Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Stable atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

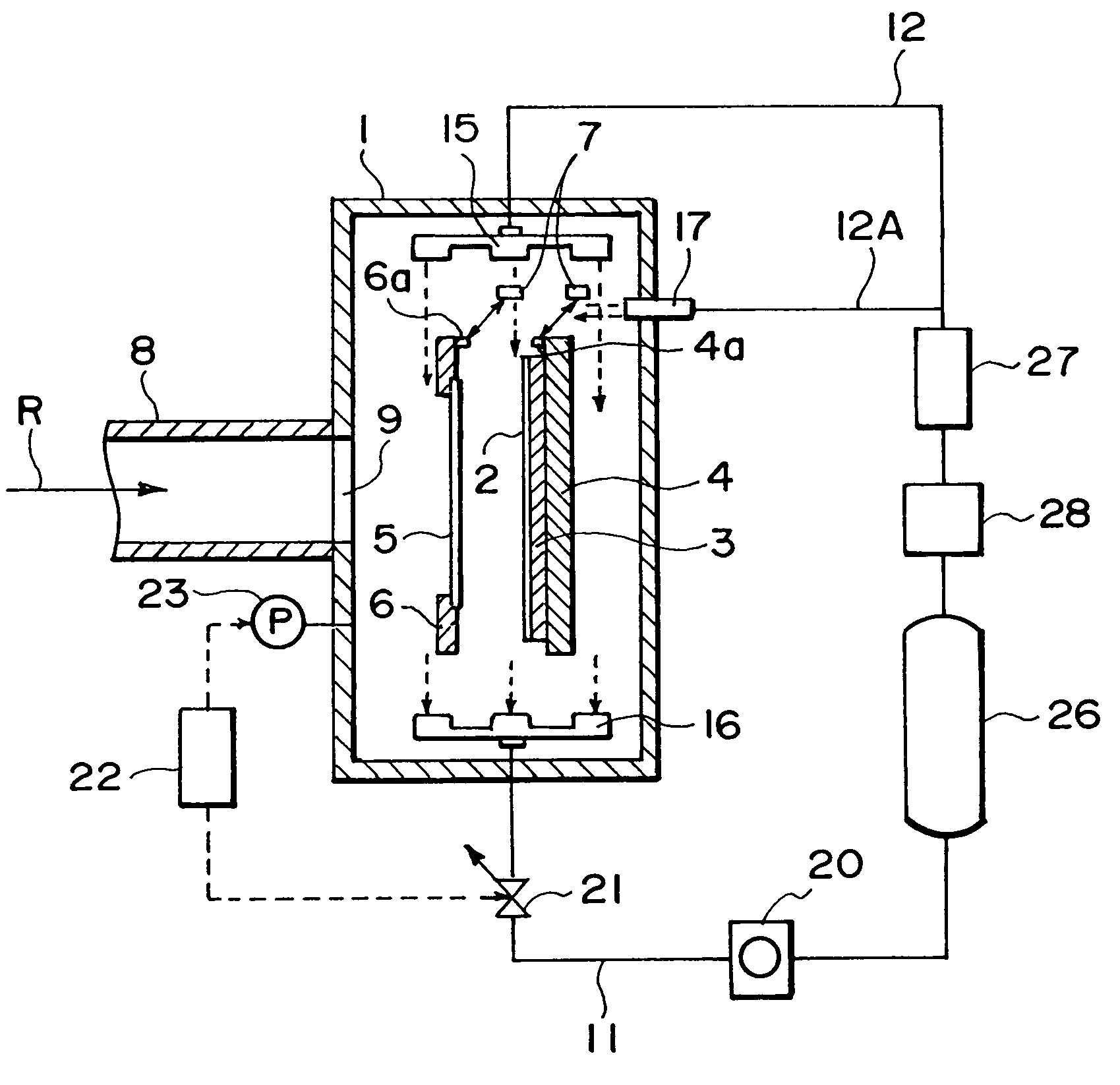

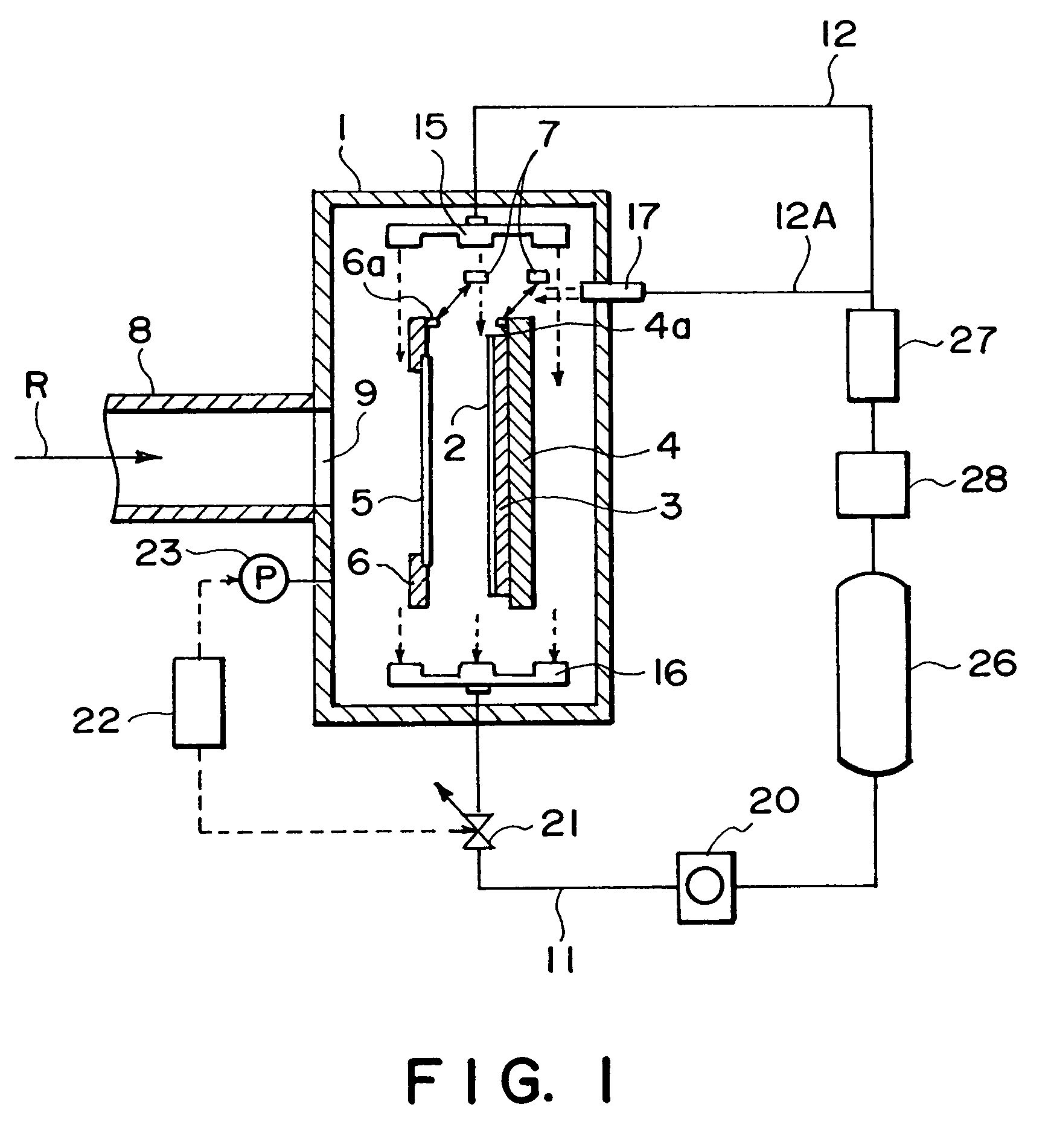

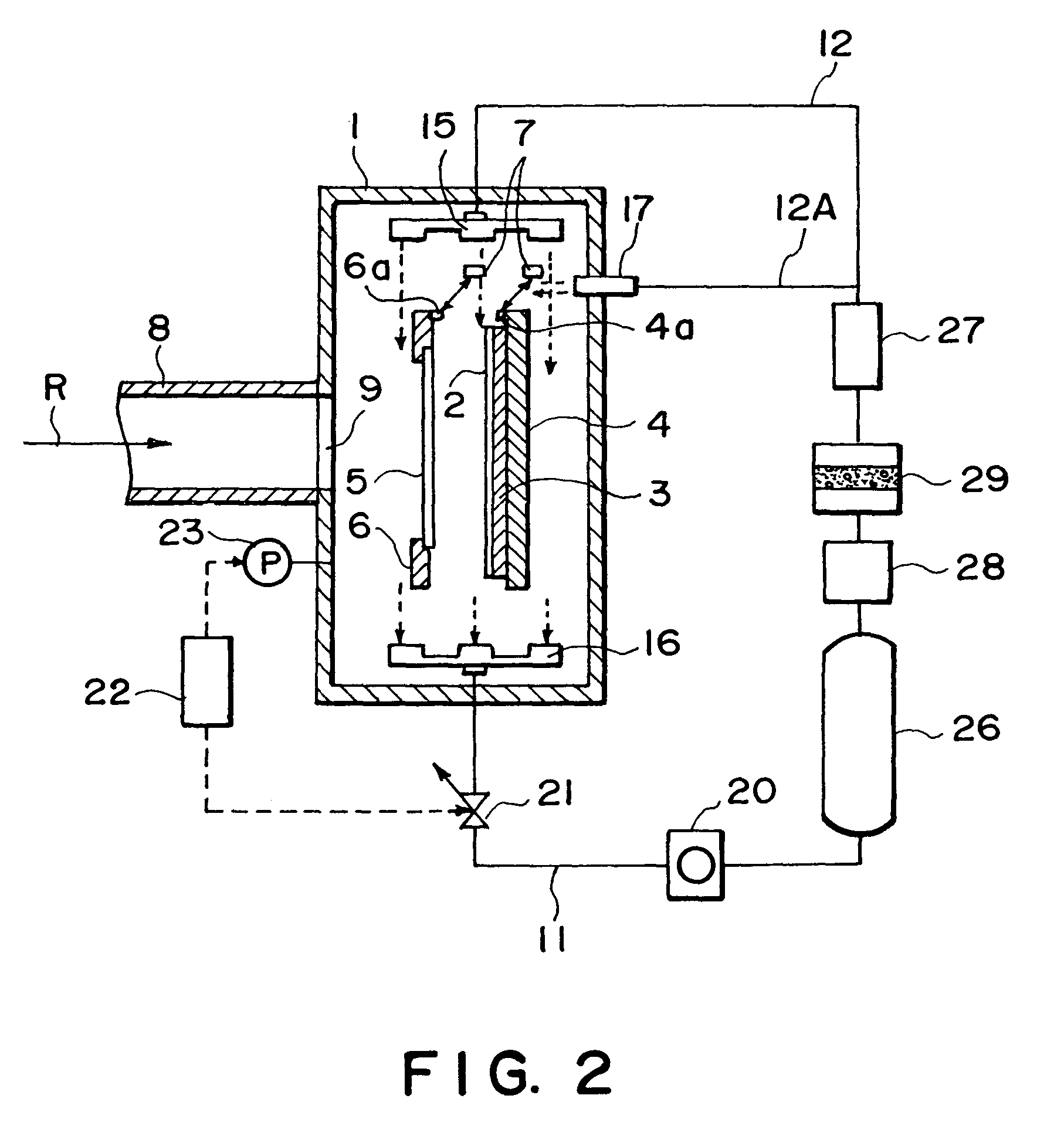

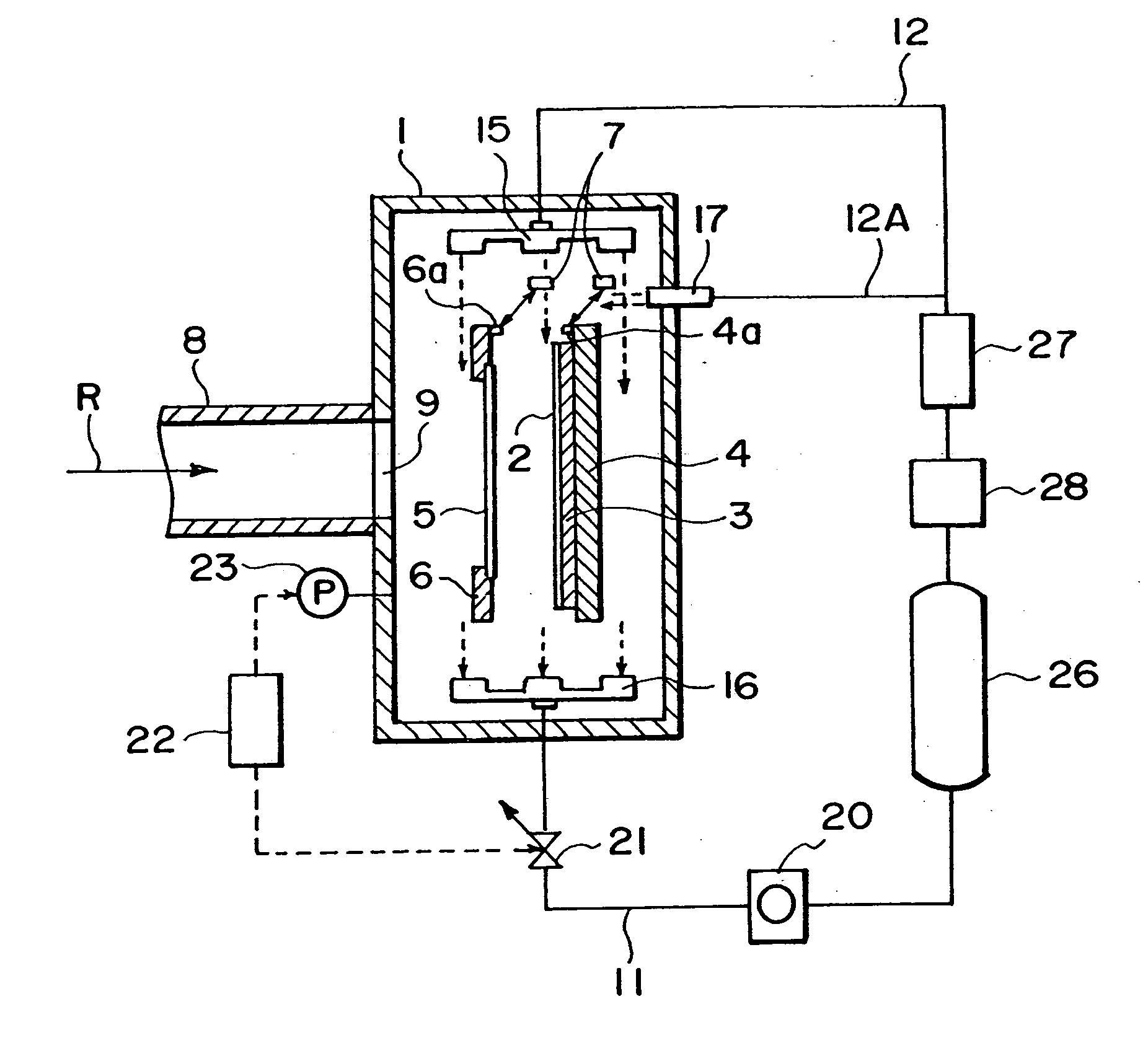

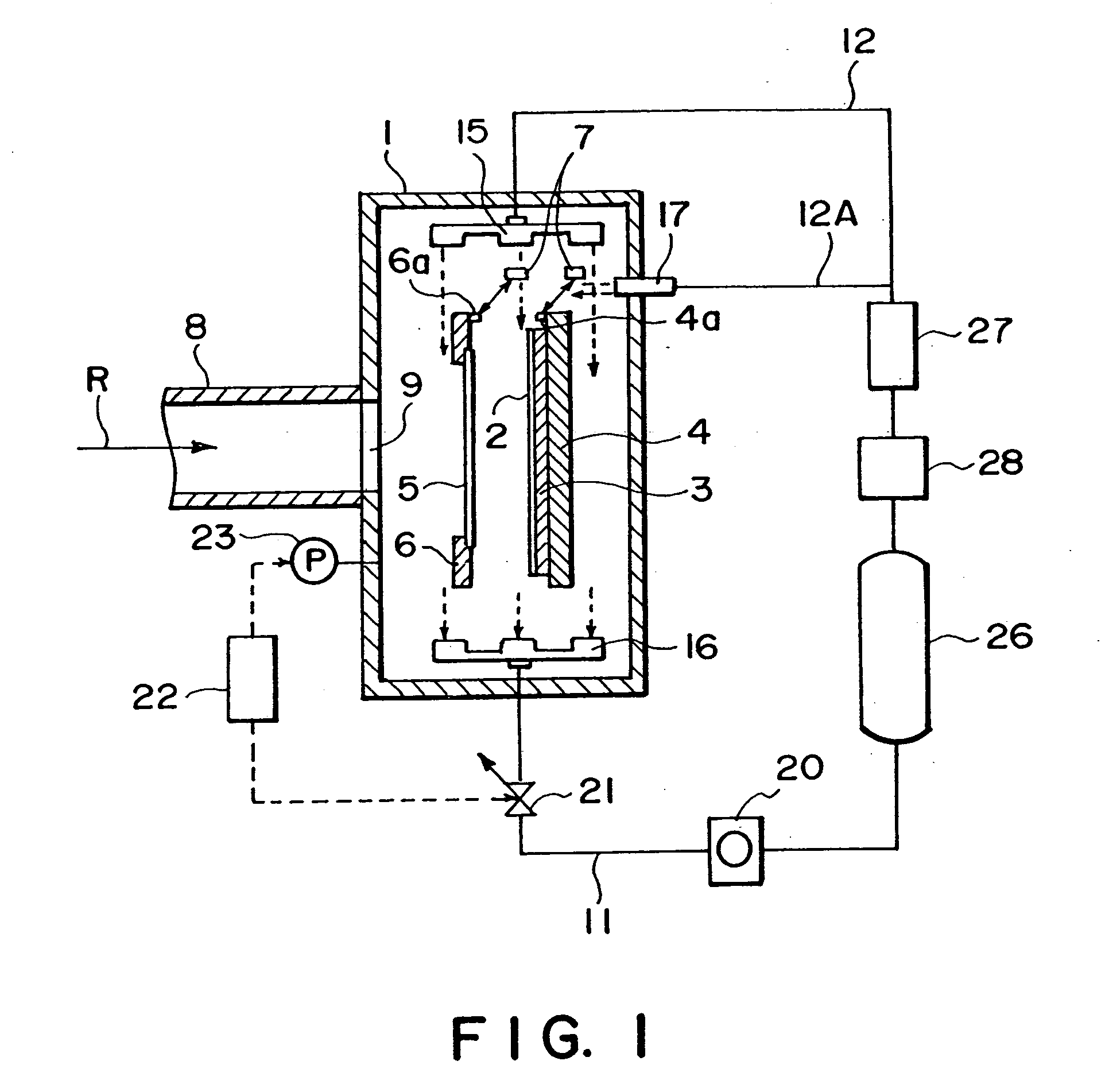

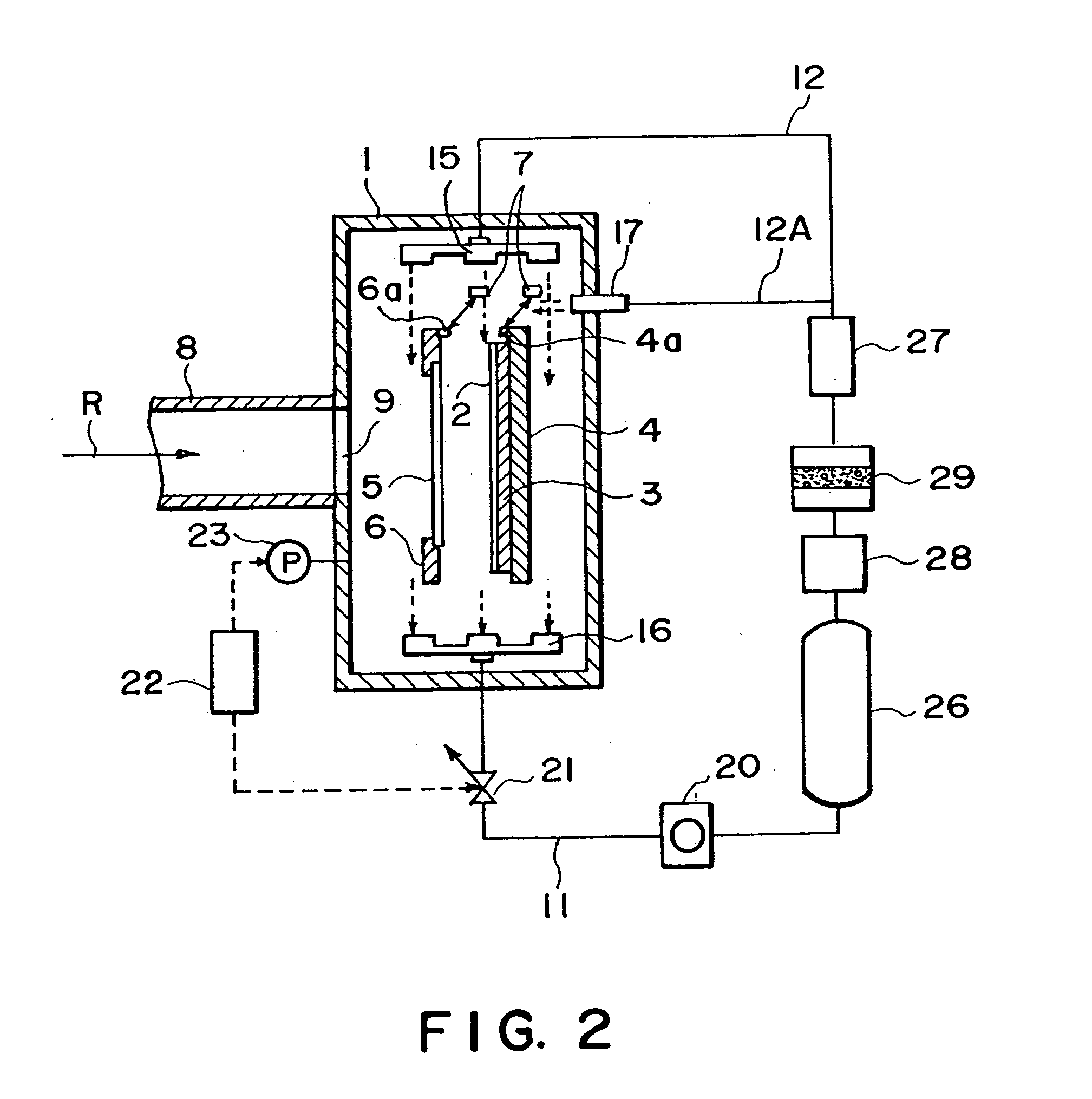

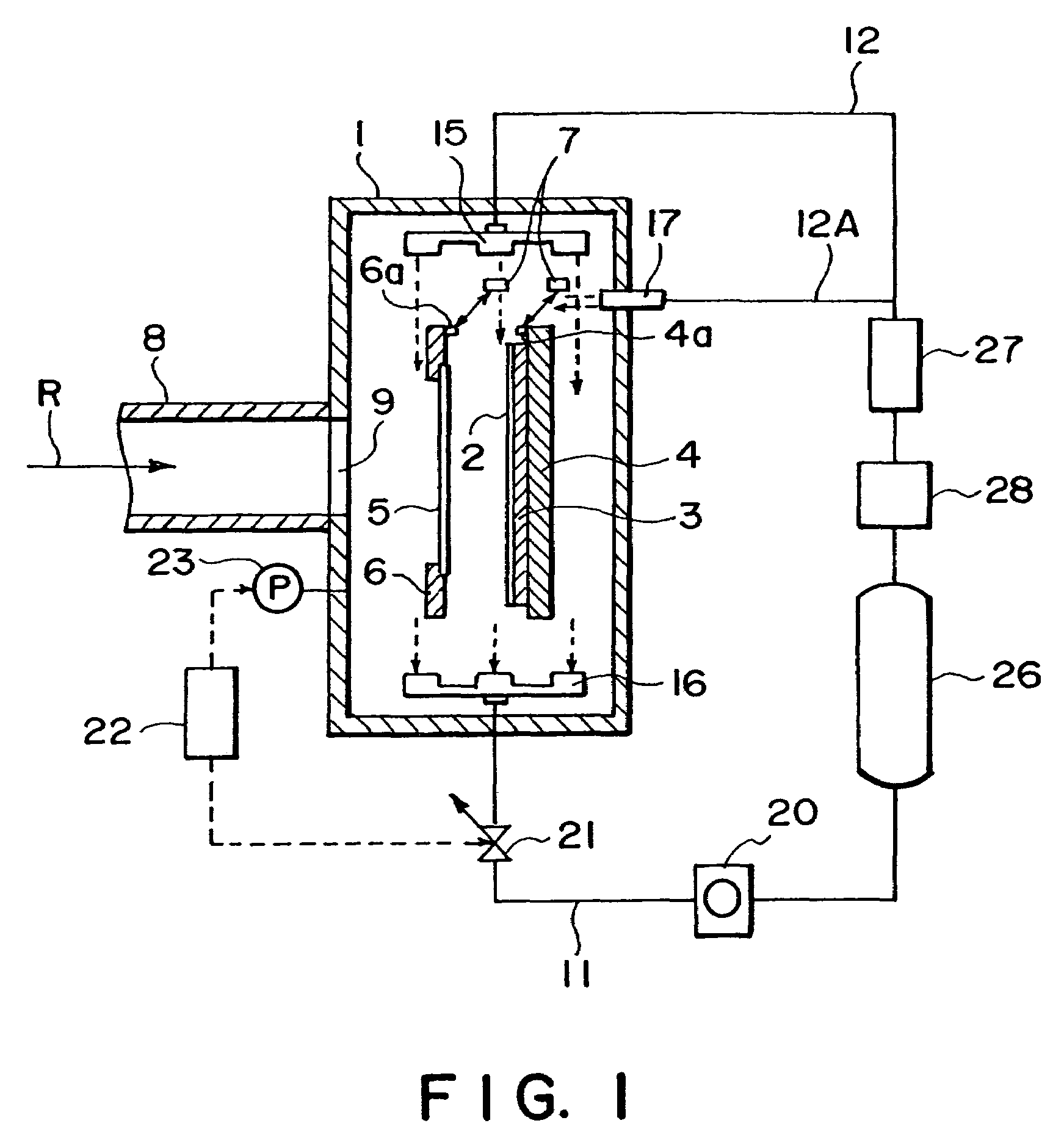

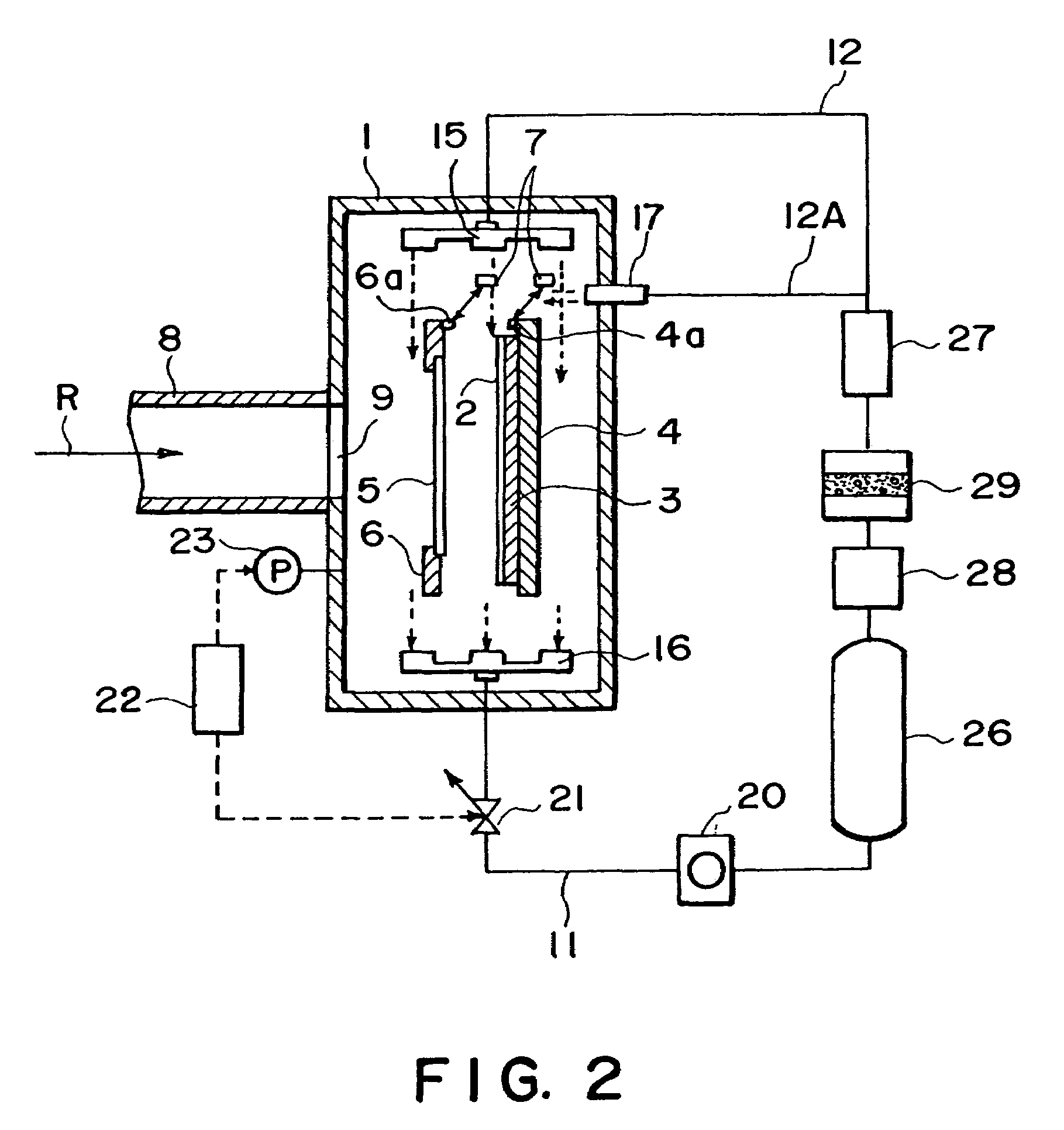

Processing apparatus, measuring apparatus, and device manufacturing method

InactiveUS6984362B2Eliminate unevennessStable atmosphereExhaust apparatusTemperatue controlInternal pressureControl system

A processing apparatus includes a sealed vacuum chamber which contains a processing portion; a pressure controlling system which keeps the internal pressure of the sealed vacuum chamber constant at a predetermined level by exhausting the ambient gas in the sealed vacuum chamber; and an ambient gas recirculating system which recirculates the ambient gas exhausted from the sealed vacuum chamber back into the sealed vacuum chamber; wherein the ambient as recirculated by the ambient gas recirculating system is blown into the sealed vacuum chamber so that a gas flow is generated in a predetermined direction along the processing portion.

