Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Tasteless" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Herba portulacae extract and solution, and preparation method and application

The invention discloses a herba portulacae extract and a preparation method thereof. The preparation method comprises the following steps of: 1, carrying out extraction and enzymolysis on fresh herba portulacae and / or dried herba portulacae with water and hydrolysis enzyme; 2, carrying out ethanol extraction on a feed solution obtained in the step 1, carrying out solid and liquid separation to obtain an extraction solution A and filter residue; 3, carrying out ethanol extraction on the filter residue obtained in the step 2, carrying out solid and liquid separation to obtain an extraction solution B and filter residue; 4, extracting the filter residue obtained the step 3 by using water, carrying out solid and liquid separation to obtain an extraction solution C; and 5, mixing the extraction solutions A, B and C obtained the step 2, 3 and 4, removing ethanol, concentrating, standing, and filtering to obtain filtrate to obtain the herba portulacae extract. The invention also discloses the herba portulacae extract solution and the preparation method thereof. A herba portulacae extract or extract solution can be used as an anti-stimulation and antianaphylaxis function component to be applied to cosmetics. The preparation method disclosed by the invention can be used for preparing the herba portulacae extract with higher effective component content, with high yield.

Owner:SHANGHAI HUIWEN BIO TECH

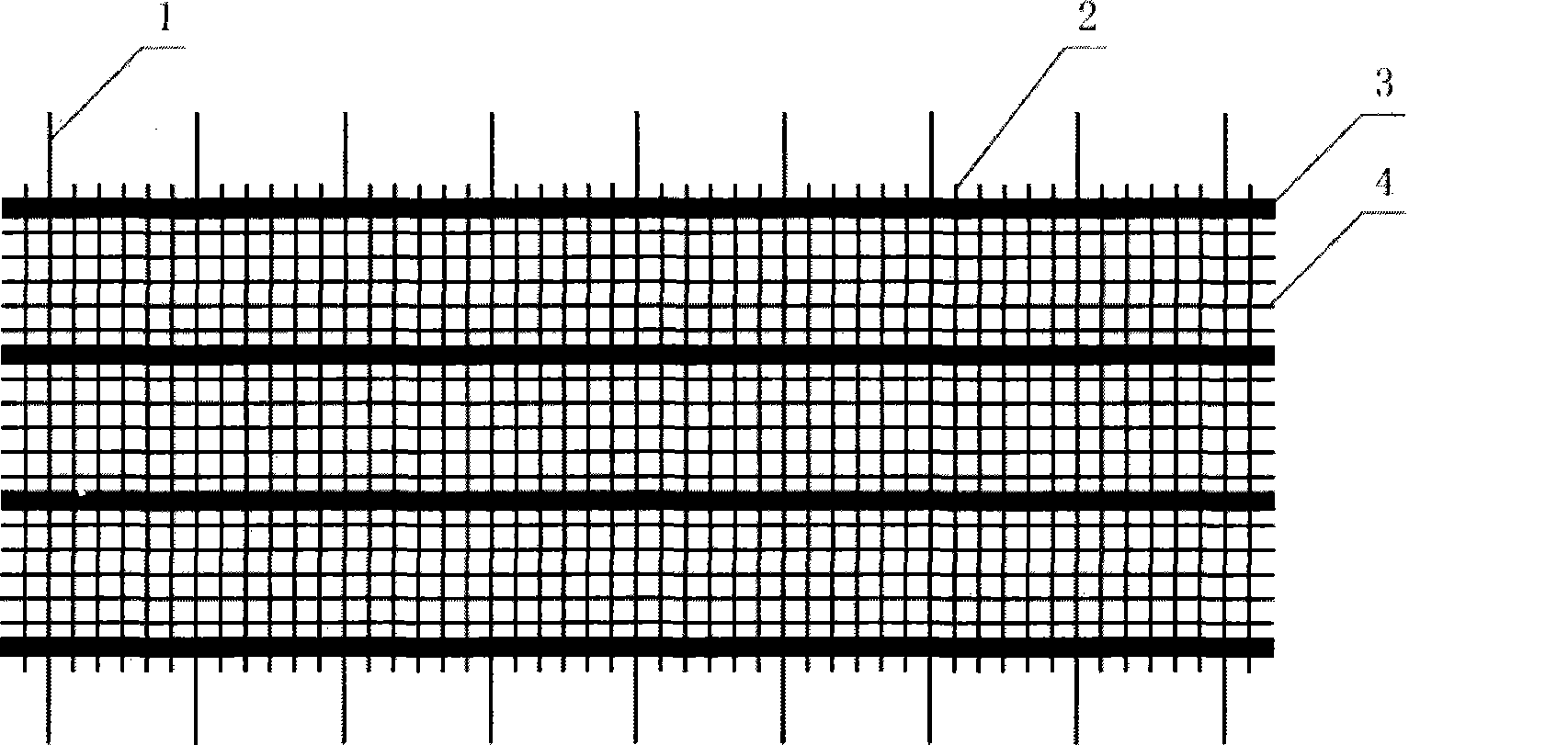

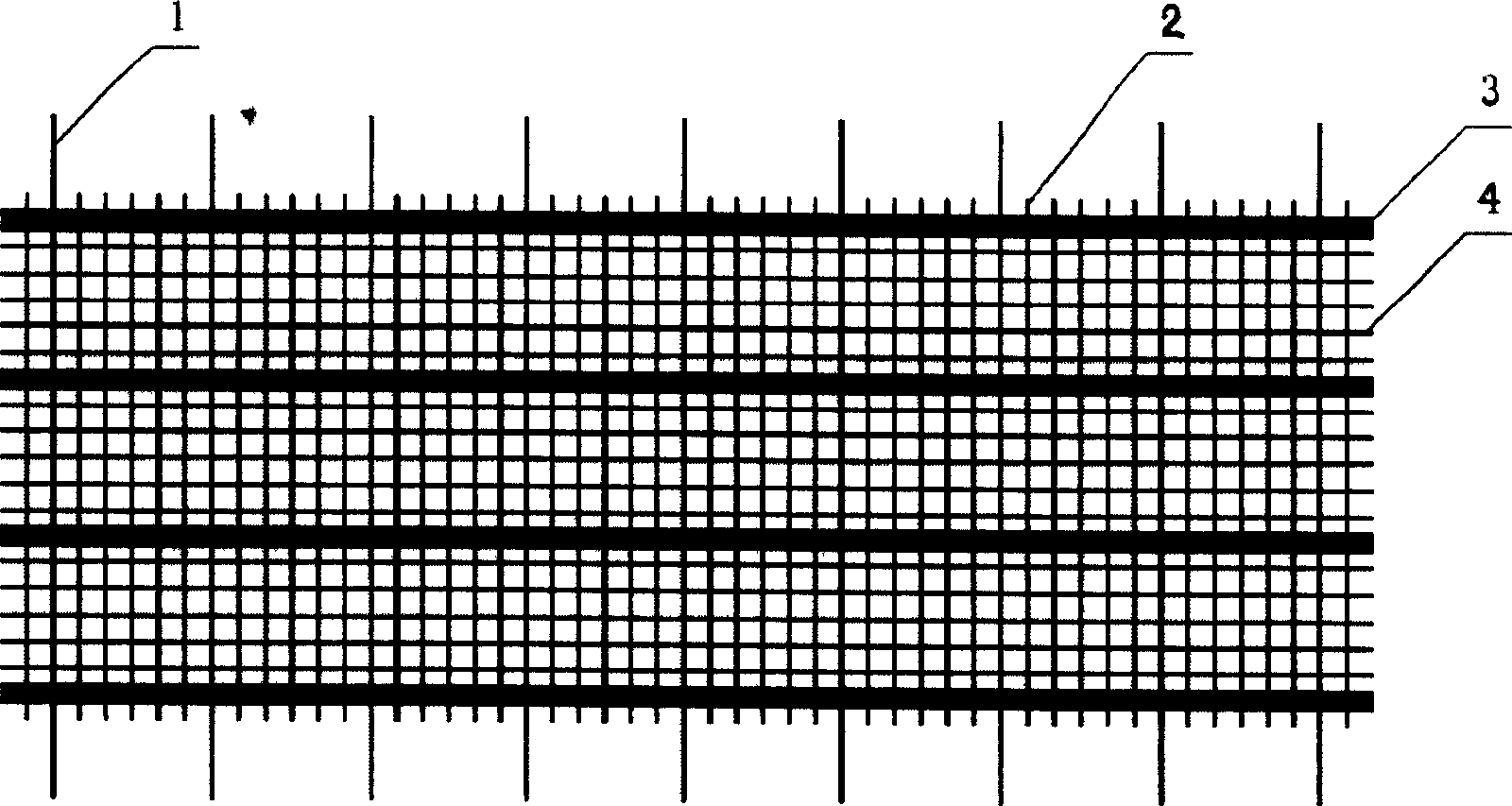

Carbon heating clothes and preparation method thereof

ActiveCN101396176AHeating up fastTastelessOhmic-resistance heatingGarment beltsSmart polymerEngineering

The invention relates to a garment and a preparation method thereof, in particular to a carbon heating garment taking carbon conductive yarns as a heating element and a preparation method thereof. The outside of the rear piece of the carbon heating garment is provided with a pocket which is positioned near the lumbar vertebrae of a human body; and the pocket is provided with a carbon heating sheet sewn and packed by nano bamboo charcoal knitted fabric, connecting wires and intelligent polymer lithium battery pack; the carbon heating sheet is connected with the anode and the cathode of the lithium battery pack by the connecting wires; and the carbon heating sheet is compounded by pressing and rolling carbon conductive fabric with an environment friendly polyurethane thin film or vinyl acetate thin film. The garment has the advantages of fast heating and temperature rise, no odor, no pollution and good effect, and the garment is an ideal warm garment with heat supply function.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

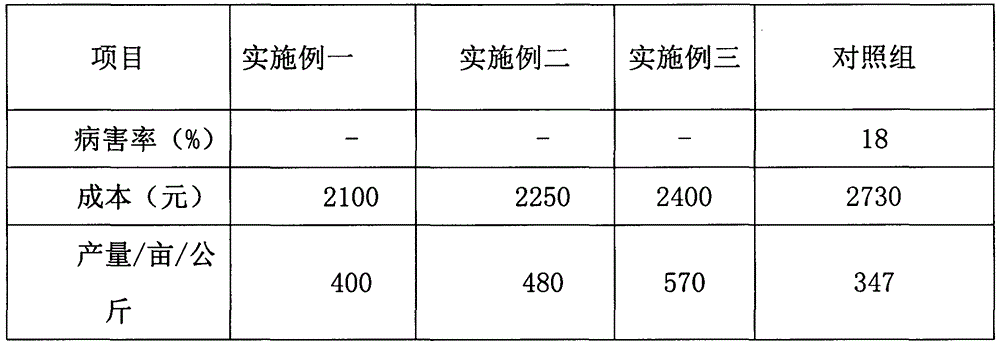

Ecological grass carp breeding method

InactiveCN105706968AImprove the quality of farmingImprove farming outputFood processingClimate change adaptationFresh water organismOperability

The invention relates to a freshwater fish breeding technology, in particular to an ecological grass carp breeding method.The method includes the following steps of appropriate pond selection, pond cleaning and arranging, fry stocking, water quality management, breeding management, disease and pest prevention and fishing.By means of the method, the breeding quality and yield of grass carps can be improved, grass carps bred through the method are fresh in meat taste and good in taste, scientific breeding management can be achieved, health care is achieved, disease and pest prevention is achieved at the same time, disease and pest prevention is thorough, the disease control rate reaches 100%, and the method is ecological, environmentally friendly, low in production cost, high in economic benefit and suitable for large-scale production.In the grass carp breeding process, through the green grass and biological fermentation feed mixed putting mode, the quality of grass carps is remarkably improved, the technology is simple, the investment cost is low, risks are small, operability is high, and the method is easy to grasp and apply and easy to popularize and promote.

Owner:曾庆海

Snow-texture heat-accumulating agent and cold-heat-accumulating product containing said agent

InactiveCN101070463AIncrease heat absorptionStay cold for a long timeProductsReagentsThermodynamicsRoom temperature

The present invention discloses a snow -feeling regenerative heat, the way of making it and regenerative heat and cold articles including this regenerative heat agent consists of three components : Celluloses derivative or starch flour derivative, sodium salt, and water. The mixture is made of the three components by proportion 3-11 to 2-10 to 40-220, according to the range of weight. It can be used as cooling or warming agents, besides it can be made into regenerative heat and cold articles including regenerative heat agent. The present invention is easily made, conveniently and widely used, and the price is cheap. This regenerative heat agent appears a high molecular gel condition to the room temperature. So it has pretty good capacity to regenerate heat. After cooling it appears a snow-feeling condition, when the temperature is raised up it absorbs more heat than the usual regenerative cold agents, so it is better in keeping cold.

Owner:刘树岭

Water-based paint and its preparation technique

InactiveCN101240139AReduce labor intensityProtect your healthEmulsion paintsBuilding materialEmulsion

The invention relates to a waterproof paint for architecture and building materials, especially to a water-base paint which is widely applied to brushing objects such as boarded floor, toy for children, corrugated paper, inner wall, outer wall, woodwork, damp proofing, cement, leak stopping, metal product, etc. The prescription of water-base paint totally differs from the traditional one, comprising: adding raw materials such as glycerin, xylitol, etc., except crylic acid emulsion, which are food-grade raw materials substantially, nontoxic and environmental-friendly absolutely. The water-base paint can be constructed directly, bring handsome looking and relieving labor strength of constructors. Furthermore, the water-base paint does not damage health of constructors, with multiple advantages of current waterproof paints.

