Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

192 results about "Microcontact printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

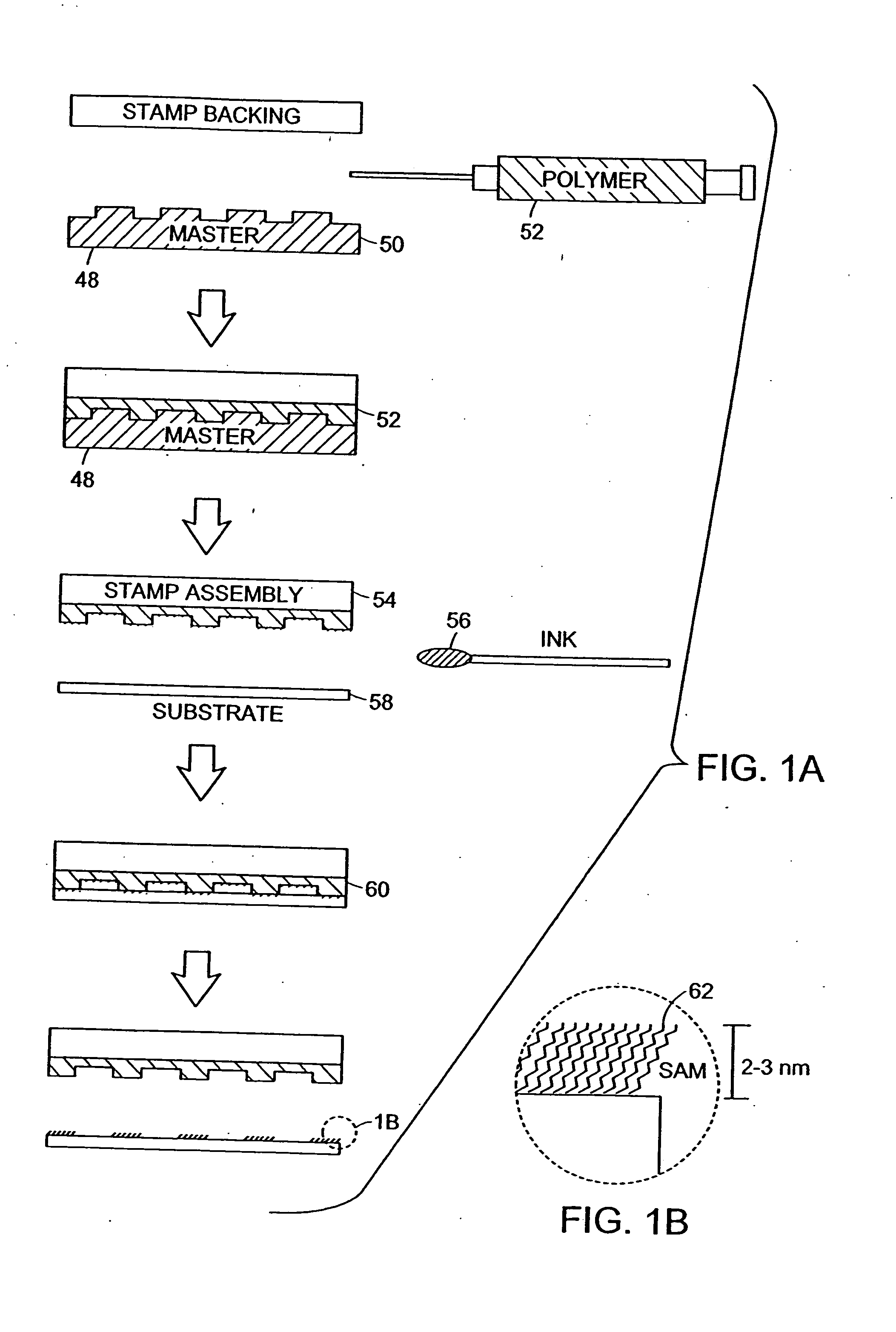

Microcontact printing (or μCP) is a form of soft lithography that uses the relief patterns on a master polydimethylsiloxane (PDMS) stamp to form patterns of self-assembled monolayers (SAMs) of ink on the surface of a substrate through conformal contact as in the case of nanotransfer printing (nTP). Its applications are wide-ranging including microelectronics, surface chemistry and cell biology.

Microcontact printing

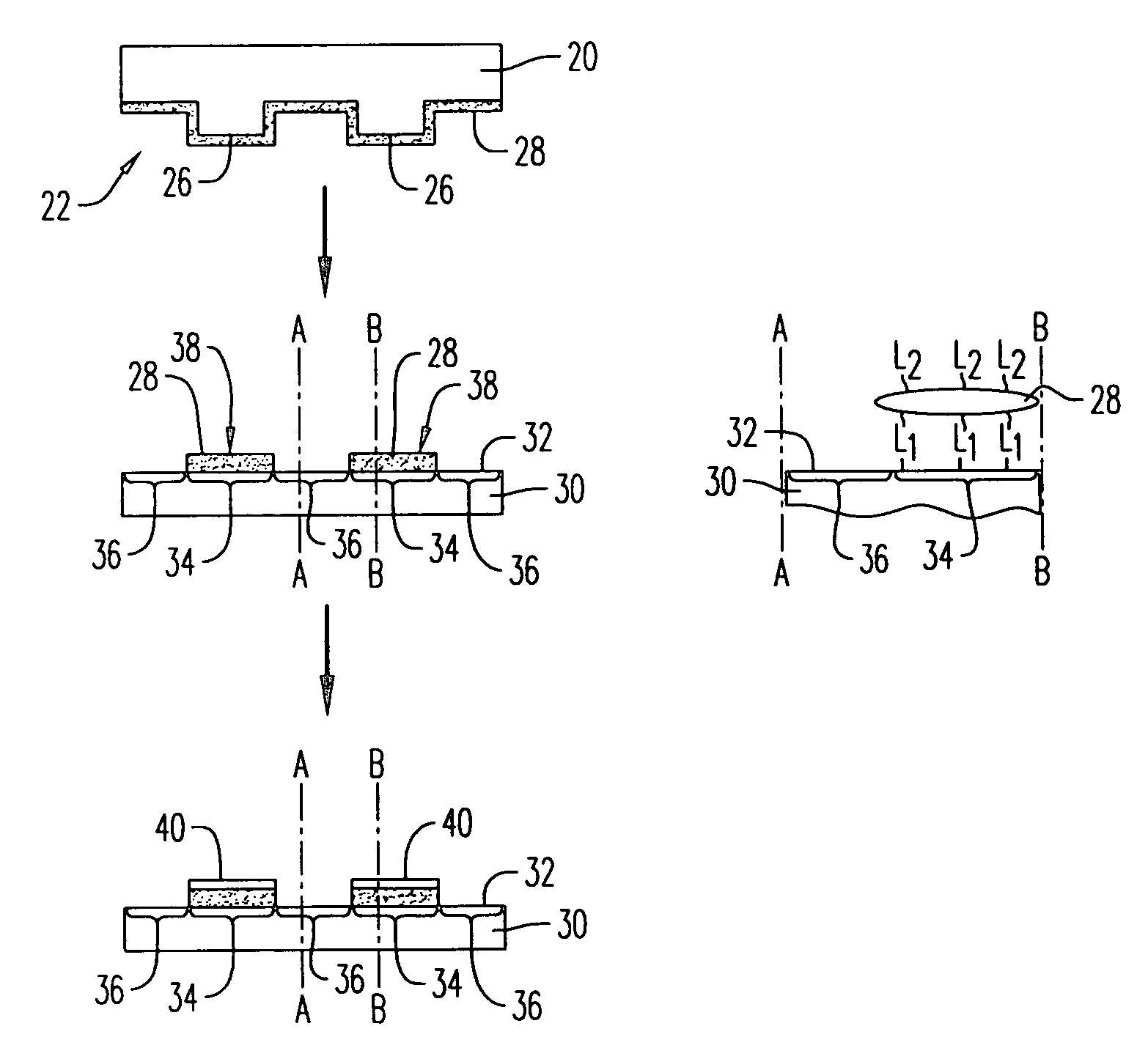

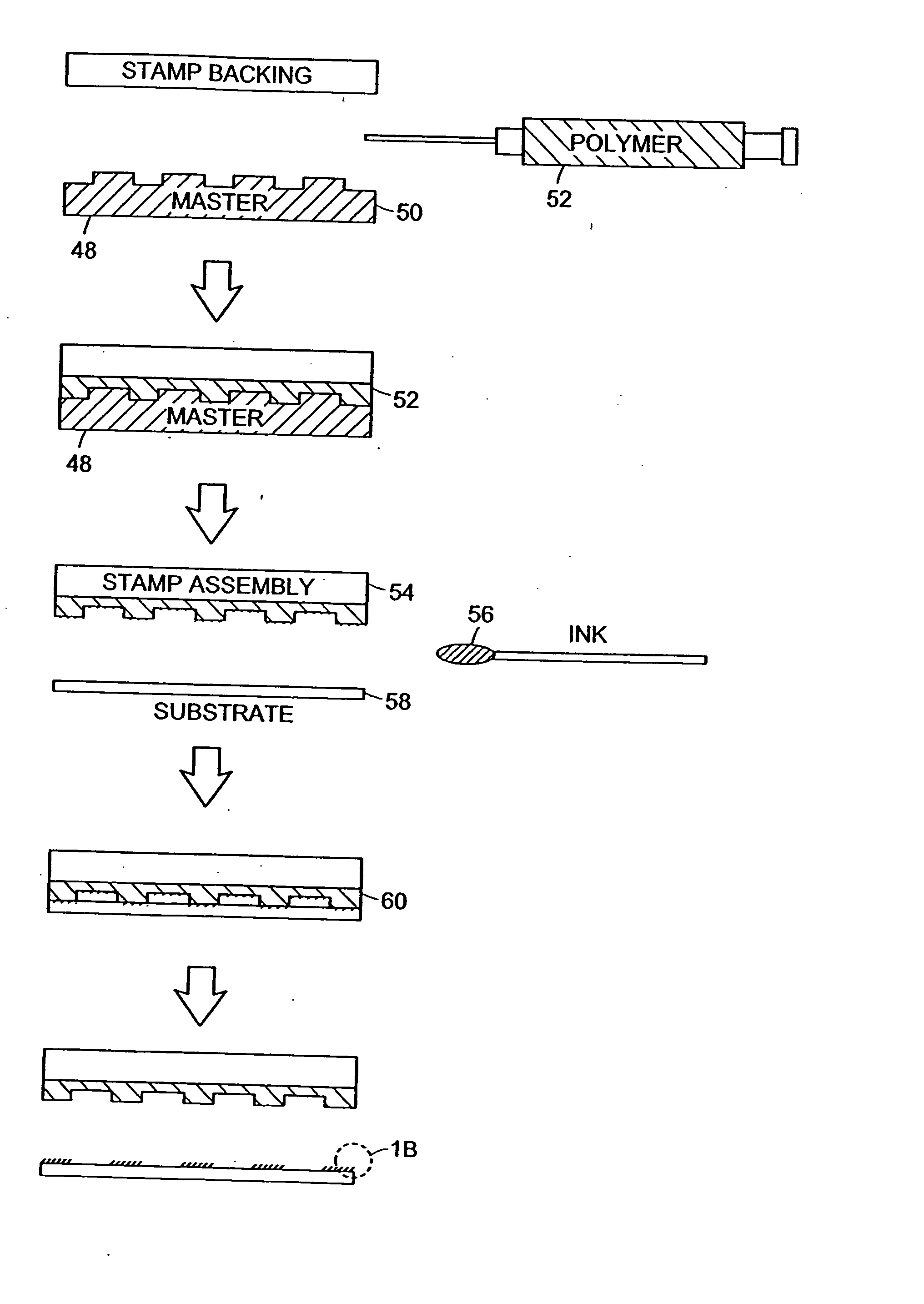

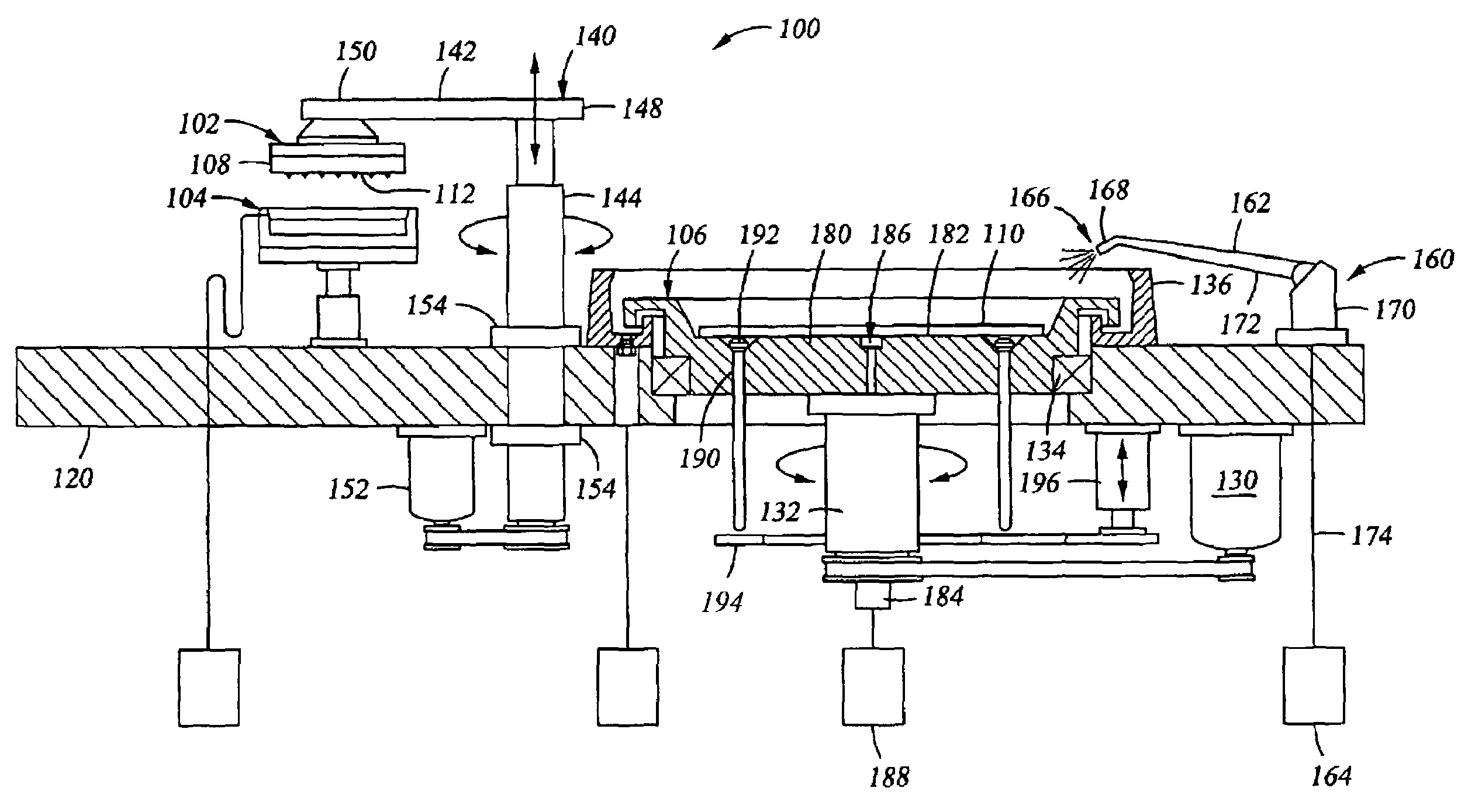

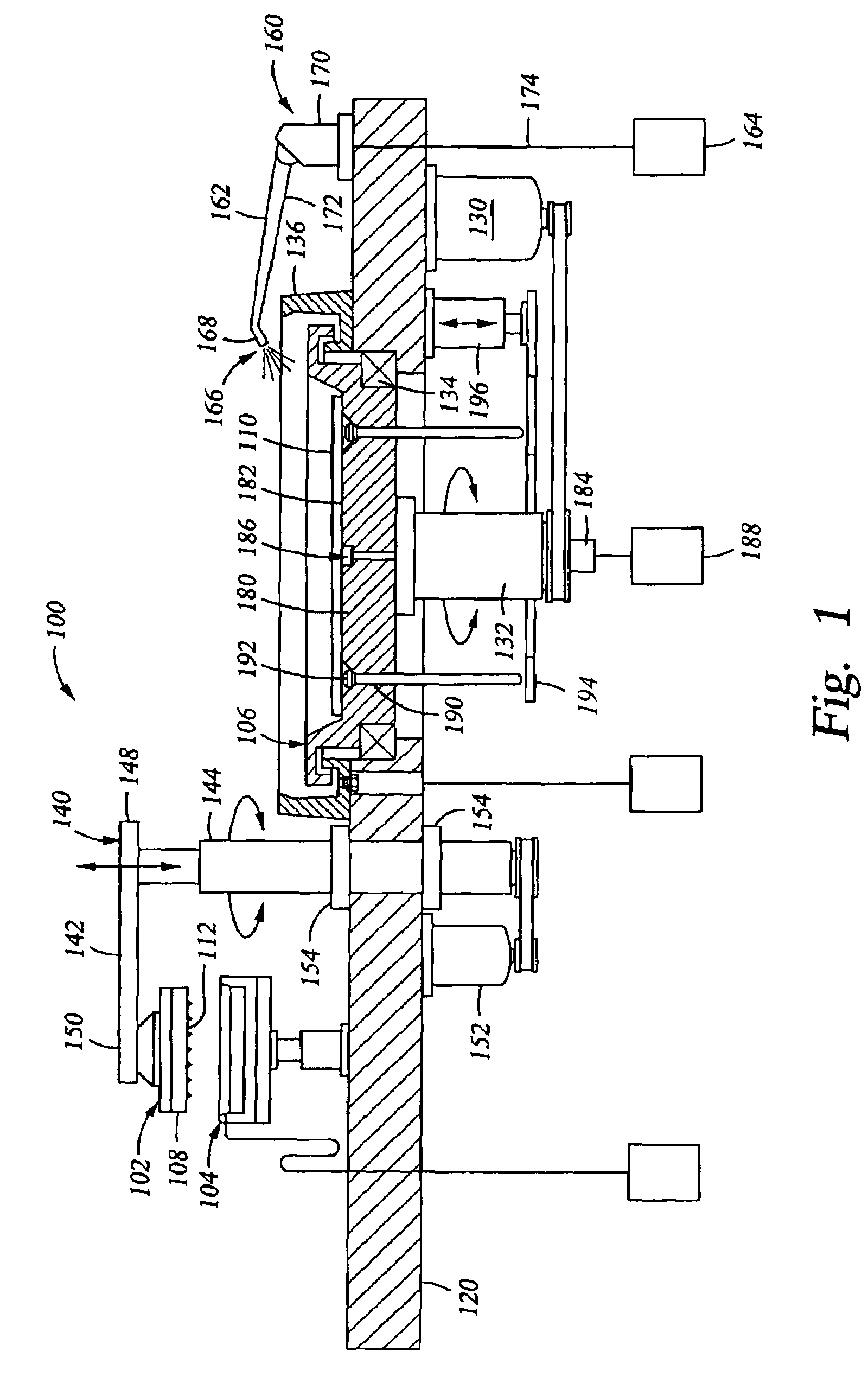

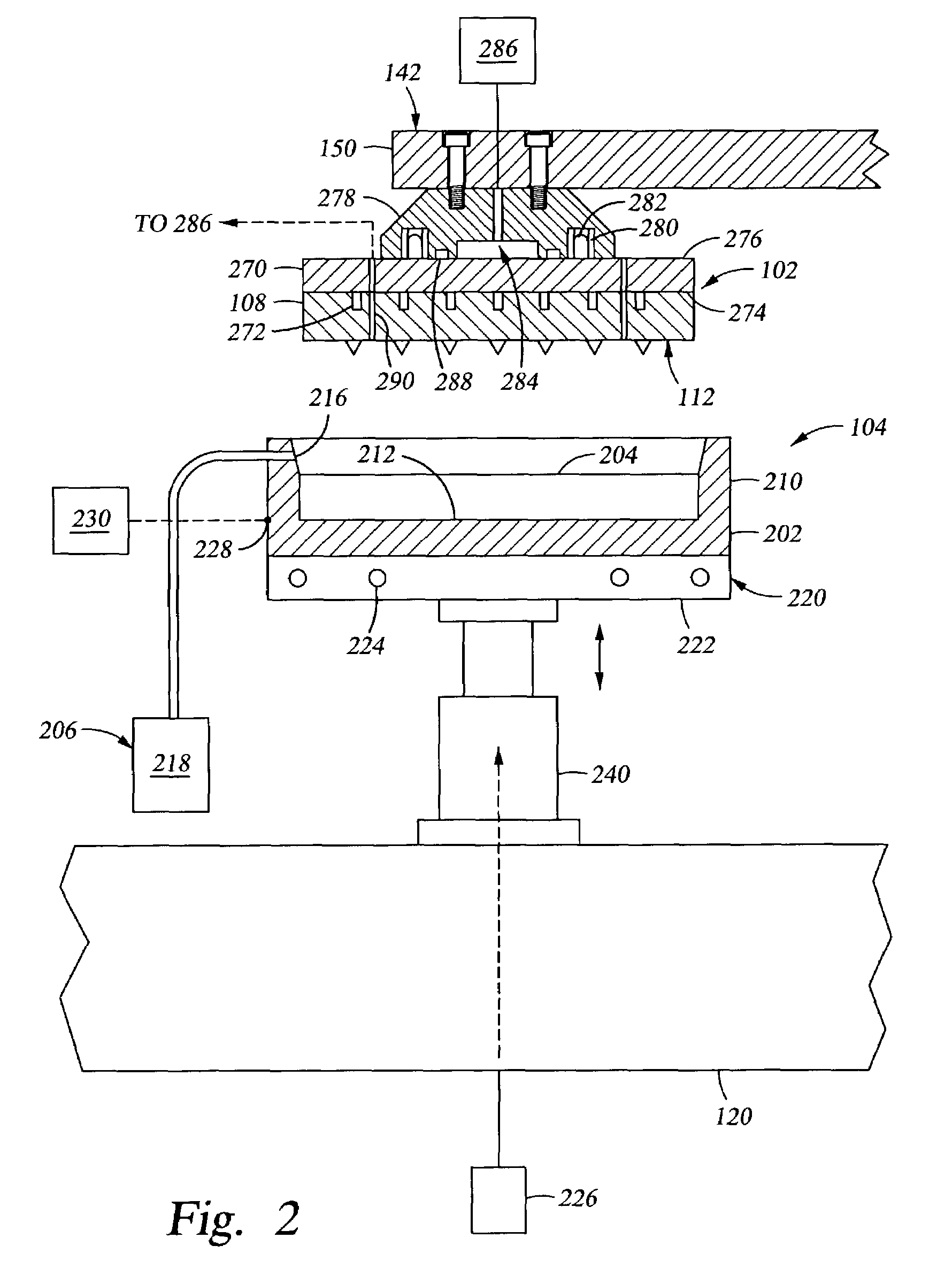

InactiveUS7117790B2Generate undesired patterning resultsControl distortionMaterial nanotechnologyNanoinformaticsMicrocontact printingEngineering