Owner:CANON KK

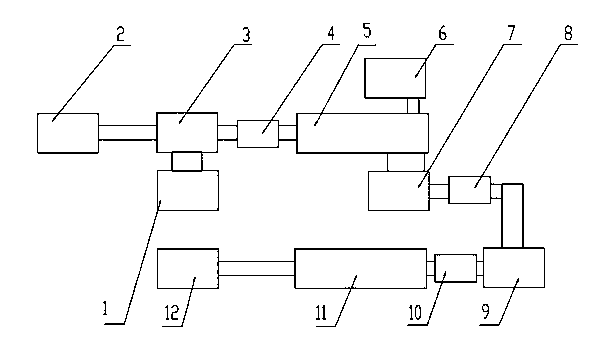

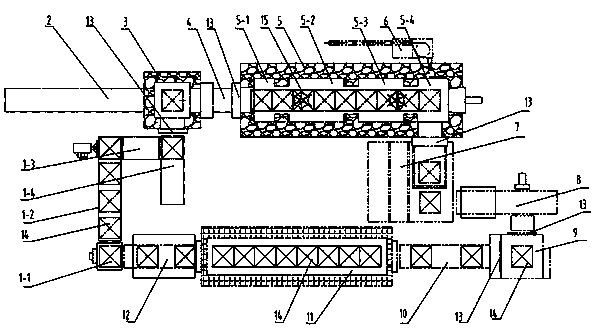

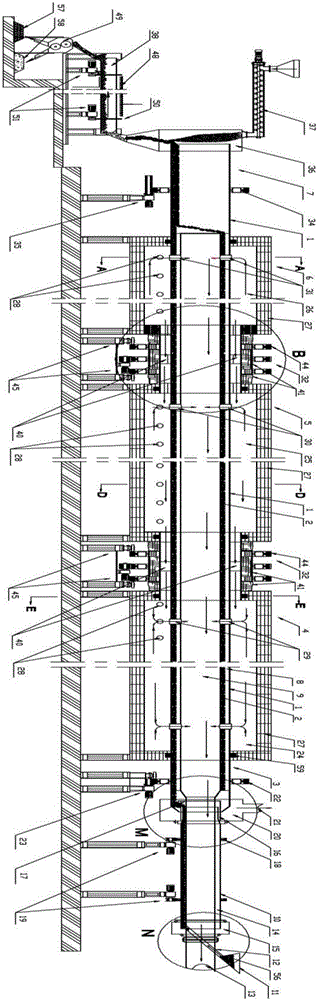

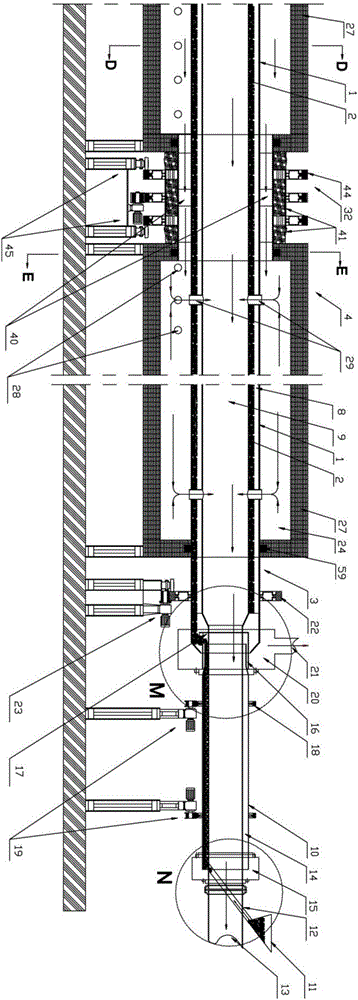

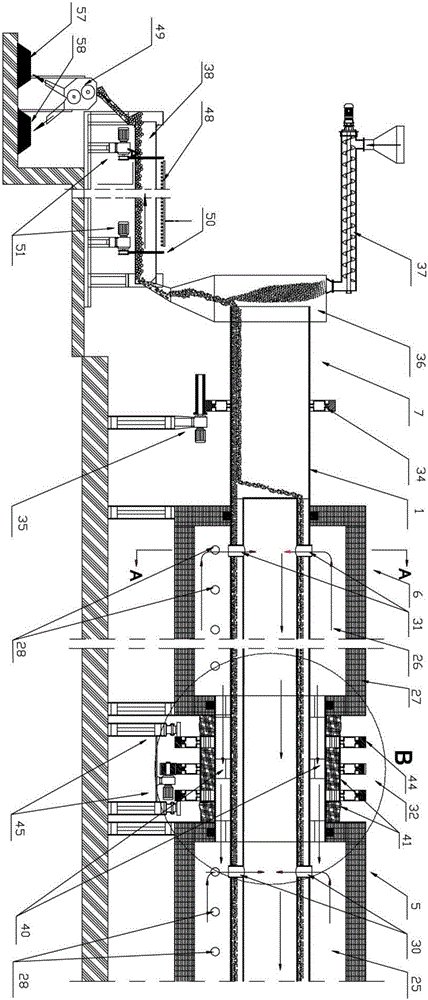

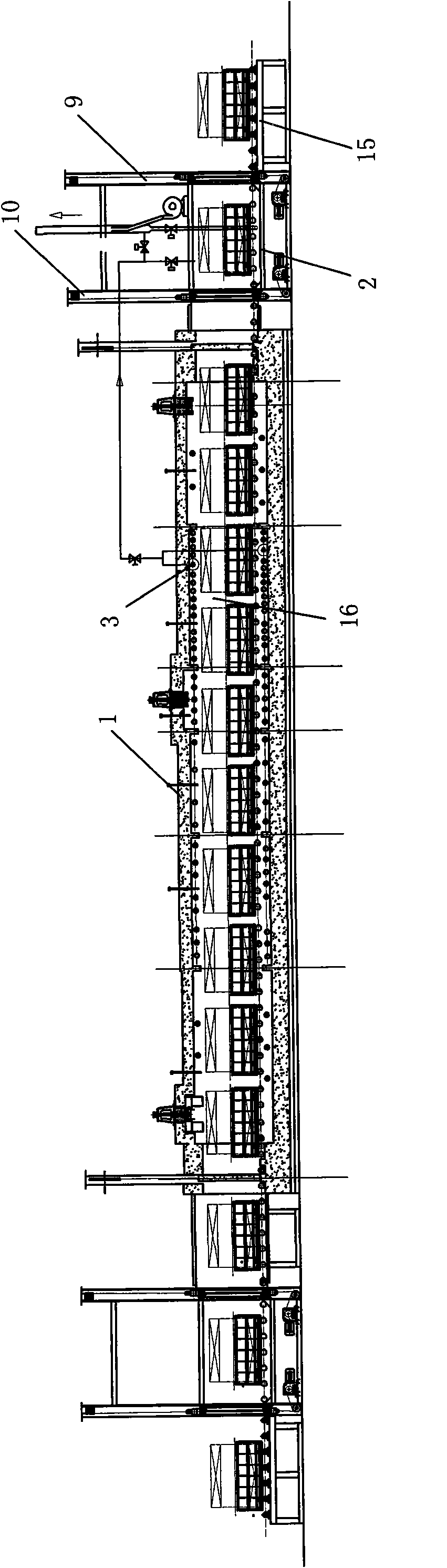

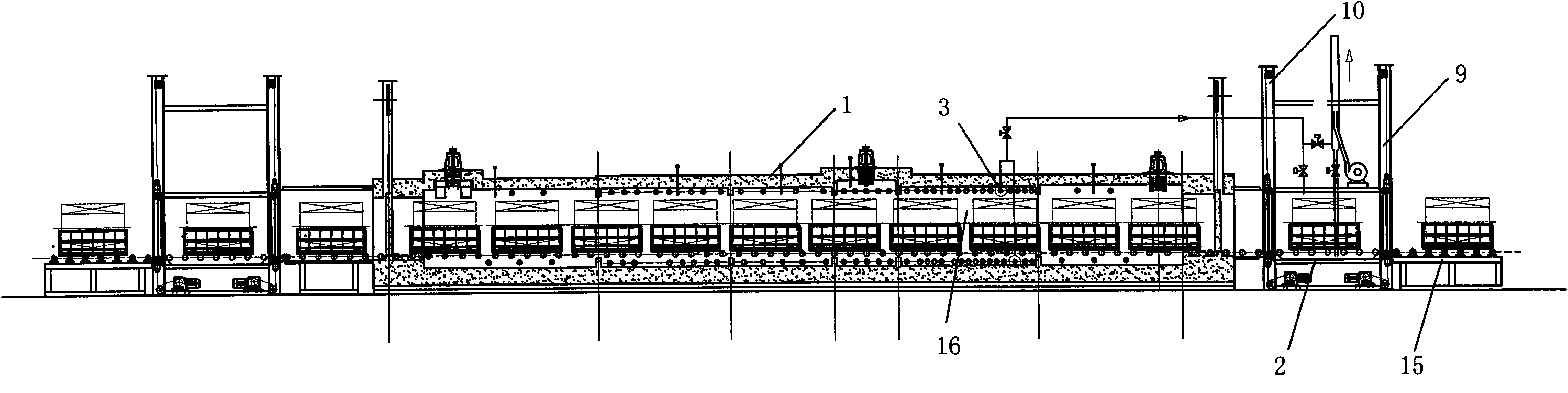

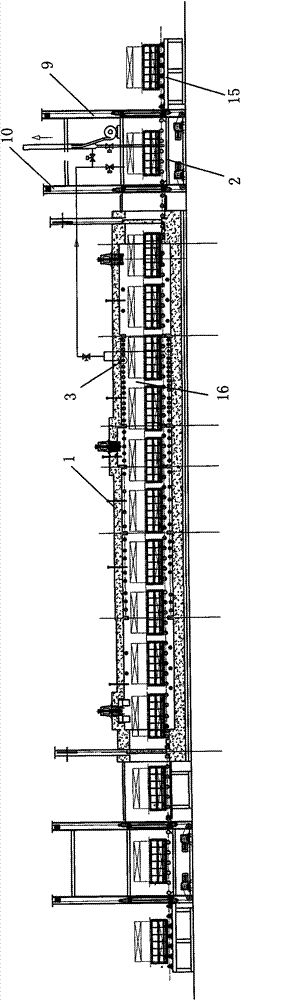

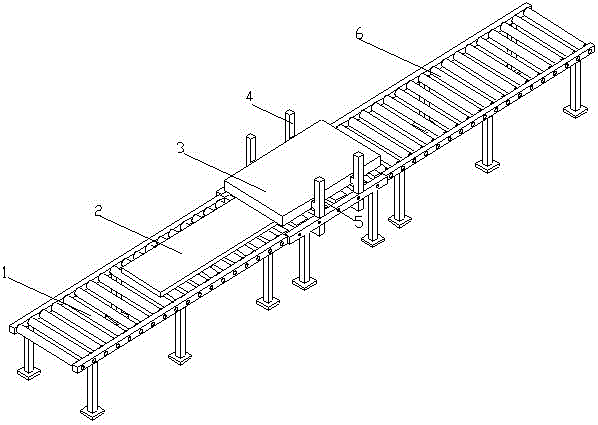

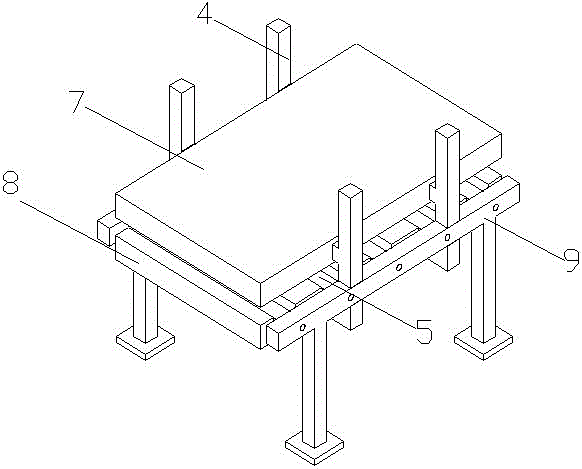

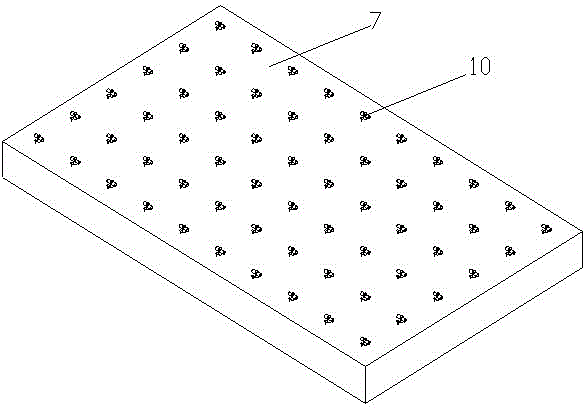

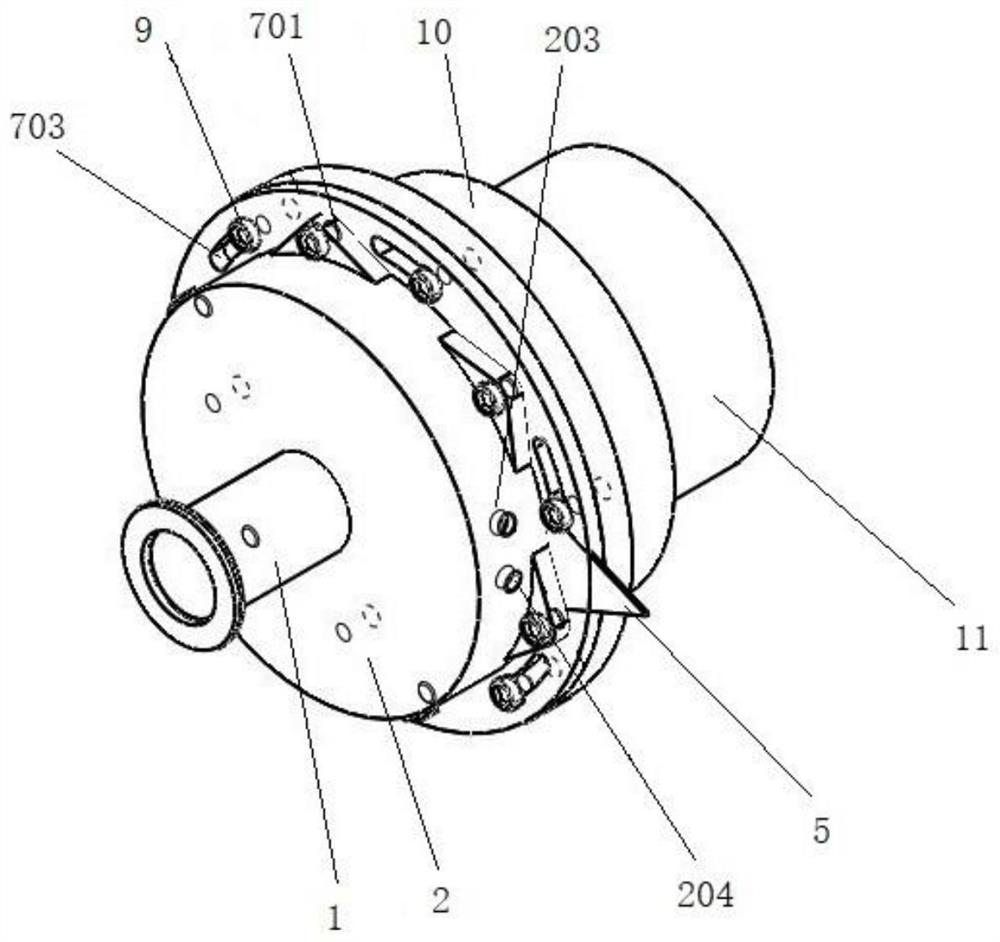

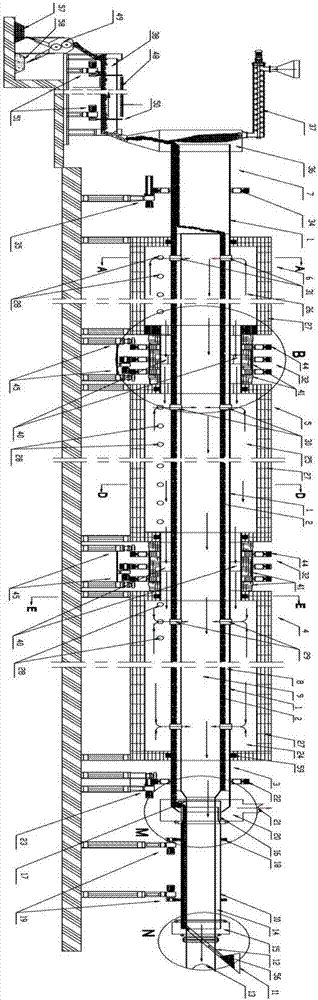

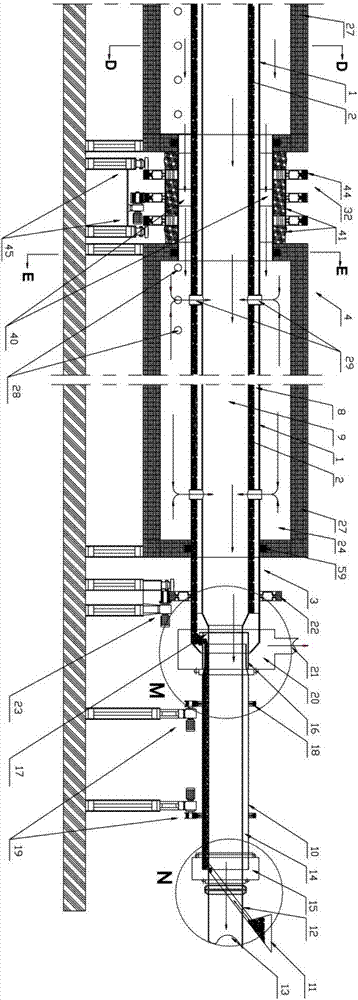

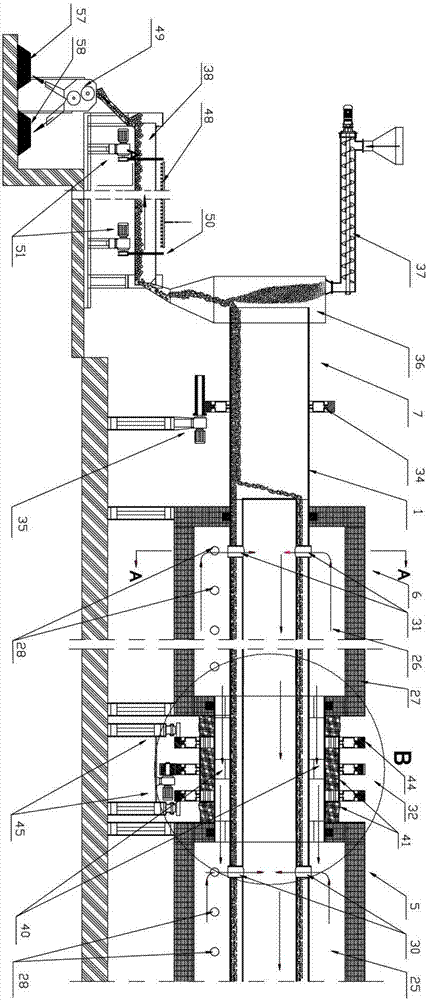

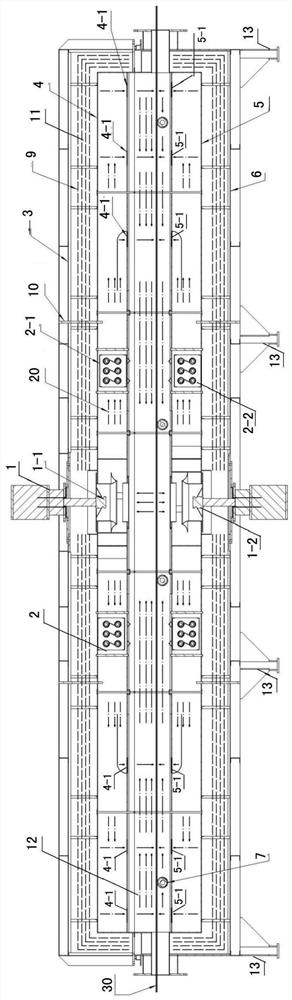

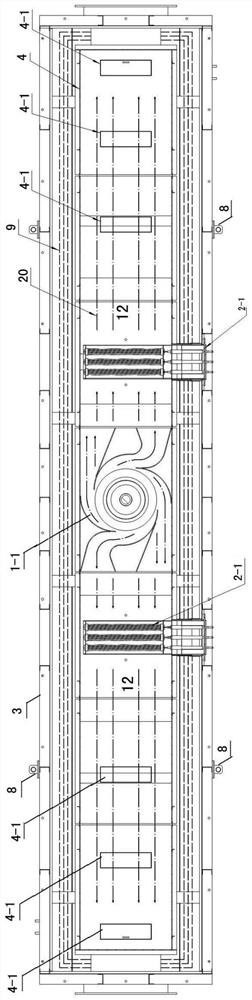

Automatic production line for saw blade heat treatment

InactiveCN103146902AGuarantee the environmentGuaranteed atmosphereFurnace typesHeat treatment furnacesProduction lineEngineering

The invention discloses an automatic production line for saw blade heat treatment, and belongs to the technical field of work piece heat treatment. The automatic production line for the saw blade heat treatment is characterized by comprising a feed mechanism, a feeding tray stepping advancing mechanism, a heat preserving furnace, a carbon-nitrogen furnace, a quenching mechanism, a cleaning machine, a tempering furnace and feeding tray conveying mechanisms, wherein the feed mechanism, the feeding tray stepping advancing mechanism, the heat preserving furnace, the carbon-nitrogen furnace, the quenching mechanism, the cleaning machine, the tempering furnace are sequentially arranged according to a manufacturing process order, and the feeding tray conveying mechanisms are arranged between each two adjacent devices. The feeding tray conveying mechanisms comprise a transition cylinder, a carbon-nitrogen furnace discharging advancing device, a quenching discharging advancing device, a tempering furnace feeding advancing device and a tempering furnace discharging advancing device, wherein the transition cylinder is arranged between the heat preserving furnace and the carbon-nitrogen furnace, the carbon-nitrogen furnace discharging advancing device is arranged on one side of the carbon-nitrogen furnace, the quenching discharging advancing device is arranged between the quenching mechanism and the cleaning machine, the tempering furnace feeding advancing device is arranged between the cleaning machine and the tempering furnace, and the tempering furnace discharging advancing device is arranged at an outlet of the tempering furnace. The automatic production line for the saw blade heat treatment has the advantages of improving production efficiency and energy use rates of the devices, ensuring heat treatment quality of saw blades due to continuous production, achieving automation operation of the whole production line and being small in number of employed workers and good in labor environment.

Owner:烟台金都锯业有限公司

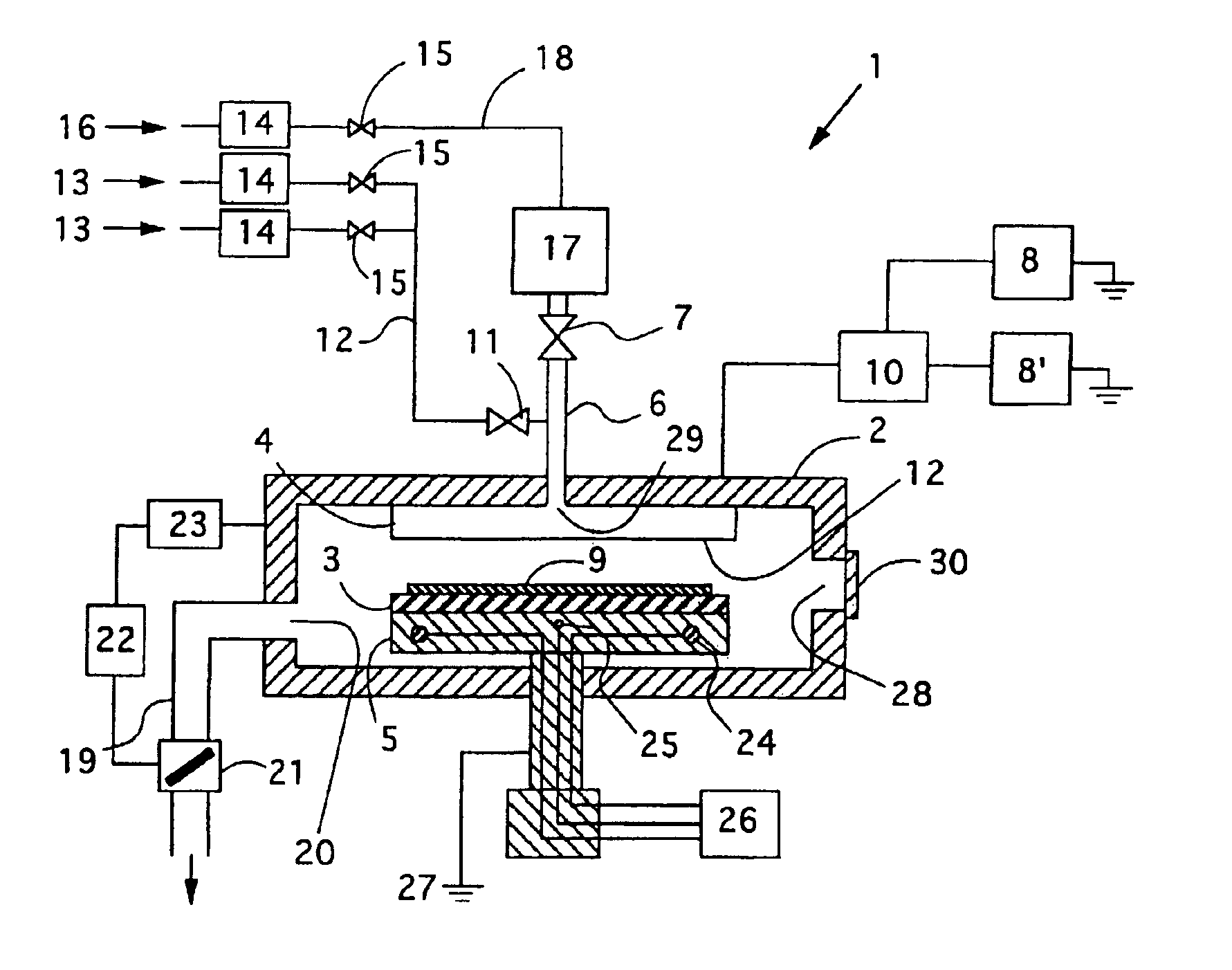

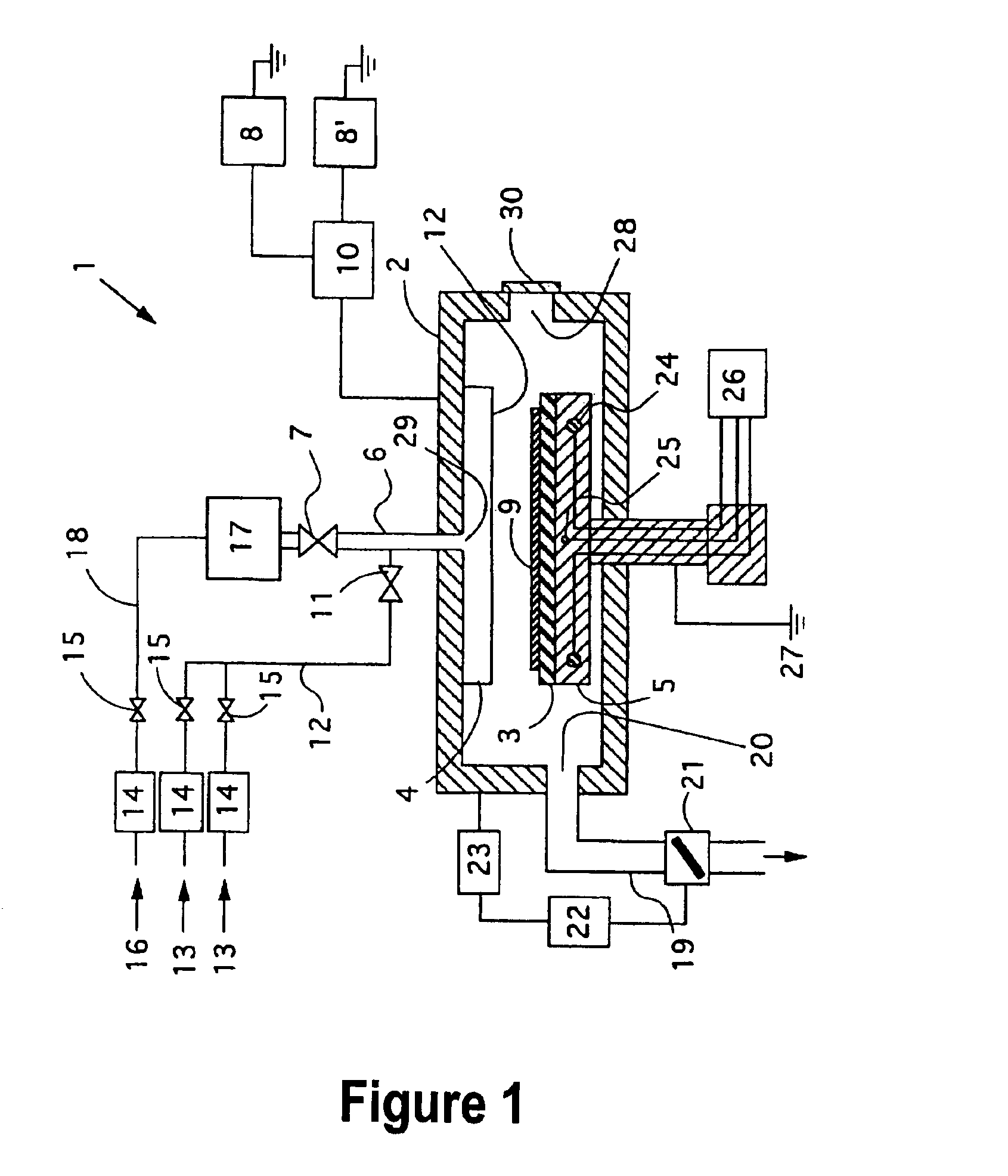

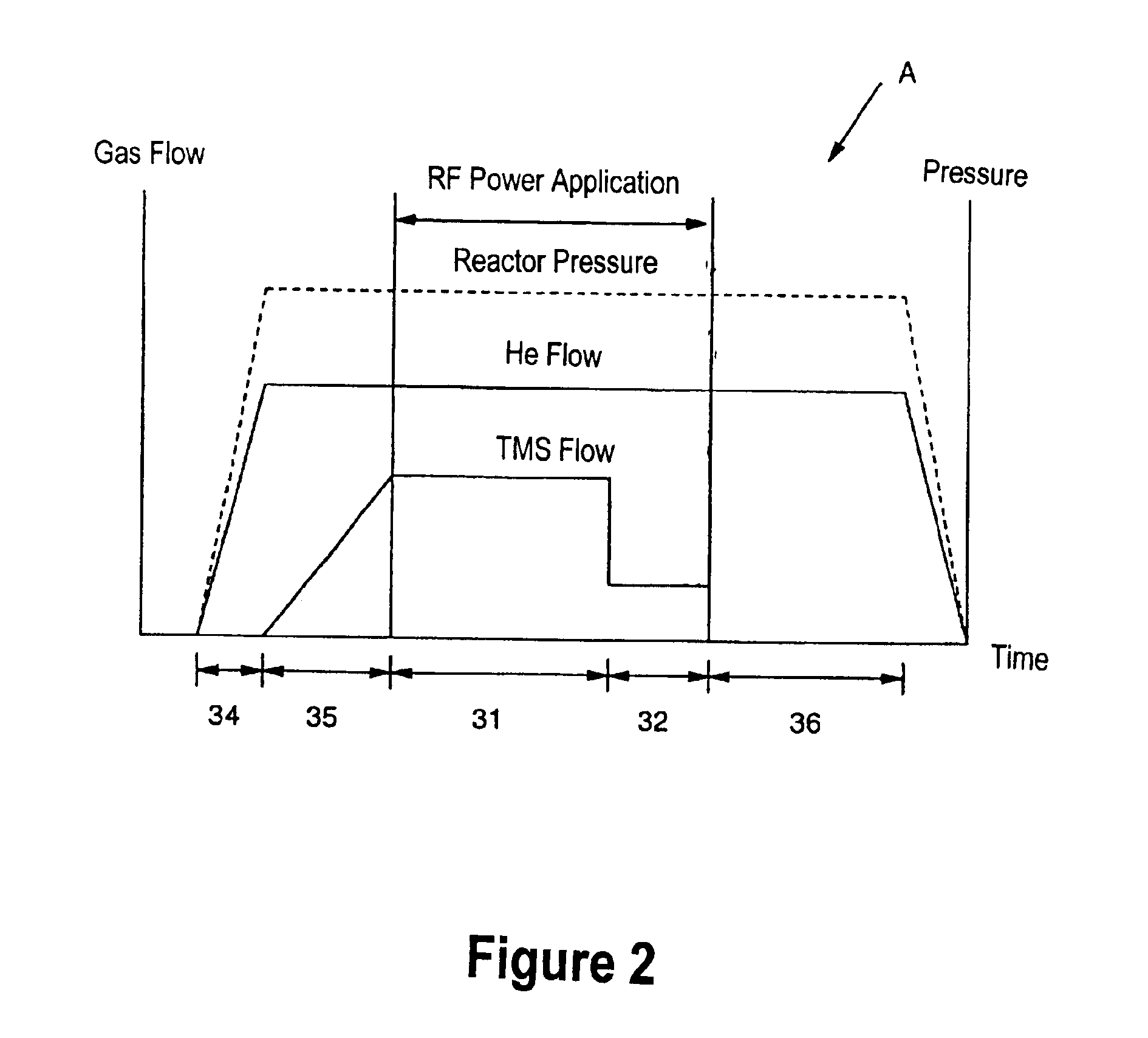

Method of manufacturing silicon carbide film

ActiveUS6919270B2Stable atmosphereWithout complicated processingSemiconductor/solid-state device manufacturingSolid state diffusion coatingRadio frequencyReaction chamber