Owner:黄敏文

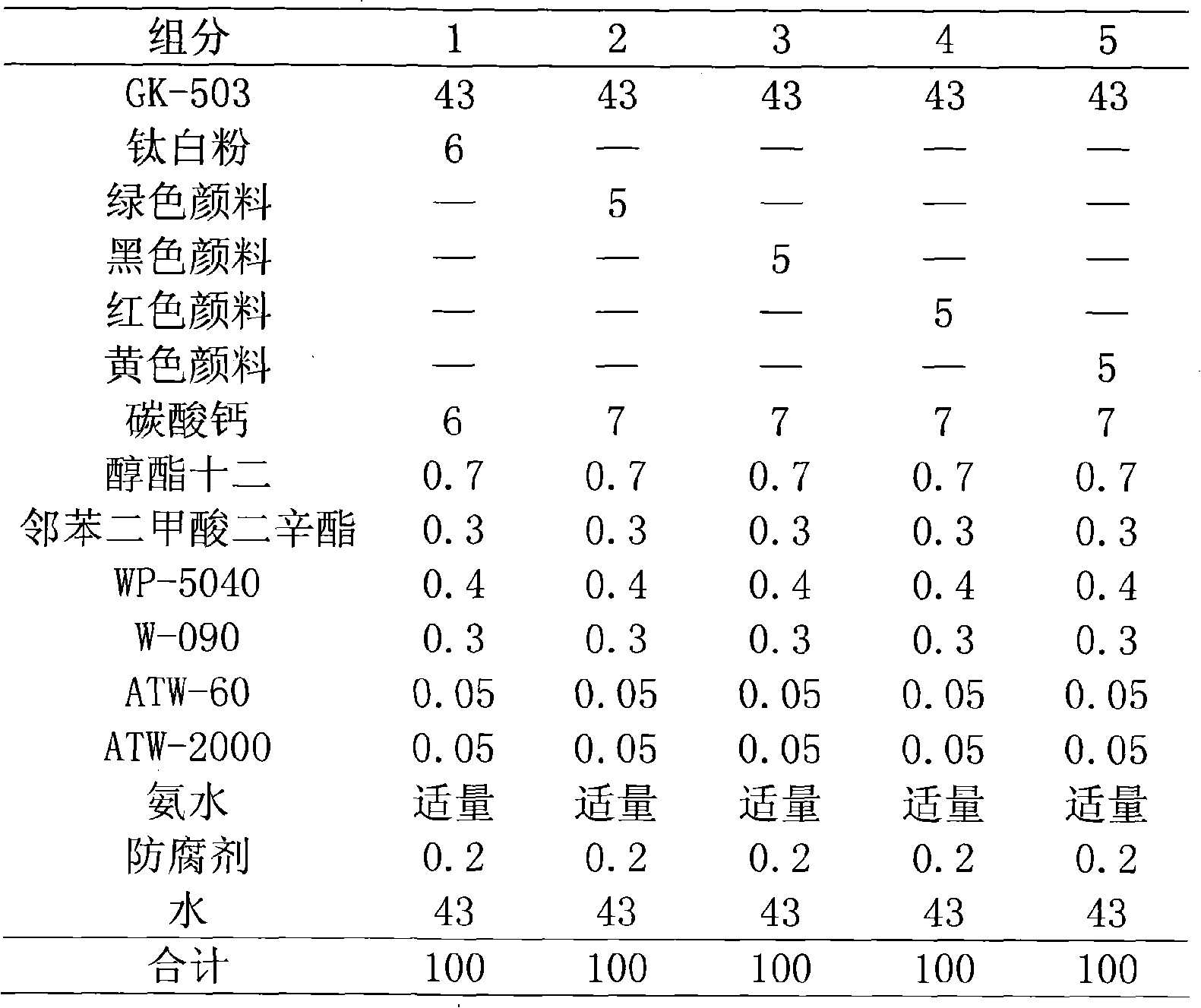

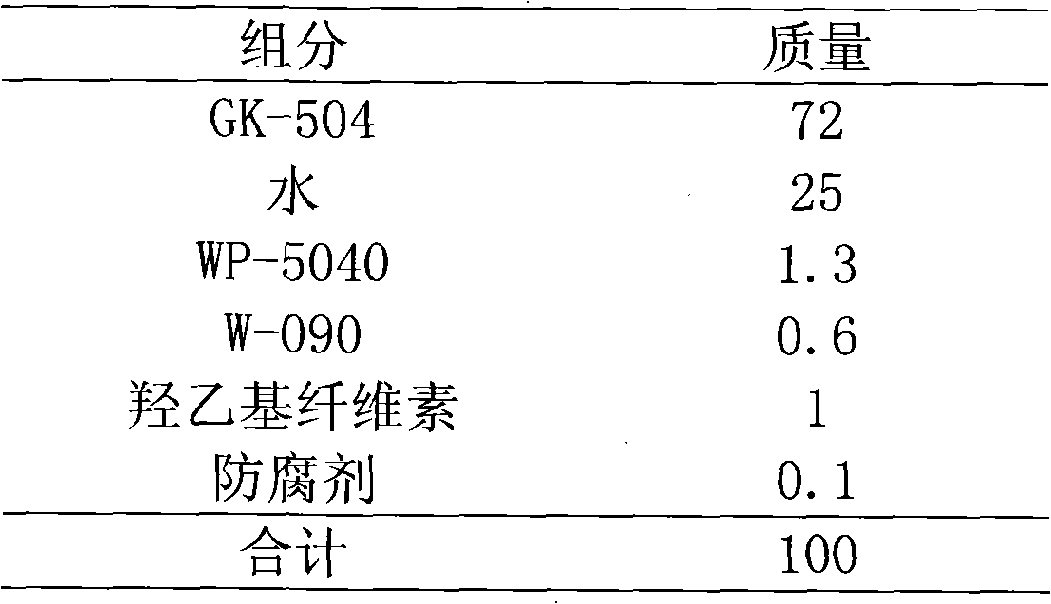

Novel water-covering water gorgeous paint and preparation thereof

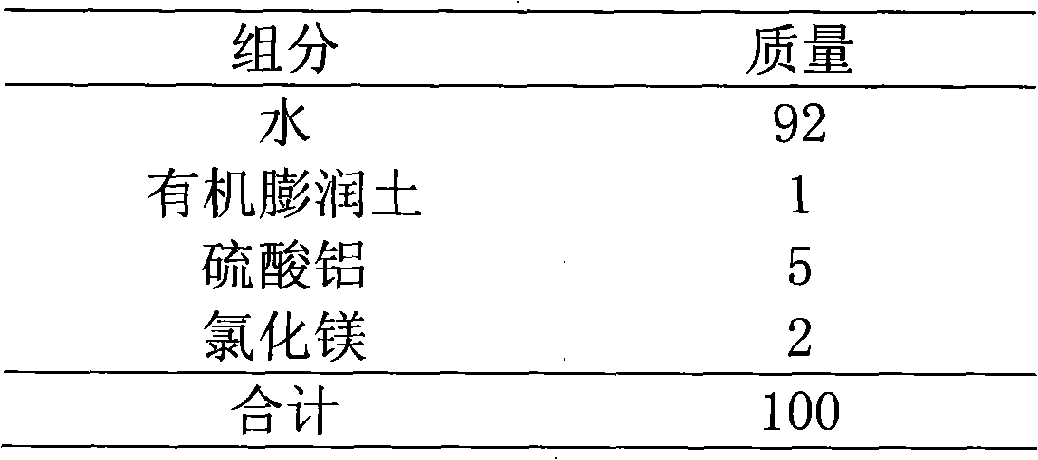

The invention provides novel water in water multicolor paint and the preparation method, which belongs to the technical field of paint preparation. Dispersant, pigment, calcium carbonate, film forming additive, antifoaming agent, thickening agent, ammonia water and anti-corrosion agent are added into the dispersing pot, after being uniformly mixed and grinded, synthetic resin emulsion and antifoaming agent are added and mixed, then thickening agent is added, thus water dispersing phase is manufactured; water, dispersant, antifoaming agent, cellulose and anti-corrosion agent are added in a container, after being mixed uniformly, water soluble resin is added and mixed, thus protective glue is manufactured; organobentonite is added in warm water and mixed to colloid, aluminum sulfate and magnesium chloride is added and mixed, thus water dispersing medium is manufactured; the water dispersing medium is added into a blender, and the water dispersing phase and the protective glue are being added while being mixed, after being cut and stirred by a screen, the water in water multicolor paint with various colors mixed and surface of dispersed particle colloidized is obtained, the paint dispersing medium and the dispersing medium is apparently separated, the gloss is high, and the decorative effect and the stability are good.

Owner:窦俊英

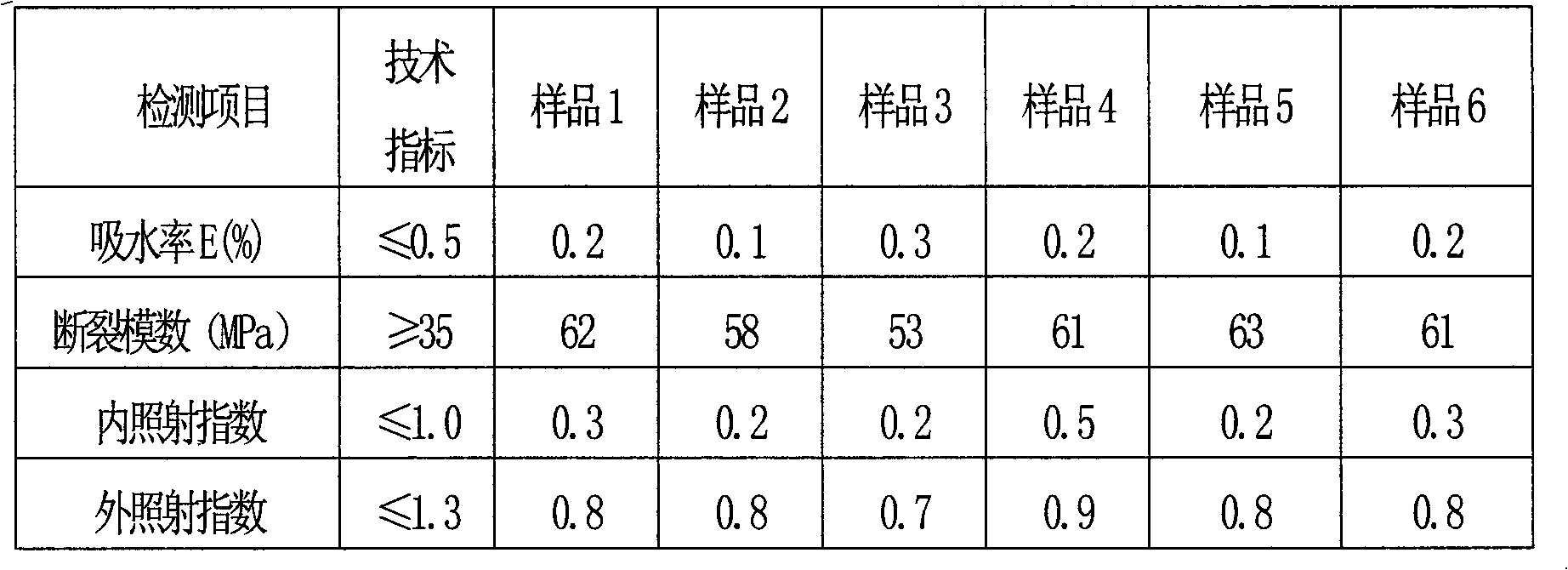

Sandstone-like porcelain exterior wall tile and production method thereof

The invention relates to an exterior wall tile and a production method thereof, in particular to a production method of a sandstone-like porcelain exterior wall tile. The production method comprises the following steps: using architecturally applicable materials to press an adobe of the exterior wall tile; adding sandstone particles with a fineness of 20-150 meshes in a suspending agent to prepare a glaze slurry; spraying or coating the glaze slurry on the surface of the adobe; drying, preheating, sintering and cooling the adobe covered with the glaze slurry to obtain a finished product. According to the invention, the whole sandstone-like porcelain exterior wall tile is prepared by only needing one sintering process, thus fuel and energy of sintering one time are saved compared with the prior art, the energy consumption and exhaust discharge of products with same specification are greatly reduced; and the whole exterior wall tile has the decorative effect similar to that of simulation sandstone, thus compared with the prior art, the exterior wall tile disclosed herein has better decorative effect and lower production cost.

Owner:重庆歌德陶瓷玛赛克制造有限公司

Multipurpose polyester film and preparation method thereof

The invention relates to a multipurpose polyester film and a preparation method thereof. The preparation method adopts a biaxial orientation technique and comprises the following steps: 1. preparation of functional assistants; 2. precrystallization and drying; 3. melt extrusion: the precrystallized and dried PET (polyethylene terephthalate) slices and the functional assistants are heated and molten by an extruder, and the melt is uniformly delivered to a die head for slab casting under the push of extrusion pressure; 4. slab casting: the uniform and stable melt from the extrusion system runs on rotating quenching rollers through the die head to form an amorphous slab; 5. longitudinal stretching and lateral stretching: the cast slab is subjected to longitudinal stretching after entering a longitudinal stretching machine, and subjected to lateral stretching after entering a lateral stretching machine; and 7. pulling, slicing, corona treatment, rolling and inspection. The method has wide application range, such as environment-friendly films, twist wrap films, high-brightness films, insulation films, capacitive films, car protecting films, bronzing films, aluminizing films and composite packaging films.

Owner:福建百宏高新材料实业有限公司

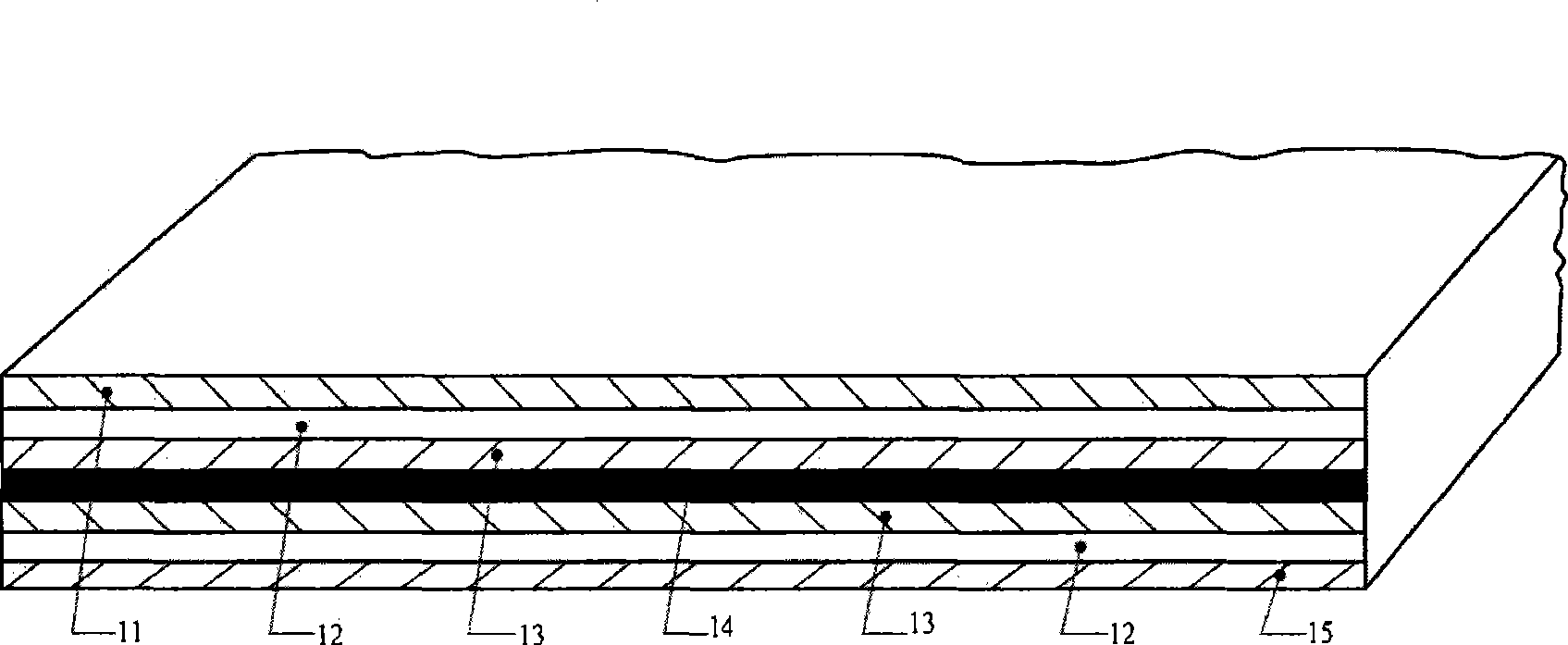

Preparation method of thermoplastic polyurethane composite material

ActiveCN103144323AUniform thicknessImprove controllabilityFlat articlesThermoplastic polyurethaneHot melt

The invention discloses a preparation method of a thermoplastic polyurethane composite material, and belongs to the technical field of calendering products. The preparation method of the thermoplastic polyurethane composite material is characterized in that open milling and roller covering are carried out through an open mill on thermoplastic polyurethane particles after the thermoplastic polyurethane particles are dried and dewatered, the thermoplastic polyurethane particles are manufactured into blank blocks, and put into a planetary extruder, plastification and vacuum defoamation are carried out, then the hermoplastic polyurethane particles are put into a four-roll calender to become a film in a calendering mode, fabric and the thermoplastic polyurethane film are compounded, and at last the thermoplastic polyurethane composite material is obtained. The invention provides a lamination method of thermoplastic polyurethane and a fabric layer, open milling and plastification are carried out on the thermoplastic polyurethane, the thermoplastic polyurethane becomes the film after hot melting and calendering, then the film is directly compounded on the fabric, an ordinary machining method of the thermoplastic polyurethane is improved, and the specifications and styles of the thermoplastic polyurethane are enabled to be diversified.

