Feeding and slag tapping method in processing of thermal decomposition of organic wastes

A technology of organic waste and feed material, which is applied in the field of feed and slag discharge during the pyrolysis process of organic waste, which can solve the problems of high investment in crushing machinery, large land occupation, high energy consumption, etc., and achieve the quality of pyrolysis products High, small workshop area, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The method of the present invention is specifically described below through an example of pyrolysis of waste tires.

[0019] The feed and slag discharge in the pyrolysis treatment of waste tires adopts a water-tight method. Among them, the feed is realized through the feed water tank, the feeding channel and the conveying device; the slag discharge is realized through the slag discharge water tank.

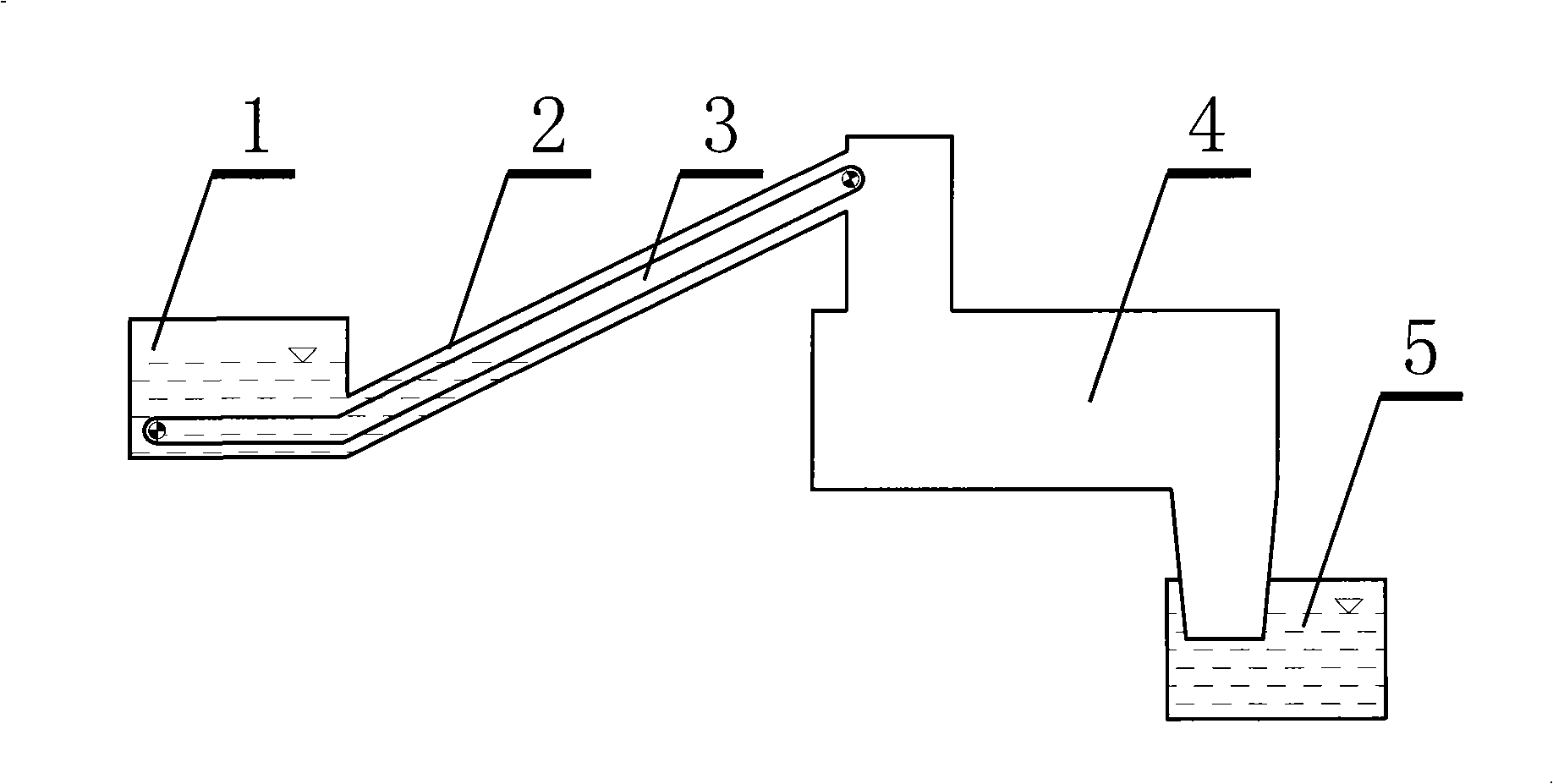

[0020] Such as figure 1 , The feed water tank 1 is a tank with an open top, and the feed channel 2 is a pipe with both ends open and side walls sealed. The feeding channel 2 is inclined upward from the inlet to the outlet, the inlet is connected with the lower part of the feed water tank 1, the outlet is sealed and connected with the feed port in the pyrolysis device 4, and the outlet is higher than the water level in the feed water tank 1 and the feed channel 2 . A part of the conveying device 3 is arranged at the bottom in the feed water tank 1 , and a part is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com