Ceramic dumping environment-protection kiln

A kind of kiln and environmental protection technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems such as poor effect, and achieve the effect of good quality, thorough and efficient catalytic reaction, and stable furnace temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

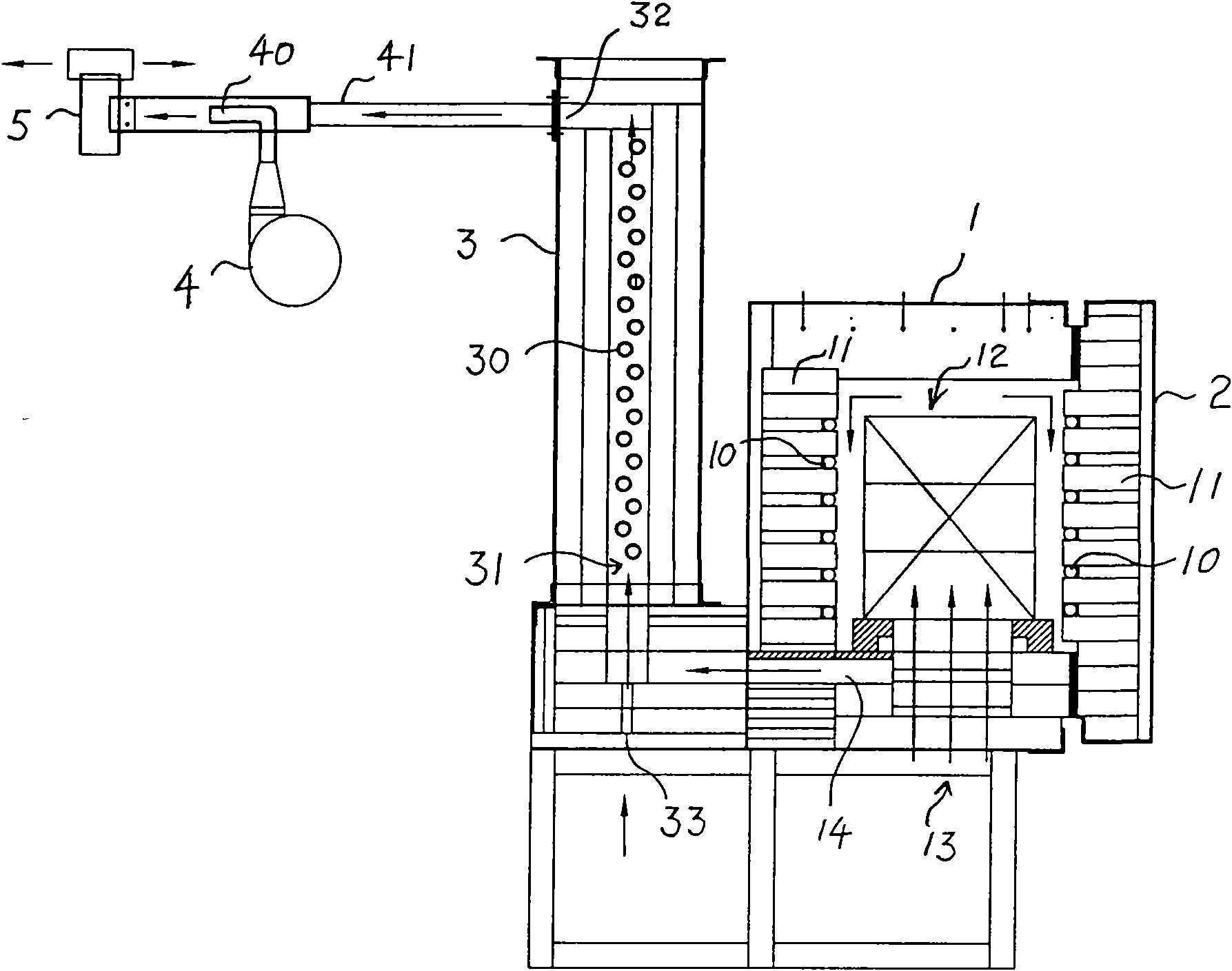

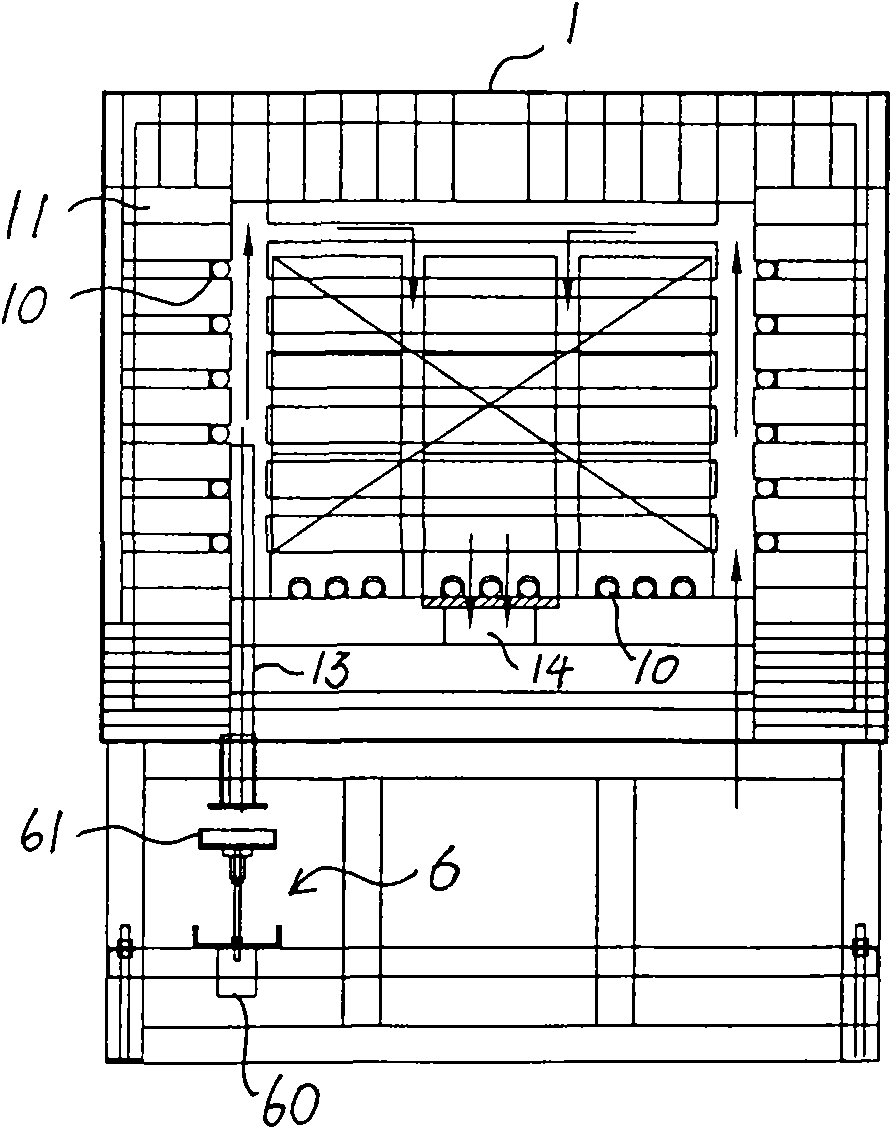

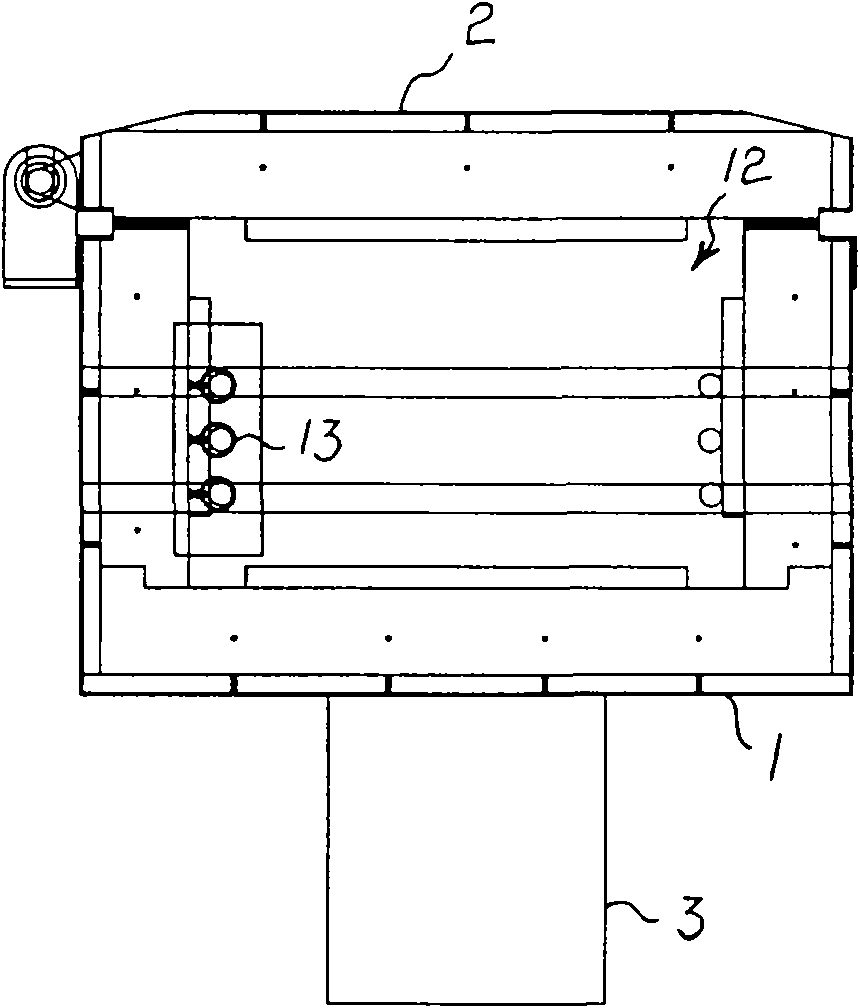

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] A ceramic debinding and environmental protection kiln, which is mainly composed of a debinding heating kiln 1 and a waste removal environmental protection furnace 3. The bottom of the debinding heating kiln 1 is provided with a debinding heating kiln air inlet duct 13 connected to the atmosphere. The space inside the debinding heating kiln 1 connected to the air inlet duct 13 of the debinding heating kiln is the debinding waste gas exhaust and suction chamber 12, and the ceramic materials for debinding treatment are placed in the debinding waste gas exhaust and suction chamber 12, and the exhaust gas is guaranteed to be exhausted. There is a certain space between the glue-treated ceramic material and the inner wall of the debinding heating kiln 1, which is convenient for air convection and fully replaces the waste gas; The collection channel 14 communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com