Loudspeaker diaphragm and its mfg. method

A vibrating diaphragm and loudspeaker technology, applied in the direction of diaphragm structure, transducer diaphragm, plane diaphragm, etc., can solve impractical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

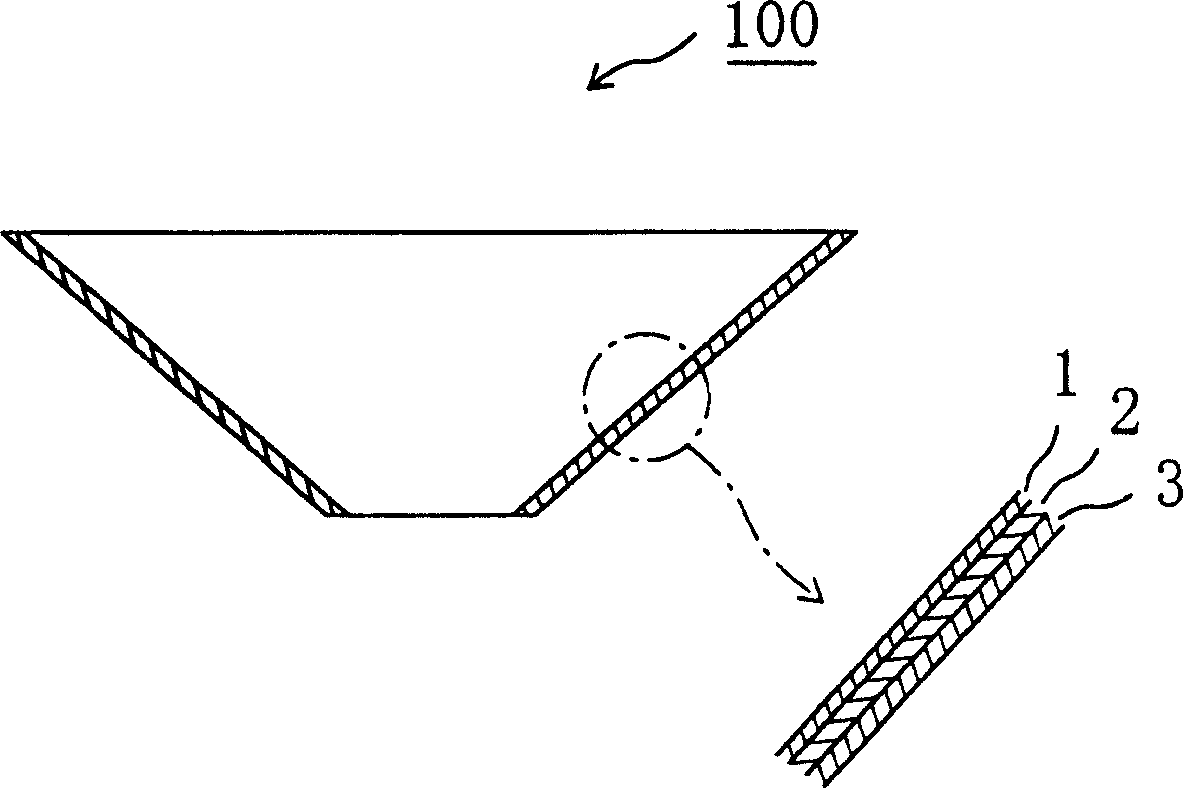

Image

Examples

Embodiment 1

[0066] A solution of unsaturated polyester was prepared with the following composition:

[0067] Unsaturated polyester resin (N350L, manufactured by Nippon Shokubai Co., Ltd.)

[0068] 100(parts)

[0069] Low shrinkage agent (MODIPER S 501, produced by NOF Corporation) 5 (parts)

[0070] Curing agent (manufactured by PEROCTA O NOF Corporation) 1.3 (parts)

[0071] A cotton woven fabric (cotton yarn count: #20, 40 warp and 40 weft, weaving density: 110 g / m 2 ) was cut into 15 cm long and 15 cm wide. The plain weave woven fabric of PEN fiber (TeijinLimited production, fineness: 1100 dtex (decitex), per inch 17 warps and 17 wefts, weaving density: 166g / m ) is cut into 15cm long, 15cm is wide, puts on cotton machine fabric so as to obtain a two-layer laminate.