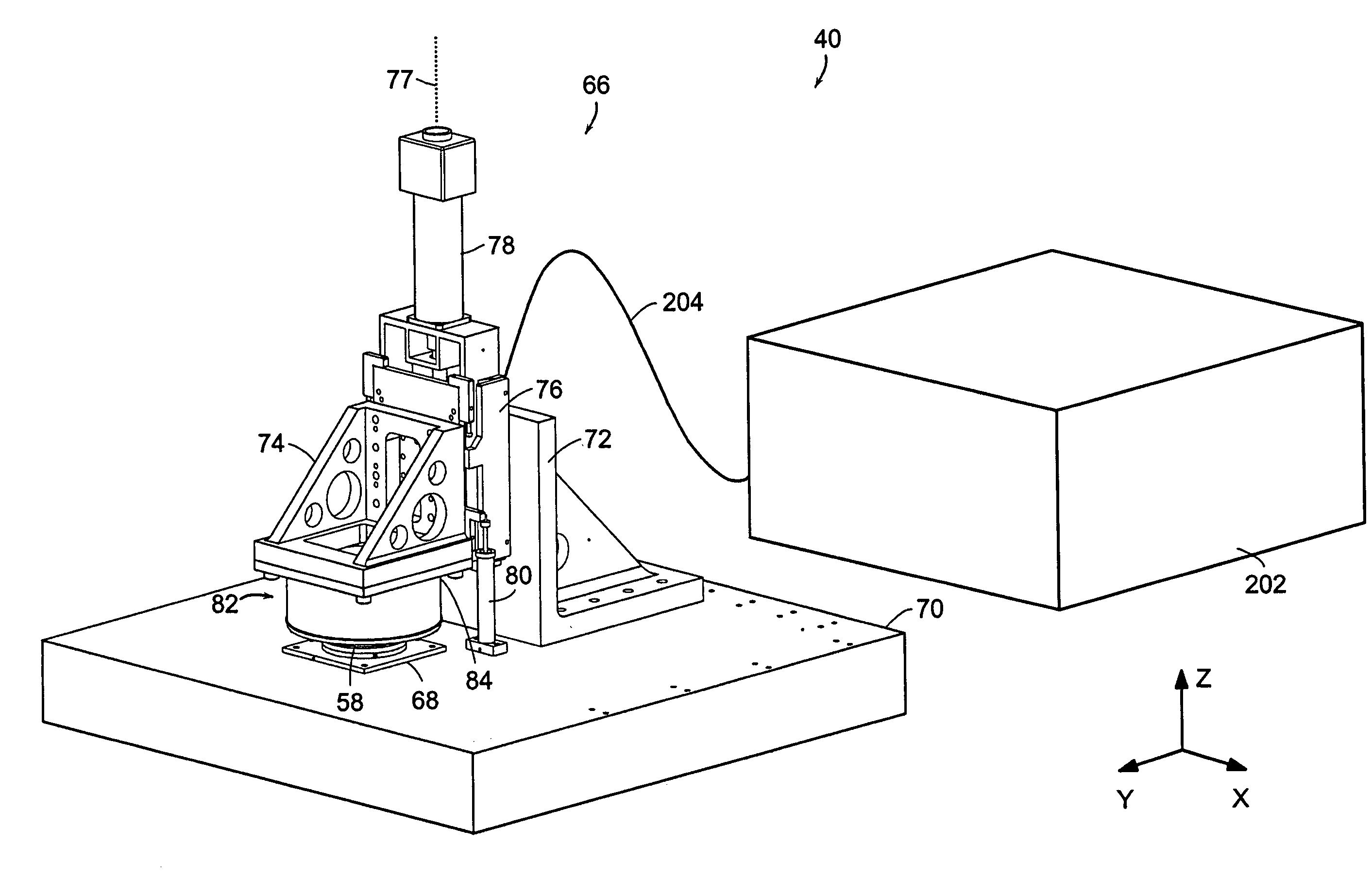

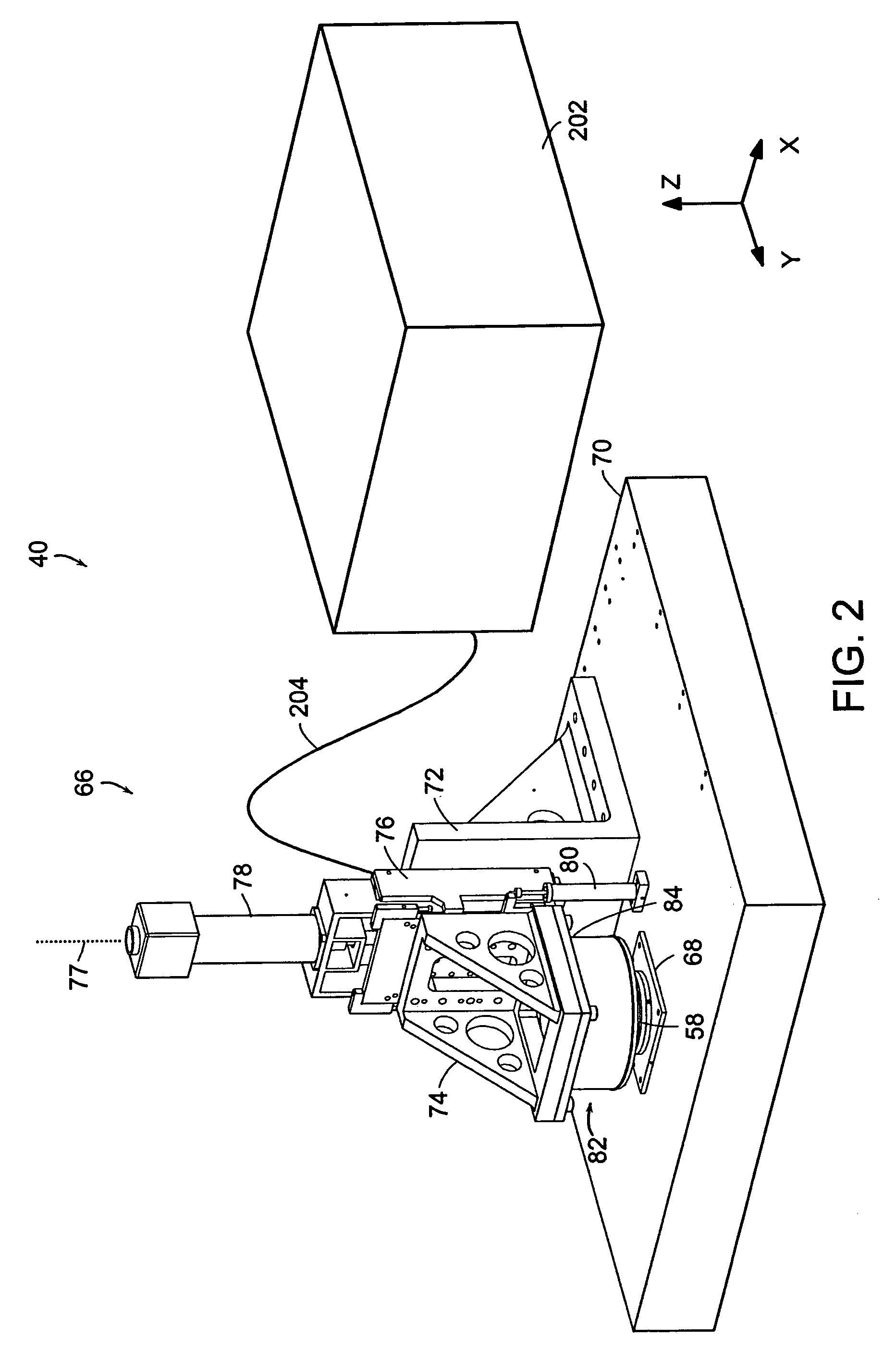

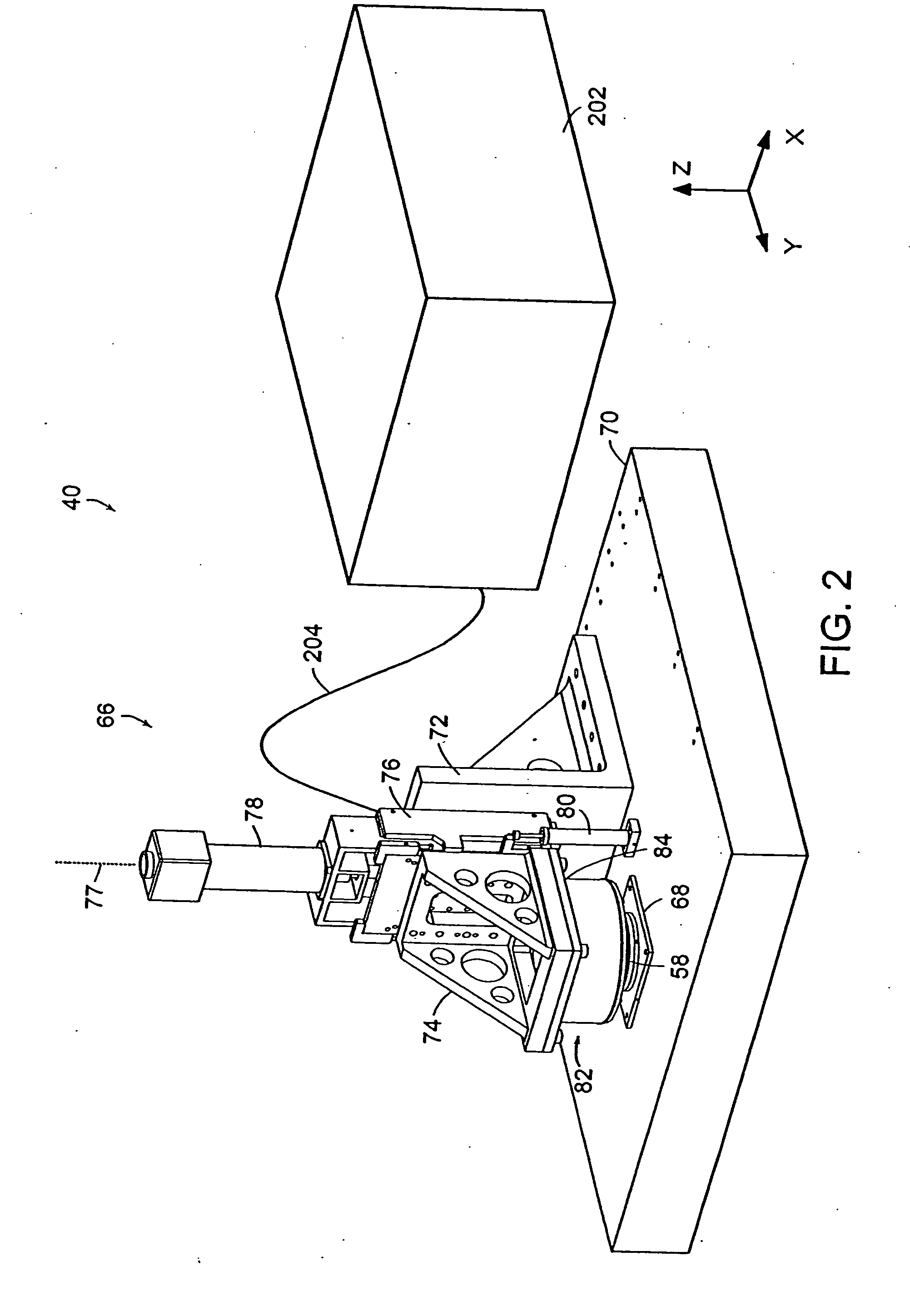

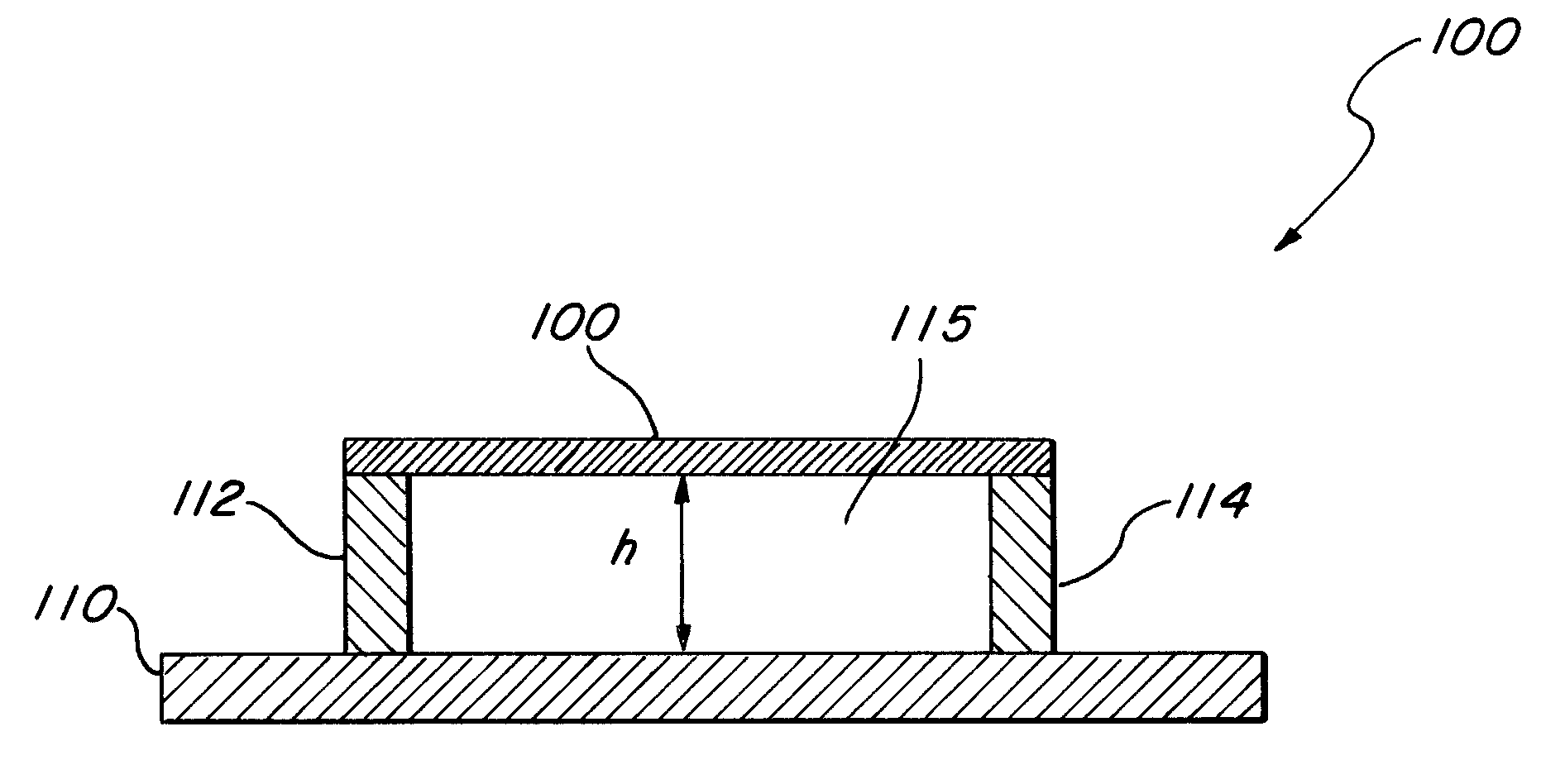

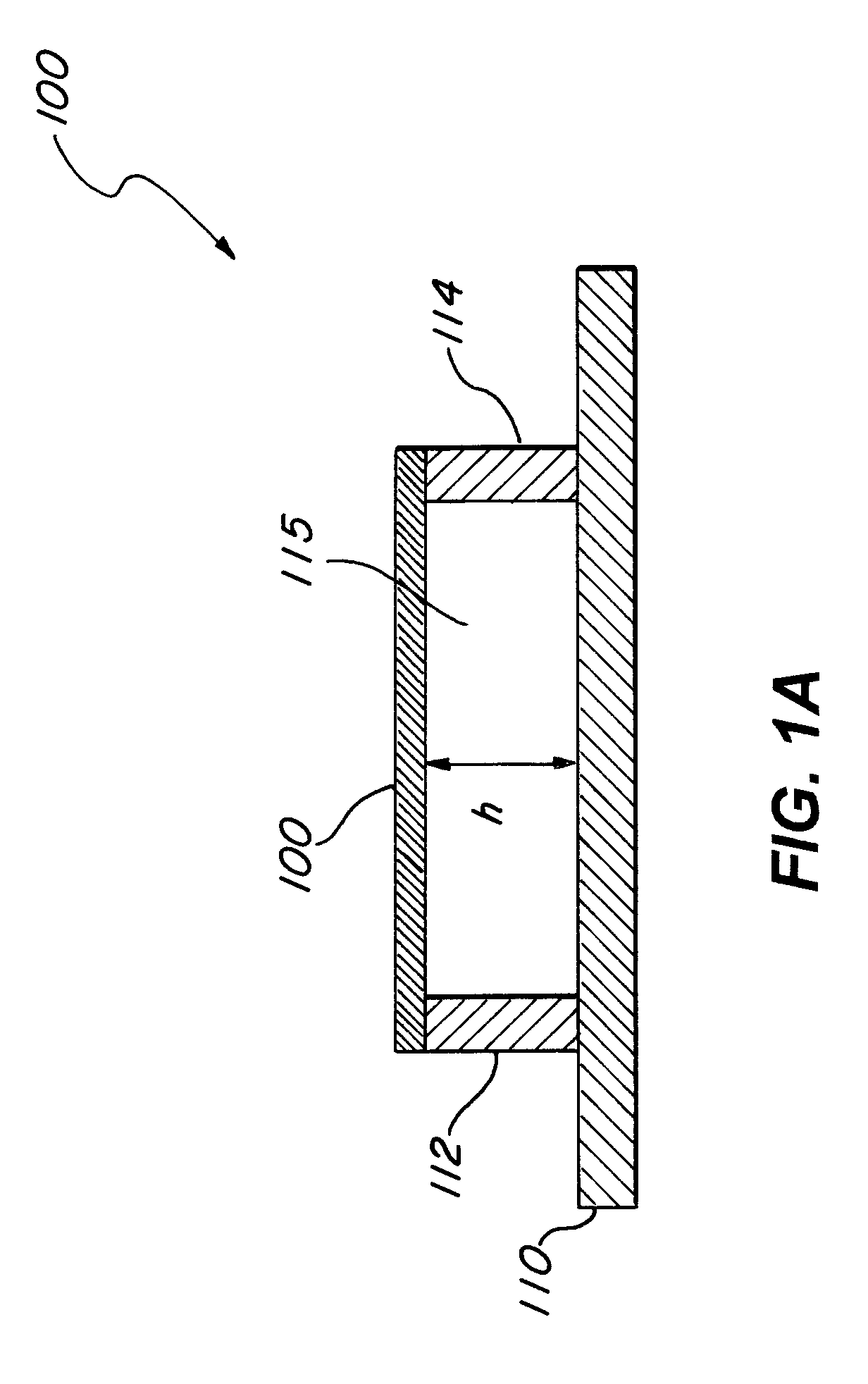

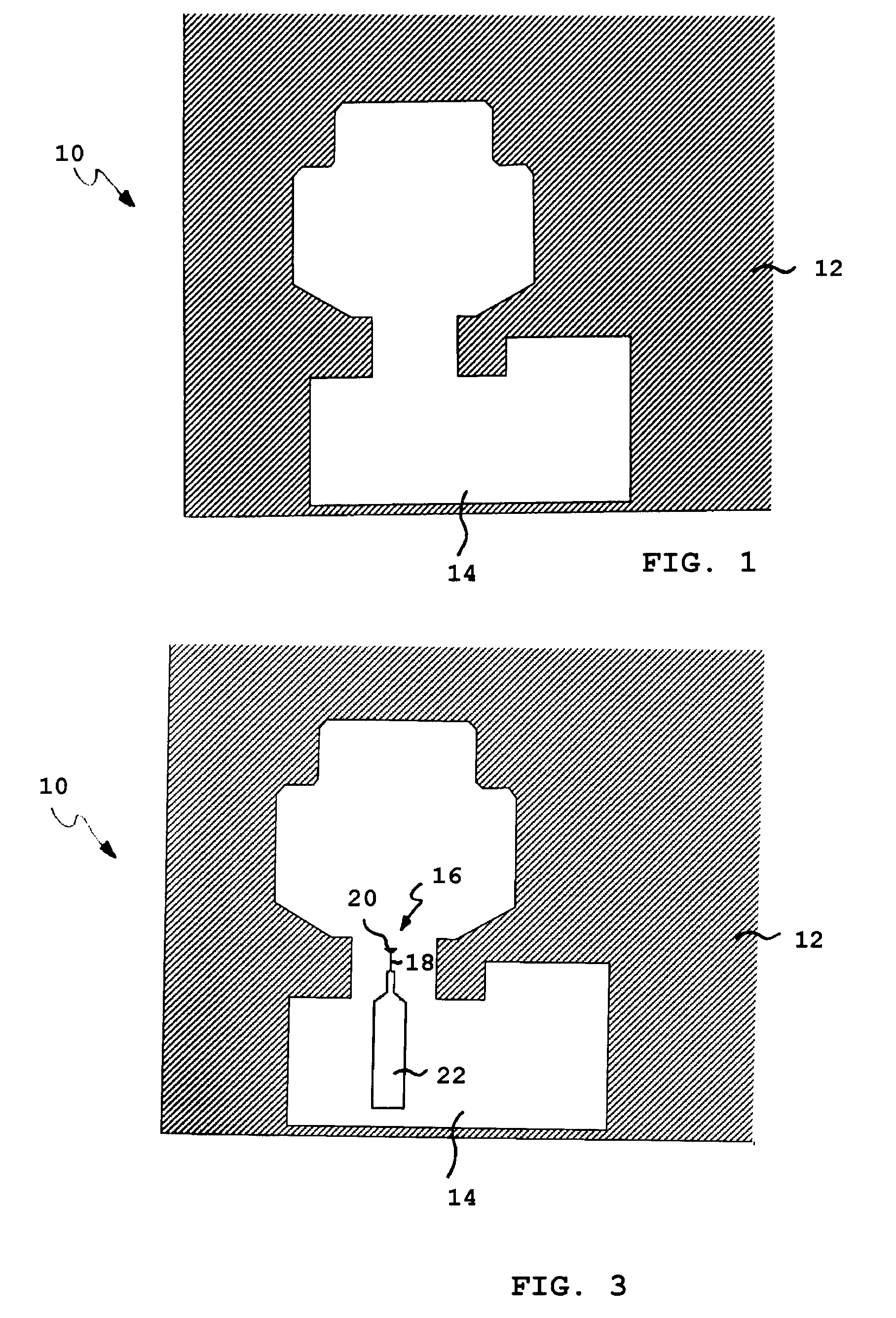

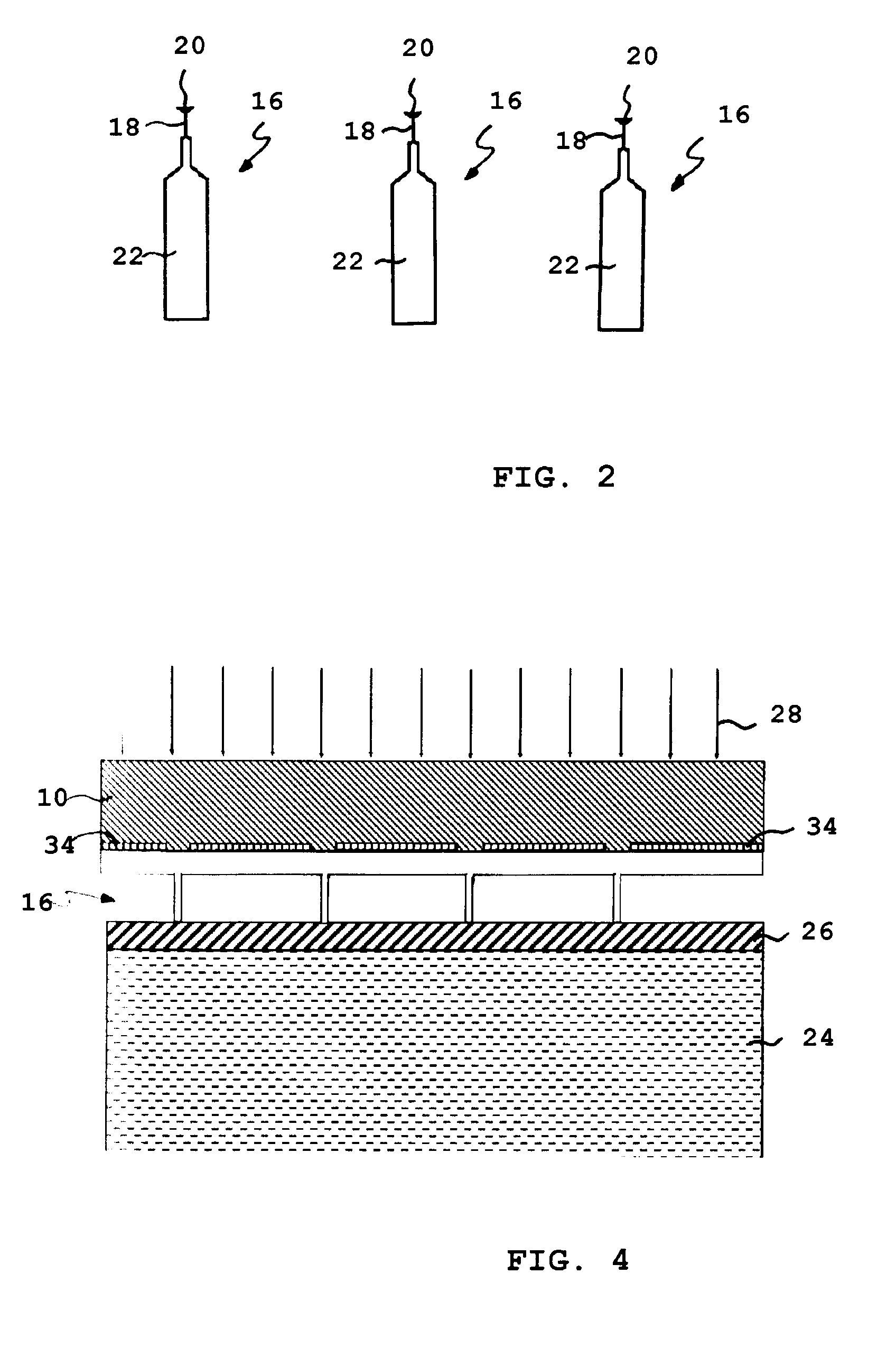

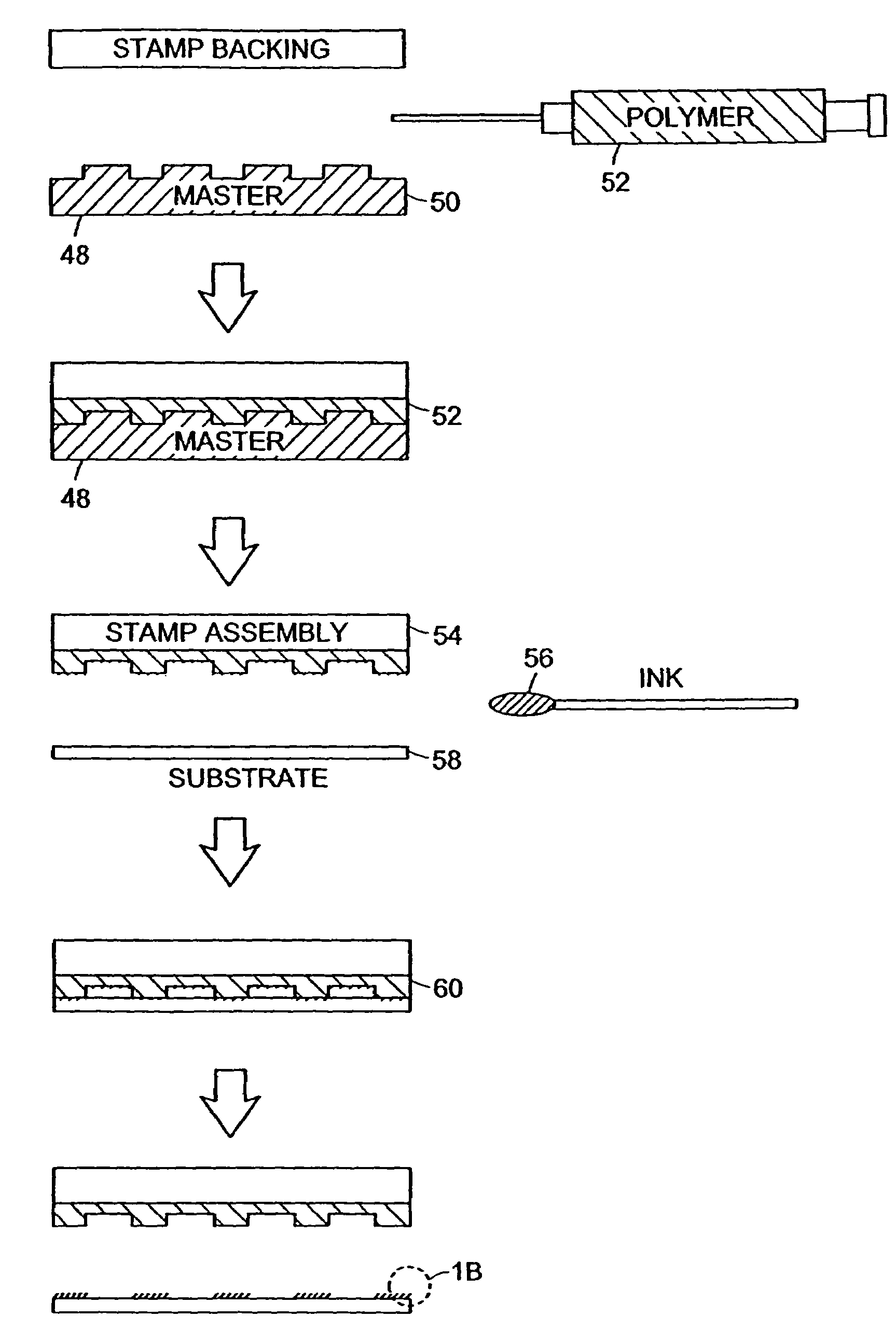

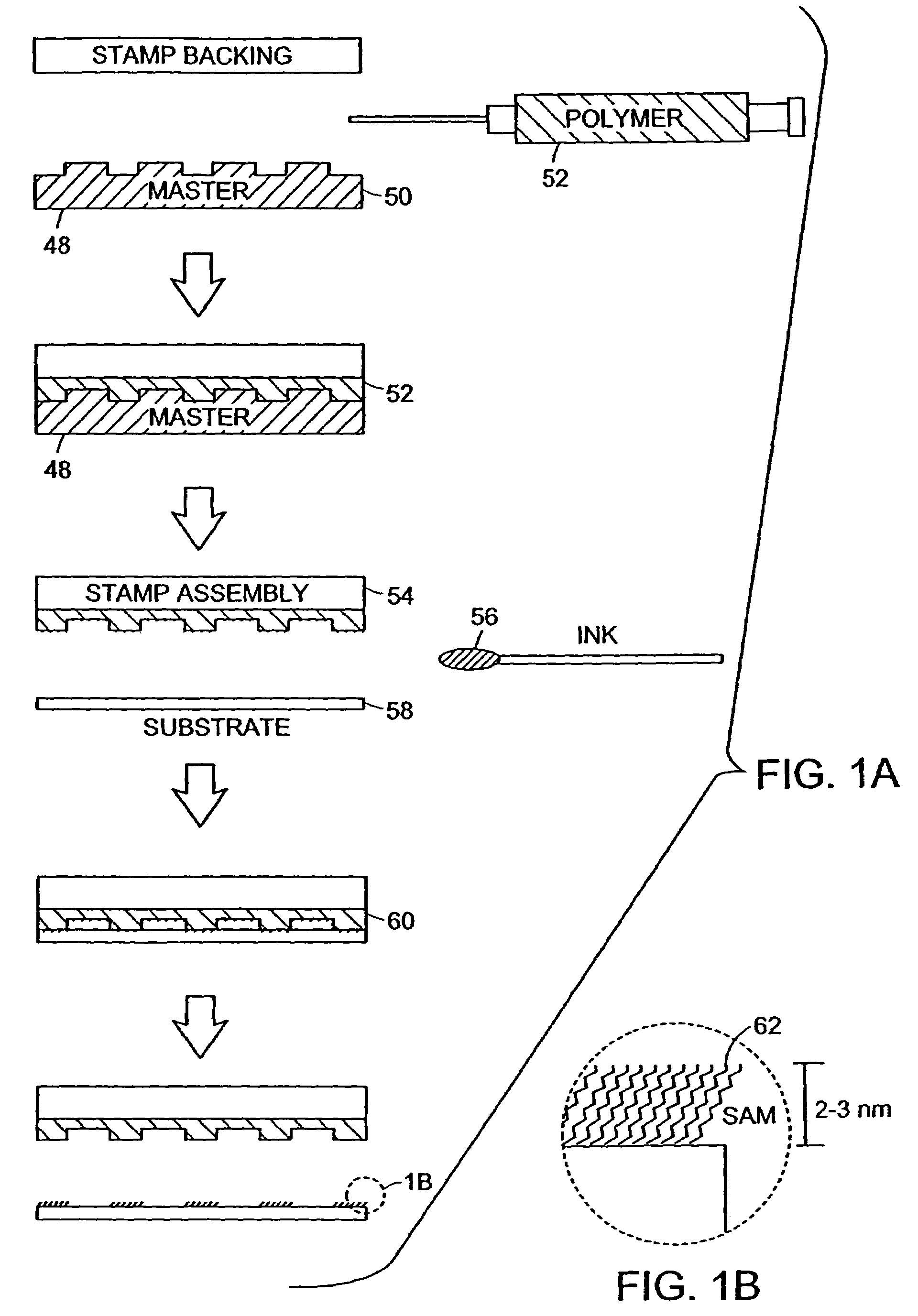

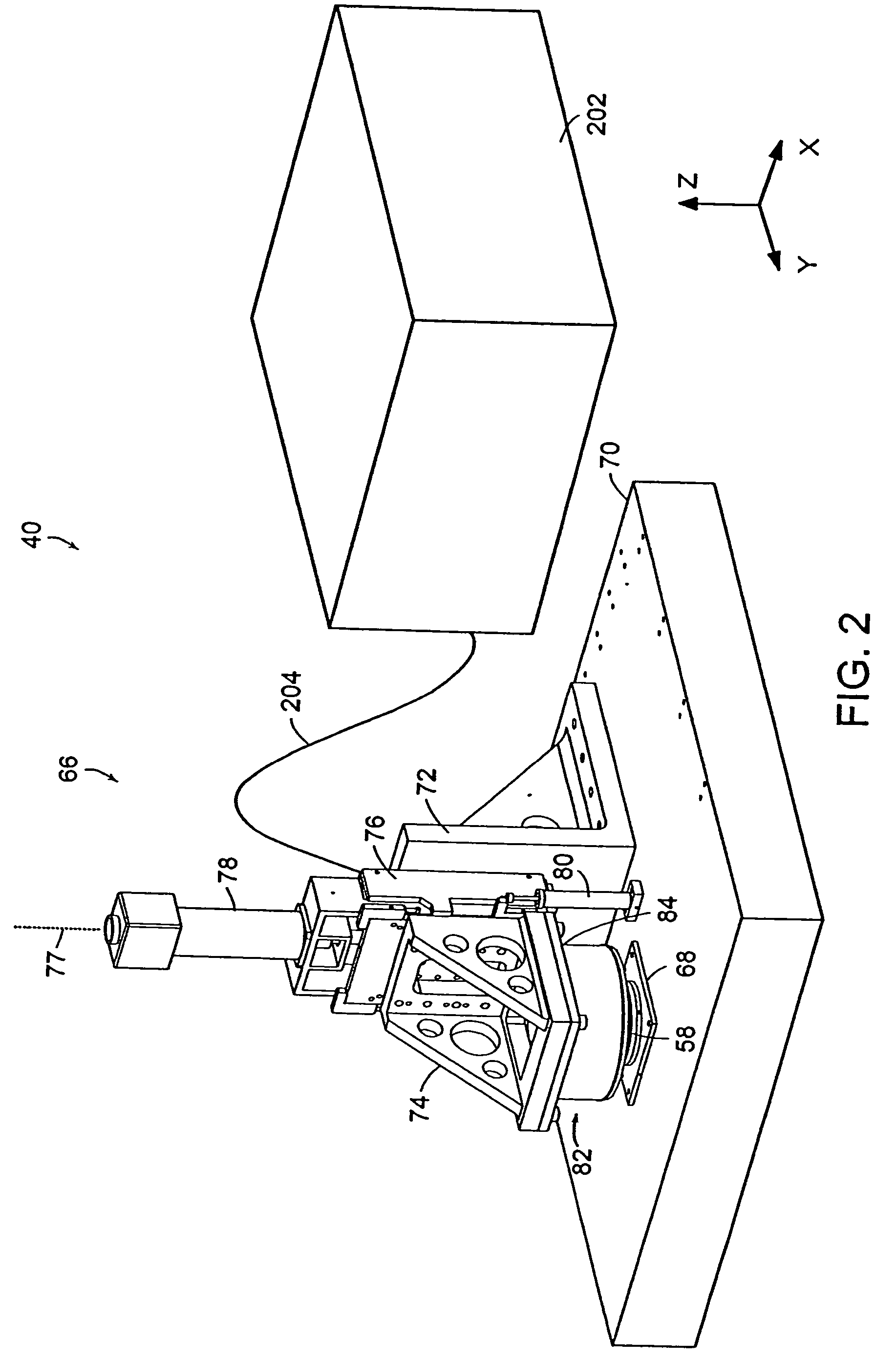

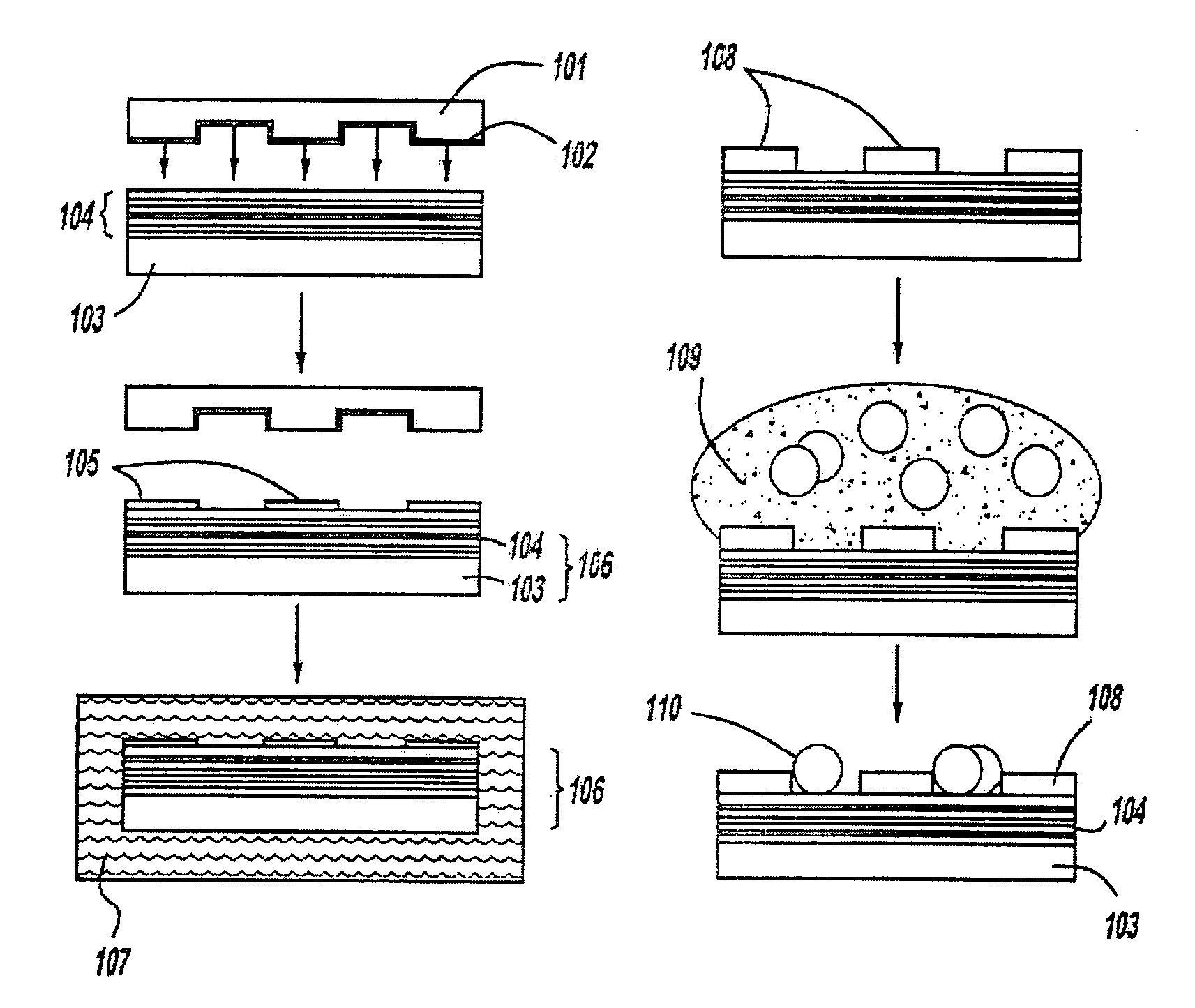

A microcontact printing tool having a print unit including a stamp head with a stamp and a wafer chuck for retaining a substrate. The stamp contained by the stamped head movable relative to the substrate by an actuator and a stage. A plurality of sensors detect the position of the stamp relative to substrate. A method of using the printing tool that includes a real-time feedback for consistent and accurate application of force during the printing of the substrate. The stamp head includes a pressure chamber carrying the stamp. The stamp backing is deflected prior to contact of the stamp with the substrate to form a minimum point and the stamp backing and the stamp is returned to a plane to create a printing propagation contact. An apparatus and method of producing the stamp on a stamp backing. The apparatus has a master backing and a stamping backing in close proximity and the stamp material drawn in through a vacuum. The stamp is separated from the master by use of a parting fluid.

