System and method for producing pellet

A technology for pellets and green pellets, which is applied in the field of systems for producing pellets, can solve the problems of low single-machine production capacity, high production and maintenance costs, uneven heating, etc., so as to reduce equipment and production costs and shorten production processes. Process, the effect of reducing the amount of powder returned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

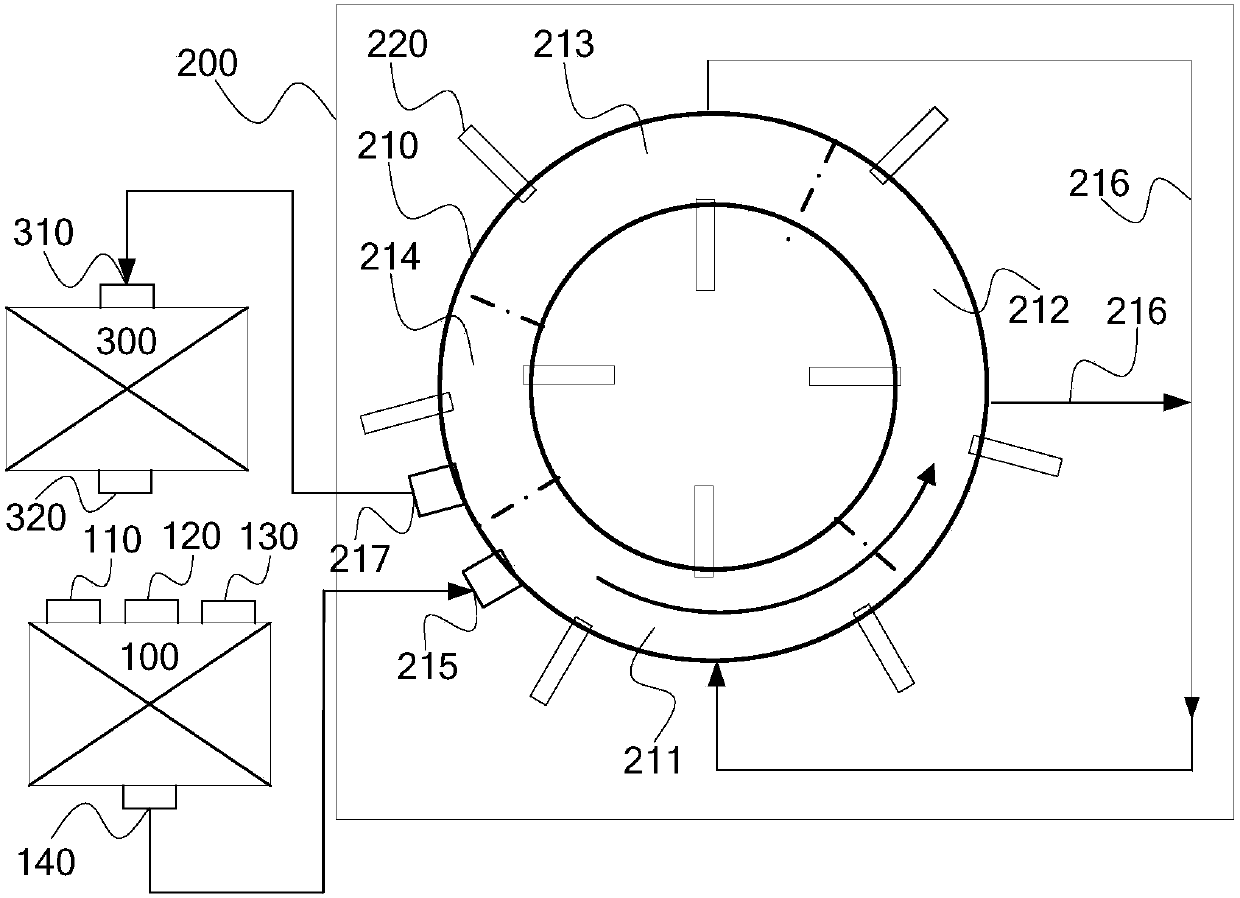

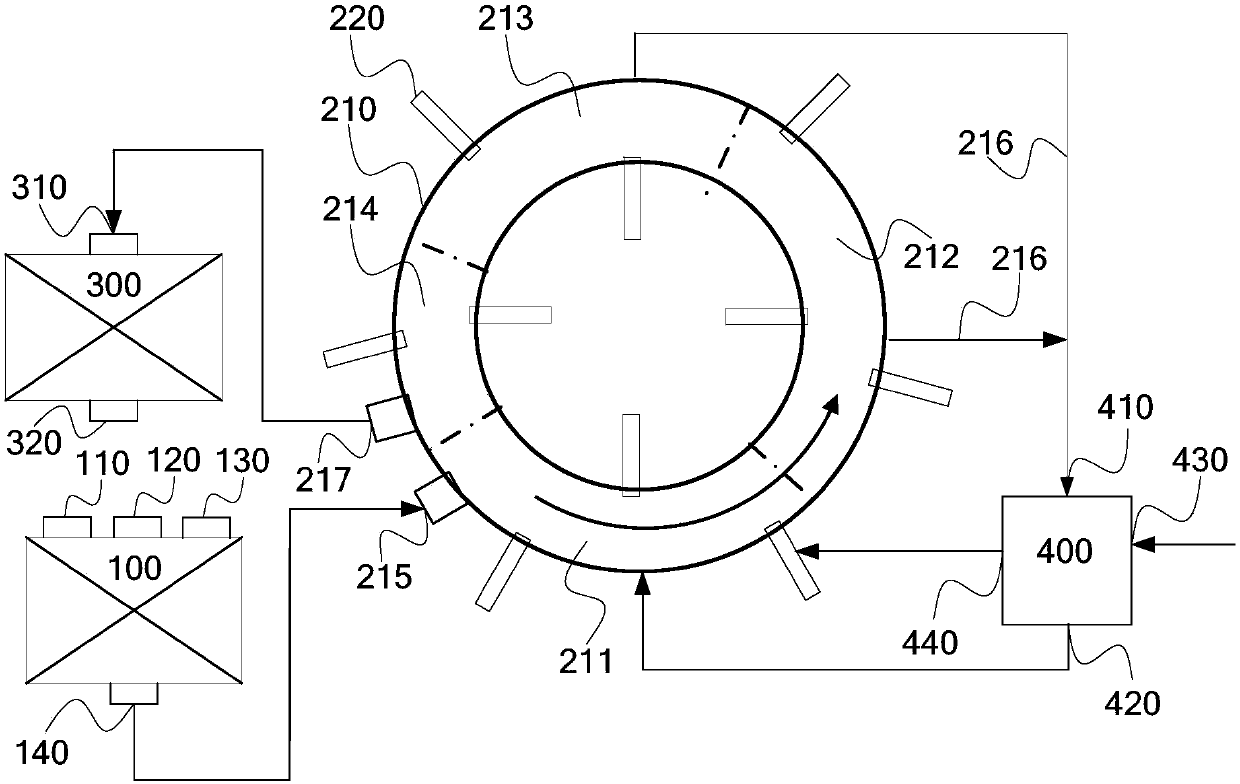

Method used

Image

Examples

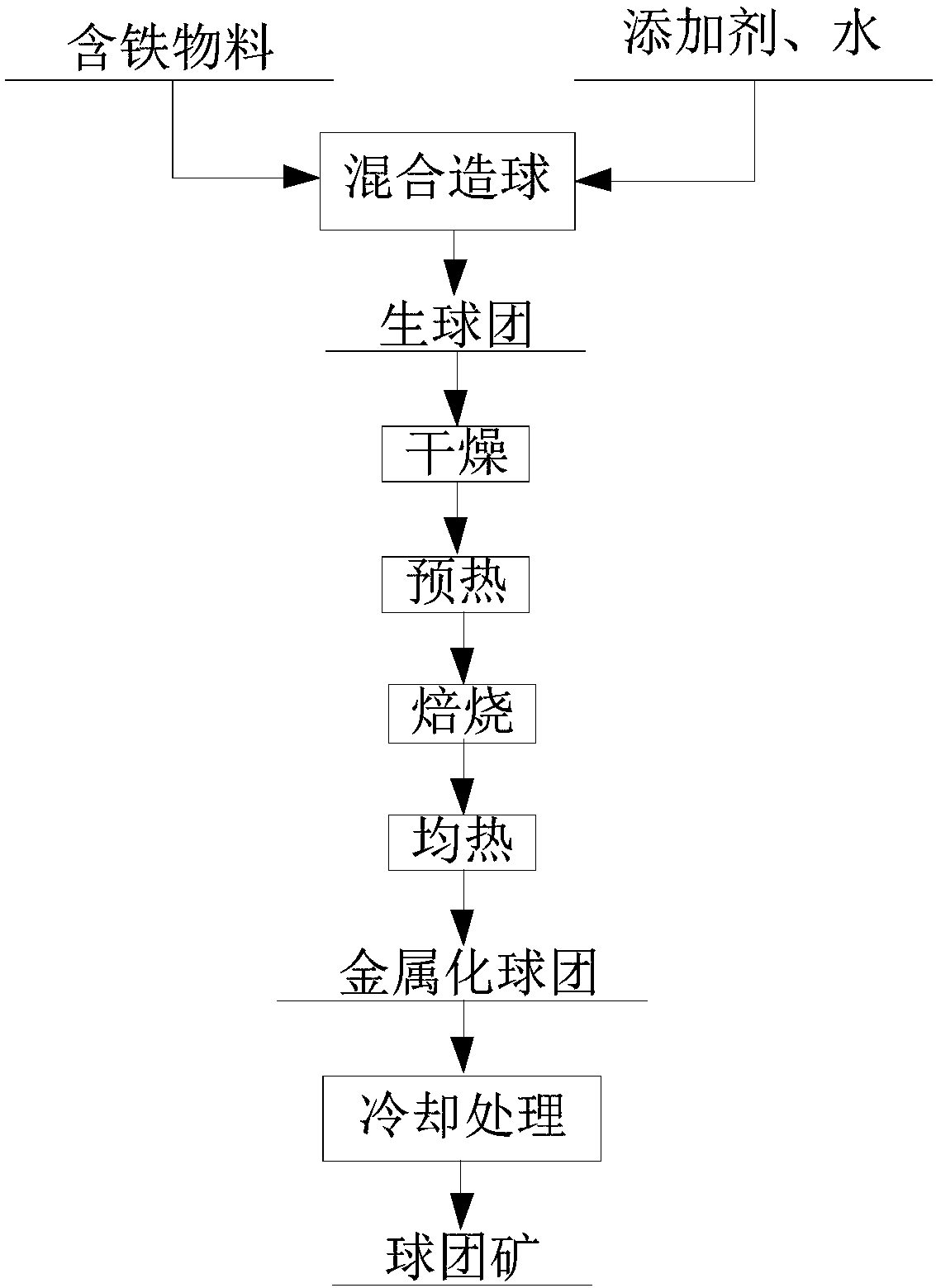

Embodiment 1

[0075] A certain hematite TFe53.6% is mixed with bentonite and water to make pellets to obtain green pellets with a particle size of 8-16mm and a moisture content of 8.7%; put the green pellets into the ring roasting device, and make the green pellets The pellets are sequentially dried, preheated, roasted and soaked through the drying zone, preheating zone, roasting zone and soaking zone to obtain metallized pellets, wherein the angle of the drying zone is 80° and the temperature is 250°C; The angle of the