Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

353 results about "Polyethylene naphthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

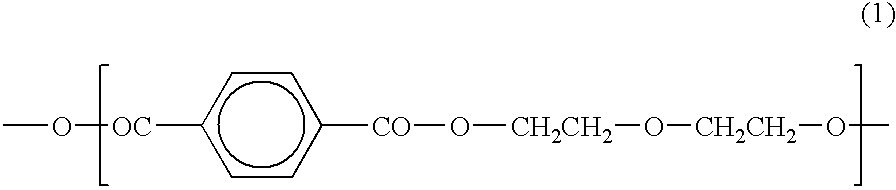

Polyethylene naphthalate (poly(ethylene 2,6-naphthalate) or PEN) is a polyester derived from naphthalene-2,6-dicarboxylic acid and ethylene glycol. As such it is related to poly(ethylene terephthalate), but with superior barrier properties.

Low layer count reflective polarizer with optimized gain

ActiveUS20110102891A1Exemplary color performanceExemplary gain performancePolarising elementsIn planeRefractive index

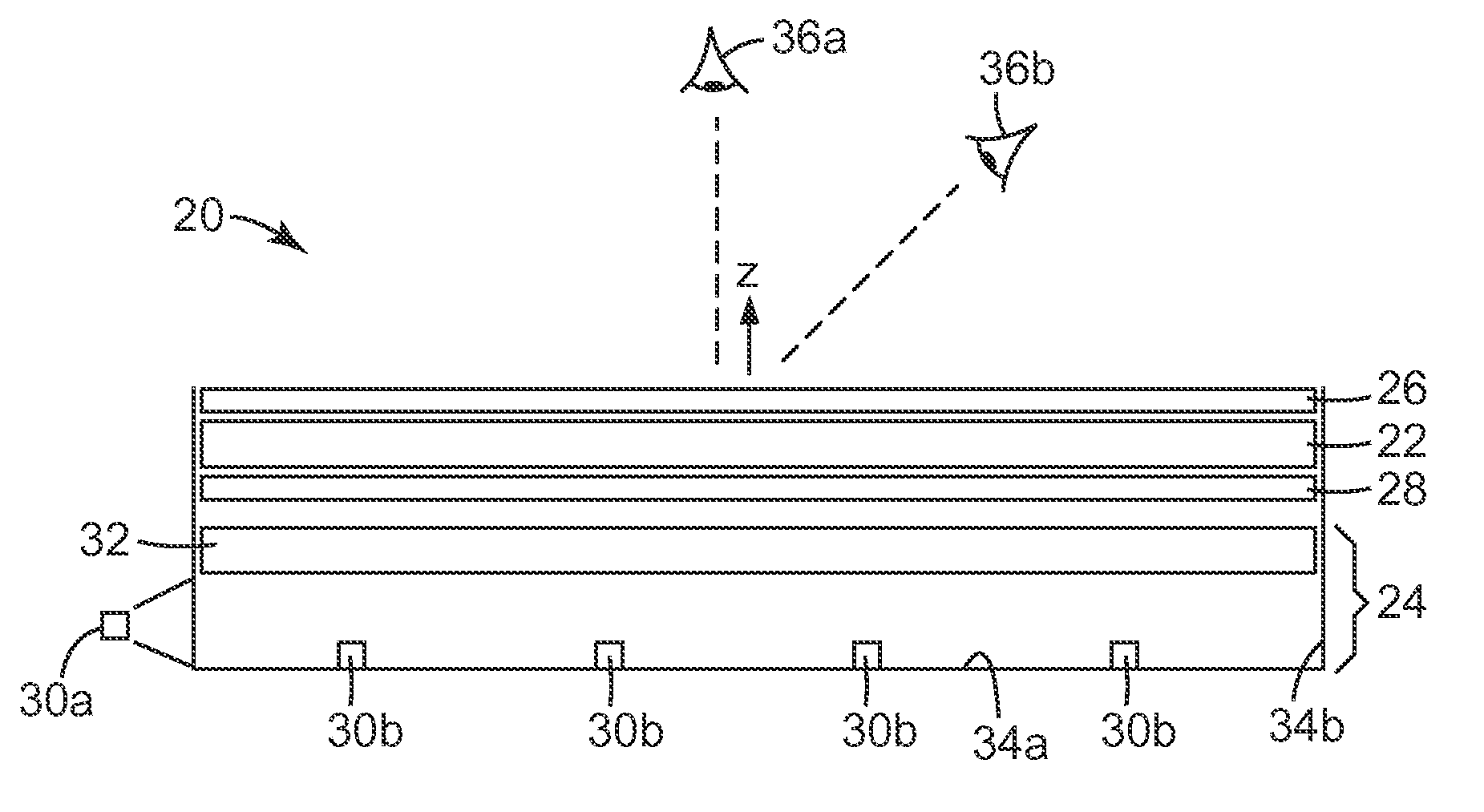

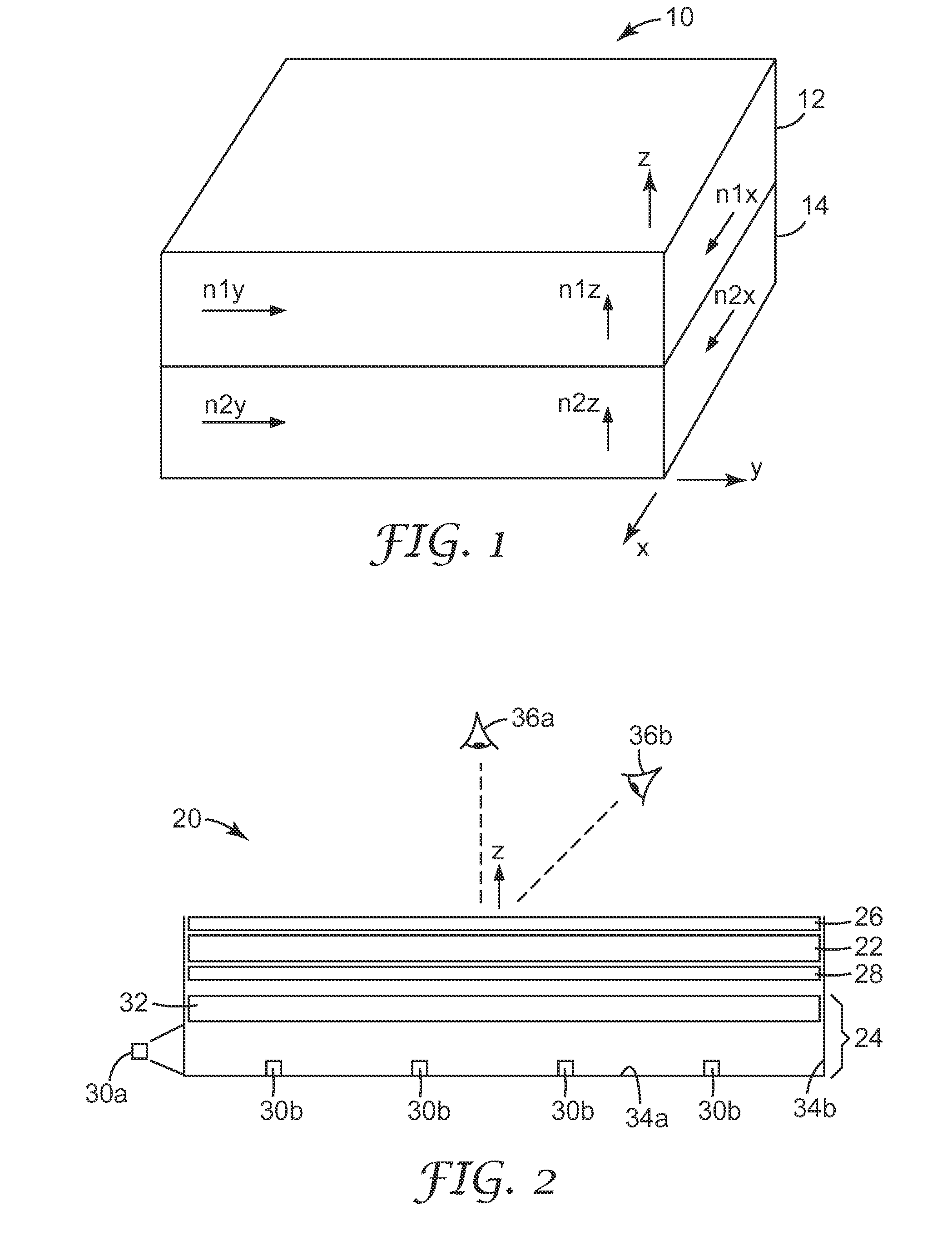

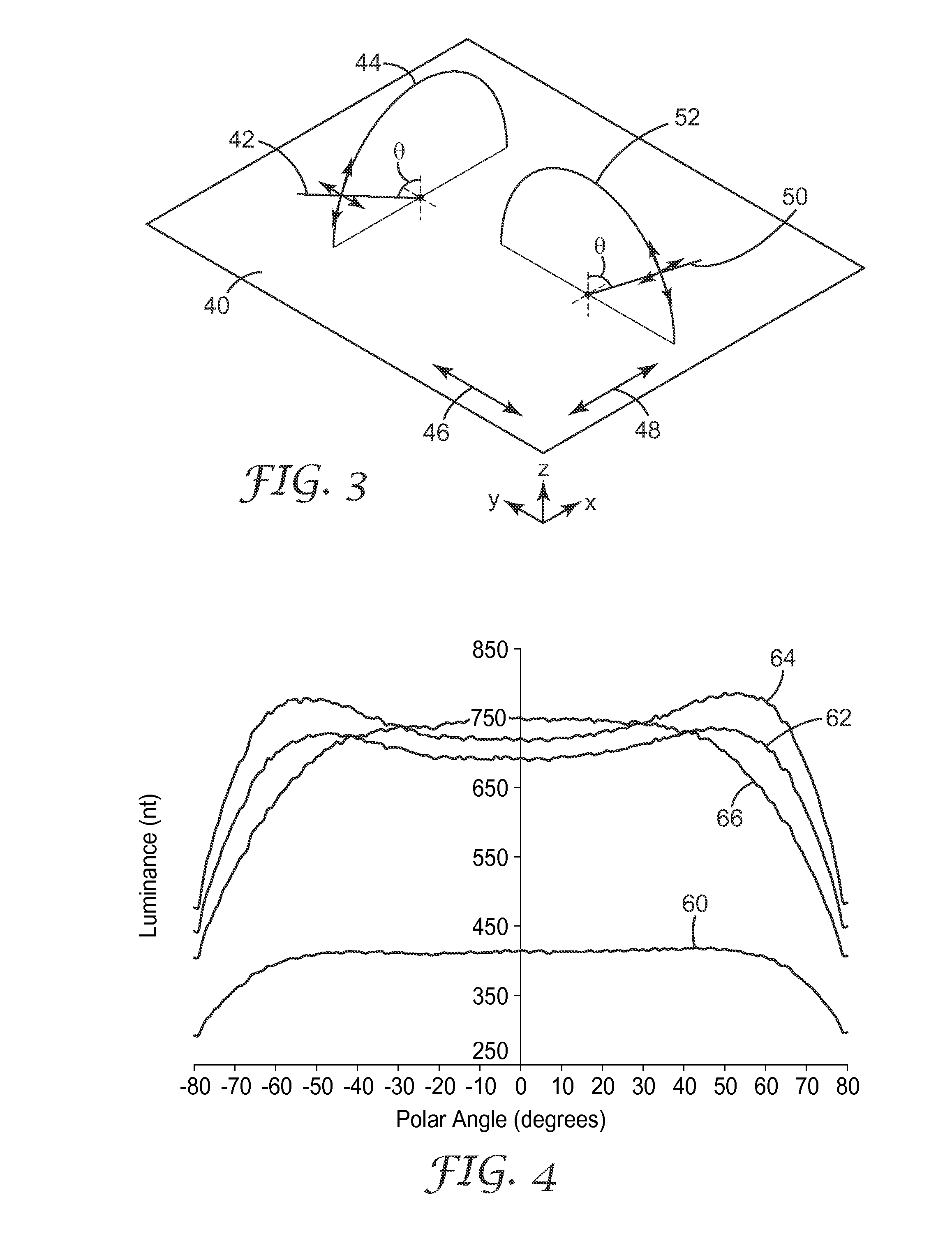

Multilayer reflecting polarizing films are disclosed having increased in-plane refractive index differences between adjacent microlayers along both the pass and block axis, and having negative refractive index differences between adjacent microlayers along the thickness or z-axis. Major front and back surfaces of the film exposed to air provide a Fresnel reflectivity component to the pass axis reflectivity, and the microlayers provide a microlayer component to the pass axis reflectivity, such microlayer component preferably having a reflectivity of p-polarized light that increases with incidence angle faster than the Fresnel reflectivity component decreases so as to substantially avoid off-axis gain peaks for p-polarized light. The films preferably utilize a relatively small total number of microlayers, arranged in a single coherent stack with monotonic optical repeat unit thickness profile, and at least some microlayers preferably include polyethylene naphthalate or a copolymer thereof.