Owner:MASSACHUSETTS INST OF TECH

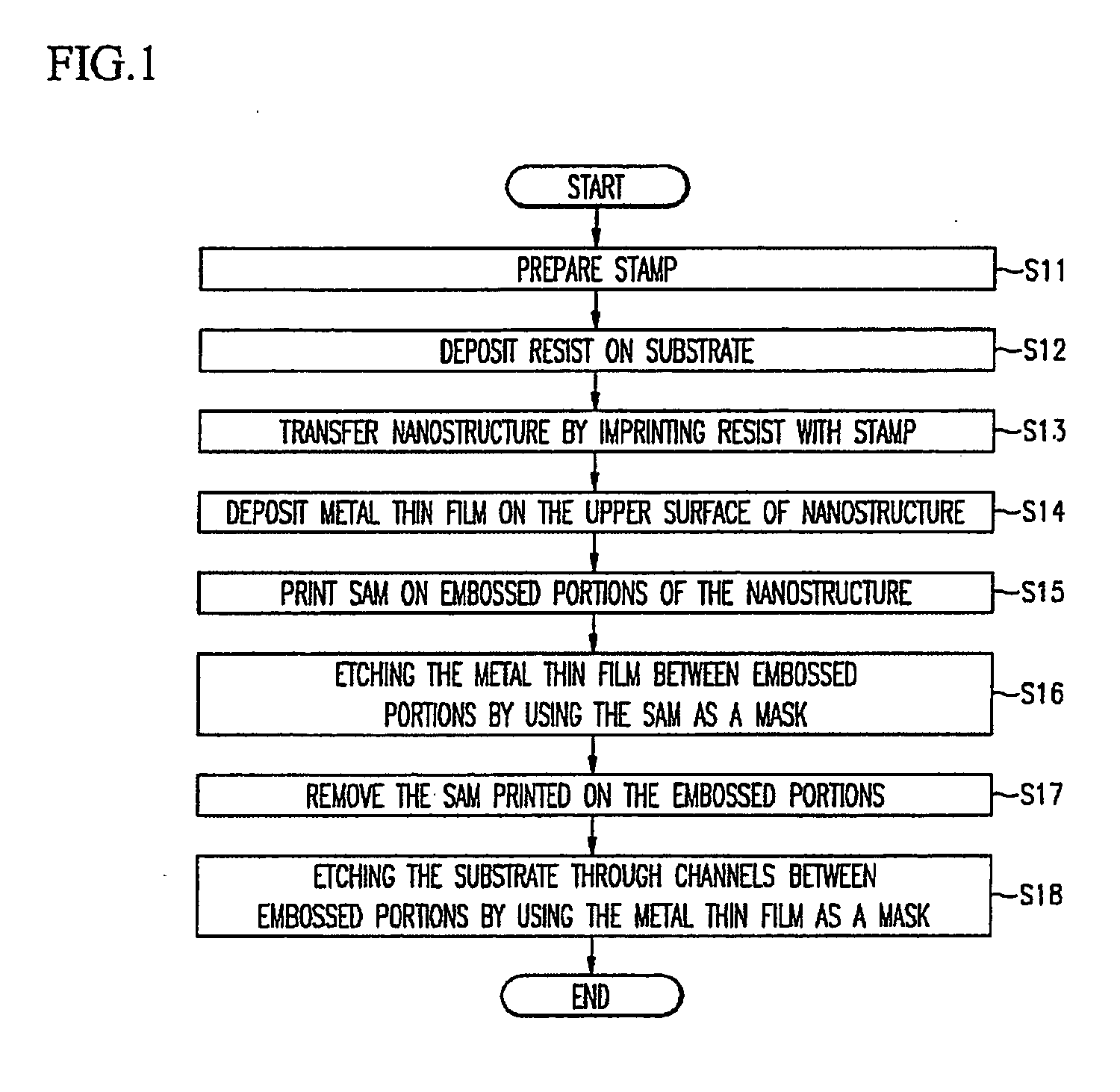

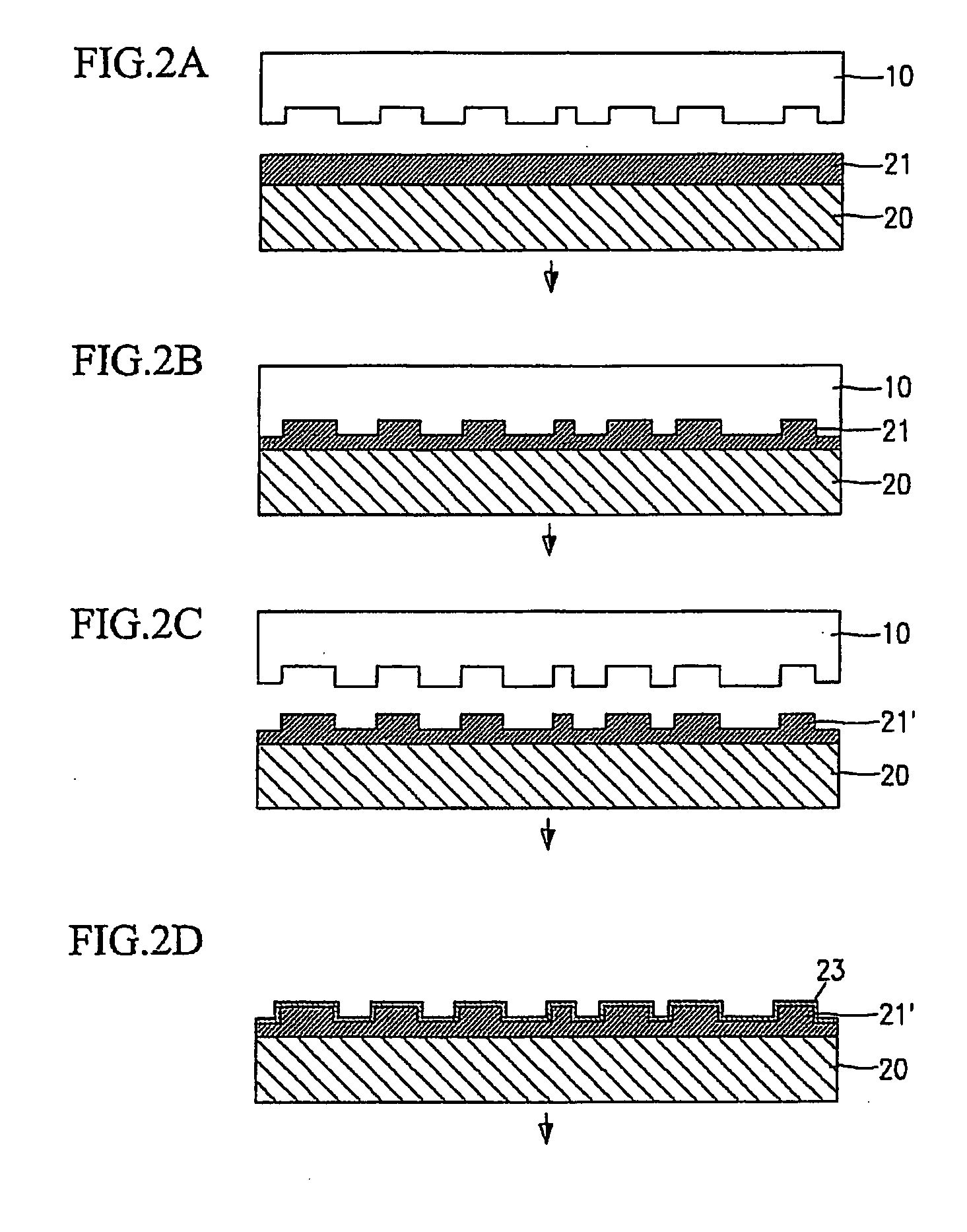

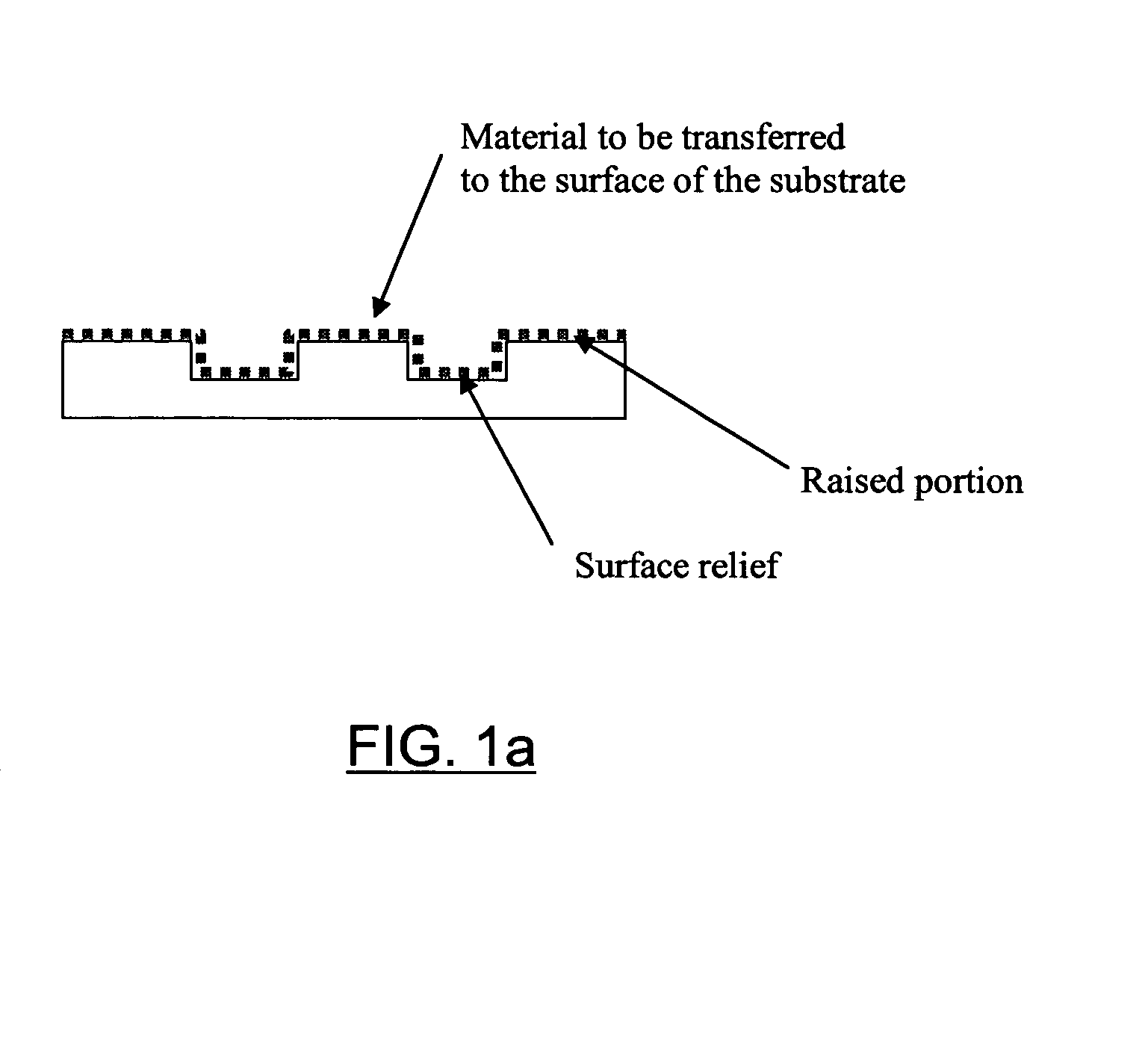

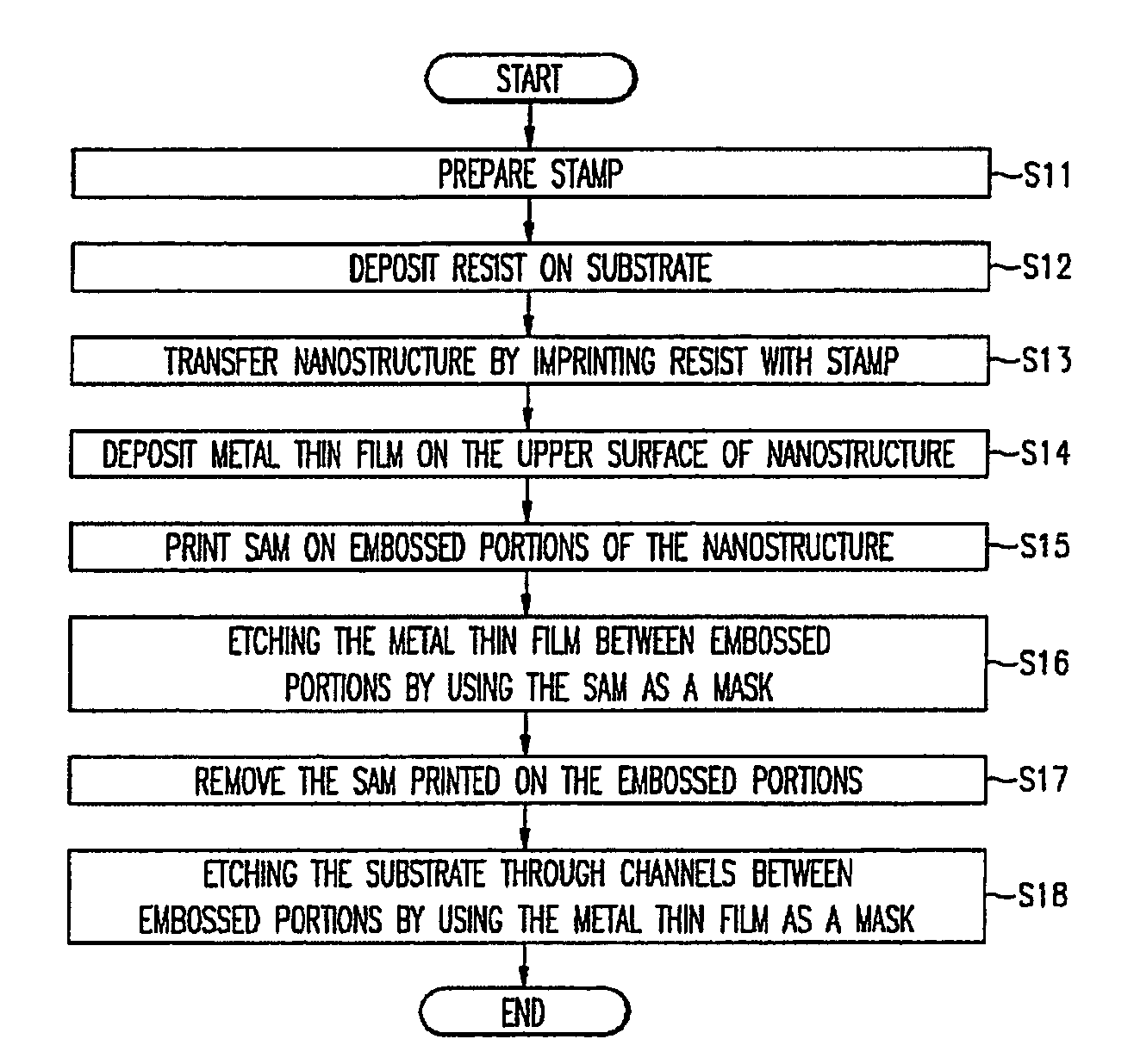

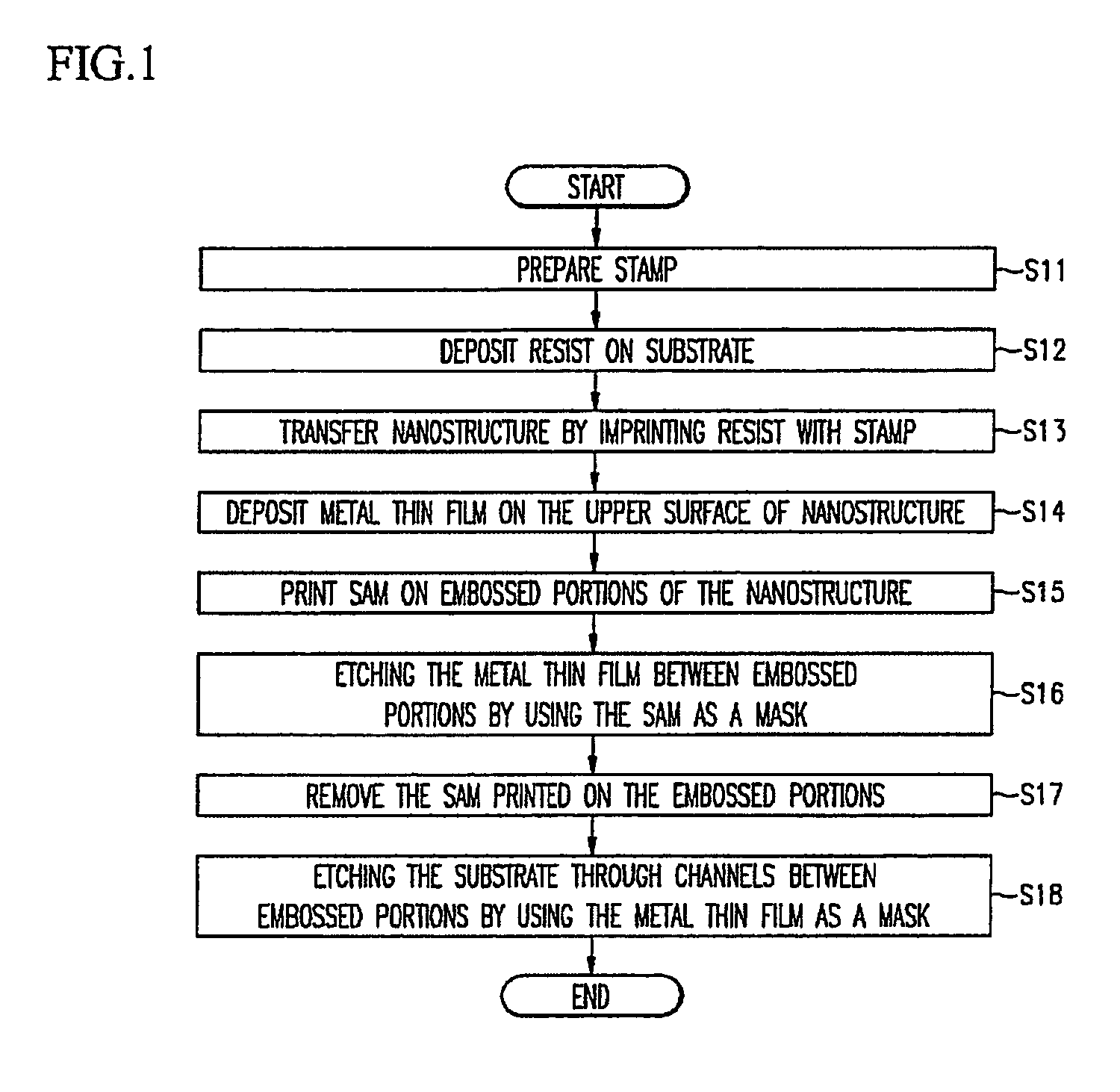

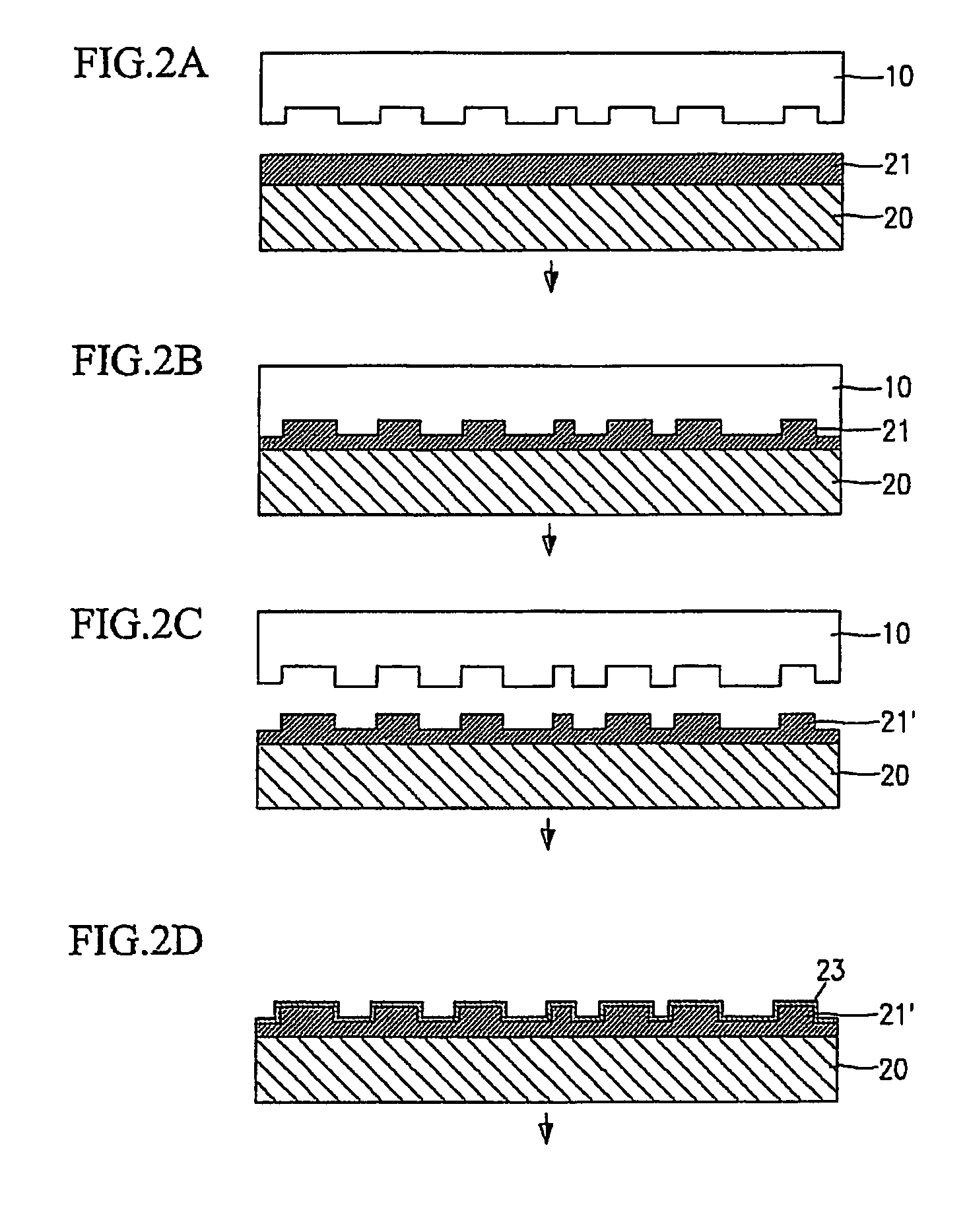

Microcontact printing method using imprinted nanostructure and nanostructure thereof

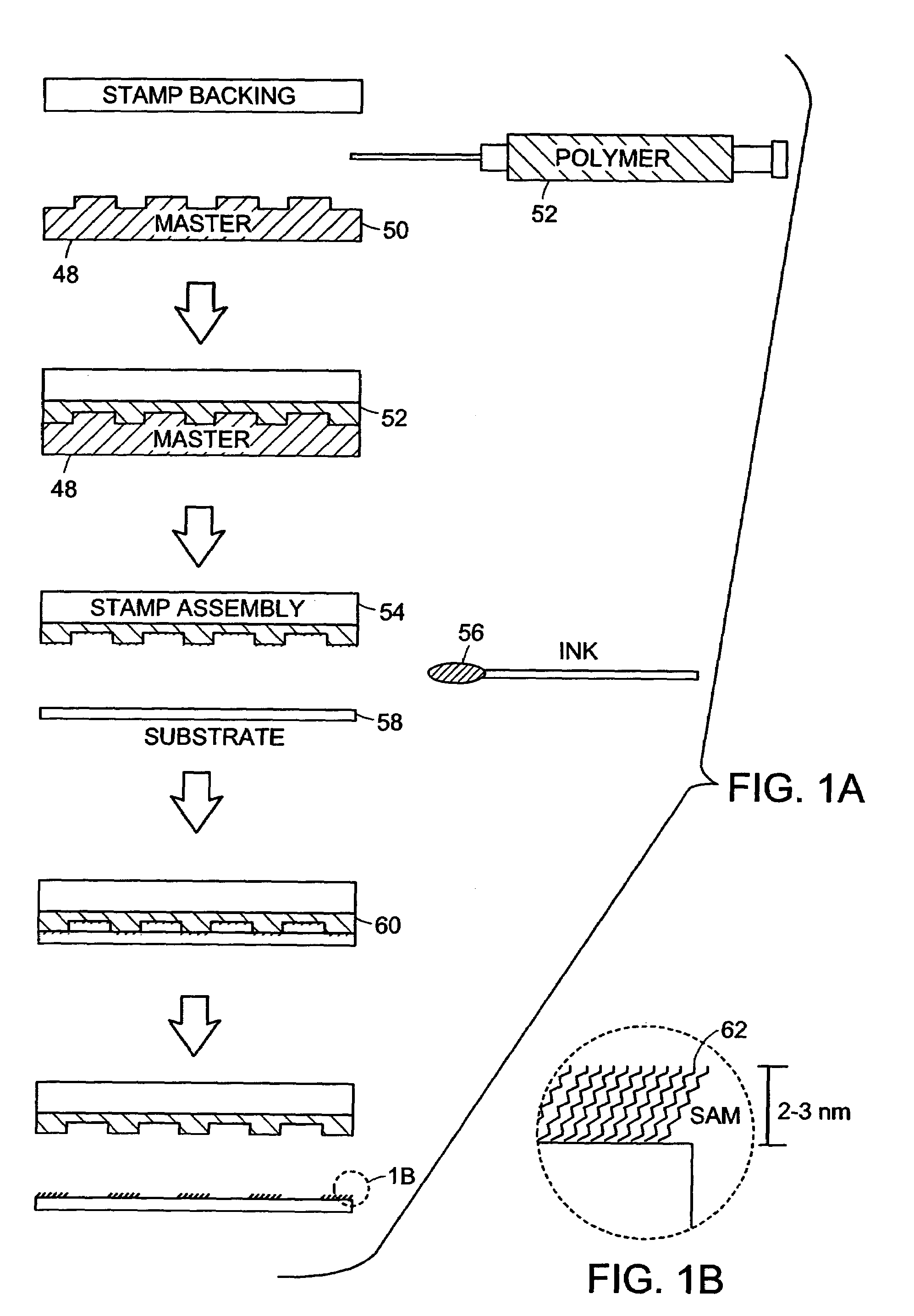

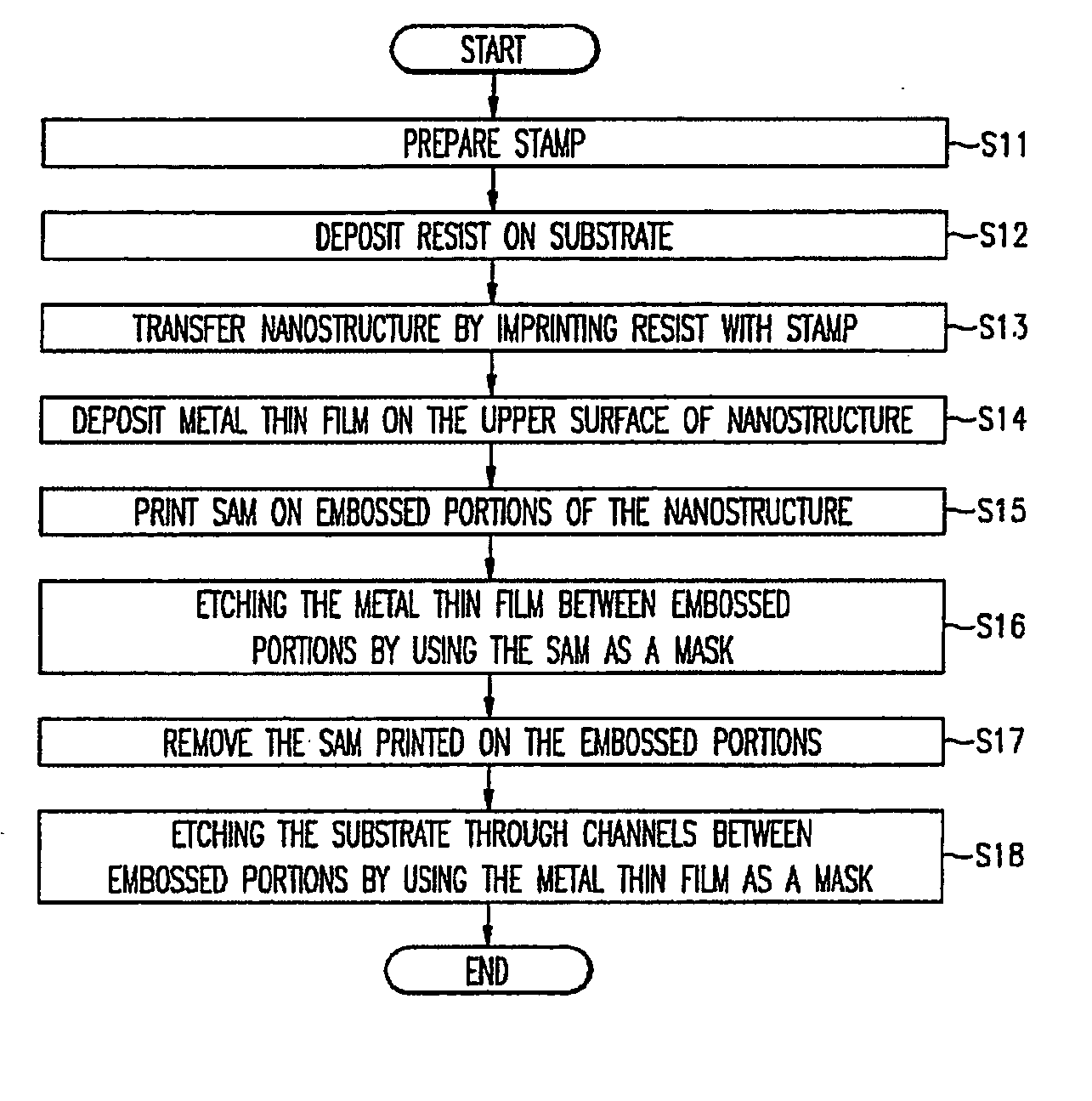

InactiveUS20050186405A1Material nanotechnologyDecorative surface effectsMicrocontact printingSelf-assembled monolayer

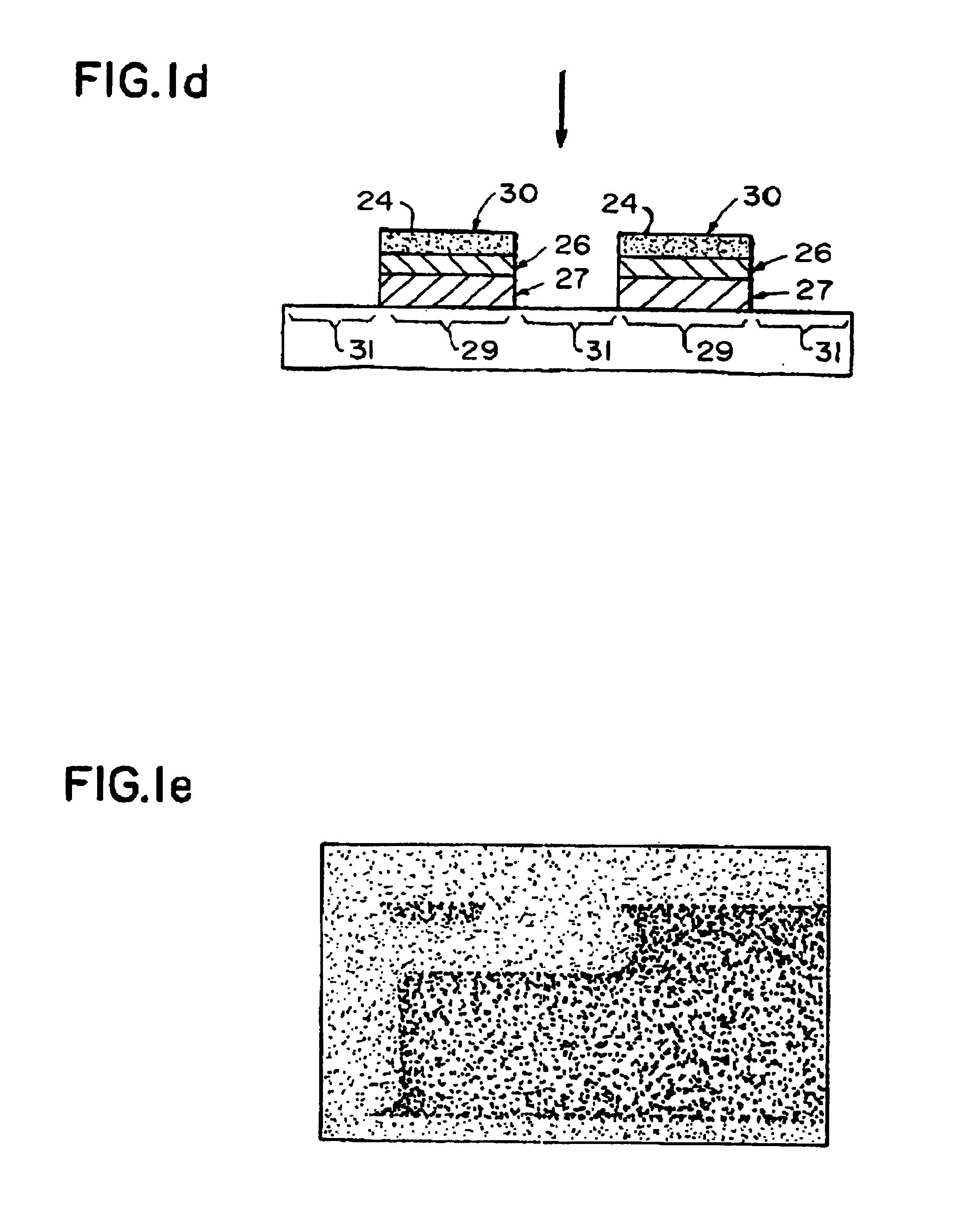

A microcontact printing method using an imprinted nanostructure is provided, wherein the microcontact printing is introduced to a nanoimprint lithography process to pattern a self-assembled monolayer (SAM) The method includes forming a nanostructure on a substrate by using the nanoimprint lithography process; and patterning the nanostructure with the microcontact printing method. The operation of patterning includes: depositing a metal thin film on the nanostructure; contacting a plate with the nanostructure to selectively print the SAM on the nanostructure, wherein the SAM is inked on the plate and the metal thin film is deposited on the nanostructure; selectively removing the metal thin film by using the SAM as a mask; removing the SAM from the nanostructure; and patterning the substrate by using the remaining metal thin film on the nanostructure as a mask.

