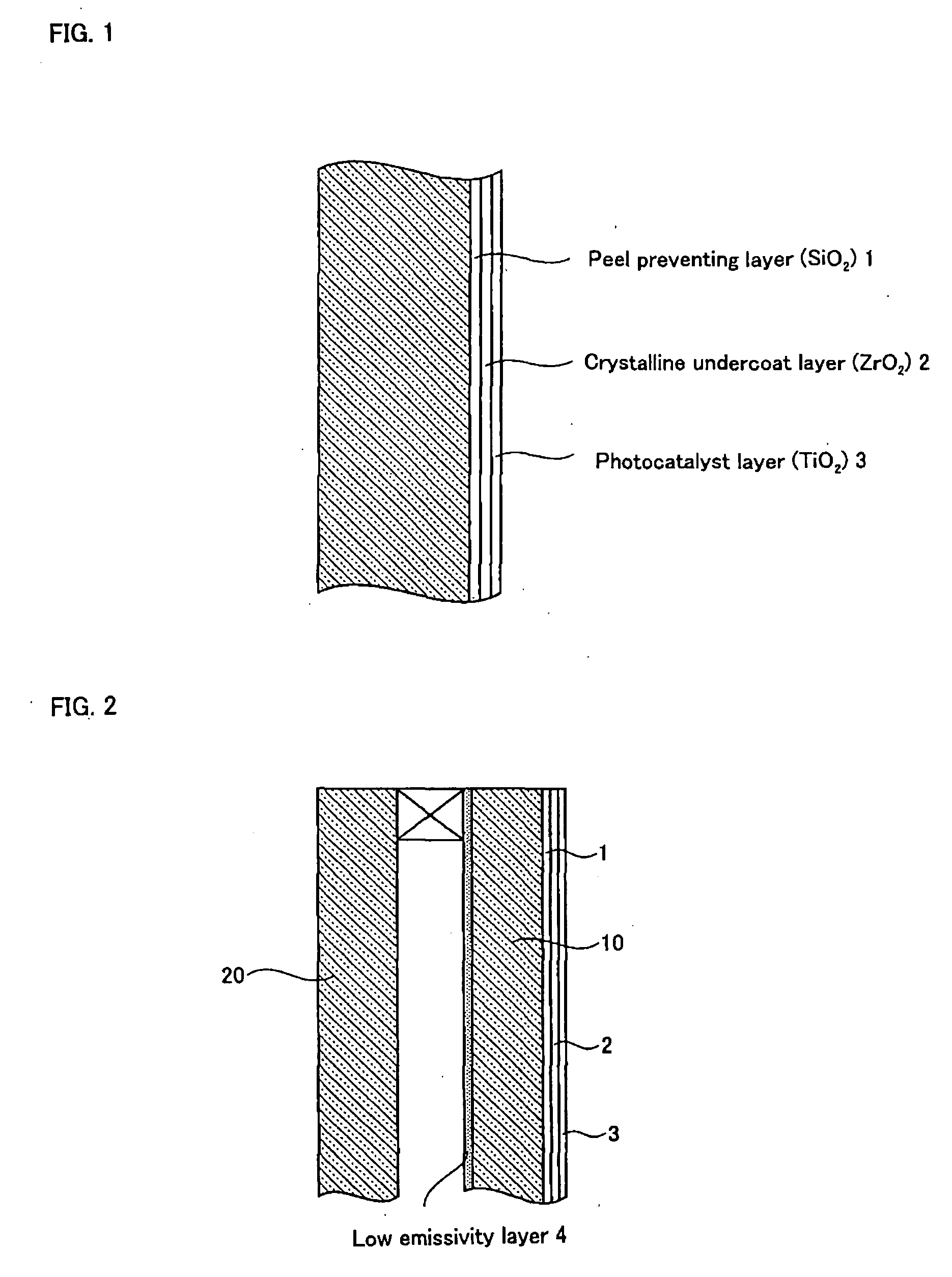

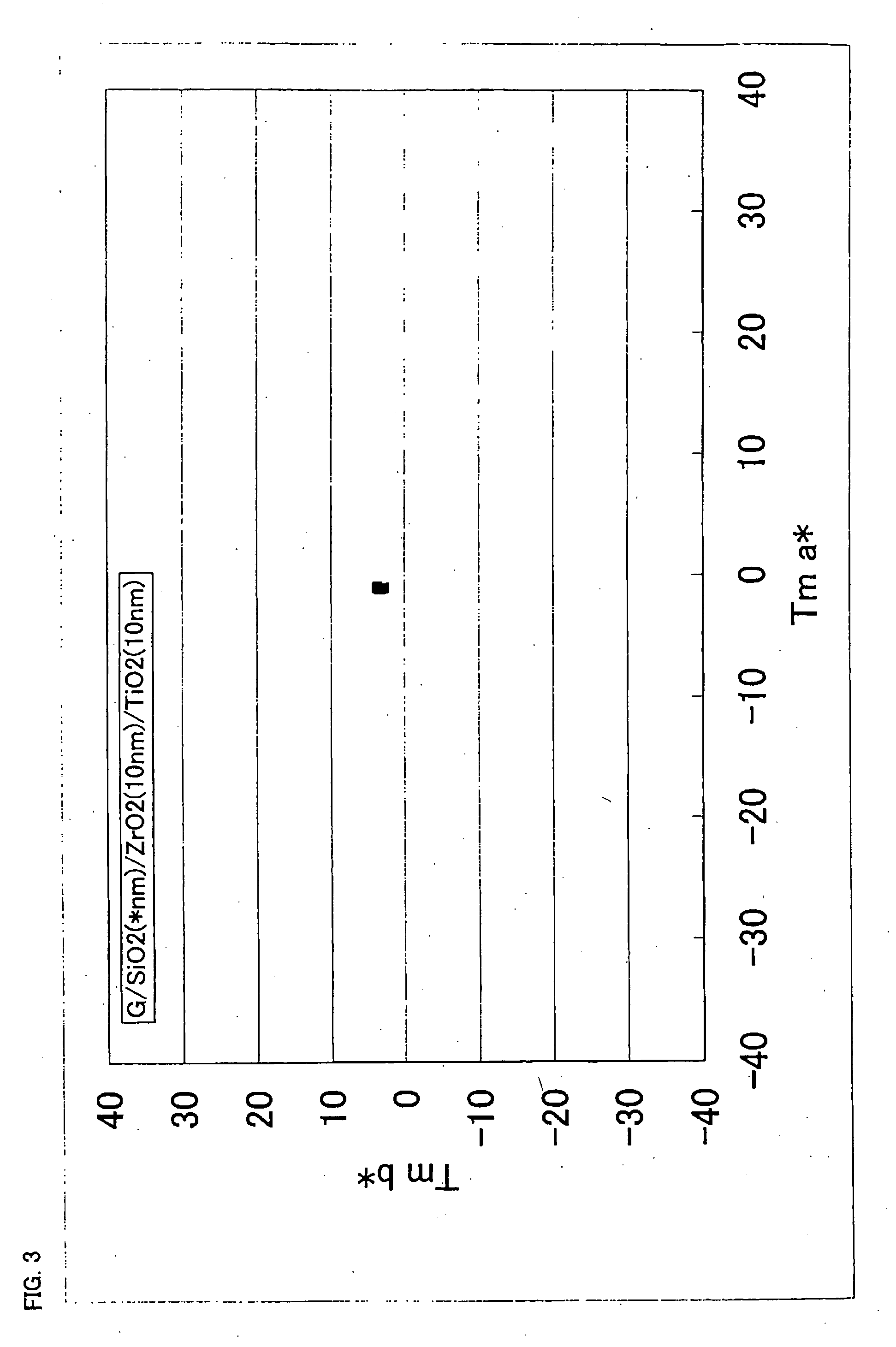

Member having photocatalytic activity and multilayered glass

InactiveUS20070031681A1High crystallinityPromote carrier generationDoors/windowsGlass/slag layered productsGlass sheetReflectivity

A member having high photocatalytic activity and multiple glass using the member are provided. A photocatalyst layer (TiO2) is formed on the surface of a substrate (glass sheet) through the intermediary of a crystalline undercoat layer (ZrO2), and no dead layer is substantially present between the photocatalyst layer and the undercoat layer. Also, provision of an amorphous layer between the substrate and the undercoat layer prevents peeling or defects between the photocatalyst layer and the substrate. In particular, by adjusting the thickness of each layer within a specific range, it is possible to obtain an article having a film configuration in which the optical feature of a reflection color, small variation of the reflectance, and a photocatalytic function are combined.