A method for forming a silicon carbide film on a semiconductor substrate by plasma CVD includes (a) introducing a raw material gas containing silicon, carbon, and hydrogen and an inert gas into a reaction chamber at a predetermined mixture ratio of the raw material gas to the inert gas; (b) applying radio-frequency power at the mixture ratio, thereby forming a curable silicon carbide film having a dielectric constant of about 4.0 or higher; and (c) continuously applying radio-frequency power at a mixture ratio which is reduced from that in step (b), thereby curing the silicon carbide film to give a dielectric constant lower than that of the curable silicon carbide film.

Owner:ASM JAPAN

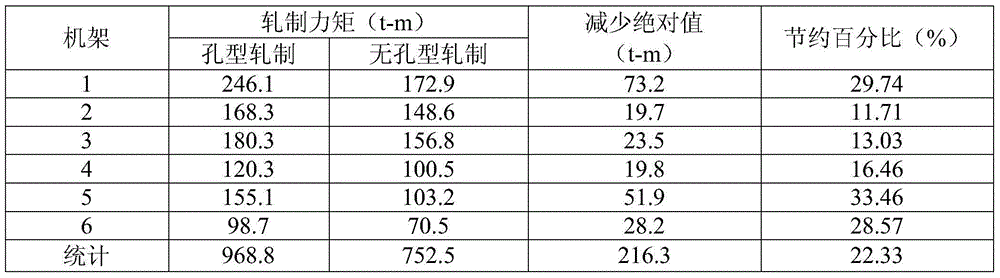

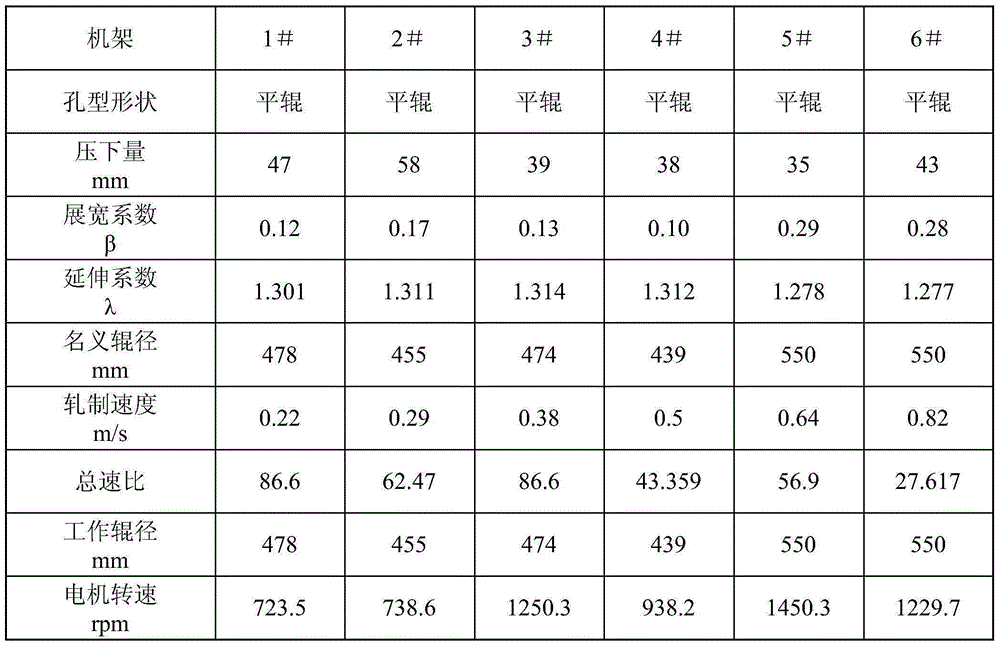

Production process for grooveless rolling of 82B wire rod by high-speed wire mill

ActiveCN104084421ASharedReduce reservesWork treatment devicesMetal rolling arrangementsWire rodEconomic benefits

The invention belongs to the technical field of rod wire deformation processes in metallurgical industry and particularly relates to a production process for grooveless rolling of an 82B wire rod by a high-speed wire mill. The production process aims that special equipment is not required, the processing cost is low, industrialized production is easy to realize, the steel off-square problem of a grooveless rolling production process is solved, the production accident rate is greatly reduced, the product quality is improved, and the economic benefit is increased. The production process adopts the technical scheme as follows: the production process comprises the following steps: (1) heating a 82B steel billet; (2) rolling by a grooveless flat-roll rough rolling unit, wherein in the rolling process, the extension coefficient of each pass is controlled from 1.20 to 1.45, the broadening coefficient ranges from 0.10 to 0.65, and the running speed of the steel billet ranges from 0.20 m / s to 1.04 m / s; (3) entering an intermediate rolling unit and a pre-finishing unit in sequence for rolling; (4) rolling by a finishing unit; (5) cooling by water and entering a wire-feeding machine to obtain the wire rod; (6) cooling by air, winding and transporting, and finally packaging and warehousing to obtain the finished high-speed 82B wire rod.

Owner:西安盛日机电科技有限公司

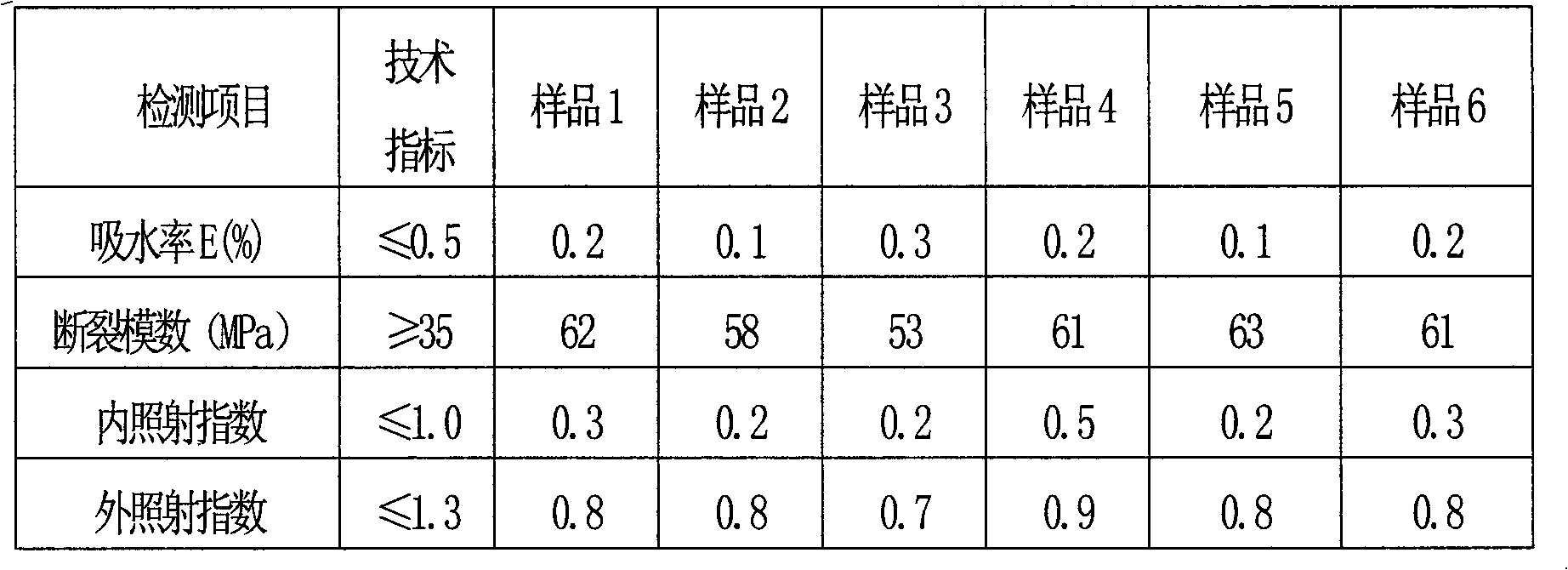

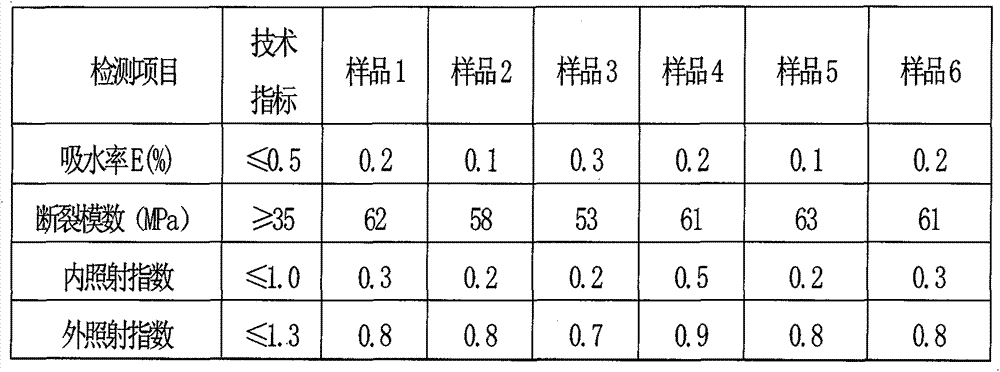

Sandstone-like porcelain exterior wall tile and production method thereof

The invention relates to an exterior wall tile and a production method thereof, in particular to a production method of a sandstone-like porcelain exterior wall tile. The production method comprises the following steps: using architecturally applicable materials to press an adobe of the exterior wall tile; adding sandstone particles with a fineness of 20-150 meshes in a suspending agent to prepare a glaze slurry; spraying or coating the glaze slurry on the surface of the adobe; drying, preheating, sintering and cooling the adobe covered with the glaze slurry to obtain a finished product. According to the invention, the whole sandstone-like porcelain exterior wall tile is prepared by only needing one sintering process, thus fuel and energy of sintering one time are saved compared with the prior art, the energy consumption and exhaust discharge of products with same specification are greatly reduced; and the whole exterior wall tile has the decorative effect similar to that of simulation sandstone, thus compared with the prior art, the exterior wall tile disclosed herein has better decorative effect and lower production cost.