Owner:KOREA INST OF MACHINERY & MATERIALS

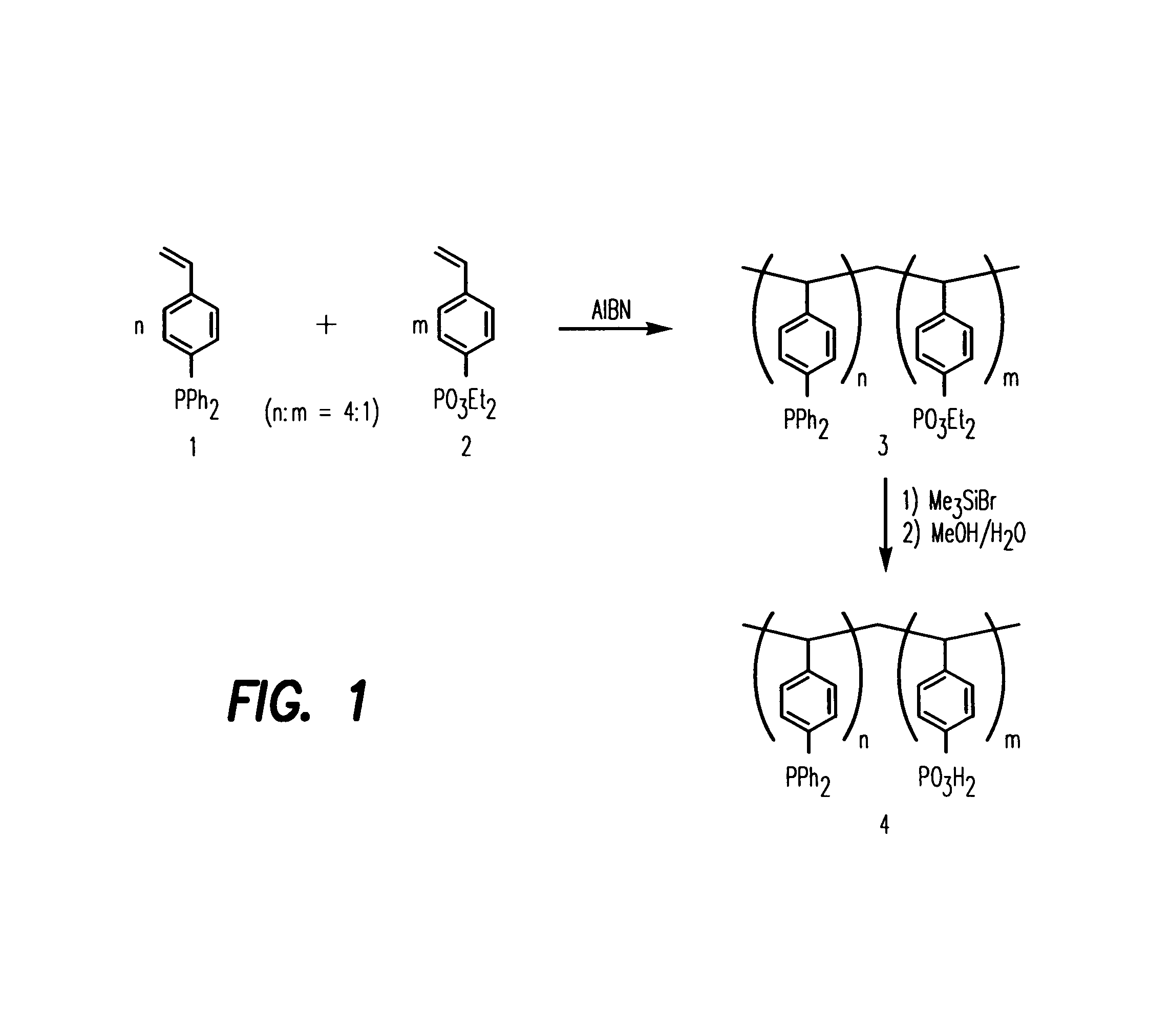

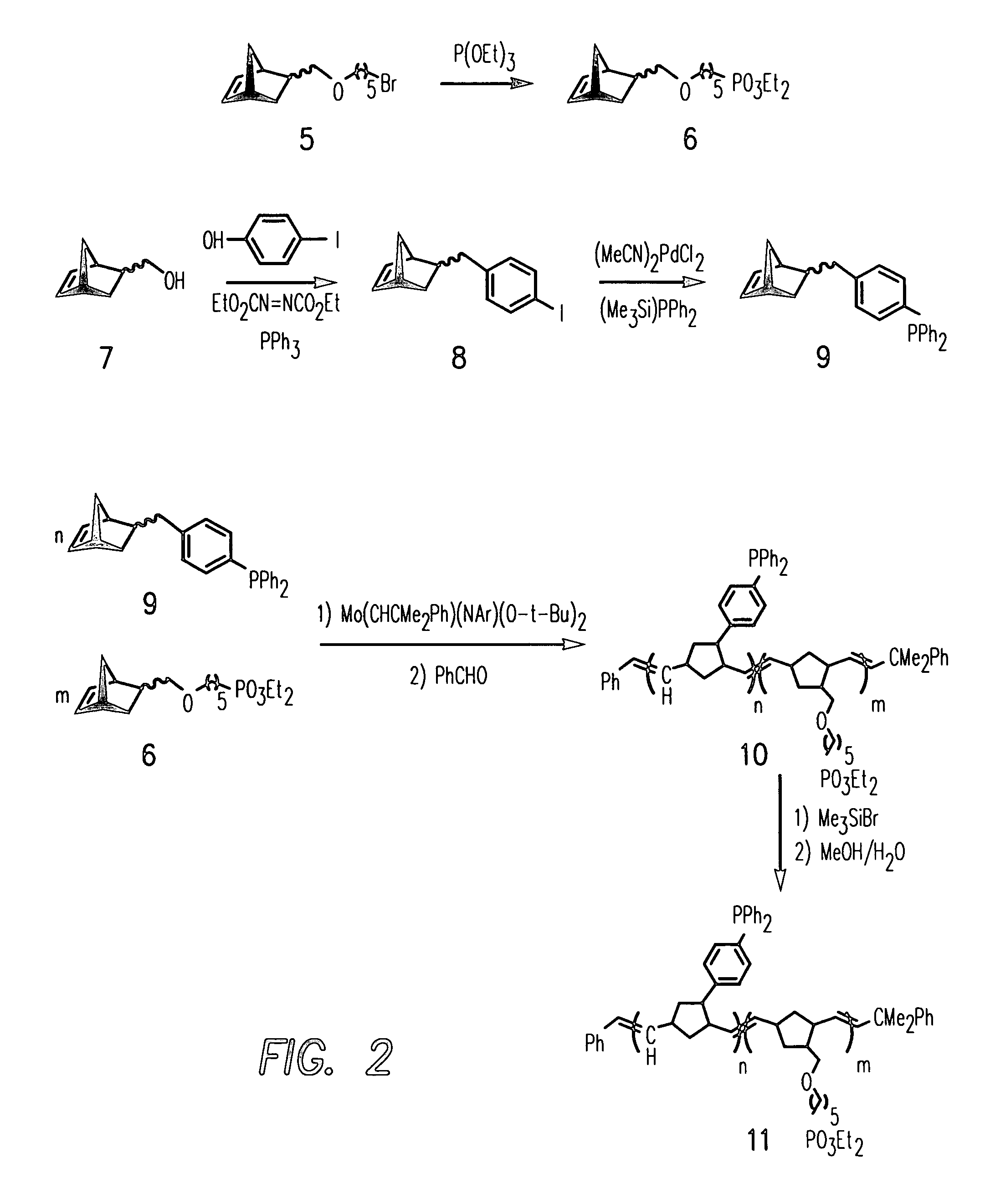

Materials and methods for immobilization of catalysts on surfaces and for selective electroless metallization

InactiveUS7087267B2Novel, convenient, rapid, and relatively inexpensiveReduce the numberOrganic-compounds/hydrides/coordination-complexes catalystsPretreated surfacesMicrocontact printingNanoparticle

A method of immobilizing a catalyst on a substrate surface involves providing novel ligating copolymers comprising functional groups capable of binding to a substrate surface and functional groups capable of ligating to catalysts such as metal ions, metal complexes, nanoparticles, or colloids; applying the ligating copolymer to a substrate surface to cause the ligating copolymer to bind thereto, and contacting the modified substrate surface with a solution of a catalyst, causing the catalyst to be ligated by the ligating copolymer and thus immobilized on the substrate surface. The ligating copolymer may be patterned on the substrate surface using a method such as microcontact printing. A method of selectively metallizing a substrate in a desired pattern involves using a ligating chemical agent comprising functional groups capable of binding to a substrate surface and functional groups capable of ligating to electroless plating catalysts; applying the ligating chemical agent to a substrate in a desired pattern using microcontact printing to cause the ligating chemical agent to bind thereto; contacting the modified substrate surface with a solution of an electroless plating catalyst, causing the catalyst to be ligated by the ligating chemical agent and thus bound to the surface; and metallizing the catalyzed regions of the substrate surface using electroless plating.

Owner:GLOBALFOUNDRIES INC

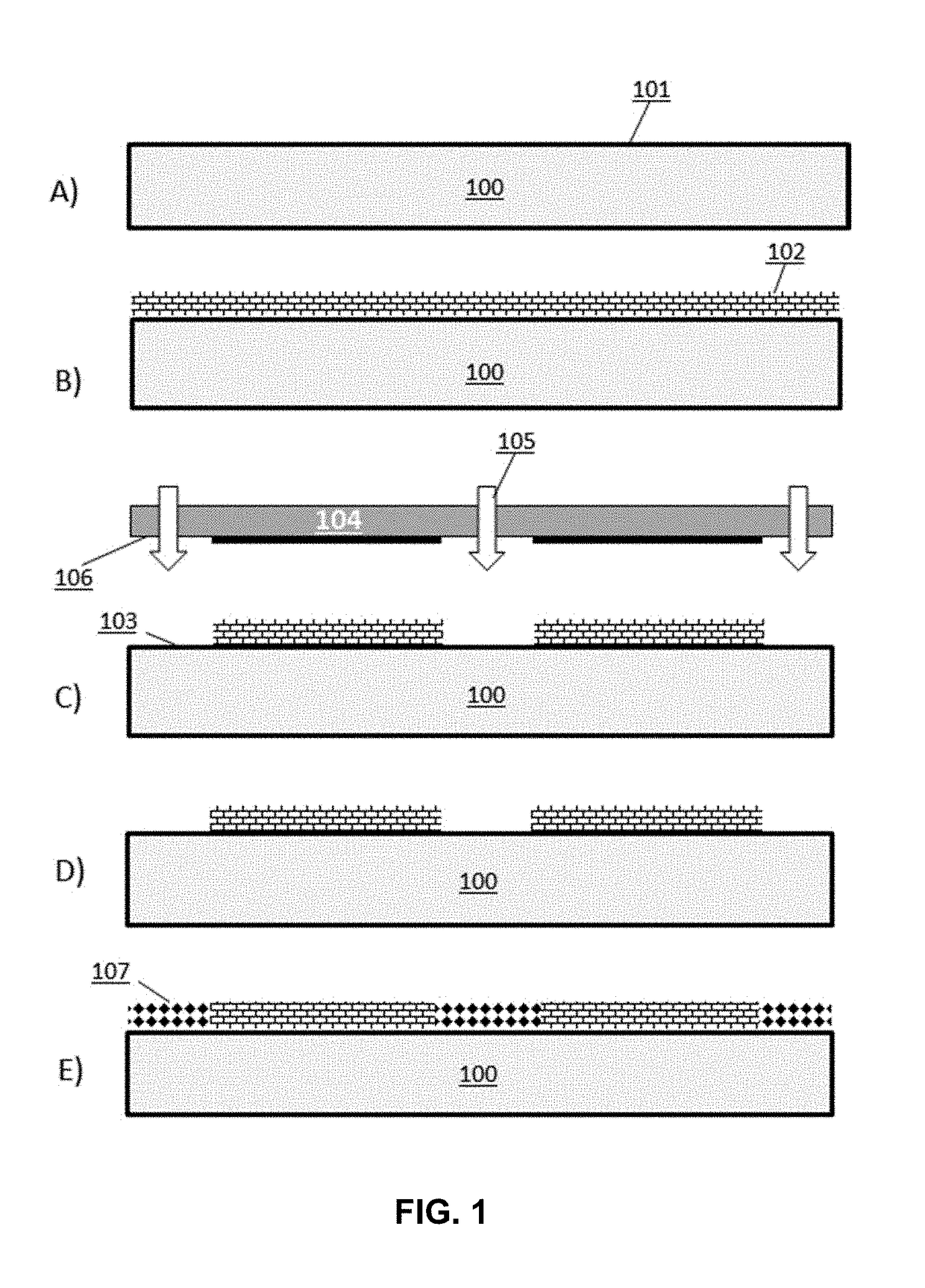

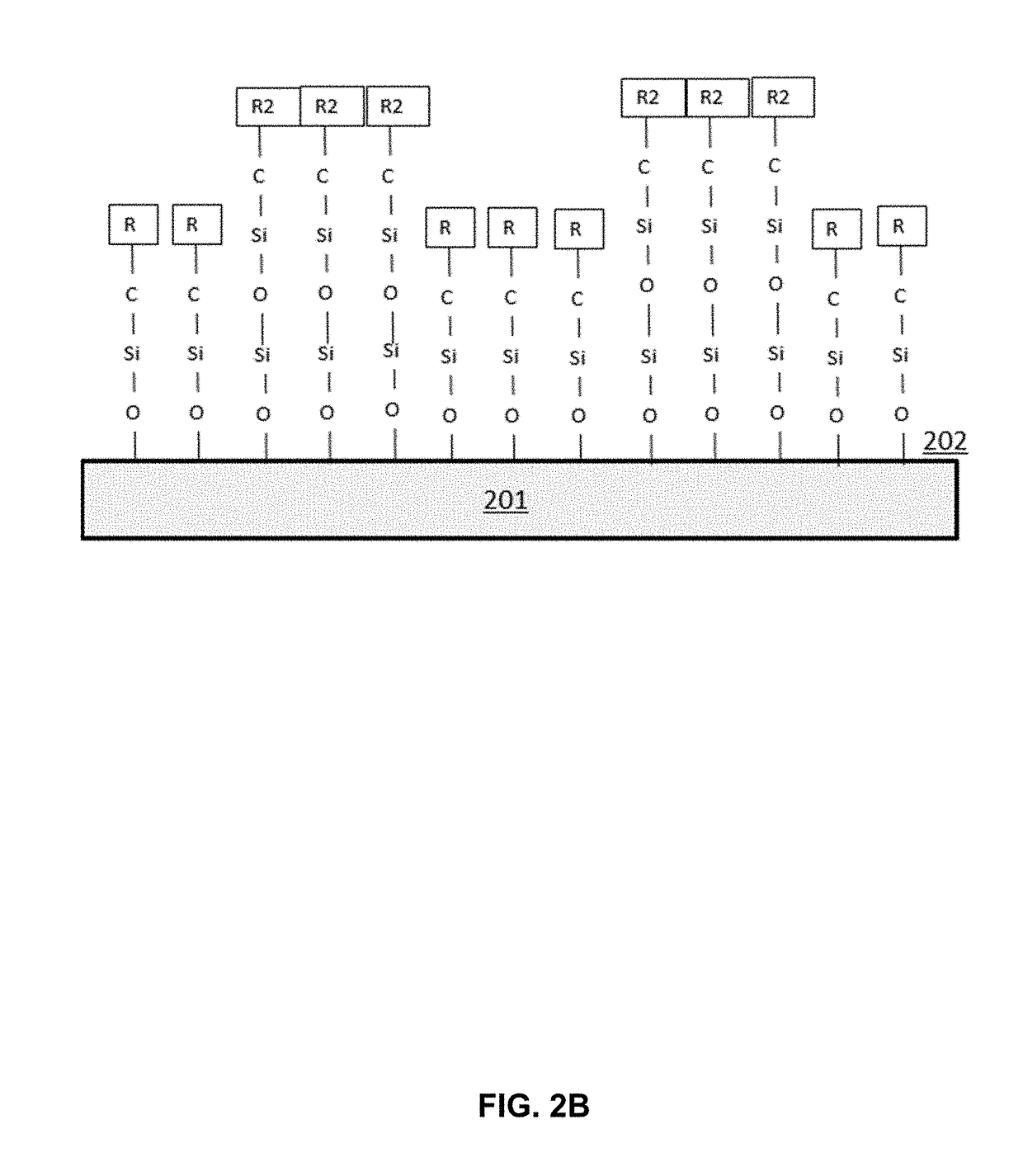

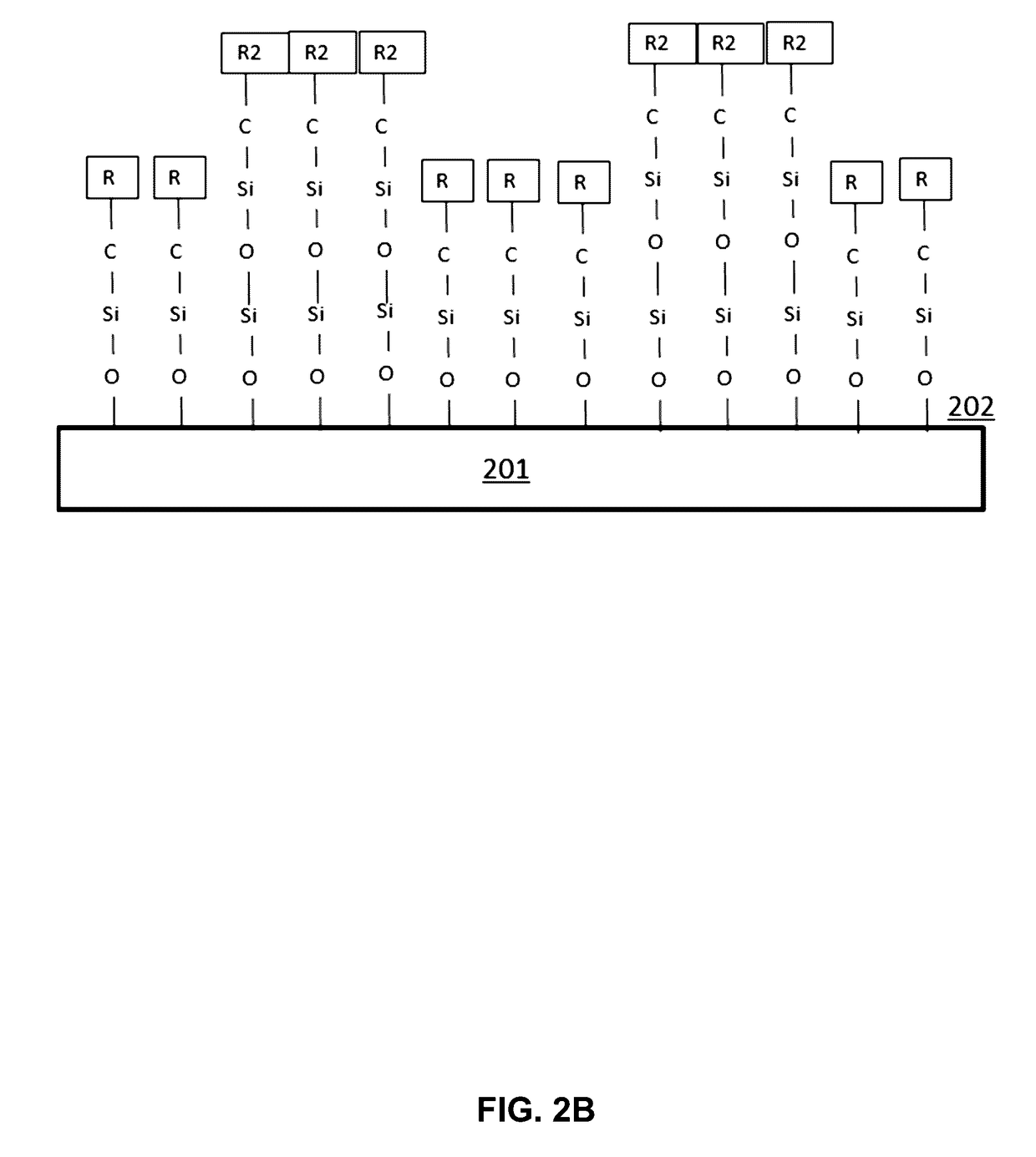

Functionalized surfaces and preparation thereof

ActiveUS9895673B2Sequential/parallel process reactionsLibrary creationMicrocontact printingBiopolymer

Compositions, devices, methods and systems are provided for differential functionalization of a surface of a structure to support biopolymer synthesis. Provided herein are processes which include use of lamps, lasers, and / or microcontact printing to add functional groups to surfaces for the efficient and uniform synthesis of oligonucleic acids.

Owner:TWIST BIOSCI

Functionalized surfaces and preparation thereof

ActiveUS20170151546A1Sequential/parallel process reactionsDNA preparationMicrocontact printingBiopolymer

Compositions, devices, methods and systems are provided for differential functionalization of a surface of a structure to support biopolymer synthesis. Provided herein are processes which include use of lamps, lasers, and / or microcontact printing to add functional groups to surfaces for the efficient and uniform synthesis of oligonucleic acids.

Owner:TWIST BIOSCI

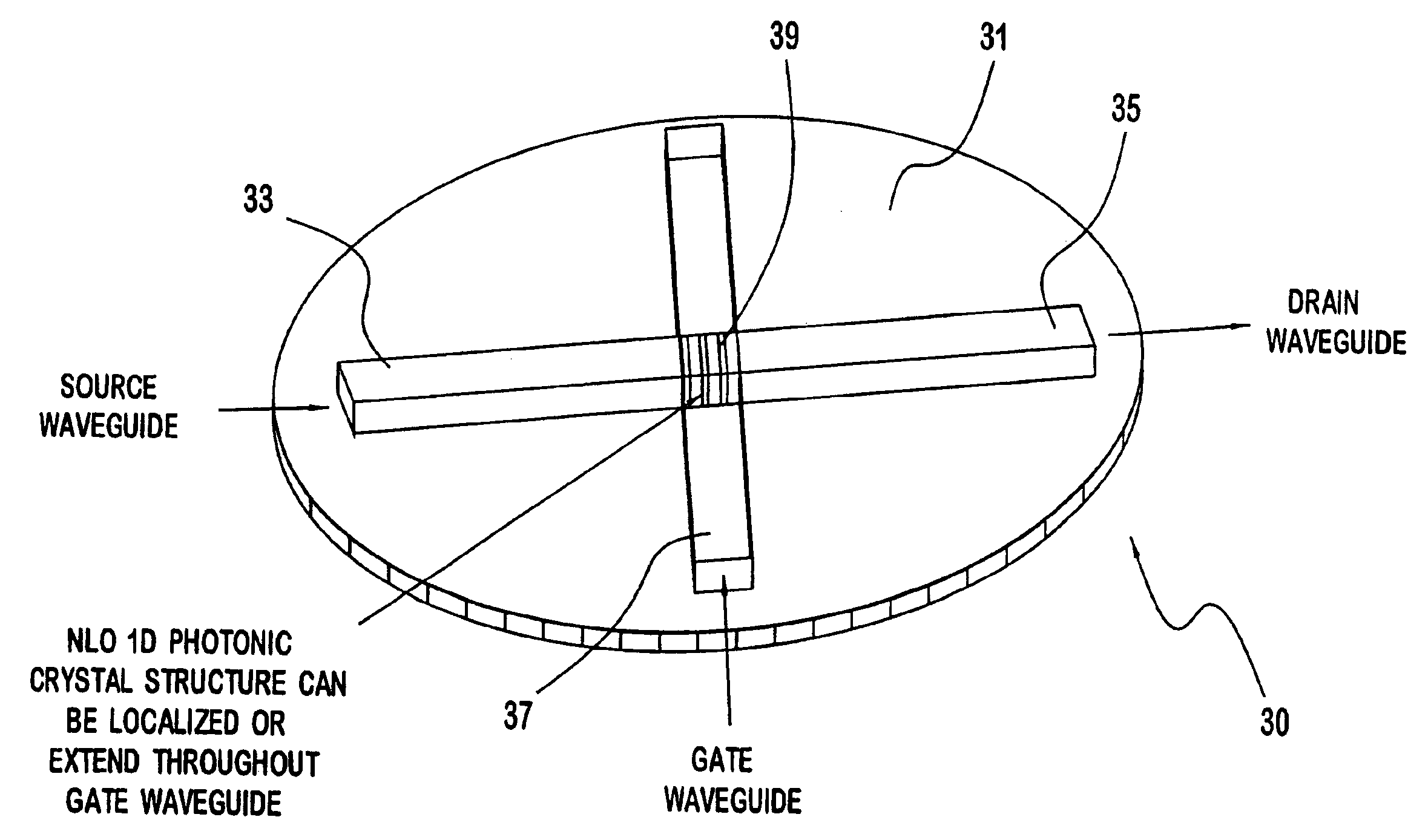

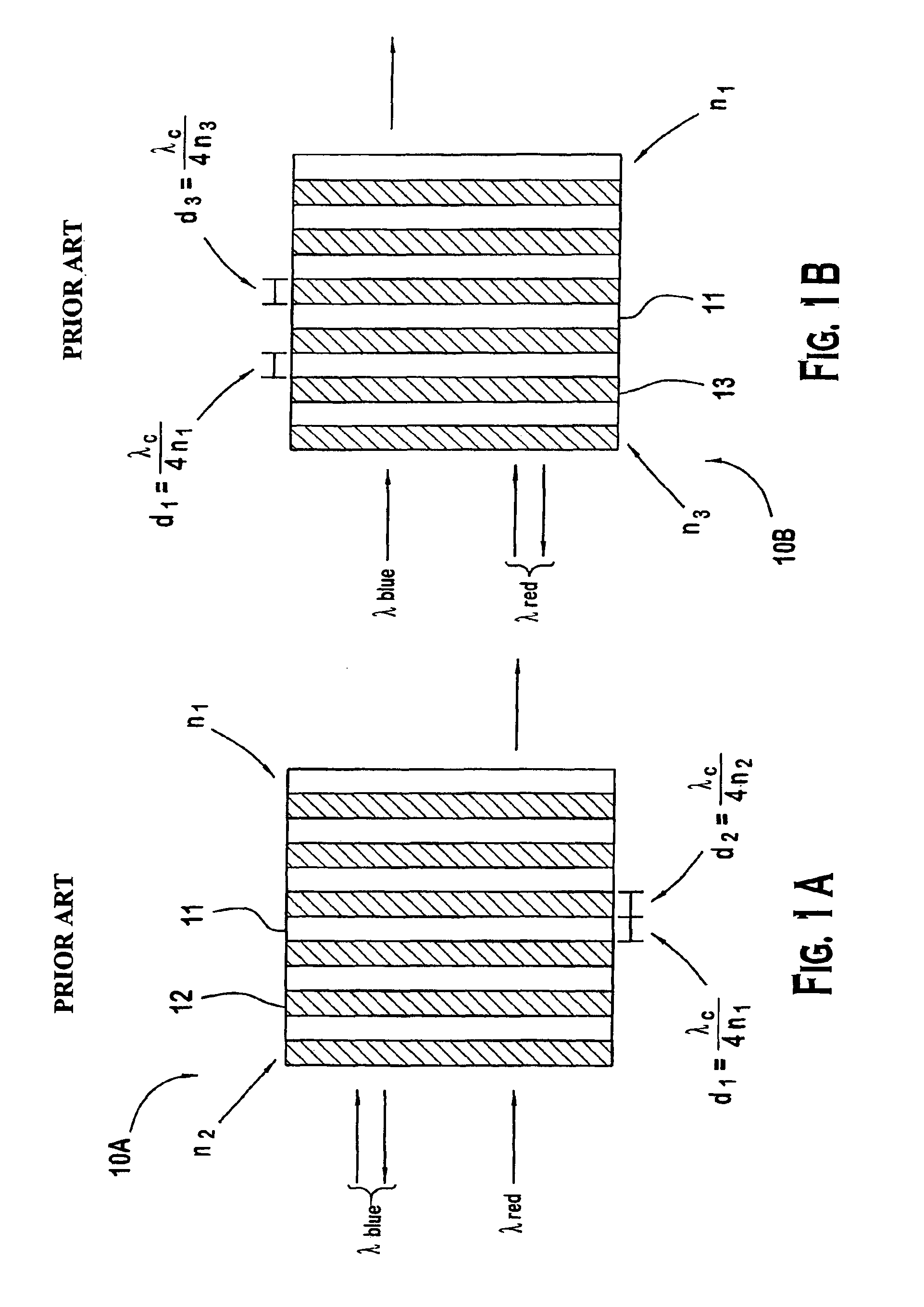

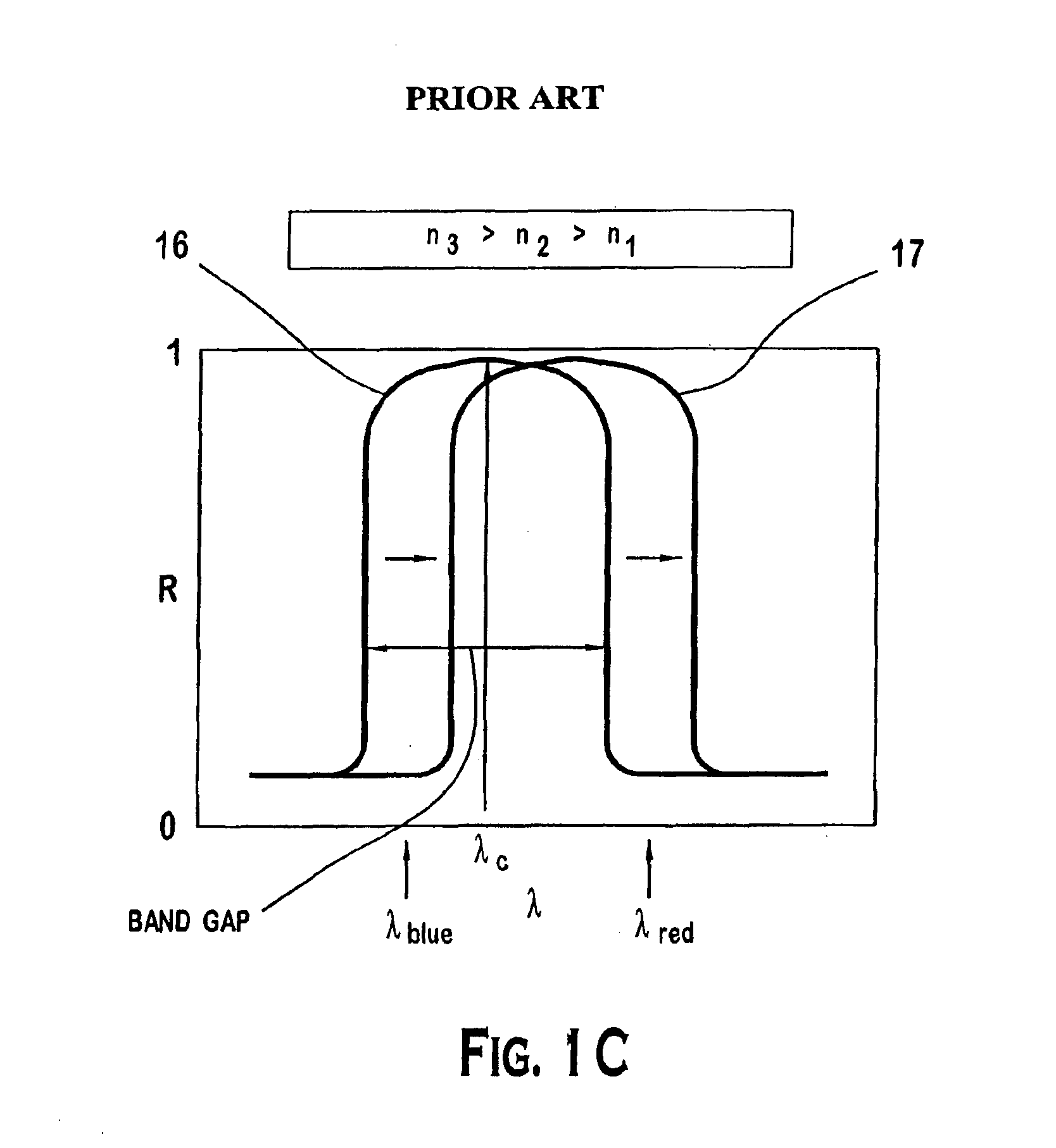

Non-linear photonic switch and method of making the same

InactiveUS6937804B2Solid-state devicesSemiconductor/solid-state device manufacturingMicrocontact printingPhotonics

A photonic switch according to the present invention may be formed using one of a selected group of non-linear optical materials. Each of the materials within this group has a refractive index that demonstrates a substantial peak as a function of wavelength, where the peak occurs at a wavelength distinct from the wavelength of the input signal. A method of producing a photonic switch according to the present invention includes fabricating source and drain waveguides using micro-molding or micro-contact printing processes, or MIMIC (micro-molding in capillaries) of a UV-curable polymer. If desired, a gate waveguide may also be formed in part by these processes. The photonic switch also includes a photonic crystal formed from non-linear optical material, which may be formed, for example, using a block copolymer and nanoparticle composite in a MIMIC or μfluidics process. Such a process may employ a functionalized mold material to align the blocks.