Owner:3M INNOVATIVE PROPERTIES CO

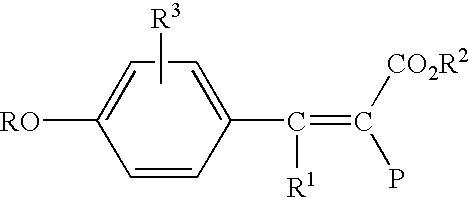

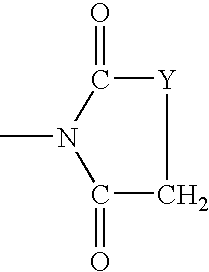

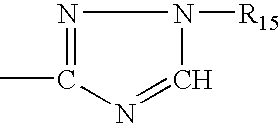

Polyester and process for preparing polyester

Owner:MITSUI CHEM INC

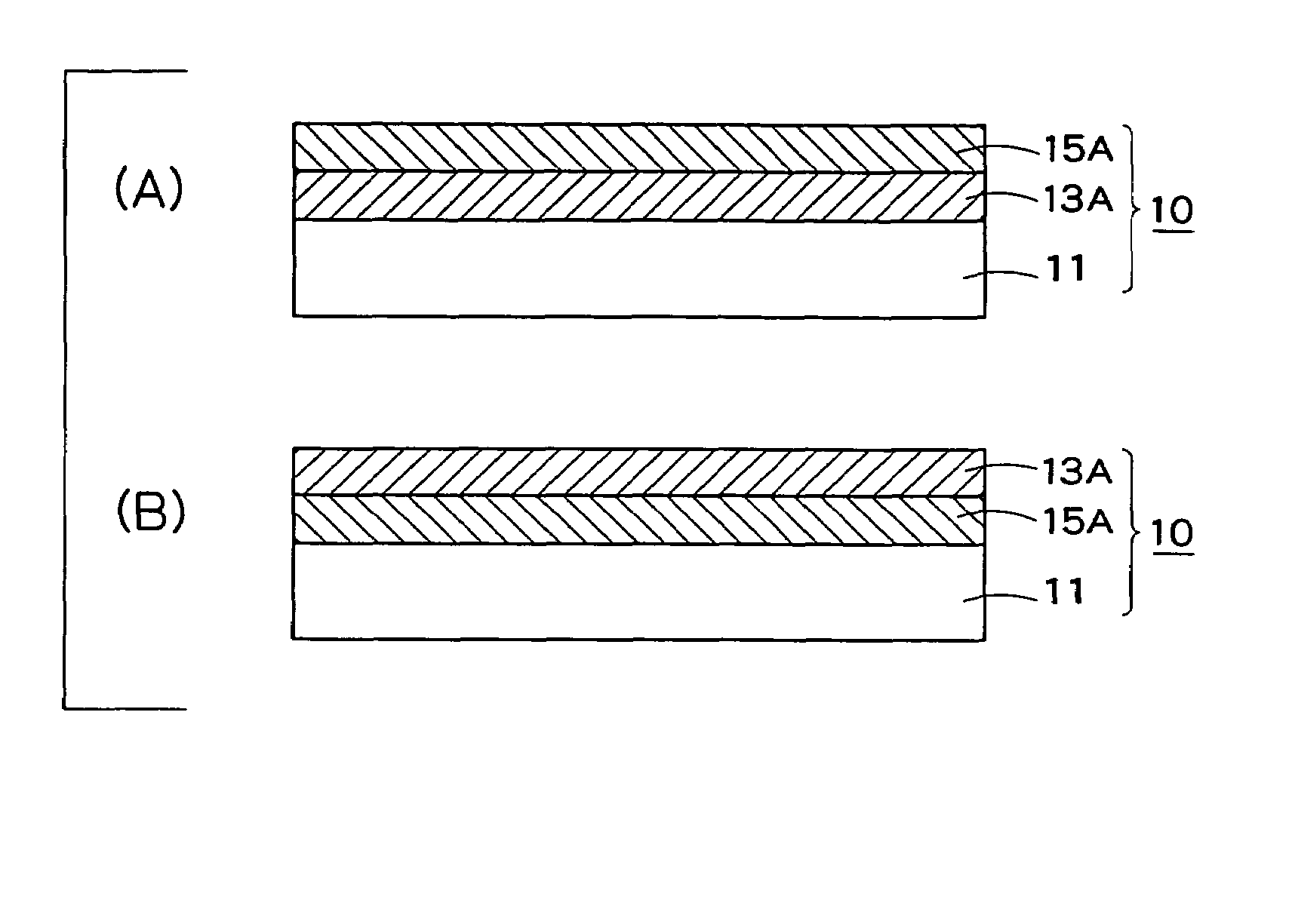

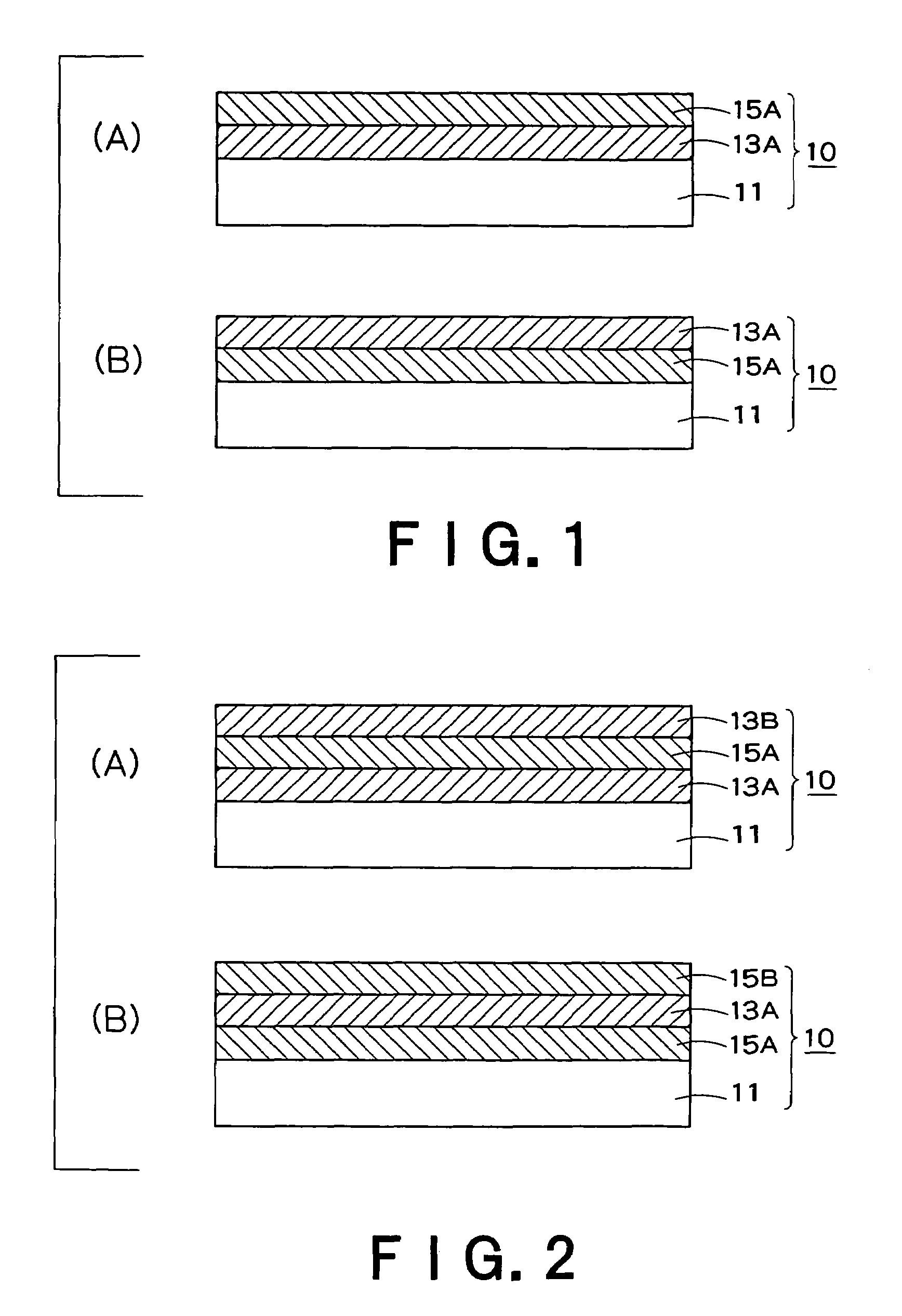

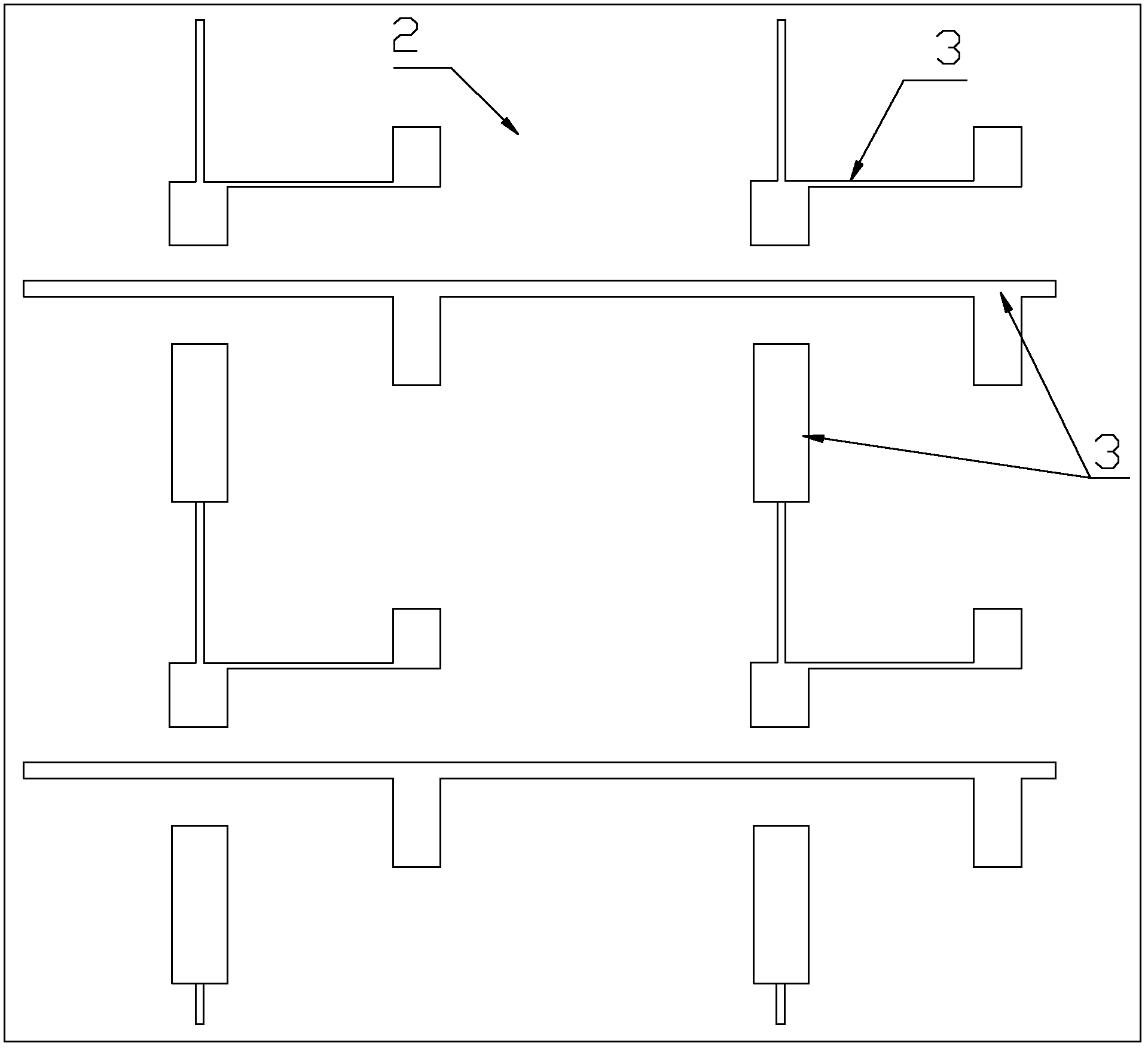

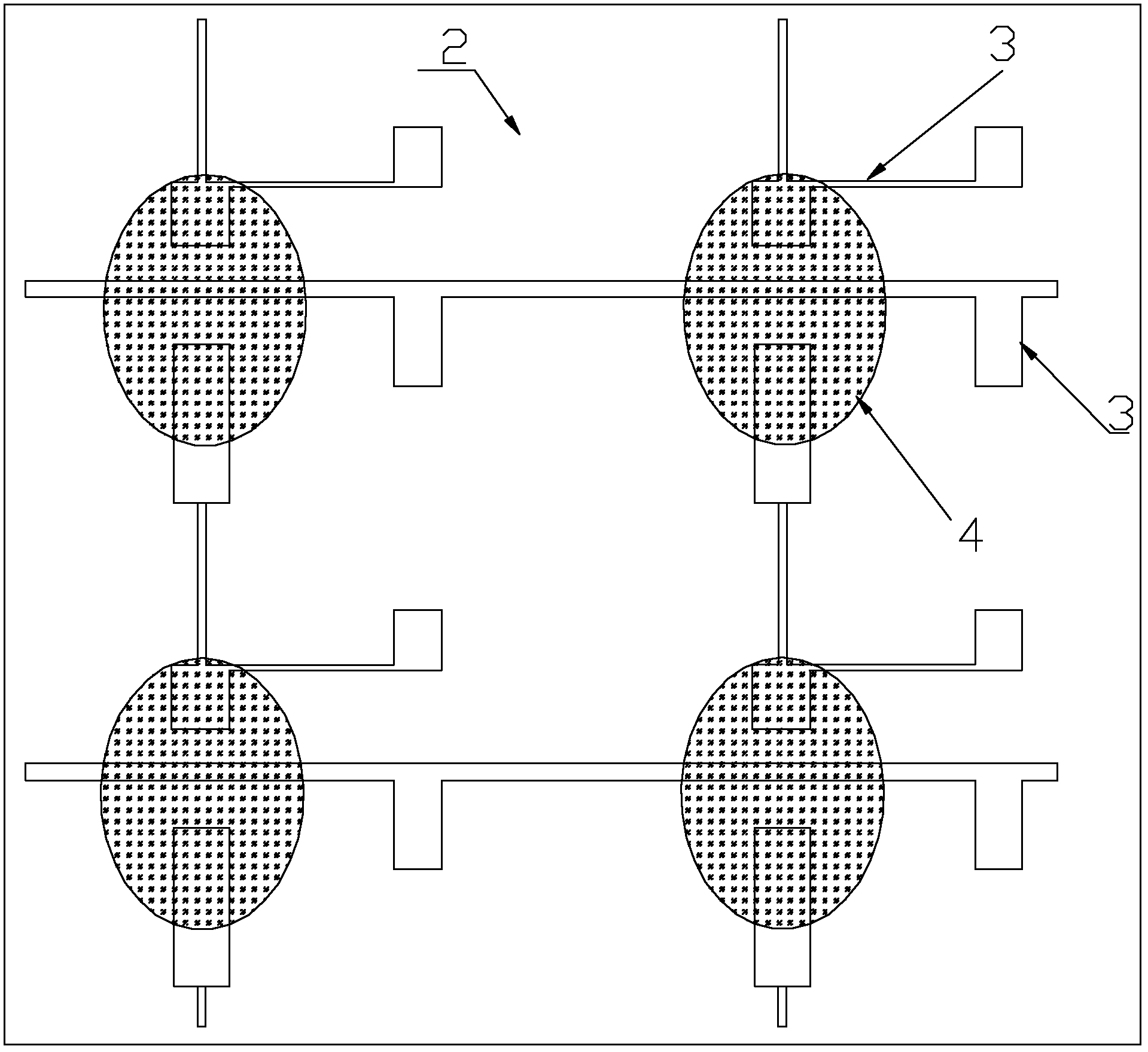

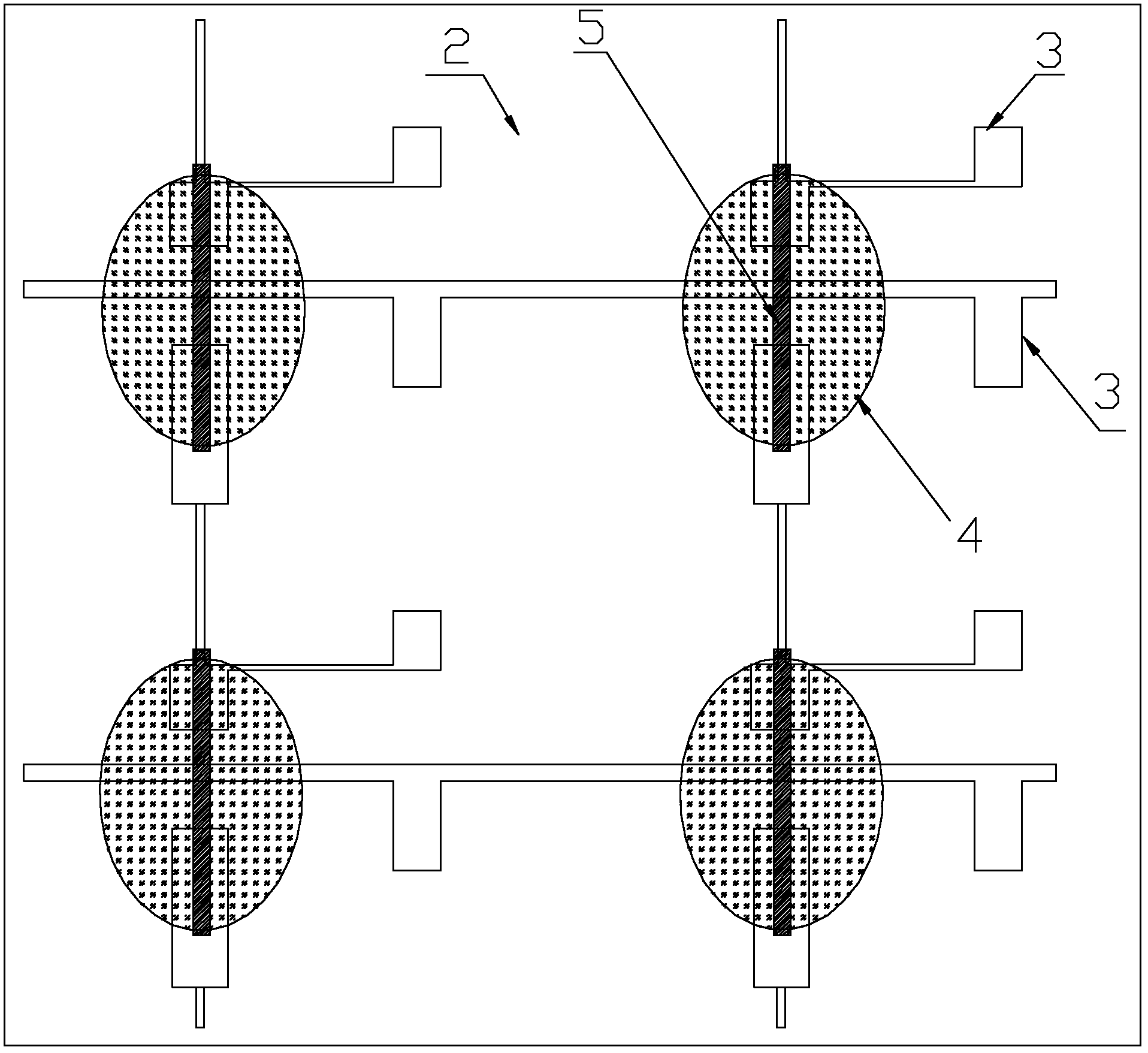

Gas barrier film, and display substrate and display using the same

ActiveUS20060093758A1Stable gas barrier layerImprove the level ofLiquid crystal compositionsElectroluminescent light sourcesWater vaporDisplay device

