Preparation method of Cr and S co-doped TiO2 nanopowder

A nano-powder and co-doping technology, applied in catalyst activation/preparation, nanotechnology, nanotechnology, etc., can solve the problem of hindering the recombination time of electrons and holes, hindering the recombination of photogenerated carriers, and low light absorption rate, etc. problem, to achieve the effect of strong ability to absorb ultraviolet light, wide light absorption range, and enhanced light absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

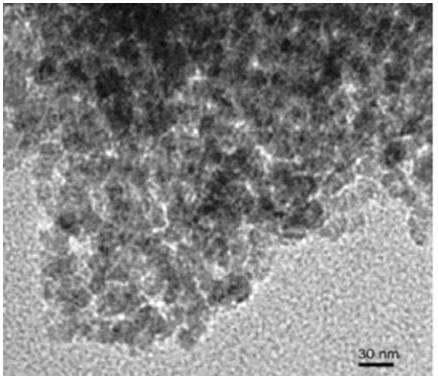

Image

Examples

Embodiment 1

[0022] A kind of Cr, S co-doped TiO 2 The preparation method of nanometer powder, concrete steps are as follows:

[0023] (1) Mix tetrabutyl titanate and absolute ethanol at a ratio of 1:2 by volume, stir continuously in a constant temperature water bath at 30°C until a transparent solution is obtained, and use it as liquid A at a stirring speed of 300 rpm;

[0024] (2) Na 2 S 2 o 3 ·5H 2 O was mixed with absolute ethanol, glacial acetic acid, and distilled water in a mass ratio of 2.48:25:20:10, stirred continuously in a constant temperature water bath at 30°C until a transparent solution was obtained, and used as liquid B at a stirring speed of 300 rpm;

[0025] (3) Add CrCl 3 ·6H 2 O was mixed with absolute ethanol, glacial acetic acid, and distilled water in a mass ratio of 2.66:25:20:10, stirred continuously in a constant temperature water bath at 30°C until a transparent solution was obtained, and used as liquid C at a stirring speed of 300 rpm;

[0026] (4) Accor...

Embodiment 2

[0031] A kind of Cr, S co-doped TiO 2 The preparation method of nanometer powder, concrete steps are as follows:

[0032] (1) Mix tetrabutyl titanate and absolute ethanol at a volume ratio of 1:3, stir continuously in a constant temperature water bath at 35°C until a transparent solution is obtained, and use it as liquid A at a stirring speed of 400 rpm;

[0033] (2) Na 2 S 2 o 3 ·5H 2 O was mixed with absolute ethanol, glacial acetic acid, and distilled water in a mass ratio of 2.48:35:20:10, and was continuously stirred in a constant temperature water bath at 35°C until a transparent solution was obtained as liquid B, and the stirring speed was 400 rpm;

[0034] (3) Add CrCl 3 ·6H 2 O was mixed with absolute ethanol, glacial acetic acid, and distilled water in a ratio of 2.66:35:20:10 by mass, stirred continuously in a constant temperature water bath at 35°C until a transparent solution was obtained, and used as liquid C at a stirring speed of 400 rpm;

[0035] (4) Ac...

Embodiment 3

[0039] A kind of Cr, S co-doped TiO 2 The preparation method of nanometer powder, concrete steps are as follows:

[0040] (1) Mix tetrabutyl titanate and absolute ethanol at a volume ratio of 1:2.5, stir continuously in a constant temperature water bath at 40°C until a transparent solution is obtained, and use it as liquid A at a stirring speed of 500 rpm;

[0041] (2) Na 2 S 2 o 3 ·5H 2 O was mixed with absolute ethanol, glacial acetic acid, and distilled water in a ratio of 2.48:30:20:10 by mass, stirred continuously in a constant temperature water bath at 40°C until a transparent solution was obtained, and used as liquid B at a stirring speed of 500 rpm;

[0042] (3) Add CrCl 3 ·6H 2 O was mixed with absolute ethanol, glacial acetic acid, and distilled water in a mass ratio of 2.66:30:20:10, stirred continuously in a constant temperature water bath at 40°C until a transparent solution was obtained, and used as liquid C at a stirring speed of 500 rpm;

[0043] (4) Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com