Owner:SURFACE LOGIX INC

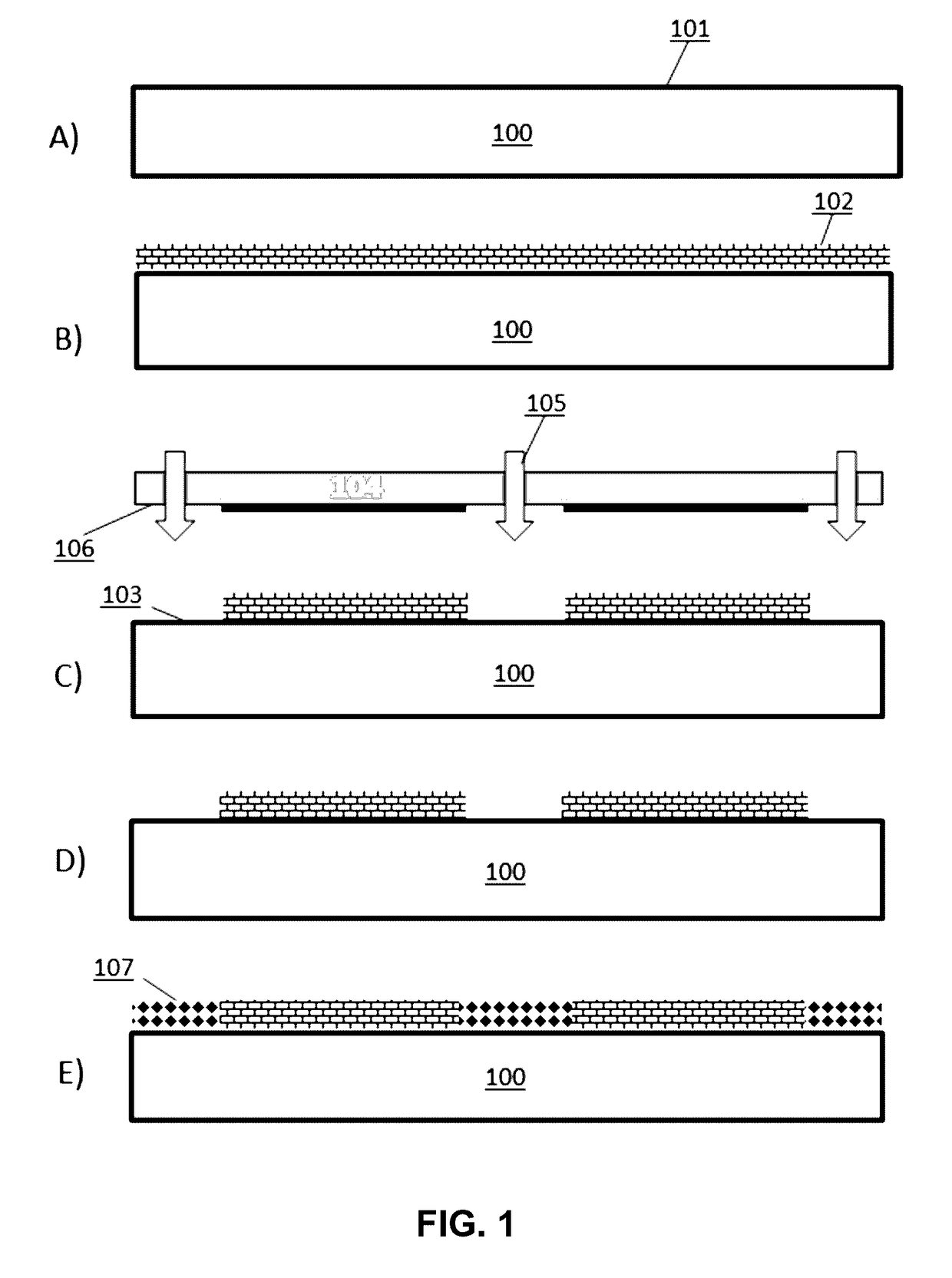

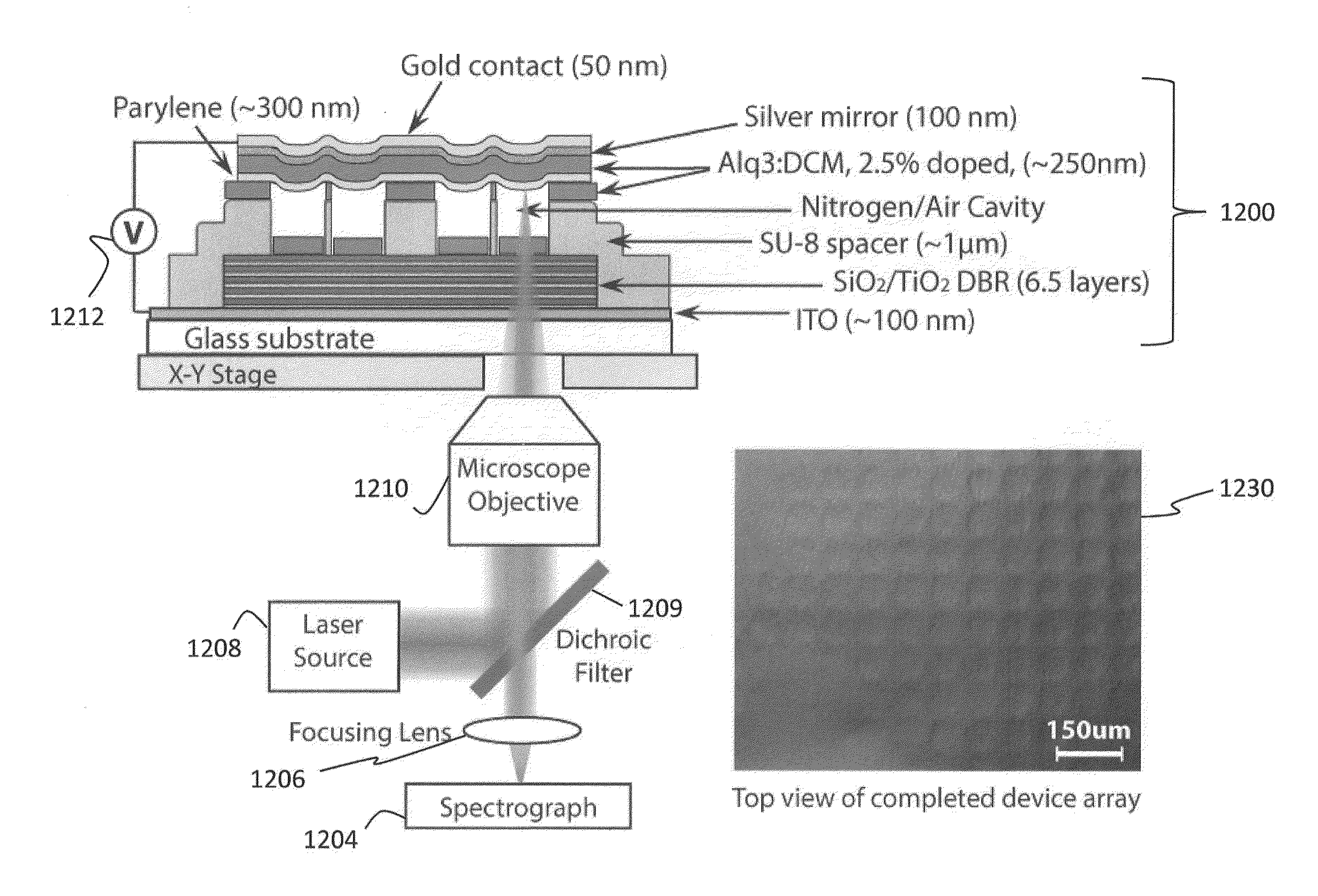

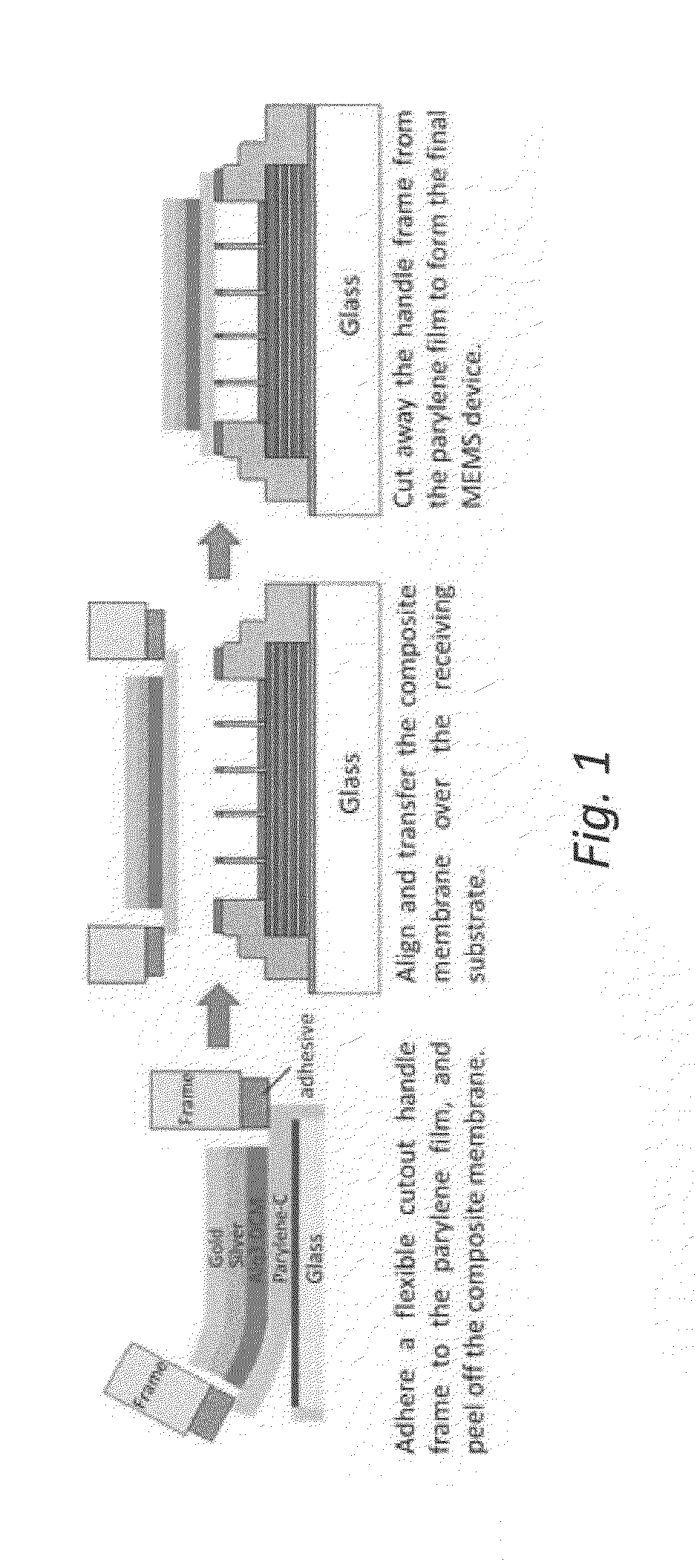

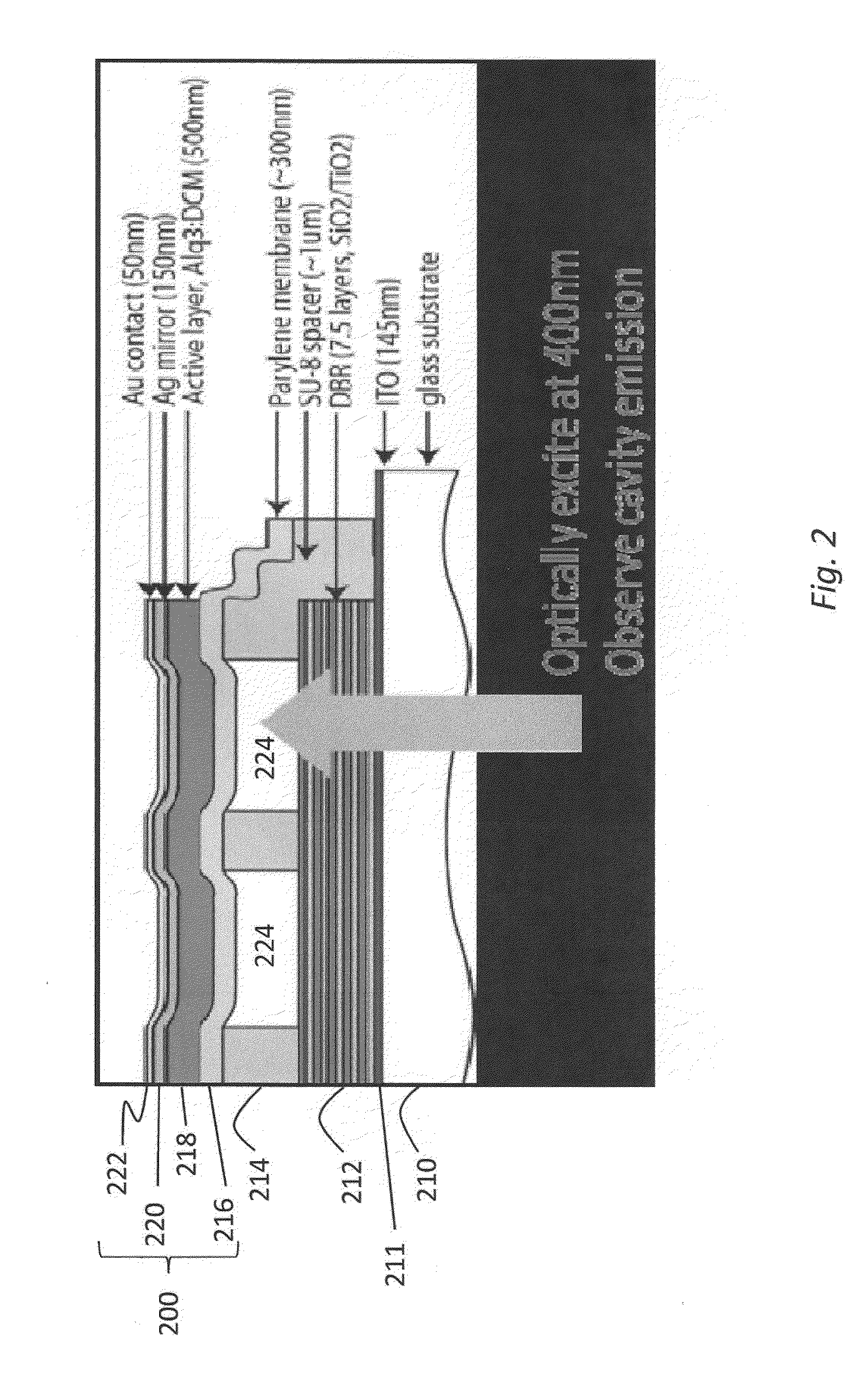

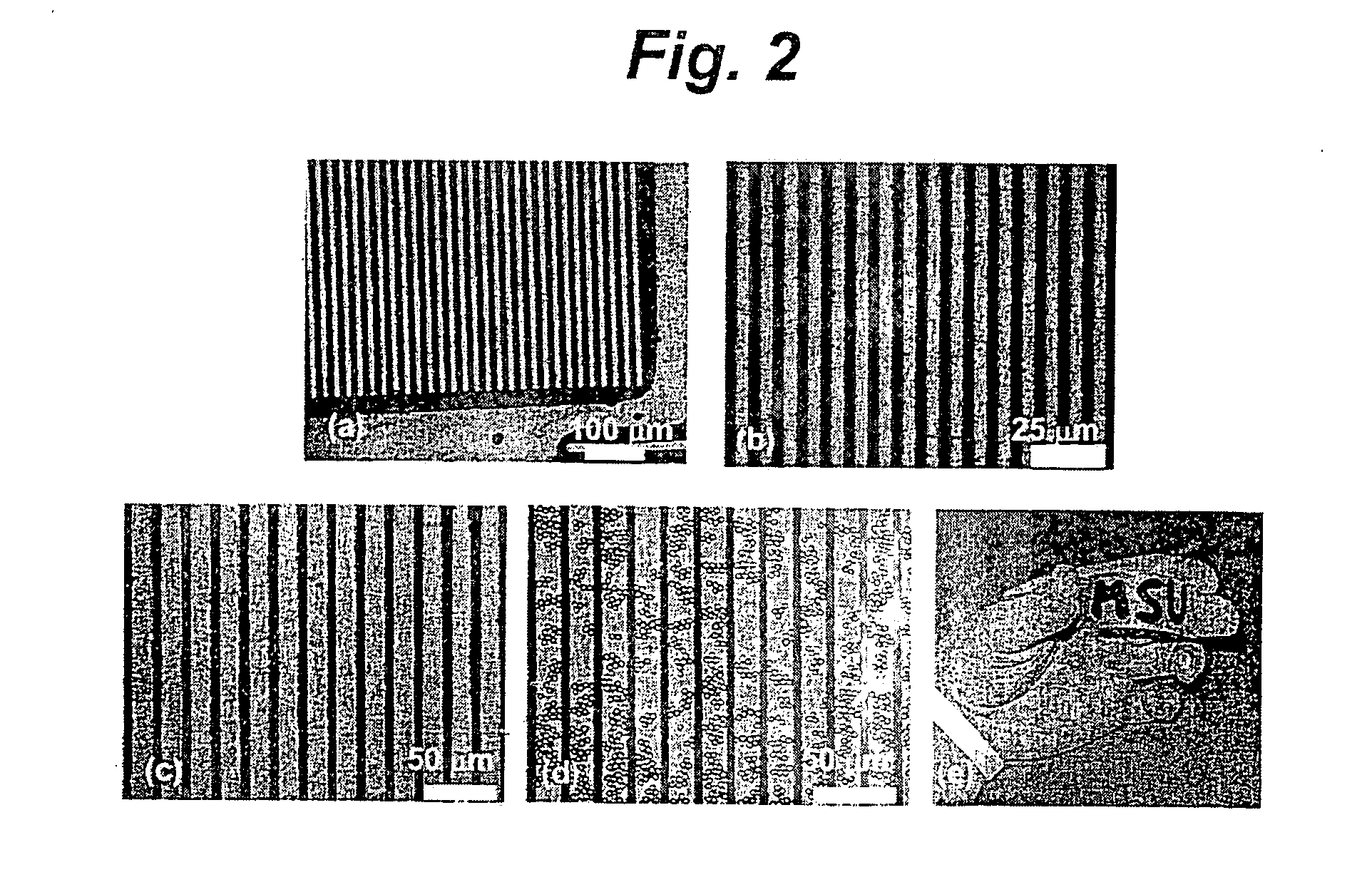

Method and applications of thin-film membrane transfer

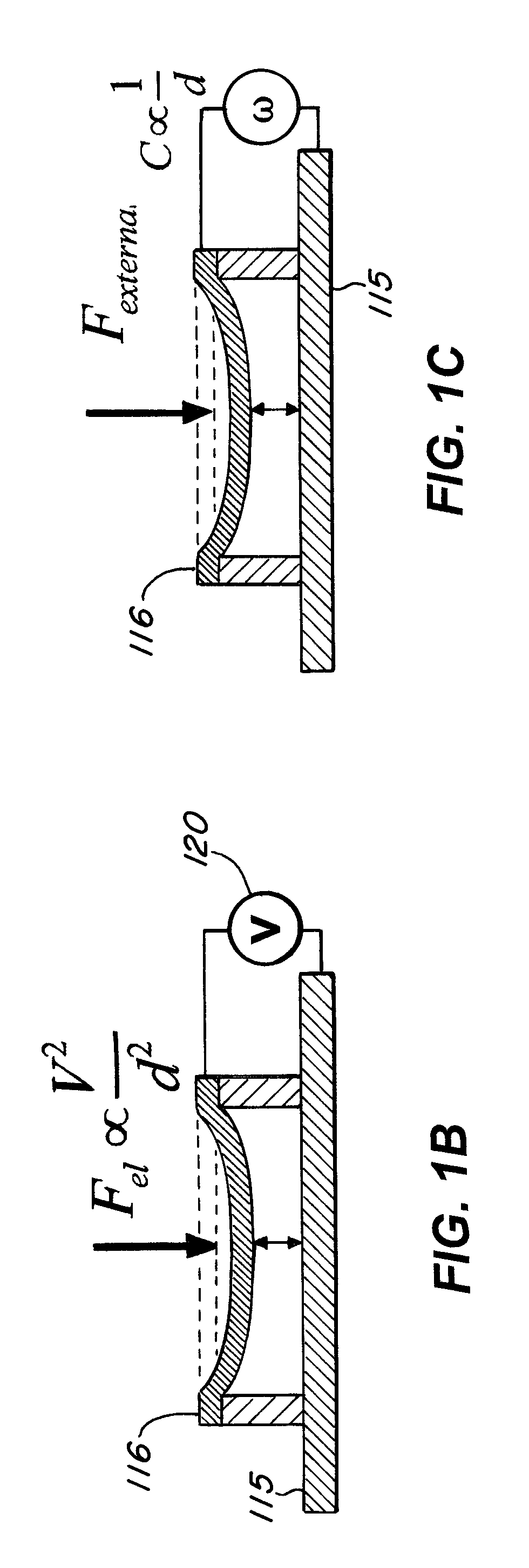

ActiveUS20150311664A1Fluid pressure measurement by electric/magnetic elementsForce measurement by measuring optical property variationMicrocontact printingExternal bias

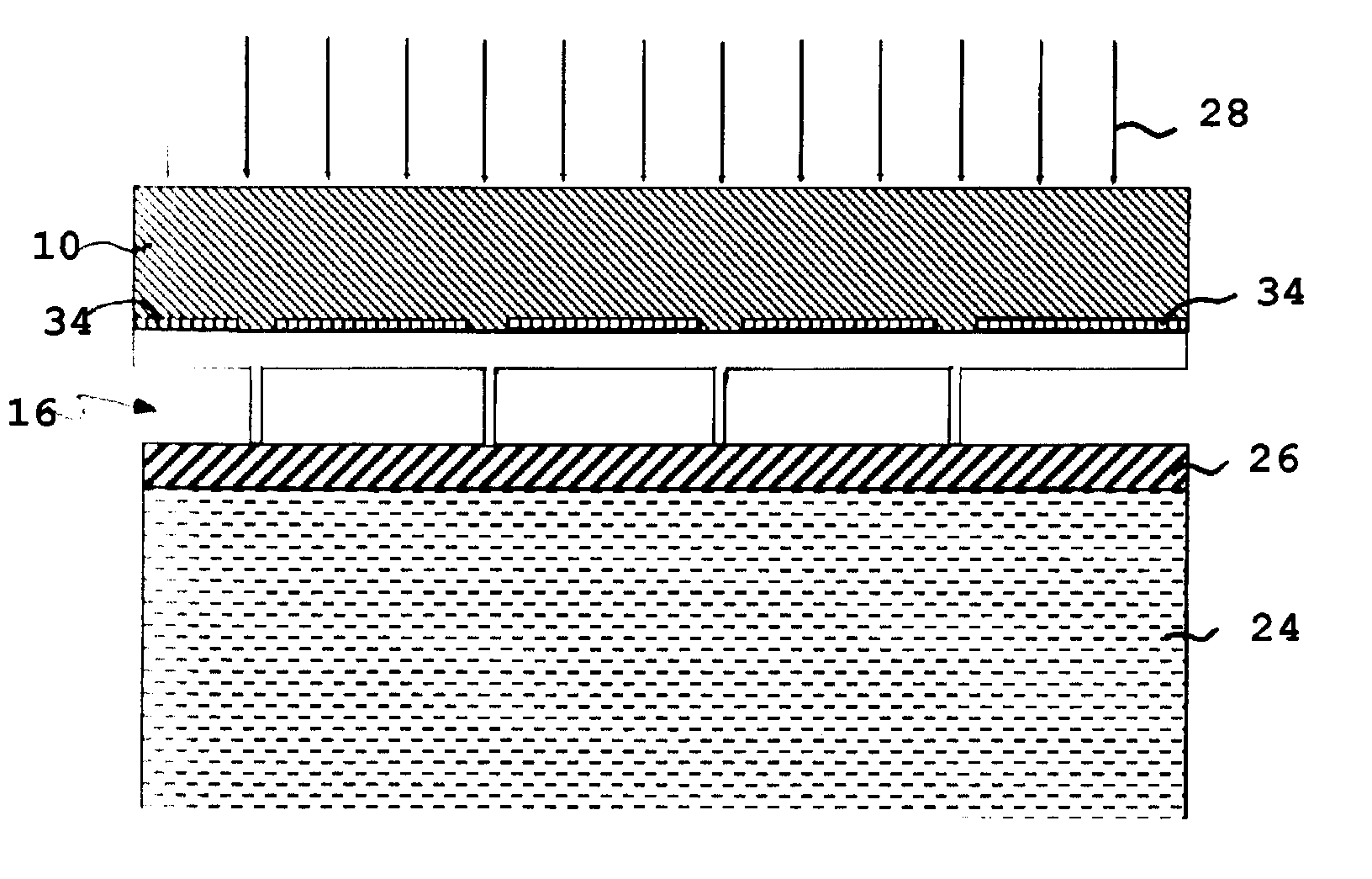

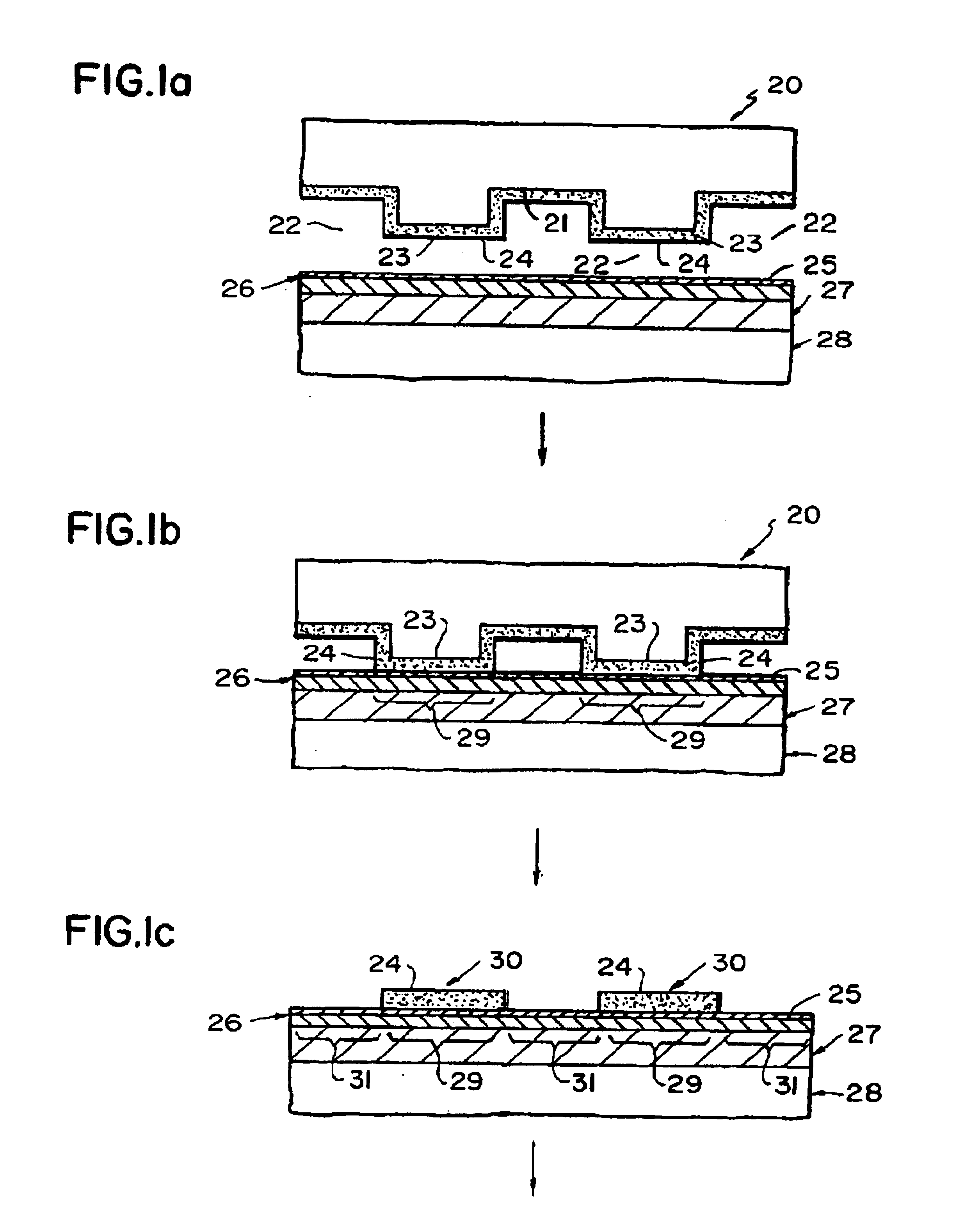

The disclosure relates to method and apparatus for micro-contact printing of micro-electromechanical systems (“MEMS”) in a solvent-free environment. The disclosed embodiments enable forming a composite membrane over a parylene layer and transferring the composite structure to a receiving structure to form one or more microcavities covered by the composite membrane. The parylene film may have a thickness in the range of about 100 nm-2 microns; 100 nm-1 micron, 200-300 nm, 300-500 nm, 500 nm to 1 micron and 1-30 microns. Next, one or more secondary layers are formed over the parylene to create a composite membrane. The composite membrane may have a thickness of about 100 nm to 700 nm to several microns. The composite membrane's deflection in response to external forces can be measured to provide a contact-less detector. Conversely, the composite membrane may be actuated using an external bias to cause deflection commensurate with the applied bias. Applications of the disclosed embodiments include tunable lasers, microphones, microspeakers, remotely-activated contact-less pressure sensors and the like.