Owner:仪征龙兴塑胶有限公司

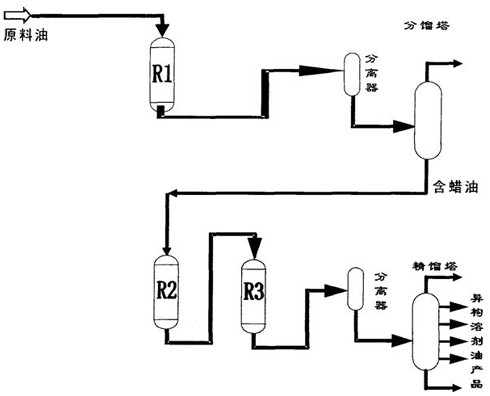

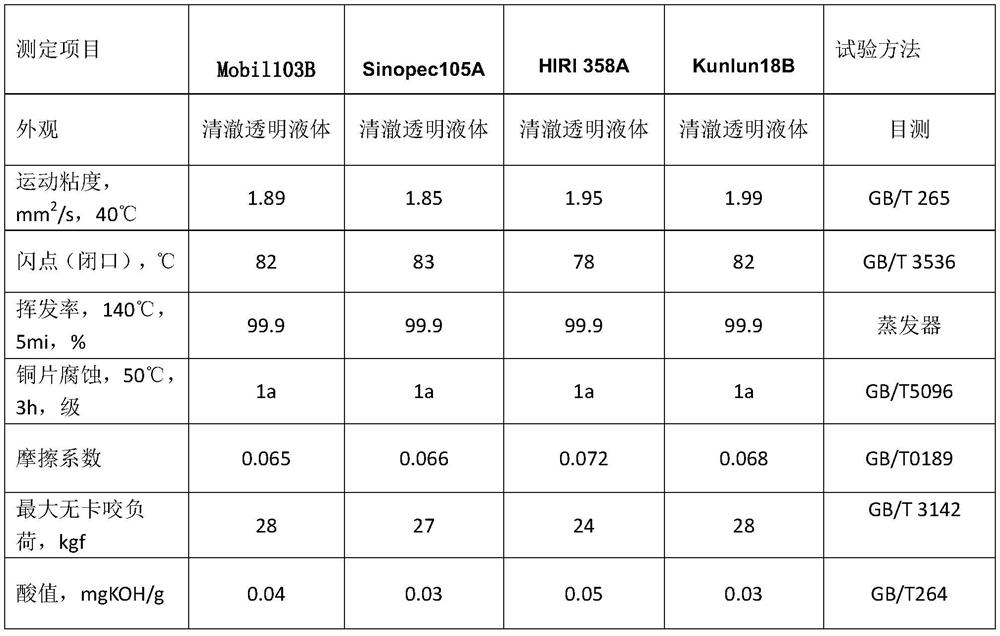

High-performance volatile fin punching oil and preparation method thereof

PendingCN112048359AStrong emulsificationGood emulsifying effectLubricant compositionAlkaneActive agent

The invention relates to high-performance volatile fin punching oil, which consists of isoparaffin base oil, a surfactant, an acid trapping agent, an oiliness agent, an extreme pressure anti-wear agent, a defoaming agent and an antirust agent. The invention further provides a preparation method of the fin stamping oil. According to the invention, the excellent lubricity of the fin during processing is ensured, the fin has a certain flash point, the safety of the fin is ensured, and a processed part can be completely volatilized at room temperature within a short time without being heated and baked, so that no residue is left. The high-performance volatile fin punching oil does not contain water, chlorine, sulfur and other corrosives, and does not corrode or rust various metal materials. The pH value of the working solution prepared from isoparaffin is 6.5-7.0, and the product waste liquid is also neutral, does not cause anaphylactic reaction to skin, does not generate acidification reaction, does not have heavy metal ions, has good biodegradability and completely meets the environmental protection requirements.

Owner:上海中孚油品集团有限公司

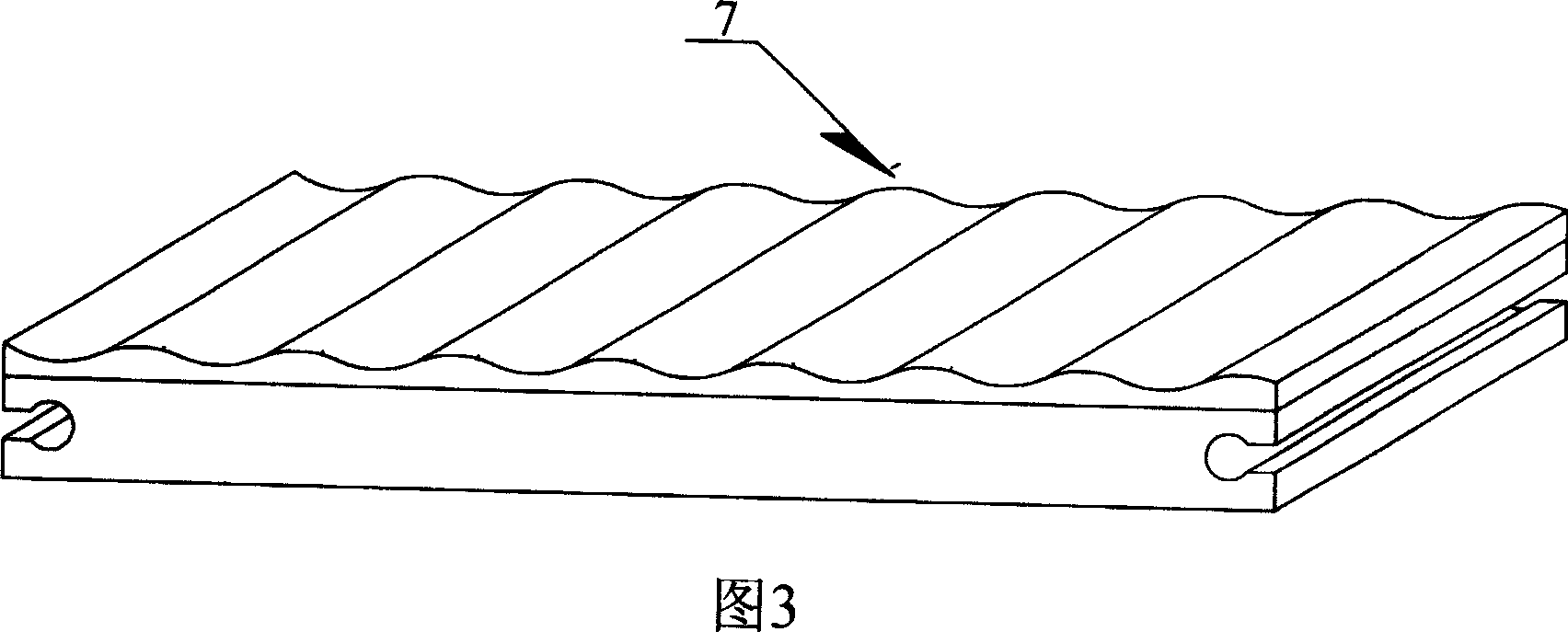

Magnesium fireproof thermal insulation inner wall board

InactiveCN1924244AGood fire protection and thermal insulation propertiesLow energy consumptionSolid waste managementBuilding componentsThermal insulationWall plate

This invention relates to magnesia insulation wall board, which has several holes with two sides are of semi-round shape or weight tank, wherein, the inner wall board is composed of magnesia sane for 95 to 120kg, powder coke for 8 to 12kg, magnesium chloride solution for 46 to 54kg, blowing agent N1 for 1 to 2kg and water for 37.5 to 56.4kg through mode shaping step. This invention has the following advantages as the following: a, good insulation property of wall board; b, light quality and good isolation ability; c, easy for shearing; d, product without poison, flavor and erosion.

Owner:李英魁

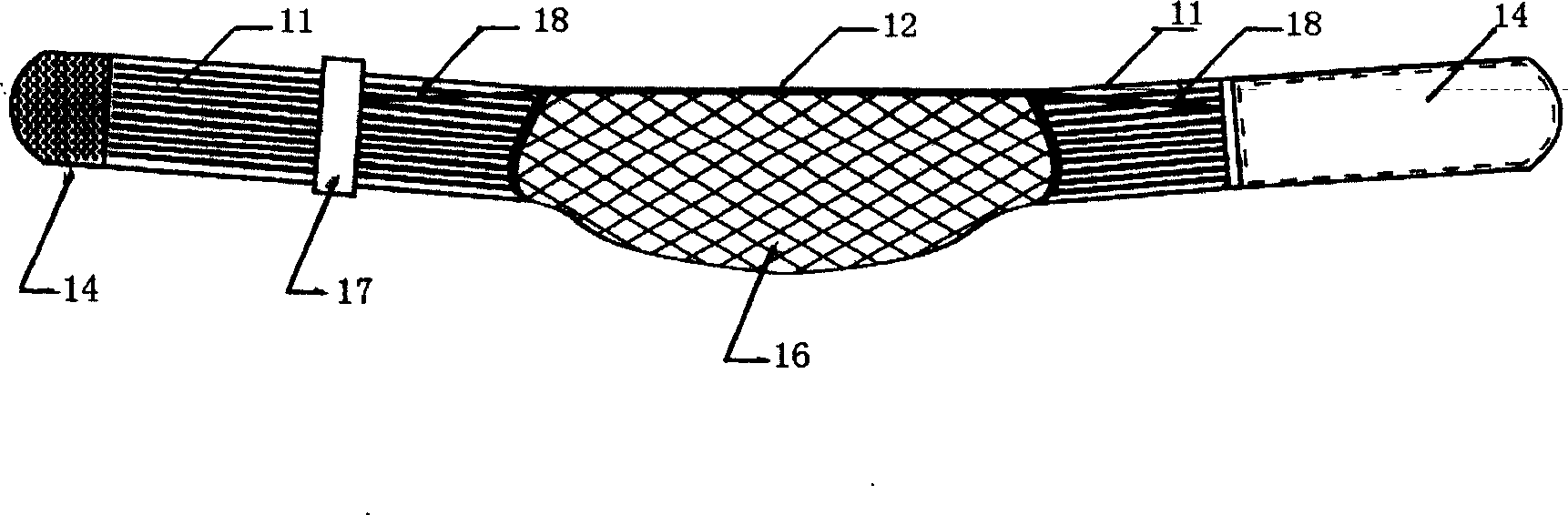

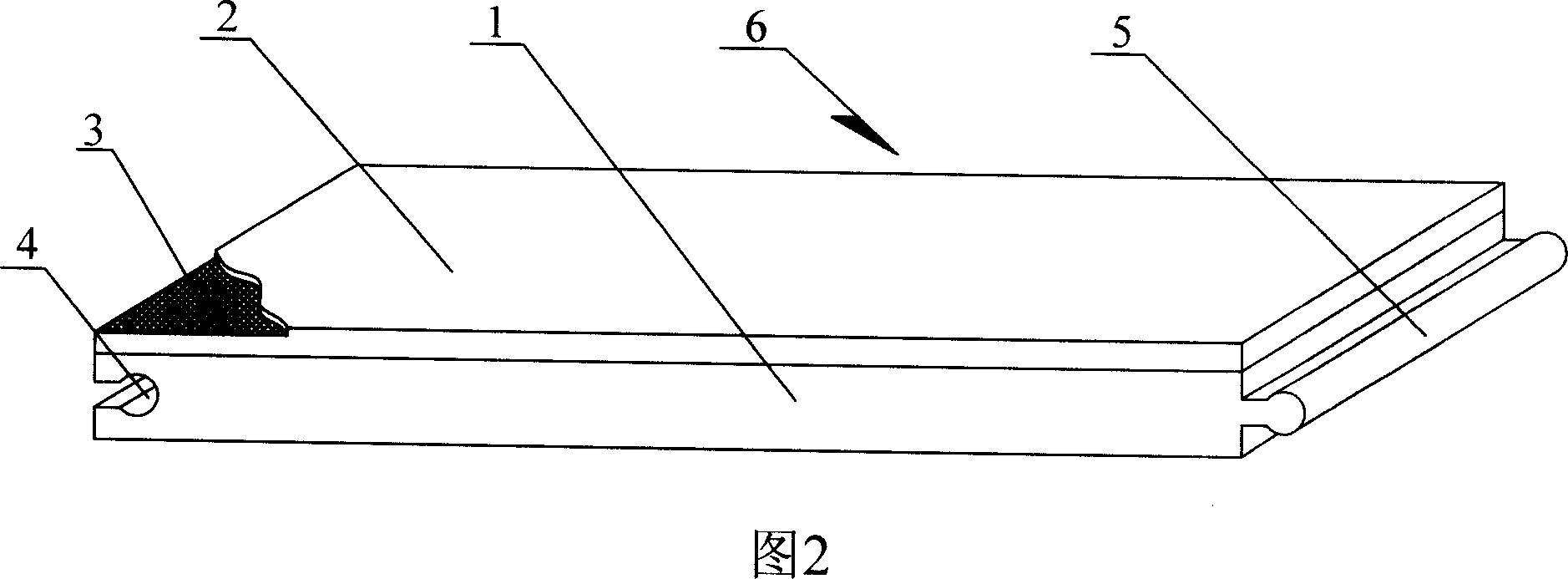

Carbon heating headscarf and preparation method thereof

The invention relates to a carbon heating scarf and a preparation method thereof. The carbon heating scarf is characterized by comprising a base cloth, a carbon heating sheet, agraffes, connecting wires and intelligent polymer lithium battery pack; the carbon heating sheet is compounded by pressing and rolling carbon conductive fabric with a environment friendly polyurethane thin film or vinyl acetate thin film, and sewn and packed by nano bamboo charcoal knitted fabric; the carbon heating sheet is connected with the intelligent polymer lithium battery pack and a thin film regulating switch in series by the connecting wires to form a circuit; the agraffes are respectively sewn in the middle part of the base cloth of the scarf and on one side of the nano bamboo charcoal fabric of the carbon heating sheet so as to bond each other. The scarf has the advantages of fast heating and temperature rise, no odor, no pollution and good heat preservation effect, and the scarf is an ideal warm scarf with heat supply function.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

Magnetic composite bentonite and preparation method of same

InactiveCN107096505ALess corrosiveNon-toxicOther chemical processesWater contaminantsSulfateWastewater

In one embodiment, the invention discloses magnetic composite bentonite and a preparation method of same. The invention relates to the field of modification and preparation of bentonite for water treatment. The magnetic composite bentonite is prepared from, by weight, 40-70 parts of bentonite, 20-40 parts of ferric oxide, 2-5 parts of ferric chloride, 2-5 parts of ferric sulfate, 2-5 parts of polyaluminum sulfate, 2-5 parts of active carbon, and 0.1-1 part of a cationic surfactant. The preparation method is simple and available. The magnetic composite bentonite can remove organic pollutants in water well and has excellent settling separation effect.

