Modified polyester film and production method thereof

A technology of modified polyester and production method, applied in the field of polyester film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

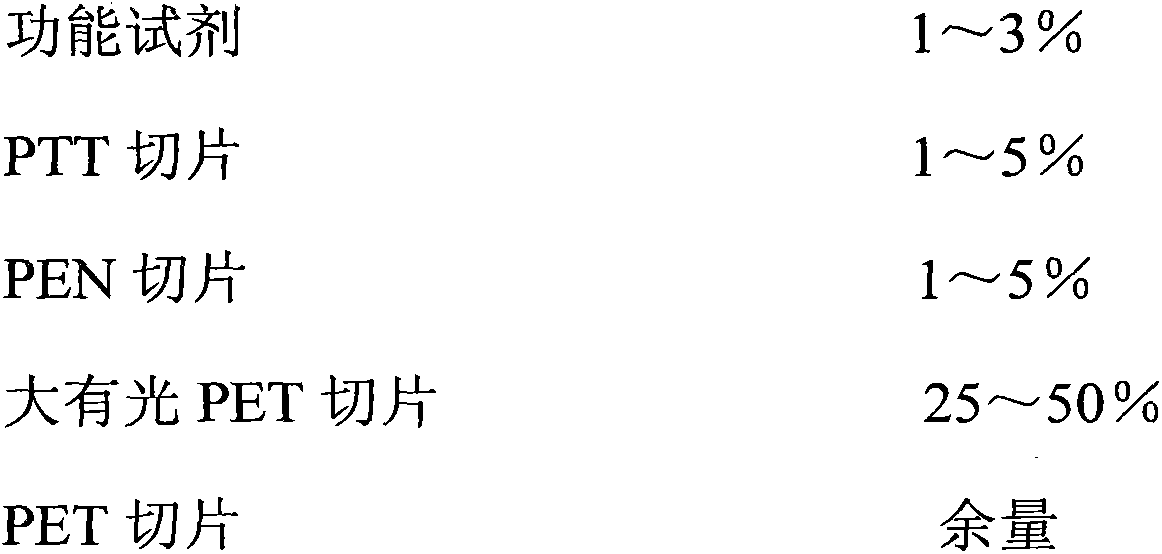

[0078] A modified polyester film is composed of functional reagents, PET slices and bright PET slices, and is characterized in that its raw material composition mass percentage is:

[0079]

[0080] The functional reagent is a capsule structure, the core layer is composite powder, the thickness ratio of the capsule layer and the core layer is 1:22; the diameter of the functional masterbatch is 0.7-7 μm;

[0081] The composite powder is tea charcoal powder containing nano-titanium dioxide and nano-zinc oxide;

[0082] A production method of a modified polyester film, which is produced by a biaxial stretching process. The specific process is: 1. Preparation of functional reagents, 2. Pre-crystallization drying, 3. Melting extrusion, 4. Casting, 5. Longitudinal stretching And transverse stretching, seven traction, slicing, corona treatment, winding, inspection, characterized in that the pre-crystallization temperature is 151 ~ 158 ℃; melt extrusion pre-crystallized and dried P...