Owner:NIPPON SHEET GLASS CO LTD

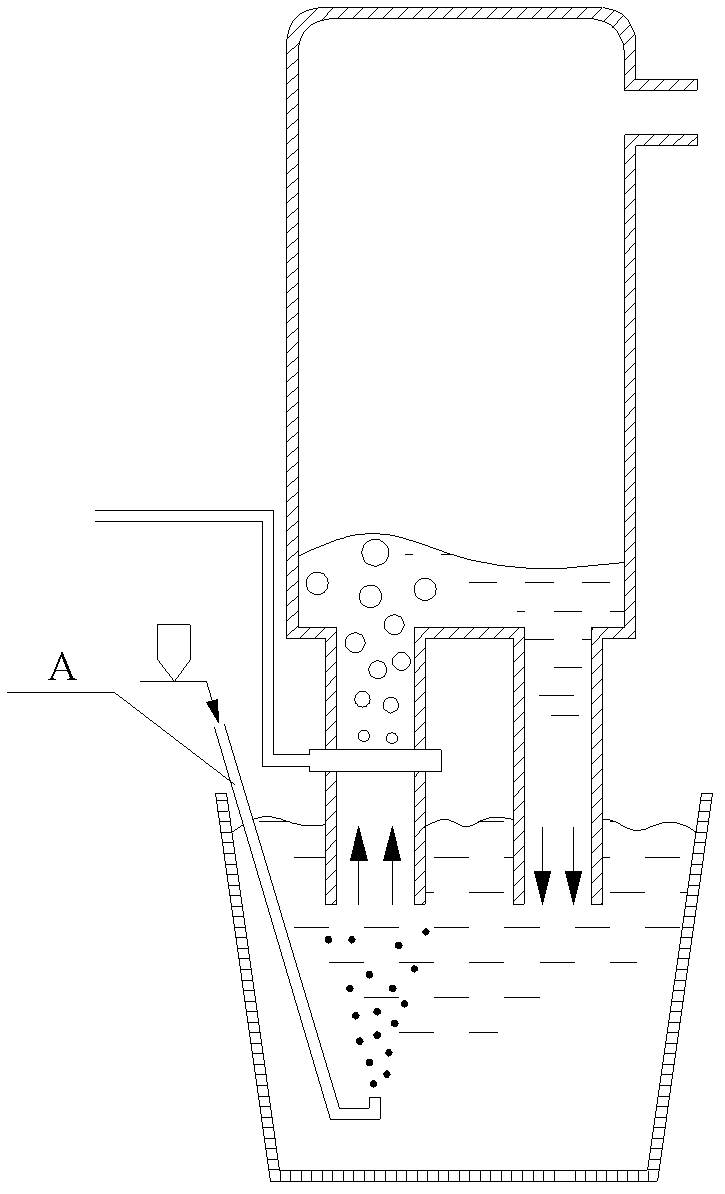

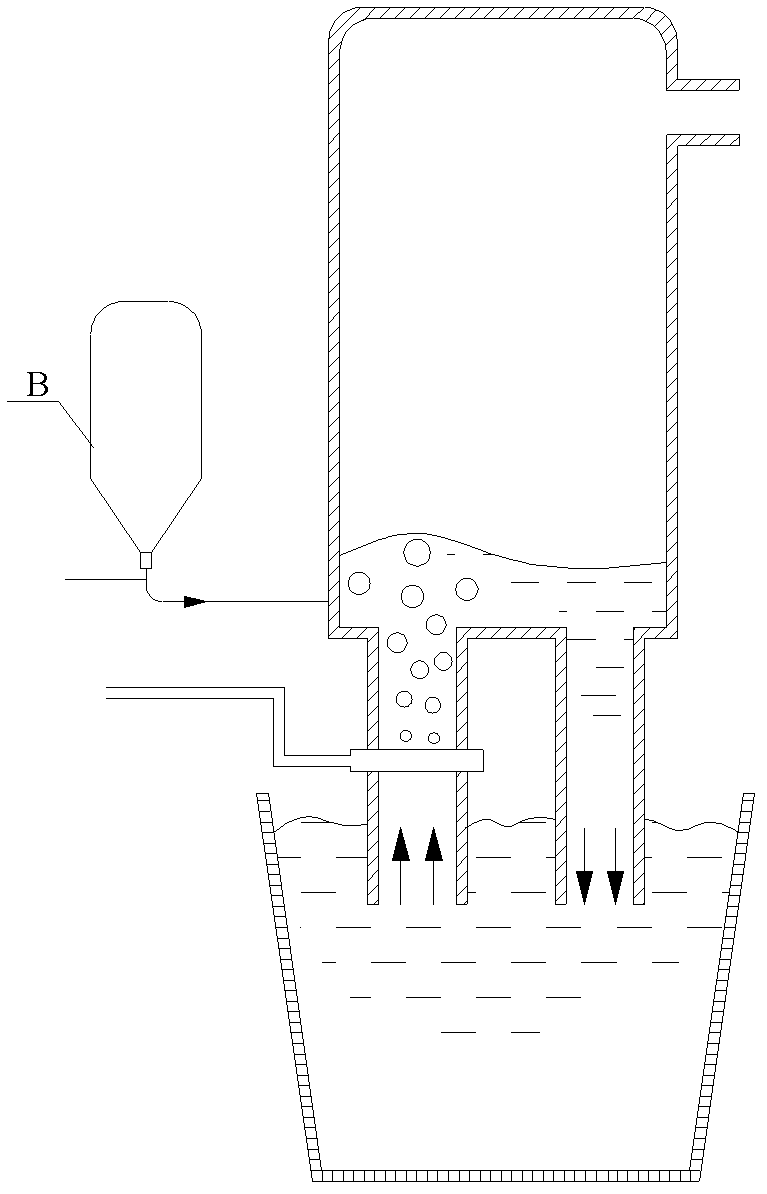

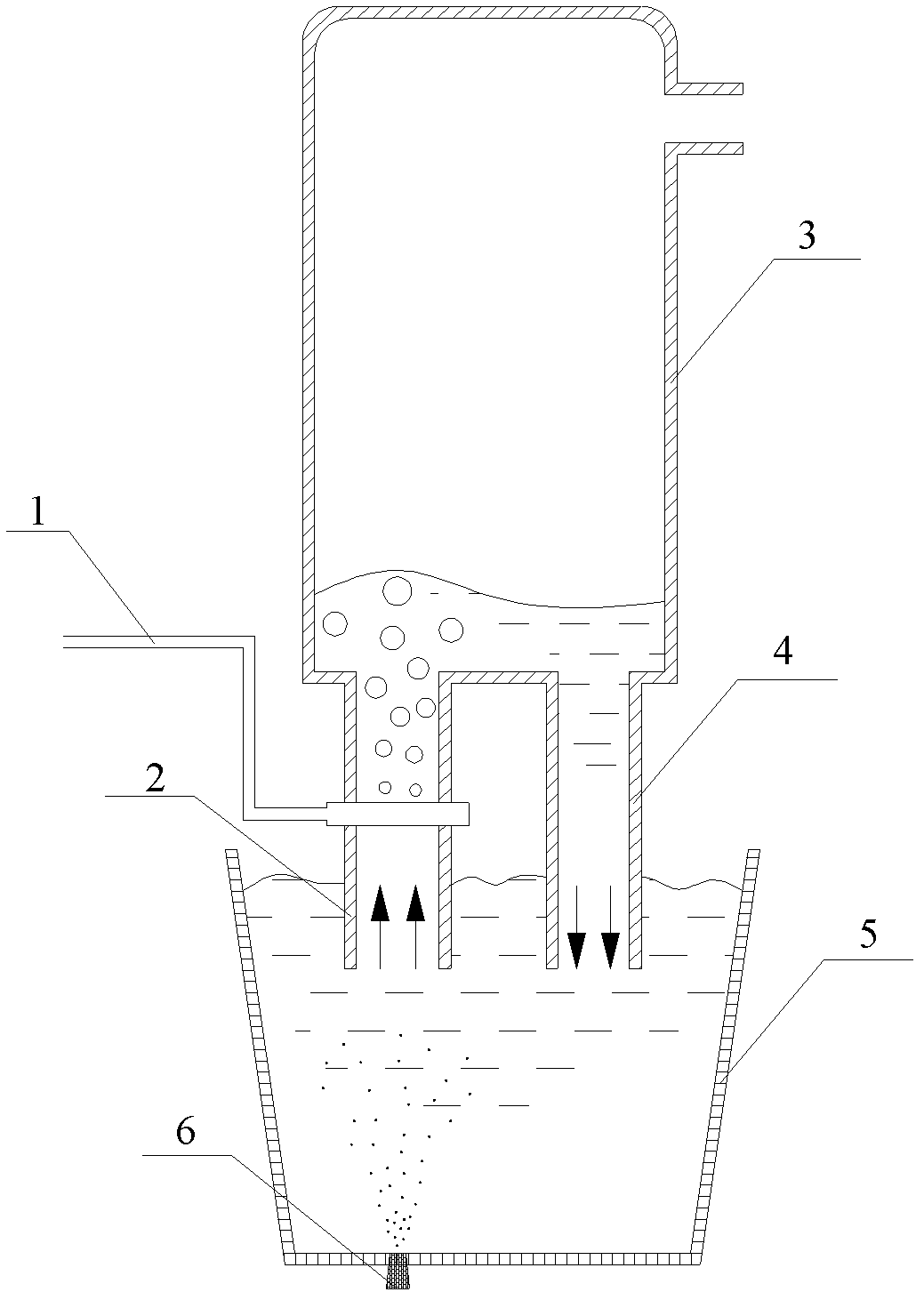

RH vacuum refining bottom blowing powder injection device

ActiveCN102560009ASolve easy blockageImprove product qualityCharge manipulationMetallurgyWater circulation

The invention relates to an RH vacuum refining bottom blowing powder injection device. The device comprises a driving gas system, a vacuum chamber, a steel ladle and a bottom blowing powder injection member, wherein the vacuum chamber is formed above the steel ladle; the driving gas system comprises a driving gas channel and an air compressor connected with the driving gas channel; an ascending pipe and a descending pipe are arranged at the bottom of the vacuum chamber and stretch into molten steel; the driving gas channel is communicated with the ascending pipe; the bottom blowing powder injection member comprises a powder injection element and a gas storage chamber; a steel sleeve is sleeved outside the powder injection element; the gas storage chamber is fixed below the powder injection element; a powder gas flow conveying pipe at the port of the gas storage chamber is connected with a powder injection system; a gap is formed on the powder injection element; one or two bottom blowing powder injection members are arranged at the bottom of the steel ladle; the distance between the bottom blowing powder injection member and the center of the bottom of the steel ladle is 0 to 0.9 time the radius of the bottom of the steel ladle; and the powder injection element penetrates through the bottom of the steel ladle. The device enhances a stirring effect and improves the quality of steel by combining vacuum refining, molten steel circular flow and bottom blowing powder injection refining.