Owner:句容康泰膨润土有限公司

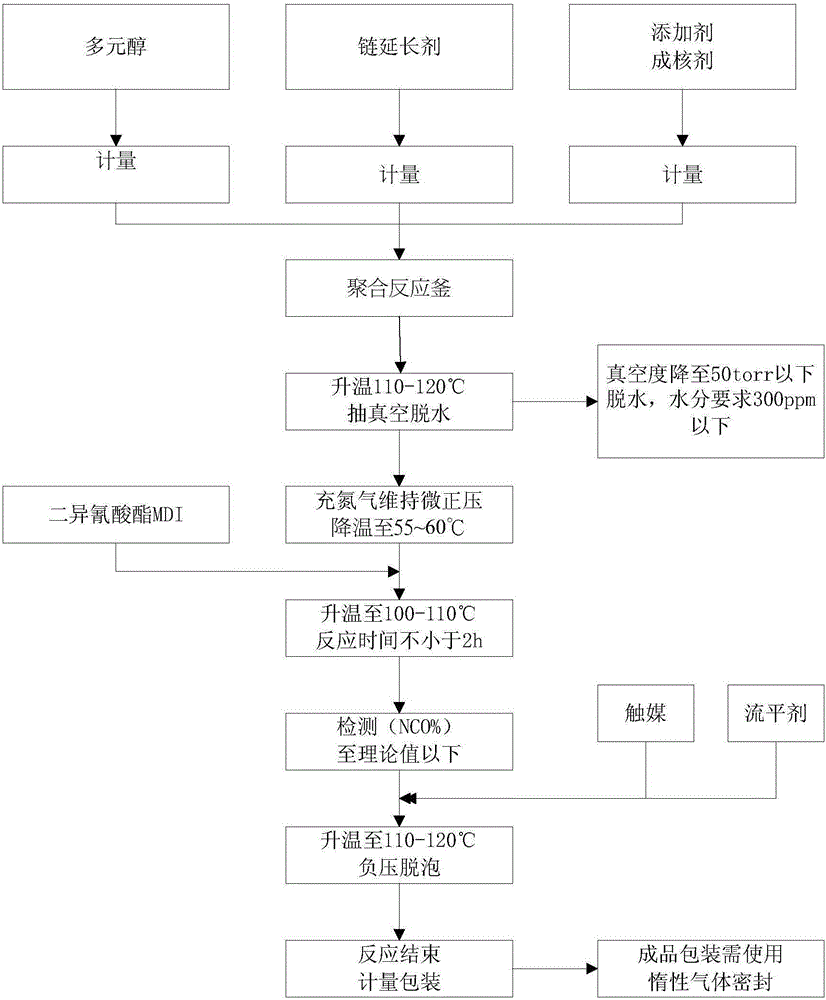

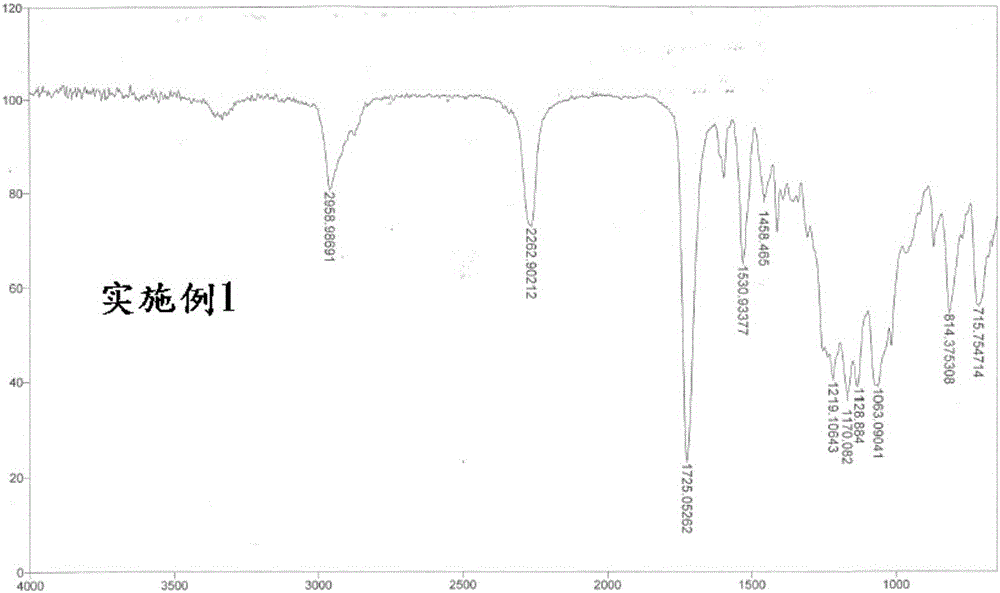

Preparation method and application of moisture reaction type polyurethane hot-melt adhesive for composite floor

The invention disclose a preparation method and application of moisture reaction type polyurethane hot-melt adhesive for a composite floor and belongs to the technical field of macromolecule material preparation .According to the method, polyester polyol, diisocyanate and chain extender are adopted as basic raw materials, auxiliary agents such as accelerant, a flatting agent and a nucleating agent are combined, and a high temperature polymerization reaction is conducted, so that the moisture reaction type polyurethane hot-melt adhesive (PUR) is obtained .A product prepared through the method is the one-component moisture reaction type polyurethane hot-melt adhesive, no cross-linking agent is used for hardening, and instead, an NCO functional group with the resin molecular chain tail end reactive is adopted for reacting with moisture to achieve cross-linking .The solid content of the product is 100%, no solvent is contained, no solvent is used in the technological process, a baking channel does not need to be arranged, cost is lowered, and no safety or environmental protection problem exists .In addition, the polyurethane adhesive product produced through the method is high in cohesive energy, good in initial adhesion and excellent in heat resistance, weather resistance, hydrolysis resistance and aging resistance after being cured and can be widely applied to processing of building decorative materials.

Owner:高鼎精细化工(昆山)有限公司

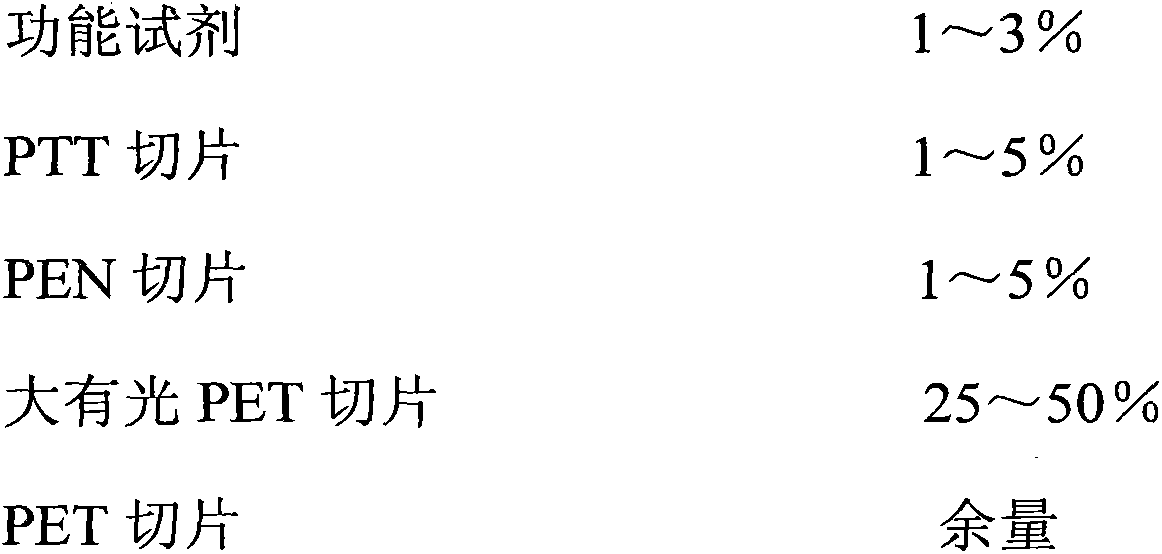

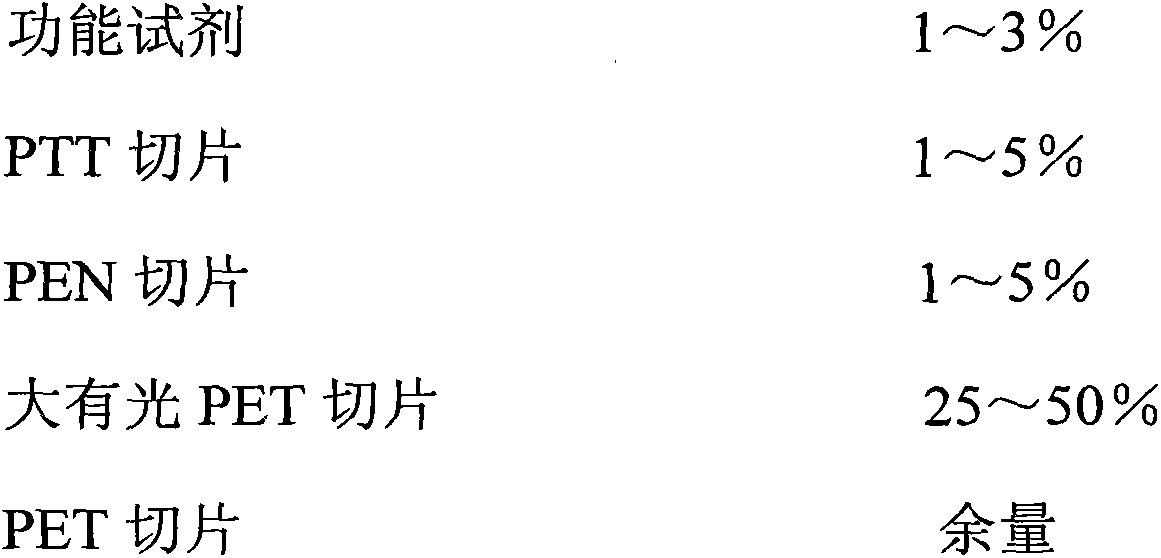

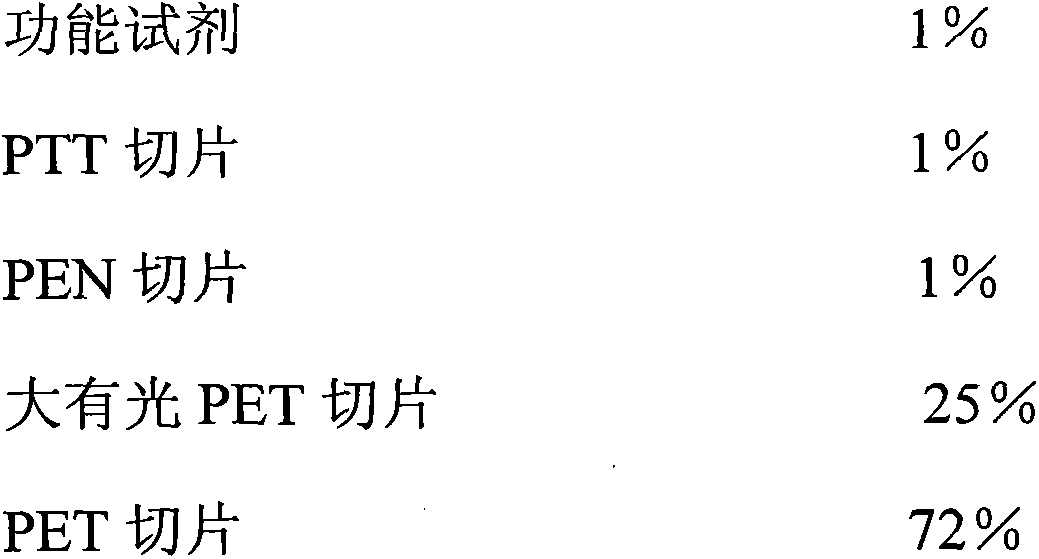

Modified polyester film and production method thereof

InactiveCN103740064AStrong ability to absorb ultraviolet raysTastelessPolyethylene terephthalate glycolPolytrimethylene terephthalate

The invention relates to a modified polyester film and a production method thereof. The modified polyester film is composed of a functional reagent, PET (Polyethylene Terephthalate) chips and large bright PET chips and is characterized by comprising the following raw materials in percentage by mass: 1-3% of functional reagent, 1-5% of PTT (Polytrimethylene Terephthalate) chips, 1-5% of PEN (Polyethylene Naphthalate) chips, 25-50% of large bright PET chips and the balance of PET chips. The modified polyester film is widely applied in the fields such as environment-friendly films, twist wrap films, high bright films, insulating films, capacitor films, laminating pouch films, gold stamped films, aluminum laminated films and composite packaging films.

Owner:沈太英

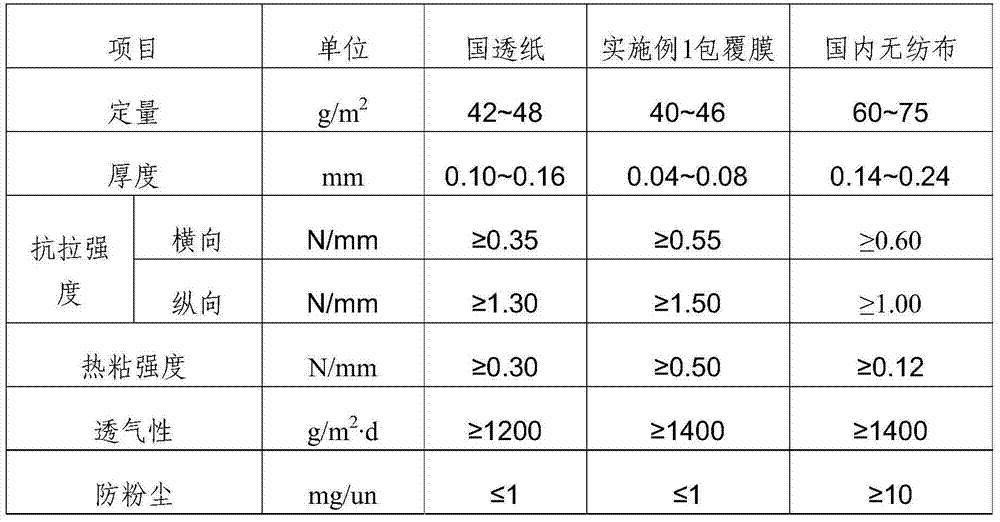

Drier coating film

ActiveCN103572647AAdapt to use requirementsHigh strengthLaminationReinforcing agents additionDesiccantHigh intensity

The invention provides a drier coating film-nonwoven paper. The invention is characterized in that the drier coating film is prepared by the following steps: preparing heat sealable tea filter paper from natural plants and natural plants with high-polymer plastic fiber, and carrying out hot press compounding with a high-polymer plastic spunbonded nonwoven fabric to obtain the drier coating film. The drier coating film has the advantages of high strength and higher dust resistance, and can adapt to production of automatic high-speed production equipment.