Embodiment 2

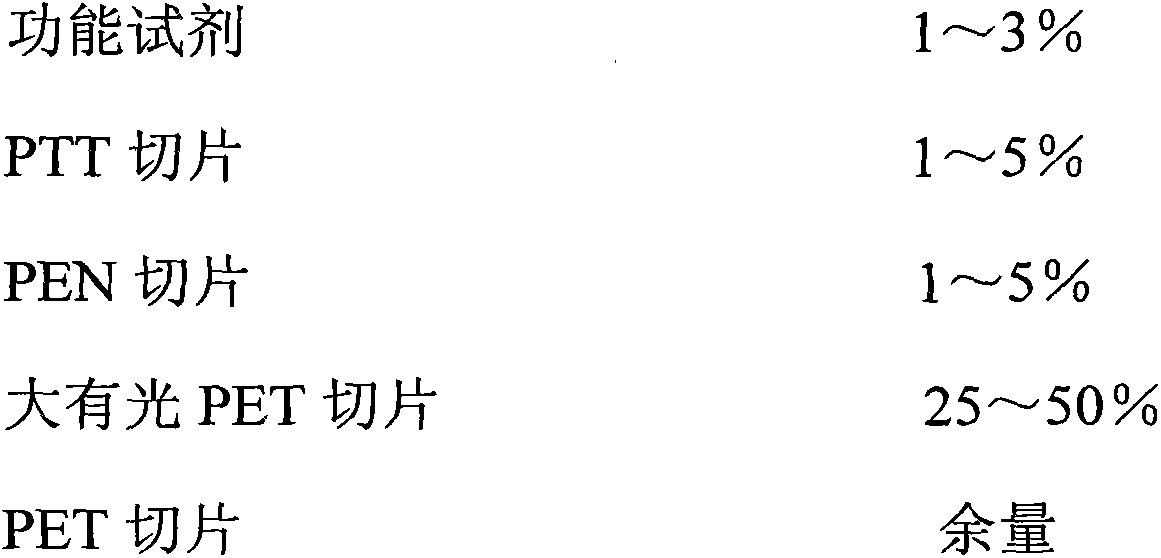

[0135] A modified polyester film is composed of functional reagents, PET slices and bright PET slices, and is characterized in that its raw material composition mass percentage is:

[0136]

[0137]

[0138] The functional reagent is a capsule structure, the core layer is composite powder, the thickness ratio of the capsule layer and the core layer is 1:22; the diameter of the functional masterbatch is 0.7-7 μm;

[0139] The composite powder is tea powder containing nano-titanium dioxide and nano-zinc oxide;

[0140] A production method of a modified polyester film, which is produced by a biaxial stretching process. The specific process is: 1. Preparation of functional reagents, 2. Pre-crystallization drying, 3. Melting extrusion, 4. Casting, 5. Longitudinal stretching And transverse stretching, seven traction, slicing, corona treatment, winding, inspection, characterized in that the pre-crystallization temperature is 151 ~ 158 ℃; melt extrusion pre-crystallized and drie...

Embodiment 3

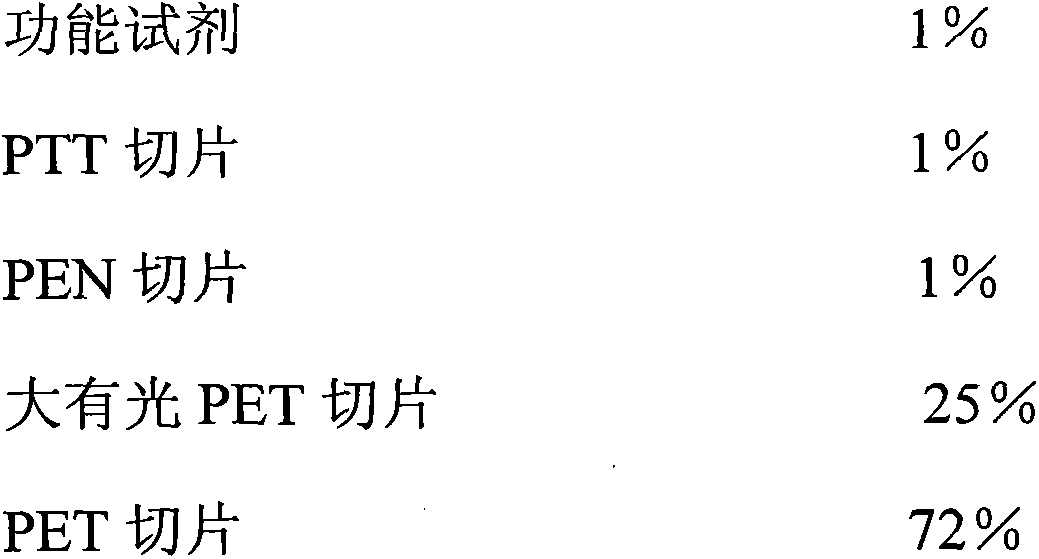

[0192] A modified polyester film is composed of functional reagents, PET slices and bright PET slices, and is characterized in that its raw material composition mass percentage is:

[0193]

[0194] The functional reagent is a capsule structure, the core layer is composite powder, the thickness ratio of the capsule layer and the core layer is 1:22; the diameter of the functional masterbatch is 0.7-7 μm;

[0195] A production method of a modified polyester film, which is produced by a biaxial stretching process. The specific process is: 1. Preparation of functional reagents, 2. Pre-crystallization drying, 3. Melting extrusion, 4. Casting, 5. Longitudinal stretching And transverse stretching, seven traction, slicing, corona treatment, winding, inspection, characterized in that the pre-crystallization temperature is 151 ~ 158 ℃; melt extrusion pre-crystallized and dried PTT slices, PEN slices, PET slices, Dayouguang PET slices and modifiers are heated and melted by the extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com