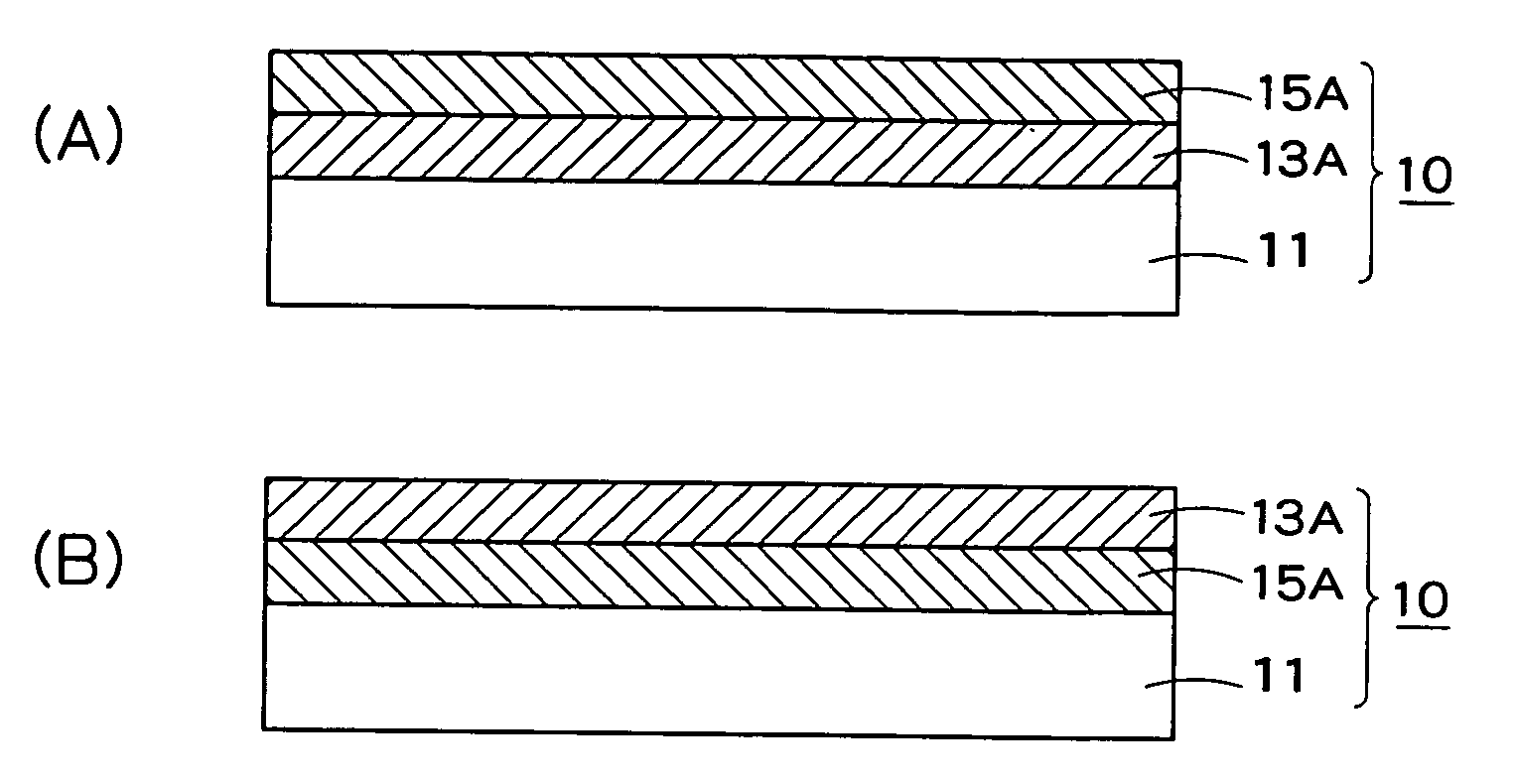

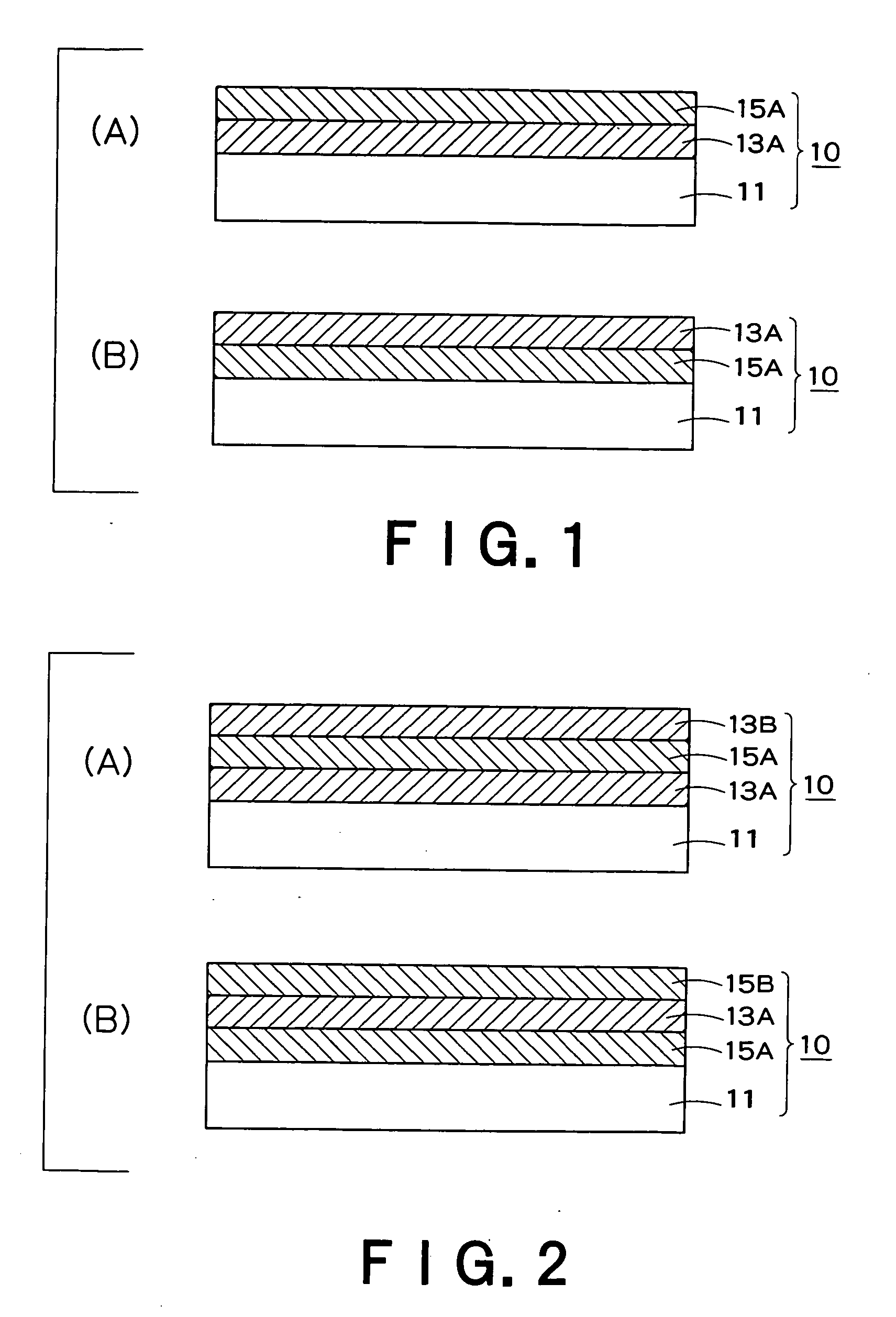

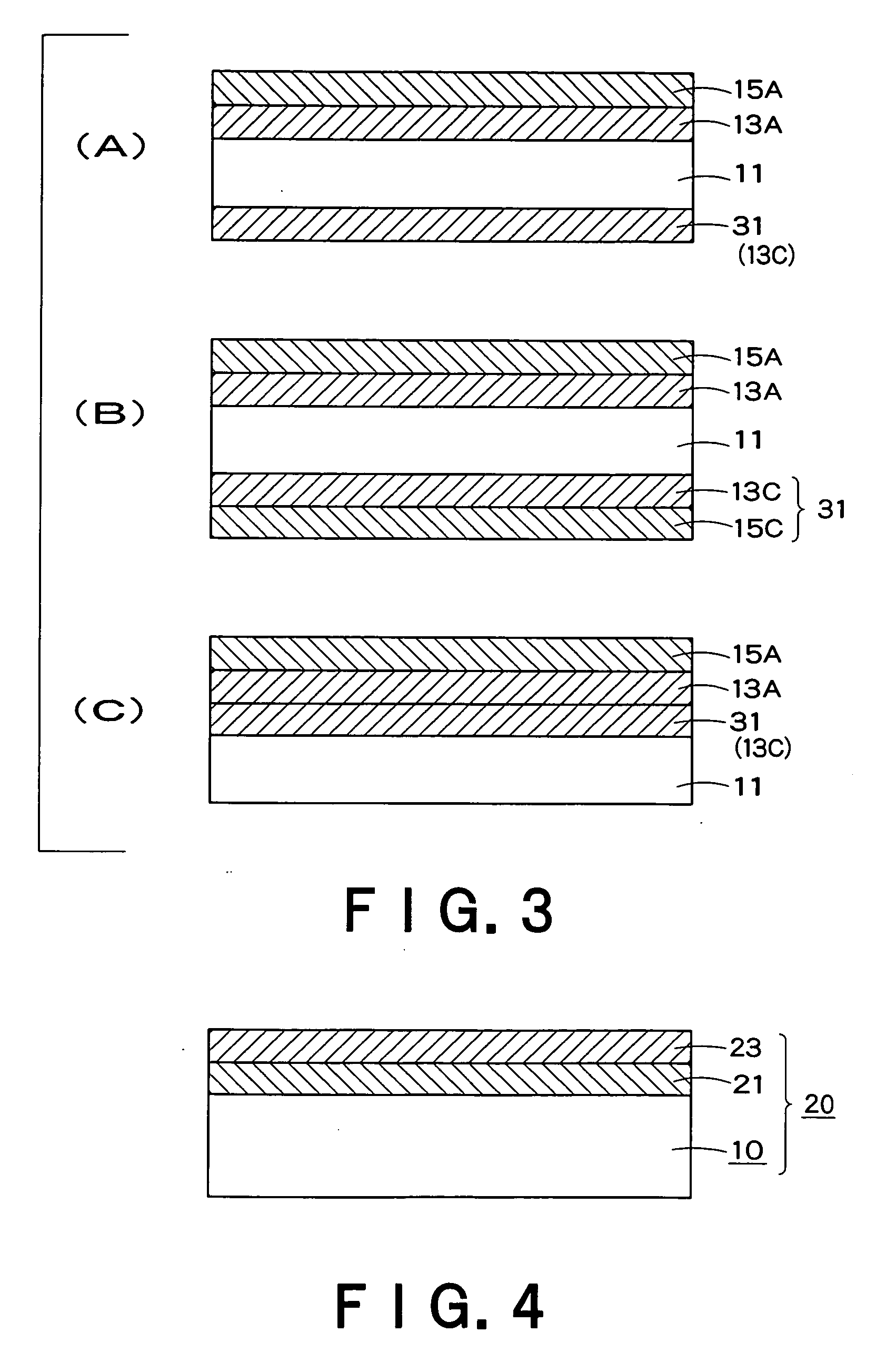

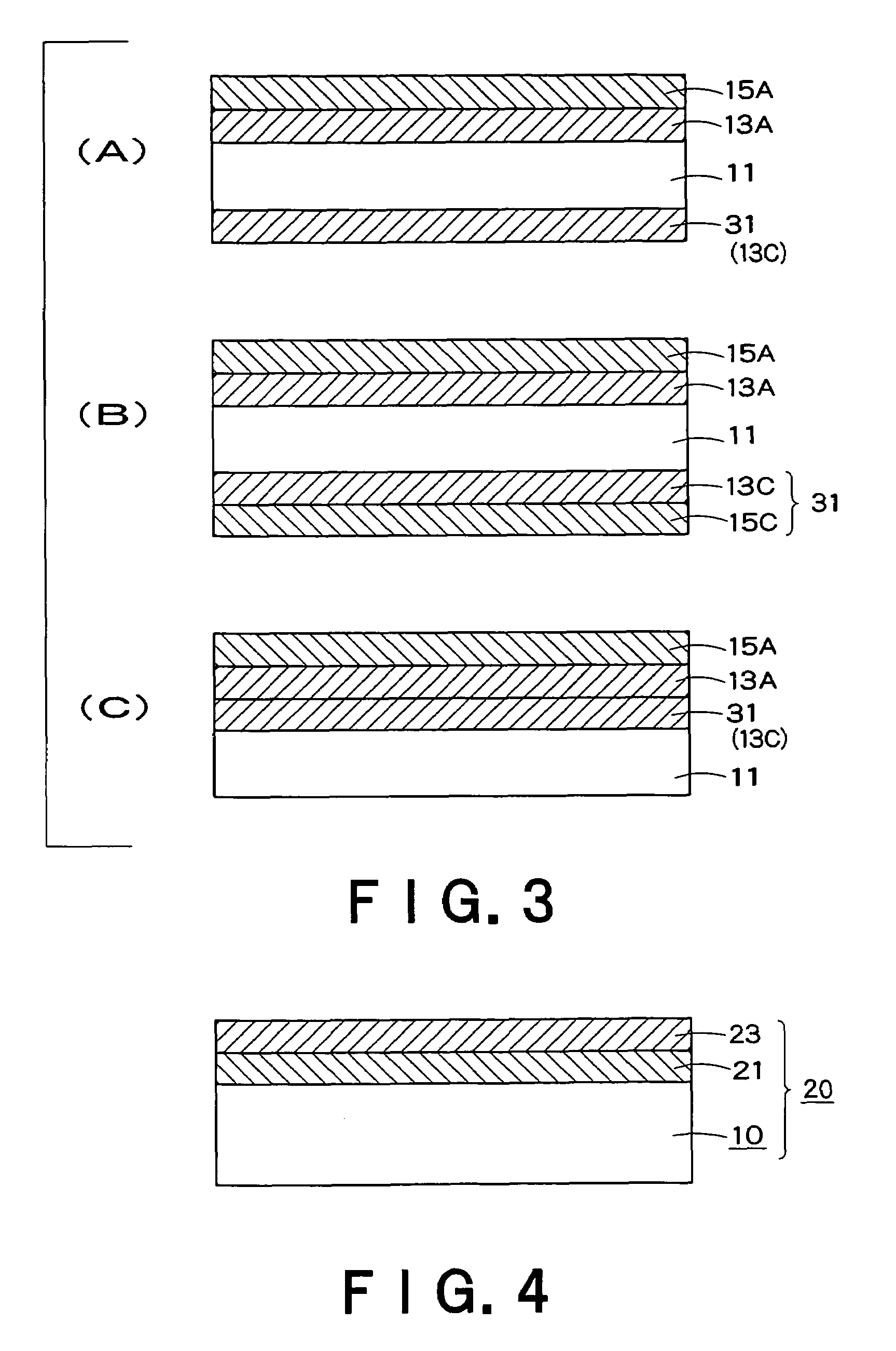

There are provided a gas barrier film, which can undergo winding processing, is less likely to cause elongation or deflection upon exposure to heat or the like during processing or use, has a high level of dimensional stability, is less likely to be attacked by chemicals or the like during processing or use, can form a stable gas barrier layer, and has a high level of gas barrier properties against water vapor, oxygen and the like, and a display substrate and a display using said gas barrier film. The gas barrier film comprises: a base material film 11 having a deflection temperature under load of 150° C. or above; and at least a gas barrier layer 13A and a smoothing layer 15A in that order, or a smoothing layer 15A and a gas barrier layer 13A in that order provided on the base material film 11. Preferably, the base material film 11 is polyethylene naphthalate, the gas barrier layer 13A is formed of an inorganic oxide, an inorganic oxynitride, an inorganic oxycarbide, or an inorganic oxycarbonitride, and the smoothing layer 15A formed of a cardo polymer, sol-gel, or a material containing an acryl structure.

Owner:DAI NIPPON PRINTING CO LTD

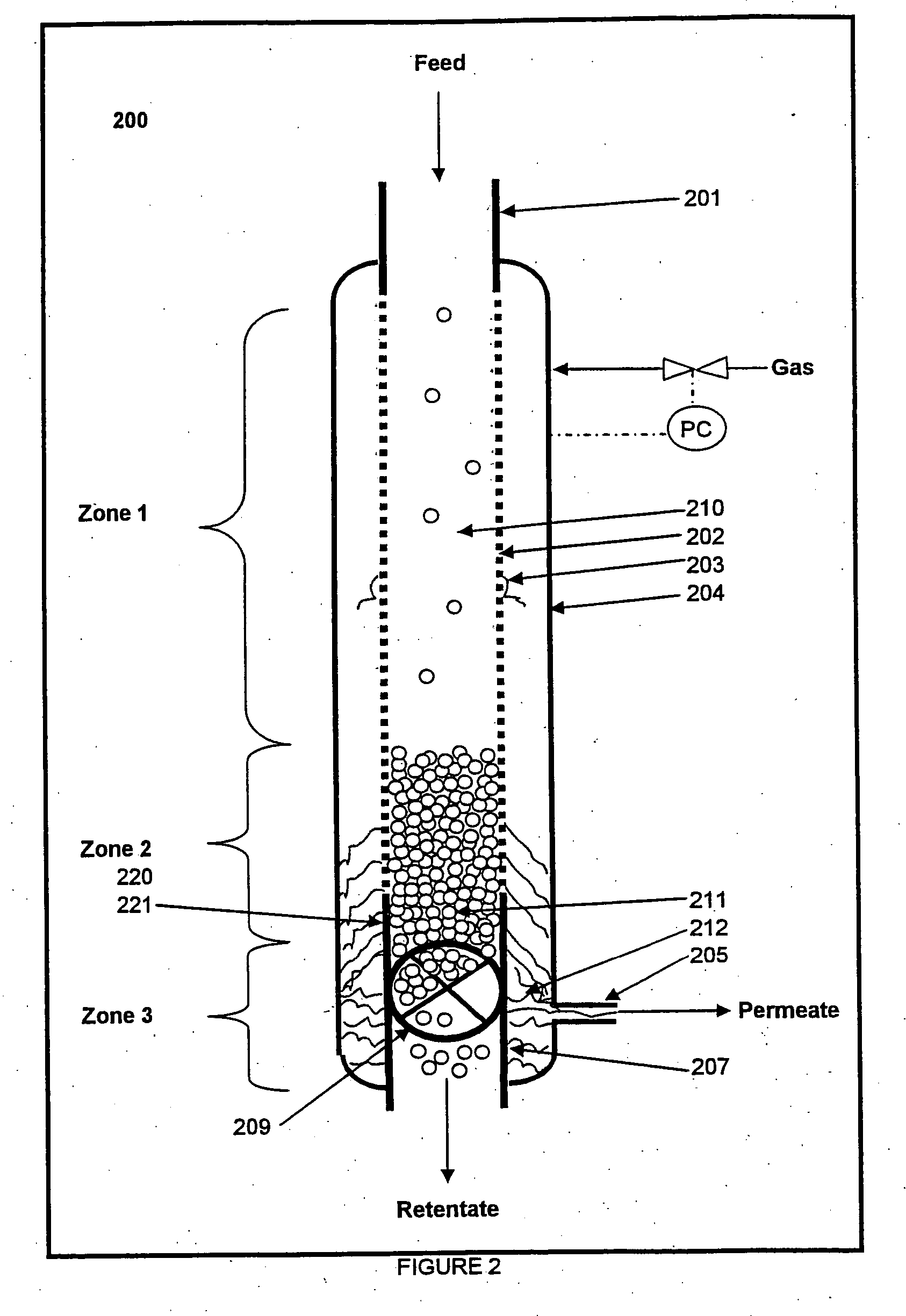

Crystallized pellet/liquid separator

ActiveUS20070062872A1Keep the pressureLow solidsWater/sewage treatment by centrifugal separationUltrafiltrationLiquid temperatureReverse osmosis

A process and apparatus which reduces the fines in a liquid discharge stream and / or increases the dryness of a solids discharge stream while under a pressure equal to or greater than the vapor pressure of the liquid. There is provided a process for separating particles such as polyethylene terephthalate or polyethylene naphthalate from a liquid in a slurry comprising: a. feeding a slurry comprising solid particles and a liquid into a within a separation zone maintained at a pressure equal to or greater than the vapor pressure of the liquid; b. contacting the slurry in the separation zone with a porous filter, optionally a microfilter, nanofilter, reverse osmosis filter, or ultrafilter, and separating liquid from the particles, wherein the liquid flows through the filter into an outer annulus defined as a space between the wall of the separation device and the filter, and said porous filter optionally having a terminal point beyond which the separated liquid does not pass from the outer annulus back through the filter; c. accumulating no liquid in the outer annulus or accumulating liquid in the outer annulus at a level below or in front of the terminal point, and continuously discharging the separated liquid from the outer annulus through a liquid outlet; d. decoupling the particles from the separation zone through the solids outlet to a low pressure below the vapor pressure of the liquid at the liquid temperature within the separation zone while maintaining a pressure on the particles prior to decoupling at or above the vapor pressure of the liquid within the separation zone.

Owner:ALPEK POLYESTER SA DE CV

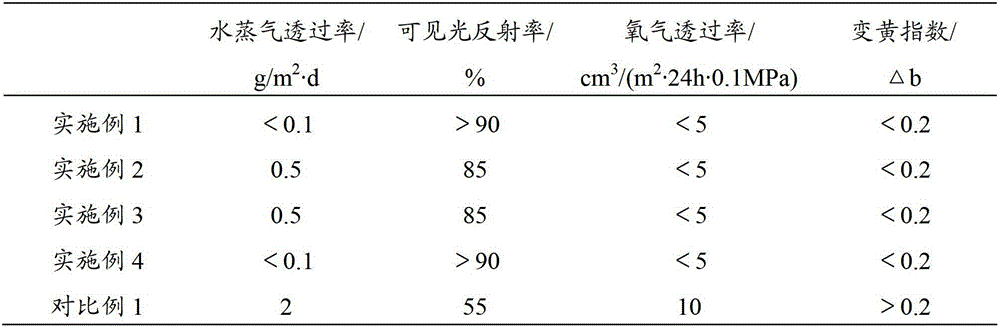

High-barrier layer flexible packaging film for isolating contents of polymer lithium battery

The invention provides a high-barrier layer flexible packaging film for isolating contents of a polymer lithium battery. The high-barrier layer flexible packaging film comprises at least two kinds of films which are combined to form a layer of composite film, wherein the composite film comprises a basic layer, a functional layer and a heat sealing layer; the high-barrier layer flexible packaging film is characterized in that: the basic layer is a copolymer film prepared by combining at least two film base materials of PP (polypropylene), CPP (chlorinated polypropylene or casting polypropylene), PE (polyethylene), PET (poly(ethylene terephthalate)), PA (polyamide) or MXD6 (aromatic polyimide), MPE (elastomer blend), PVDC (polyvinyl dichloride), EVOH (ethylene-vinyl alcohol), PEN (polyethylene naphthalate) and GT, or by complexing pairwise; and a high-barrier water-tolerant modified PVA (poly vinyl alcohol) coating film is coated on the copolymer film base materials. The high-barrier layer flexible packaging film has excellent gas barrier property, remarkably low oxygen permeability, water resistance, corrosion resistance, good high temperature resistance and great barrier property, and resists organic solvents and highly-volatile substances. In the invention, the high-barrier PVA is preferably coated on various base materials to obtain a base layer serving as a high-barrier layer which has great barrier property and excellent performance in resisting gas, water, corrosion, ultraviolet rays and the like.