Owner:昆山威胜干燥剂研发中心有限公司

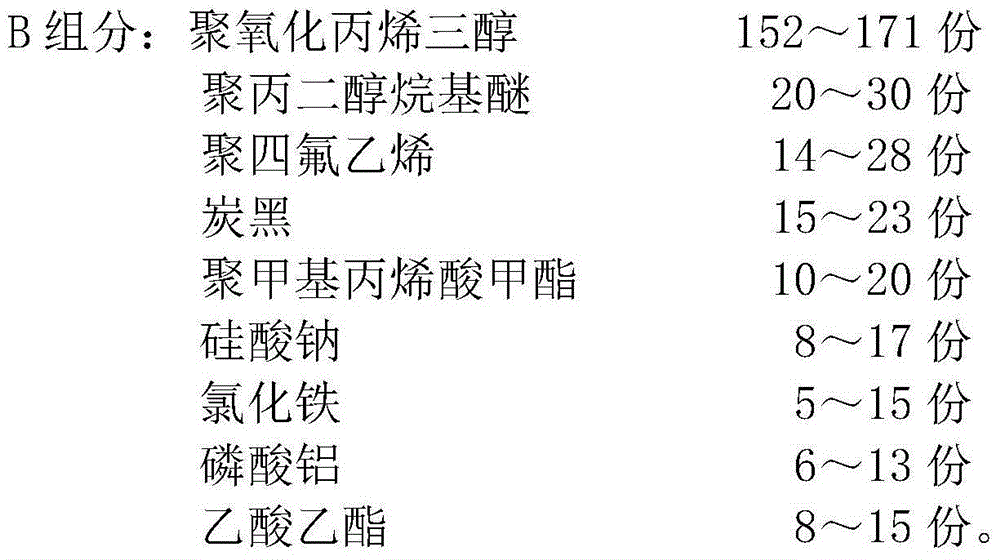

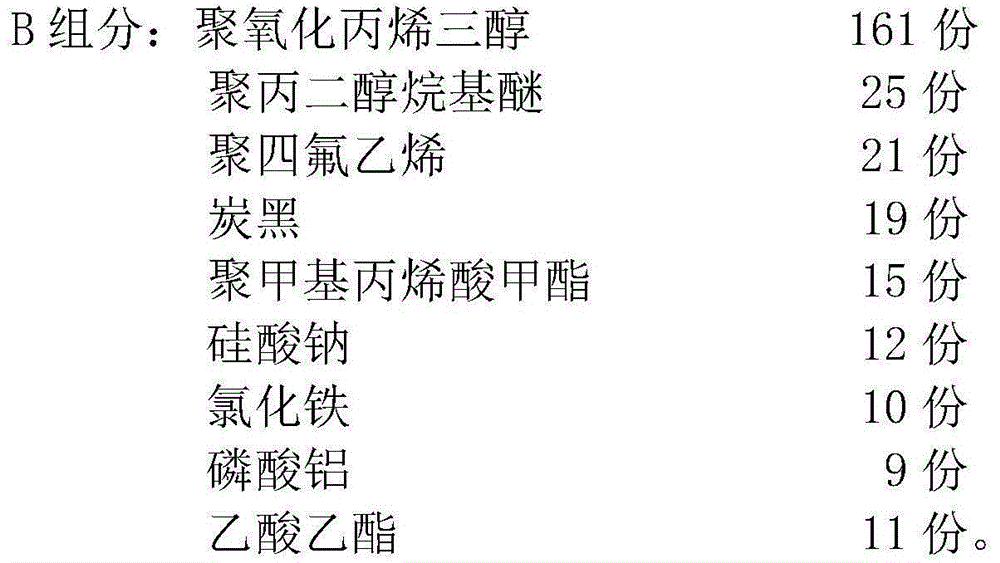

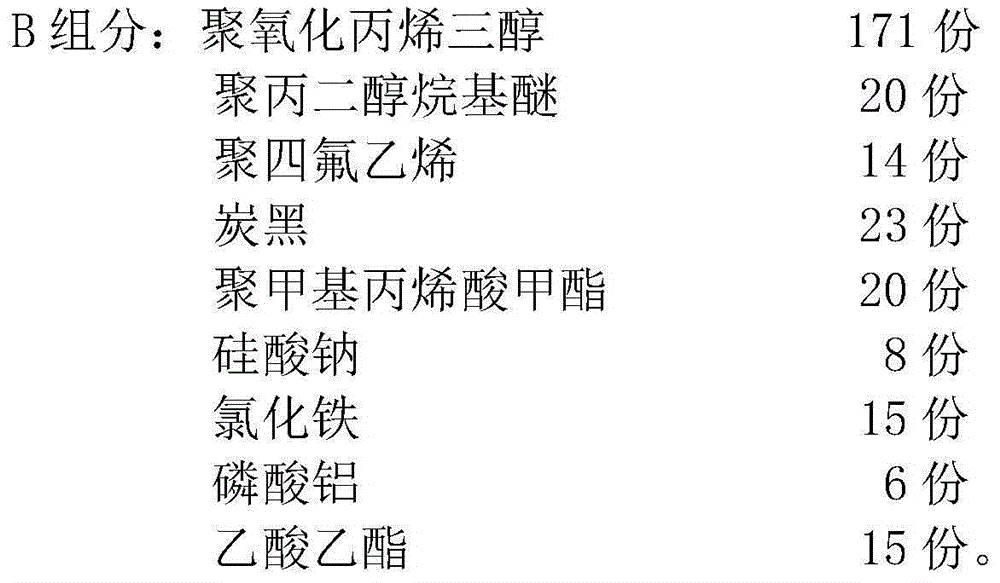

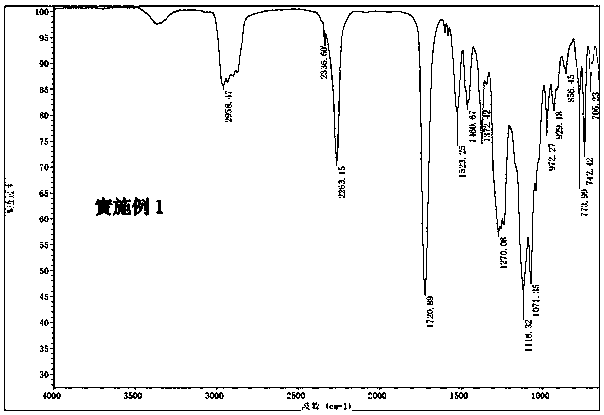

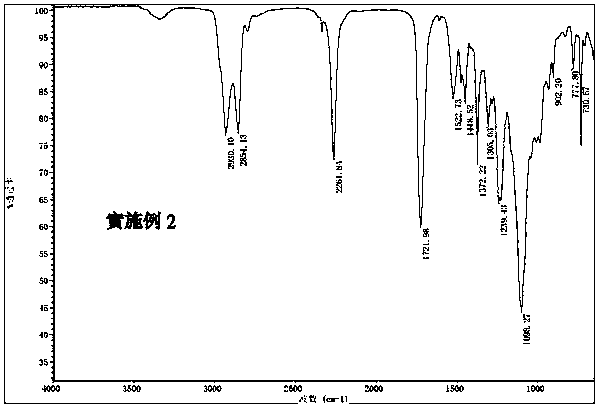

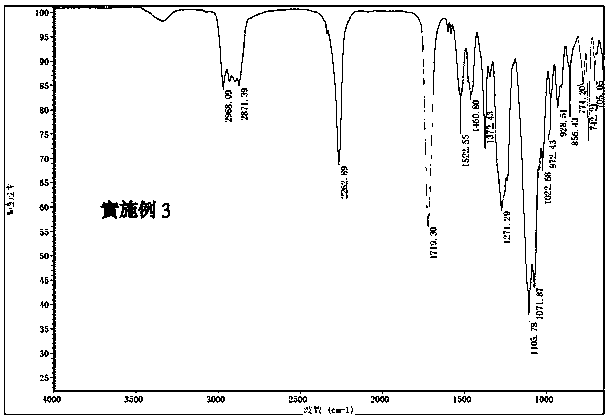

Two-component polyurethane construction sealant

ActiveCN105199654AStrong water resistanceGood weather resistanceNon-macromolecular adhesive additivesOther chemical processesPolymethyl methacrylateALUMINUM PHOSPHATE

The invention relates to the technical field of building materials, in particular to a two-component polyurethane construction sealant. The two-component polyurethane construction sealant is prepared from a component A and a component B, wherein the component A and the component B are prepared from raw materials in parts by weight as follows: component A is prepared from diethylphenyl diisocyanate; the component B is prepared from polyoxypropylene triol, polypropylene glycol-alkyl ether, polytetrafluoroethylene, carbon black, polymethyl methacrylate, sodium silicate, ferric chloride, aluminum phosphate and ethyl acetate. The two-component polyurethane construction sealant has the advantages of high water resistance, high ageing resistance, good viscosity and long storage life.

Owner:广西象州天华科技防水材料有限责任公司

One-component solvent-free polyurethane adhesive for photovoltaic module back panel compounding and preparation method of polyurethane adhesive

InactiveCN109370504AImprove hydrolysis resistanceExcellent heat and humidity resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyethylene terephthalate glycolPolyurethane adhesive

The invention discloses a one-component solvent-free polyurethane adhesive for photovoltaic module back panel compounding and a preparation method of the polyurethane adhesive and belongs to the technical field of photovoltaic module back panels. The method comprises the following steps: by using one or multiple polyhydric alcohols and taking one or multiple diisocyanates as basic raw materials, matching a catalyst, a flatting agent, an antioxidant, a light stabilizer and other additives, and performing high temperature polymerization, thereby obtaining the polyurethane prepolymer. The productdisclosed by the invention belongs to one-component solvent-free polyurethane adhesives. Curing is performed without using a cross-linking agent, but cross-linking is realized by reacting NCO functional groups with reactivity at the tail end of molecular chains of resins and moisture. The product has solid content of 100% and does not contain any solvent, no solvent is used in the process, a drying tunnel is not needed for reducing the cost, and the security and environmental protection problems are solved. Moreover, the solvent-free polyurethane adhesive product produced by the method disclosed by the invention has excellent adhesive force, excellent weather resistance, dual-85 aging resistance and PCT accelerated aging performance on PET (Polyethylene Terephthalate), EVA (Ethylene-VinylAcetate), PVDF (Polyvinylidene Fluoride) fluororesin films and the like.

