Production method of sandstone-like porcelain exterior wall tile

A production method and technology for imitating sandstone, applied in the field of porcelain exterior wall tiles and their production processes, can solve the problems of turbid color, prolong processing time, increase raw material cost, etc., and achieve hard particles, clear outlines and expressive products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

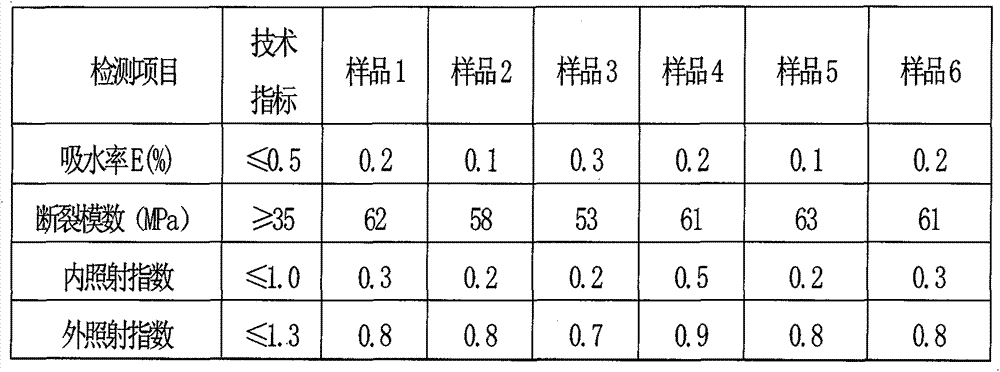

Examples

Embodiment 1

[0028] The raw material formula of the green body: 35% of quartz sand, 25% of shale, 30% of quartz sand tailings, 10% of construction concrete slag, crushed to pass through a 3-mesh sieve, and then pressed into a green body under a pressure of 180KPa;

[0029] Sand formula: glycerin: water: feldspar: quartz sand: shale: quartz sand tailings: glass slag weight ratio is 0.3: 20: 15: 10: 15: 25: 15, prepared into glaze slurry and then coated on the blank body surface;

[0030] The green body coated with glaze slurry was dried at 150°C for 10 minutes, then heated up and preheated for 25 minutes at a preheating temperature of 600°C, and then sintered at 1180°C for 30 minutes to obtain sample 1.

Embodiment 2

[0032] The raw material formula of the green body: 32% of quartz sand, 25% of shale, 35% of quartz sand tailings, 8% of concrete and masonry slag, crushed to pass through a 5-mesh sieve, and then pressed into a green body under a pressure of 200KPa;

[0033] Sand grain formula: bentonite: water: feldspar: quartz sand: shale: quartz sand tailings: tile waste residue = 3:17:10:10:15:30:15, prepared into glaze slurry and sprayed on the surface of the green body;

[0034] The body coated with glaze slurry was dried at 200°C for 10 minutes, then heated up and preheated for 28 minutes, the preheating temperature was 750°C, and then sintered at 1200°C for 27 minutes to obtain sample 2.

Embodiment 3

[0036] The raw material formula of the green body: 33% of quartz sand, 24% of shale, 35% of quartz sand tailings, 8% of marble slag, crushed to pass through a 5-mesh sieve, and then pressed into a green body under a pressure of 230KPa;

[0037] Sand formula: bentonite: water: feldspar: quartz sand: shale: quartz sand tailings: ceramic waste slag = 1:30:10:10:10:30:15, prepared into glaze slurry and then sprayed on the surface of the green body;

[0038] The green body coated with glaze slurry was dried at 180°C for 10 minutes, then heated up and preheated for 30 minutes, the preheating temperature was 700°C, and then sintered at 1180°C for 25 minutes to obtain sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com