Owner:刘继福

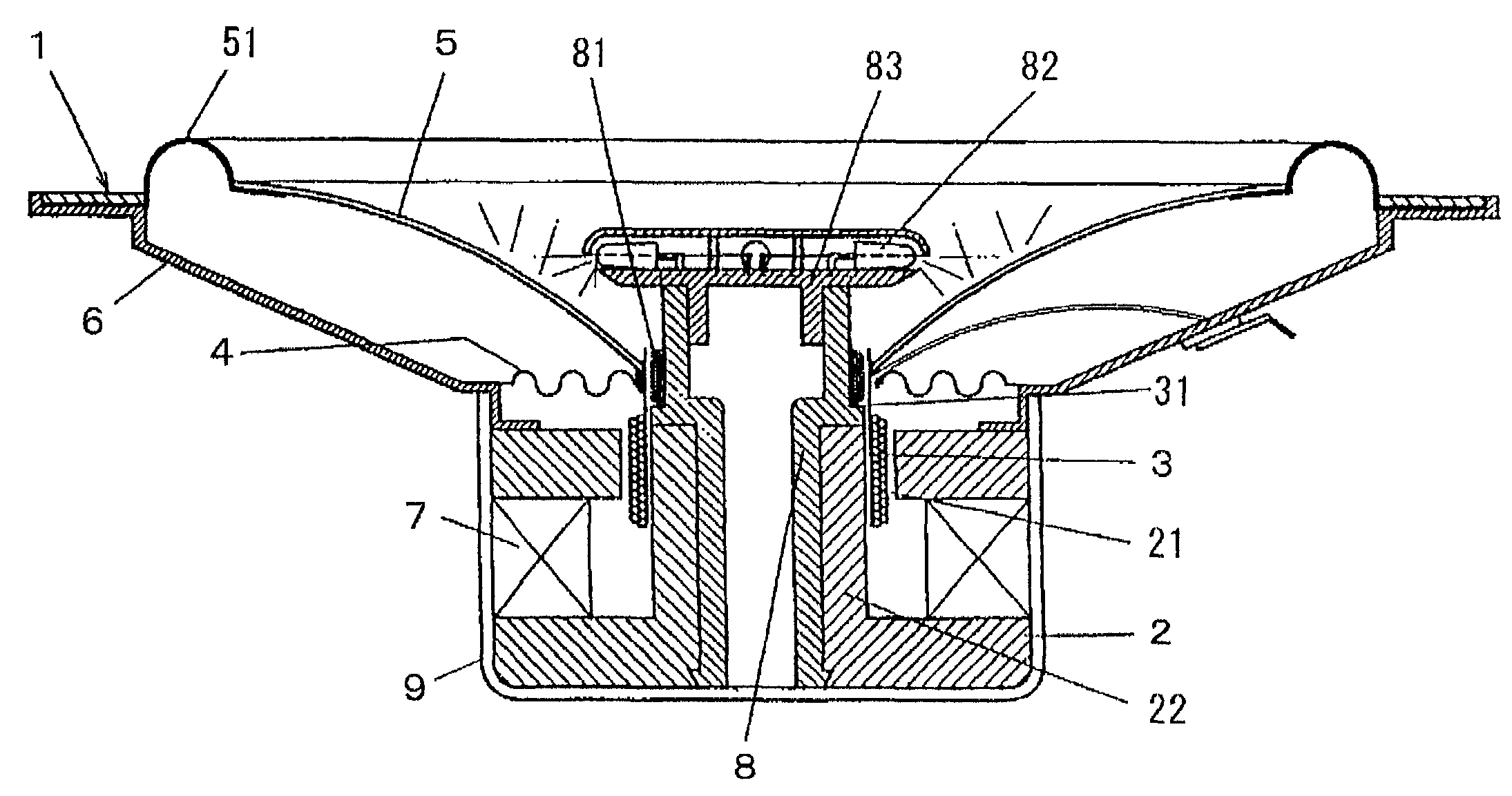

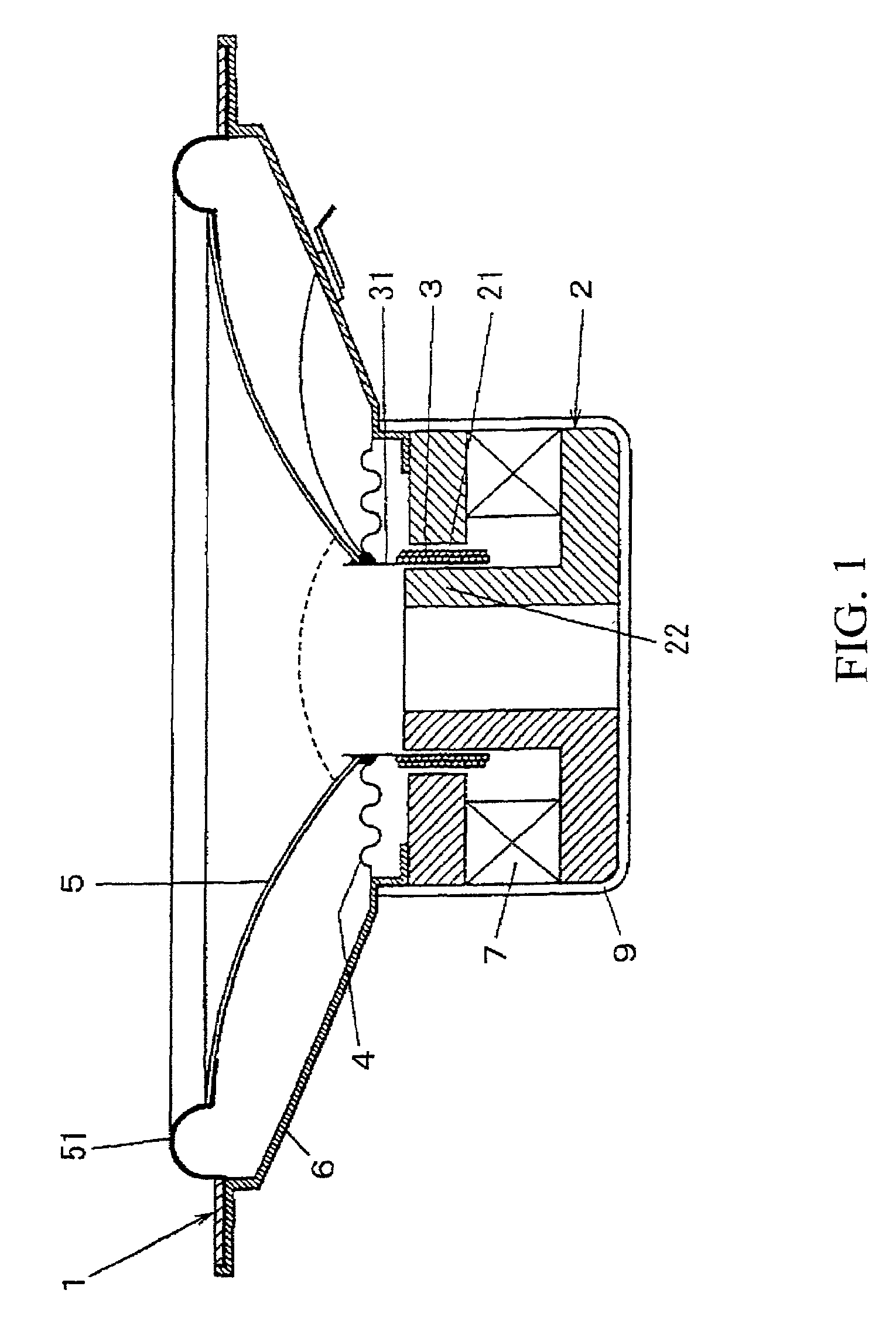

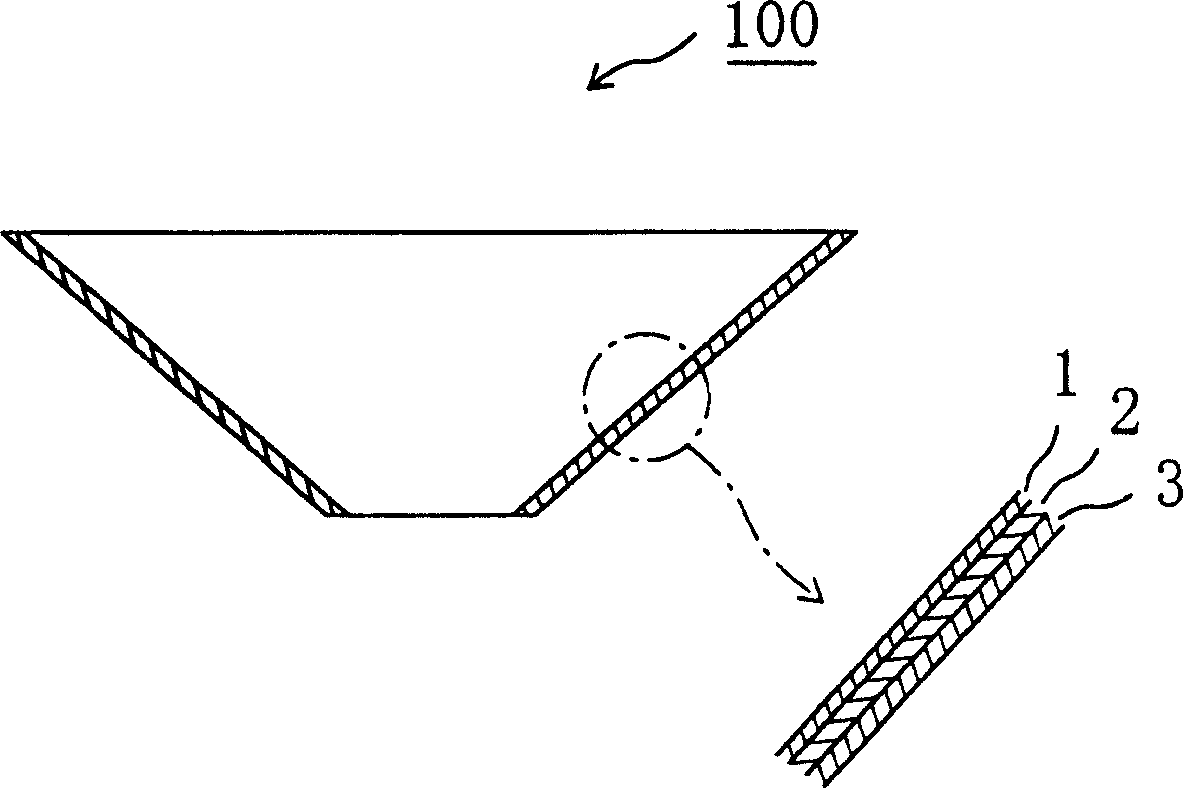

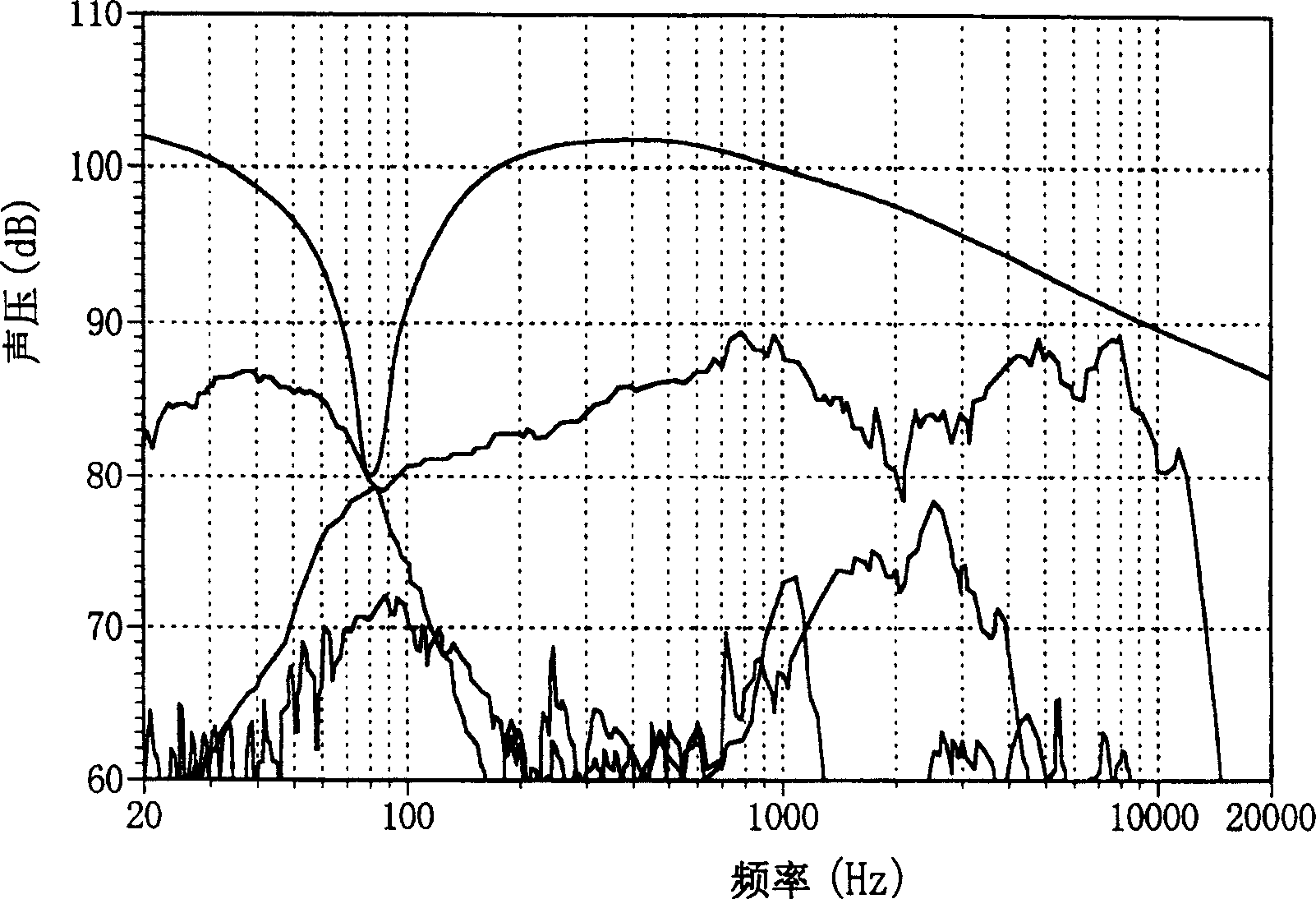

Loudspeaker

InactiveUS7123738B1Light weightLarge internal lossLight source combinationsPoint-like light sourceSound qualityEngineering

The present invention is directed to a speaker using lightweight, highly rigid diaphragm having excellent frequency characteristic and improving resistance to environment (including resistance to UV and resistance to fading). For this end, the speaker utilizes a cone-shaped diaphragm made from foamed or cellular resin such as polyethylene terephthalate (PET) resin or polyethylene naphthalate (PEN) resin with 30 μm average cell size. The use of such cone-shaped diaphragm is effective to improve sound quality of the speaker.

Owner:PANASONIC CORP +1

Compositions and method for improving reheat rate of PET using activated carbon

ActiveUS20040249113A1Improving reheat rateMinimize impactEnvelopes/bags making machineryButtonsActivated carbonPolyester

A polyester composition, a preform, and a bottle, containing a polyester such as polyethylene terephthalate or polyethylene naphthalate and activated carbon to enhance the rate for reheating the composition is provided. Activated carbon may be added in the presence of active phosphorus containing compounds, or at any stage in the melt phase after prepolymerization and after the polyester polymer is solidified. Polyester concentrates containing activated carbon may be added to bulk polyesters to make preforms suitable for blowing into bottles.