Owner:重庆歌德陶瓷玛赛克制造有限公司

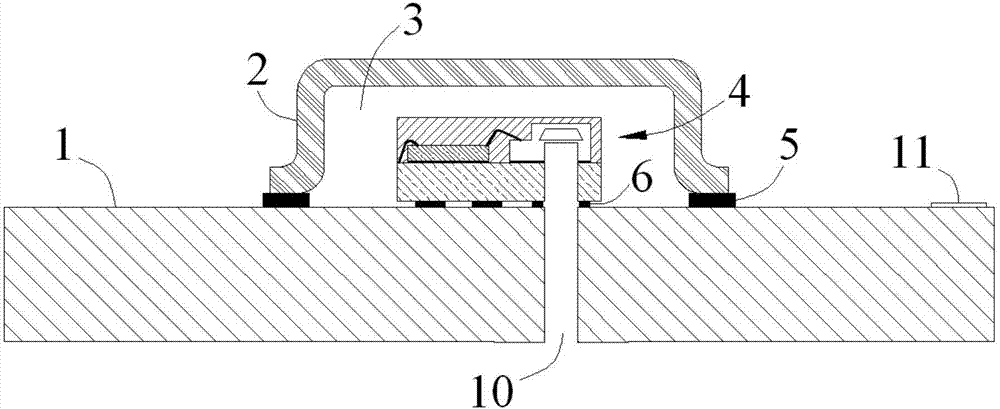

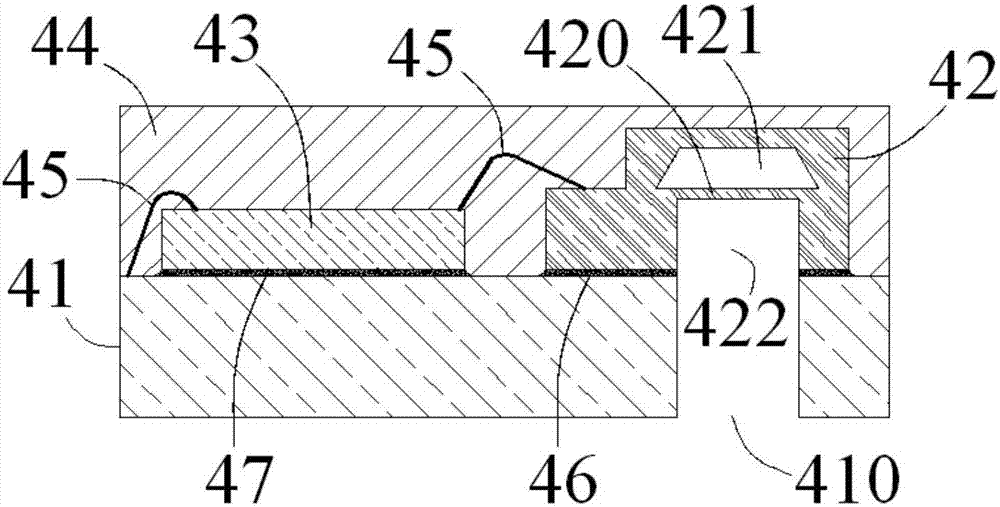

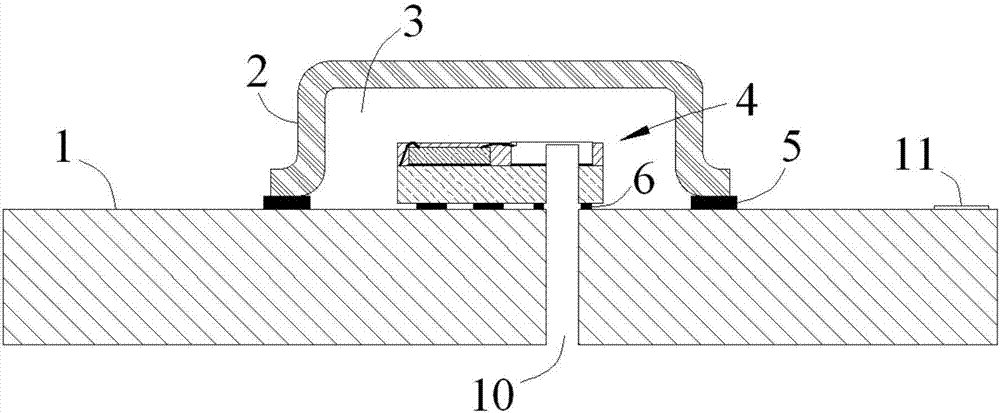

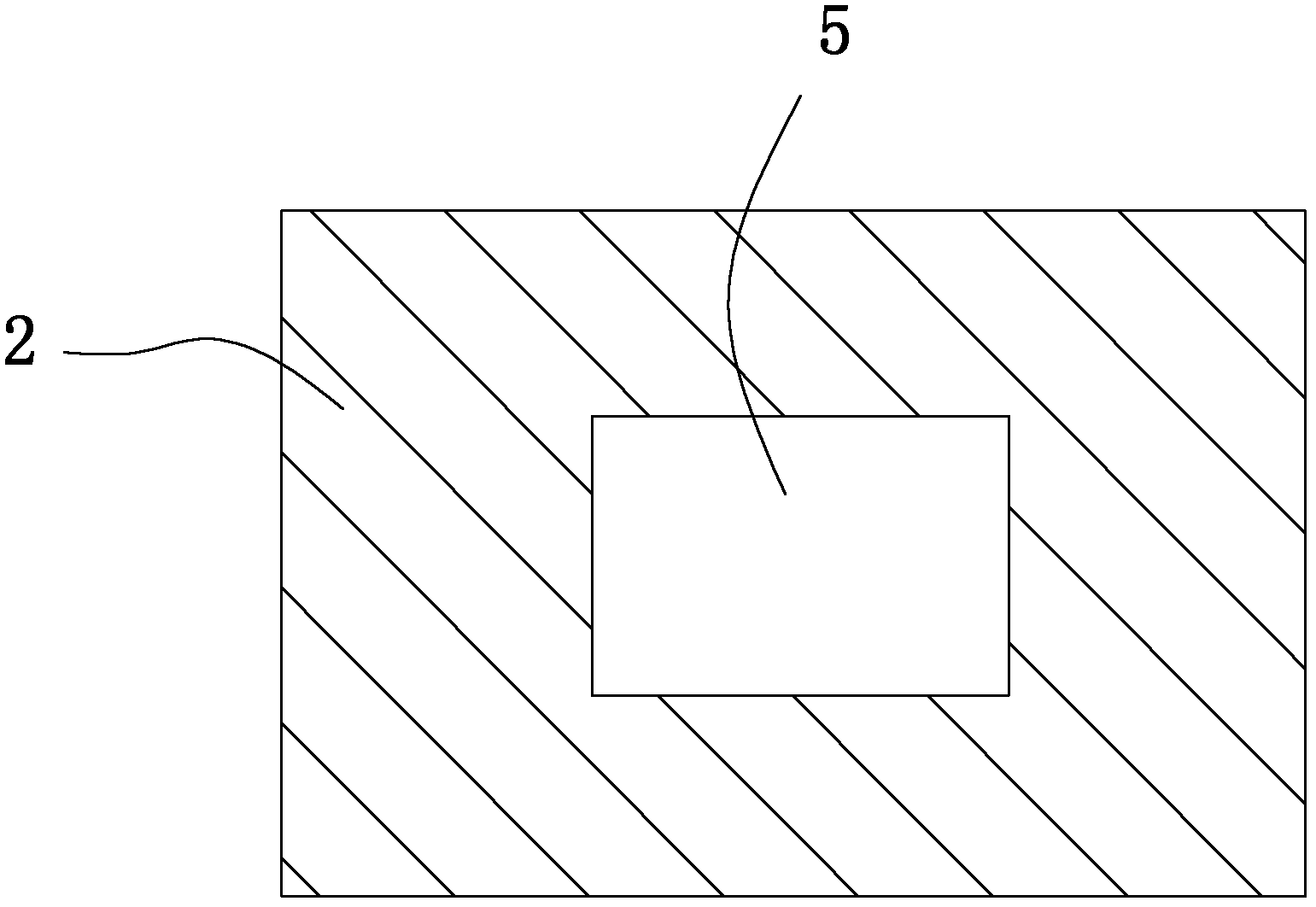

Micro sensor packaging structure and manufacturing process thereof

InactiveCN107036740AEasy to form a standardized packageReduce processForce measurement using piezo-resistive materialsEngineeringIsolation techniques

The invention discloses a micro sensor packaging structure and a manufacturing process thereof. A pressure sensor and a circuit processing chip are packaged together and clad via a cladding layer, so that a standard package is easily formed, batch calibration can be realized, and the procedure of adding a conditioning circuit is saved; and the pressure sensitive film of the pressure sensor is directly in contact with a fluid to be detected via a packaging bottom plate and through holes in a substrate, so that a series of complex processes such as filling oil and the like in the traditional dielectric isolation technology are saved, and the micro sensor packaging structure has obvious advantages on packaging size and packaging cost of the pressure sensor and can effectively solve the problem that liquid pressure and gas pressure are directly detected with low cost.

Owner:昆山灵科传感技术有限公司

Production process of winebottles with decorations

The invention discloses a production process of winebottles with decorations and can effectively reduce the occurrence probability of black spots on the surfaces of glass winebottles. The production process of winebottles with decorations comprises: a. applying appliques on the external surfaces of the glass winebottles; b. placing the multiple glass winebottles with appliques into the inner cavity of a decoration firing furnace for baking, so that a coloured glaze can be welded on the external surfaces of the glass winebottles. Specifically, step b consists of the steps of: while putting the multiple glass winebottles in the decoration firing furnace, keeping the volume sum of coloured glazes of appliques on the multiple glass winebottles at an amount of V1 and the inner cavity volume of the decoration firing furnace at an amount of V2, with the ratio of V1 to V2 less than or equal to 0.01 per thousand, and controlling an equal space between any two glass winebottles; heating the glass winebottles to a temperature of 580DEG C-590DEG C in the decoration firing furnace by means of preheating and temperature raising, and making the coloured glazes firmly welded on the external surfaces of the glass winebottles through an insulation process; cooling the glass winebottles. The process provided in the invention can effectively prevent formation of black spots on the surfaces of glass winebottles.

Owner:SICHUAN SWELLFUN

Whole-body two-sided flame separating type heating rotary kiln and method for producing direct reduction iron co-production carbon base fertilizer

ActiveCN106636519AIncrease production capacityReduce sizeRotary drum furnacesHigh concentrationWhole body

The invention relates to a whole-body two-sided flame separating type heating rotary kiln and a method for producing direct reduction iron co-production carbon base fertilizer. According to the invention, a rotary kiln cylinder is composed of two cylinders namely an outer cylinder and an inner cylinder; an in-depth reduction chamber is formed between the outer cylinder and the inner cylinder and is divided into 6 to 12 in-depth reduction chambers by support partition boards; each separated in-depth reduction chamber is filled with equivalent reduced material, the filling rate is increased by 6 to 12 times, and the productivity of direct reduction iron of the rotary kiln is also increased by 6 to 12 times, so that the production capacity of the kiln is greatly improved, the kiln size is relatively reduced, and the investment on the kiln is also greatly reduced relatively. Except carbon, biomass materials including straws and the like can be used as a reduction agent, so that pollution to the environment caused by combustion of the biomass materials is avoided, waste materials are recycled, high-concentration coal gas and by-products of co-production biochar base fertilizer are recycled, energy conservation, emission reduction and carbon drop are realized, and NOx is not generated.

Owner:辽宁盛京时代科技有限公司

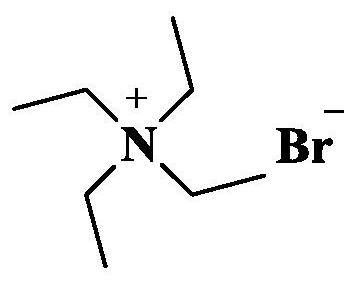

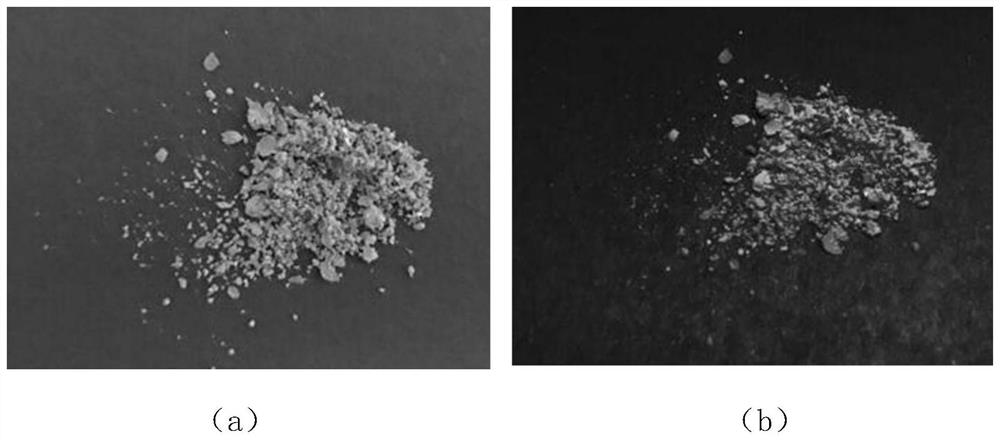

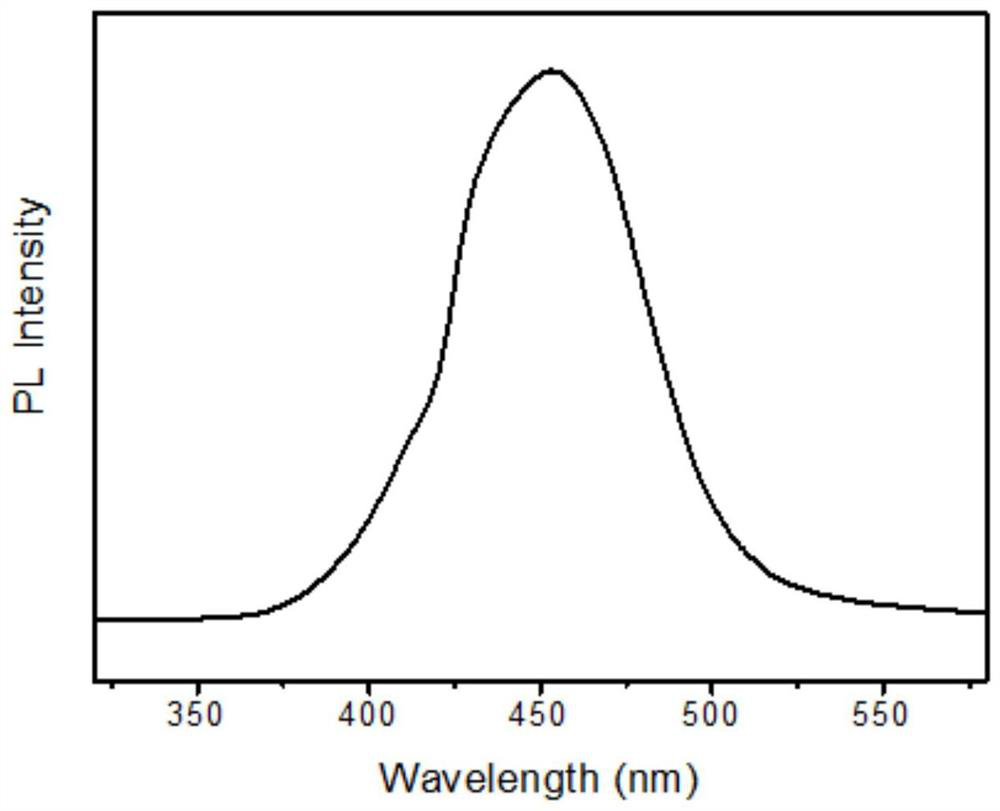

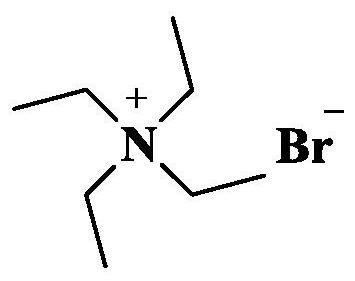

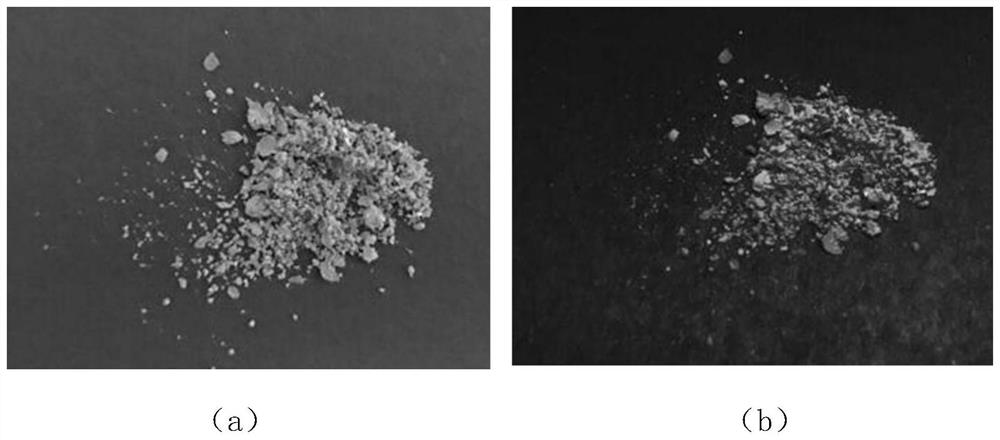

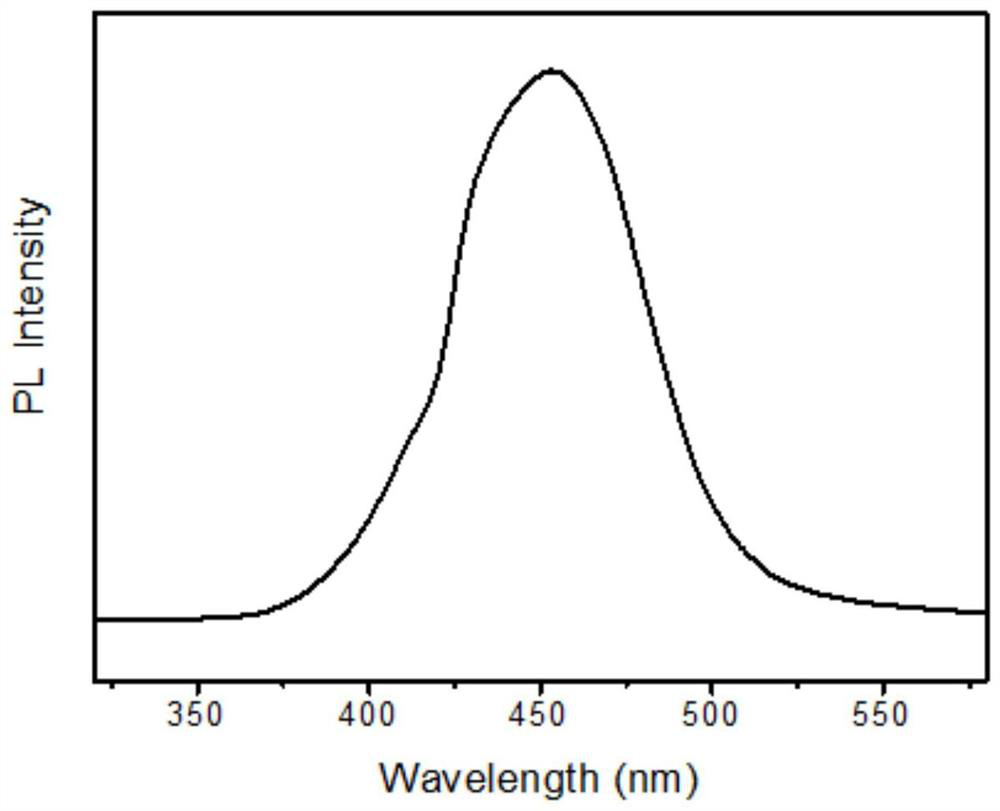

Organic-inorganic hybrid halide luminescent material as well as preparation method and application thereof

ActiveCN112521938AEasy to prepareExcellent optical propertiesAmino preparation from aminesLuminescent compositionsHalogenPhysical chemistry

The invention discloses an organic-inorganic hybrid halide luminescent material as well as a preparation method and application thereof, the luminescent material is an organic-inorganic hybrid copper-based halide based on quaternary ammonium salt, the structural formula is AmCun X(m+n), A is an organic chain part of the quaternary ammonium salt, X is any combination of one or more anions of halogen ions Cl<->, Cl<->, Br<-> and I<->, and m and n are each an integer of 1-3. The organic-inorganic hybrid halide prepared based on the quaternary ammonium salt and the copper base has the characteristics of high PLQY, tunable spectrum, good stability in atmosphere, environmental friendliness and the like.

Owner:XI AN JIAOTONG UNIV

Processing apparatus, measuring apparatus, and device manufacturing method

InactiveUS20050271558A1Reduce the amount of vibrationSave spaceExhaust apparatusVacuum evaporation coatingInternal pressureControl system

A processing apparatus includes a sealed vacuum chamber which contains a processing portion; a pressure controlling system which keeps the internal pressure of the sealed vacuum chamber constant at a predetermined level by exhausting the ambient gas in the sealed vacuum chamber; and an ambient gas recirculating system which recirculates the ambient gas exhausted from the sealed vacuum chamber back into the sealed vacuum chamber; wherein the ambient as recirculated by the ambient gas recirculating system is blown into the sealed vacuum chamber so that a gas flow is generated in a predetermined direction along the processing portion.