Owner:MASSACHUSETTS INST OF TECH

Microcontact printing

InactiveUS20070261574A1Generate undesired patterning resultsControl distortionMaterial nanotechnologyMechanical working/deformationMicrocontact printingEngineering

A microcontact printing tool having a print unit including a stamp head with a stamp and a wafer chuck for retaining a substrate. The stamp contained by the stamped head movable relative to the substrate by an actuator and a stage. A plurality of sensors detect the position of the stamp relative to substrate. A method of using the printing tool that includes a real-time feedback for consistent and accurate application of force during the printing of the substrate. The stamp head includes a pressure chamber carrying the stamp. The stamp backing is deflected prior to contact of the stamp with the substrate to form a minimum point and the stamp backing and the stamp is returned to a plane to create a printing propagation contact. An apparatus has a master backing and a stamping backing in close proximity and the stamp material drawn in through a vacuum. The stamp is separated from the master by use of a parting fluid.

Owner:MASSACHUSETTS INST OF TECH

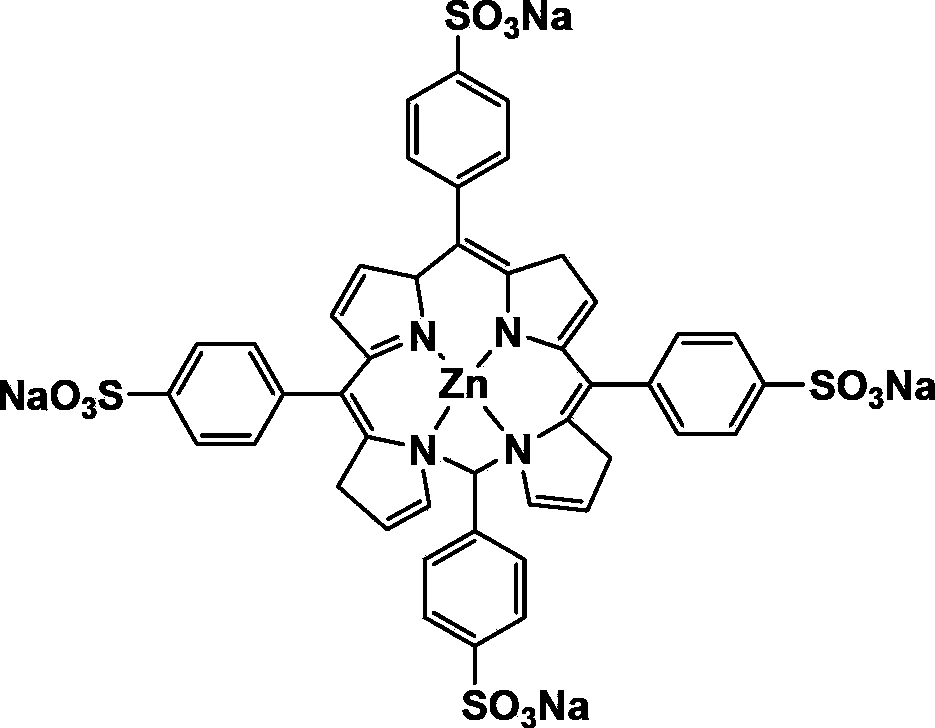

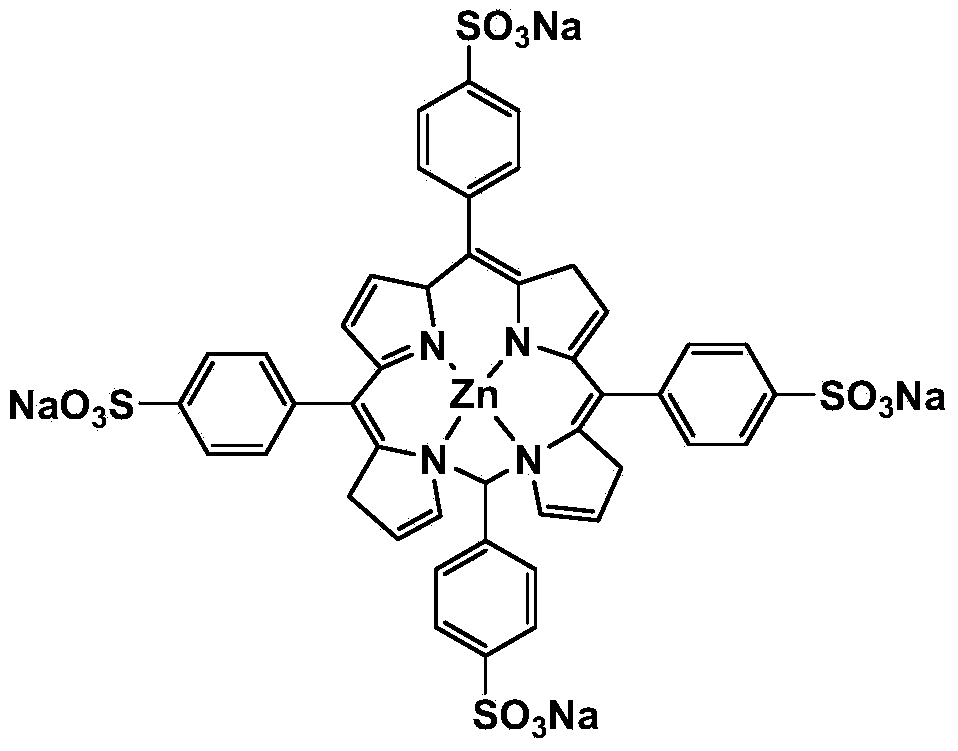

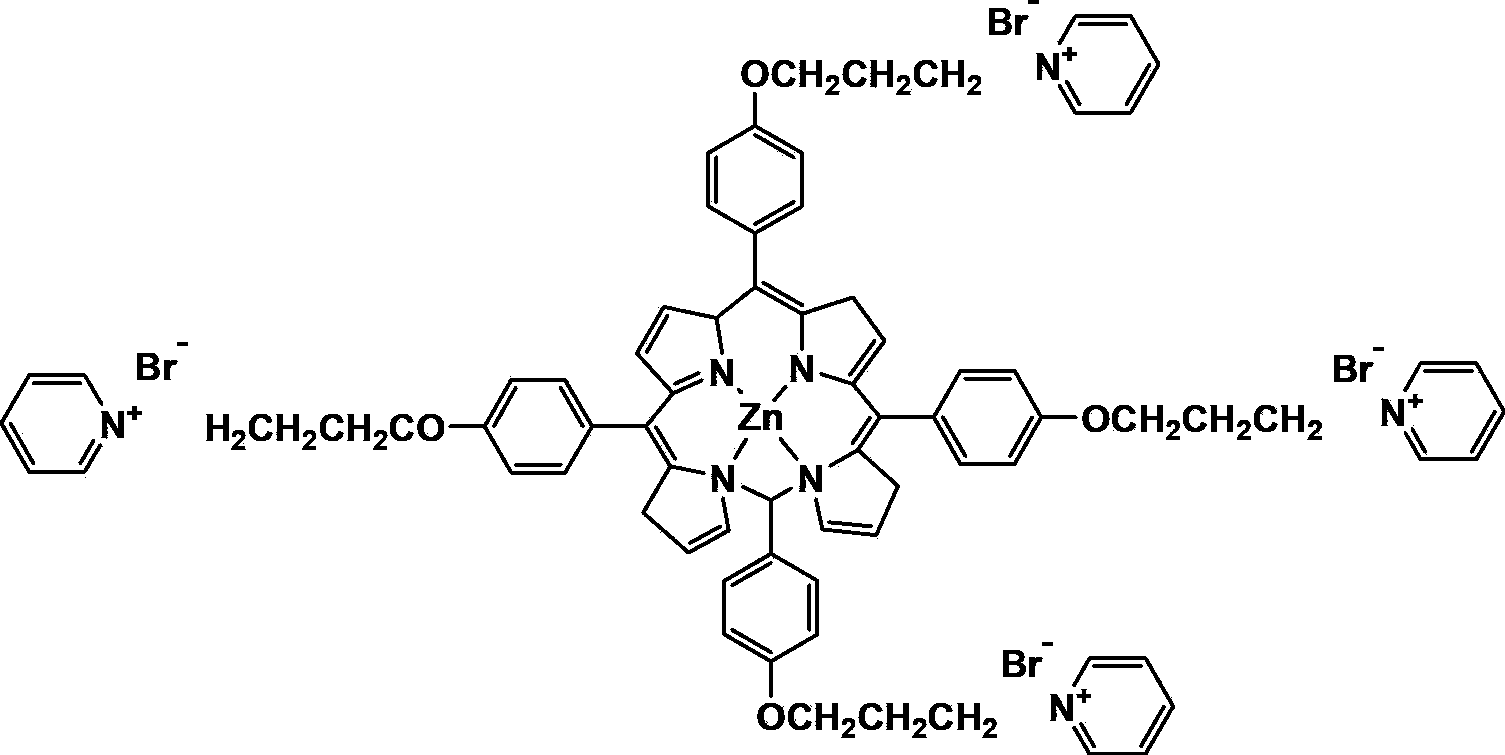

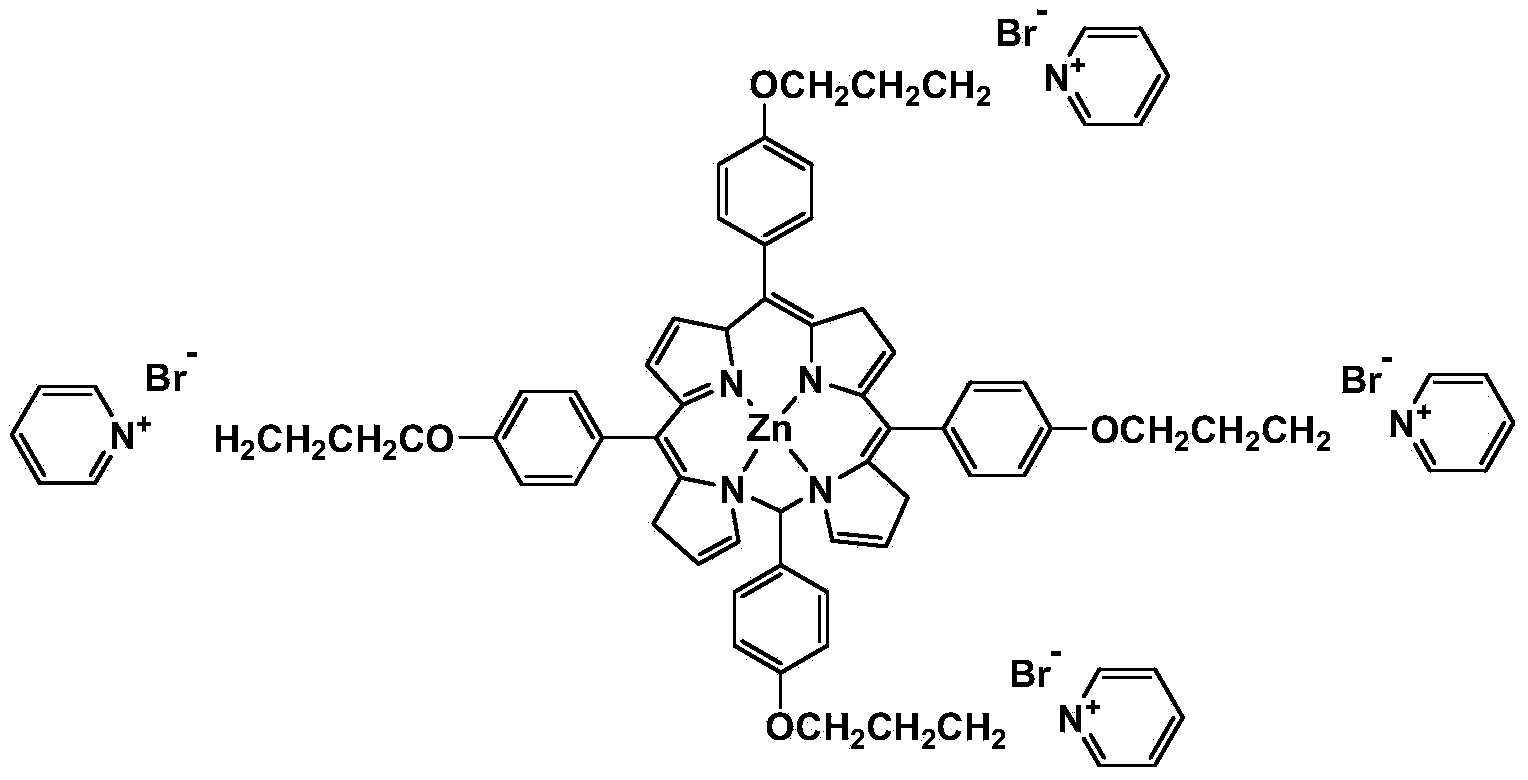

Use of water-soluble tetra sodium sulfonate phenyl porphyrin metal complex in microcontact printing

ActiveCN102964910BReduce usageSoluble in waterInksLiquid/solution decomposition chemical coatingSolubilityMicrocontact printing

The invention discloses a method for applying a water-soluble tetra sodium sulfonate phenyl porphyrin metal complex to microcontact printing. The method comprises the following specific steps of: 1) substrate carboxylation; 2) preparation of 5,10,15,20-tetra sodium sulfonate phenyl zinc porphyrin water solution; 3) microcontact printing; and 4) chemical plating. The method has the beneficial effects that 1. the obtained pattern is exquisite and fine and a new thought is provided for the microcontact printing industry; and 2. as a printing agent, the 5,10,15,20-tetra sodium sulfonate phenyl zinc porphyrin water solution has water solubility, can reduce use of organic solvents, has the advantages of environment-friendliness, low cost and stability and has great potential in industrial application.

Owner:南通博亿峰都新材料科技有限公司

Application of zinc phthalocyanine complex as ink in micro-contact printing

InactiveCN102516841BReduce bloatReduce distortionInksOther printing apparatusMicrocontact printingPolyimide substrate

The invention discloses application of a zinc phthalocyanine complex as ink in micro-contact printing. The 2-propyl alcohol solution of 8(Octanohydroxamic)-zinc phthalocyanine serves as micro-contact printing ink; the pattern of a Polydimethylsiloxane (PDMS) seal is transferred to the surface of carboxylation polyethylene terephthalate, polyethylene naphthalate or polyimide substrate; and a delicate metal pattern is obtained on the substrate with a chemical plating method. The application of the zinc phthalocyanine complex as the ink in the micro-contact printing has the beneficial effect that the common phenomena of pattern inflation and pattern torsion in the micro-contact printing can be reduced by the phthalocyanine metal complex ink, and the phthalocyanine metal complex ink has a lowpreparation cost and great potential in the industrial application and is stable.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Use of water-soluble zinc porphyrin complex in microcontact printing

ActiveCN102964909BReduce usageSoluble in waterInksLiquid/solution decomposition chemical coatingMicrocontact printingChemical plating

Owner:西安方舟包装工业有限公司

Method And Apparatus for Microcontact Printing of MEMS

ActiveUS20100188796A1Enabling MEMS fabricationFast preparationLamination ancillary operationsLaminationMicrocontact printingEngineering

The embodiments disclosed herein are directed to fabrication methods useful for creating MEMS via microcontact printing by using small organic molecule release layers. The disclose method enables transfer of a continuous metal film onto a discontinuous platform to form a variable capacitor array. The variable capacitor array can produce mechanical motion under the application of a voltage. The methods disclosed herein eliminate masking and other traditional MEMS fabrication methodology. The methods disclosed herein can be used to form a substantially transparent MEMS having a PDMS layer interposed between an electrode and a graphene diaphragm.

Owner:MASSACHUSETTS INST OF TECH

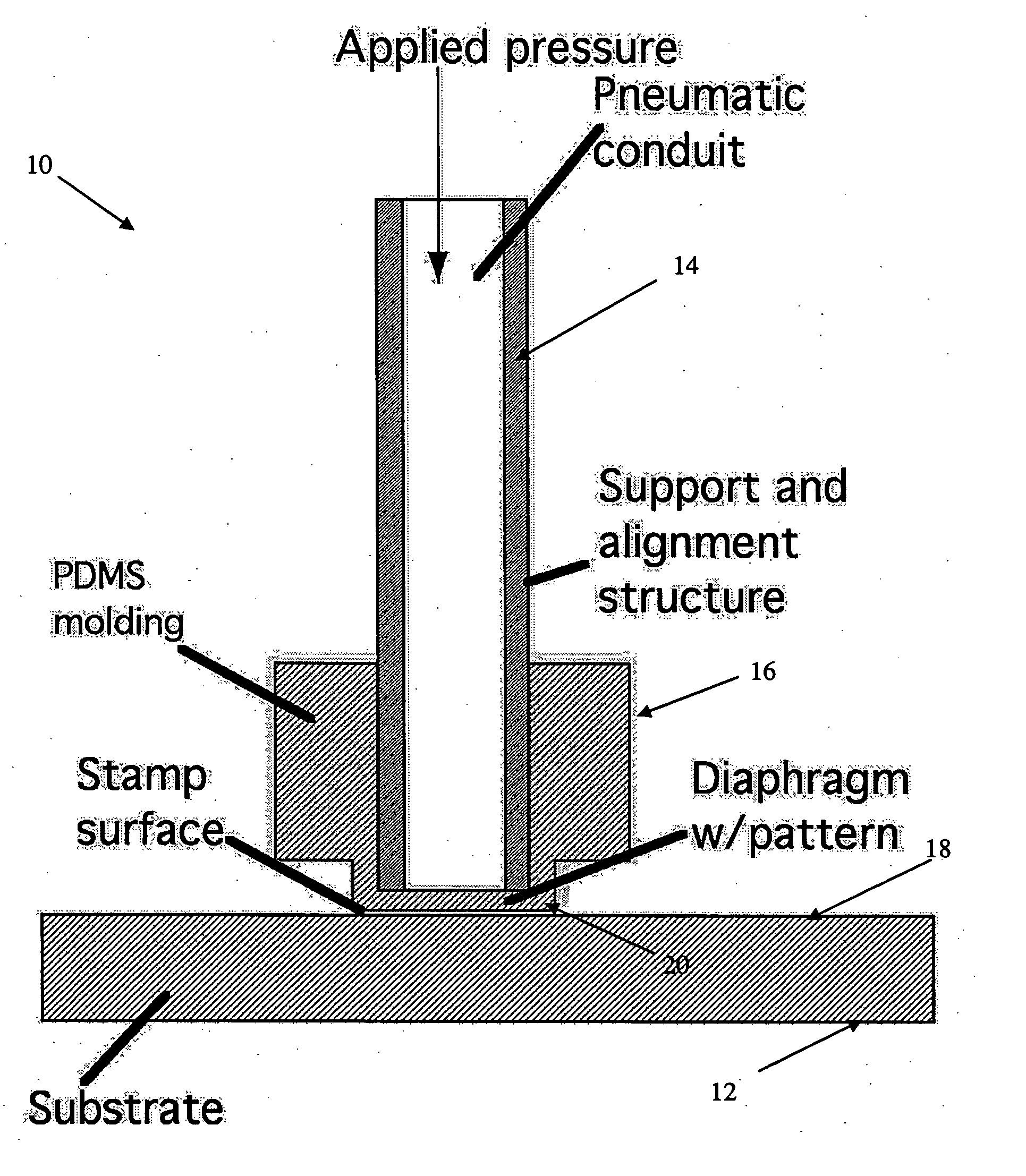

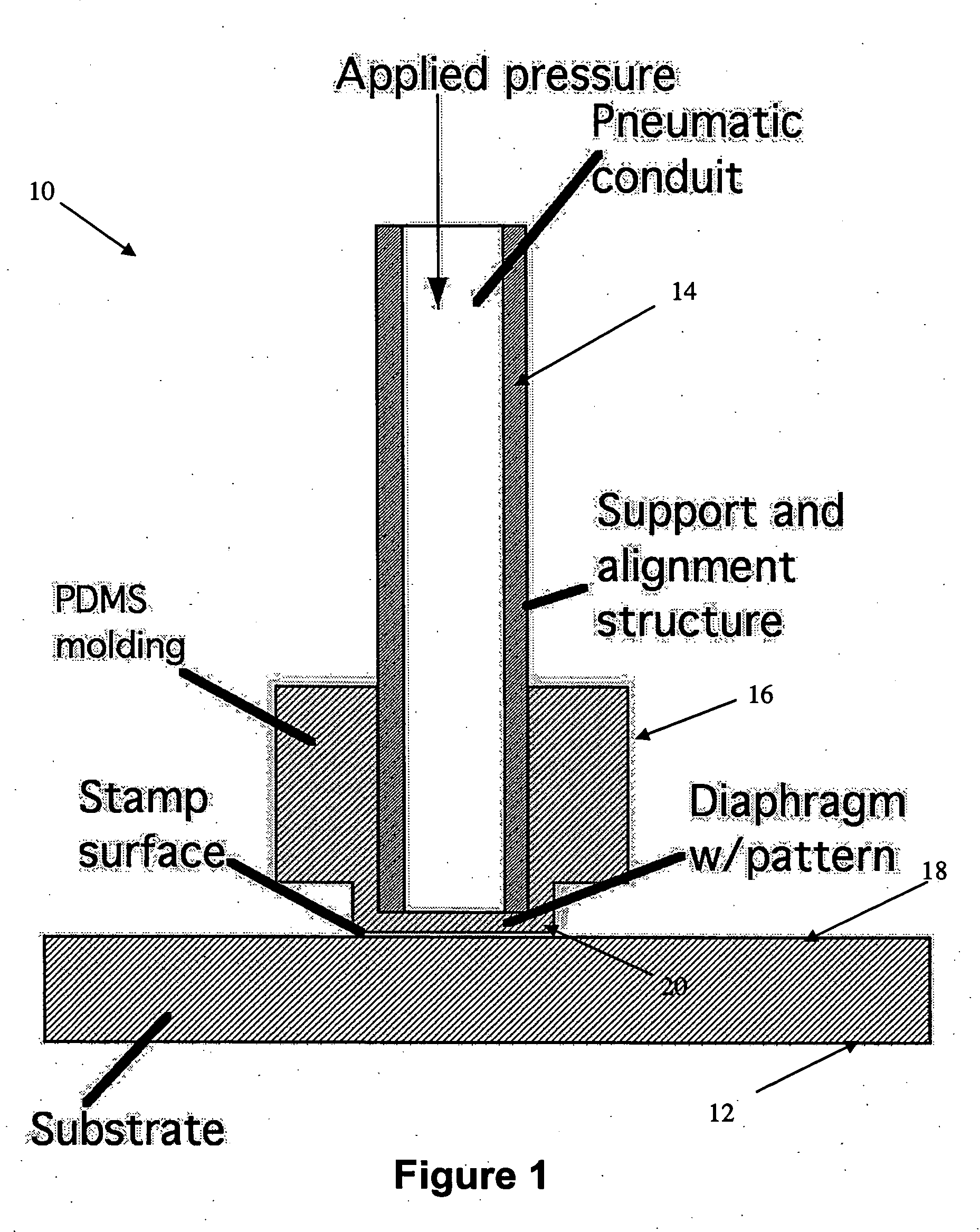

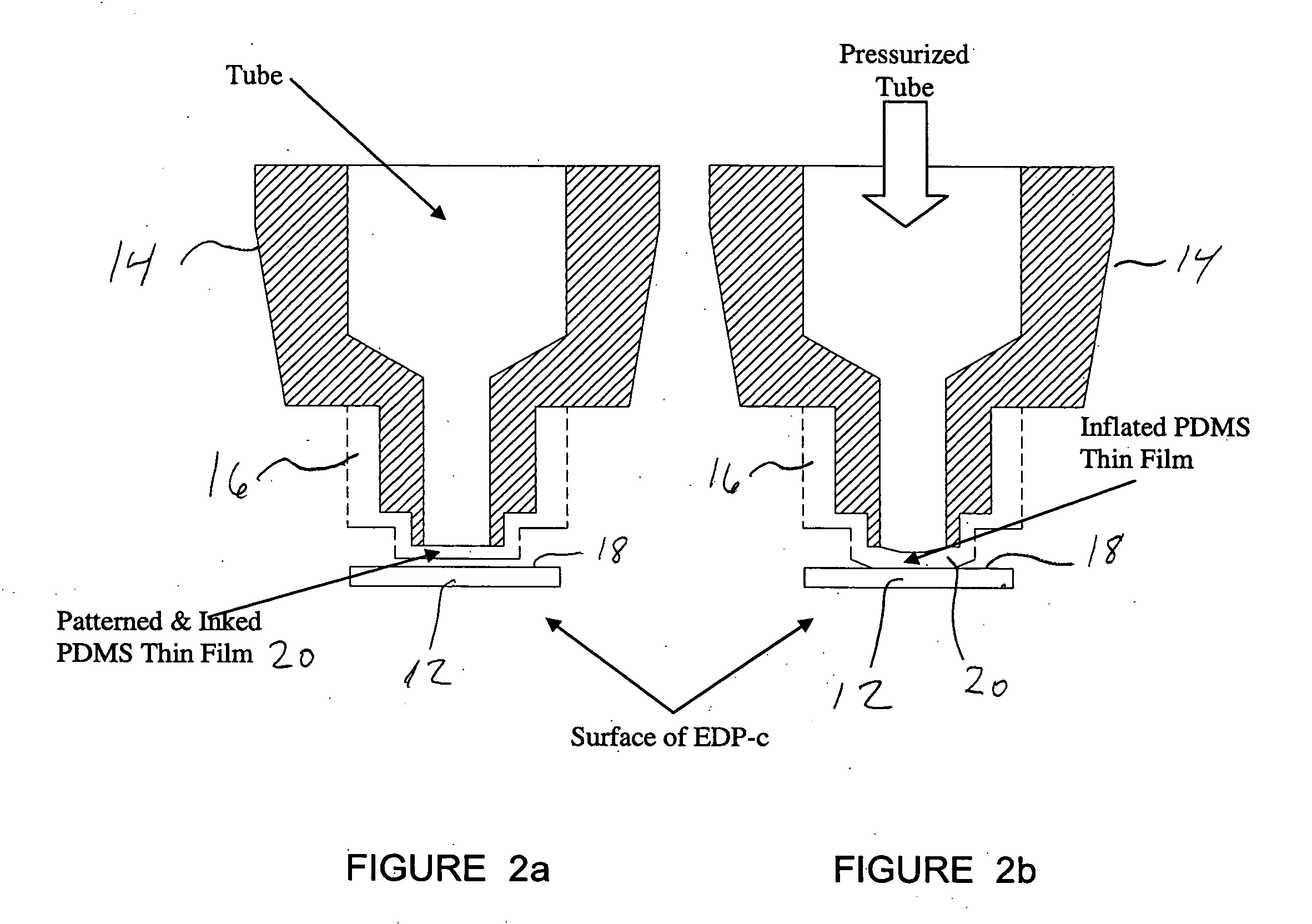

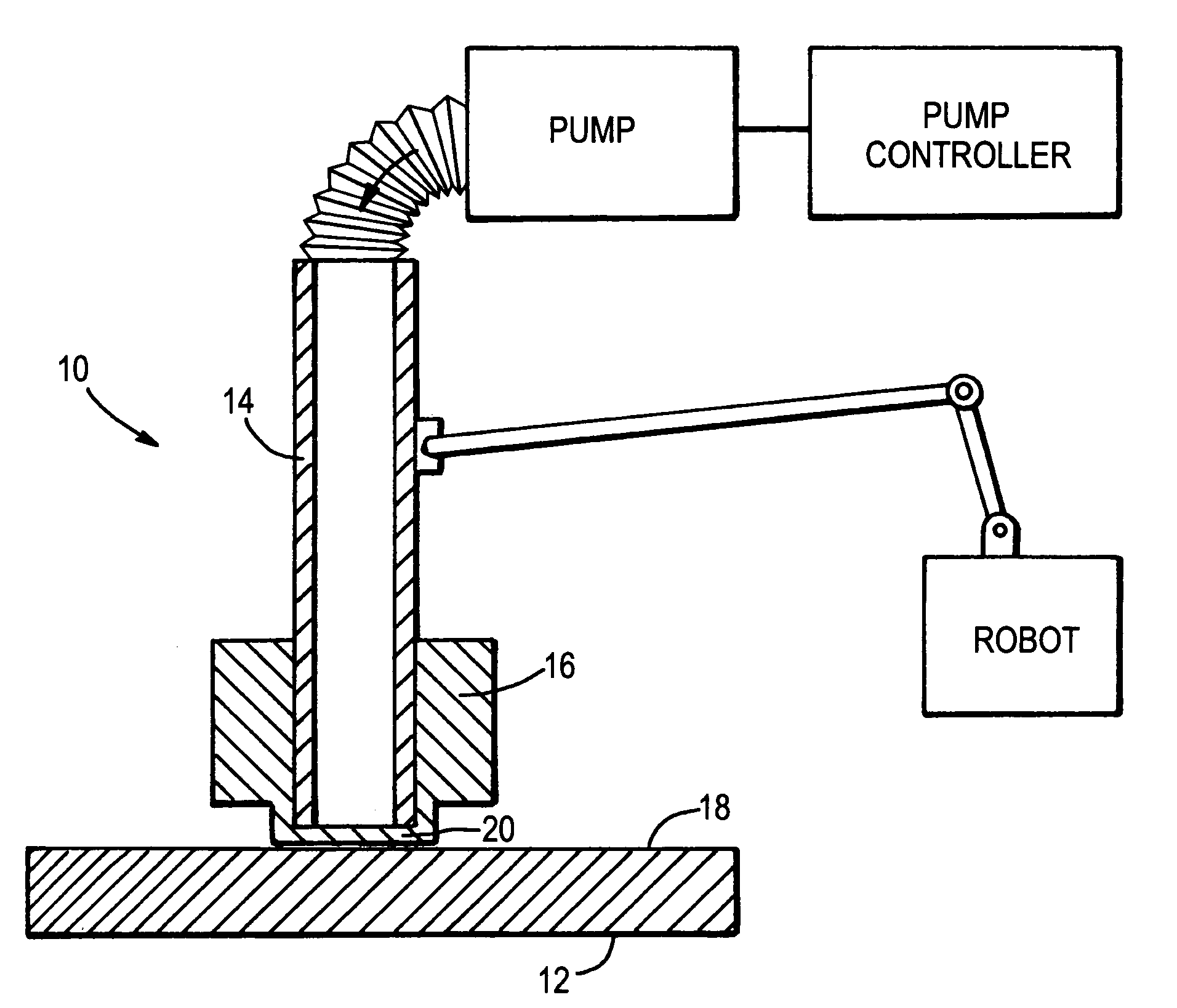

Method and apparatus for micro-contact printing

InactiveUS20050139103A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMicrocontact printingMulti material

The present invention provides an apparatus for producing patterns on a surface of a substrate. The apparatus includes a rigid support member such as a rigid tubular structure having first and second opposed ends and a fluid flow passageway extending therethrough. A printing stamp is attached at one of the opposed ends of the rigid support member. The printing stamp has a flexible diaphragm portion which has an outer surface which is coated with one or more materials in a pre-selected pattern. A pneumatic pressurizing mechanism communicating with an inner surface of the flexible diaphragm portion through the fluid flow passageway is used to bias the flexible diaphragm portion outwardly into intimate and substantially uniform contact with the surface of the substrate for transferring the pre-selected pattern onto said surface. The rigid tubular supports are attached to a robotic positioning mechanism for providing control of positioning of the stamp relative to the substrate surface.