Owner:高鼎精细化工(昆山)有限公司

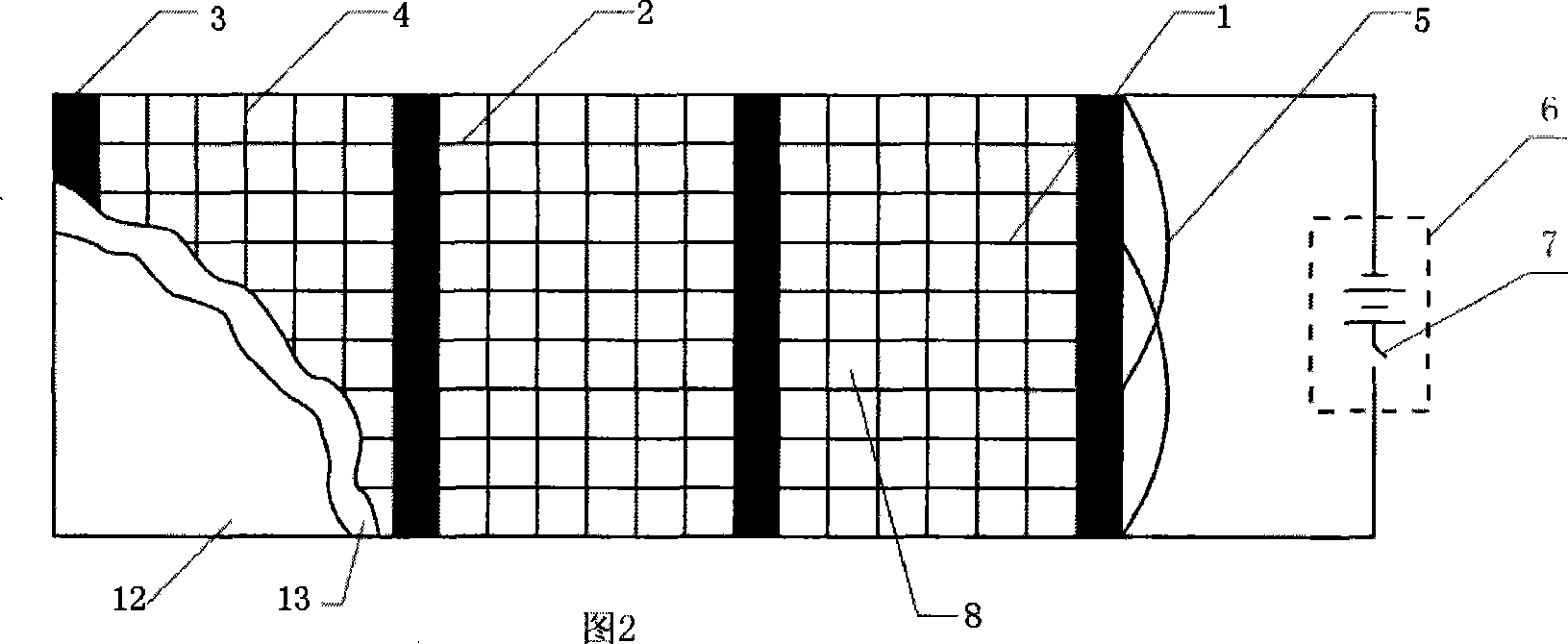

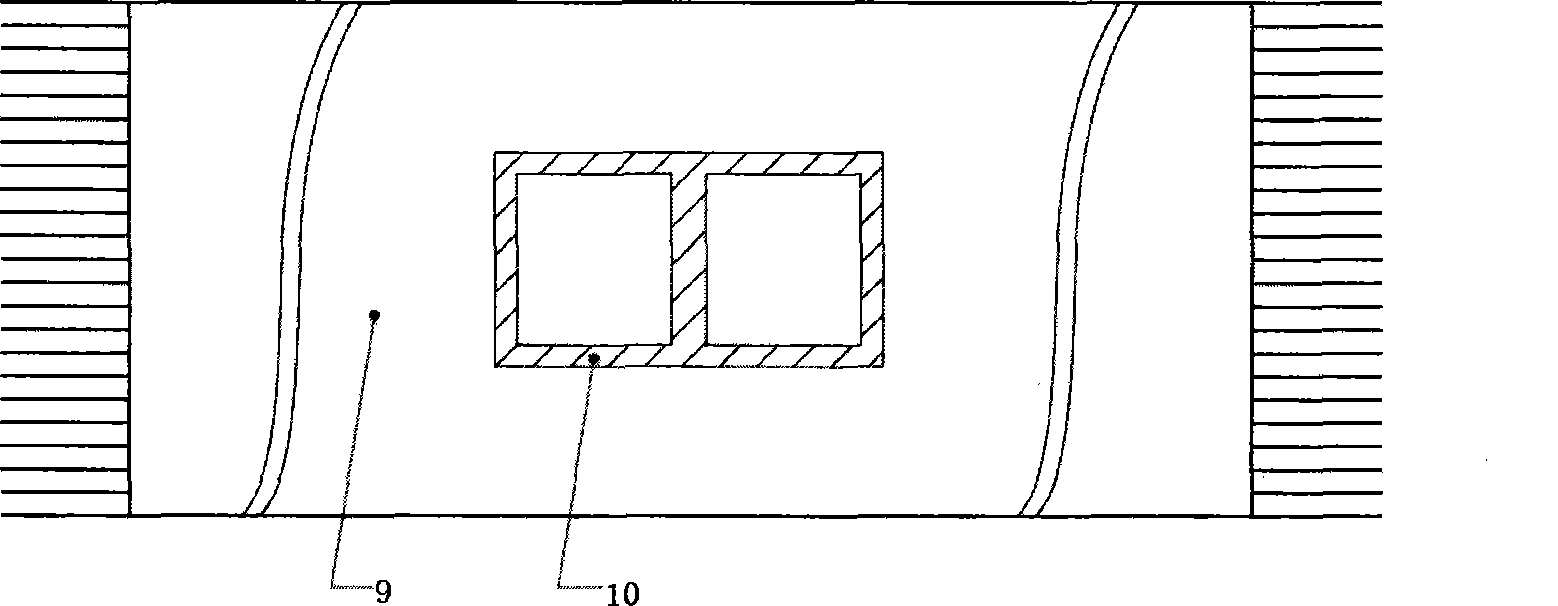

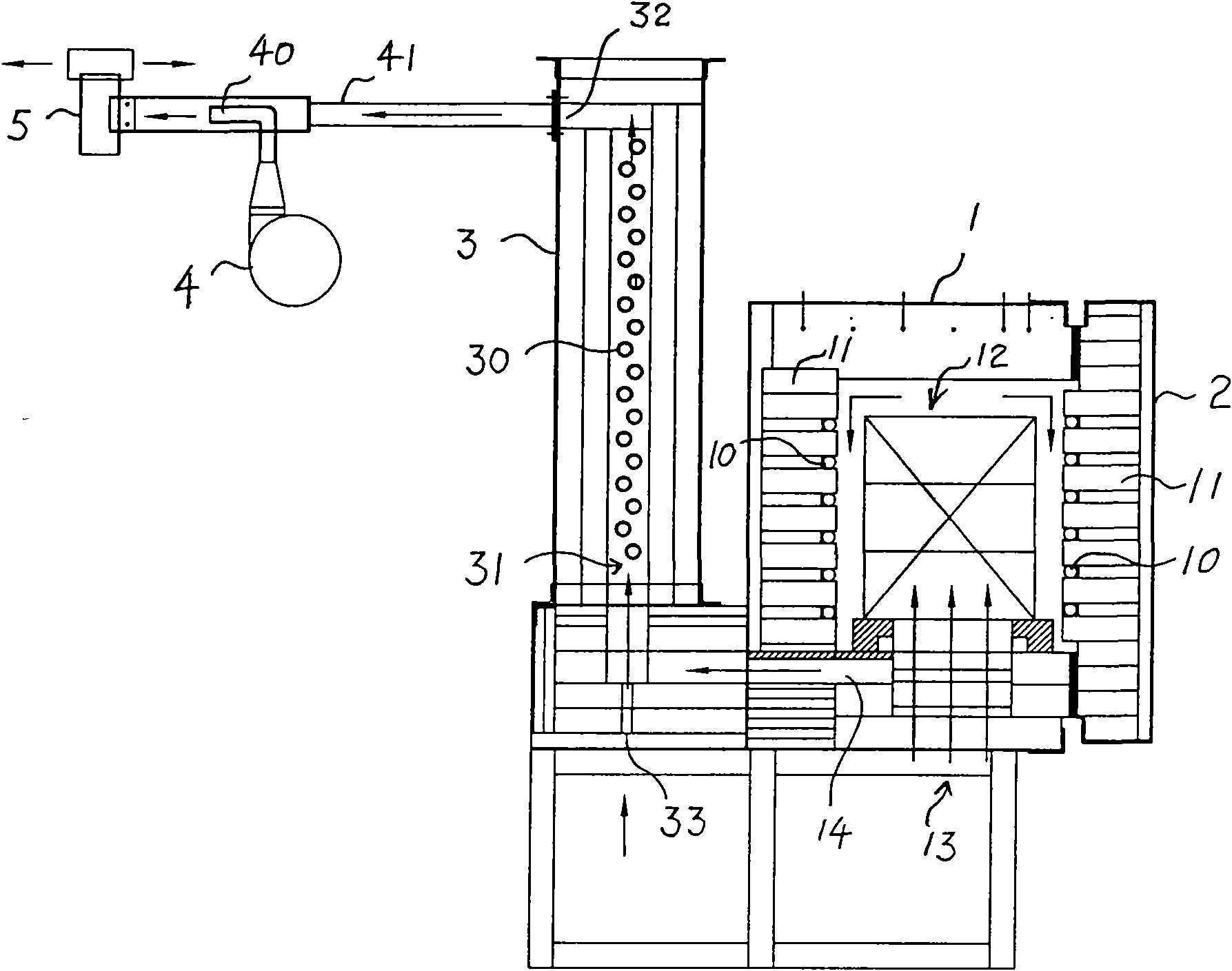

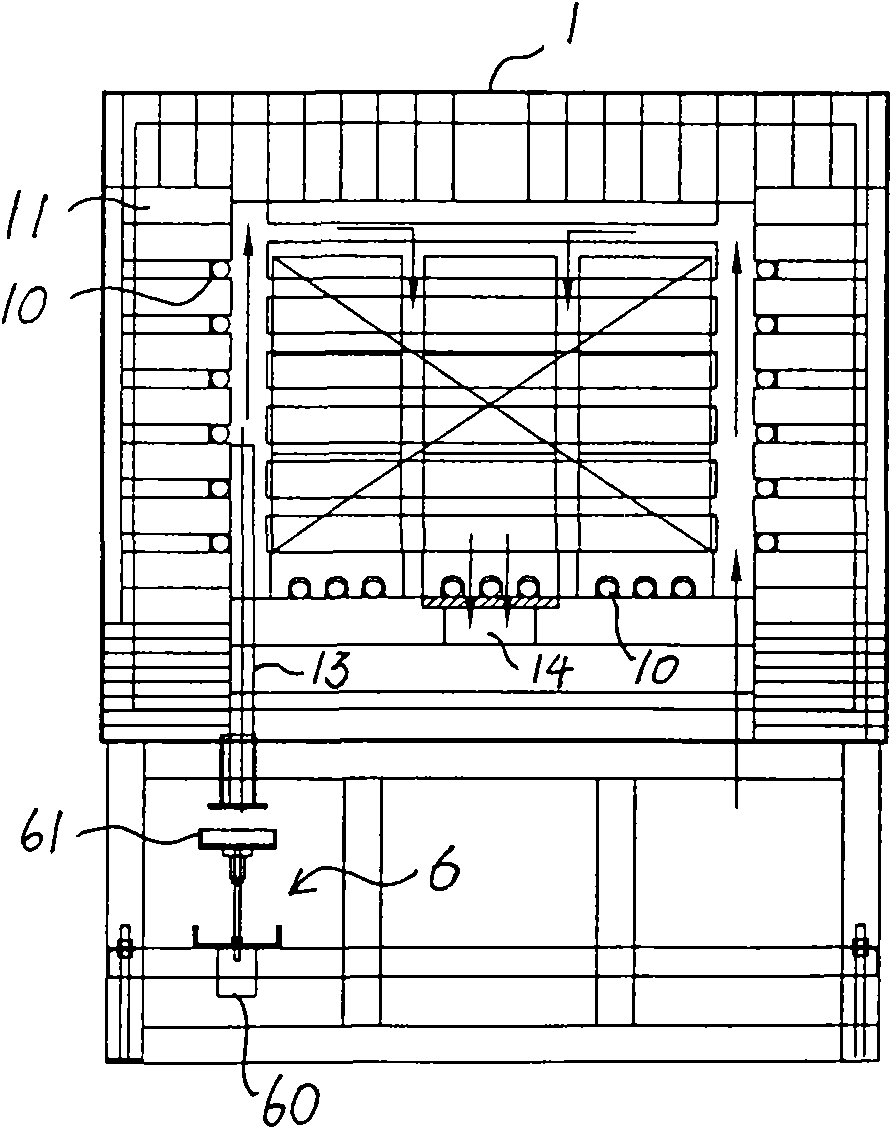

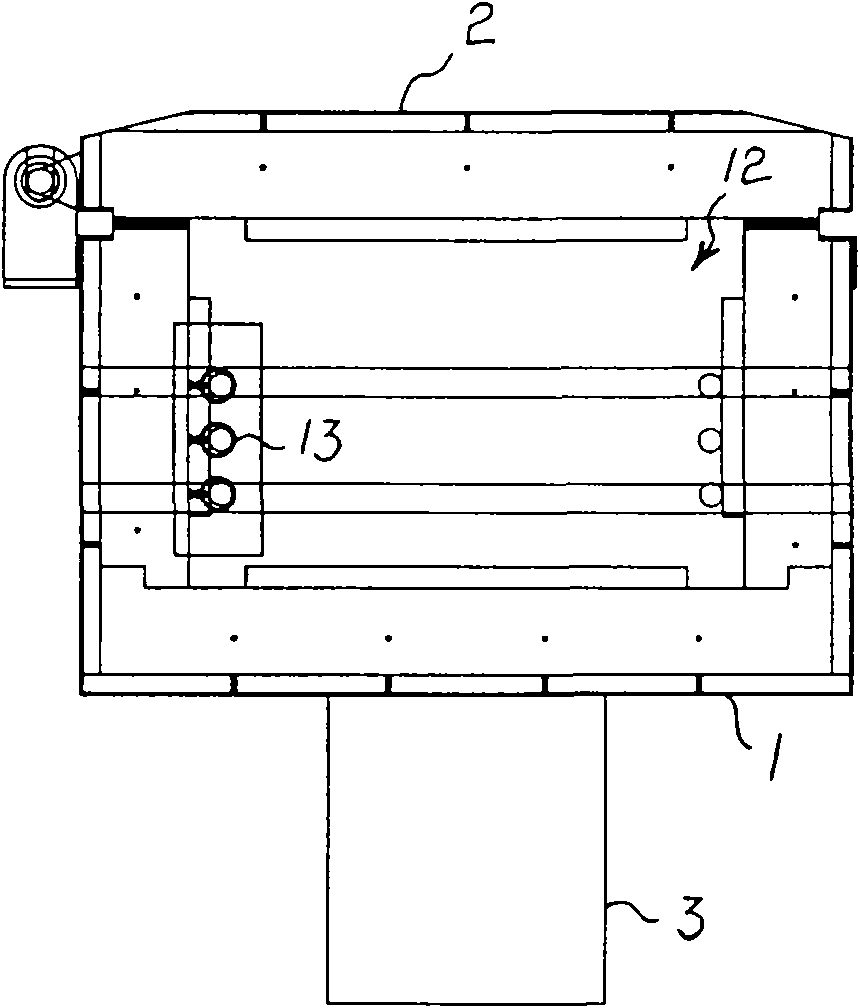

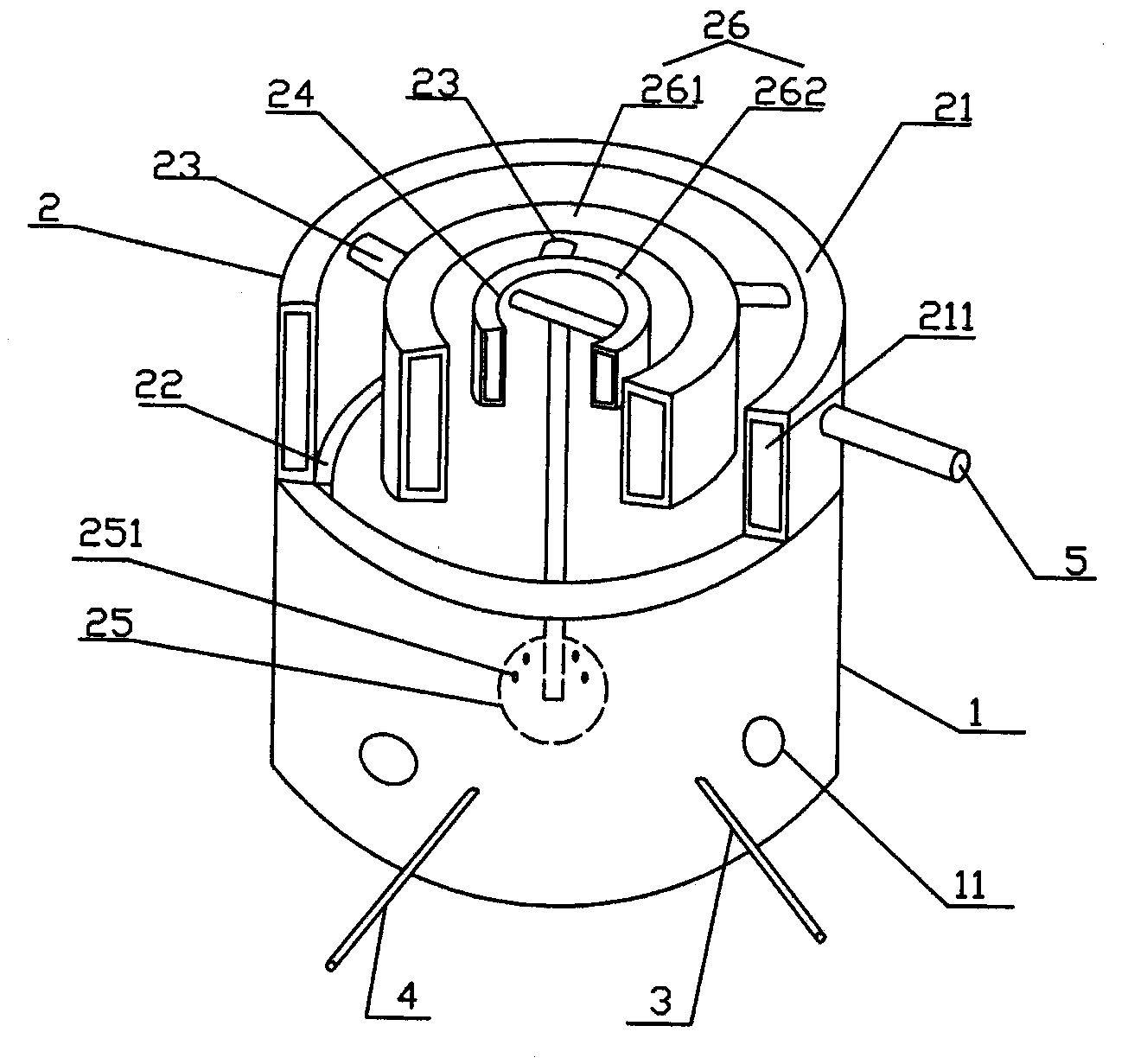

Ceramic dumping environment-protection kiln

InactiveCN101875560ADischarge fullyStable furnace temperature uniformityDispersed particle separationFurnace temperatureExhaust pipe

The invention relates to a ceramic dumping environment-protection kiln which is characterized in that: the ceramic dumping environment-protection kiln is mainly composed of a dumping heating kiln (1) and a waste removal environment-protection furnace (3), the bottom part of the dumping heating kiln (1) is provided with a dumping heating kiln air inlet duct (13), the space of the inner part of the dumping heating kiln (1) communicated with the dumping heating kiln air inlet duct (13) is a dumping waste gas pumping chamber (12), the dumping waste gas pumping chamber (12) is communicated with a high-temperature catalyst chamber (31) in the waste removal environment-protection furnace (3) by a dumping waste gas collection channel (14) at the bottom part of the dumping heating kiln (1), a thermal catalyst element (30) is arranged in the high-temperature catalyst chamber (31), an exhaust port (32) communicated with the high-temperature catalyst chamber (31) is arranged at the upper part of the waste removal environment-protection furnace (3), and the exhaust port (32) is connected with a programmable jet flow blower (4) by an exhausts pipe (41). The ceramic dumping environment-protection kiln has the advantages of full and complete waste exhaust, stable furnace temperature uniformity, good dumping quality and thorough and high-efficiency catalytic reaction.

