Method and device for preparing crude silver alloy through anode slime

A technology of anode slime and coarse silver, which is applied in the field of metallurgy, can solve the problems of high production cost, low thermal efficiency, and long process, and achieve the effects of low cost, good thermal efficiency, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

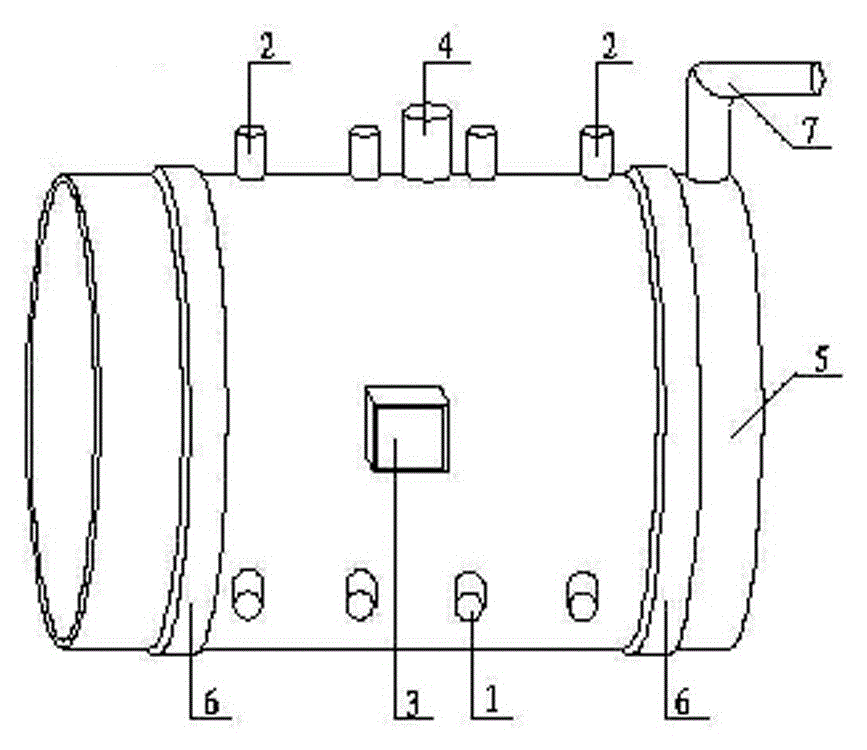

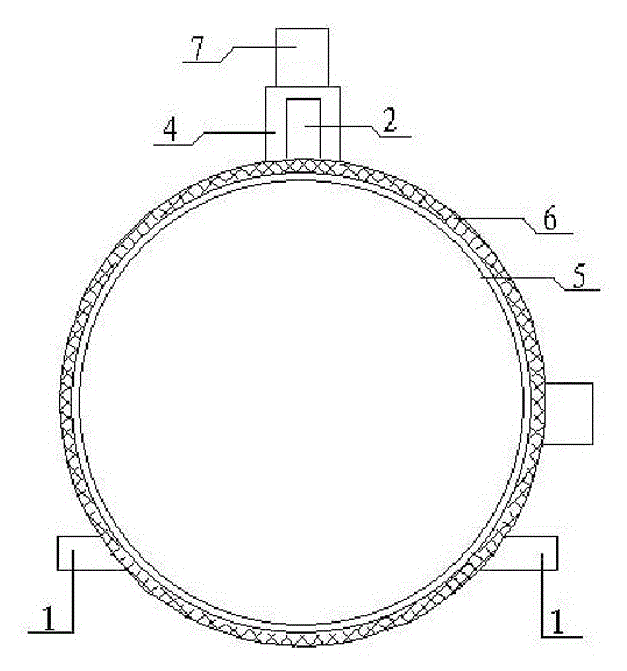

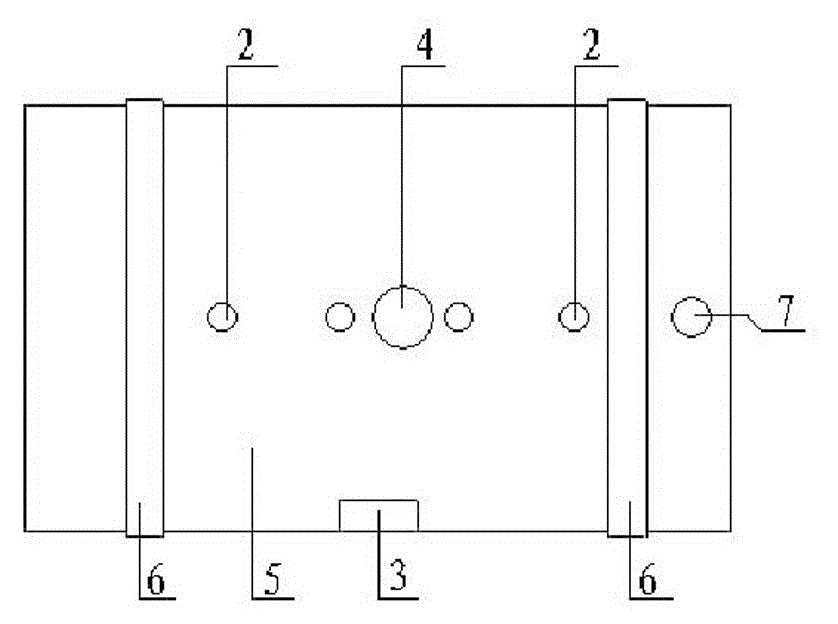

Image

Examples

Embodiment 1

[0044] (1) Bake 40t of anode slime (Pb15.0wt%, Sb40.0wt%, Ag5.0wt%) at 60°C to make anode slime, particle size Φ20mm, moisture 10%, and put it into the hopper for feeding.

[0045] (2) Add 10t of anode slime into the side-top composite smelting converter from the feed port, open the top spray gun of the side-top composite smelting converter, keep the furnace temperature at 700°C, and the anode slime is completely melted after 60 minutes; then, lift the top spray gun away Melt pool, start side blowing lance. Add the remaining 30t of anode slime evenly in 1 hour, and keep the air volume of the side blowing spray gun at 20000m 3 / h, wind pressure 3500Pa, oxygen concentration 30%. When melting, the furnace temperature rises to 1100°C, and the melting time is 6 hours.

[0046] (3) Control the air volume of the side blowing spray gun to 30000m 3 / h, wind pressure 4000Pa, oxygen enrichment concentration 45%, blowing time 4h, furnace temperature 1200℃, add 0.8t of soda ash for oxid...

Embodiment 2

[0050] (1) Bake 20t of anode slime (Pb20.0wt%, Sb30.0wt%, Ag15.0wt%) at 80°C to make anode slime, particle size Φ40mm, moisture 20%, put into the hopper for feeding.

