Preparation method and application of moisture reaction type polyurethane hot-melt adhesive for composite floor

A polyurethane hot-melt adhesive and moisture-responsive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve fire and explosion hazards, unsuitable for sustainable development, and solvent environmental pollution and other problems, to achieve the effect of a wide range of applicable substrates, reducing the instability of finished product quality, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

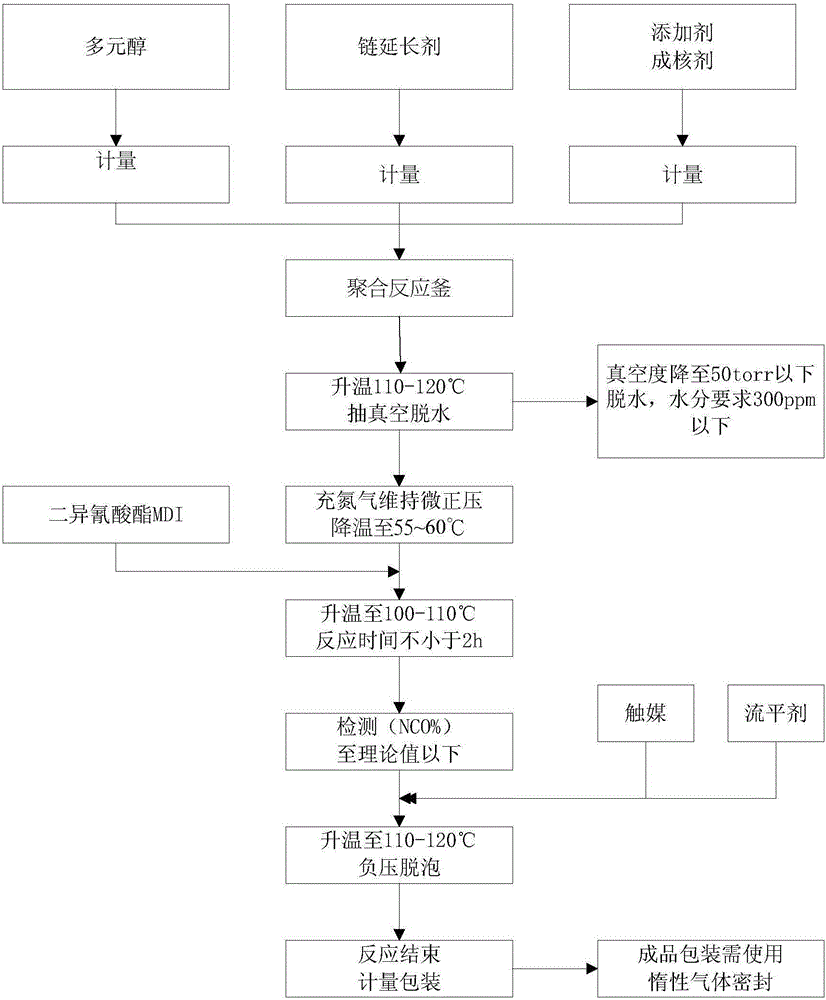

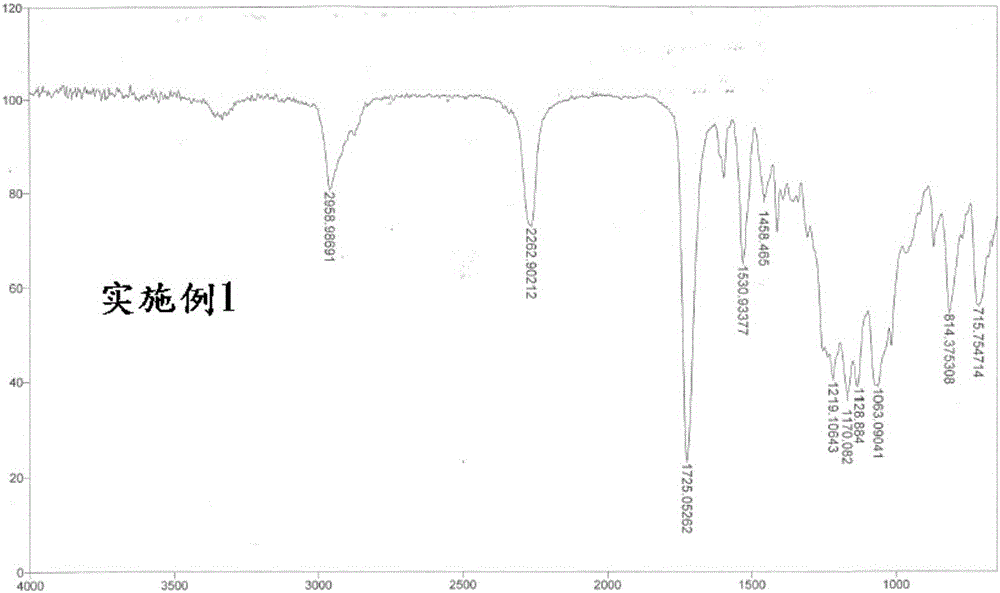

[0087] Such as figure 1 As shown, the present invention prepares the method for moisture-responsive polyurethane hot-melt adhesive for composite flooring comprising the following steps:

[0088] Use two kinds of polyol esters: polybutylene adipate (molecular weight: 3000), polyethylene adipate (molecular weight: 2000), chain extender 1.4-BG, put into the reactor The above three raw materials are further added with a nucleating agent, and the added amount of the nucleating agent is 0.6-0.8% of the total weight of the above three raw materials.

[0089] Heat and melt the raw materials in the polymerization reactor, stir and mix evenly, heat slowly to make the material temperature reach 110-120°C, vacuumize the reactor to reduce the vacuum degree in the reactor to below 50torr, then start dehydration, and continue the negative pressure state for 1-3h After nitrogen filling, return to normal pressure to detect the moisture value contained in the material. If the moisture value re...

Embodiment 2

[0096] The present embodiment is roughly the same as Example 1, and the difference is that polyol ester uses polybutylene adipate (molecular weight is 3000), polyethylene adipate (molecular weight is 2000), polybutylene adipate (molecular weight is 2000), The weight ratio of polyneopentyl glycol isophthalate (molecular weight: 2200) and chain extender 1,4-butanediol (BG) is set to 100:27.6:27.6:3.6. Aromatic polyester polyols are introduced into the formula to improve the bonding performance of the adhesive, especially for high-gloss PVC films, acrylic sheets and smooth wood-plastic sheets. Finally, perform a performance test, such as image 3 The infrared spectrogram analysis shown, the test results of mechanical properties and physical and chemical properties are shown in Table 2, and then the aging properties are shown in Table 3.

Embodiment 3

[0098] This embodiment is roughly the same as Example 1, the difference is that the polyol ester uses poly-1,6-hexanediol adipate (molecular weight is 3700), polyneopentyl isophthalate (molecular weight is 2200), chain extender 1,6-hexanediol (HG), the weight ratio is set to 100:100:8.0. In the formulation, 1,6-hexanediol adipate with a molecular weight of 3700 is used to improve the crystallization performance of the adhesive, and an aromatic polyester polyol is added to improve the adhesion to the southern bonding substrate (low polarity). The product in this example is composed of spectrum As shown in the picture, 728cm -1 There is an obvious sharp peak, which has the main characteristic peak of aromatic polyester polyol. This product has very high initial adhesive strength, especially suitable for gluing low-polarity materials, honeycomb panels and solid wood composite floor panels. Finally, perform a performance test, such as Figure 4 The infrared spectrogram analysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com