preheating zone is 105° and the temperature is 350-950°C; the angle of the roasting zone is 135° and the temperature is 1350°C; the angle of the soaking zone is 40° and the temperature is 1100°C; the thickness of the fabric is 60mm. The metallized pellets were subjected to a cooling treatment to obtain pellets having an average compressive strength of 2695 N / ball and a FeO content of 0.21%.

Embodiment 2

[0077] A certain magnetite TFe61.2% is mixed with bentonite and water to make pellets to obtain green pellets with a particle size of 8-16mm and a moisture content of 9.3%; put the green pellets into the ring-shaped roasting device, and make the green pellets The pellets are sequentially dried, preheated, roasted and soaked in the overdrying zone, preheating zone, roasting zone and soaking zone in order to obtain metallized pellets, wherein the angle of the drying zone is 75° and the temperature is 200 ℃; the angle of the preheating zone is 135°, and the temperature is 400-1000°C; the angle of the roasting zone is 120°, and the temperature is 1250°C; the angle of the soaking zone is 30°, and the temperature is 1050°C; the thickness of the fabric is 100mm. The metallized pellets were cooled to obtain pellets, wherein the pellets had an average compressive strength of 3250N / ball and a FeO content of 0.63%.

Embodiment 3

[0079] A certain limonite TFe45.6% is mixed with bentonite and water to make pellets to obtain green pellets with a particle size of 8-16mm and a moisture content of 12.3%; put the green pellets into the ring roasting device, and make the green pellets The pellets are sequentially dried, preheated, roasted and soaked through the drying zone, preheating zone, roasting zone and soaking zone in order to obtain metallized pellets, wherein the angle of the drying zone is 105° and the temperature is 300°C; The angle of the preheating zone is 120° and the temperature is 400-1000°C; the angle of the roasting zone is 105° and the temperature is 1300°C; the angle of the soaking zone is 30° and the temperature is 1000°C; the cloth thickness is 150mm. The metallized pellets were subjected to a cooling treatment to obtain pellets having an average compressive strength of 2234 N / ball and a FeO content of 0.81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com