Owner:李锦桥

Inelastic lace trimming and production method thereof

ActiveCN103481607AReflect tough textureGood dispersionSynthetic resin layered productsArtifical filament manufactureYarnPolyester

The invention relates to an inelastic lace trimming and a production method of the inelastic lace trimming. A lace layer is combined on inelastic fabric and is formed by weaving polyester and nylon composite yarn and modified nylon yarn, and the mass ratio of the polyester and nylon composite yarn to the modified nylon yarn is 1:1. The production technology is simple in process, and large-scale industrial production can be carried out. The polyester and nylon composite yarn has the weaving and dyeing performance of both polyester and nylon and can be twisted together for weaving production, and thus the polyester and nylon composite yarn not only can show special texture and metal brilliance of metal wires but also is softer and comfortable than the metal wires. Meanwhile, the hard texture of the inelastic trimming can be shown better, and the lace trimming is inelastic fabric and can be widely applied.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Multipurpose nylon lace and manufacturing method thereof

The invention relates to a multipurpose nylon lace and a manufacturing method thereof. The multipurpose nylon lace adopts a two-layer combined structure. A surface layer is arranged on the base layer; the surface layer is made of positive ion polyester fibers; the base layer is made of spandex fibers and multipurpose polyamide fabrics; the mass ratio of the spandex fibers to the multipurpose polyamide fabrics is 1:49. Nano zinc oxide of the multipurpose nylon lace is high in capacity for absorbing ultraviolet, can shield both long-wave ultraviolet (UVA) with the wavelength of 320-400mm and middle-wave ultraviolet (UVB) with the wavelength of 280-320nm, is non-toxic and odorless, cannot stimulate the skin, cannot be decomposed and go bad, is high in stability and white, can be colored according to different objects, is low in cost, can be used for producing odor-resistant, antimicrobial and anti-ultraviolet fibers and can absorb odor and purify air.

Owner:陈曦

Chinese globeflower flower herb tea and preparation method thereof

The invention belongs to the technical field of preparation of herb tea, and particularly relates to Chinese globeflower flower herb tea and a preparation method thereof. The Chinese globeflower flower herb tea provided by the invention is mainly prepared through scientific matching of Chinese globeflower flowers, hericium erinaceus, prebiotics, bamboo juice, lemon peel and mint. The Chinese globeflower flower herb tea disclosed by the invention is delicately fragrant and refreshing in mouth feel, safe to drink, suitable for four seasons and suitable for both old and young, has the functions of clearing heat, removing toxicity, invigorating the spleen, nourishing the stomach, alleviating constipation symptoms, conditioning bacterial equilibrium, restoring consciousness, improving eyesight, clearing heat from the throat, improving the condition of the throat and the like, can enhance the immunity of the human bodies, and has favorable health-care effects.

Owner:GUANGDONG ROC MEDICINAL TECH CO LTD

Water-based textile dyeing antibacterial auxiliary

InactiveCN105544207AGood contact antimicrobial effectLong-term antibacterial effectBiochemical fibre treatmentChemistryEmulsion

The invention discloses a water-based textile dyeing antibacterial auxiliary. The water-based textile dyeing antibacterial auxiliary is prepared from 20-300 parts of starch, 20-50 parts of nano materials, 9-20 parts of pigment, 2-5 parts of water-based initiator, 10-15 parts of an inorganic antibacterial agent, 5-8 parts of a dispersing agent, 50-80 parts of printing ink and 15-19 parts of emulsion. The product is favorable for reduction of environment loads, improvement of production efficiency and reduction of production cost and is moderate in adhesive force.

Owner:ZHONGSHAN LVLANG ADDITIVES CO LTD

Aromatic mothproof mouldproof drying agent

InactiveCN103749558ATastelessNo corrosionBiocidePest repellentsAdditive ingredientSandalwood extract

The invention relates to a drying agent, and particularly relates to an aromatic mothproof mouldproof drying agent. The aromatic mothproof mouldproof drying agent is characterized by being prepared from the following ingredients in parts by weight: 30-60 parts of silica gel, 25-50 parts of mothproof agent, 3-10 parts of Chinese agilawood extract, and 3-10 parts of sandalwood extract. The aromatic mothproof mouldproof drying agent has the characteristics of having aroma, being non-toxic, odorless, non-corrosion, pollution-free and the like, and can be used for proofing moth and mould of articles such as clothes, leather, shoes, bags, textiles and the like.

Owner:DALIAN ZHAOYANG SOFTWARE TECH

Disposable foaming pad and preparation method thereof

The invention relates to the technical field of foaming pads, and particularly discloses a disposable foaming pad which comprises the following components: natural rubber, butadiene styrene rubber, asoftener, a reinforcing agent, a dispersing agent, a physical lubrication anti-aging agent, stearic acid, white factice, a foaming agent, a reinforcing colorant, zinc oxide, a foaming aid, a cross-linking agent and an accelerant. The invention further provides a preparation method of the disposable foaming pad. The disposable foaming pad is prepared through banburying, open milling, pressurizing,shaping and vulcanizing, and compared with an existing foaming pad, the disposable foaming pad has excellent road holding performance, slip resistance, skin friendliness, good harmony, good elasticity, light specific gravity, no smell, environmental friendliness, attractiveness, capability of being matched with various colors, no cracking, low cost, high benefit, wide application, and good marketprospects and depths.

Owner:义乌市大胜橡塑制品有限公司

Dispersion printing process of polyester sanded cloth

The invention discloses a dispersion printing process of a polyester sanded cloth. The dispersion printing process comprises: (1) carrying out desizing-deoiling-whitening first bath; (2) heating a working liquid to 120 DEG C from a room temperature; (3) cooling the working liquid to 80 DEG C from 120 DEG C; (4) carrying out dehydration-width opening-wool scouring; (5) carrying out shaping treatment; (6) carrying out magnetic bar printing, wherein the shaped polyester sanded cloth is subjected to wool suction treatment through a wool suction device in front of a printing machine, the obtained shaped polyester sanded cloth is placed in a slurry containing a synthetic thickener and a dye, and magnetic bar printing is performed; (7) carrying out dry steaming; (8) carrying out water washing, wherein the steamed polyester sanded cloth is subjected to water washing with an environmentally friendly powerful reducing agent; and (9) carrying out shaping drying on the washed polyester sanded cloth. With the dispersion printing process of the present invention, the process steps and the process time are substantially reduced, the production efficiency is improved, and the obtained printed cloth is stable and reliable.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

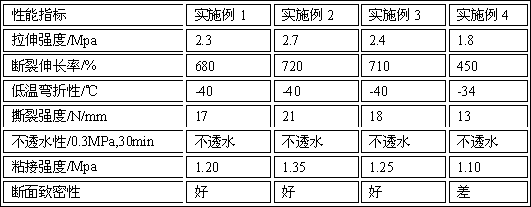

Preparation method of single-component polyurethane waterproofing paint

ActiveCN109504268ATastelessImprove mechanical propertiesPolyurea/polyurethane coatingsPolymer sciencePolyol

The invention discloses a preparation method of single-component polyurethane waterproofing paint. The preparation method comprises the following steps: 1) mixing polyether polyol and a porous microbead carrier getter, heating the mixture, dehydrating the mixture in vacuum, and making the mixture react with isocyanate to generate a prepolymer of which the end group is -NCO, wherein the weight ratio of the polyether polyol to the isocyanate is (3 to 8) to 1; 2) adding the prepolymer prepared in the step 1) into a catalyst, and performing a polymerization reaction to obtain the single-componentpolyurethane waterproof paint. The paint prepared with the method is free from MOCA, tar oil, solvents and heavy metals, is odorless after curing, is environmentally friendly and nontoxic, and has superior mechanical performance, chemical performance and superior waterproofing performance. The product conforms to the limit of harmful substance in GB / T19250-2013, and can be constructed on wet substrates.