Owner:AXELA

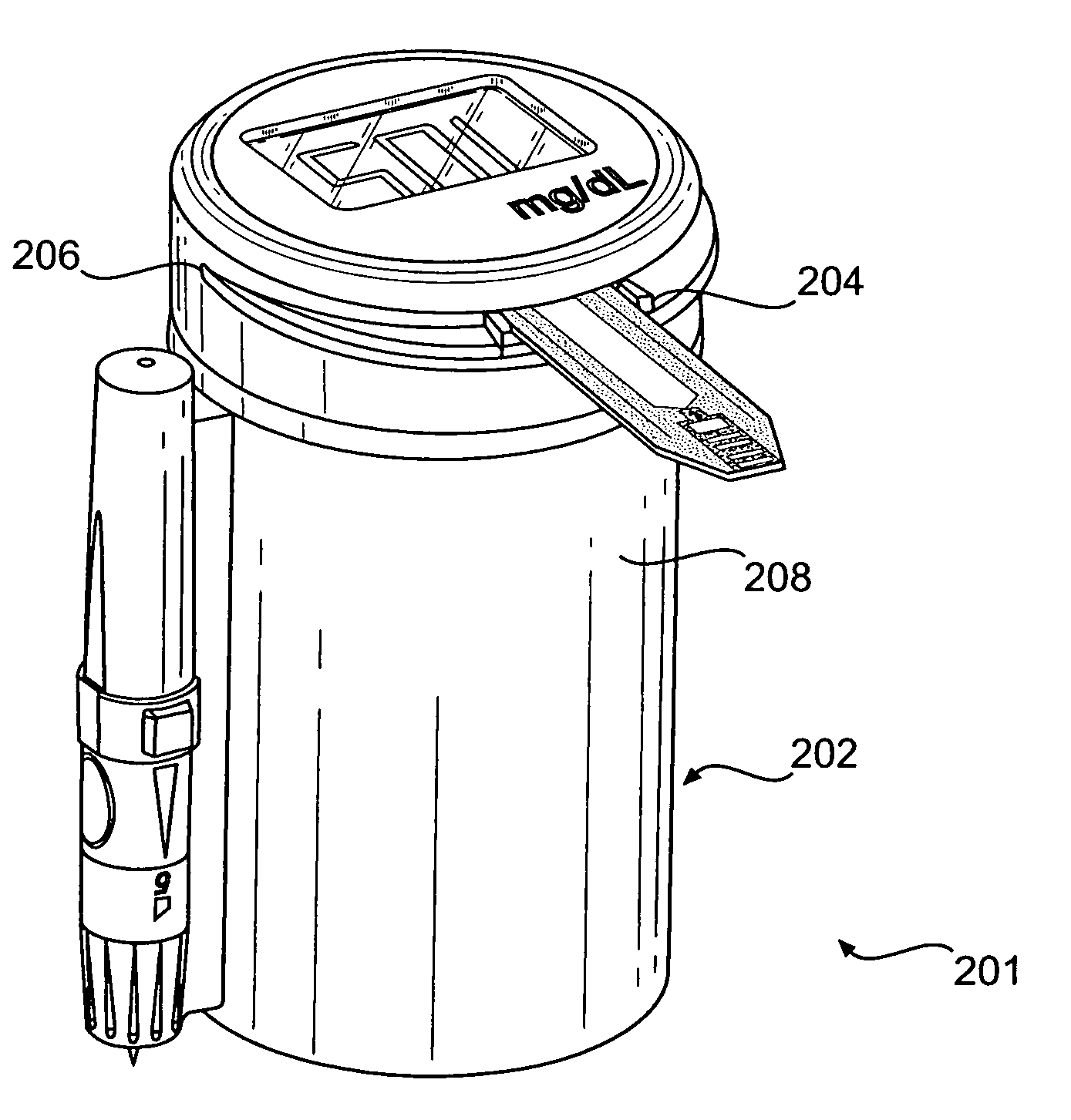

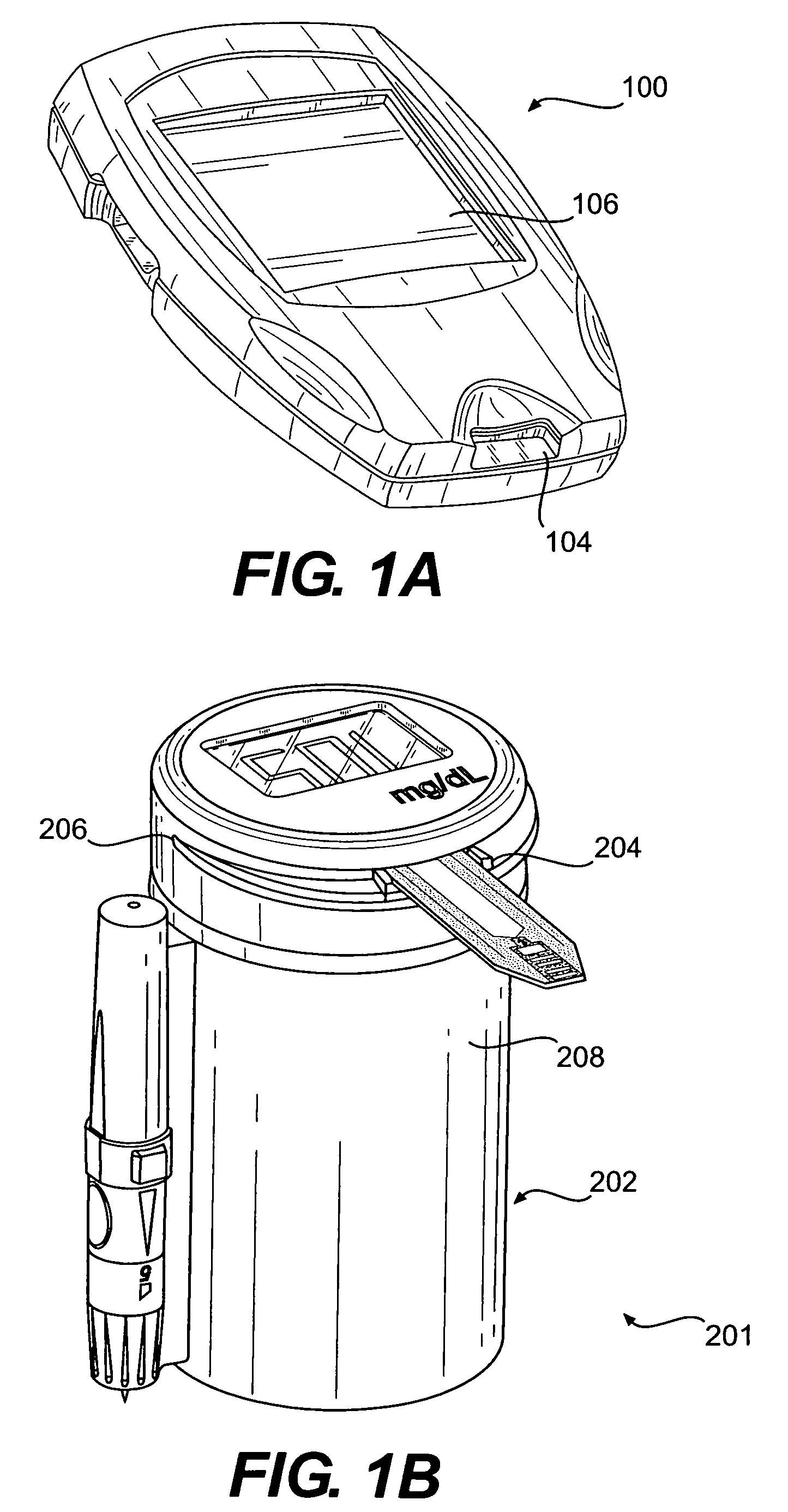

Diagnostic test media and methods for the manufacture thereof

The present disclosure relates to the manufacture of diagnostic test media used for measuring the concentration of analytes in a sample fluid. More specifically, the disclosure relates to using a method of microcontact printing or microtransfer molding for the manufacture of diagnostic test media.

Owner:NIPRO DIAGNOSTICS INC

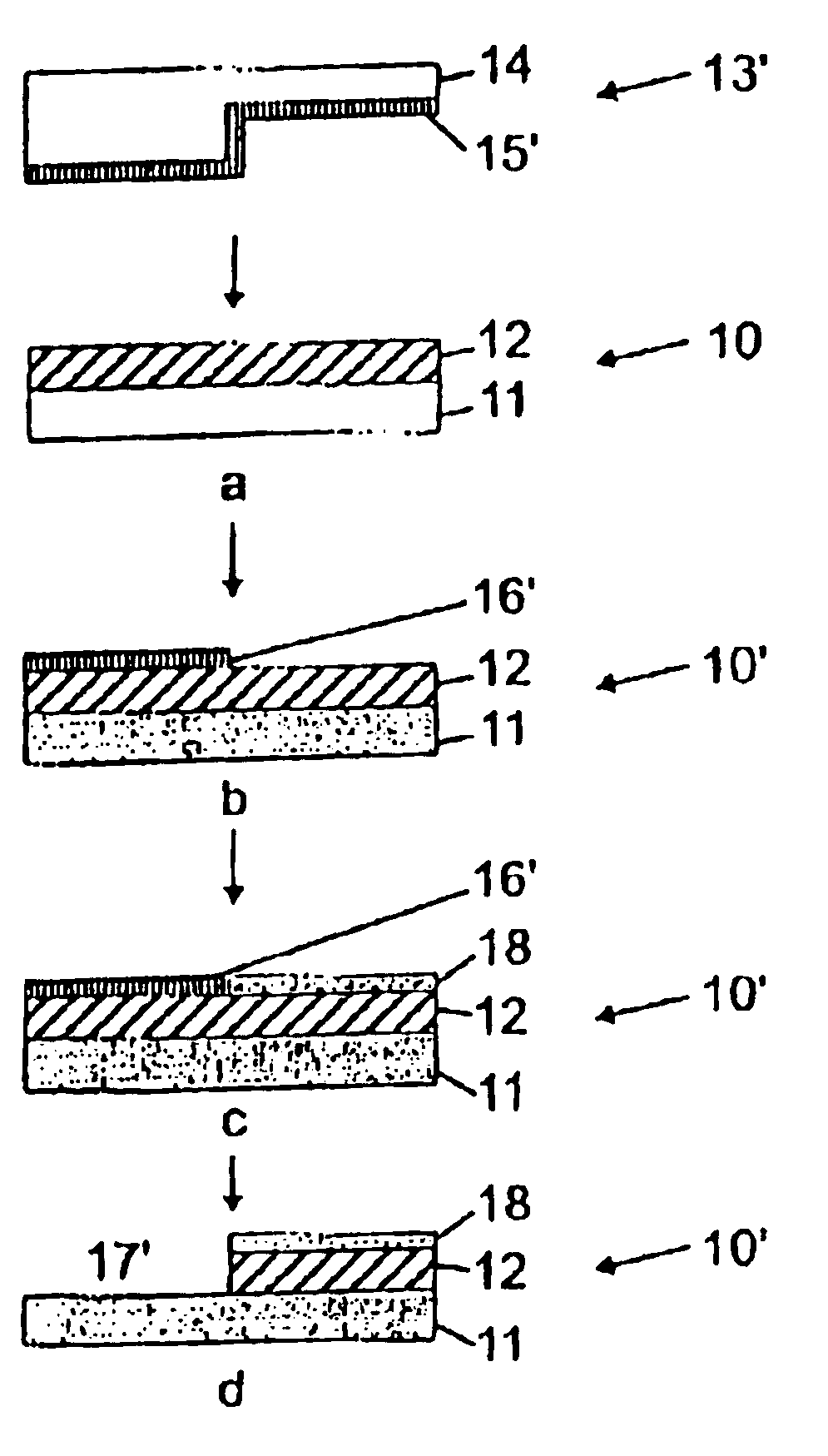

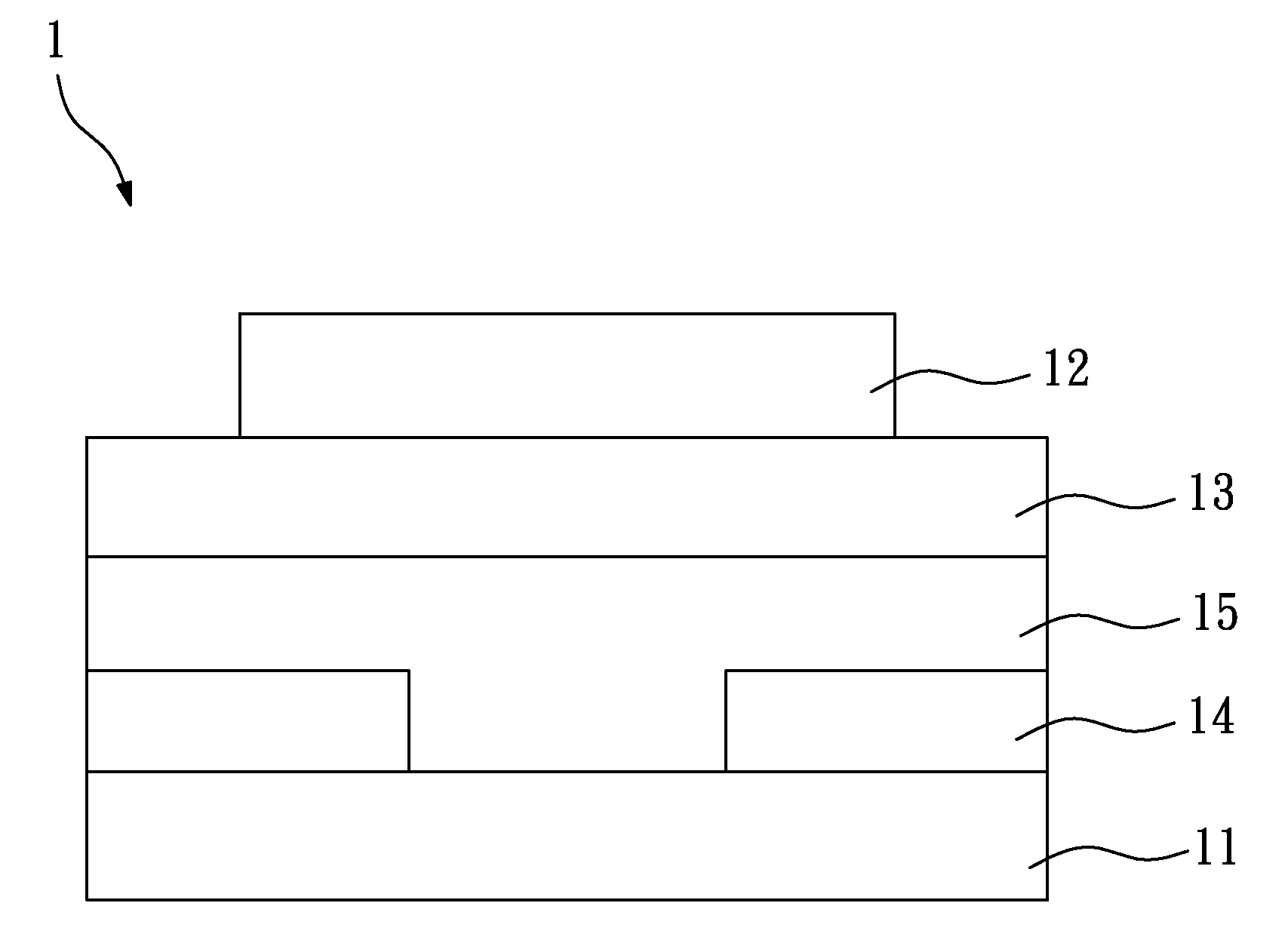

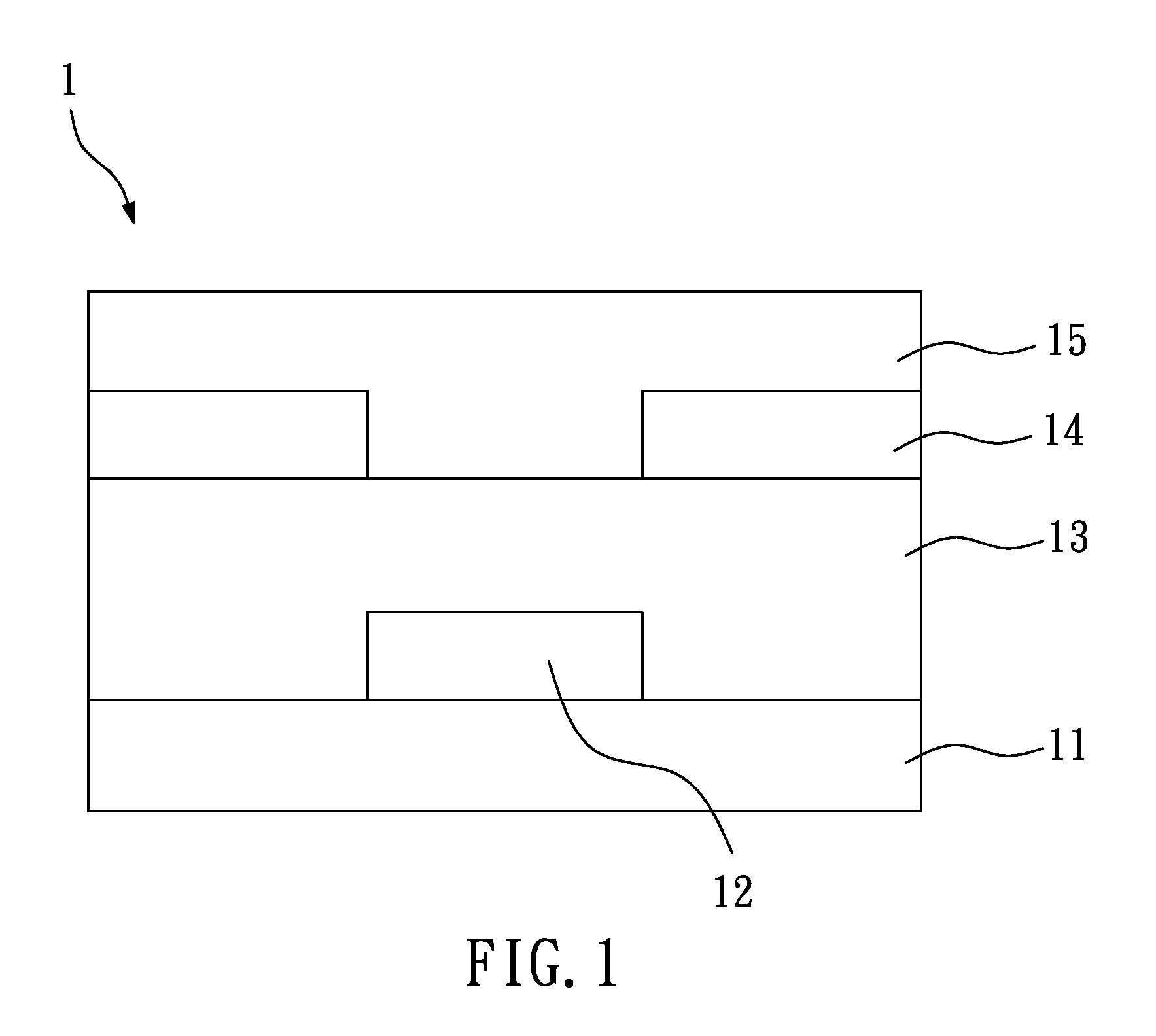

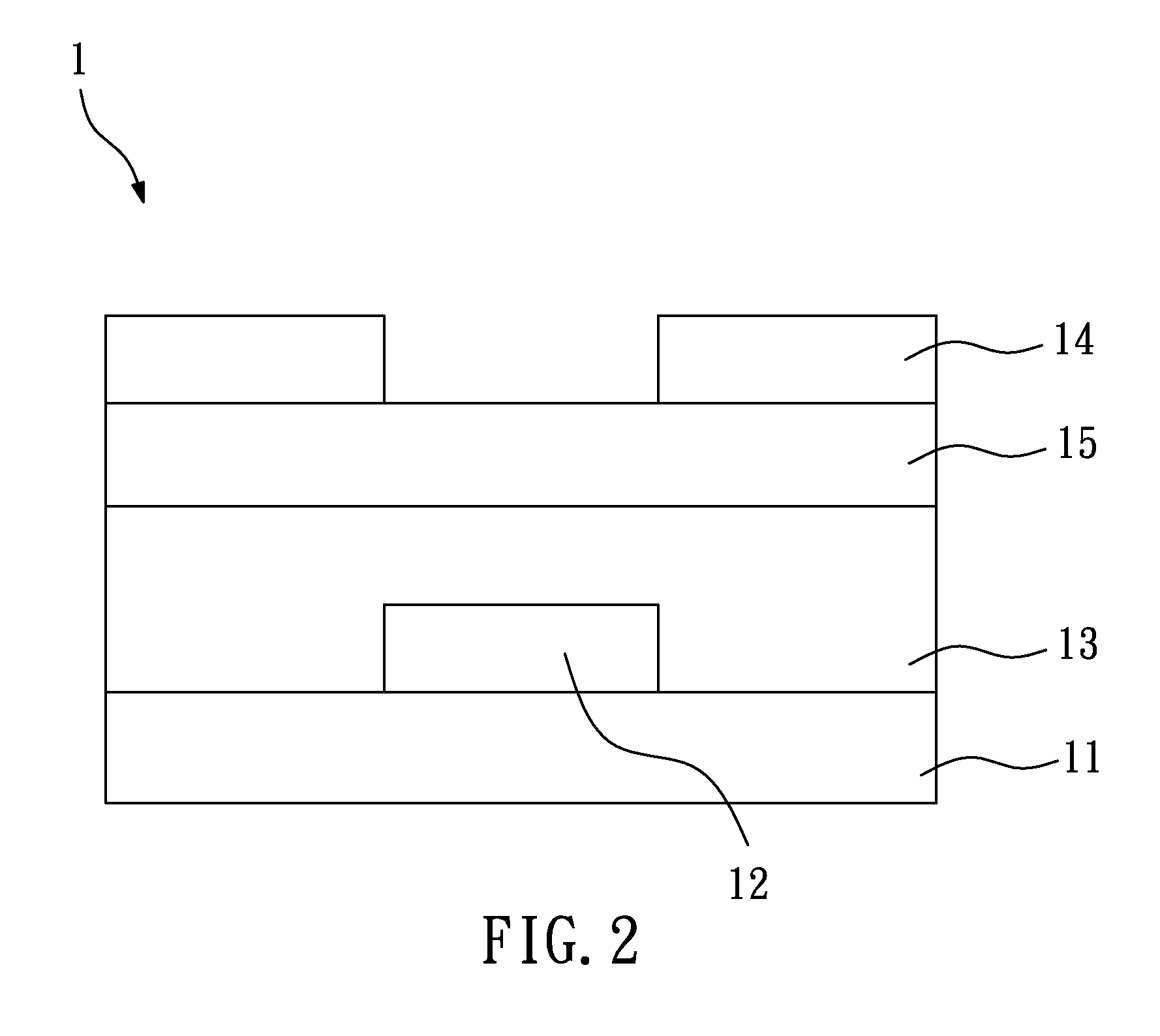

Method of patterning the surface of an article using positive microcontact printing

InactiveUS6893966B2Improve mechanical stabilityLow costMaterial nanotechnologyDecorative surface effectsMicrocontact printingPentaerythritol

There is disclosed a method of patterning an article (10) including a layer (12) of copper formed onto an insulating substrate (11) using a positive microcontact printing (MCP) process. In a preferred embodiment where the metal is copper (Cu) and the substrate is a silicon wafer, the method includes removing the native oxide presents on the Cu in a solution of HCl. Then, a stamp (13′) having a patterned polydimethylsiloxane (PDMS) body (14) is linked with a 0.2 mM solution of pentaerythritol-tetrakis(3-mercaptopropionate) (PTMP) in ethanol for 1 min, to form the inking layer (15′). The stamp is applied on the Cu layer to print a first self-assembled monolayer (SAM) (16′) according to a desired pattern. The article is dipped in a solution of ECT which is then adsorbed only in the non printed regions, forming a second SAM (18) in a configuration that is complementary to the desired pattern. Finally, the printed areas of the Cu layer are removed using a peroxodisulfate etch bath.

Owner:IBM CORP

Method and apparatus for metallization of large area substrates

A system and method for processing large area substrates. In one embodiment, a system for processing large area substrates includes prep station, a stamping station and a stamp that is automatically moved between the stamping station and the prep station. The stamping station is adapted to retain a large area substrate thereon. The stamp has a patterned bottom surface that is adapted for microcontact printing. The prep station is for applying a precursor to the patterned bottom surface of the stamp. In one embodiment, a method for processing large area substrates includes the steps of disposing a large area substrate on a platen, inking a stamp adapted for microcontact printing, and automatically contacting a bottom of the stamp to the large area substrate supported on a platen.

Owner:APPLIED MATERIALS INC

Method for the manufacture of micro structures

InactiveUS20050130074A1Reduce widthEasy to integratePhoto-taking processesDecorative surface effectsMicrocontact printingMaterials science

Method for the Manufacture of Micro Structures A method for the manufacture of micro structures in substrates is provided. The method uses a combination of photolithographic mask technology and micro contact printing.

Owner:IBM CORP

Method of forming patterned nickel and doped nickel films via microcontact printing and uses thereof

InactiveUS6866791B1Convenient and inexpensive to manufactureMaterial nanotechnologyLiquid surface applicatorsMicrocontact printingDerivatization

The process of derivatization and patterning of surfaces, and more particularly to the formation of self-assembled molecular monolayers on metal oxide surfaces using microcontact printing and the derivative articles produced thereby.

Owner:IBM CORP

Preparation method for multielement dissymmetrical microsphere and heterogeneous microsphere shell

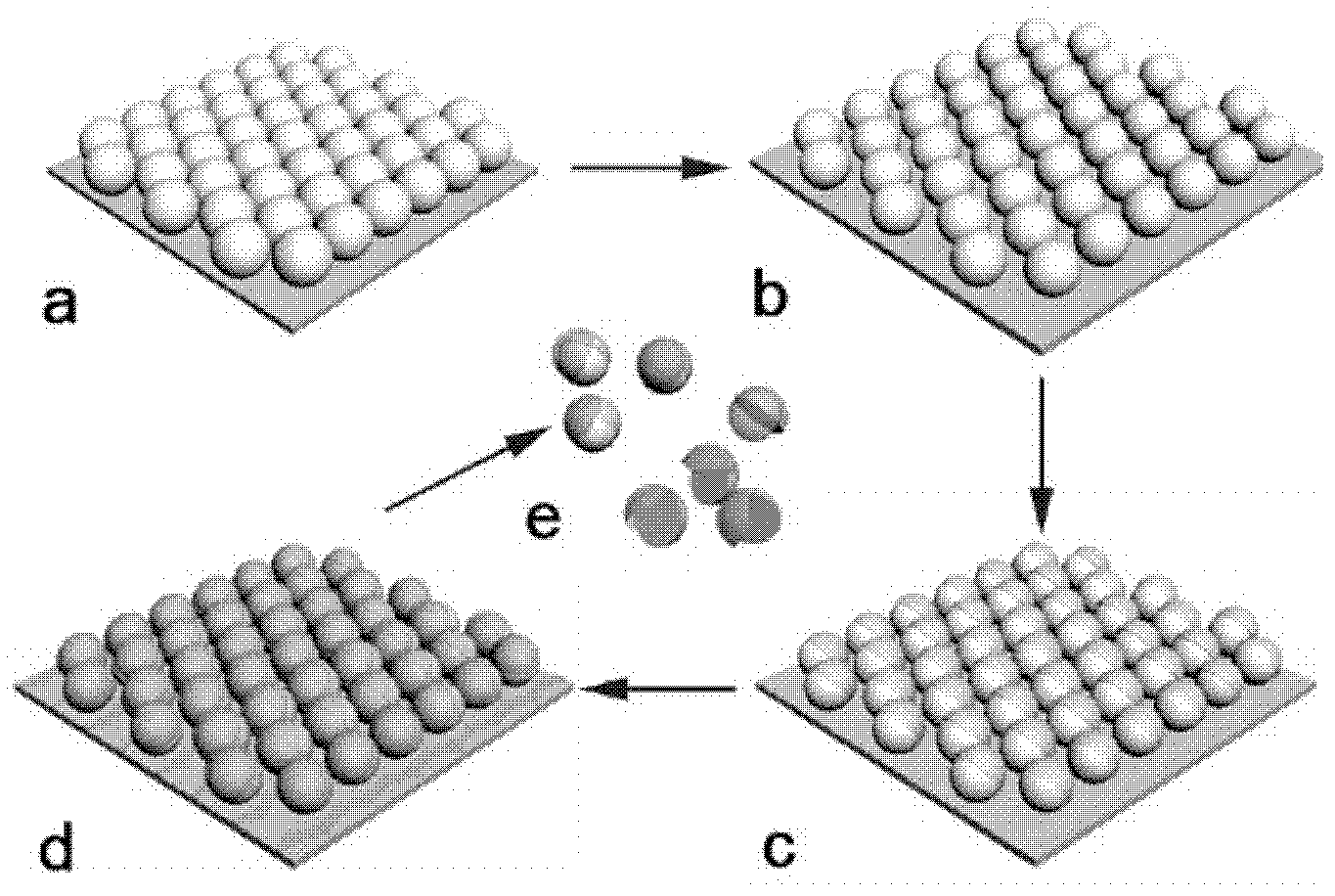

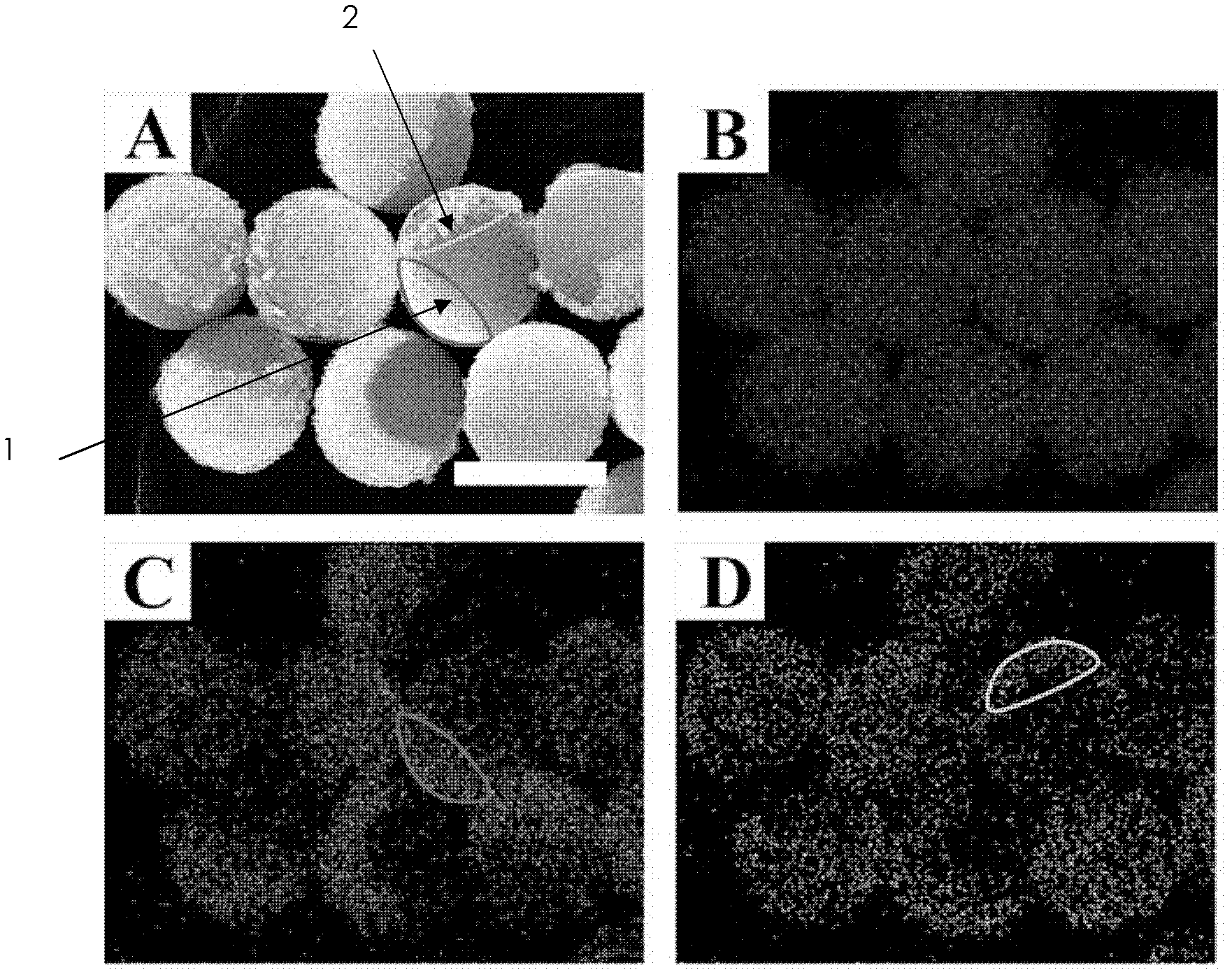

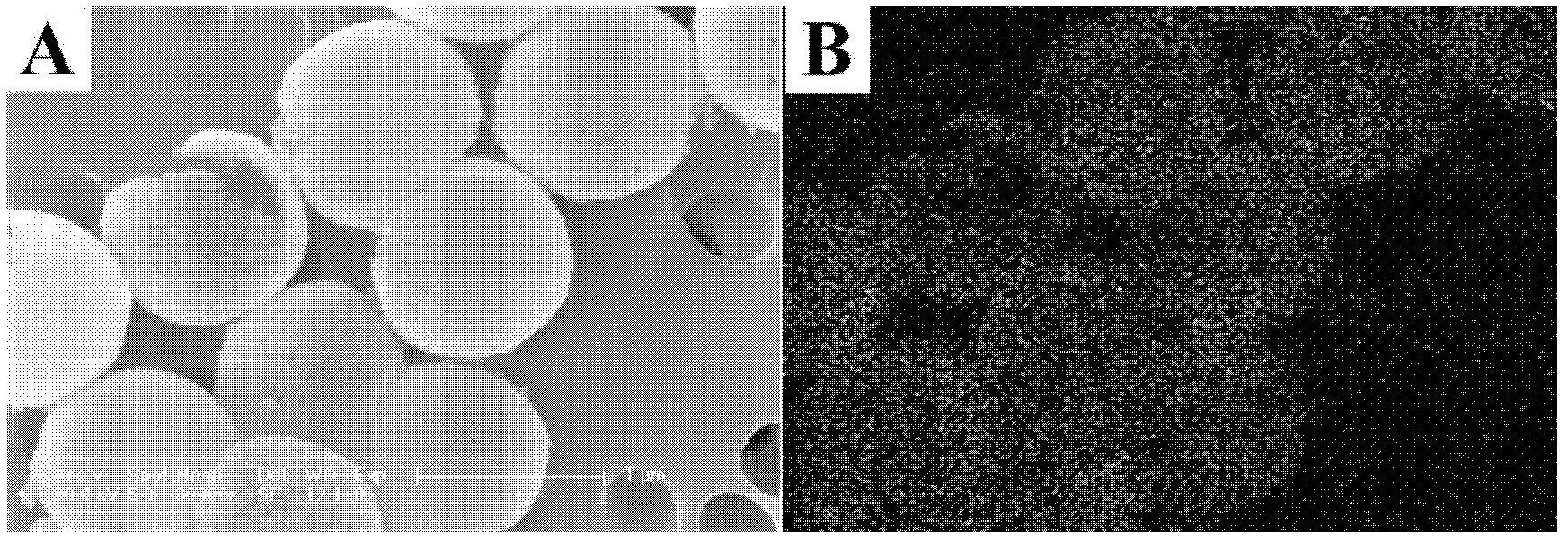

InactiveCN102583226AImprove stabilitySimple and fast operationDecorative surface effectsChemical vapor deposition coatingMicrocontact printingMicrosphere

The invention belongs to the scientific field of materials, particularly relates to a preparation method for a multielement dissymmetrical microsphere and a heterogeneous microsphere shell. The method comprises the following steps: a single-layered non-close-packed silicon dioxide colloidal crystal is prepared through an improved micro-contact printing technology, and the dissymmetrical microsphere and the heterogeneous microsphere shell are prepared through the combination with an angle-controllable non-close-packed silicon dioxide colloidal crystal deposition and etching technology. During the whole process, the operation is simple and convenient, the consumption is low, the process is clean, the controllability is high, and high stability of the dissymmetrical microsphere and the microsphere shell are achieved. Various dissymmetrical microspheres compounded by various kinds of materials are simply prepared through controlling the period, the deposition angle and the deposition frequency of the non-close-packed colloidal crystal and the kind of the deposition materials, and the corresponding heterogeneous microsphere shell can be obtained through chemically etching the silicon dioxide microsphere. The dissymmetrical microsphere and the heterogeneous microsphere shell, which are prepared through the invention, have important significance in scientific researches or practical applications.