Owner:NORTHEASTERN UNIV

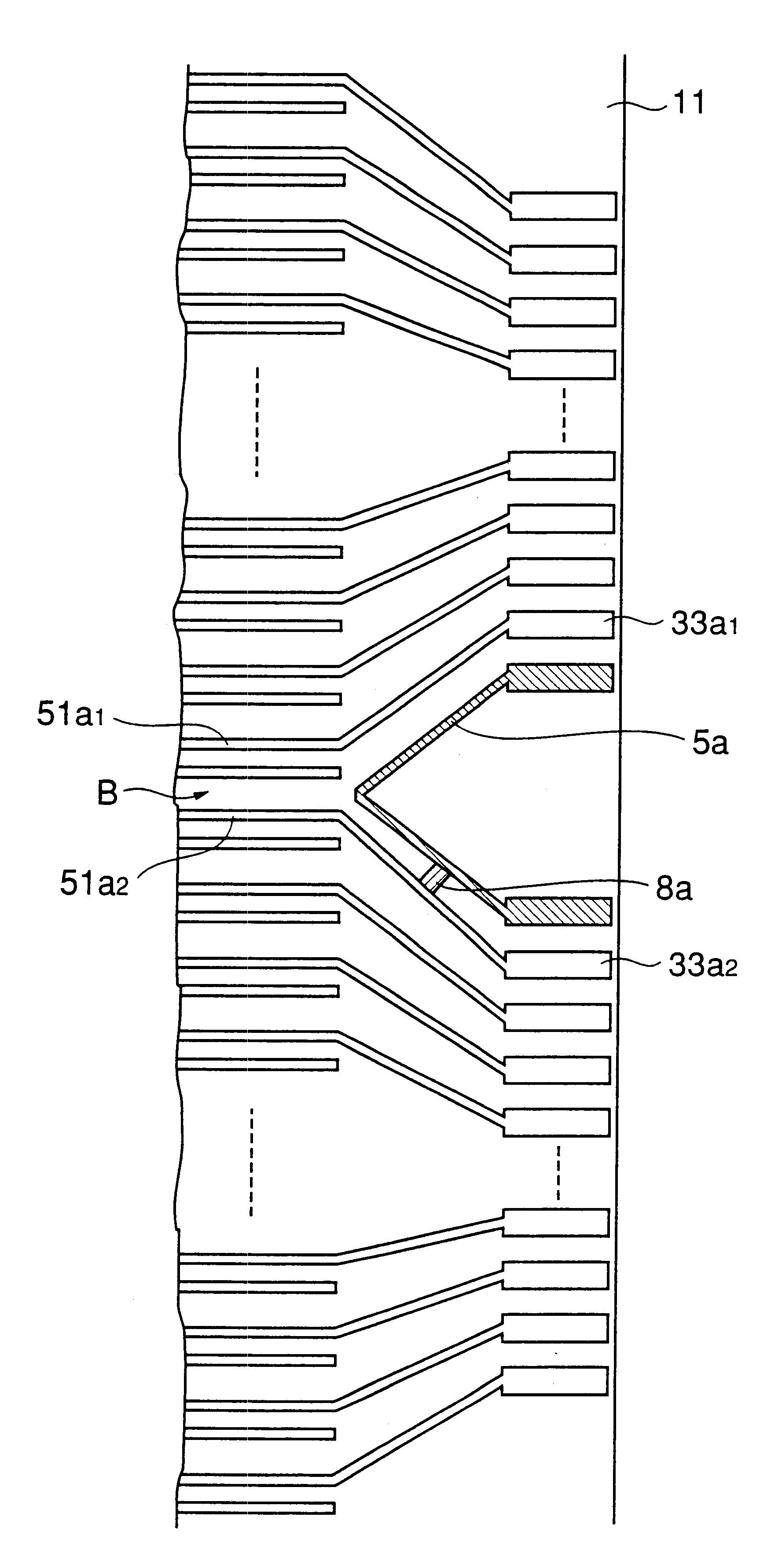

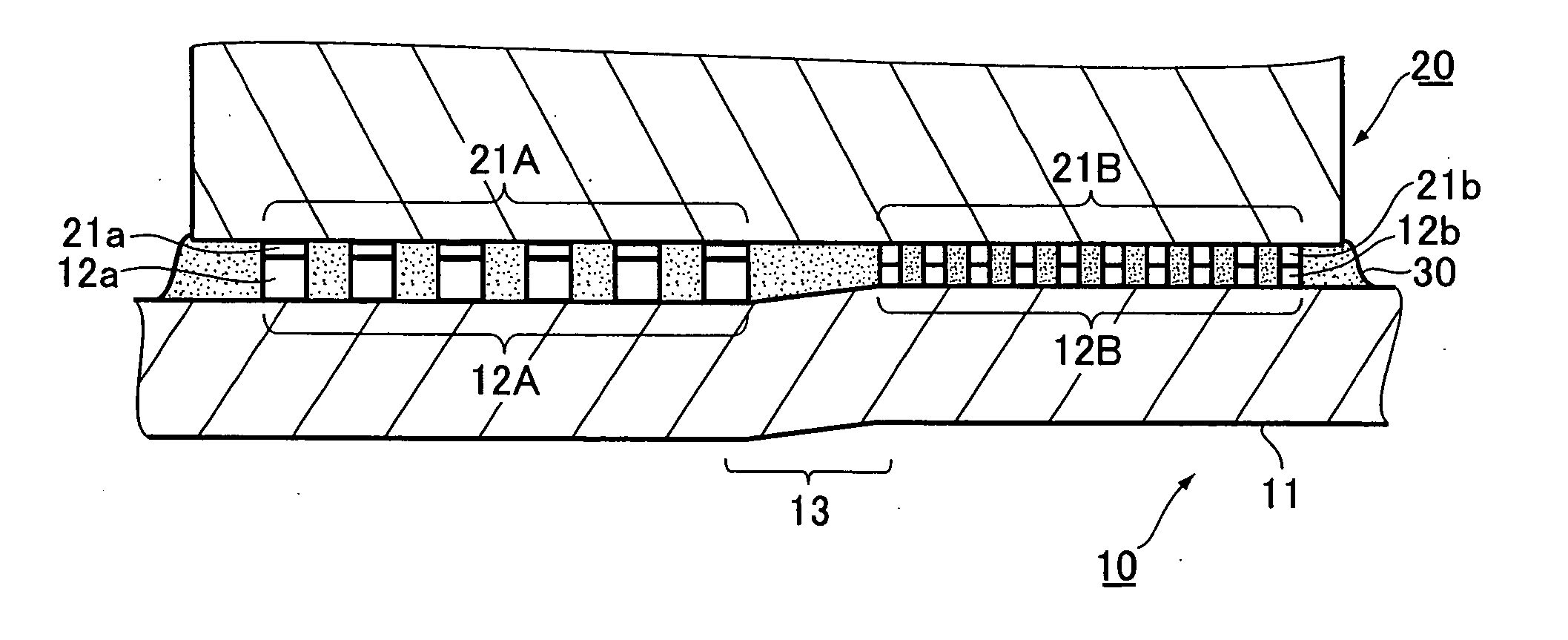

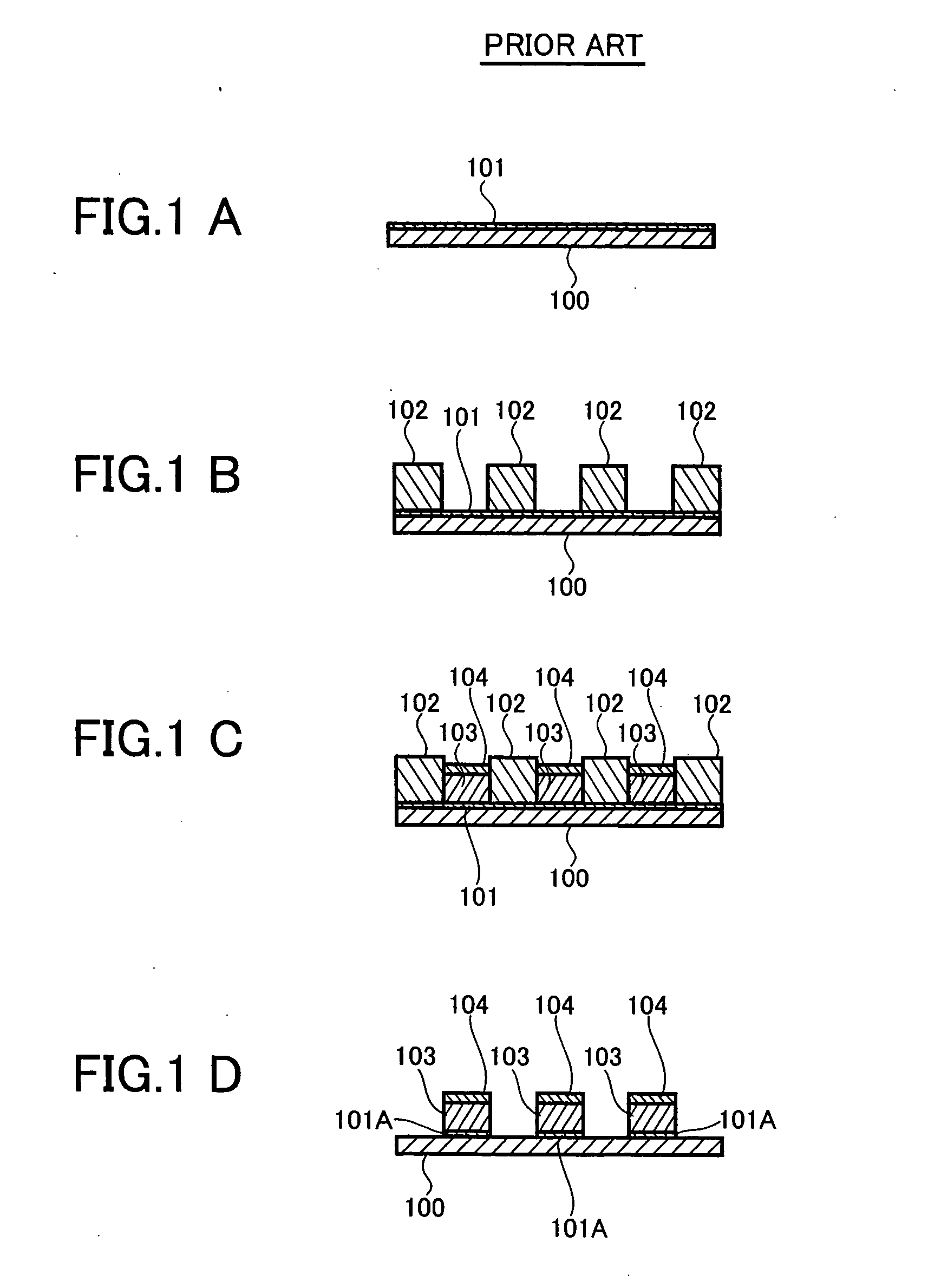

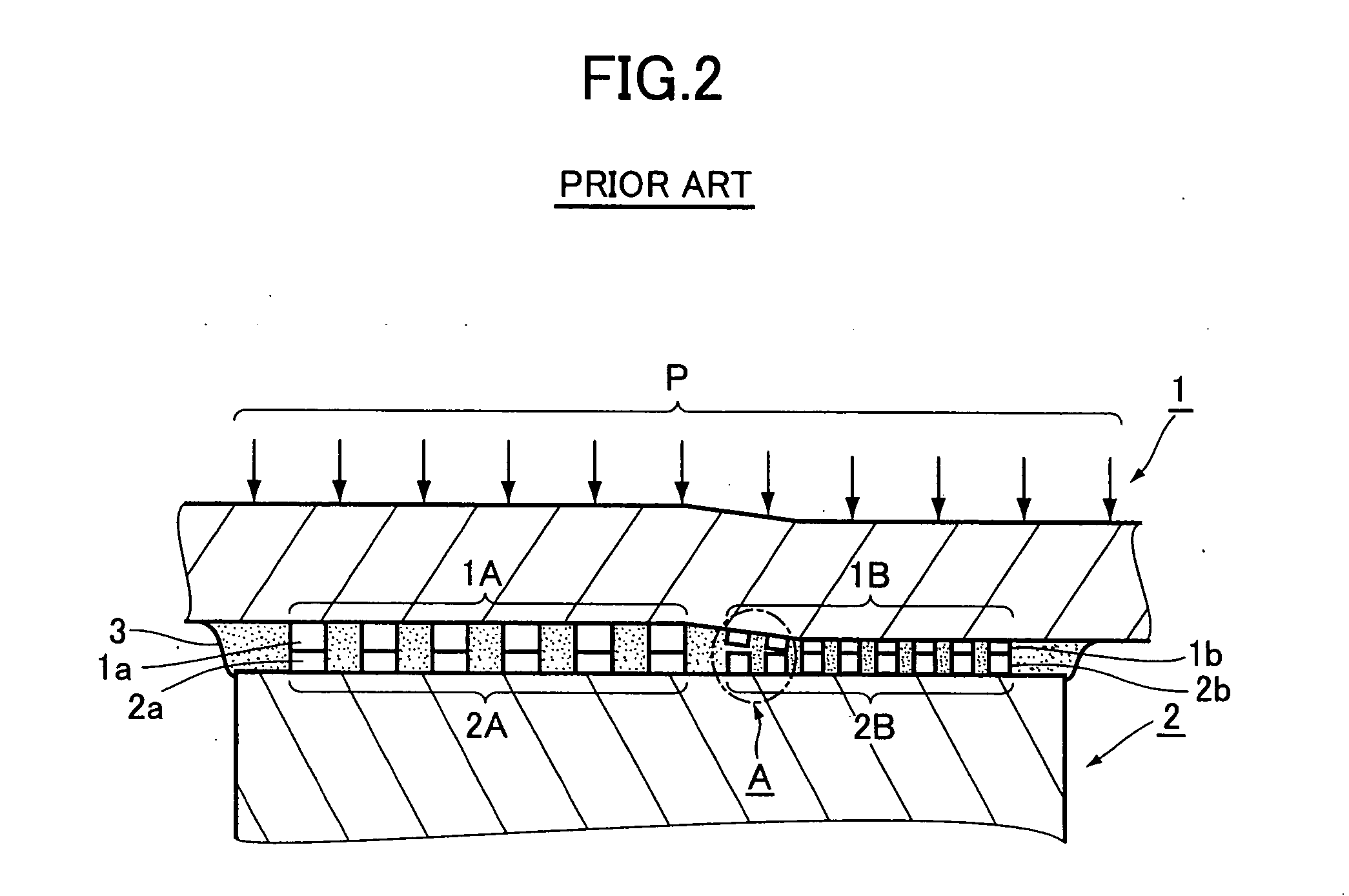

Flexible circuit board mounted with semiconductor chip and method for mounting semiconductor chip

InactiveUS20050039945A1Prevent unsuccessful bondingEliminate unevennessPrinted circuit assemblingFinal product manufactureFlexible circuitsSemiconductor chip

A flexible circuit board is provided to prevent unsuccessful interconnection between the wirings of the flexible circuit board and the output terminals of a semiconductor chip, the flexible circuit board having a plurality of sections of wirings of different sizes, each section including a pattern of wirings of the same size. The flexible circuit board has predetermined patterns of wirings on an insulating material base, and the wirings are electrically connected to the output terminals of a semiconductor chip. A pattern of the wirings of the same size forms a first wiring section, while another pattern of the wirings of the same size form a second wiring section. The flexible circuit board is provided with a pattern transition region between the neighboring wiring sections with wirings of different sizes to avoid unsuccessful interconnection which would be otherwise caused by the difference in size between the wirings.