Owner:CANON KK

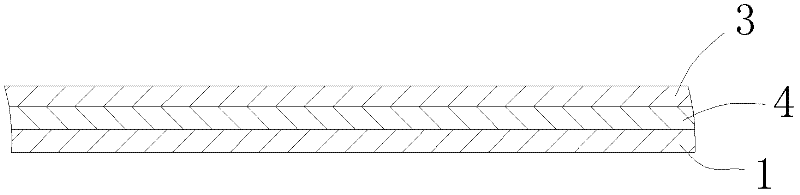

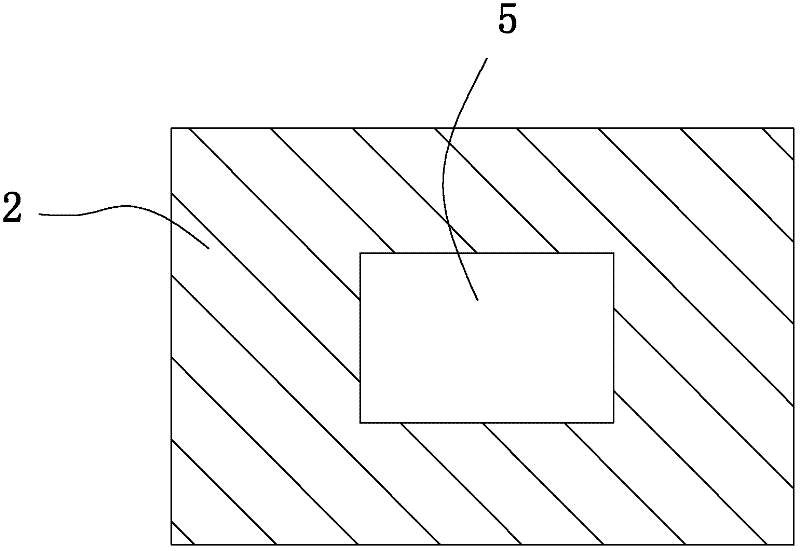

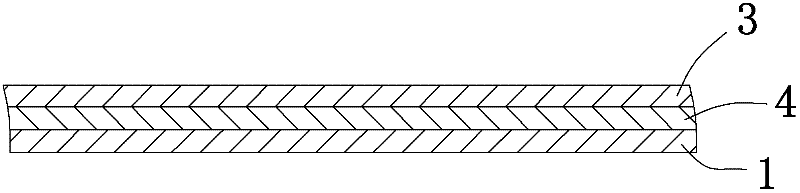

Titanium-alloy supporting ring fusion-welding gas shield trailing cover and shielding method

The invention discloses a titanium-alloy supporting ring fusion-welding gas shield trailing cover and a shielding method. A trailing cover main body of a shield trailing cover is of a box structure and provided with an opening in the front face and an opening in the bottom face; a welding gun nozzle mounting hole is formed in the front end of the top face of the trailing cover main body, and an upper pipe with argon is arranged on the top face of the trailing cover main body; an inclined side plate is connected to the lower end of the left side face of the trailing cover main body and is inclined toward the outer side of the trailing cover main body; a web is connected to the right side face of the trailing cover main body, and a side pipe with argon is connected to the side face of the web; and the lower end of the inclined side plate and the lower end of the right side face of the inclined side plate are each of a circular arc structure which has the same curvature with the welding face of an outer circle of a supporting ring. The titanium-alloy supporting ring fusion-welding gas shield trailing cover can ensure that the heat affected area with the temperature of welding seam molten pool and parts exceeding 400 DEG C is not oxidized.

Owner:AECC AVIATION POWER CO LTD

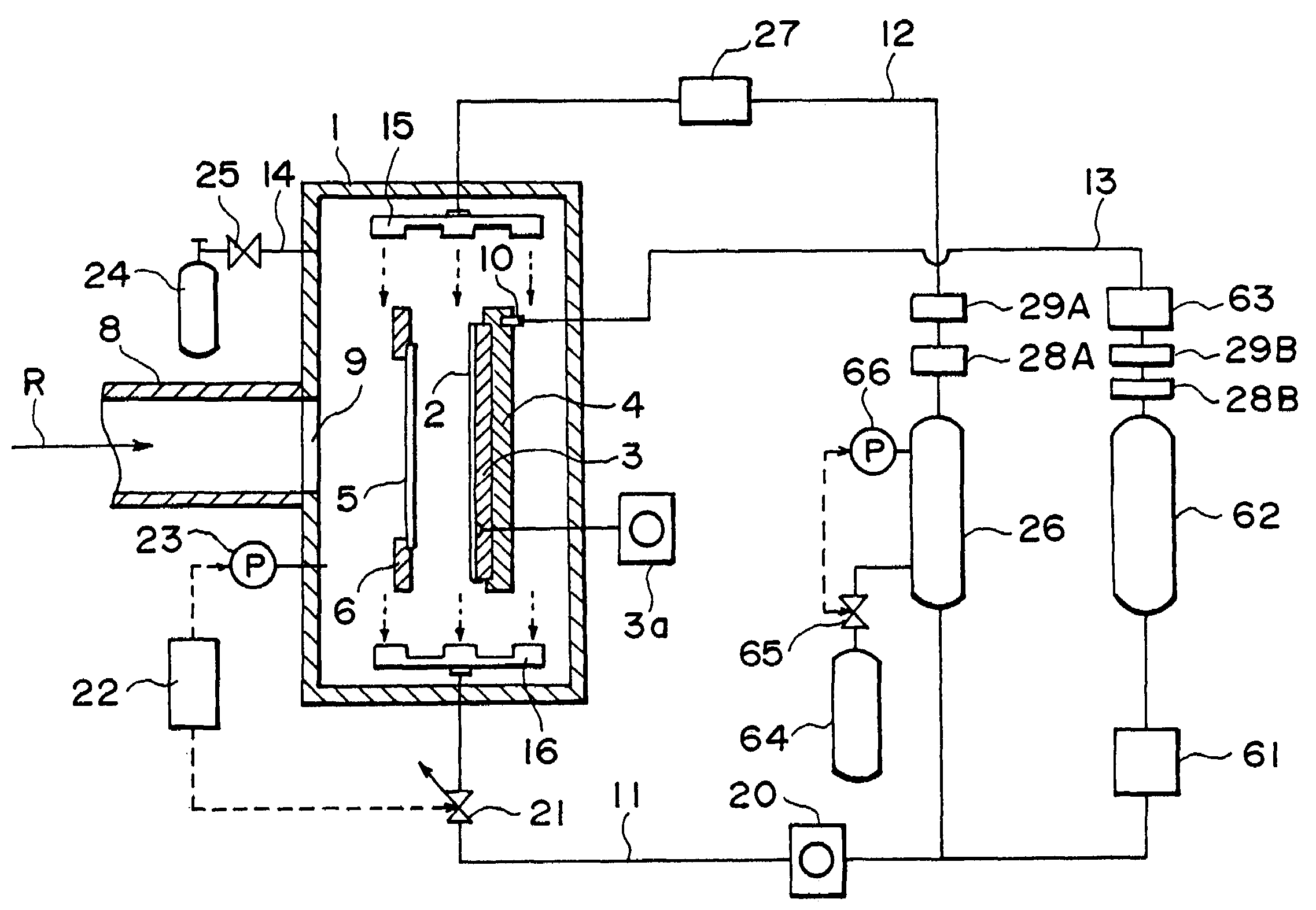

Exposure apparatus with tanks storing helium gas and method of manufacturing device using exposure apparatus

InactiveUS7566422B2Eliminate unevennessStable atmosphereExhaust apparatusVacuum evaporation coatingInternal pressureControl system

A processing apparatus includes a sealed vacuum chamber which contains a processing portion; a pressure controlling system which keeps the internal pressure of the sealed vacuum chamber constant at a predetermined level by exhausting the ambient gas in the sealed vacuum chamber; and an ambient gas recirculating system which recirculates the ambient gas exhausted from the sealed vacuum chamber back into the sealed vacuum chamber; wherein the ambient as recirculated by the ambient gas recirculating system is blown into the sealed vacuum chamber so that a gas flow is generated in a predetermined direction along the processing portion.

Owner:CANON KK

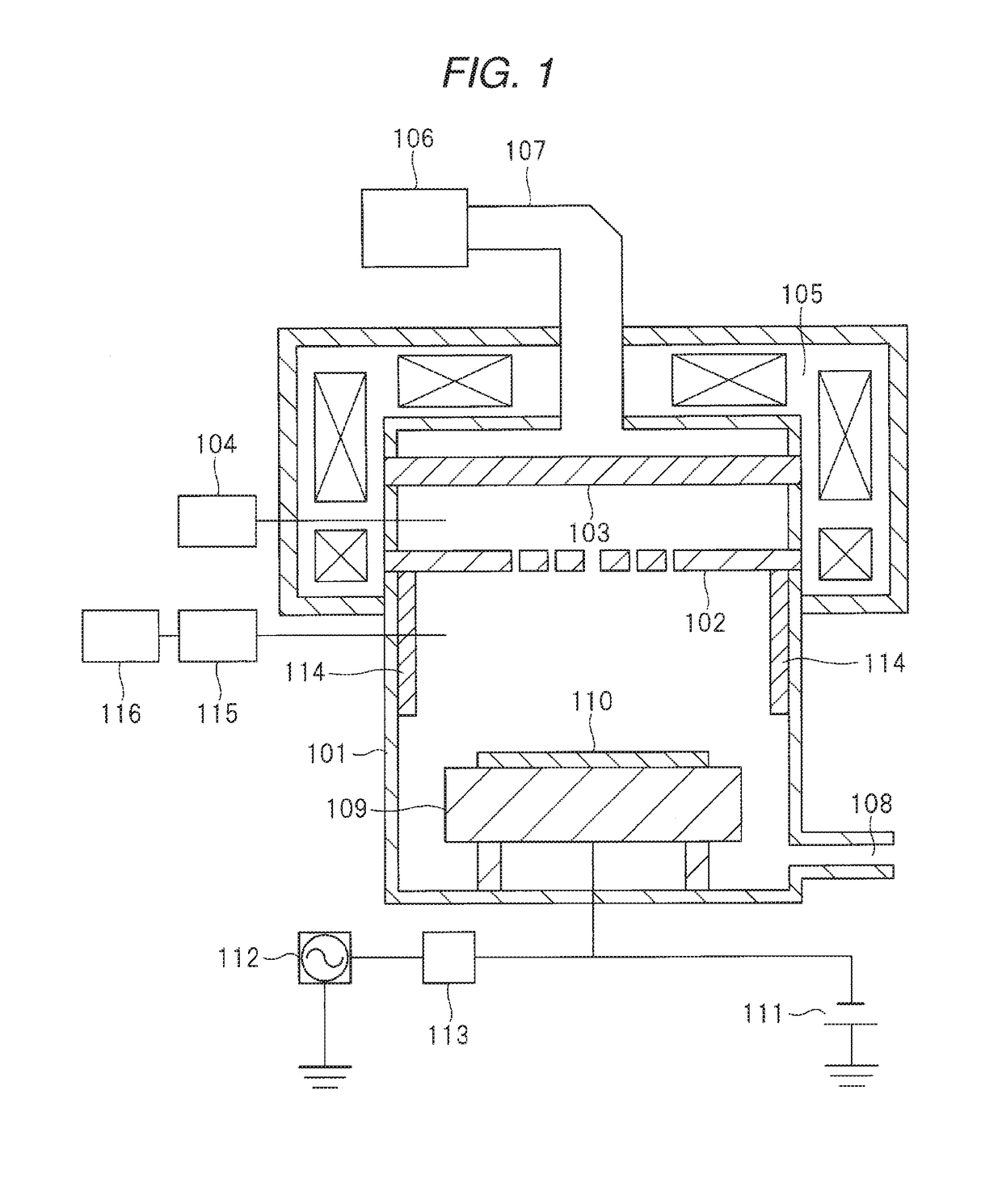

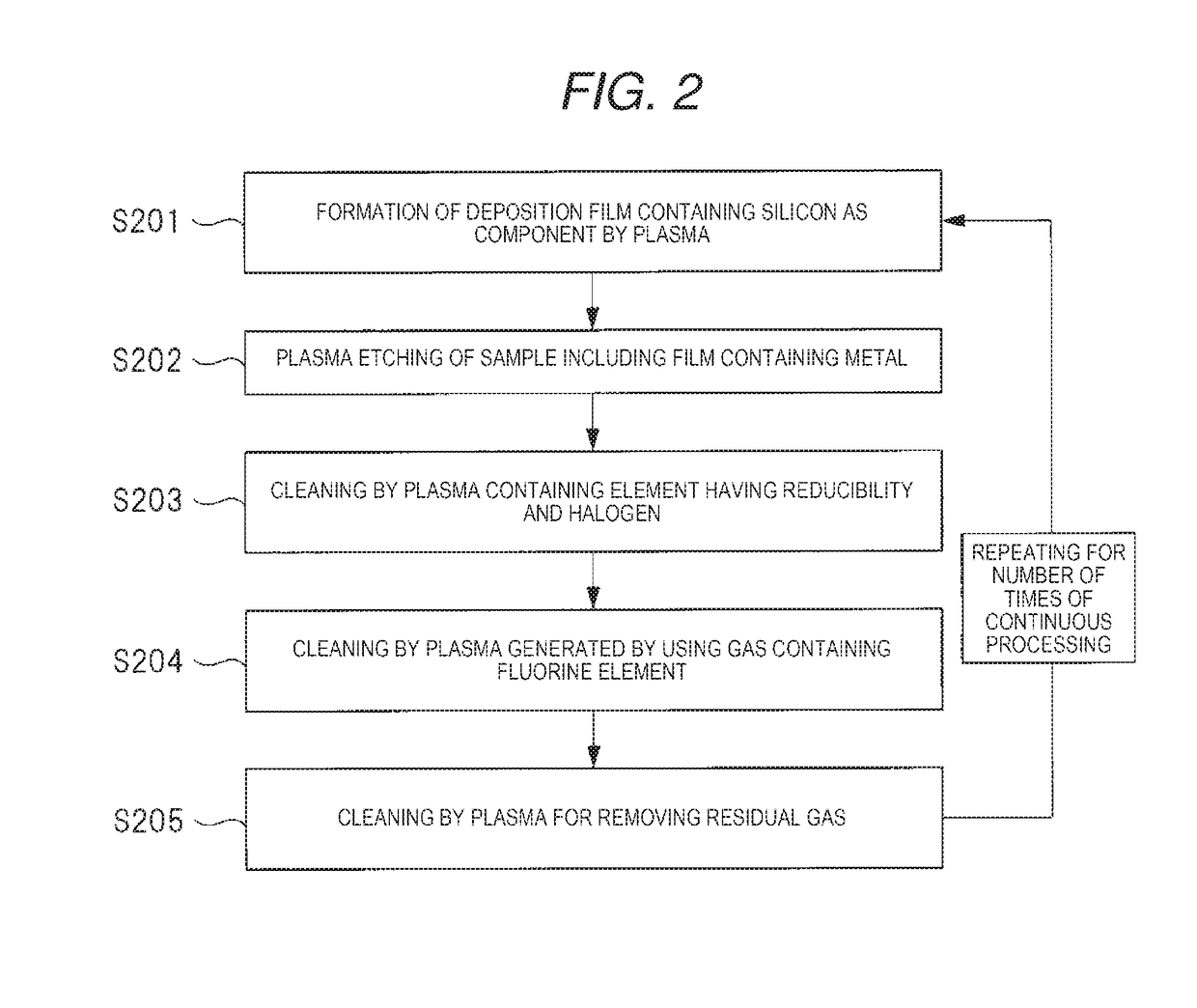

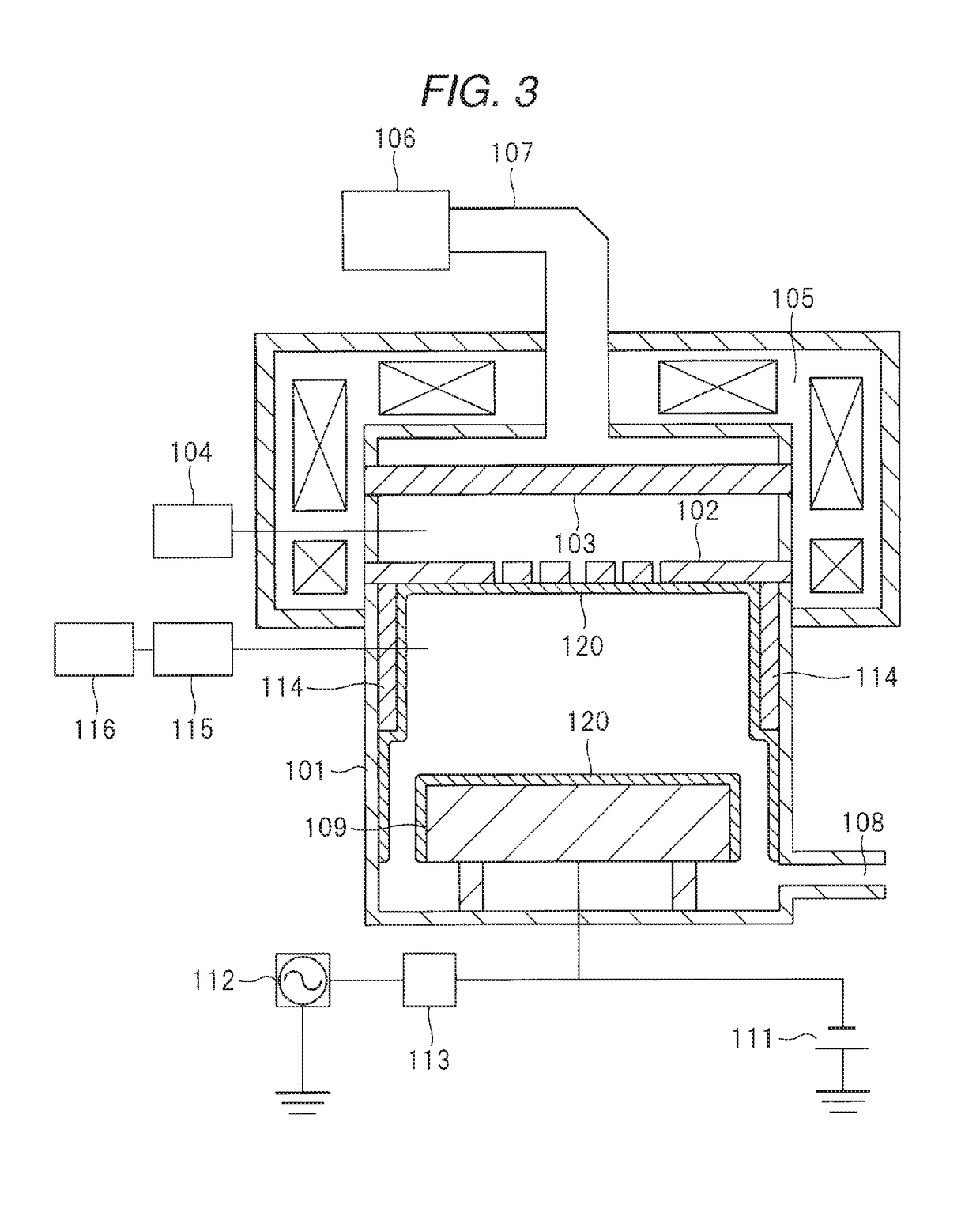

Plasma processing method

ActiveUS10184173B1Eliminate residueStable atmosphereSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSiliconPlasma processing

A plasma processing method includes forming a deposition film containing silicon as a component in a processing chamber by generating a first plasma in the processing chamber; plasma etching of a sample in which a film containing a metal is formed in the processing chamber; and removing of a metal-based reaction product by generating a second plasma including an element having reducibility and halogen. The plasma processing method further includes removing the deposition film by a third plasma generated by using gas containing a fluorine element; and removing residual gas by a fourth plasma.

Owner:HITACHI HIGH-TECH CORP

Production method of sandstone-like porcelain exterior wall tile

The invention relates to an exterior wall tile and a production method thereof, in particular to a production method of a sandstone-like porcelain exterior wall tile. The production method comprises the following steps: using architecturally applicable materials to press an adobe of the exterior wall tile; adding sandstone particles with a fineness of 20-150 meshes in a suspending agent to prepare a glaze slurry; spraying or coating the glaze slurry on the surface of the adobe; drying, preheating, sintering and cooling the adobe covered with the glaze slurry to obtain a finished product. According to the invention, the whole sandstone-like porcelain exterior wall tile is prepared by only needing one sintering process, thus fuel and energy of sintering one time are saved compared with the prior art, the energy consumption and exhaust discharge of products with same specification are greatly reduced; and the whole exterior wall tile has the decorative effect similar to that of simulation sandstone, thus compared with the prior art, the exterior wall tile disclosed herein has better decorative effect and lower production cost.