[0051] (2) Put 5t of anode slime into the side-top composite smelting converter from the feed port, open the top spray gun of the side-top composite smelting converter, keep the furnace temperature at 900°C, and completely melt the anode slime after 20 minutes; then, lift the top spray gun away In the molten pool, start the side-blowing spray gun, and then add the remaining 15t of anode slime evenly in 40 minutes, and keep the air volume of the side-blowing spray gun at 18000m 3 / h, wind pressure 2400Pa, oxygen enrichment concentration 28%, raise the furnace temperature to 1300°C, and the melting time is 4h.

[0052] (3) Control the air volume of the side blowing spray gun to 15000m 3 / h, wind pressure 3000Pa, oxygen enrichment concentration 40%, blowing time 2h, furnace temperature 1300℃, add 0.6t of soda ash ...

Embodiment 3

[0056] (1) Bake 30t of anode slime (Pb18.0wt%, Sb35.0wt%, Ag10.0wt%) at 100°C to make anode slime, particle size Φ40mm, moisture 20%, put into the hopper for feeding.

[0057] (2) Add 10t of anode slime into the side-top composite smelting converter from the feed port, open the top spray gun of the side-top composite smelting converter, keep the furnace temperature at 800°C, and completely melt the anode slime after 30 minutes; then, lift the top spray gun away Melt pool, start side blowing lance. Add the remaining 20t of anode slime evenly in another 50 minutes, and keep the air volume of the side blowing spray gun at 18000m 3 / h, wind pressure 3000Pa, oxygen enrichment concentration 30%. When melting, the furnace temperature rises to 1200°C, and the melting time is 5 hours.

[0058] (3) Keep the air volume of the side blowing spray gun at 18000m 3 / h, wind pressure 3500Pa, oxygen enrichment concentration 43%, blowing time 3h, furnace temperature 1100℃, add 0.7t of soda as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com