Owner:ALPEK POLYESTER SA DE CV

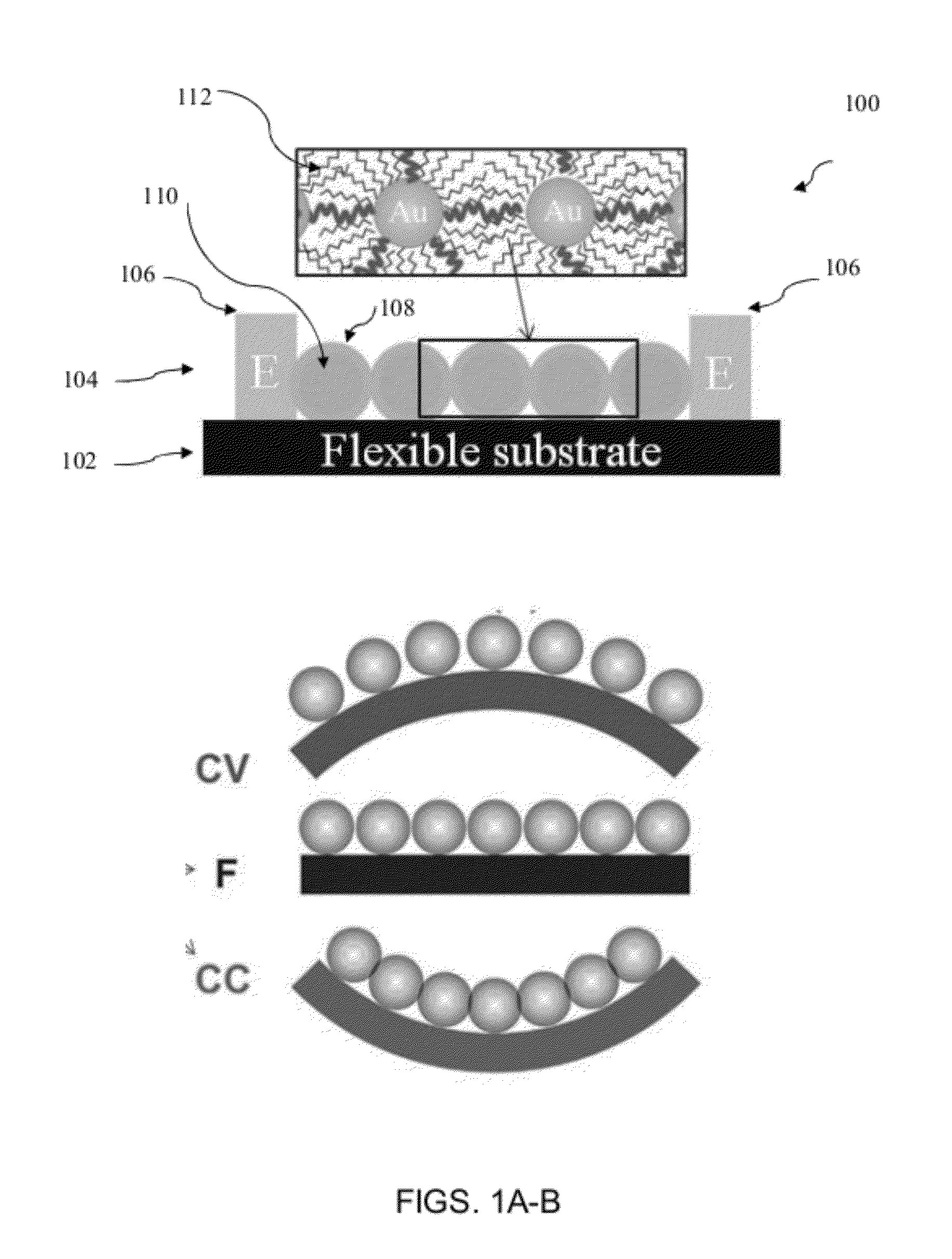

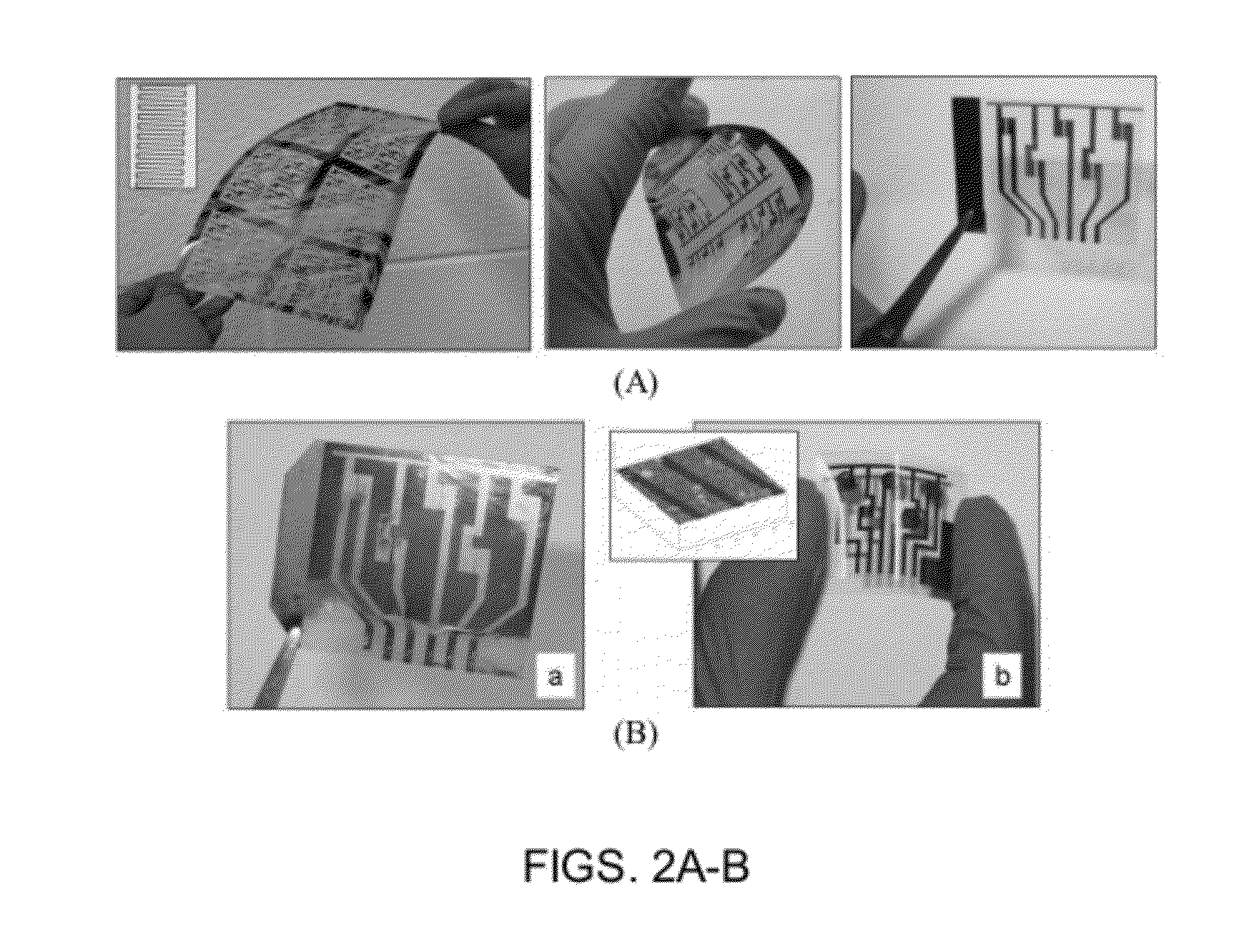

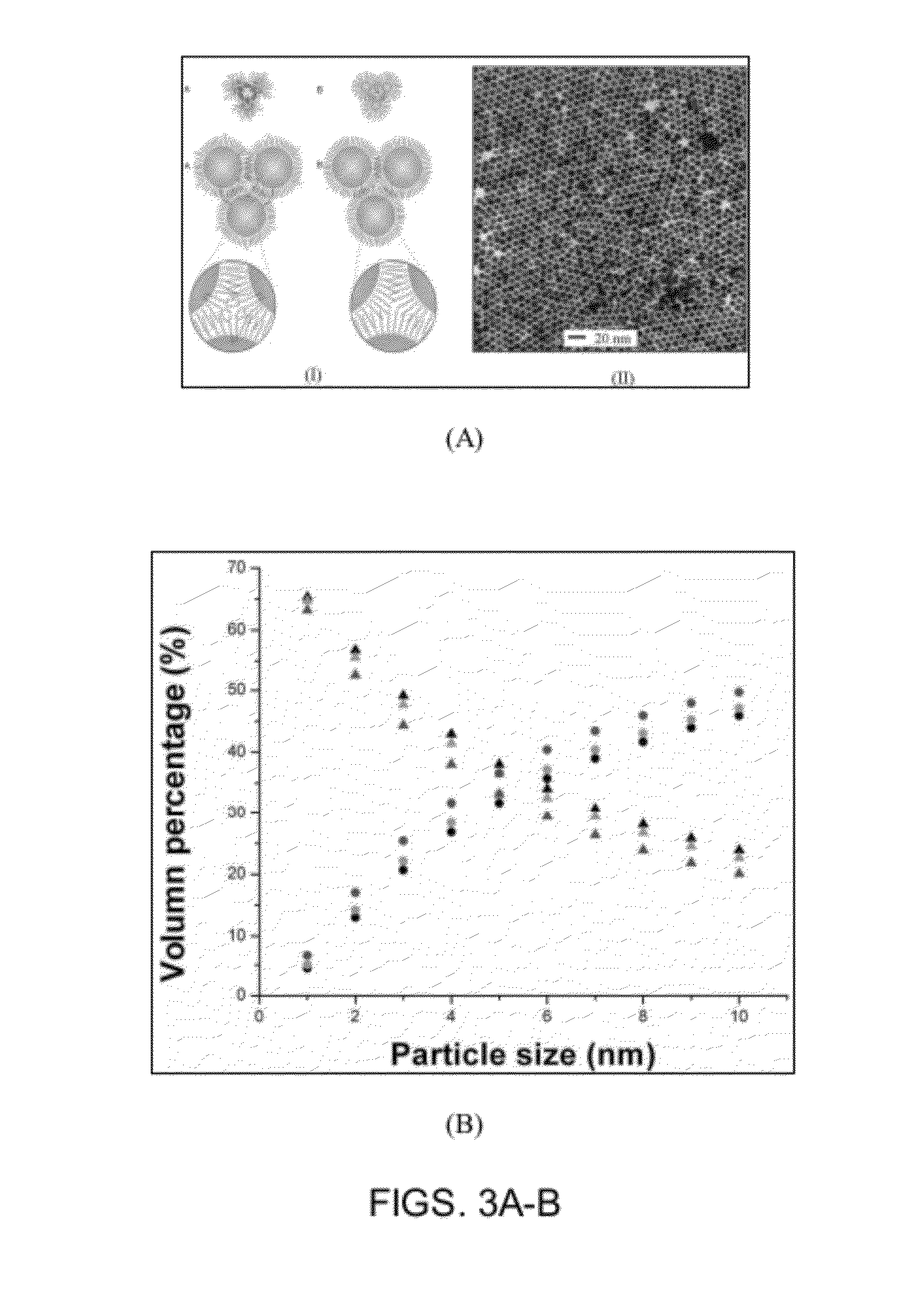

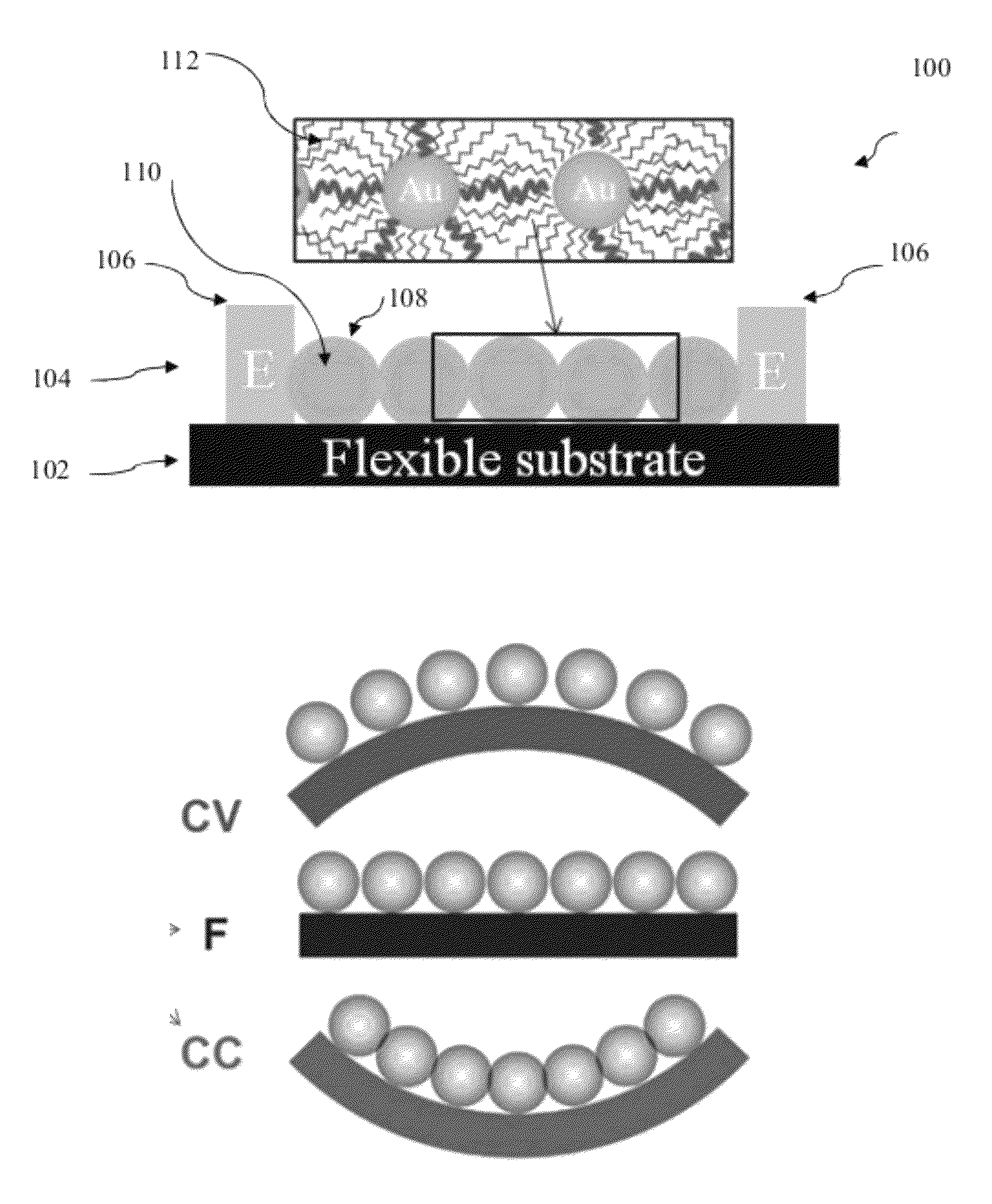

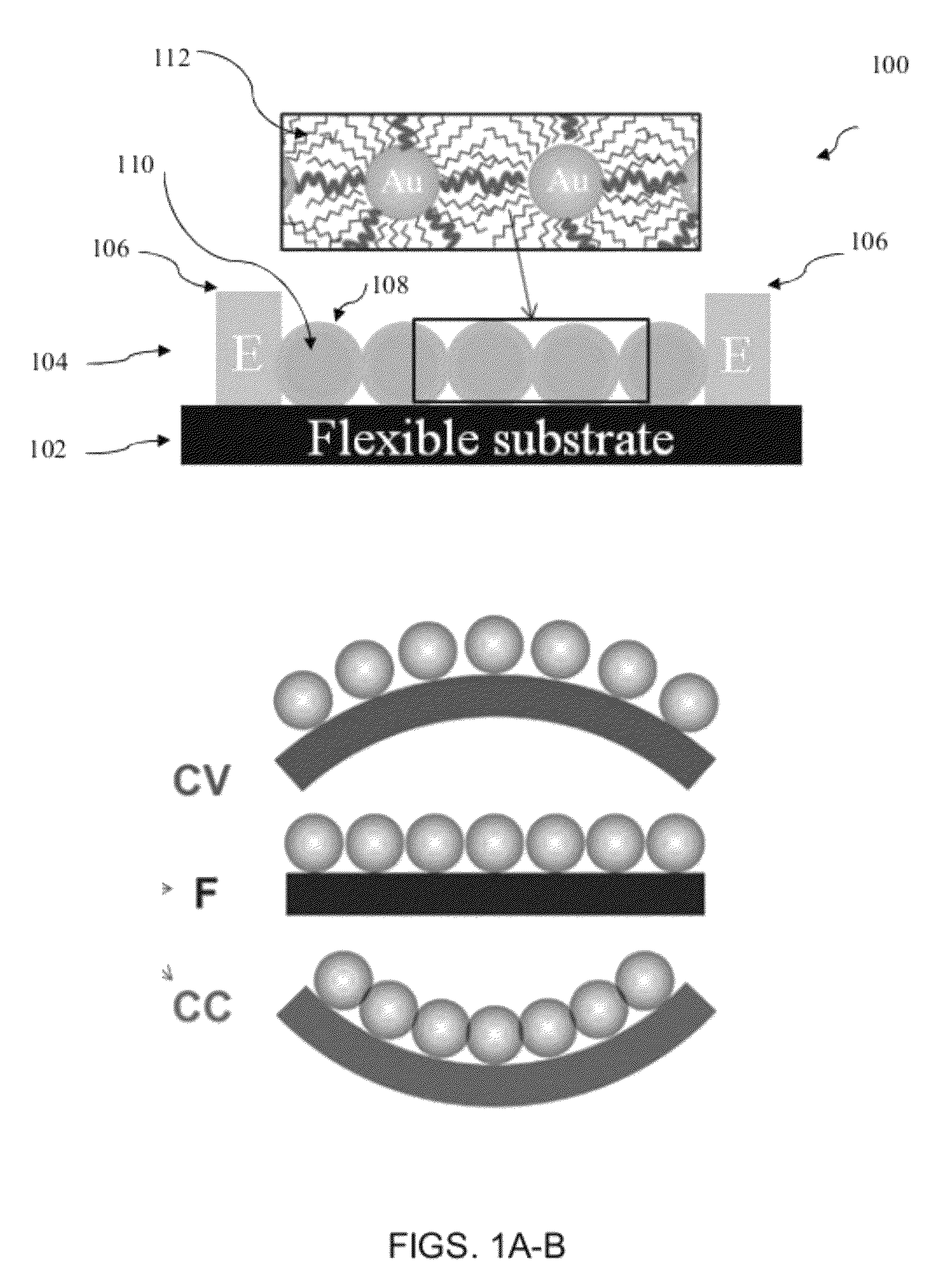

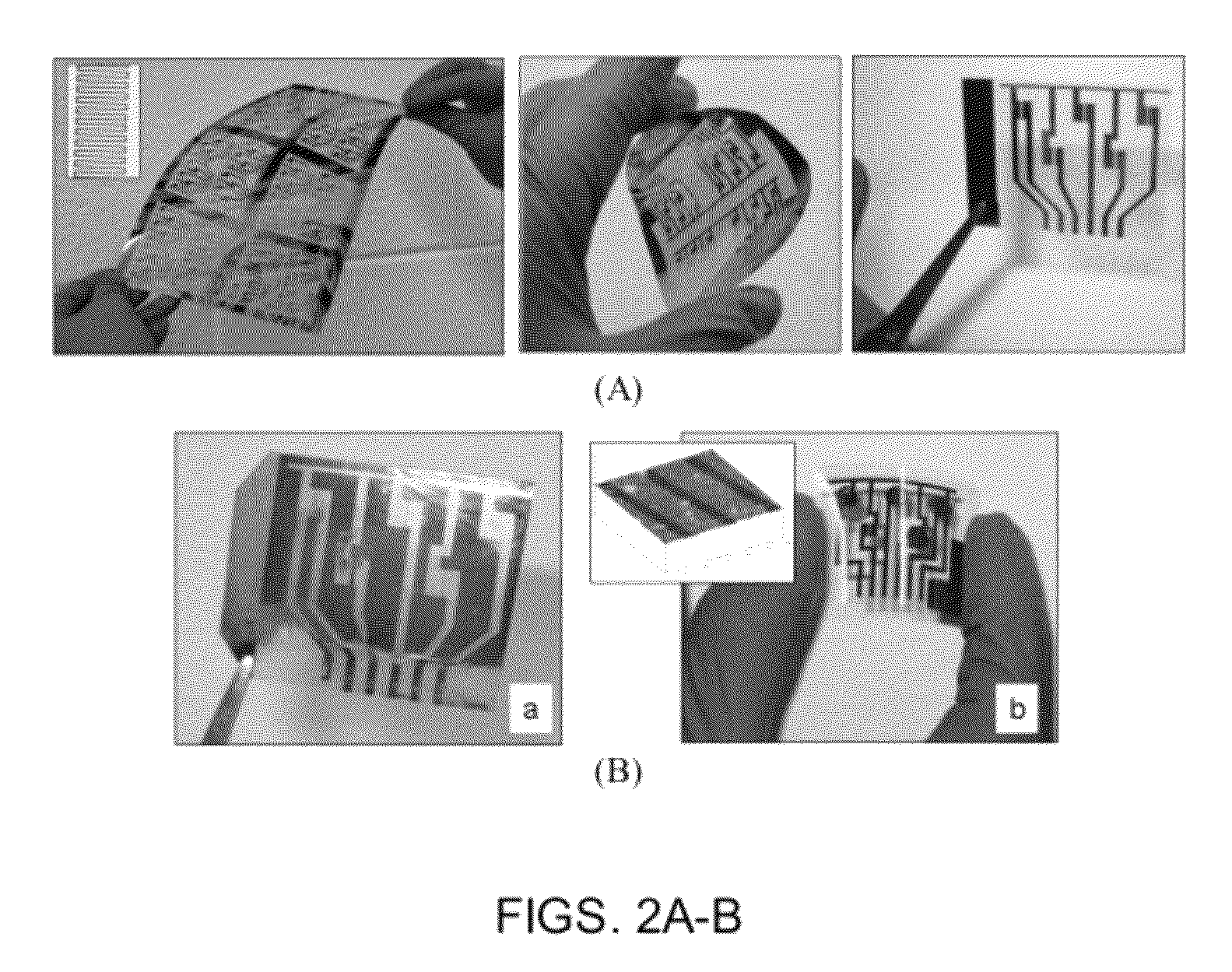

Flexible multi-moduled nanoparticle-structured sensor array on polymer substrate and methods for manufacture

ActiveUS20120156099A1Efficient detectionMaterial nanotechnologyNanosensorsSensor arrayHand held devices

A flexible chemiresistor (CR) sensor for sensing a molecule of interest in a fluid (liquid or gas) is provided. The flexible CR sensor comprises a flexible chemiresistor (CR) module. The flexible CR module comprises a flexible substrate such polyethylene terephthalate (PET), polyethylene naphthalate (PEN) or polyimide (PI), and a thin film nanoparticle assembly assembled on the flexible substrate. The thin film nanoparticle assembly comprises metal or metal alloy core, ligand-capped nanoparticles and molecular linkers connecting the nanoparticles. The flexible CR sensor and an intelligent pattern recognition engine can be incorporated in a handheld device that can detect a molecule of interest in a fluid (e.g., a liquid or gas) accurately, rapidly, and without false positives. Any sensing array nanomaterial, pattern recognition, and compact / or electronic hardware can be integrated to achieve a desired detection limit and response speed.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Multilayer composite having a barrier action

A multilayer composite comprising at least the following layers:I. a layer I of a polyamide molding composition andII. a layer II of a polyester molding composition, where the layers are firmly bonded to each other without use of an additional layer of bonding agent, wherein the polyester molding composition comprises a mixture of:a) from 80-99% by weight of a polyalkylene 2,6-naphthalate selected from the group consisting of polyethylene 2,6-naphthalate and polybutylene 2,6-naphthalate, andb) from 1-20% by weight of one or more compounds containing at least two isocyanate groups, wherein, in addition, the isocyanate groups from component IIb are present in layer II in a concentration of from 0.03-3% by weight.

Owner:DEGUSSA AG

Medical Containers and Treating Method for Producing Medical Containers

InactiveUS20080110852A1Excellent gas barrier performanceGood chemical resistancePharmaceutical containersLarge containersHeat resistanceEngineering

