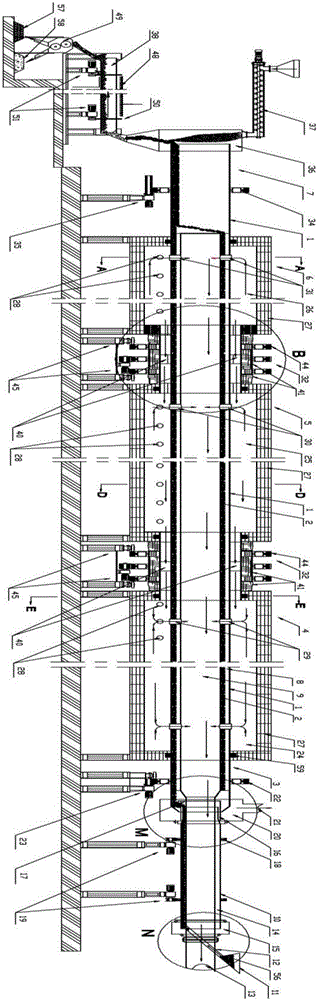

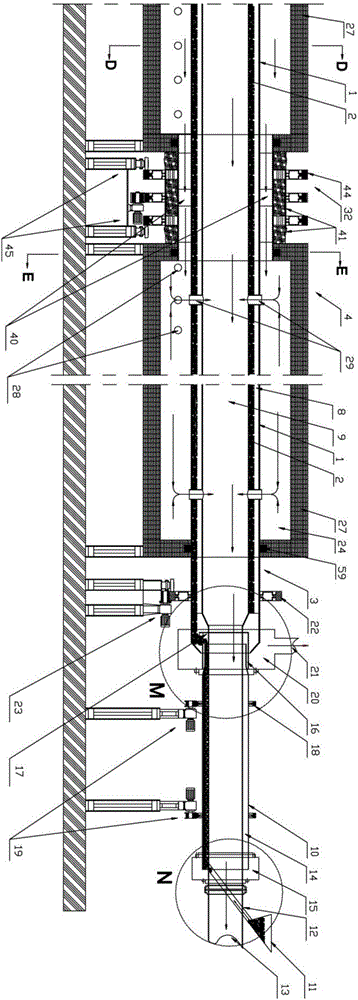

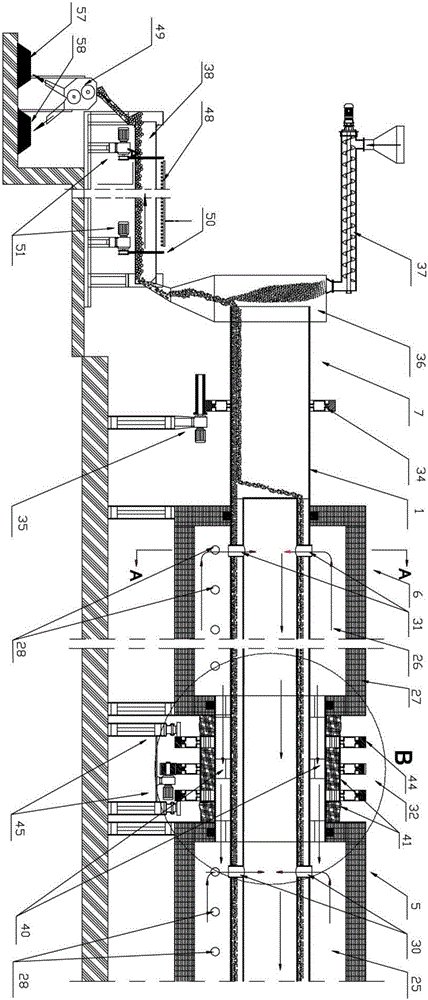

Whole-body two-sided flame separating type heating rotary kiln and method for producing direct reduction iron co-production carbon base fertilizer

A rotary kiln, double-sided technology, applied in the direction of rotary drum furnace, furnace, furnace type, etc., can solve the problems of short reduction kiln, small kiln scale, instability, etc., to increase production capacity, reduce investment, reduce The effect of the specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Add 45% biomass carbonized particles according to the weight of iron oxide scale, particle size ¢8mm×6mm, mix the two into the flame-type rotary kiln, reduce at 1080°C for 2.5h, and discharge through the cooling section, It is covered and protected by biomass material particles, cooled to 150°C by a cooling drum, and the direct reduced iron product of 1-20mm is separated by dry magnetic separation, and then polished to a fineness of 0-1mm, which is high-quality chemical metal iron powder , water purifying agent or reduced iron powder product; take the dried and carbonized biomass carbon materials separated by dry magnetic separation with a particle size of 0-8mm, and sieve out the coarse particles with a fineness of 2-8mm as The reducing agent is recycled, and the mixture with a fineness of 0-2 mm under the sieve is a by-product of carbon-based fertilizer.

[0106] The product indicators are as follows:

[0107] 1) Reduced iron products

[0108]

[0109] 2) Carbon-...

Embodiment 2

[0112] Add 50% biomass carbon particles (after the straw is squeezed and dried) according to the weight of the wire-drawn oxide scale, the particle size is ¢8mm×8mm, put the two into the flame-type rotary kiln, and reduce it at 1050°C for 2.6h. After the cooling section is discharged, it is covered with biomass material particles for protection, and cooled to 150°C by a cooling drum; the 1-20mm direct reduced iron product separated by dry magnetic separation is cold-pressed into pellets, which are used as smelting high-quality The reduced iron product of special steel is the metal cold briquetting (MBI) product; take the dried and dry-distilled biomass carbon material with a particle size of 0-8mm separated by dry magnetic separation, and screen out the fineness of 2 Coarse particles of -8mm are recycled as a reducing agent, and the mixture with a fineness of 0-2mm under the sieve is a by-product of carbon-based fertilizer.

[0113] The product indicators are as follows:

[0...

Embodiment 3

[0120] Crush and sort the gas-cutting slag into 2-10mm particles, add 48% carbonized biomass carbon particles according to the weight of the gas-cutting slag, and the particle size is ¢6.5mm×7mm. Reduction for 2.8 hours, after being discharged from the cooling section, covered with biomass material particles for protection, and cooled to 180°C through a cooling drum; take the 1-20mm direct reduced iron product separated by dry magnetic separation, and grind it into a 0- 1mm fineness, that is, high-quality chemical metal iron powder, water purifying agent or reduced iron powder products; take the dried and dry-distilled biomass carbon materials with a particle size of 0-8mm separated by dry magnetic separation, and screen out the fine Coarse particles with a fineness of 2-8mm are recycled as a reducing agent, and the mixture with a fineness of 0-2mm under the sieve is a by-product of carbon-based fertilizer.

[0121] The product indicators are as follows:

[0122] 1) Reduced i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com