Owner:重庆歌德陶瓷玛赛克制造有限公司

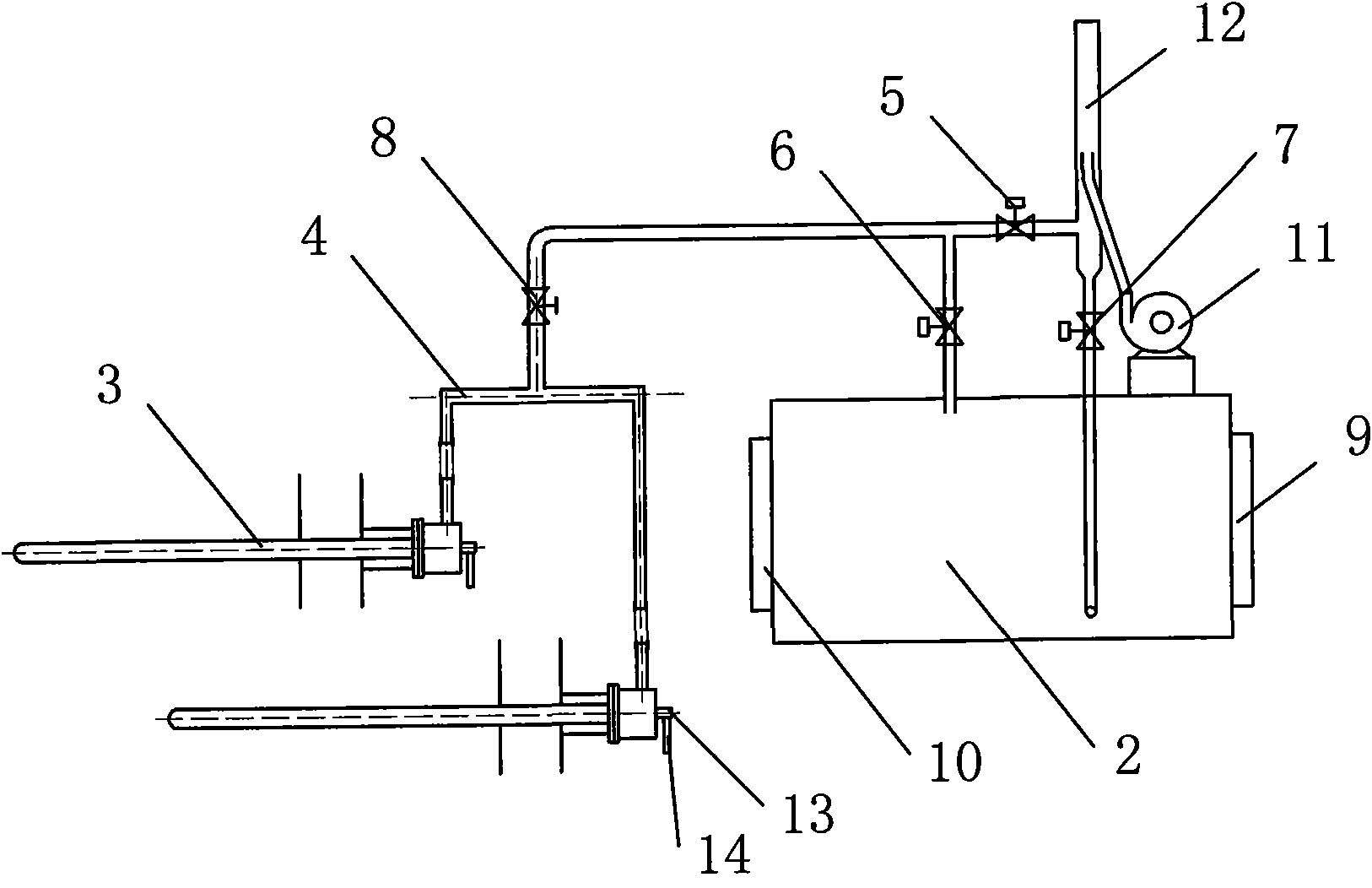

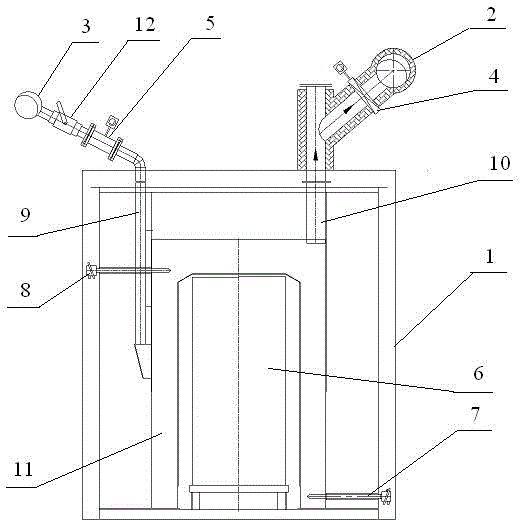

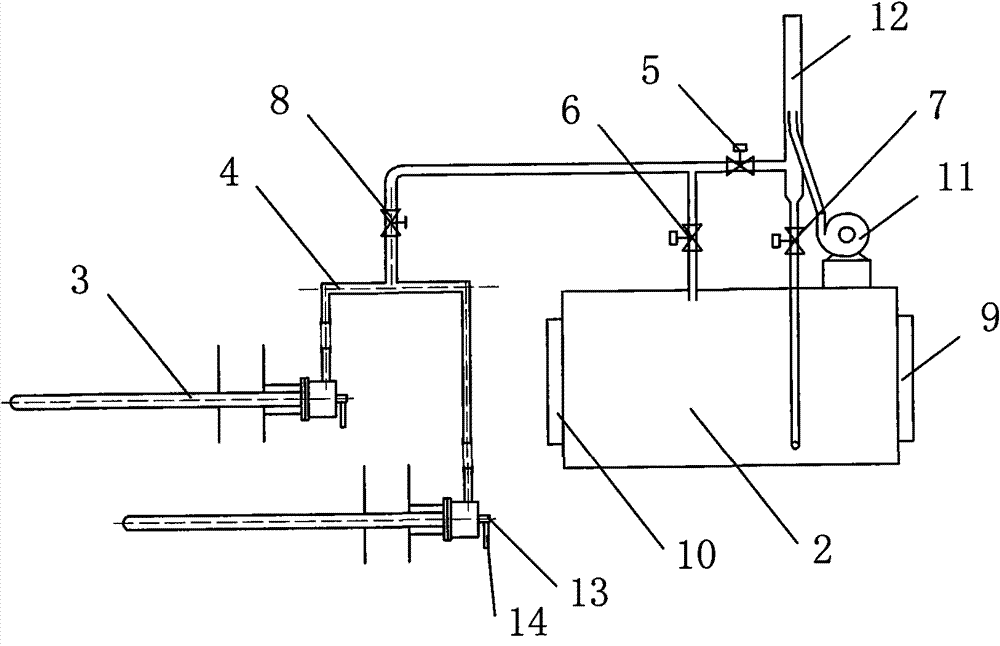

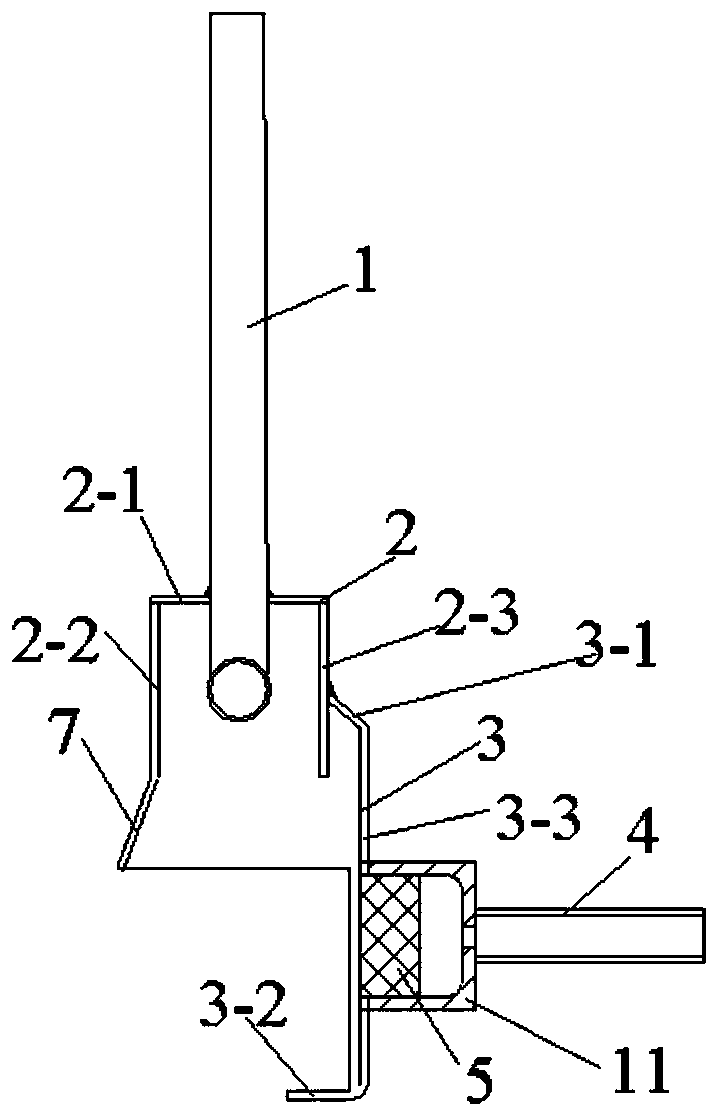

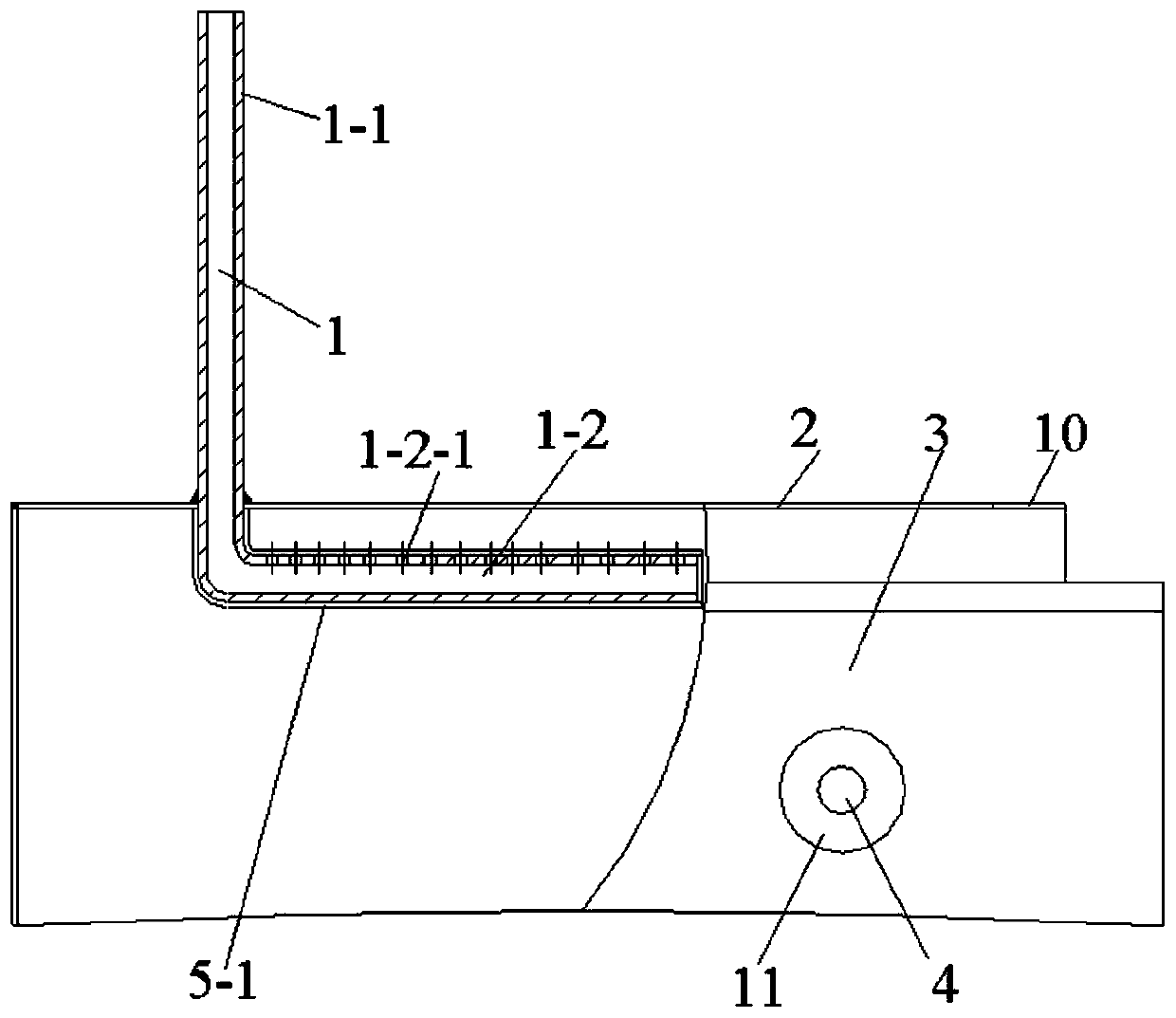

Waste gas protection system for thermal treatment furnace and control method

ActiveCN102051458AReduce entryStable atmosphereMaintainance of heating chambersEngineeringThermal treatment

The invention relates to a waste gas protection system for a thermal treatment furnace and a control method. The system comprises a furnace body and a feeding table, an air displacement chamber is formed between the inlet of the furnace body and the feeding table, a No.1 door is arranged between the air displacement chamber and the feeding table, and a No.2 door is arranged between the air displacement chamber and the inlet of the furnace body; a fuel gas radiation pipe in the furnace body is connected with the input end of a fourth valve through an exhaust pipe, one path of the output end of the fourth valve is communicated with a burner waste gas exhaust pipe through a first valve, and the other path of the output end of the fourth valve is communicated with the cavity of the air displacement chamber through a second valve; and the burner waste gas exhaust pipe is communicated with the cavity of the air displacement chamber through a third valve, the system is provided with a blower, and the output port of the blower is arranged in the burner waste gas exhaust pipe. The system has the advantages that: a vacuum chamber is replaced by using the air displacement chamber, and the air in the air displacement chamber is displaced by using CO2 serving as a main component of the waste gas, so the air entering the furnace is reduced, and stability of furnace atmosphere is realized.

Owner:HANGZHOU JINZHOU TECH CO INC

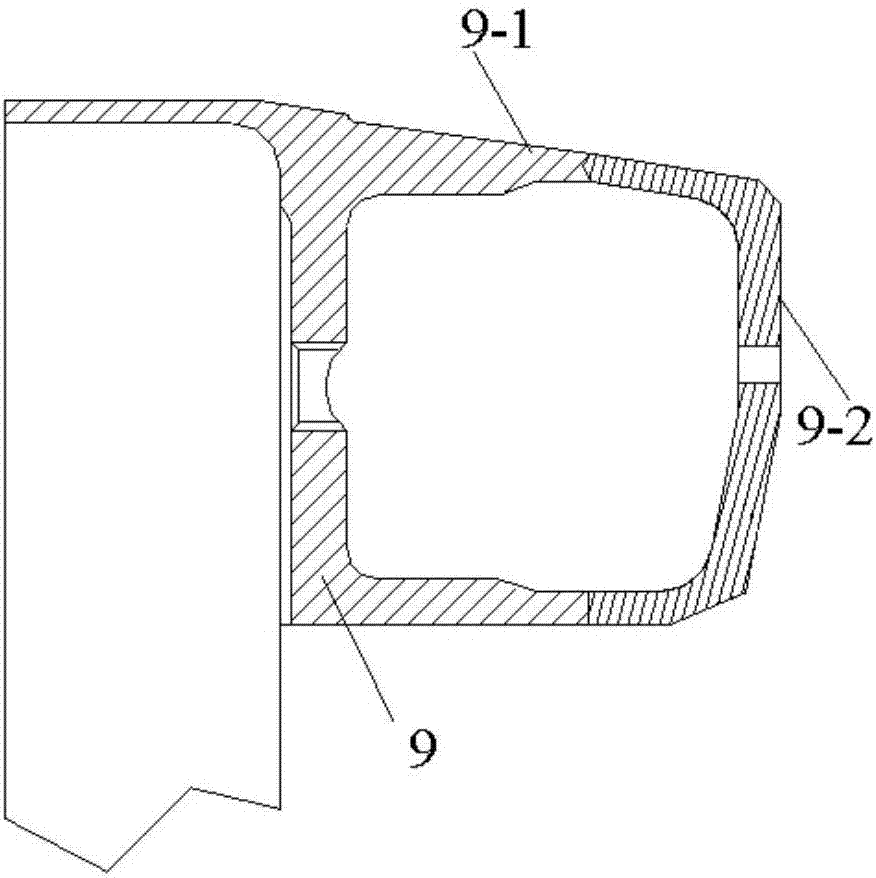

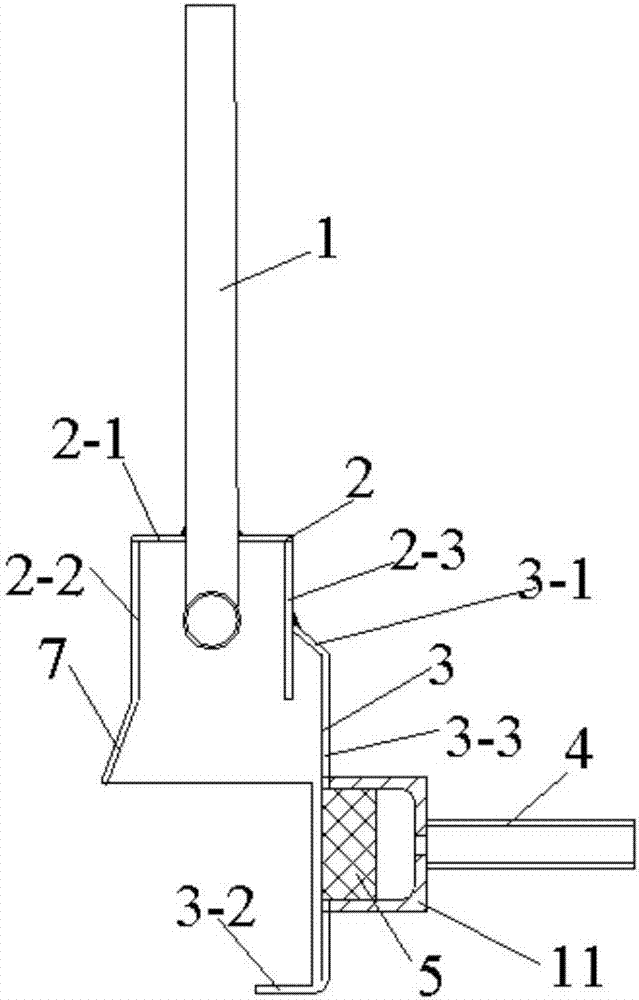

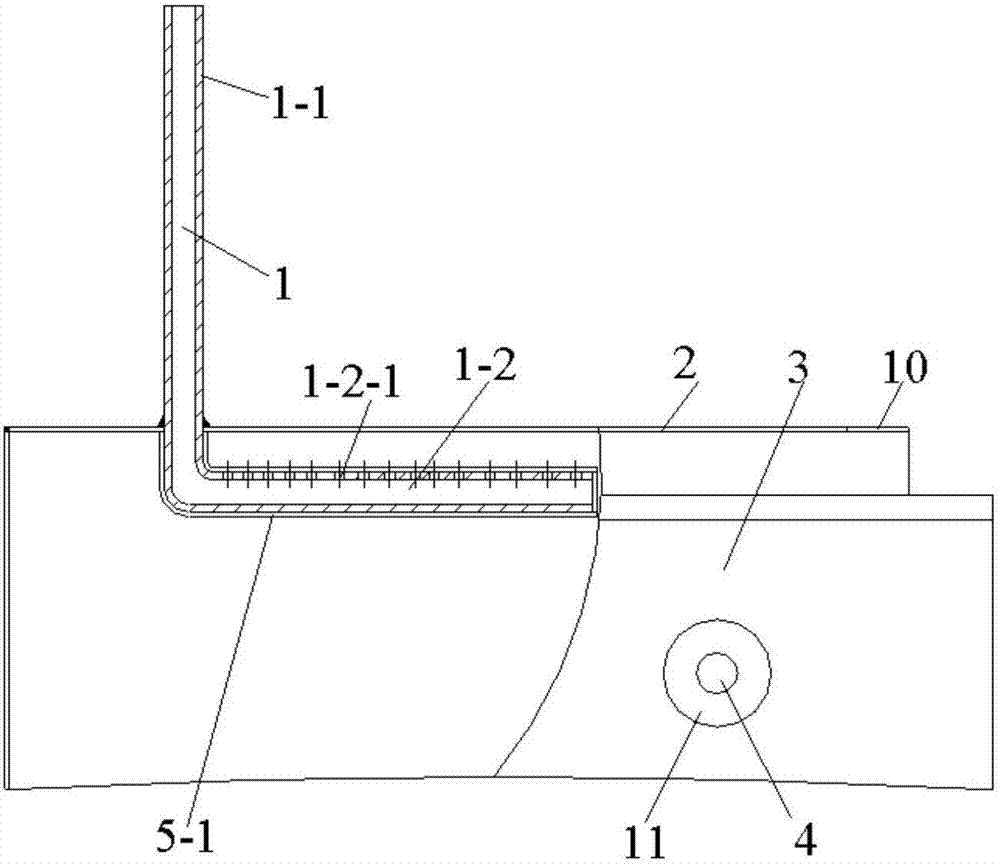

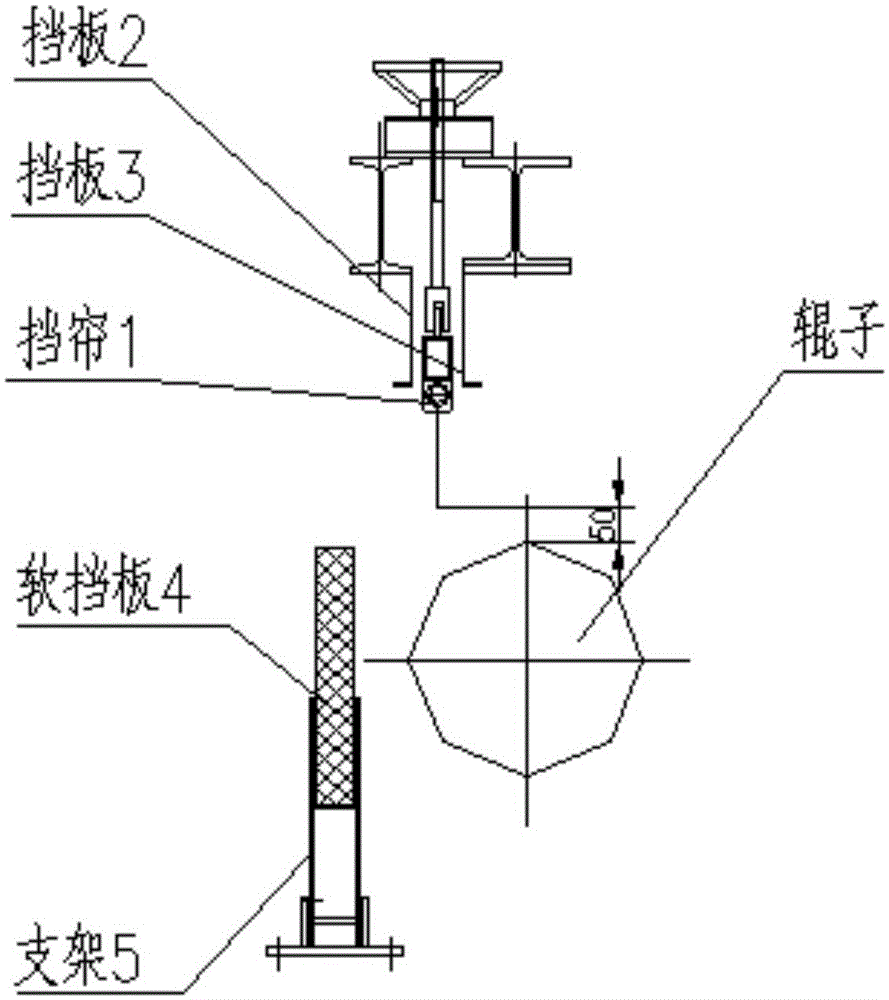

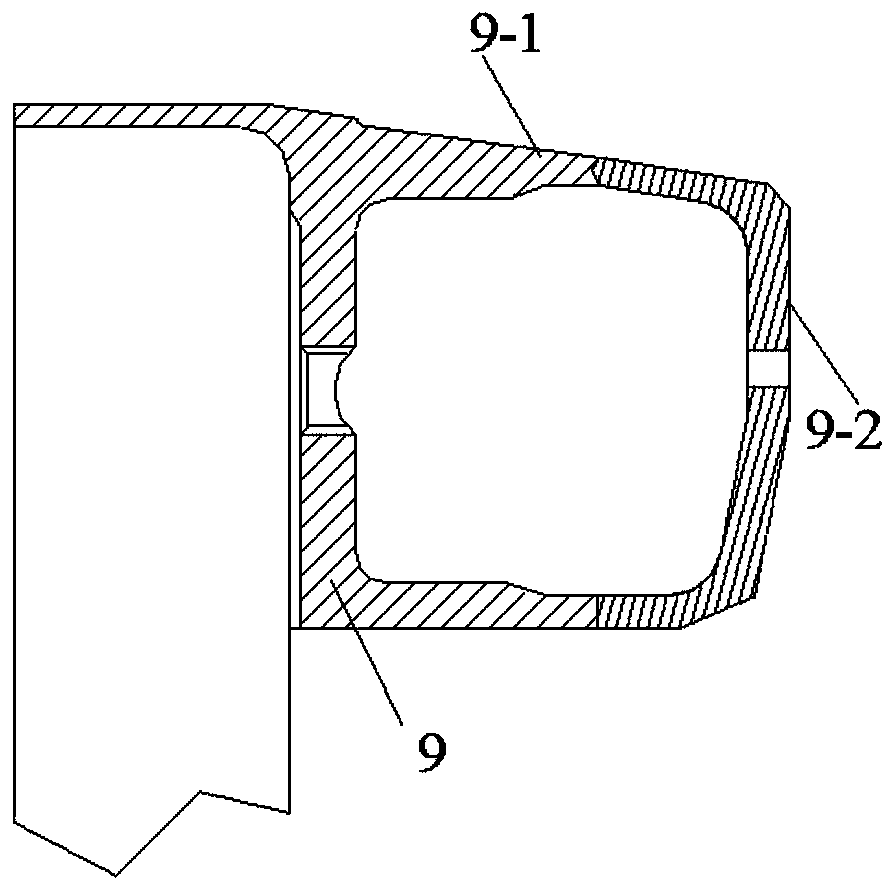

D zone sealing apparatus of glass anneal kiln

A D zone sealing apparatus of a glass anneal kiln includes an upper part and a lower part, wherein the upper part and the lower part and an anneal kiln roller table form a sealing barrier, thereby stopping influence on a C zone due to forced convection air in an R zone. According to the D zone sealing apparatus of the glass anneal kiln, a sealing barrier is formed with the anneal kiln roller table for stopping the influence on the C zone due to forced convection air in the R zone, so that the gas flow in an anneal front portion is stable, thereby ensure stability of internal atmosphere in the glass anneal kiln.