Owner:JILIN UNIV

Microcontact printed thin film capacitors

The invention relates to thin film single layers, electronic components such as multilayer capacitors which utilize thin film layers, and to their methods of manufacture. Chemical solution deposition and microcontact printing of dielectric and electrode layers are disclosed. High permittivity BaTiO3 multilayer thin film capacitors are prepared on Ni foil substrates by microcontact printing and by chemical solution deposition. Multilayer capacitors with BaTiO3 dielectric layers and LaNiO3 internal electrodes are prepared, enabling dielectric layer thicknesses of 1 μm or less. Microcontact printing of precursor solutions of the dielectric and electrode layers is used.

Owner:PENN STATE RES FOUND +1

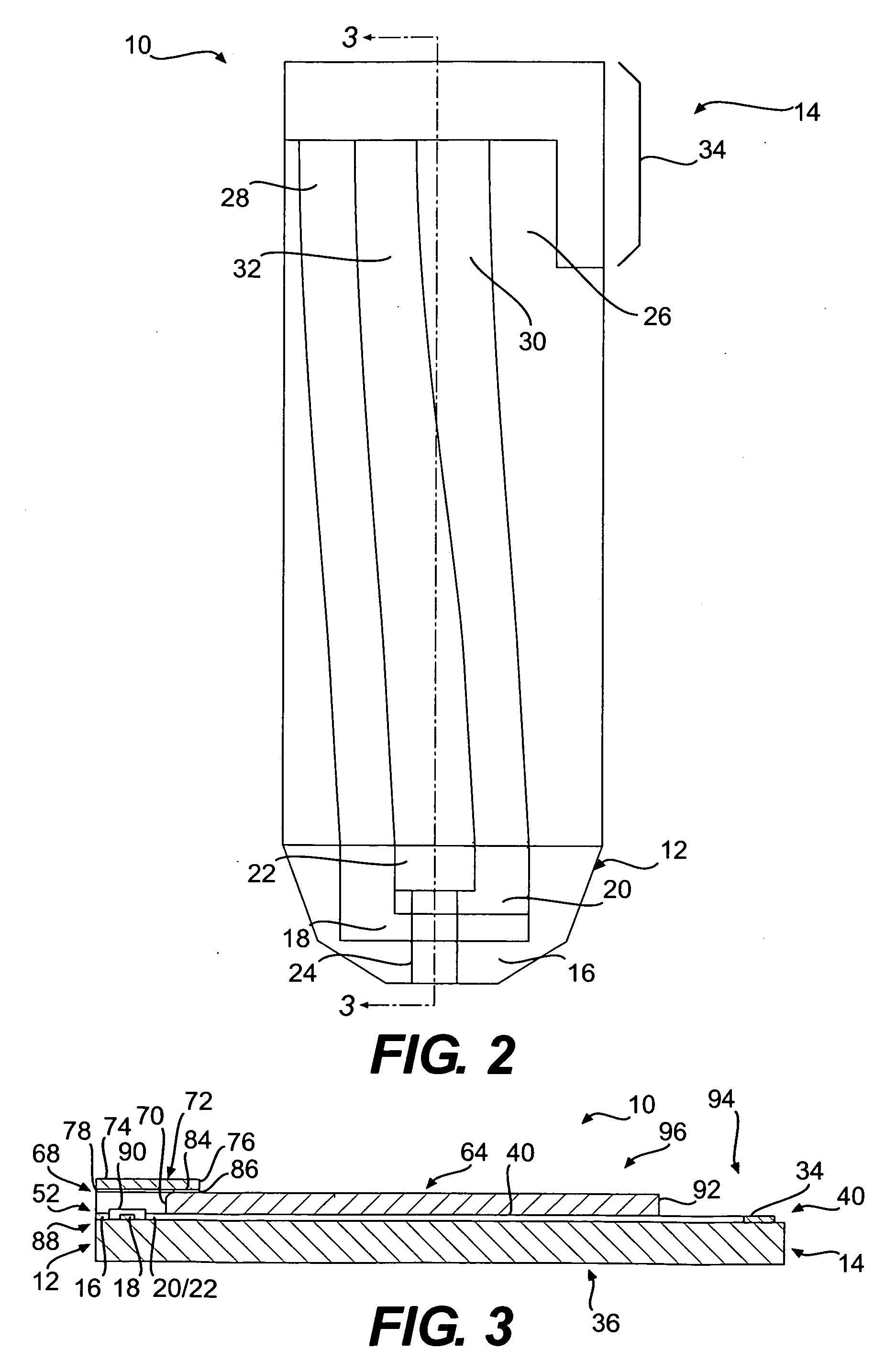

Microcontact printing

InactiveUS7665983B2Generate undesired patterning resultsControl distortionMaterial nanotechnologyMechanical working/deformationMicrocontact printingActuator

A microcontact printing tool having a print unit including a stamp head with a stamp and a wafer chuck for retaining a substrate. The stamp contained by the stamped head movable relative to the substrate by an actuator and a stage. A plurality of sensors detect the position of the stamp relative to substrate. A method of using the printing tool that includes a real-time feedback for consistent and accurate application of force during the printing of the substrate. The stamp head includes a pressure chamber carrying the stamp. The stamp backing is deflected prior to contact of the stamp with the substrate to form a minimum point and the stamp backing and the stamp is returned to a plane to create a printing propagation contact. An apparatus has a master backing and a stamping backing in close proximity and the stamp material drawn in through a vacuum. The stamp is separated from the master by use of a parting fluid.

Owner:MASSACHUSETTS INST OF TECH

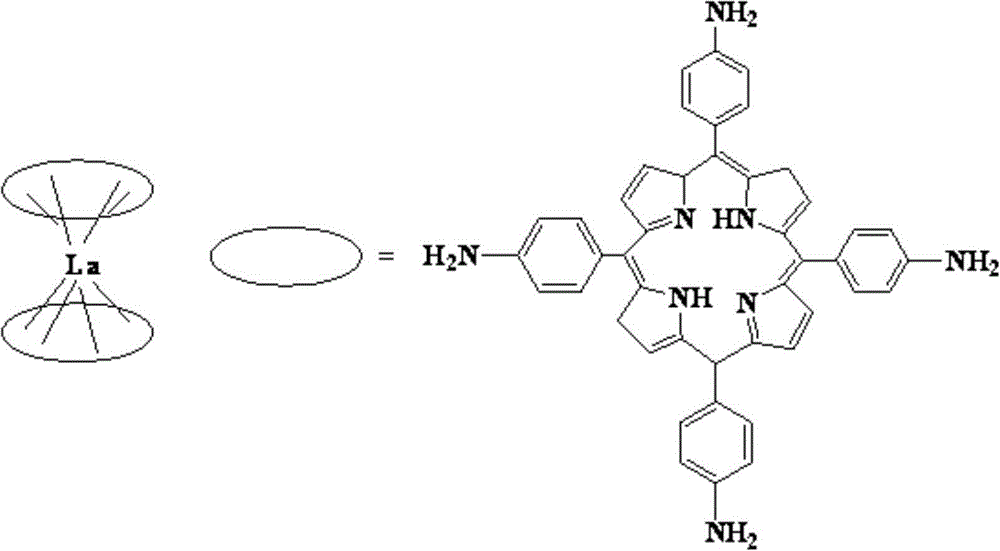

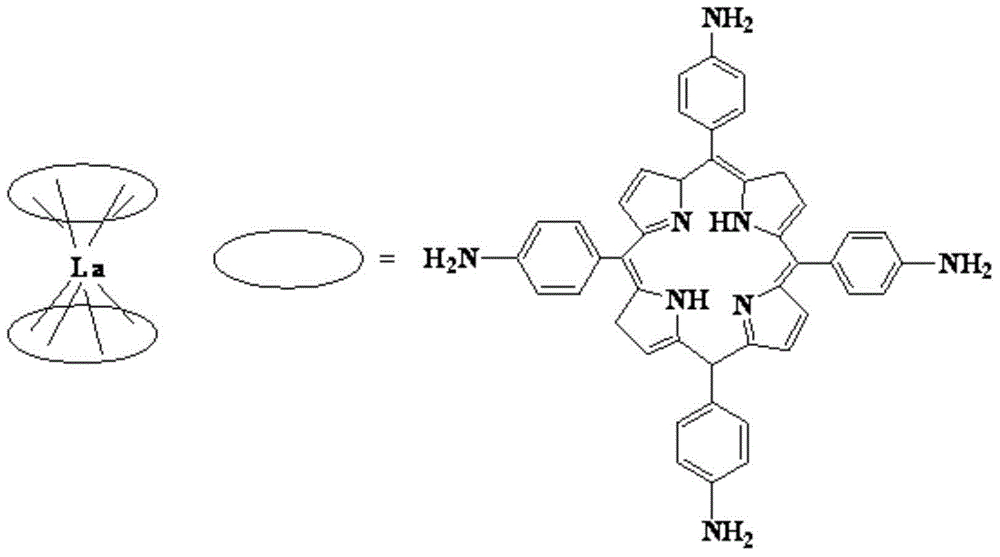

Water-soluble double-sandwich-type La metalloporphyrin complex and application thereof in micro-contact printing technique

ActiveCN104387835AHigh resolutionSmooth responseOrganic chemistryInksMicrocontact printingPolymer substrate

The invention relates to a water-soluble double-sandwich-type La metalloporphyrin complex. The invention also provides an application of the water-soluble double-sandwich-type La metalloporphyrin complex in a micro-contact printing technique. Metal patterns are prepared on the surface of a polymer substrate frequently used in the electronic industry by adopting an aqueous solution of bis(5,10,15,20-tetra-p-amino phenyl porphyrin)-La complex as micro-contact printing ink and a novel idea is provided for micro-contact printing industry.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Application of zinc phthalocyanine complex as ink in micro-contact printing

InactiveCN102516841AReduce bloatReduce distortionInksOther printing apparatusMicrocontact printingPolyimide substrate

The invention discloses application of a zinc phthalocyanine complex as ink in micro-contact printing. The 2-propyl alcohol solution of 8(Octanohydroxamic)-zinc phthalocyanine serves as micro-contact printing ink; the pattern of a Polydimethylsiloxane (PDMS) seal is transferred to the surface of carboxylation polyethylene terephthalate, polyethylene naphthalate or polyimide substrate; and a delicate metal pattern is obtained on the substrate with a chemical plating method. The application of the zinc phthalocyanine complex as the ink in the micro-contact printing has the beneficial effect that the common phenomena of pattern inflation and pattern torsion in the micro-contact printing can be reduced by the phthalocyanine metal complex ink, and the phthalocyanine metal complex ink has a lowpreparation cost and great potential in the industrial application and is stable.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Selective metal patterns using polyelect rolyte multilayer coatings

InactiveUS20080014356A1Coating stabilityProcess economyMaterial nanotechnologyPretreated surfacesMicrocontact printingElectroless deposition

Processes for creating versatile and selective metal patterns (such as copper and nickel) combine the use of PEM coatings, microcontact printing (MCP), and electroless deposition. MCP is used to pattern a charged catalyst (such as palladium and stannous ions) onto oppositely charged PEM coated substrates. The substrate is then placed into an electroless deposition bath where a metal selectively plates at the catalyzed regions.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

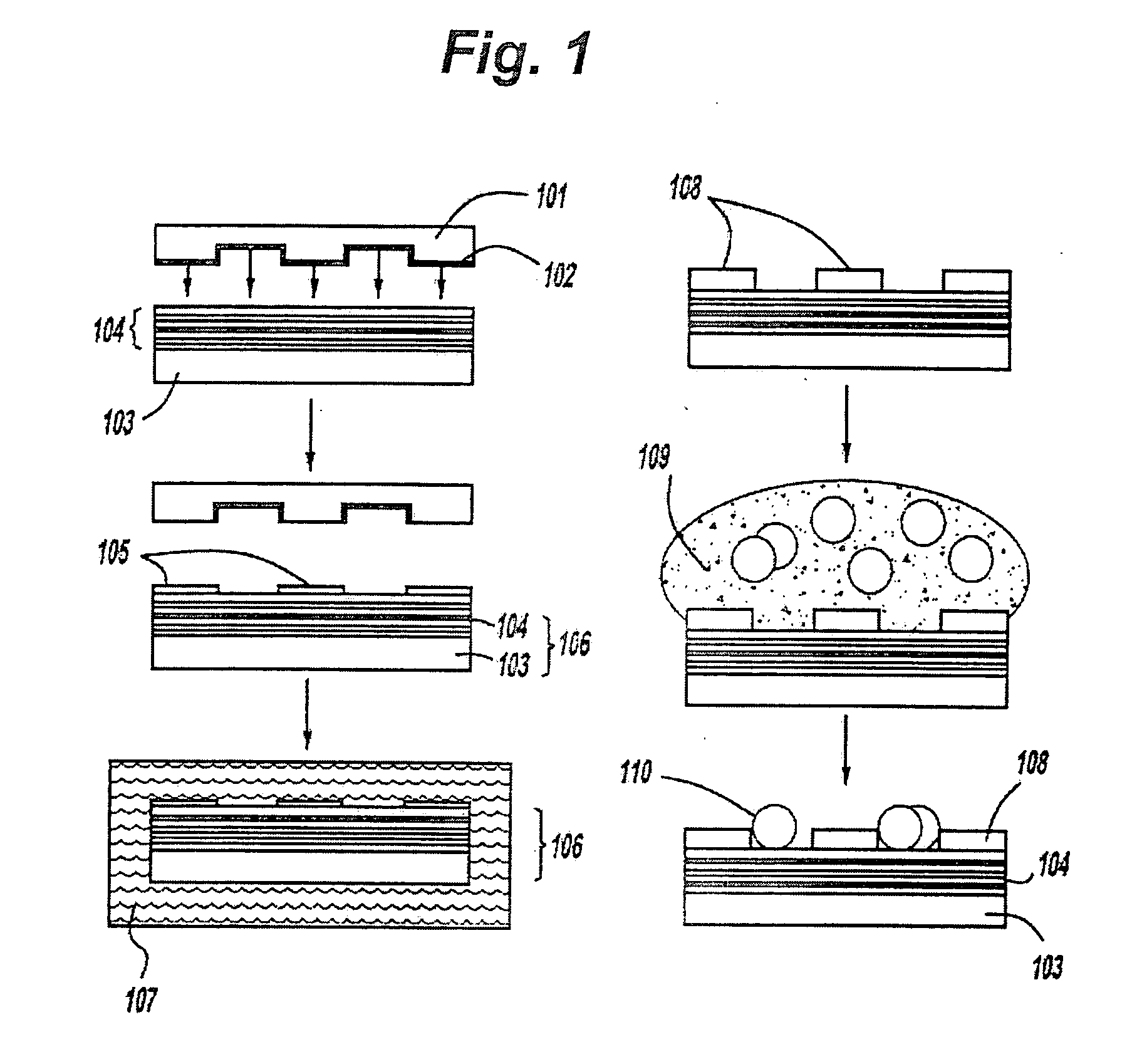

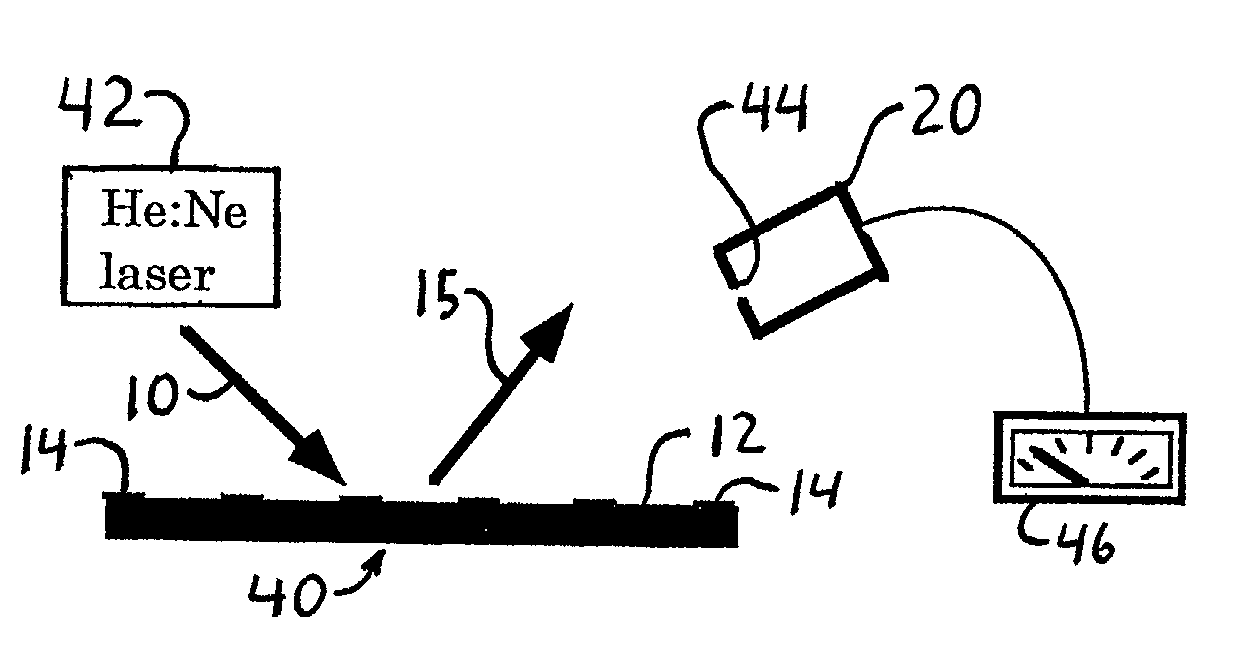

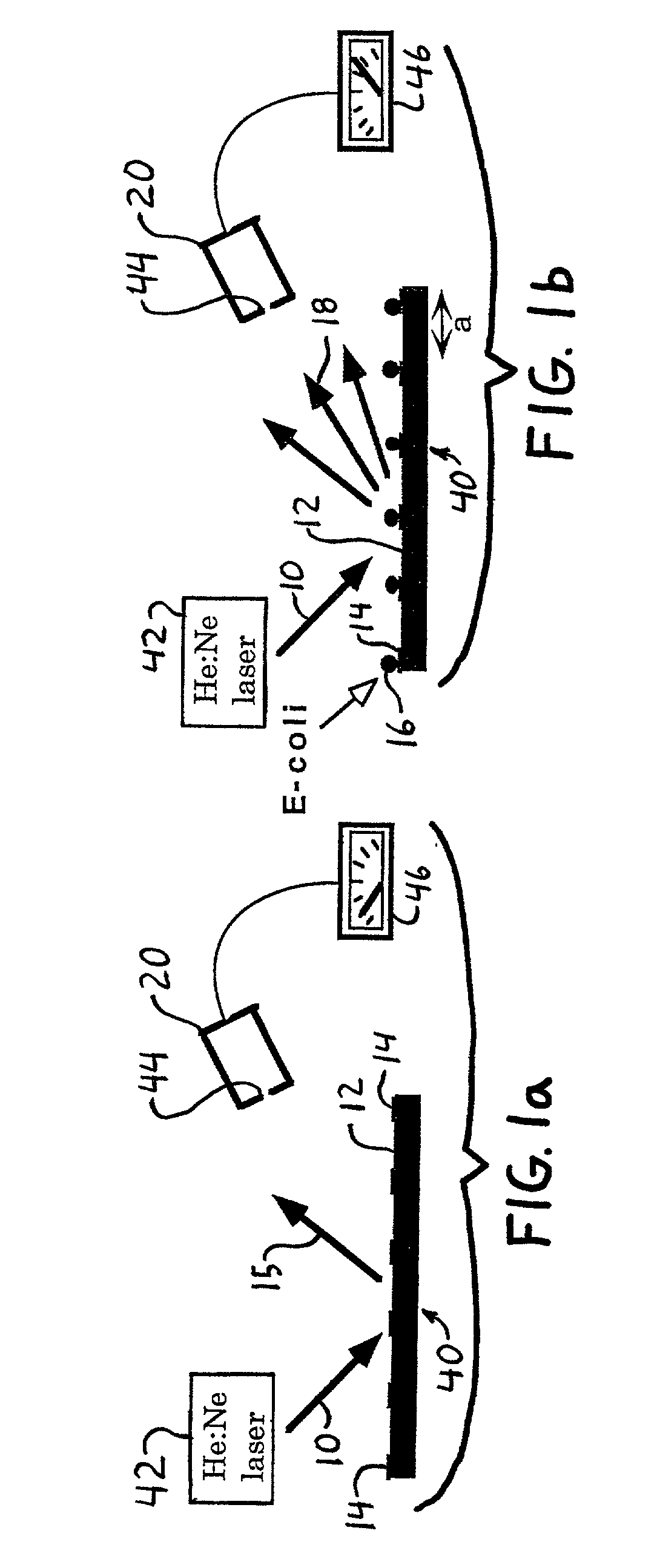

Diffraction-based cell detection using a micro-contact-printed antibody grating

InactiveUS20020037593A1Material nanotechnologyScattering properties measurementsMicrocontact printingEscherichia coli

An optical biological detector is able to bind specific targeted bacterial cells by stamping an antibody grating pattern onto a silicon surface. The antibody grating alone produces insignificant optical diffraction, but upon immunocapture of the targeted cells, the optical phase change produces a diffraction pattern. Micro-contact printing provides a method for placing the antibody grating pattern directly onto a substrate surface with no additional processes or binding chemicals. Antibodies or other biologically active material may be stamped directly onto clean native oxide silicon substrates with no other chemical surface treatments. Direct binding of the antibodies to the silicon occurs in a way that still allows them to function and selectively bind antigen. The performance of the sensor was evaluated by capturing Escherichia coli O157:H7 cells on the antibody-stamped lines and measuring the intensity of the first order diffraction beam resulting from the attachment of cells. The diffraction intensity increases in proportion to the cell density bound on the surface.

Owner:CORNELL RES FOUNDATION INC

Method and apparatus for micro-contact printing

InactiveUS6981445B2Not excessively stretchedBioreactor/fermenter combinationsBiological substance pretreatmentsMicrocontact printingMulti material

Owner:AXELA

Microcontact printing method using imprinted nanostructure and nanostructure thereof

InactiveUS7442316B2Material nanotechnologyDecorative surface effectsMicrocontact printingSelf-assembled monolayer

A microcontact printing method using an imprinted nanostructure is provided, wherein the microcontact printing is introduced to a nanoimprint lithography process to pattern a self-assembled monolayer (SAM). The method includes forming a nanostructure on a substrate by using the nanoimprint lithography process; and patterning the nanostructure with the microcontact printing method. The operation of patterning includes: depositing a metal thin film on the nanostructure; contacting a plate with the nanostructure to selectively print the SAM on the nanostructure, wherein the SAM is inked on the plate and the metal thin film is deposited on the nanostructure; selectively removing the metal thin film by using the SAM as a mask; removing the SAM from the nanostructure; and patterning the substrate by using the remaining metal thin film on the nanostructure as a mask.

Owner:KOREA INST OF MACHINERY & MATERIALS

Fabrication method of organic thin-film transistors

InactiveUS20110117695A1Improve fidelitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmMicrocontact printing

This invention discloses a fabrication method of organic thin-film transistors (OTFTs) using the micro-contact printing. The OTFT can be of the bottom-gate or top-gate configuration. The micro-contact printing operation of this fabrication method does not require clean-room environment and high processing temperature, and does not have the problem of 2D shrinkage of the printed patterns either. Furthermore, the pre-wetting technique employed in the micro-contact printing results in improved fidelity in the pattern transfer and solves the problems of pairing and cross-talking between neighboring patterns.

Owner:METAL INDS RES & DEV CENT

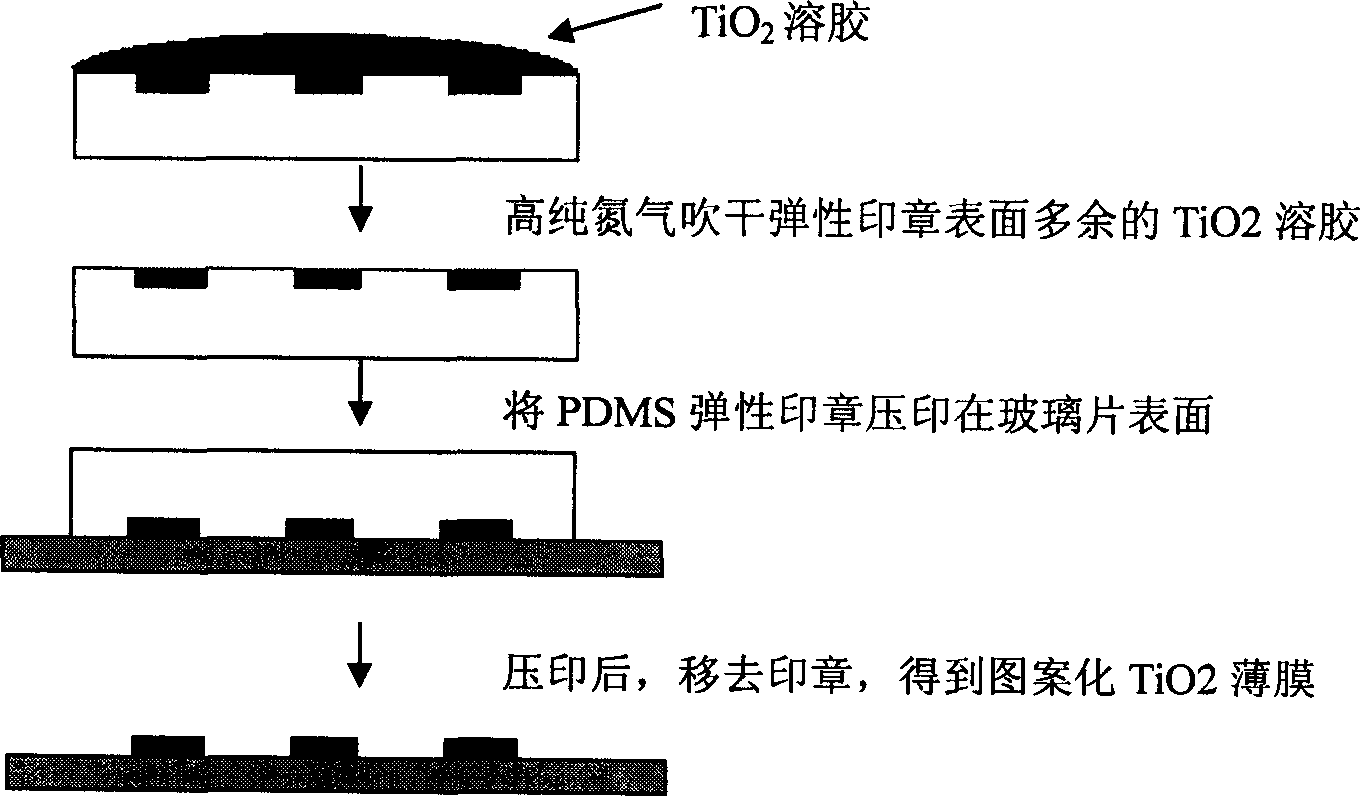

Preparation method of patterned titanium dioxide micro structure

InactiveCN1785683AImprove clarityHigh resolutionDuplicating/marking methodsTitanium dioxideMicrocontact printingImage resolution

A process for preparing the patterned TiO2 microstructure includes such steps as photoetching on the surface of monosilicon to form a pattern, using it as template, filling polydimethylsiloxane on its surface, ageing, stripping to obtain an elastic seal, using TiO2 sol as í‹inkíŒ, microcontact printing on substrate by embossing to obtain the TiO2 film with patterned microstructure.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Terahertz wave quasi-optics polaroid sheet and preparation method thereof

The invention discloses a terahertz wave quasi-optics polaroid sheet and a preparation method thereof. The terahertz wave quasi-optics polaroid sheet comprises a metal wire grating structure and a polymer substrate. The manufacturing method of the terahertz wave quasi-optics polaroid sheet comprises the step of printing metal on the clean and dry polymer substrate to manufacture the polaroid sheet with the wire grating structure through an aerosol spray printing or micro-contact printing method, wherein the metal comprises one of aluminum, gold, silver and copper, and materials of the polymer substrate are selected from a terahertz wave band high-permeability thin polymer film. The invention can realize the manufacturing method of the terahertz wave quasi-optics polaroid sheet which has low cost, high accuracy and more specialized application by utilizing an electronic printing technology.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com