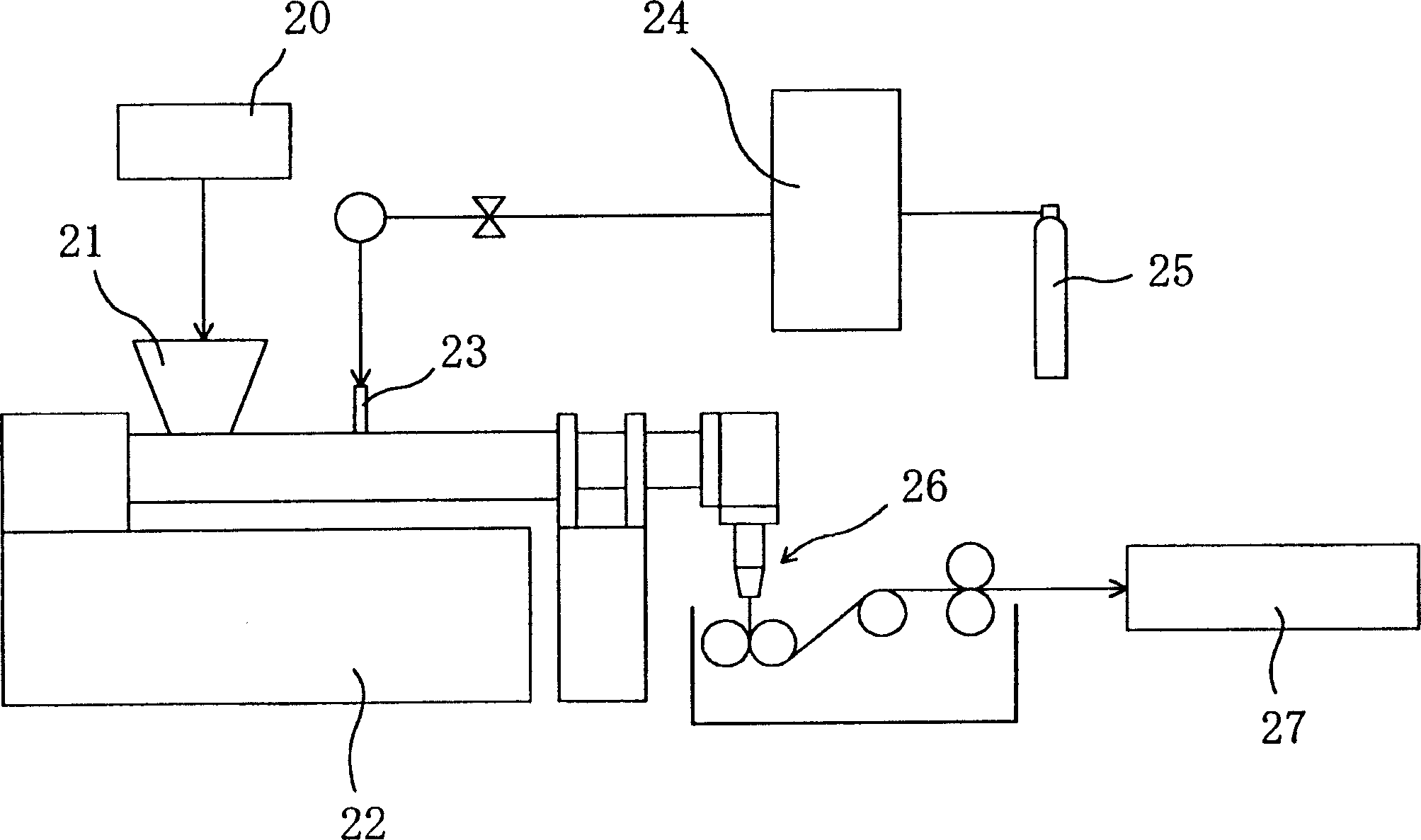

[0072] An opening with a diameter of approximately 13 cm was formed in the central portion of a stainless steel plate approximately 16 cm long by 16 cm wide to obtain ...