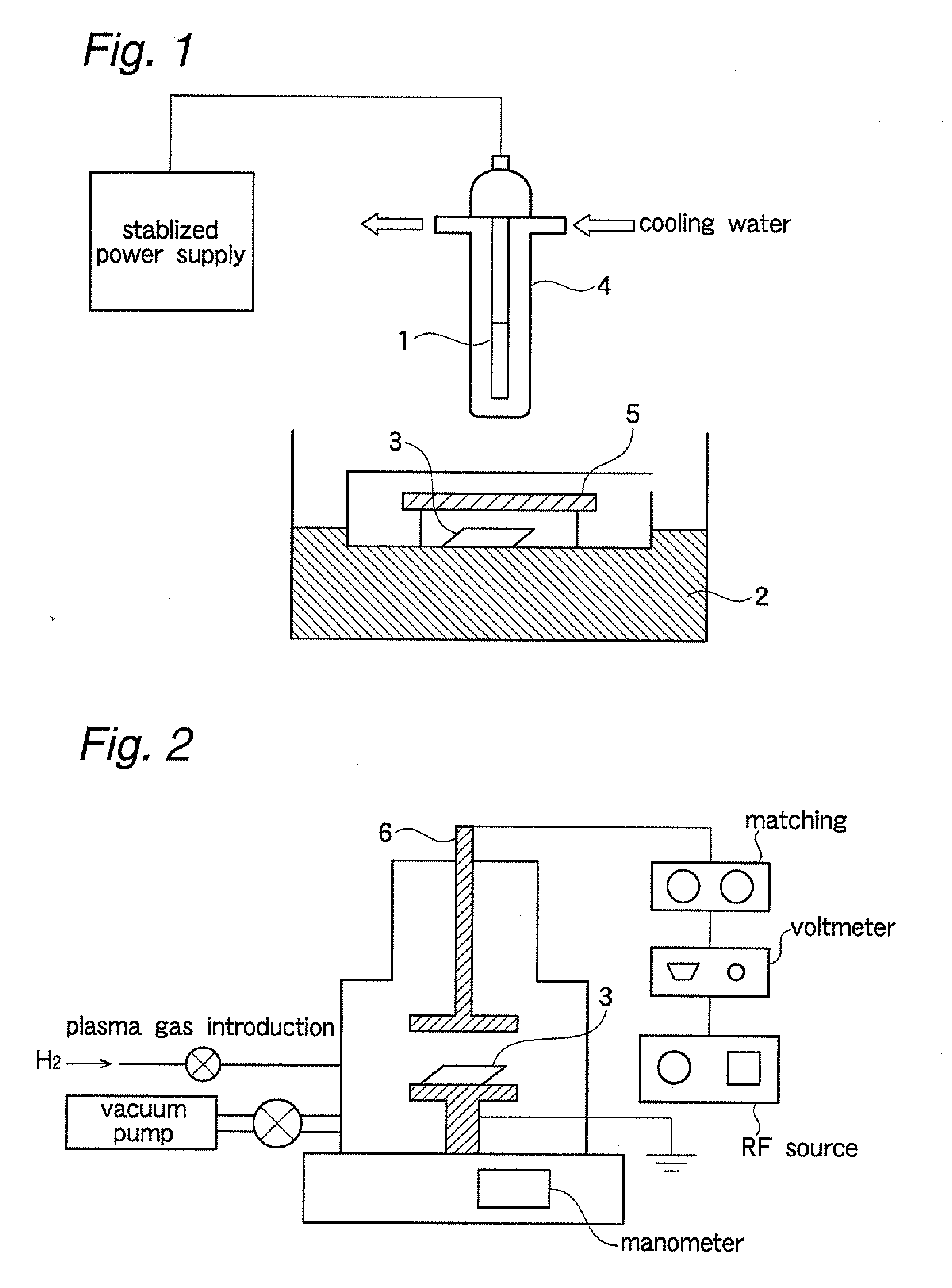

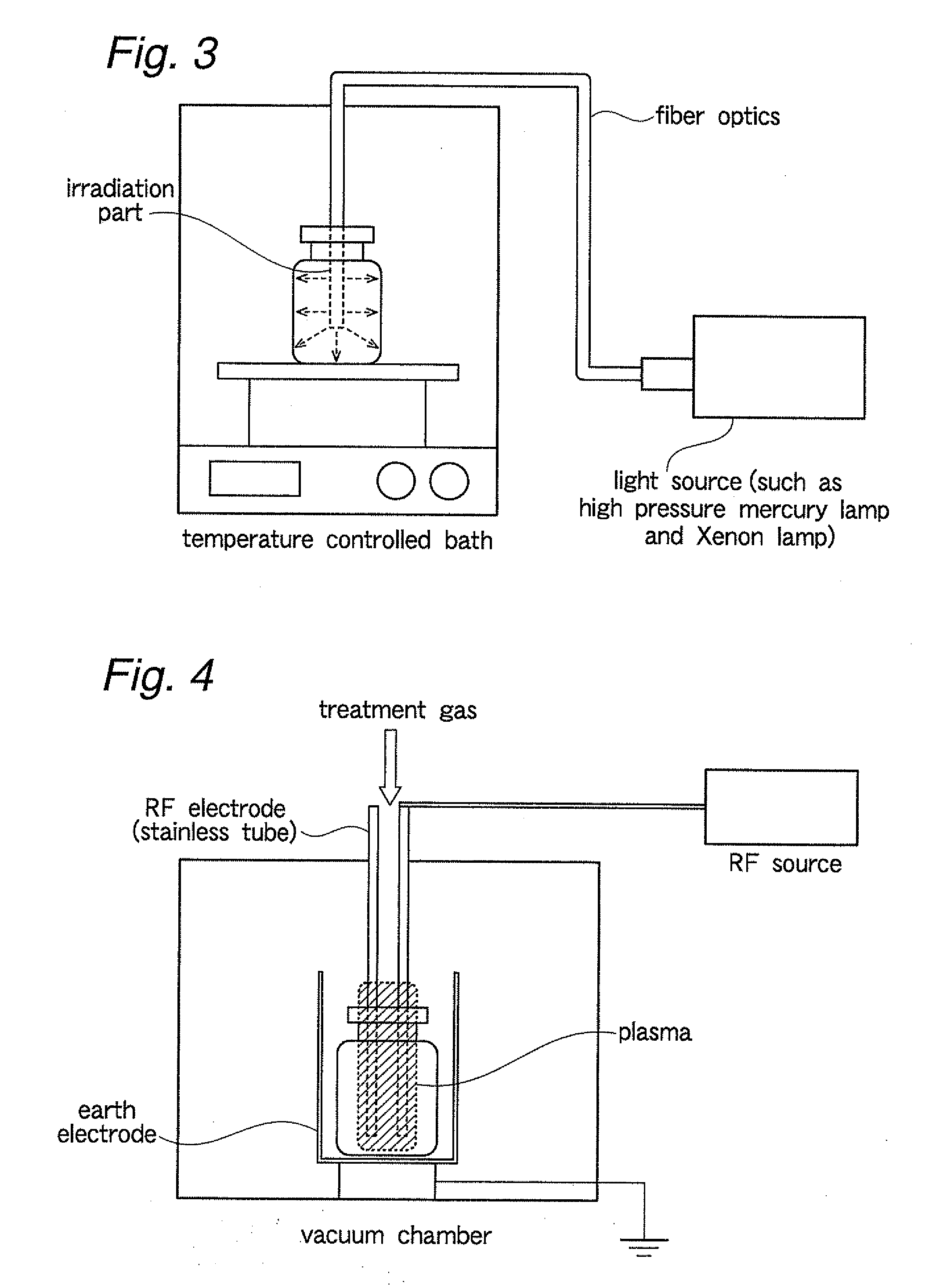

A medical container is excellent in solvent resistance, low gas permeability and heat resistance. A treating method for producing such medical containers is also disclosed.The medical container includes a polyethylene naphthalate resin and includes a liquid-contact part which is on an inner surface of the container, the liquid-contact part being resistant to leaching of a component of the container as a result of being irradiated with light and / or plasma. The light for irradiation may have a wavelength in the range of 350 to 450 nm. The medical container may be a vial or a syringe. The treating method for producing a medical container includes irradiating a liquid-contact part of a polyethylene naphthalate medical container with light and / or plasma.

Owner:DAIKYO SEIKO LTD

Polymer lithium ion battery core outer package forming material

InactiveCN102431239AImprove shielding effectNot easy to peel offSynthetic resin layered productsMetal layered productsHigh resistancePolyvinyl alcohol

The invention provides a polymer lithium ion battery core outer package forming material, and aims at providing a battery core outer package forming material with the advantages that the blocking performance is very high, the cold punching forming performance is good, and puncture resistance, electrolyte resistance stability and organic solvent and high-volatile substance resistance can be realized. An outer resistance layer lamination layer body is formed by at least one layer of heat resistance resin film: any one material from polyethylene glycol terephthalate (PET), biaxially oriented polyamide (BOPA) and polyethylene naphthalate (PEN) or coexistence of two materials from PET, BOPA and PEN through co-extrusion compounding, aluminum foils in a resistance permeation layer lamination body at least comprise 0.9 weight percent to 1.5 weight percent of Fe, a high-resistance layer lamination body comprises a base layer, a function layer and a hot sealing layer, the base layer is a co-polymer film formed by paired compounding or the combination of at least two kinds of film substrates in polystyrene (PP), chlorinated polypropylene (CPP), polyurethane (PE), PET, polyamide (PA) or metaxylylene diamine (MPE) elastic body polymer blends, polyvinyl dichloride (PVDC), ethylene vinyl silane (EVOH), PEN and transpeptidase (GT), and a high-resistance water-resistance modified polyvinyl acetate (PVA) coating film is respectively coated on the co-polymer film substrate. The polymer lithium ion battery core outer package forming material revolutionarily solves the electrolyte resistance stability problem.

Owner:刘继福

Loudspeaker diaphragm and its mfg. method

A loudspeaker diaphragm having light weight and an excellent balance between a rigidity and an internal loss, and a simple and inexpensive method for manufacturing such a diaphragm are provided. A loudspeaker diaphragm according to the present invention includes a base layer having a woven fabric of a polyethylene naphthalate fiber impregnated with a thermosetting resin, and optionally a thermoplastic resin layer and / or a thermoplastic elastomer layer. The polyethylene naphthalate fiber is preferably an untwisted fiber. A fiber / resin ratio in the base layer is preferably in the range of 60 / 40 to 80 / 20. Preferably, the thermoplastic resin layer has a finely foamed structure and an average diameter of a cell in the finely foamed structure is 10 to 60 mum.

Owner:ONKYO KK

Heat conductive insulating material and preparation method thereof

InactiveCN101225234AImprove breakdown voltageEasy to passPlastic/resin/waxes insulatorsSynthetic resin layered productsGlass fiberHeat conducting

The invention discloses a heat-conducting insulation material and a preparation method; concretely, by weight, ethylene silicone 20 to 60 portion, heat-conducting powder 40 to 80 portion, coupling agent 0.1 to 1.5 portion, antifoamer 2 to 5 portion, white carbon black 2 to 5 portion are mixed evenly, solidified and moulded to form the heat-conducting insulation material. Glass fiber or polyethylene naphthalate (PEN) or polyimide film is adopted to strengthen the penetration resistance and the tear resistance in the process of application. The insulation material is used between an electronic device and a radiator in a power supply, an automobile, a generator and other devices, can cram the unevenness surface between the electronic device and the radiator, and so reduce the thermal resistance, and accelerate the heat transfer.

Owner:NANJING KAIHUI IND TECH

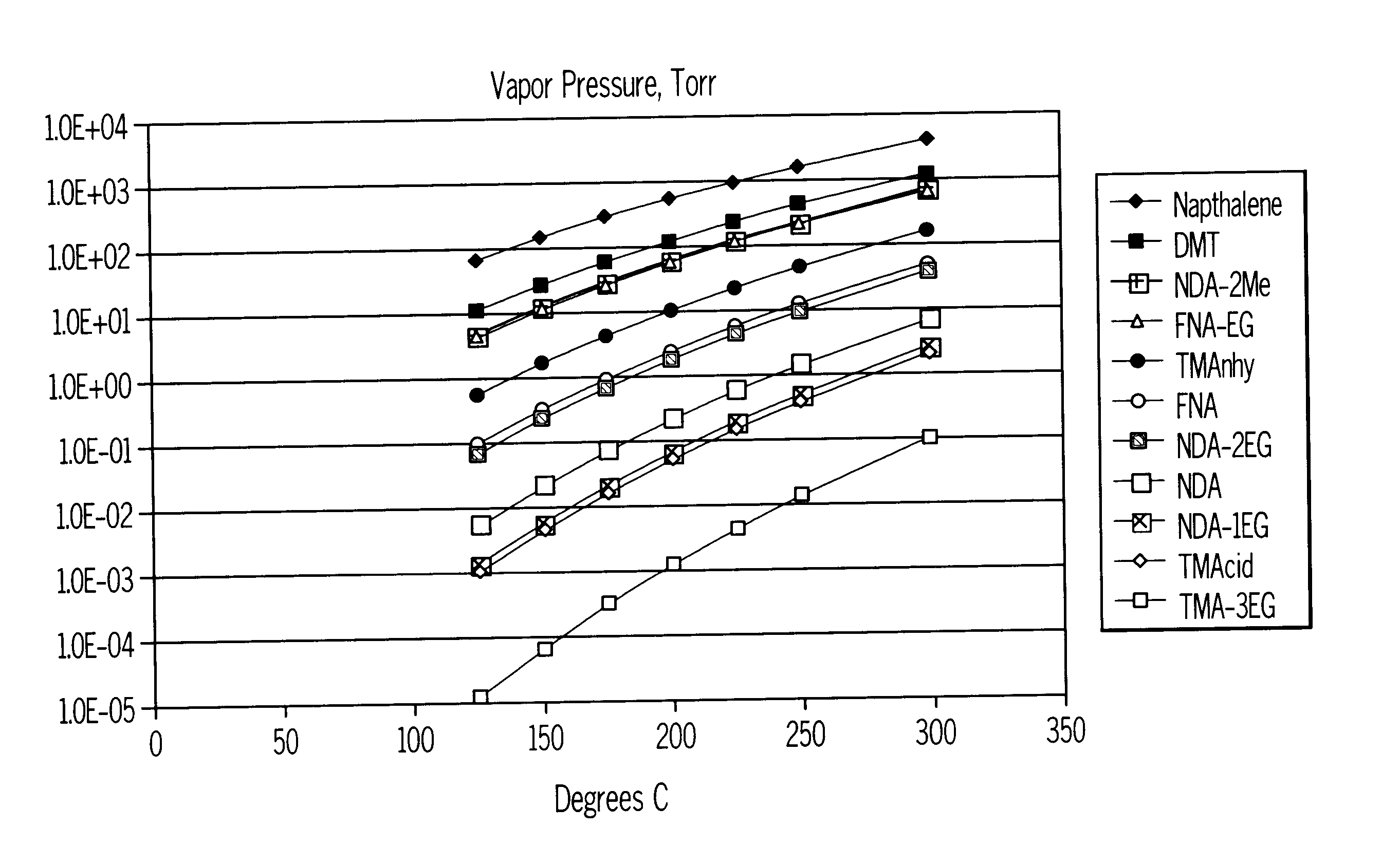

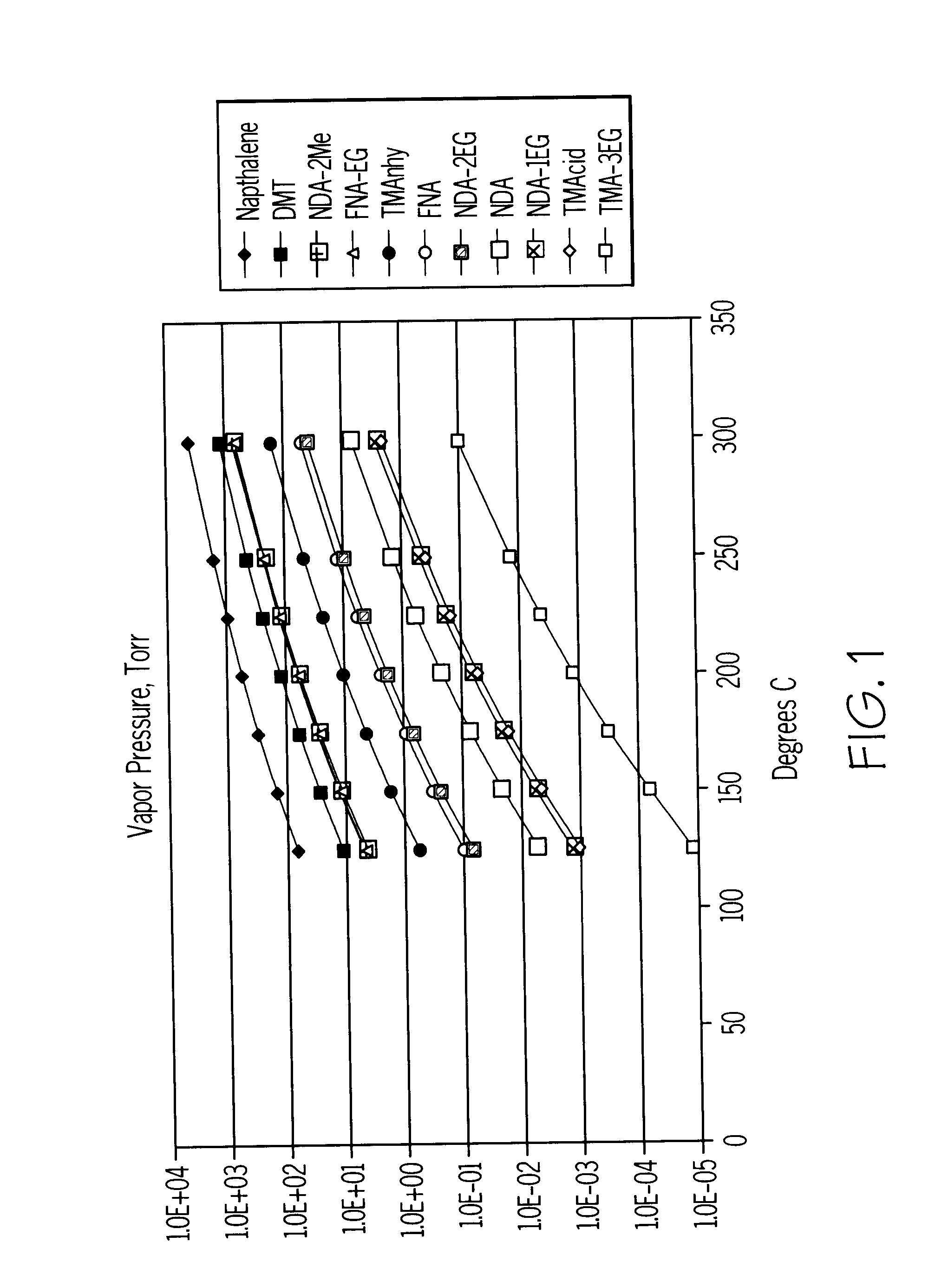

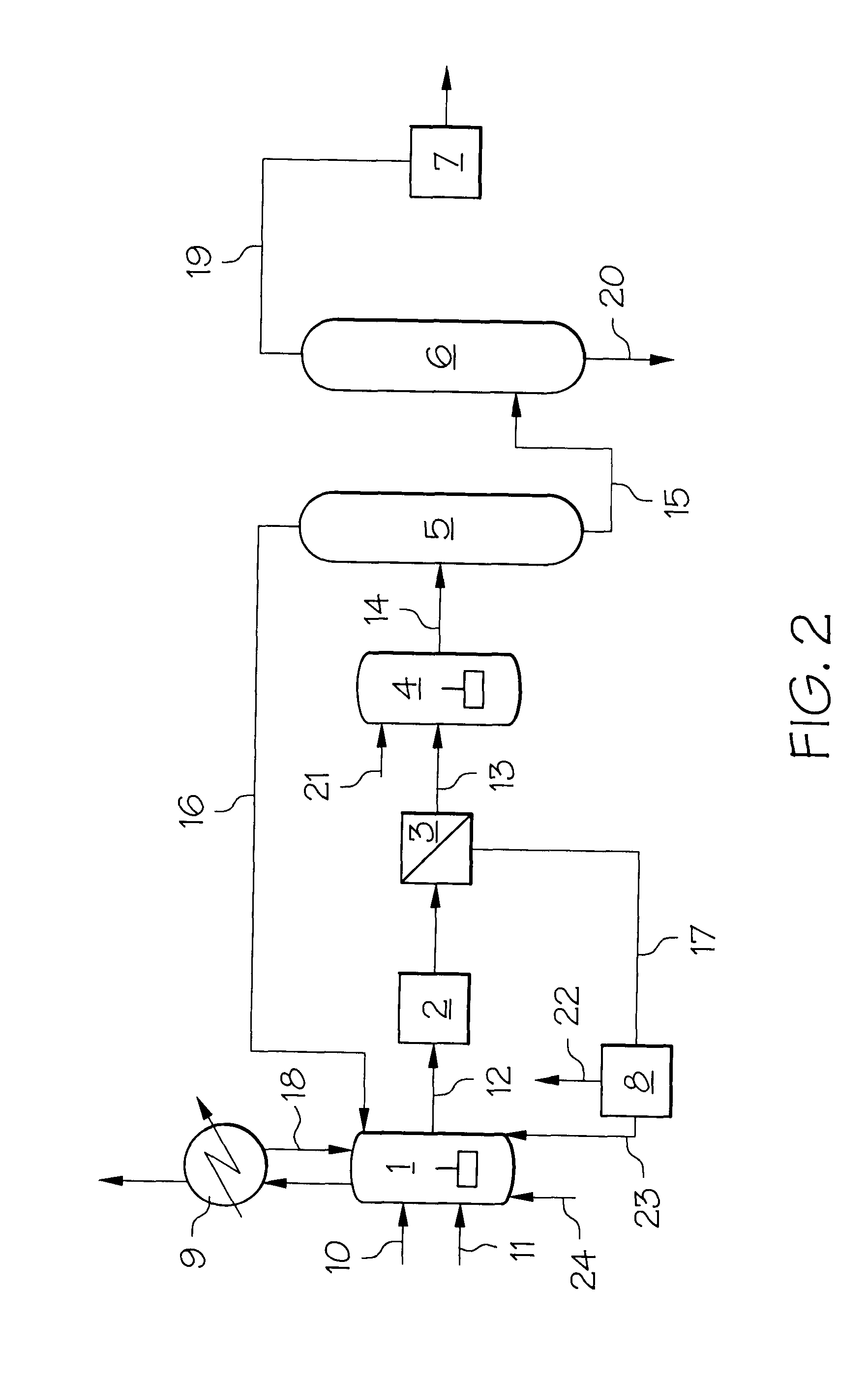

Production, purification and polymerization of aromatic dicarboxylic acids

InactiveUS6642407B2Reduce pressureOrganic compound preparationCarboxylic acid esters separation/purificationPolyesterPartial oxidation

This invention provides a process for purifying the crude aromatic dicarboxylic acids produced by oxidation of dialkyl aromatic hydrocarbons and for using the purified acids in the preparation of polyethylene terephthalate, polyethylene naphthalate and other polyesters. The invention simplifies the manufacturing process by converting the crude aromatic acids into bis-glycol esters in an esterification reactor 4, from which the esterified partial oxidation impurities present in the oxidation product are removed by distillation in distillation tower 5. After removal of the volatile impurities, the dicarboxylic acid esters can separated by distillation in distillation tower 6 or by crystallization and converted to polyesters by polycondensation. The volatile impurities removed as overhead from tower 5 can be recycled as stream 16 to the oxidation reactor where they act as oxidation promoters thereby optionally allowing for a bromine-free oxidation process for dialkyl aromatic hydrocarbons.