Owner:CHINA TRIUMPH INT ENG

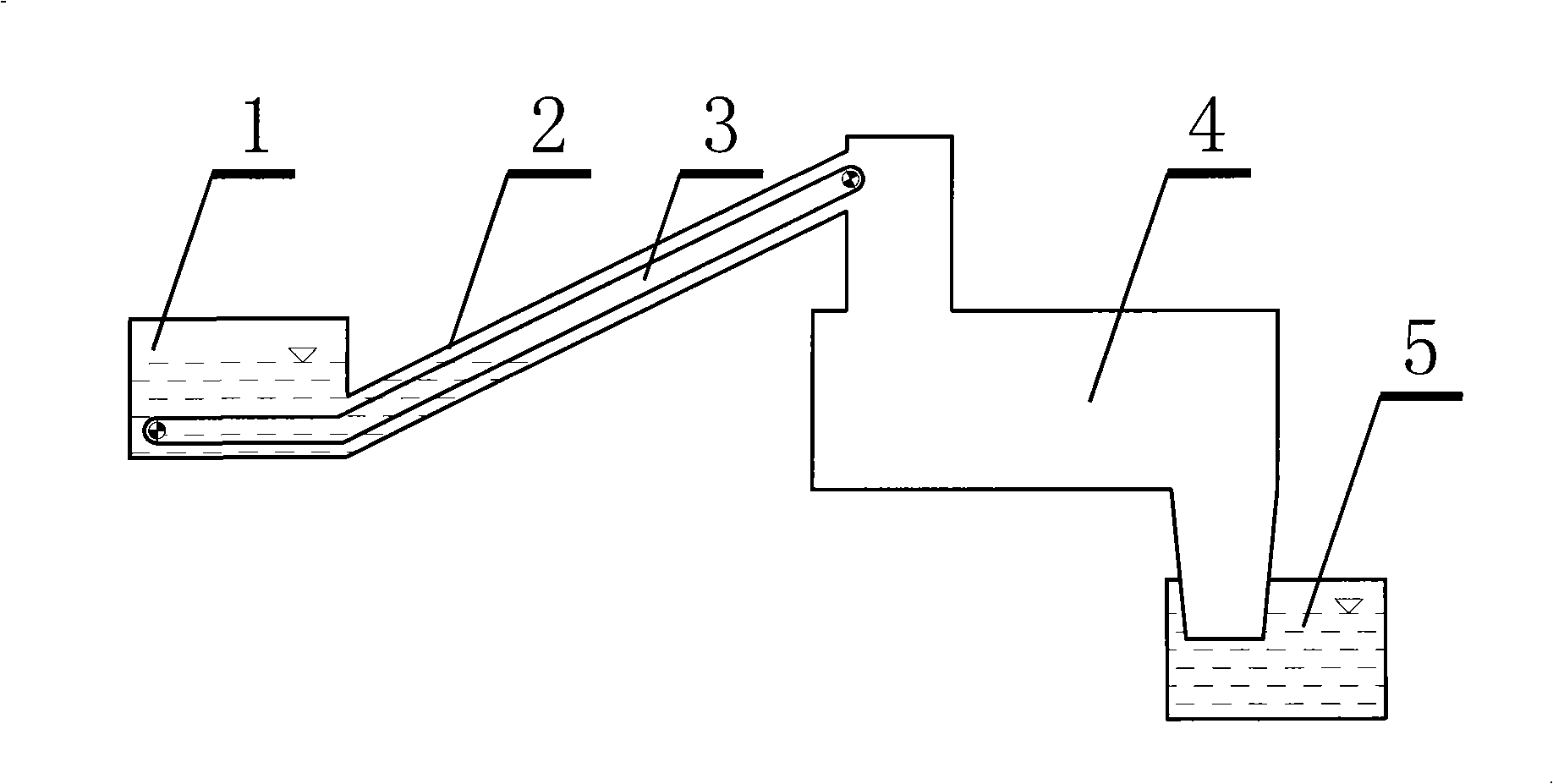

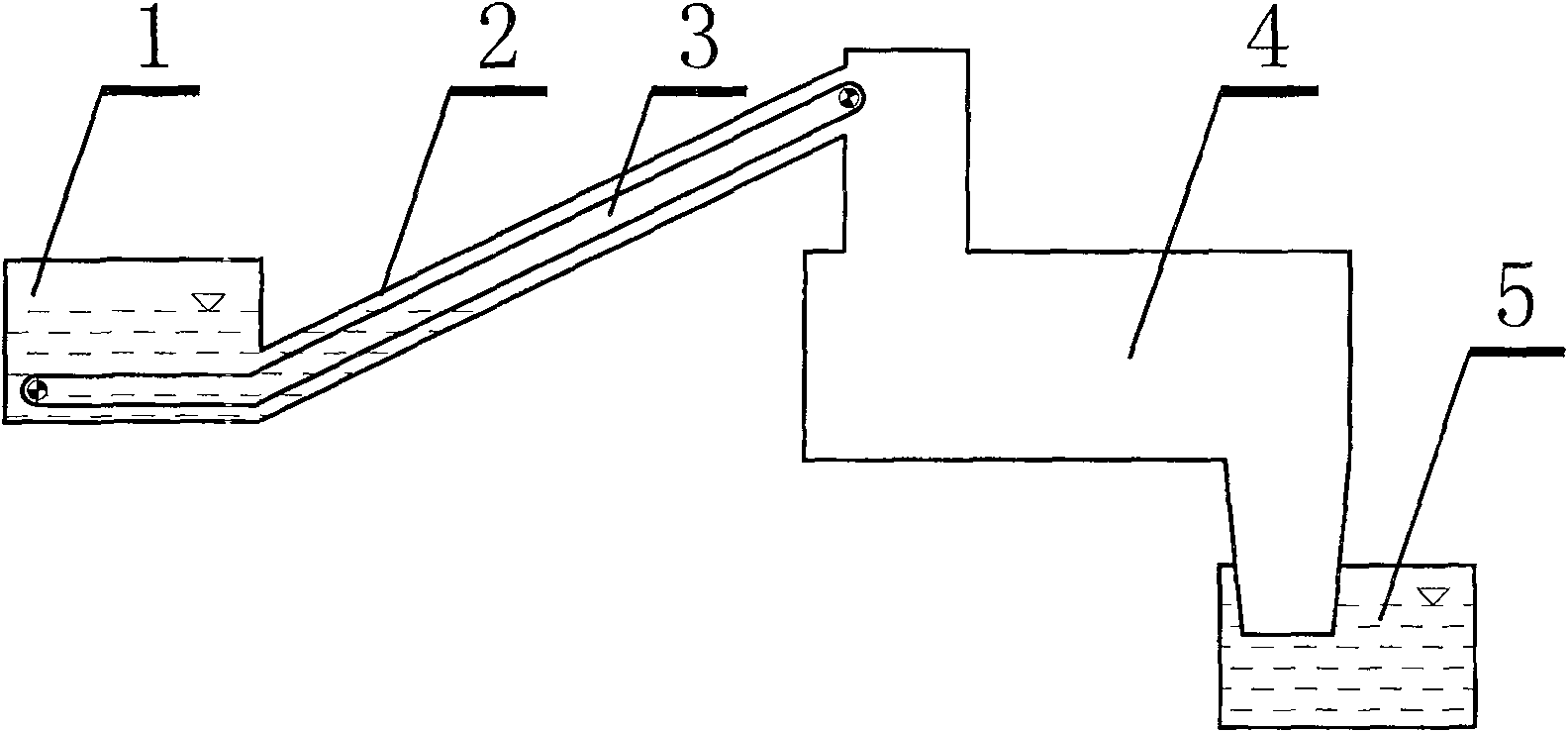

Feeding and slag tapping method in processing of thermal decomposition of organic wastes

InactiveCN101406893ALess one-time investmentReduce power consumptionSolid waste disposalIncinerator apparatusSlagHigh energy

The invention relates to a method for material charging and slag discharging during the pyrolysis treatment of organic waste. Crushing treatment which is adopted in the prior art has high investment, high energy consumption and difficult maintenance. The method is realized through the mode of water sealing. The method comprises the following steps: during the material charging process, strip and blocky organic waste is sent into a material charging water tank, the organic waste goes down onto a conveying device on the bottom of the material charging water tank through the self gravity of the waste and is conveyed from an inlet of a charging passage to an outlet of the charging passage by the conveying device, and enters a feed port of a pyrolysis device; and during the slag discharging process, the strip and blocky slag produced by pyrolysis directly drops into a slag discharging water tank arranged below a slag discharging port through the slag discharging port. The method does not crush the material to be pyrolyzed, has a remarkable energy-saving effect, lower manufacturing cost of the device, and improves efficiency of the recycling synthesis treatment of the organic waste.

Owner:南京绿展能源有限公司

Automatic air renewal system for SCR plate type catalyst calcining furnace

InactiveCN104613780AStable pressureStable atmosphereMaintainance of heating chambersWaste heat treatmentLow activityExhaust fumes

The invention discloses an automatic air renewal system for an SCR plate type catalyst calcining furnace. The automatic air renewal system for the SCR plate type catalyst calcining furnace solves the problem that product defects such as unqualified product calcination quality or low activity are prone to occurring in the prior art. The automatic air renewal system for the SCR plate type catalyst calcining furnace is characterized in that an exhaust gas exhausting device is composed of an exhaust branch pipe (10), an exhaust main pipe (2) and an exhausted flow detection controller (4) which are arranged on the top of the calcining furnace (1); a fresh air supplementary device is composed of an air supplementary branch pipe (9), a fresh air main pipe (3) and an air supplementary flow detection controller (5) which are arranged on one side of the furnace wall; meanwhile a temperature detector (7) and a pressure detector (8) are arranged in the calcining furnace (1), and the temperature detector (7) and the pressure detector (8) are connected with an industrial computer network through circuits. The automatic air renewal system for the SCR plate type catalyst calcining furnace has the advantages that the design is reasonable, the operation is convenient, and the air supplementary and the air exhaust can be carried out effectively and automatically in a balanced mode. The produced SCR plate type denitration catalyst is stable and high in product quality, the product quality is improved, and the automatic air renewal system is worthy of popularization.

Owner:湖北华夏窑炉工业(集团)有限公司

Feeding and slag tapping method in thermal decomposition processing of organic wastes

InactiveCN100586589CLess one-time investmentReduce power consumptionSolid waste disposalIncinerator apparatusSlagHigh energy

The invention relates to a method for material charging and slag discharging during the pyrolysis treatment of organic waste. Crushing treatment which is adopted in the prior art has high investment,high energy consumption and difficult maintenance. The method is realized through the mode of water sealing. The method comprises the following steps: during the material charging process, strip and blocky organic waste is sent into a material charging water tank, the organic waste goes down onto a conveying device on the bottom of the material charging water tank through the self gravity of the waste and is conveyed from an inlet of a charging passage to an outlet of the charging passage by the conveying device, and enters a feed port of a pyrolysis device; and during the slag discharging process, the strip and blocky slag produced by pyrolysis directly drops into a slag discharging water tank arranged below a slag discharging port through the slag discharging port. The method does not crush the material to be pyrolyzed, has a remarkable energy-saving effect, lower manufacturing cost of the device, and improves efficiency of the recycling synthesis treatment of the organic waste.

Owner:南京绿展能源有限公司

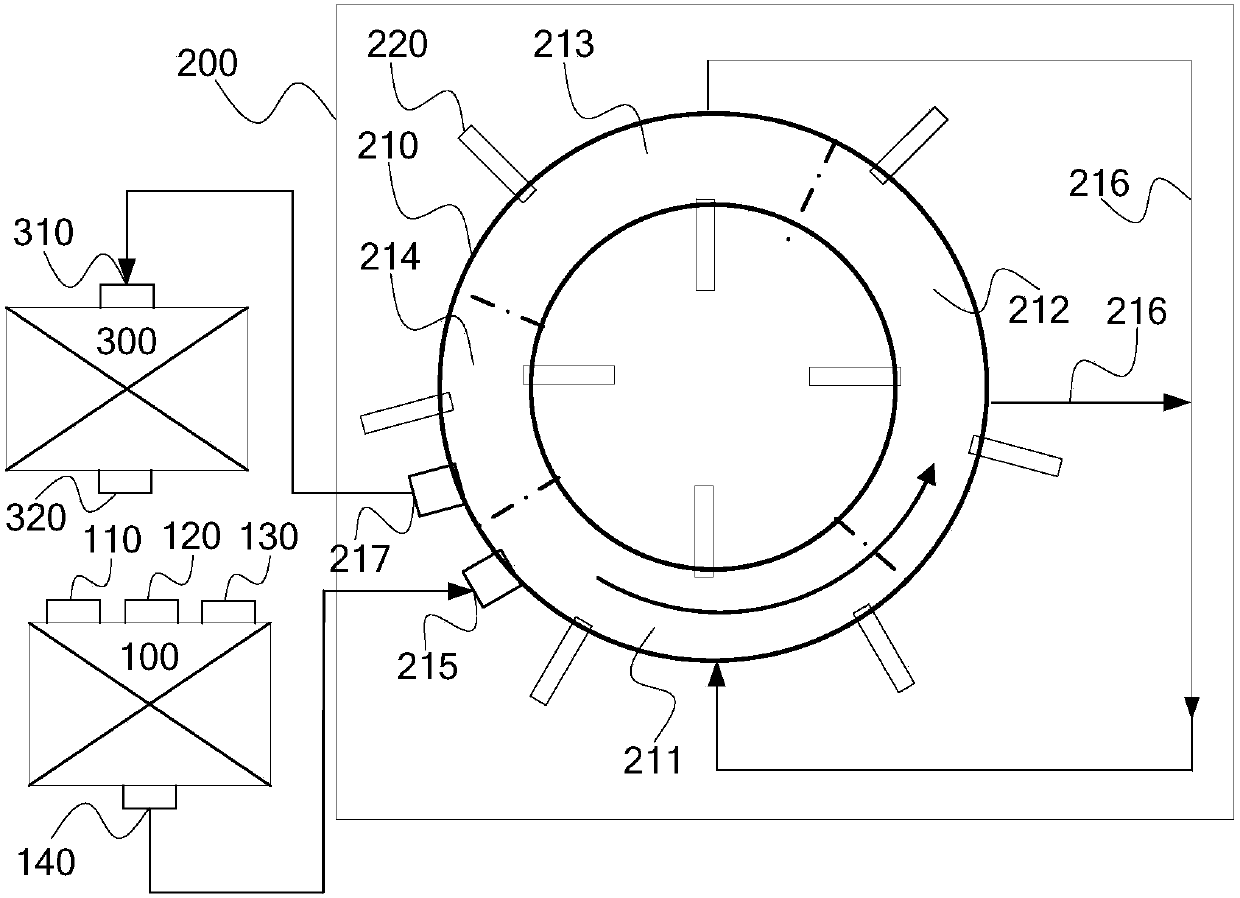

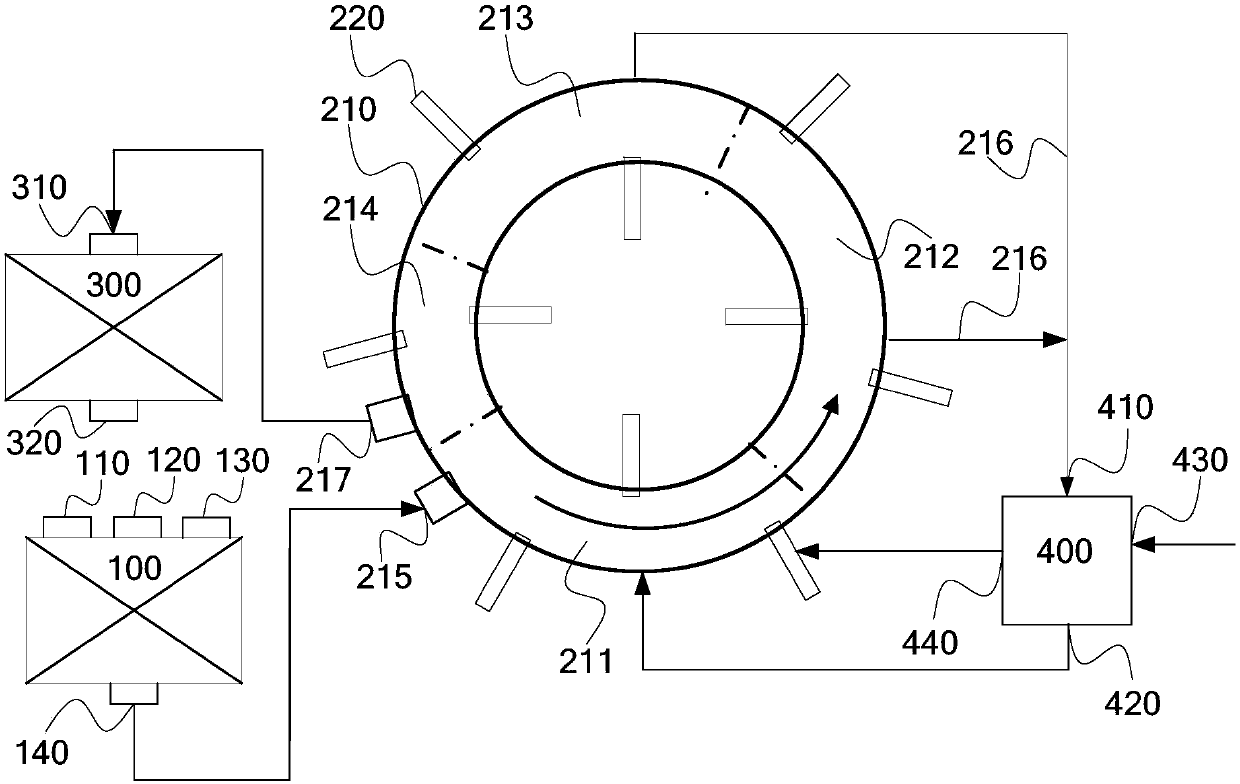

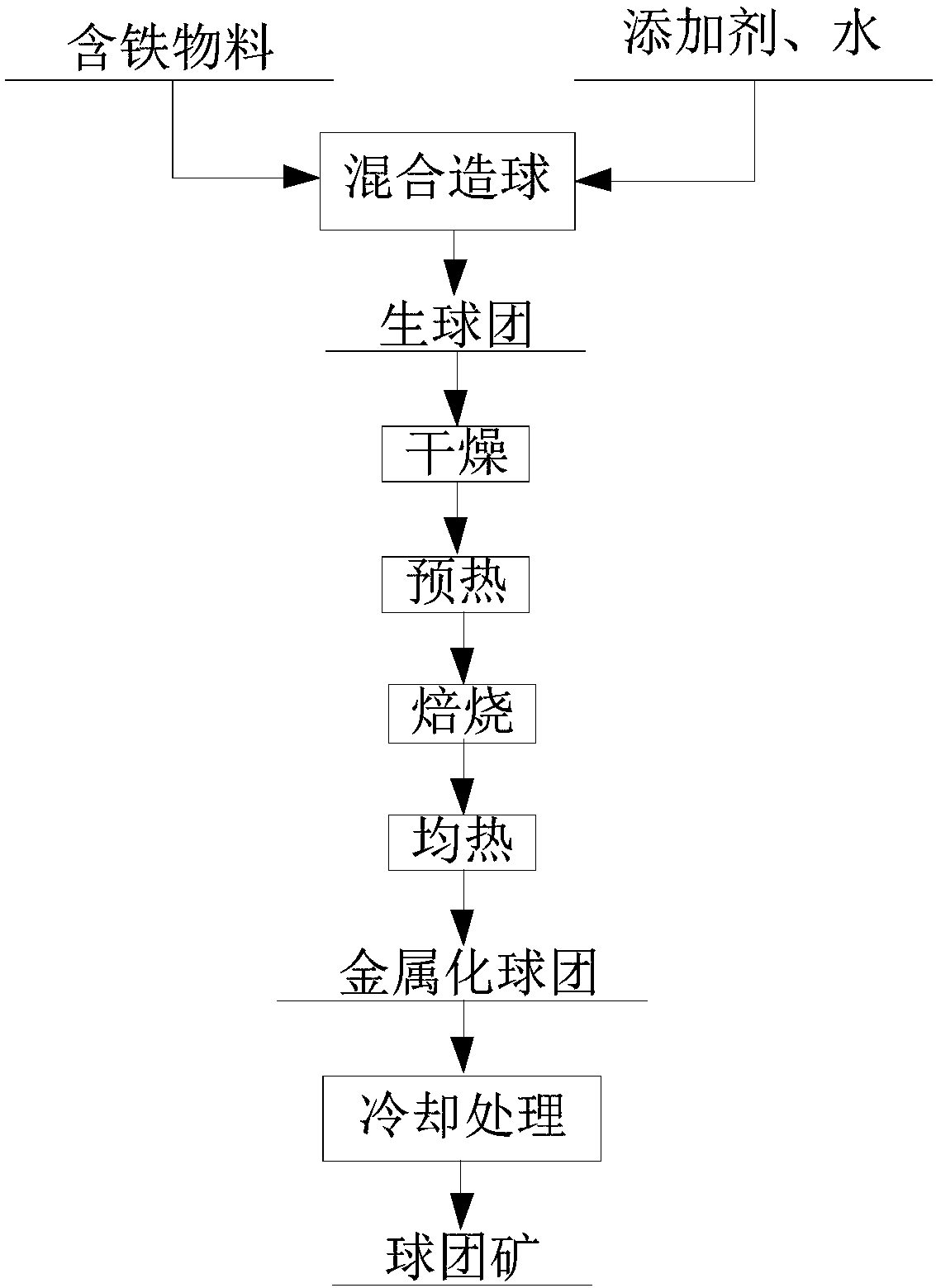

System and method for producing pellet

The invention discloses a system and a method for producing a pellet, wherein the system comprises a pellet making device, an annular roasting device and a cooling device; the pellet making device comprises an iron-containing material inlet, an additive inlet, a water inlet and a raw pellet outlet; the annular roasting device comprises an annular furnace body and a plurality of nozzles; a furnacechamber is defined inside the furnace body; a drying region, a preheating region, a roasting region and a uniform heating region which communicate with one another are defined in the furnace chamber;the drying region comprises a feeding hole which is connected with the raw pellet outlet; the preheating region and the roasting region are each provided with a flue; the uniform heating region comprises a discharging hole; the bottom wall of the annular furnace body is rotatable and is suitable for supporting a material to sequentially pass through the drying region, the preheating region, the roasting region and the uniform heating region; and the plurality of nozzles are arranged on the inner wall of the annular furnace body and are suitable for injecting gas and air into the furnace chamber. The system is low in equipment cost and production cost and applicable to various iron-containing materials, and when being adopted for producing the pellet, the system also has the advantages of short technological process, good pellet quality and the like.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Waste gas protection system for thermal treatment furnace and control method

ActiveCN102051458BReduce entryStable atmosphereMaintainance of heating chambersThermal treatmentProtection system

The invention relates to a waste gas protection system for a thermal treatment furnace and a control method. The system comprises a furnace body and a feeding table, an air displacement chamber is formed between the inlet of the furnace body and the feeding table, a No.1 door is arranged between the air displacement chamber and the feeding table, and a No.2 door is arranged between the air displacement chamber and the inlet of the furnace body; a fuel gas radiation pipe in the furnace body is connected with the input end of a fourth valve through an exhaust pipe, one path of the output end ofthe fourth valve is communicated with a burner waste gas exhaust pipe through a first valve, and the other path of the output end of the fourth valve is communicated with the cavity of the air displacement chamber through a second valve; and the burner waste gas exhaust pipe is communicated with the cavity of the air displacement chamber through a third valve, the system is provided with a blower, and the output port of the blower is arranged in the burner waste gas exhaust pipe. The system has the advantages that: a vacuum chamber is replaced by using the air displacement chamber, and the air in the air displacement chamber is displaced by using CO2 serving as a main component of the waste gas, so the air entering the furnace is reduced, and stability of furnace atmosphere is realized.

Owner:HANGZHOU JINZHOU TECH CO INC

Intelligent adjusting method for air convection in induction furnace during online-moving heating of steel plate

ActiveCN105648202AReduce convectionAvoid convectionFurnace typesIncreasing energy efficiencyControl systemInductor

The invention discloses an intelligent adjusting method for air convection in an induction furnace during online-moving heating of a steel plate. Firstly, the steel plate enters the heating induction furnace through a furnace front roller bed and is heated in the induction furnace, and an air flow detecting device of an air flow detecting and adjusting system mounted on the inner surface of an upper inductor is used for detecting air flowing in the induction furnace in real time and sending detection data to an intelligent processing unit; secondly, the intelligent processing unit is used for working out the air flowing direction and strength in the induction furnace according to the detection data and working out the air flow rate and the acting direction needed for counteracting air flowing, and worked-out results are sent to a PLC control system; thirdly, the PLC control system gives out adjusting commands to an air blowing device of the air flow detecting and adjusting system, and the adjusting commands include the air flow rate command and the air flow direction command; and fourthly, the air blowing device carries out real-time air-blowing adjustment, so that air convection in the furnace is lowered to an allowed range.