Embodiment 2

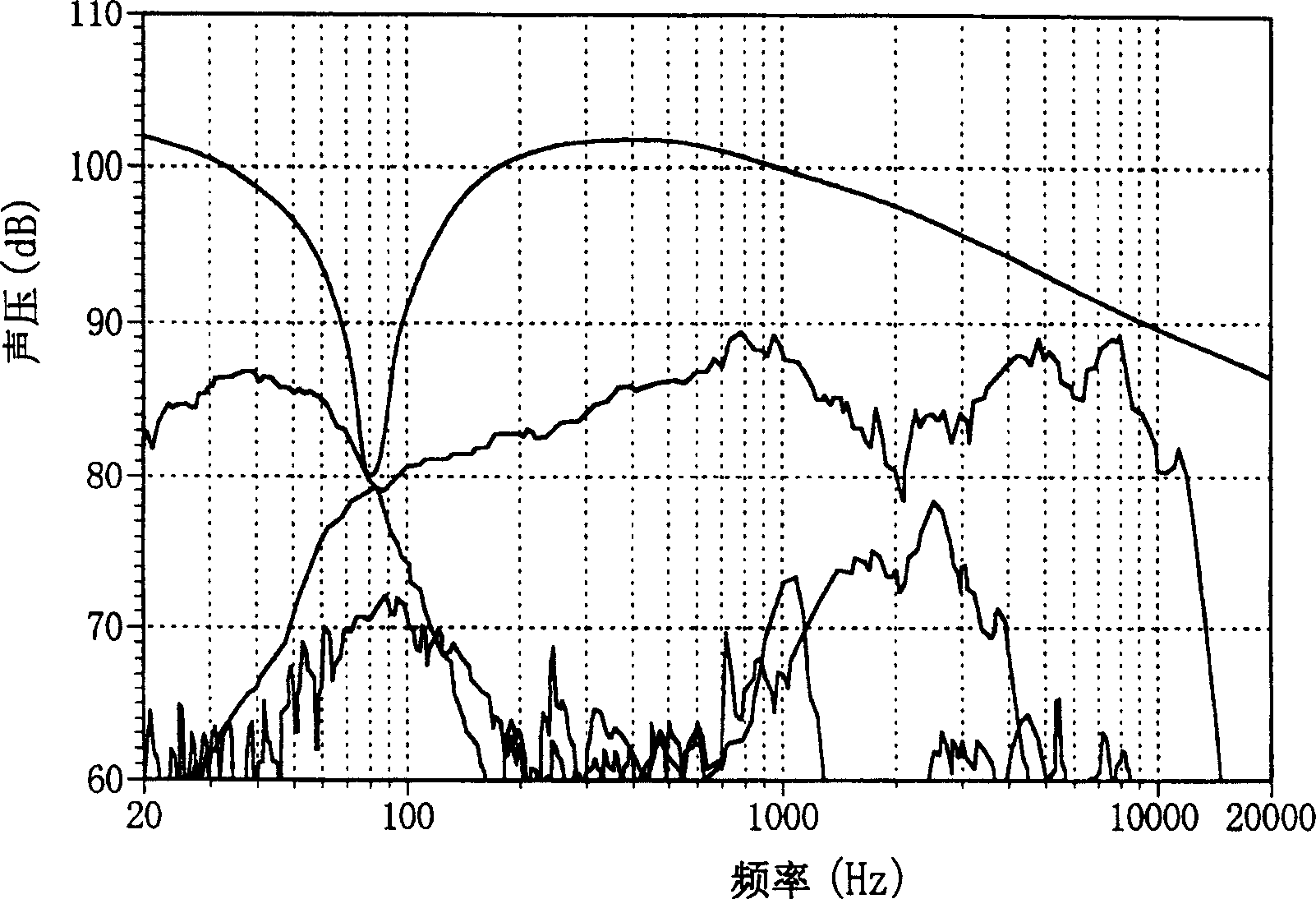

[0078] A loudspeaker vibrating diaphragm was manufactured in the same manner as in Example 1, except that a liquid crystal polymer non-woven fabric (Kuraray Co., Ltd. produced, its trade name was Vectran, fiber fineness: 1600 denier, and METSUK (fabric density): 60g / m2) instead of cotton woven fabric. The vibrating membrane thus obtained was subjected to the same measurement as in Example 1. The results are listed in Table 1. Also, frequency characteristics of a speaker employing the diaphragm thus obtained were measured. The results are shown in Figure 4 middle.

Embodiment 3

[0080] Loudspeaker diaphragms were produced in the same manner as in Example 1, except that the plain woven fabric of PEN fibers was impregnated with 5 parts of melamine (based on 100 parts of fabric), and then laminated on the cotton woven fabric . The vibrating membrane thus obtained was subjected to the same measurement as in Example 1. The results are shown in Table 1 above. Also, frequency characteristics of a speaker employing the diaphragm thus obtained were measured. The results are shown in Figure 5 middle. Furthermore, the contact angle was measured in the same manner as in Example 1 on the vibrating membrane thus obtained. The results are shown in Table 2 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com