Owner:EXXONMOBIL CHEM PAT INC

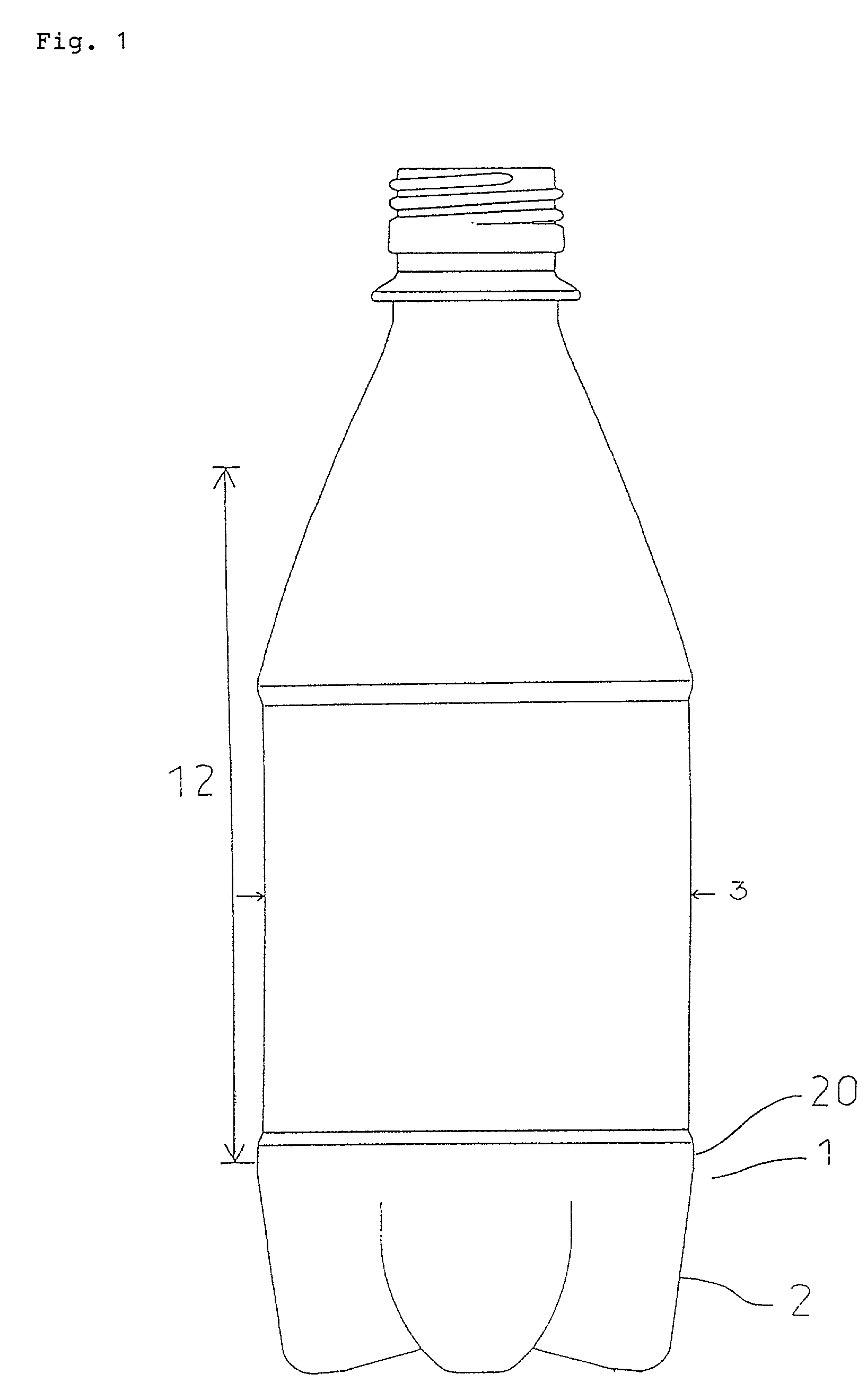

Polyester resin composition and a bottle therefrom

The present invention relates to a resin composition comprising polyethylene terephthalate and polyethylene naphthalate and a process for preparing the composition. The present invention relates also to a bottle produced from the composition and a process for the preparation of the bottle. The resin composition according to the present invention is prepared by melt-kneading (A) polyethylene terephthalate with (B) polyethylene naphthalate in a proportion of the ethylene naphthalate unit to a total of (A) and (B) of from 5 to 15 mole %, with a kneading extruder in a ratio of an extruder output rate to a screw rotation speed of 0.1 to 1.4 kg / hr.rpm. The present composition gives a bottle superior in transparency and in resistance to heat and pressure despite that it has a transesterification of 20% or lower.

Owner:NISHIHARA SHUN ICHI +3

Polyarylene sulfide resin composition

InactiveUS6042910AImprove adhesionSynthetic resin layered productsThin material handlingEpoxyShell molding

A polyarylene sulfide resin composition comprising (A) a polyarylene sulfide resin, (B) an aliphatic or saturated cyclic polycarbodiimide resin or a precursor thereof, and preferably (C) reactive silicone compound grains, and (D) a polyethylene naphthalate resin or (E) a filler, which improves excellent properties exhibited by polyarylene sulfide resins, and which is also endowed with an excellent adhesion characteristics to adhesives such as epoxy resins. In addition, a molded article obtained by molding a polyarylene sulfide resin composition endowed with such excellent properties is useful as a container for accommodating an electric component material. Such a molded article may also be used as an electronic component having conductive portions which are totally or partially accommodated in the container, wherein the conductive portions are seled by a sealant encapsulated in the container.

Owner:IDEMITSU KOSAN CO LTD

Laser-markable film

InactiveUS20080076065A1Photosensitive materialsPhotomechanical apparatusMedicinePolyethylene naphthalate

The present invention is directed to a biaxially oriented, heat-set, at least two-layer coextruded film formed from polyethylene terephthalate (PET) or polyethylene 2,6-naphthalate (PEN) that optionally includes additional comonomer-derived units. The film includes a base layer and at least one outer layer. The base layer includes a white pigment and a laser absorber which has been coated with a carbonizing polymer.

Owner:MITSUBISHI POLYESTER FILM

Application of zinc phthalocyanine complex as ink in micro-contact printing

InactiveCN102516841BReduce bloatReduce distortionInksOther printing apparatusMicrocontact printingPolyimide substrate

The invention discloses application of a zinc phthalocyanine complex as ink in micro-contact printing. The 2-propyl alcohol solution of 8(Octanohydroxamic)-zinc phthalocyanine serves as micro-contact printing ink; the pattern of a Polydimethylsiloxane (PDMS) seal is transferred to the surface of carboxylation polyethylene terephthalate, polyethylene naphthalate or polyimide substrate; and a delicate metal pattern is obtained on the substrate with a chemical plating method. The application of the zinc phthalocyanine complex as the ink in the micro-contact printing has the beneficial effect that the common phenomena of pattern inflation and pattern torsion in the micro-contact printing can be reduced by the phthalocyanine metal complex ink, and the phthalocyanine metal complex ink has a lowpreparation cost and great potential in the industrial application and is stable.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Gas barrier film, and display substrate and display using the same

ActiveUS7378157B2Avoid excessive deflectionLess to elongationElectroluminescent light sourcesSynthetic resin layered productsDisplay devicePolyethylene naphthalate

Owner:DAI NIPPON PRINTING CO LTD

Polymeric composition suitable for manufacturing pasteurizable containers

InactiveUS20090035502A1Improve thermal stabilityImprove barrier propertiesLayered productsFibre treatmentPolymer sciencePolyethylene naphthalate

A polymeric composition suitable for manufacturing pasteurizable containers comprising, polyethylene terephthalate (PET) in the ratio of about 80 to about 95 mass % by mass of the total composition; polyethylene naphthalate (PEN) in the ratio of about 20 to about 5 mass % by mass of the total composition; tungsten trioxide in the range of 10 to 100 ppm by mass of the composition and particle size of 2 to 20 microns; and optionally a nucleating agent and a polycondensation catalyst.

Owner:FUTURA POLYESTERS LTD PARAGON CONDOMINIUM

LED module fabrication process with patterned transparent thin-film electrodes

ActiveCN102290506AWith graphic functionReduce manufacturing costSemiconductor devicesManufacturing technologyPolyvinyl chloride

The invention relates to the technical field of a luminous display device, in particular to a novel graphical manufacturing technology of a nanometer material base transparent thin-film electrode; the manufacturing technology is characterized by comprising the following preparing steps of: a. preparing a raw material of a transparent conductive thin-film for standby application; using polyimide or one of PET (Polyethylene Terephthalate), PEN (Polyethylene Naphthalate), PC (Polycarbonate), PVC (Polyvinyl Chloride), PMMA (Polymethyl Methacrylate) and PES (Polyethersulfone) as a transparent flexibility substrate; b. preparing an insulating layer; c. preparing a graphical transparent conductive electrode; d. preparing a double-layer crossing or a multilayer graphical transparent conductive electrode; e. coating an LED (Light Emitting Diode); f. drying; and g. coating the film on the surface. Compared with the prior art, the manufacturing technology has the advantages that the novel thin-film electrode with the graphical function can be manufactured on the flexibly transparent base, the thin-film and the technology are combined with the manufacturing technology of a transparent LED (Light Emitting Diode) display device, a product is transparent and attractive and can be repeatedly bent and used and the manufacturing cost is low.

Owner:SUZHOU SUNLIGHTS TECH

Water-resistant high-temperature-resistant single-component waterborne polyurethane adhesive and preparation method thereof

InactiveCN108342181AHigh strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention discloses a water-resistant high-temperature-resistant single-component waterborne polyurethane adhesive and a preparation method thereof and relates to the technical field of polyurethane adhesives. The adhesive comprises, by weight, 30-40 parts of polytetrahydrofuran glycol, 15-22 parts of polycarbonate diol, 3-7 parts of poly-2,6-polyethylene naphthalate polyester glycol, 17-25 parts of diisocyanate, 2-5 parts of chain extender, 0.5-2 parts of silane coupling agent modified silicon dioxide nanoparticles, 0.1-0.6 part of dibutyltin dilaurate, 4-8 parts of acetone, 1-3 parts oftriethylamine, 0.05-0.1 part of sodium hydroxide and an appropriate amount of water. Polytetrahydrofuran and polycarbonate diol are adopted as oligomer polyhydric alcohols in raw materials for preparing polyurethane, and added poly-2,6-polyethylene naphthalate polyester glycol is introduced to a soft-segment part of polyurethane; by adding silane coupling agent modified silicon dioxide nanoparticles, the mechanical properties and heat resistance of the adhesive can be improved; the prepared adhesive is high in adhesive force and excellent in water resistance and high temperature resistance, and the application range of the adhesive is enlarged.

Owner:佛山市三水日邦化工有限公司

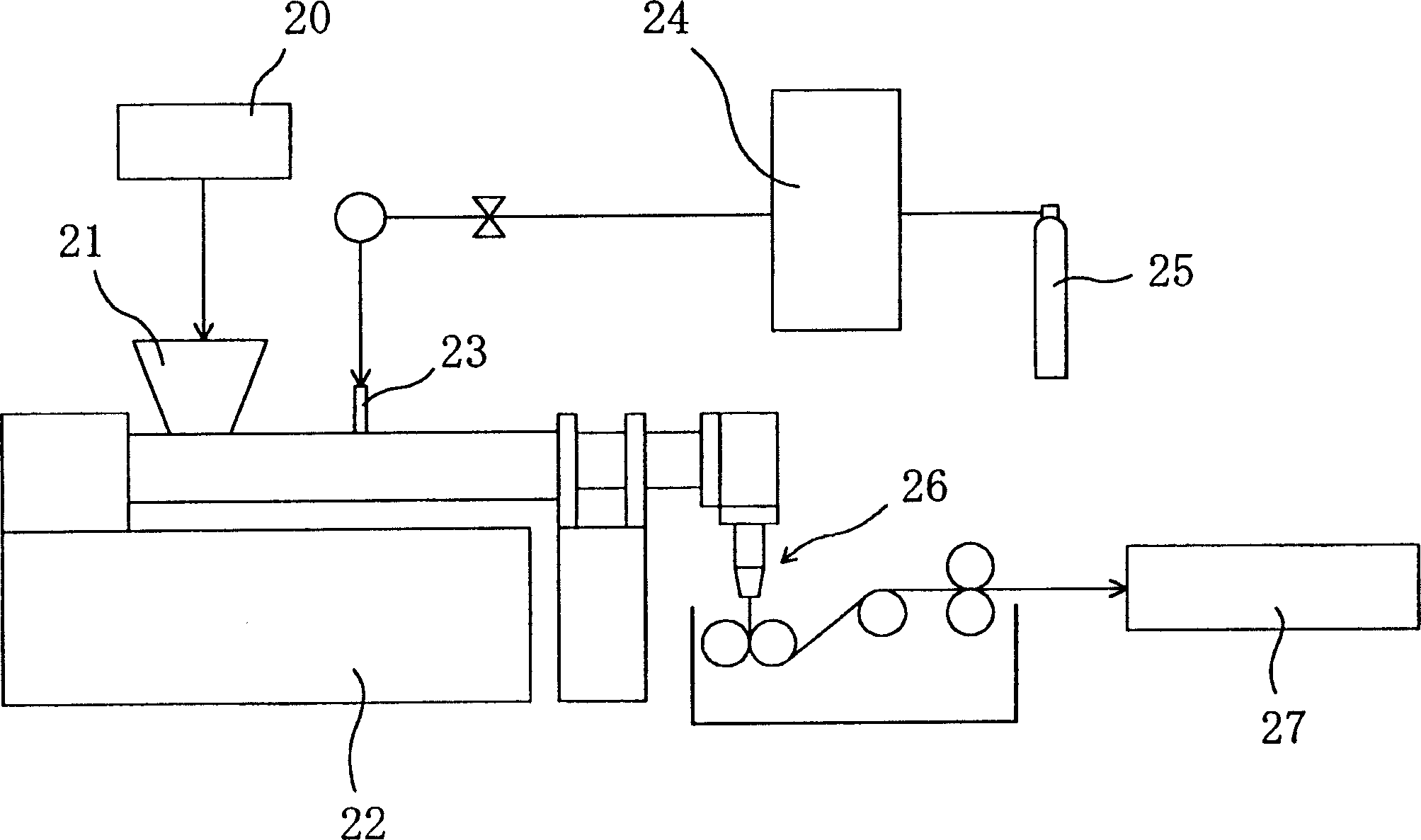

Process to Deposit Diamond Like Carbon as Surface of a Shaped Object

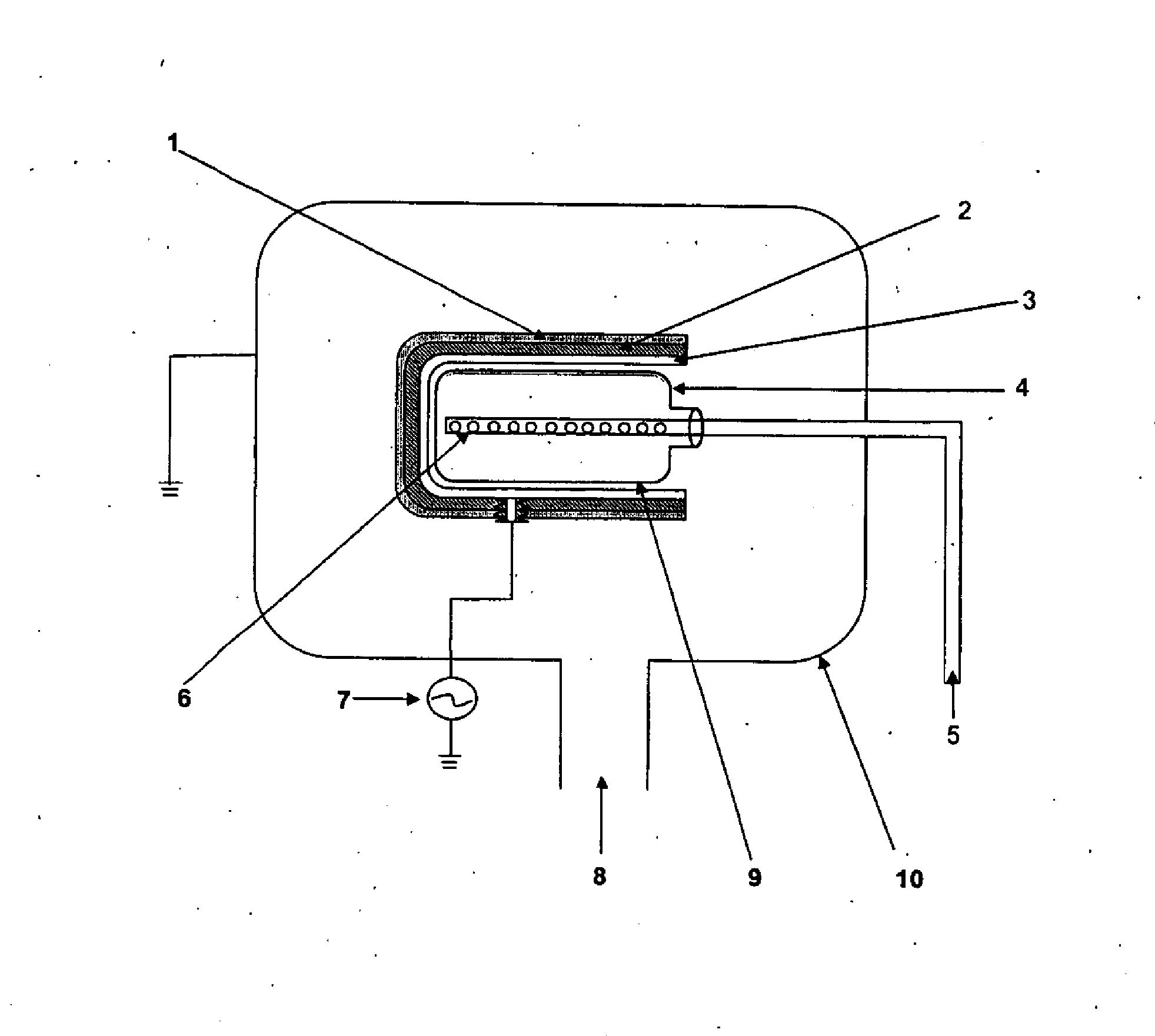

InactiveUS20120045592A1Accurate frequencyMinimize and completely avoid damageElectric discharge tubesLinings/internal coatingsDiamond-like carbonCompanion animal

A plasma based deposition process to deposit thin film on the inner surfaces of the shaped objects such as plastic or metallic object like bottles, hollow tubes etc. at room temperature has been developed. In present invention uniform hydrogenated amorphous carbon (also called Diamond-Like Carbon, DLC) films on inner surfaces of plastic bottles is successfully deposited. Applications of such product include entire food and drug industries. There is a huge demand of polyethylene terephthalate (PET) or polyethylene naphthalate (PEN)) bottles, meant for the storage of potable water, carbonated soft drinks, wines, medicines etc. However, the higher cost prohibits their wide, spread use. The cheaper alternative is to use plastic bottles inside coated with chemically inert material such as Diamond-Like Carbon (DLC) will be commercially viable. Inventor process can be scaled up for mass production. This process can also be used for coating on inner surface of metallic cane or tube with a carbide forming interlayer (like hydrogenated amorphous silicon) to get the DLC films with better adhesion to inner surface of metals.