Owner:BAOSHAN IRON & STEEL CO LTD

Atmosphere tubular furnace cooling device and cooling method

ActiveCN112097525AEasy to operateEasy to processMuffle furnacesFurnace cooling arrangementsTube furnaceWater trap

The invention discloses an atmosphere tubular furnace cooling device and a cooling method. The cooling device comprises a gas transmission device, a water cooling device, a vacuum sealing device, an interface device and a locking device; one end of the gas transmission device is fixedly connected with the water cooling device in a sealed manner; the water cooling device is in full-plane sealing connection with the vacuum sealing device; a water inlet end opening and a water outlet end opening of the water cooling device are connected with corresponding end openings of an external water sourcethrough reducers respectively; vortexes are formed in a water path; the other end of the vacuum sealing device is connected with an end opening of a vacuum atmosphere tubular furnace through the interface device in a sealed manner; the water cooling device, the vacuum sealing device, the interface device and the end opening of the vacuum atmosphere tubular furnace are connected in a sealing mannerby the locking device; and the gas transmission device, the water cooling device, the vacuum sealing device and the interface device are concentrically connected with the vacuum atmosphere tubular furnace. The problems about heat dissipation and vacuum sealing performance of the two ends of a furnace tube of an existing atmosphere tubular furnace in the product sintering process are solved, and the cooling device is widely applied to a cooling system of the vacuum atmosphere tubular furnace.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

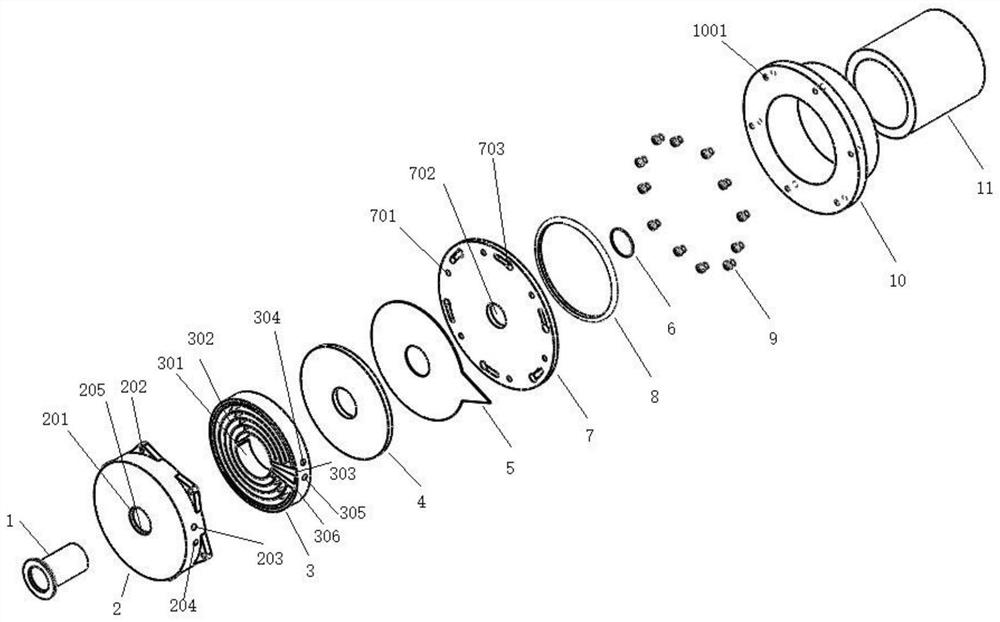

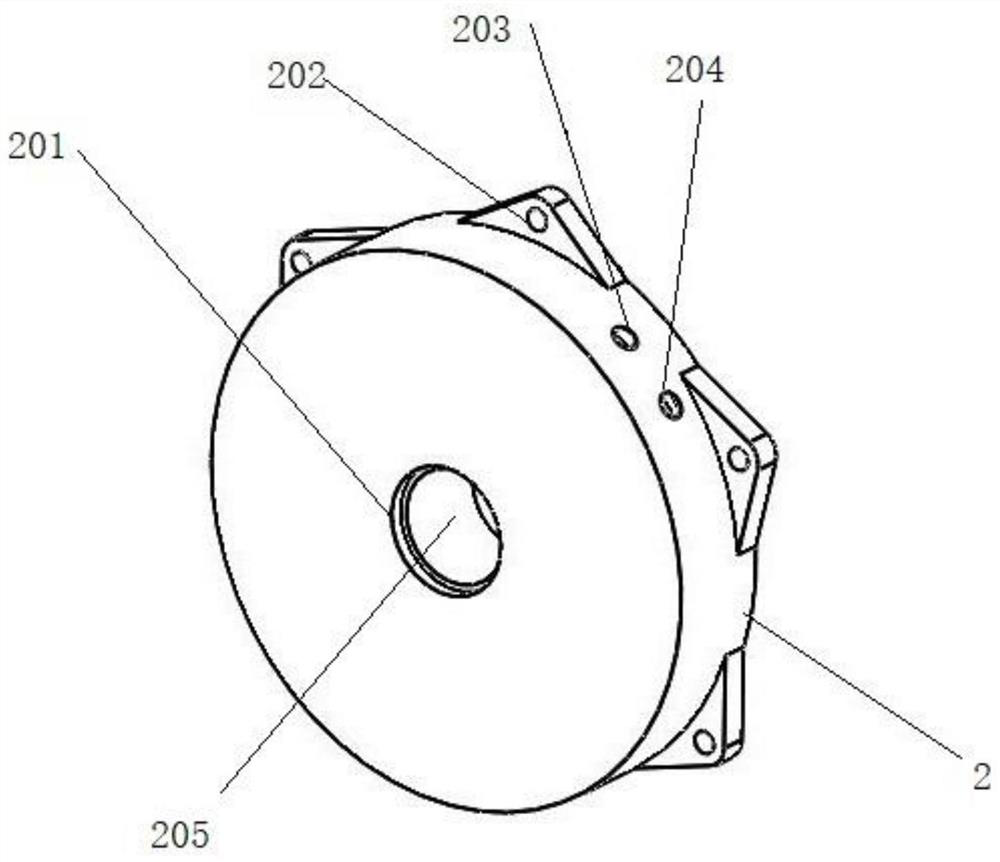

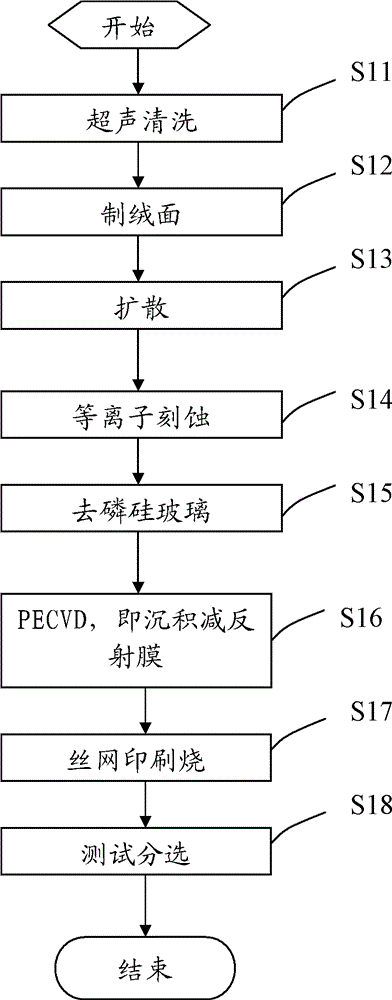

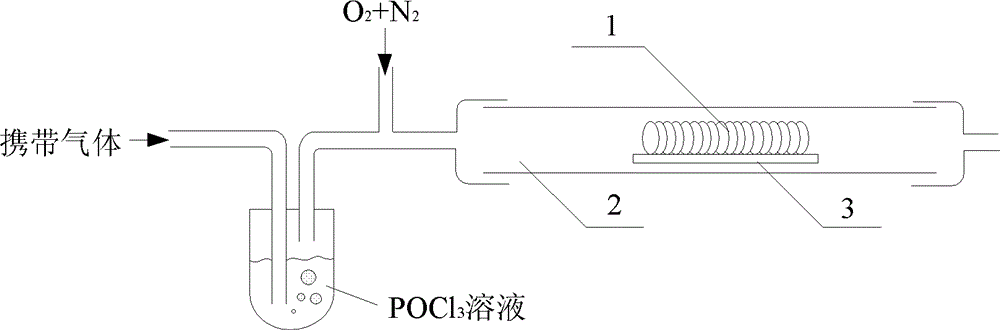

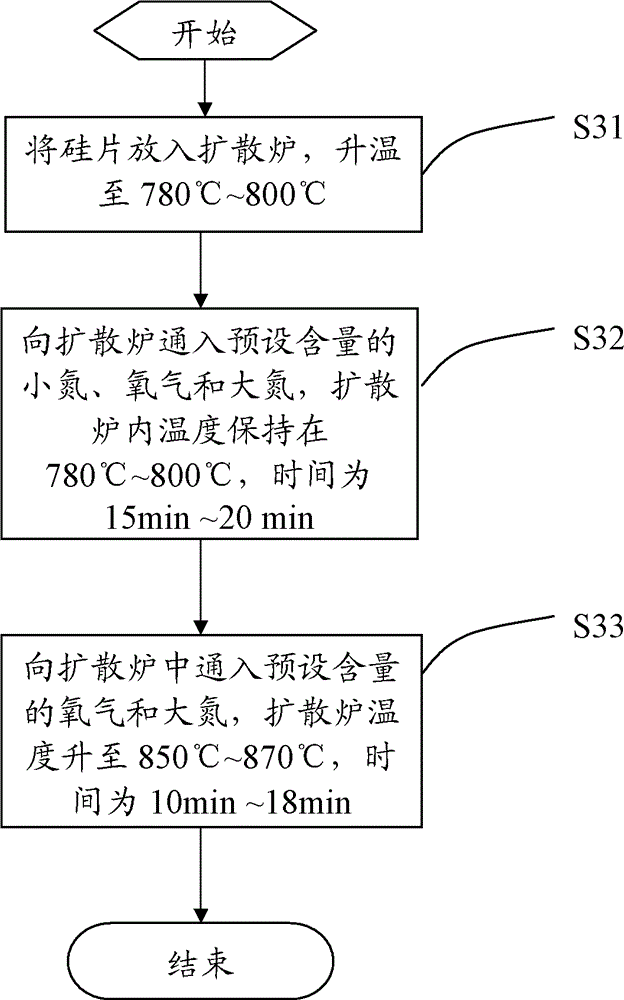

Crystalline silicon solar cell and diffusion method thereof

ActiveCN102254991BReduced activityReduce disturbanceFinal product manufacturePhotovoltaic energy generationDiffusion methodsMetallurgy

The invention discloses a crystalline silicon solar cell and a diffusion method thereof. The method comprises the following steps of: putting a silicon chip into a diffusion furnace and raising the temperature to 780-800 DEG C; introducing a preset amount of small nitrogen, oxygen and large nitrogen into the diffusion furnace through a diffusion furnace tube and keeping the internal temperature of the diffusion furnace at 780-800 DEG C for 15-20 minutes; introducing a preset amount of oxygen and large nitrogen into the diffusion furnace through the diffusion furnace tube and raising the internal temperature of the diffusion furnace to 850-870 DEG C for 10-18 minutes; and cooling the diffusion furnace and taking the silicon chip out, wherein the gas flow in the diffusion furnace tube is constant in the entire diffusion process. The depth of a PN junction of a solar cell produced with the method is small, the square resistance is more uniform, and the conversion efficiency of the solar cell is increased.

Owner:JETION SOLAR HLDG

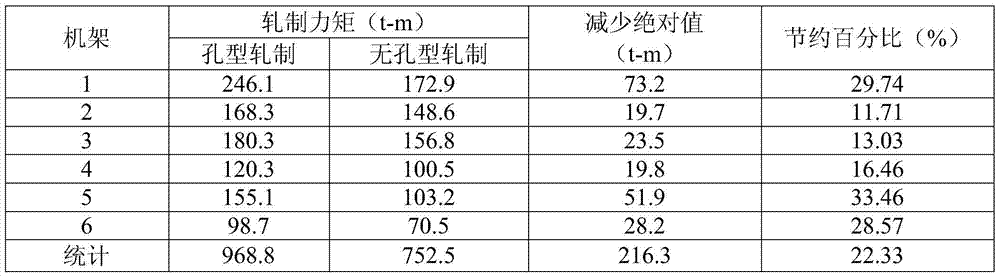

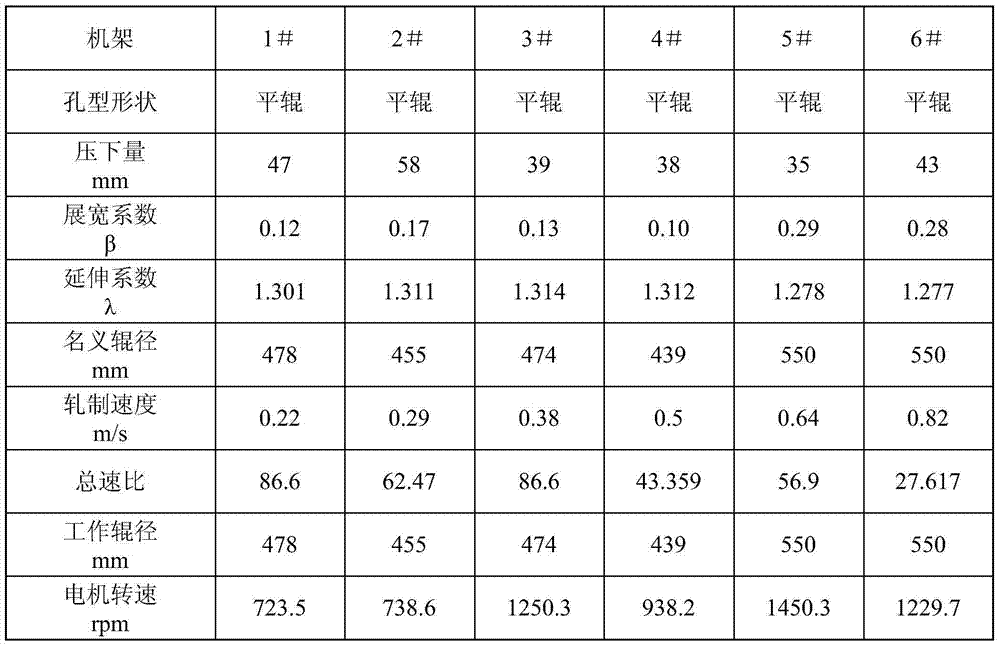

A production process for rolling 82b wire rod without holes in a high-speed wire rod mill

ActiveCN104084421BSharedReduce reservesWork treatment devicesMetal rolling arrangementsWire rodStrip mill

The invention belongs to the technical field of rod wire deformation processes in metallurgical industry and particularly relates to a production process for grooveless rolling of an 82B wire rod by a high-speed wire mill. The production process aims that special equipment is not required, the processing cost is low, industrialized production is easy to realize, the steel off-square problem of a grooveless rolling production process is solved, the production accident rate is greatly reduced, the product quality is improved, and the economic benefit is increased. The production process adopts the technical scheme as follows: the production process comprises the following steps: (1) heating a 82B steel billet; (2) rolling by a grooveless flat-roll rough rolling unit, wherein in the rolling process, the extension coefficient of each pass is controlled from 1.20 to 1.45, the broadening coefficient ranges from 0.10 to 0.65, and the running speed of the steel billet ranges from 0.20 m / s to 1.04 m / s; (3) entering an intermediate rolling unit and a pre-finishing unit in sequence for rolling; (4) rolling by a finishing unit; (5) cooling by water and entering a wire-feeding machine to obtain the wire rod; (6) cooling by air, winding and transporting, and finally packaging and warehousing to obtain the finished high-speed 82B wire rod.

Owner:西安盛日机电科技有限公司

An organic-inorganic hybrid halide luminescent material and its preparation method and application

ActiveCN112521938BEasy to prepareExcellent optical propertiesAmino preparation from aminesLuminescent compositionsHalogenStructural formula

The invention discloses an organic-inorganic hybrid halide luminescent material and its preparation method and application. The luminescent material is an organic-inorganic hybrid copper-based halide based on a quaternary ammonium salt, and its structural formula is A m Cu n x (m+n) , where A is the organic chain part of the quaternary ammonium salt, X is the halogen ion Cl ‑ , Cl ‑ , Br ‑ , I ‑ One or any combination of several anions, m and n are integers from 1 to 3, respectively. The organic-inorganic hybrid halide prepared based on the quaternary ammonium salt and the copper base has the characteristics of high PLQY, tunable spectrum, good stability in the atmosphere, and environmental friendliness.

Owner:XI AN JIAOTONG UNIV

Whole body double-sided flame-insulated heating rotary kiln and method for producing direct reduced iron and co-producing carbon-based fertilizer

ActiveCN106636519BIncrease production capacityReduce sizeRotary drum furnacesHigh concentrationFilling rate

The invention relates to a whole-body double-sided flame-separated heating rotary kiln and a method for producing direct reduced iron and co-producing carbon-based fertilizer. The rotary kiln cylinder body designed in the present invention is designed as an outer cylinder and an inner cylinder, and a deep reduction chamber is formed between the outer cylinder and the inner cylinder, which is divided into 6 to 12 deep reduction chambers by supporting partitions. The same amount of reduced materials can be filled in the deep reduction chamber of the deep reduction chamber, the filling rate is increased by 6 to 12 times, and the direct reduced iron production capacity of the rotary kiln is also increased by 6 to 12 times, which greatly increases the production capacity of the kiln, and is also relatively The specification of the kiln is reduced, and the investment of the kiln is relatively greatly reduced. Biomass materials such as straws other than coal can be used as reducing agents, which solves the environmental pollution caused by the incineration of biomass materials, turns waste into treasure, and simultaneously recovers high-concentration gas and co-produced bio-carbon-based fertilizer by-products, and realizes Energy saving, emission reduction and carbon reduction, and does not produce NOx.

Owner:辽宁盛京时代科技有限公司

A titanium alloy supporting ring fusion welding gas protection drag cover and protection method

The invention discloses a titanium-alloy supporting ring fusion-welding gas shield trailing cover and a shielding method. A trailing cover main body of a shield trailing cover is of a box structure and provided with an opening in the front face and an opening in the bottom face; a welding gun nozzle mounting hole is formed in the front end of the top face of the trailing cover main body, and an upper pipe with argon is arranged on the top face of the trailing cover main body; an inclined side plate is connected to the lower end of the left side face of the trailing cover main body and is inclined toward the outer side of the trailing cover main body; a web is connected to the right side face of the trailing cover main body, and a side pipe with argon is connected to the side face of the web; and the lower end of the inclined side plate and the lower end of the right side face of the inclined side plate are each of a circular arc structure which has the same curvature with the welding face of an outer circle of a supporting ring. The titanium-alloy supporting ring fusion-welding gas shield trailing cover can ensure that the heat affected area with the temperature of welding seam molten pool and parts exceeding 400 DEG C is not oxidized.

Owner:AECC AVIATION POWER CO LTD

Production process of winebottles with decorations

The invention discloses a production process of winebottles with decorations and can effectively reduce the occurrence probability of black spots on the surfaces of glass winebottles. The production process of winebottles with decorations comprises: a. applying appliques on the external surfaces of the glass winebottles; b. placing the multiple glass winebottles with appliques into the inner cavity of a decoration firing furnace for baking, so that a coloured glaze can be welded on the external surfaces of the glass winebottles. Specifically, step b consists of the steps of: while putting themultiple glass winebottles in the decoration firing furnace, keeping the volume sum of coloured glazes of appliques on the multiple glass winebottles at an amount of V1 and the inner cavity volume ofthe decoration firing furnace at an amount of V2, with the ratio of V1 to V2 less than or equal to 0.01 per thousand, and controlling an equal space between any two glass winebottles; heating the glass winebottles to a temperature of 580DEG C-590DEG C in the decoration firing furnace by means of preheating and temperature raising, and making the coloured glazes firmly welded on the external surfaces of the glass winebottles through an insulation process; cooling the glass winebottles. The process provided in the invention can effectively prevent formation of black spots on the surfaces of glass winebottles.

Owner:SICHUAN SWELLFUN

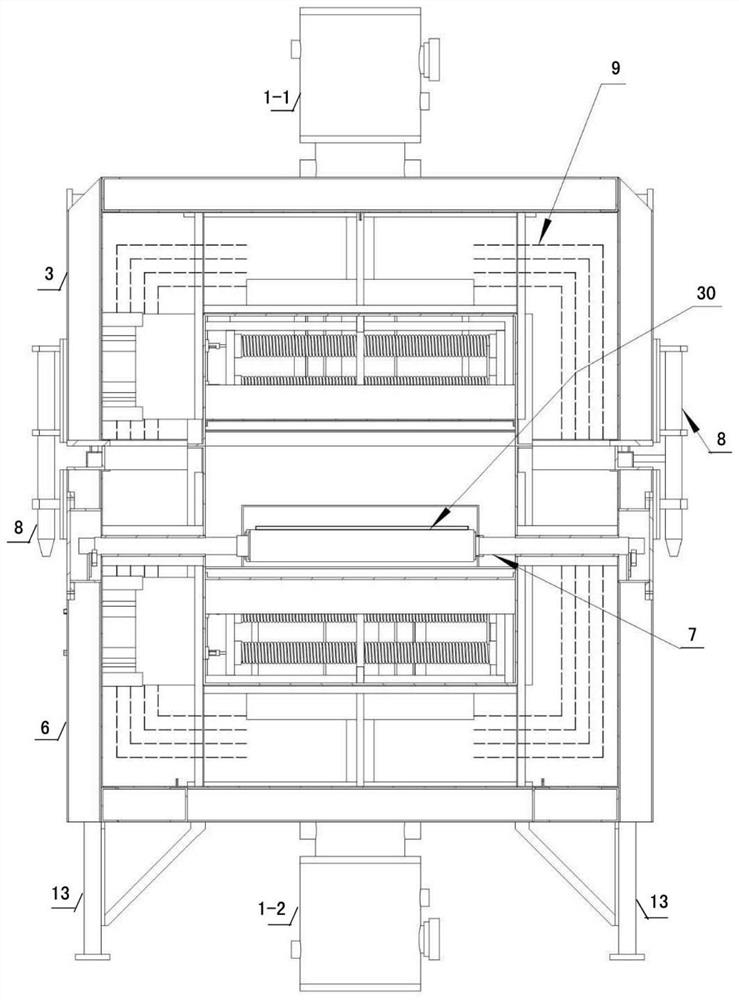

Improved structure strong wind tempering furnace for steel belt heat treatment

PendingCN112342365AInput stableFix stability issuesFurnace typesHeat treatment furnacesThermodynamicsTempering

The invention relates to an improved structure strong wind tempering furnace for steel belt heat treatment, the improved structure strong wind tempering furnace comprises a furnace body and a furnacecover, and is characterized in that an upper lining box is arranged in an inner cavity of the furnace cover, a lower lining box is arranged in an inner cavity of the furnace body, the upper lining boxis arranged above a workpiece processing channel, the lower lining box is arranged below the workpiece processing channel, and a structure for sealing the workpiece processing channel is formed; a plurality of ventilation openings are respectively formed in the bottom surface of the upper lining box and the top surface of the lower lining box to form a protective atmosphere circulation loop; twowater-cooling fans are arranged and comprise an upper water-cooling fan and a lower water-cooling fan, the upper water-cooling fan is arranged in the inner cavity of the furnace cover, the lower water-cooling fan is arranged in the inner cavity of the furnace body, and an upward and downward opposite blowing structure is formed; and four sets of heating boxes are arranged and comprise the upper heating boxes and the lower heating boxes, the upper heating boxes are arranged in the inner cavity of the furnace cover, the lower heating boxes are arranged in the inner cavity of the furnace body, and an up-down opposite heating structure is formed. The improved structure strong wind tempering furnace has the characteristics of stable protective atmosphere input, uniform workpiece heating and thelike.

Owner:GUANGDONG STRONG METAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com