Owner:山西四方九瑞防水技术有限公司

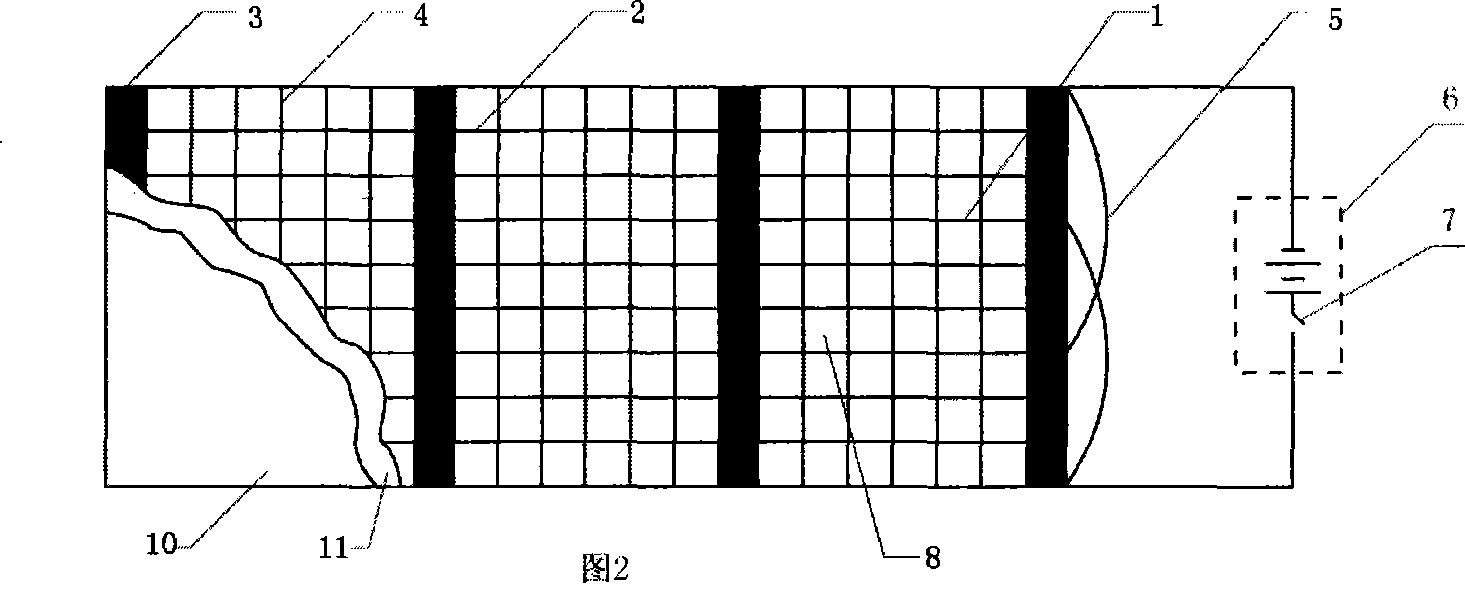

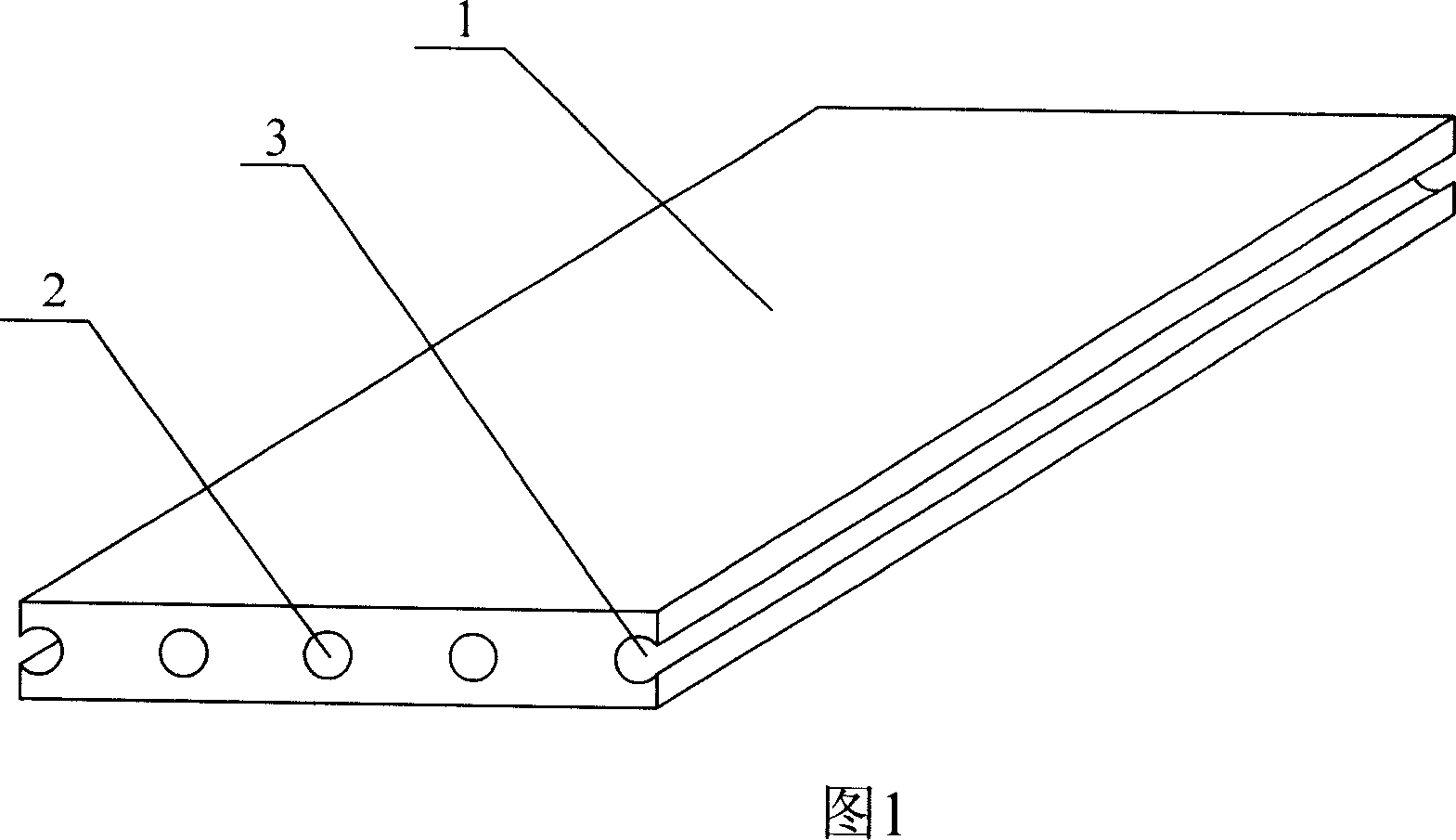

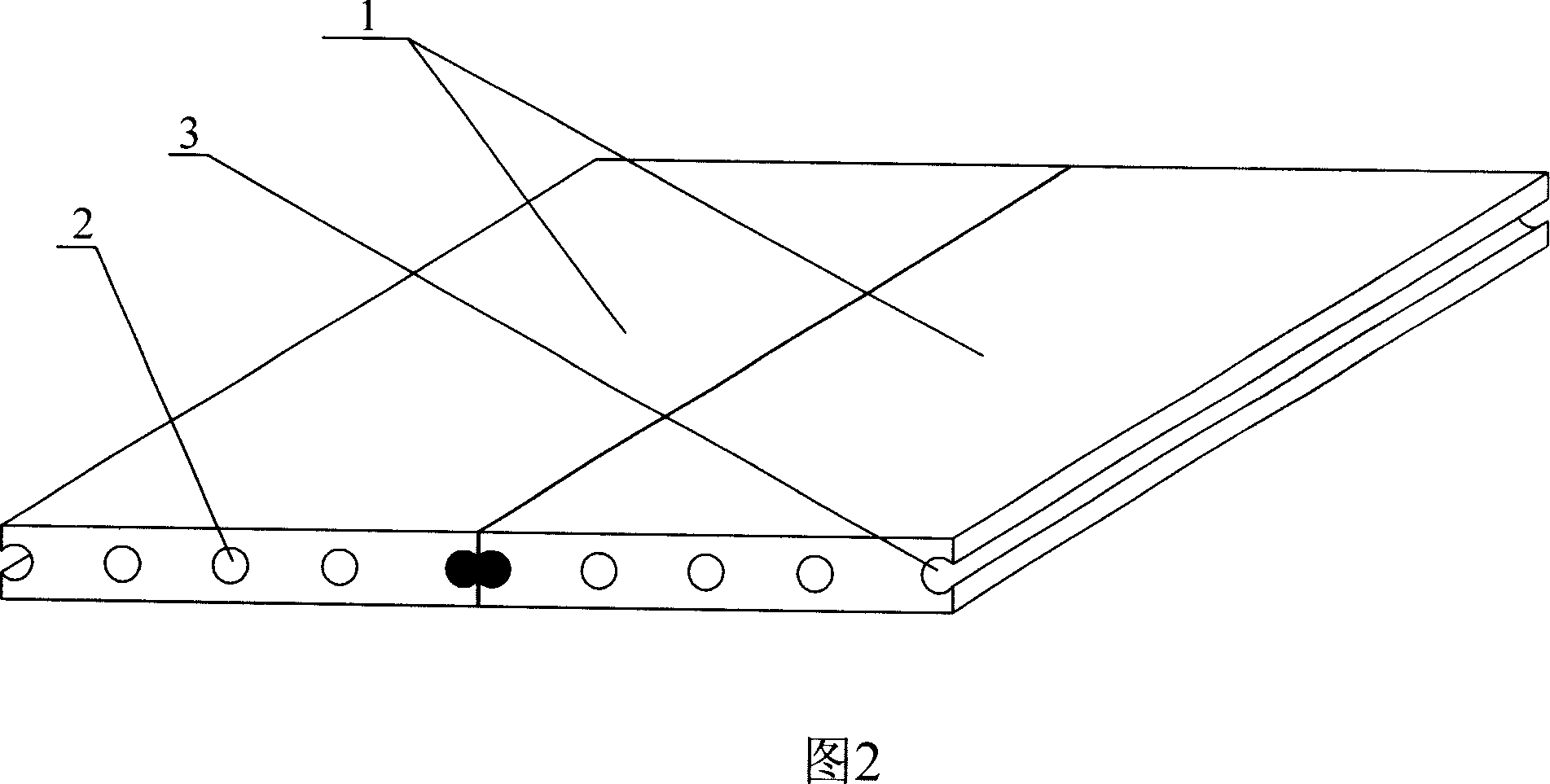

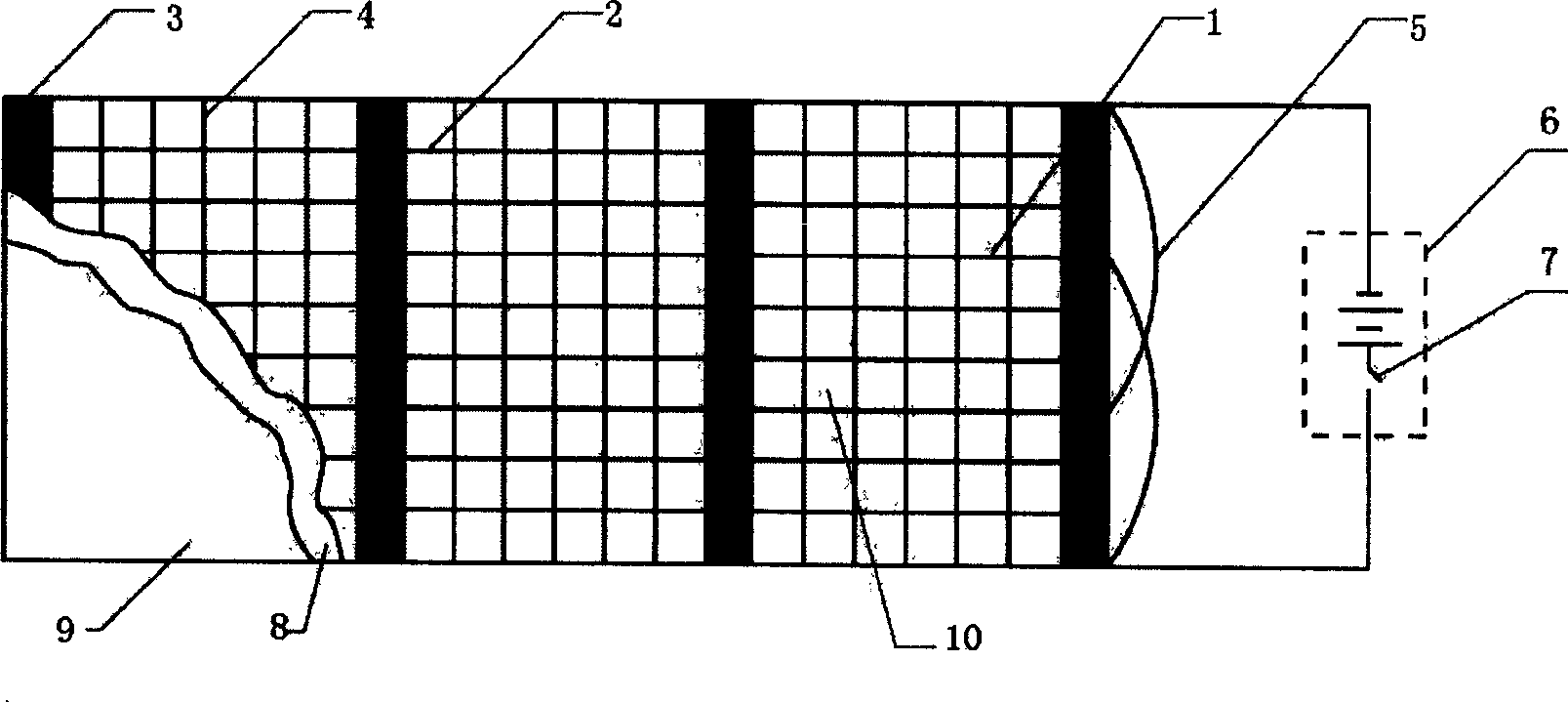

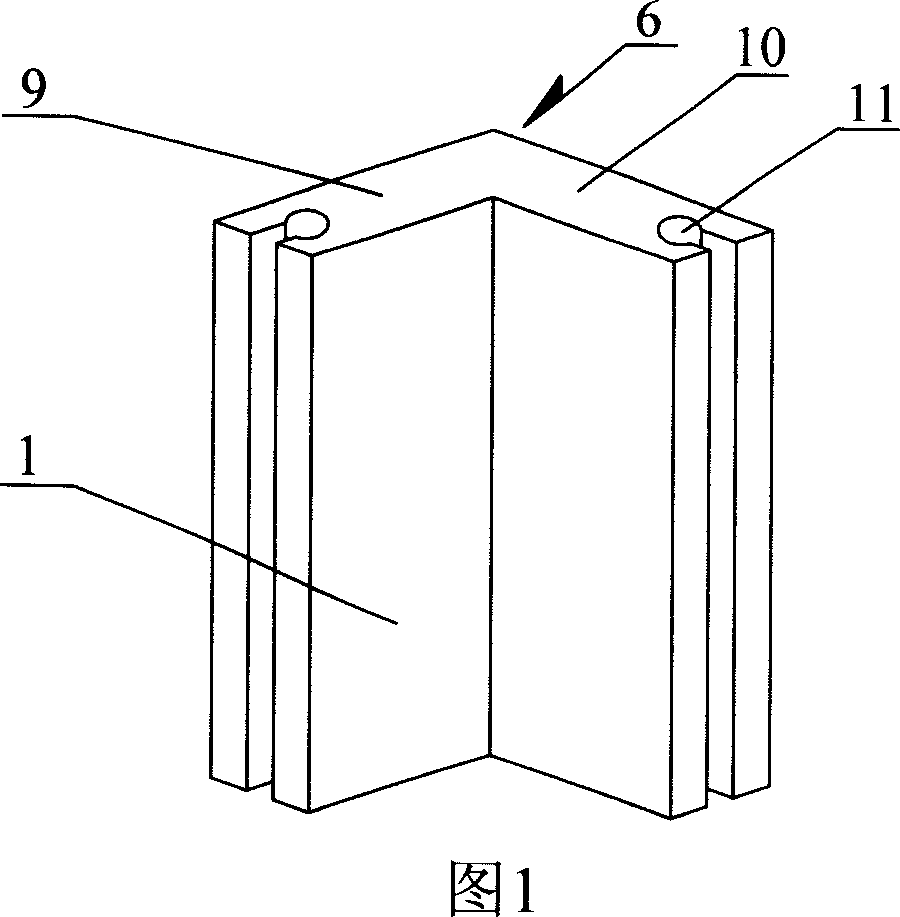

Carbon heating waistband and preparation method thereof

InactiveCN101396310AHeating up fastTastelessOhmic-resistance heatingTherapeutic coolingSmart polymerEngineering

The invention relates to a carbon heating waistband and a preparation method thereof. The waistband comprises a lumbar support, a patch pocket, an elastic band, a fibula, a battery bag, a carbon heating piece, a connecting lead, and an intelligent polymer lithium battery; a warp direction static wire in the carbon heating piece adopts the parallel connection mode, and then is connected with the positive set and the negative set of the lithium battery; the elastic band is connected with the two ends of the waistband; the fibula is respectively connected with the two ends of the elastic band; the lumbar support are weaved by three layers of textile fabrics and forms two patch pockets; the internal layer patch pocket is close to the waist of human body, made of knitting fishnet and used for putting the heating element; the outer layer is made of woven fabric and used for putting flexible synthetic glass thin material according to the requirements; the battery bag is arranged at one end of the elastic band and can be adjusted according to the requirements. The waistband has the advantages of quick heating and warming, being odourless and pollution-free, good effect, and is an ideal heat supplying and insulation waistband.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

High-temperature energy-saving furnace

InactiveCN103968431ASimple structureLow priceDomestic stoves or rangesLiquid heating fuelAutomotive engineeringOil pressure

The invention discloses a high-temperature energy-saving furnace comprising an igniter arranged on a furnace base, an ignition oil inlet and a furnace pipe which is buckled on the furnace base and communicated with an oil delivery pipeline, wherein the furnace pipe comprises an outer pipe, a pipe base, fuel pipes, a three-way pipeline, an evaporation ball body and at least one inner pipe; the pipe base is fixedly arranged at the bottom of the outer pipe; the oil delivery pipeline is communicated with the outer pipe; the outer pipe and each inner pipe as well as the inner pipes are communicated through the fuel pipes, tapered in diameter and coaxially arranged; the three-way pipeline is respectively communicated with the inner pipes and an inner oil delivery cavity of the evaporation ball body at the bottoms of the inner pipes; the upper part of the evaporation ball body is provided with multiple oil spit holes. According to the furnace, liquid fuel is converted into gas fuel through cyclic gasification of the furnace pipe, the fuel molecular formula effect of the liquid fuel is changed, the use ratio of the gas fuel is increased by 30-40% when being compared with that of existing fuel, the pressure of the fuel is improved and then the combustion temperature is increased accordingly, no smoke, smell and carbon deposition residue exist in the combustion process, the full utilization of resources is realized, and the low-carbon, energy-saving and environment-friendly effects are realized.

Owner:康智文

Special plate for module type vehicle comprising living accommodation

InactiveCN1924243AEasy constructionEasy to assembleConstruction materialSolid waste managementEpoxyFoaming agent

This invention relates to module caravan special board, which comprises outside wall board, house cover board and isolation board. The invention is characterized by the following: the outside wall board and cover board form inner and outer boards, wherein, the inner board is composed of magnesia sand for 90 to 120kg, magnesium chloride solution for 60 to 80kg, powder coke for 20 to 40kg, calcium sulfate for 0.2 to 0.5kg, modifier agent A1 or MBS resin for 0.2 to 0.5kg; the mode shape comprises upper compound ring resin layer; the indoor isolation board is composed of magnesia sand for 95 to 120kg, powder coke for 8 to 12kg, magnesium chloride resolution for 46 to 54kg, blowing agent N1 or ADC for 1 to 2kg through mixing, blowing steps with magnesia particle larger than 150, magnesia for 80 to 85 percentage, magnesium chloride larger than 45 percentage and powder coke particle larger than 150.

Owner:李英魁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com