Owner:COUNCIL OF SCI & IND RES

Polyester films

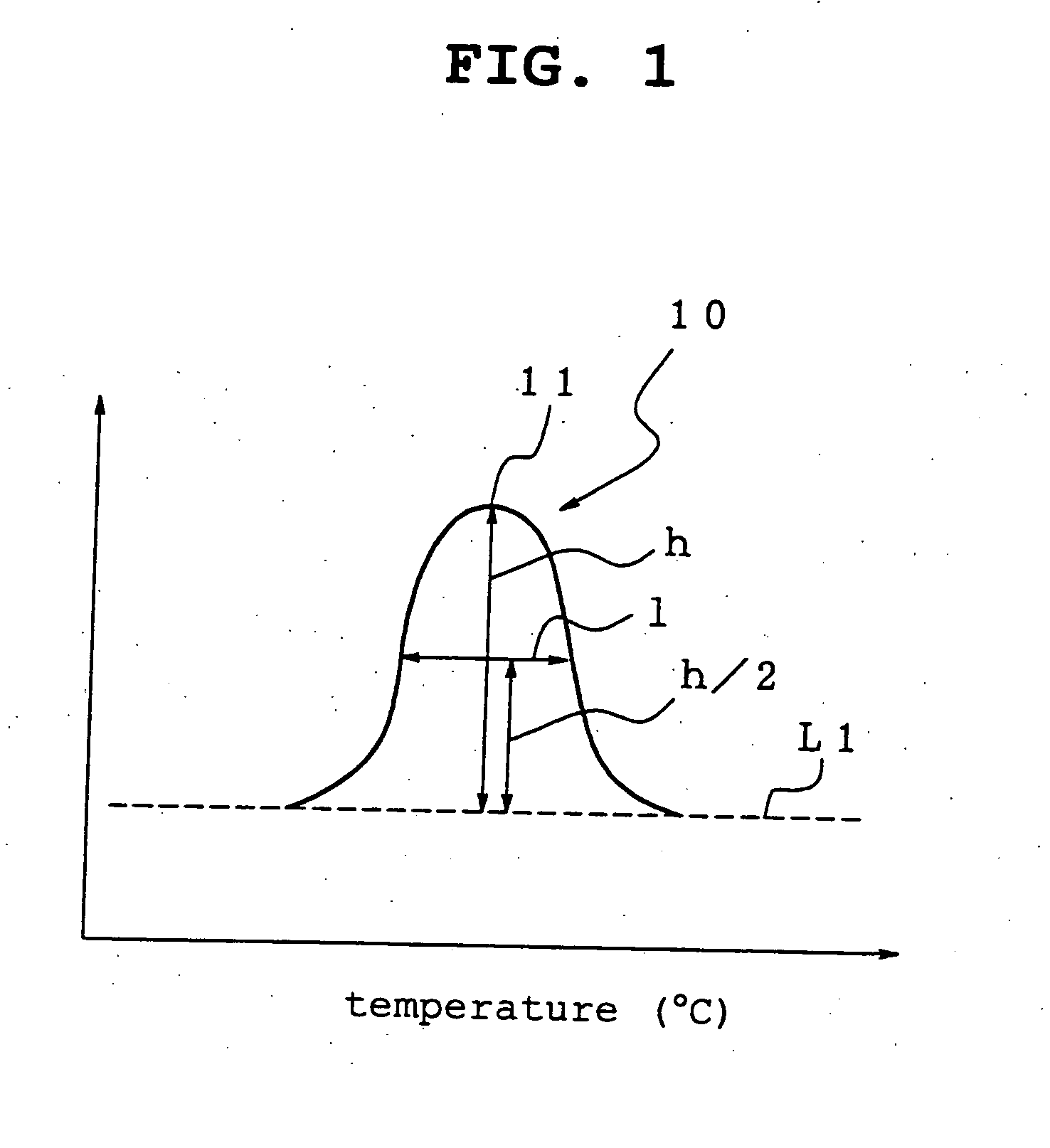

InactiveUS20050118442A1Superior in mechanical characteristicSuperior in design propertySynthetic resin layered productsDomestic containersChemistryCrystallinity

The present invention is a polyester film obtained by blending 10-90 wt % of polyester (A) containing ethylene terephthalate as a main constituent component and 90-10 wt % of crystalline polyester (B) different from this polyester (A), which has a half value width of a recrystallization peak obtained by a differential scanning calorimeter (DSC) by lowering temperature of not more than 0.25. The crystalline polyester (B) is preferably a polyester selected from polybutylene terephthalate (PBT), polytrimethylene terephthalate (PTT) and polyethylene 2,6 naphthalate (PEN). According to the polyester of the present invention, a polyester film superior in mechanical characteristic and design property and having high crystallinity, which can be used alone or adhered to a metal sheet and which is free of whitening even when the film is heat treated at near or not lower than the melting point can be obtained, and further, a polyester film having such superior resistance to whitening (design property), which is not easily damaged, can be obtained.

Owner:TOYO TOYOBO CO LTD

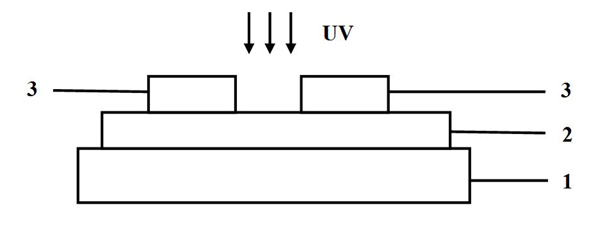

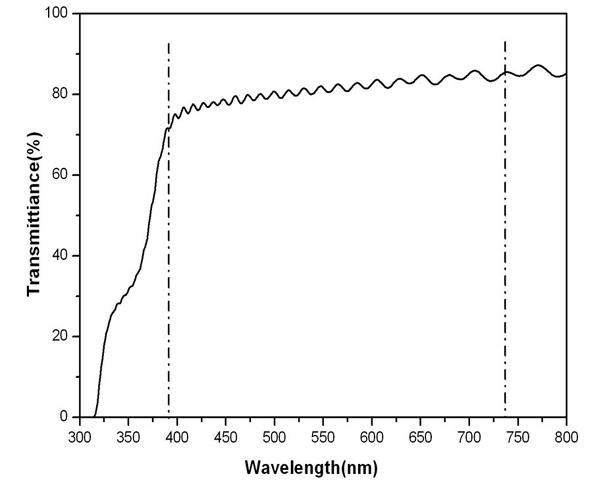

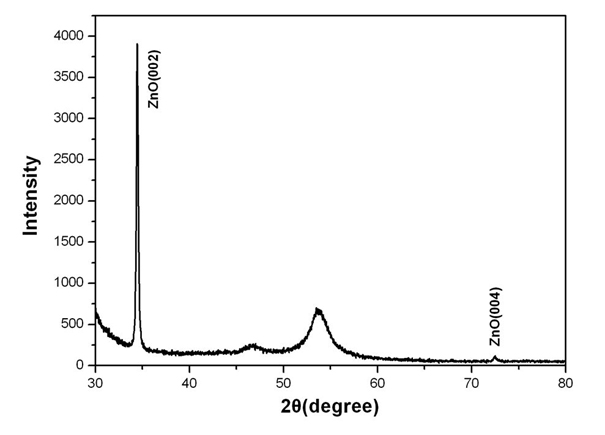

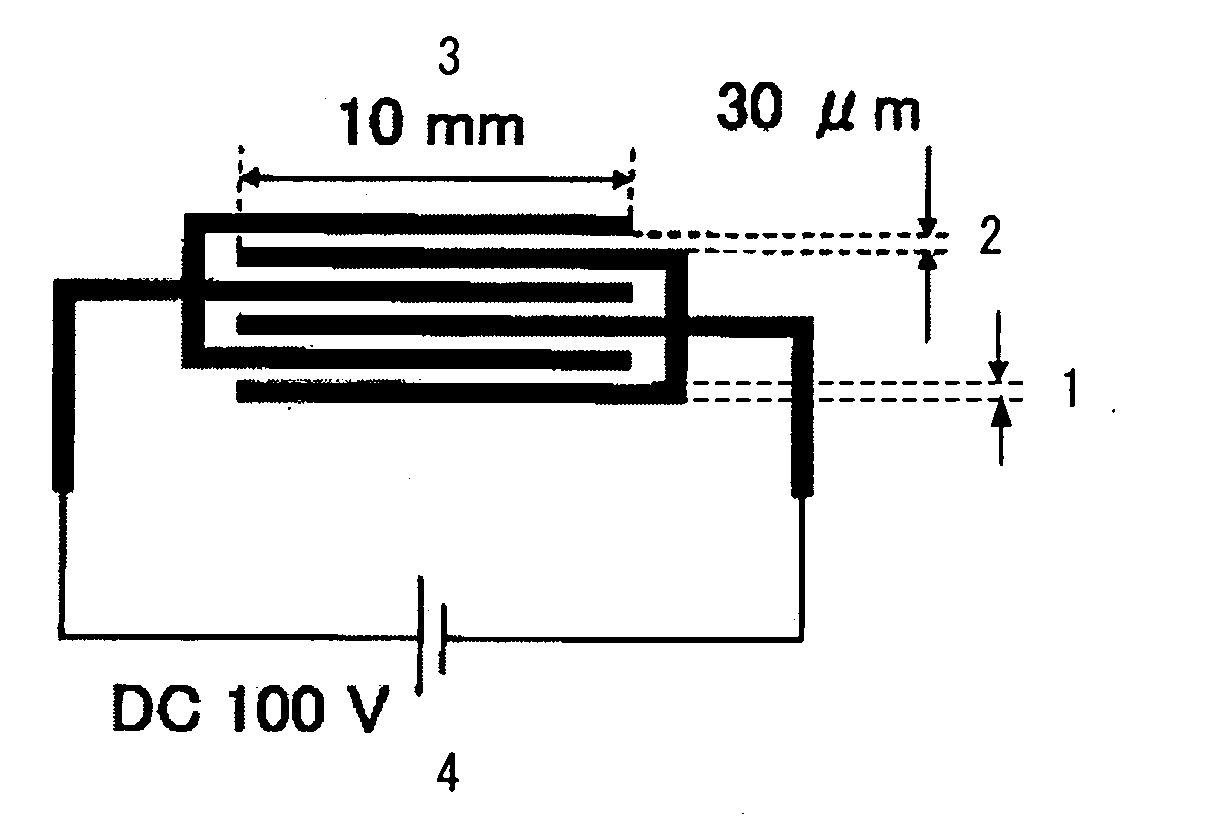

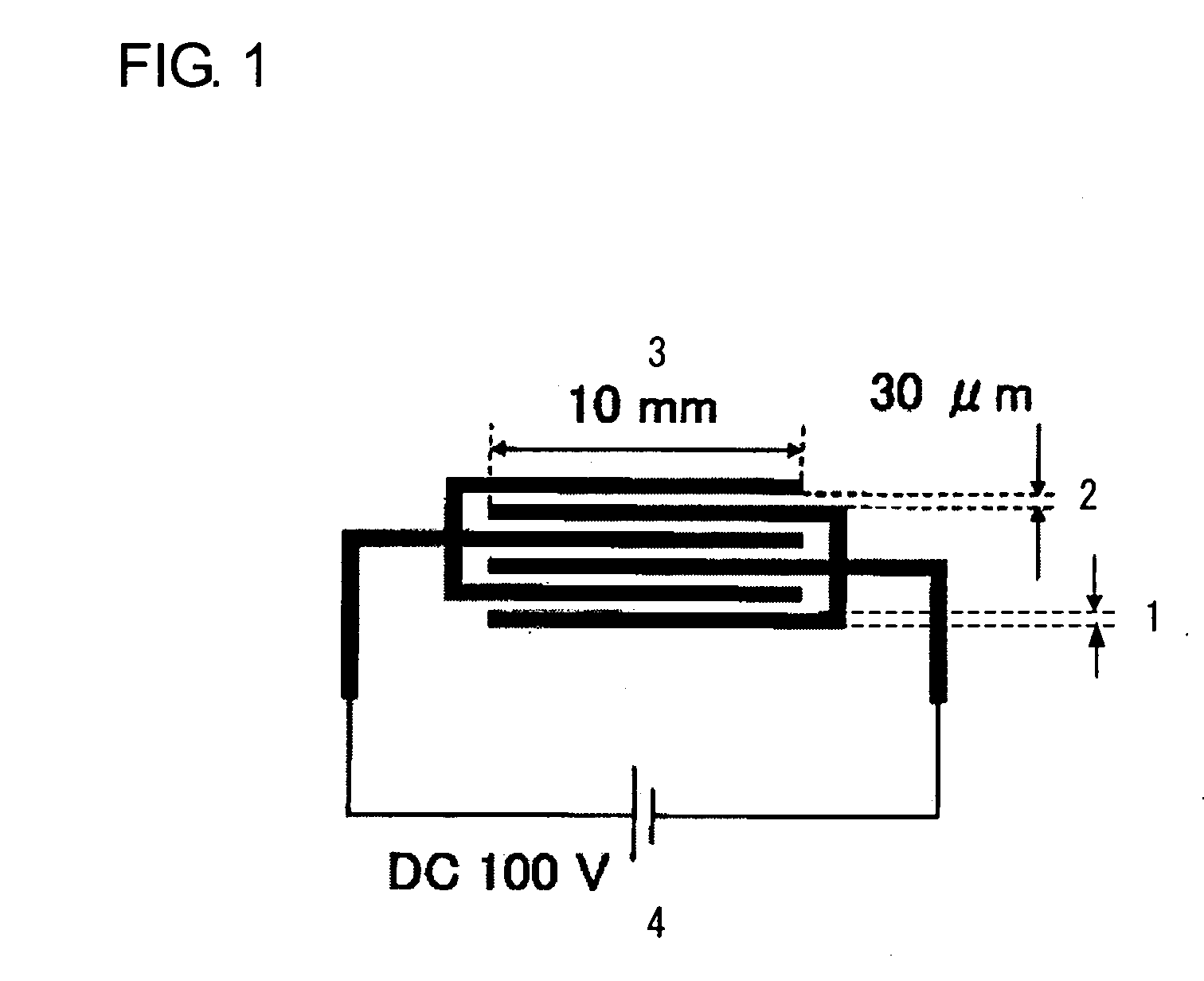

Transparent flexible ultraviolet detector and preparation method thereof

InactiveCN101807619AAchieve transparencyImprove flexibilityFinal product manufactureSemiconductor devicesUltraviolet detectorsPolyethylene terephthalate glycol

The invention discloses a transparent flexible ultraviolet detector and simultaneously discloses a preparation thereof. The transparent flexible ultraviolet detector comprises a transparent plastic substrate, a ZnO-based active layer is deposited on the surface of the transparent plastic substrate, and transparent interdigital electrodes are arranged on the surface of the ZnO-based active layer; and the transparent plastic substrate is a polyethylene terephthalate film, a polyethylene naphthalate film, a polysulfone resin film or an organic glass film. The invention realizes the transparency and flexibility of the ultraviolet detector and broadens the application scope of the ultraviolet detector. In addition, the whole preparation process of the ultraviolet detector is completed at the room temperature, the process flow is simple, the ZnO material resources are rich and non-toxic, and the preparation process is suitable for industrial production.

Owner:HENAN UNIVERSITY

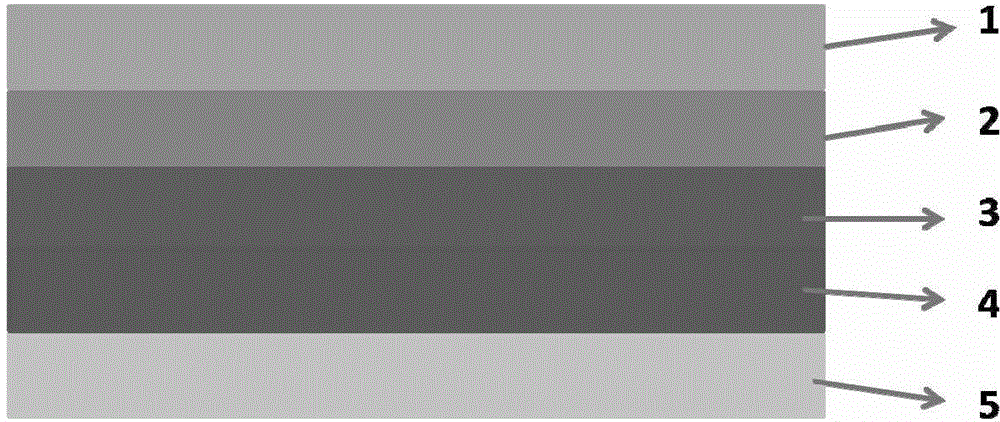

Solar cell back plate and solar cell

ActiveCN102945877AExtend your lifeHigh gas barrierSynthetic resin layered productsPhotovoltaic energy generationSolar cellOxygen

The invention provides a solar cell back plate. The solar cell back plate comprises a weather-resistant layer, a bonding layer combined on the weather-resistant layer, a barrier layer combined on the bonding layer, a structure enhancement layer, and a bonding reflective layer combined on the structure enhancement layer, wherein the barrier layer comprises an inorganic layer combined on the bonding layer, and an organic layer combined on the inorganic layer; the inorganic layer is made from an inorganic oxide and / or an inorganic nitride; the organic layer is made from polyethylene naphthalate; and the structure enhancement layer is combined on the organic layer in the barrier layer. The solar cell back plate prepared by the invention has high gas barrier property, and can effectively prevent erosion of vapor and oxygen, thereby enhancing the anti-aging property of the back plate and prolonging the service life of the solar cell.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

Flexible multi-moduled nanoparticle-structured sensor array on polymer substrate and methods for manufacture

A flexible chemiresistor (CR) sensor for sensing a molecule of interest in a fluid (liquid or gas) is provided. The flexible CR sensor comprises a flexible chemiresistor (CR) module. The flexible CR module comprises a flexible substrate such polyethylene terephthalate (PET), polyethylene naphthalate (PEN) or polyimide (PI), and a thin film nanoparticle assembly assembled on the flexible substrate. The thin film nanoparticle assembly comprises metal or metal alloy core, ligand-capped nanoparticles and molecular linkers connecting the nanoparticles. The flexible CR sensor and an intelligent pattern recognition engine can be incorporated in a handheld device that can detect a molecule of interest in a fluid (e.g., a liquid or gas) accurately, rapidly, and without false positives. Any sensing array nanomaterial, pattern recognition, and compact / or electronic hardware can be integrated to achieve a desired detection limit and response speed.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Oriented Polyester Film

ActiveUS20080032144A1Good dimensional stabilitySmall coefficientMagnetic materials for record carriersElectroluminescent light sourcesPolyesterWorking temperature

An object of the invention is to provide such an oriented polyester film that has a constant thickness, and is excellent in dimensional stability at a high temperature and dimensional stability to temperature change in a working temperature range. The invention relates to an oriented polyester film containing as a major component of a substrate layer polyethylene-2,6-naphthalene dicarboxylate, being stretched at least in one direction, and having a film thickness of from 12 to 250 μm, wherein (1) a coefficient of linear thermal expansion αt at a temperature of from 30 to 100° C. is from 0 to 15 ppm / ° C. in both longitudinal and width directions of the film, and (2) a thermal shrinkage rate at 100° C. for 10 minutes is 0.5% or less in both longitudinal and width directions of the film.

Owner:TEIJIN DUPONT FILMS JAPAN

High strength, fast crystallization polyester composite material and preparation thereof

The invention provides a polyester composite material composition. The composition comprises the following components by weight portion: 100 weight portions of polyester, 5 to 60 weight portions of polynaphthalic acid glycol ester fibers, 0.8 to 1.8 weight portions of nucleator, and 0 to 1 weight portion of optional processing agent. The polyester composite material composition can be used for preparing polyester composite material with quick crystallization and high strength.

Owner:HEFEI GENIUS NEW MATERIALS

Application of zinc phthalocyanine complex as ink in micro-contact printing

InactiveCN102516841AReduce bloatReduce distortionInksOther printing apparatusMicrocontact printingPolyimide substrate

The invention discloses application of a zinc phthalocyanine complex as ink in micro-contact printing. The 2-propyl alcohol solution of 8(Octanohydroxamic)-zinc phthalocyanine serves as micro-contact printing ink; the pattern of a Polydimethylsiloxane (PDMS) seal is transferred to the surface of carboxylation polyethylene terephthalate, polyethylene naphthalate or polyimide substrate; and a delicate metal pattern is obtained on the substrate with a chemical plating method. The application of the zinc phthalocyanine complex as the ink in the micro-contact printing has the beneficial effect that the common phenomena of pattern inflation and pattern torsion in the micro-contact printing can be reduced by the phthalocyanine metal complex ink, and the phthalocyanine metal complex ink has a lowpreparation cost and great potential in the industrial application and is stable.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com