Owner:TOHOKU PIONEER CORP

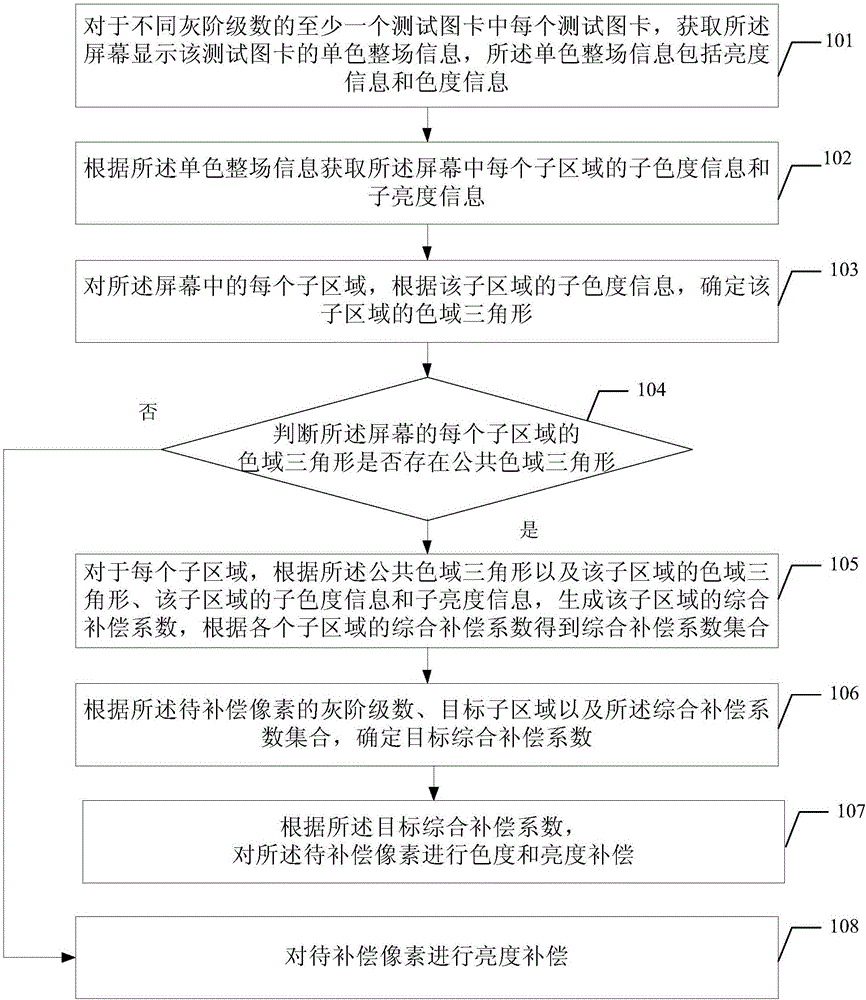

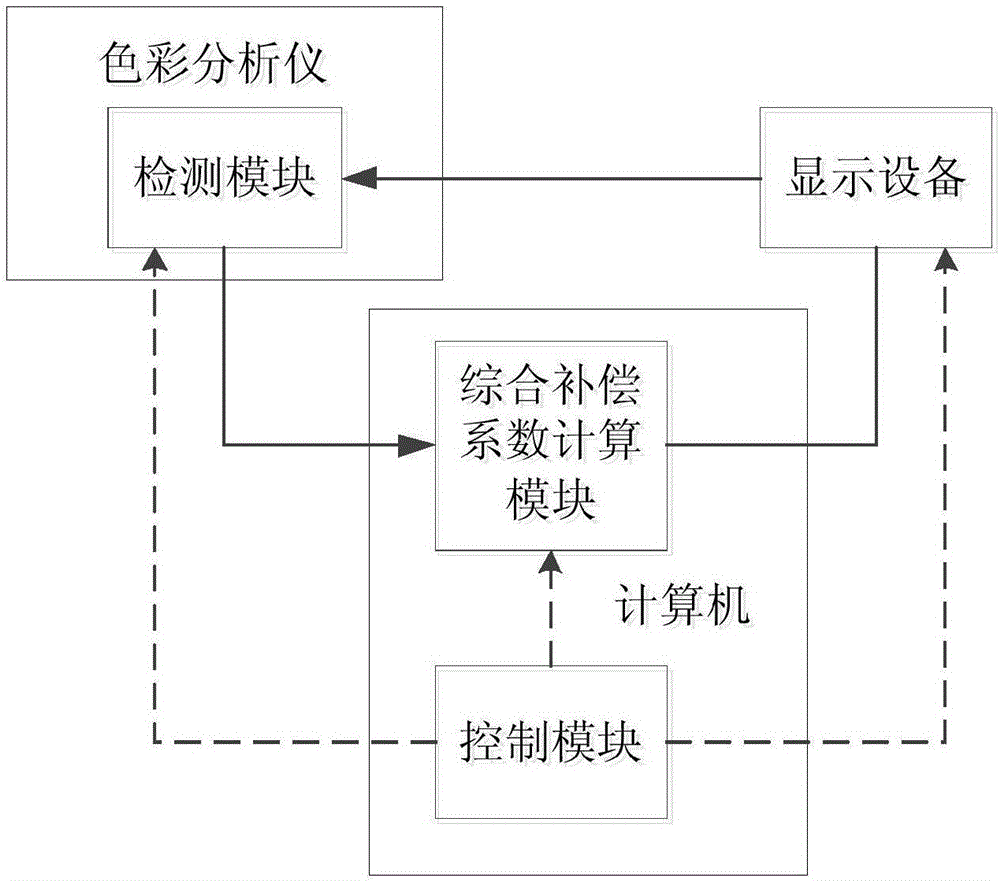

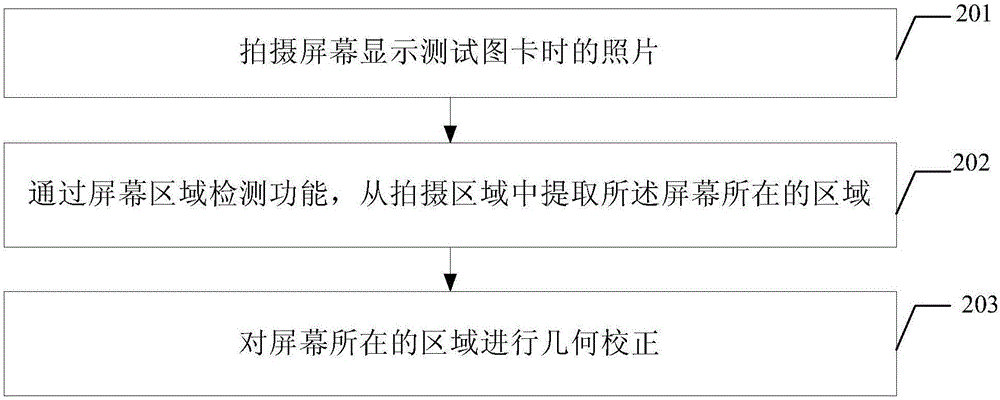

Method and device for eliminating screen non-uniformity

ActiveCN106782429AEliminate unevennessGuaranteed color gamut coverageBrightness and chrominance signal processing circuitsCathode-ray tube indicatorsPreconditionGamut

The invention provides a method and a device for eliminating screen non-uniformity. The method comprises the following steps: in accordance with test graphic cards of multiple gray-scale levels, generating a comprehensive compensating coefficient of each subarea under each gray-scale level, so that a comprehensive compensating coefficient set is obtained; and then, for a specific to-be-compensated pixel, determining a target comprehensive compensating coefficient in accordance with a target subarea of the gray-scale level and the comprehensive compensating coefficient set after the gray-scale level of the to-be-compensated pixel and the target subarea are determined, and compensating the to-be-compensated pixel in accordance with the target comprehensive compensating coefficient. Both chroma information and brightness information are taken into full consideration in a process of generating the comprehensive compensating coefficients; therefore, compensation to both chroma mura and brightness mura can be taken into consideration when the to-be-compensated pixel is compensated by virtue of the comprehensive compensating coefficients, so that color gamut coverage is guaranteed to the greatest extent, and the chroma mura and brightness mura are eliminated under the precondition of guaranteeing the color gamut coverage.

Owner:上海顺久电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com