Crystalline silicon solar cell and diffusion method thereof

A technology of solar cell sheet and diffusion method, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low conversion efficiency of solar cells, achieve uniform sheet resistance, stable atmosphere, and improve spectral responsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

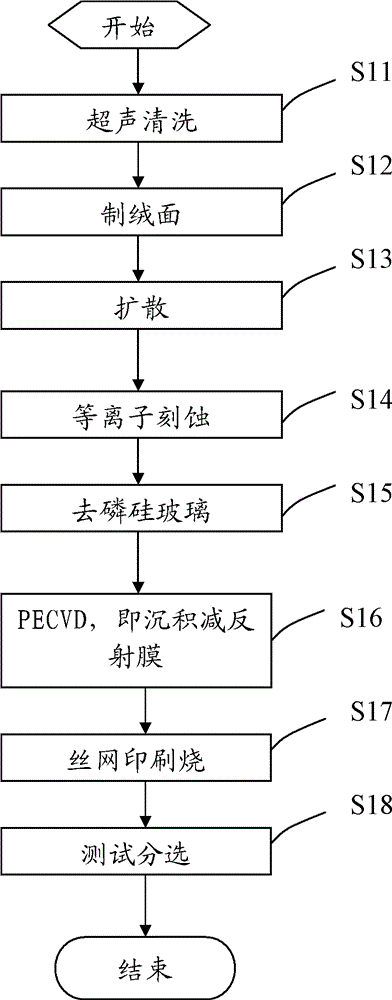

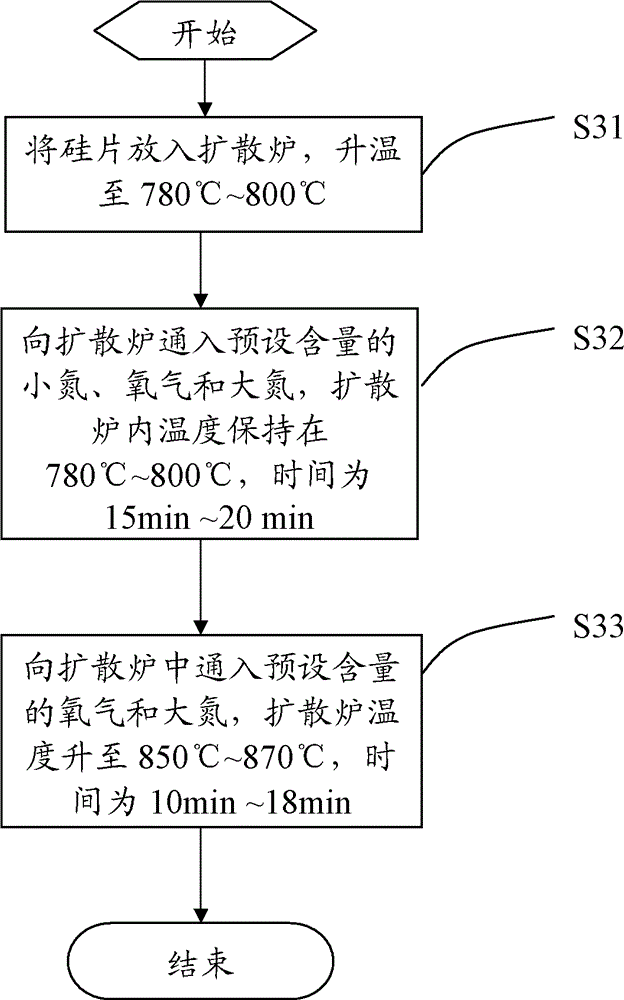

[0042] This embodiment provides a diffusion method, which is mainly applied to the production of crystalline silicon solar cells. The basic process is as follows: image 3 As shown, including the following steps:

[0043] Step S31: Put the silicon wafer in a diffusion furnace and raise the temperature to 780°C to 800°C.

[0044] Preferably it is 790 degreeC.

[0045] Step S32: Inject small nitrogen and oxygen with a volume flow ratio of 4:1 to 7:1 through the diffusion furnace tube, and at the same time introduce large nitrogen of 5L / min to 7L / min, and the temperature in the diffusion furnace is maintained at 780°C ~800℃, time is 15min~20min.

[0046] The flow rate of small nitrogen is preferably 1.3 L / min, the flow rate of oxygen is preferably 0.3 L / min, the flow rate of large nitrogen is preferably 5.4 L / min, and the time is preferably 17 min.

[0047] Step S33: Pass 2L / min~3L / min oxygen and 4L / min~5L / minL large nitrogen into the diffusion furnace through the diffusion furnace tube,...

Embodiment 2

[0078] This embodiment provides a crystalline silicon solar cell prepared by the diffusion method described in the previous embodiment.

[0079] The PN junction depth of the solar cell is between 0.18um and 0.22um, that is, about 0.2um; the unevenness of the sheet resistance is controlled within 4%; the conversion efficiency is between 16.5% and 17.5%, and the average value can reach 16.84%.

[0080] The junction depth of the solar cell is shallower than the junction depth under the existing diffusion technology, and the unevenness of the sheet resistance is also reduced a lot, which is higher than the average conversion efficiency under the existing diffusion technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com