Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1663 results about "Damp proofing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Damp proofing or a Damp-Proof in construction is a type of moisture control applied to building walls and floors to prevent moisture from passing into the interior spaces. Dampness problems are among the most frequent problems encountered in residences.

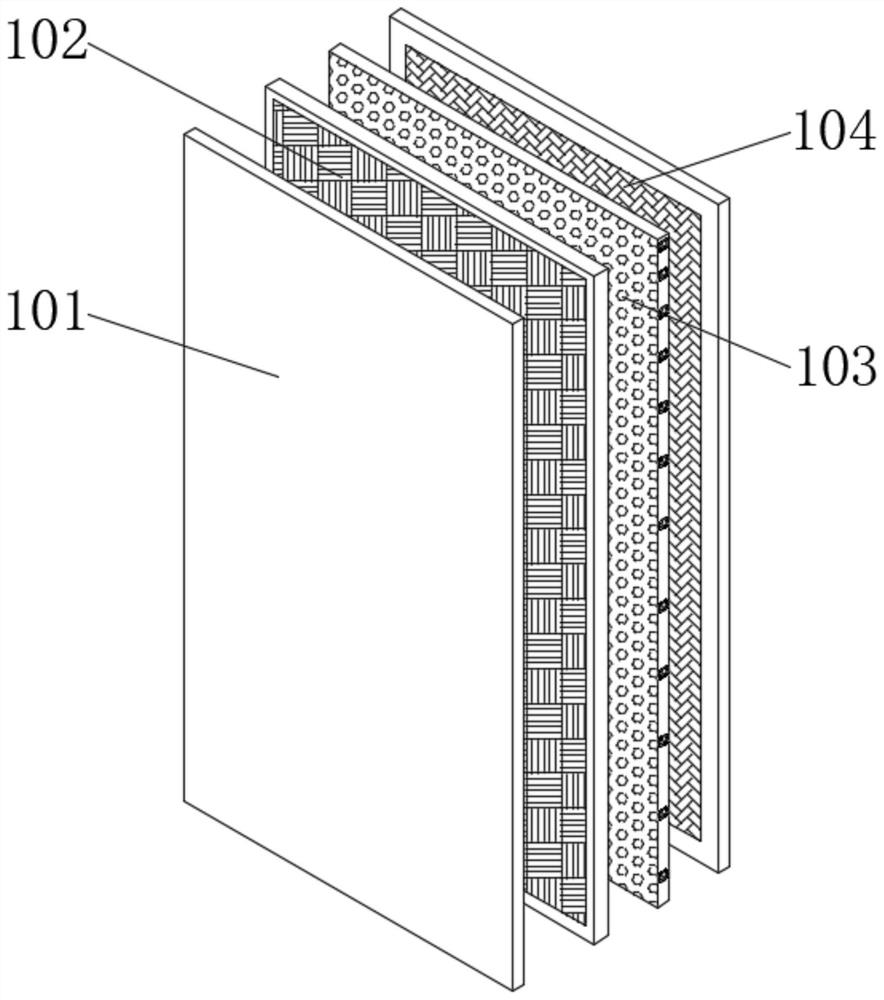

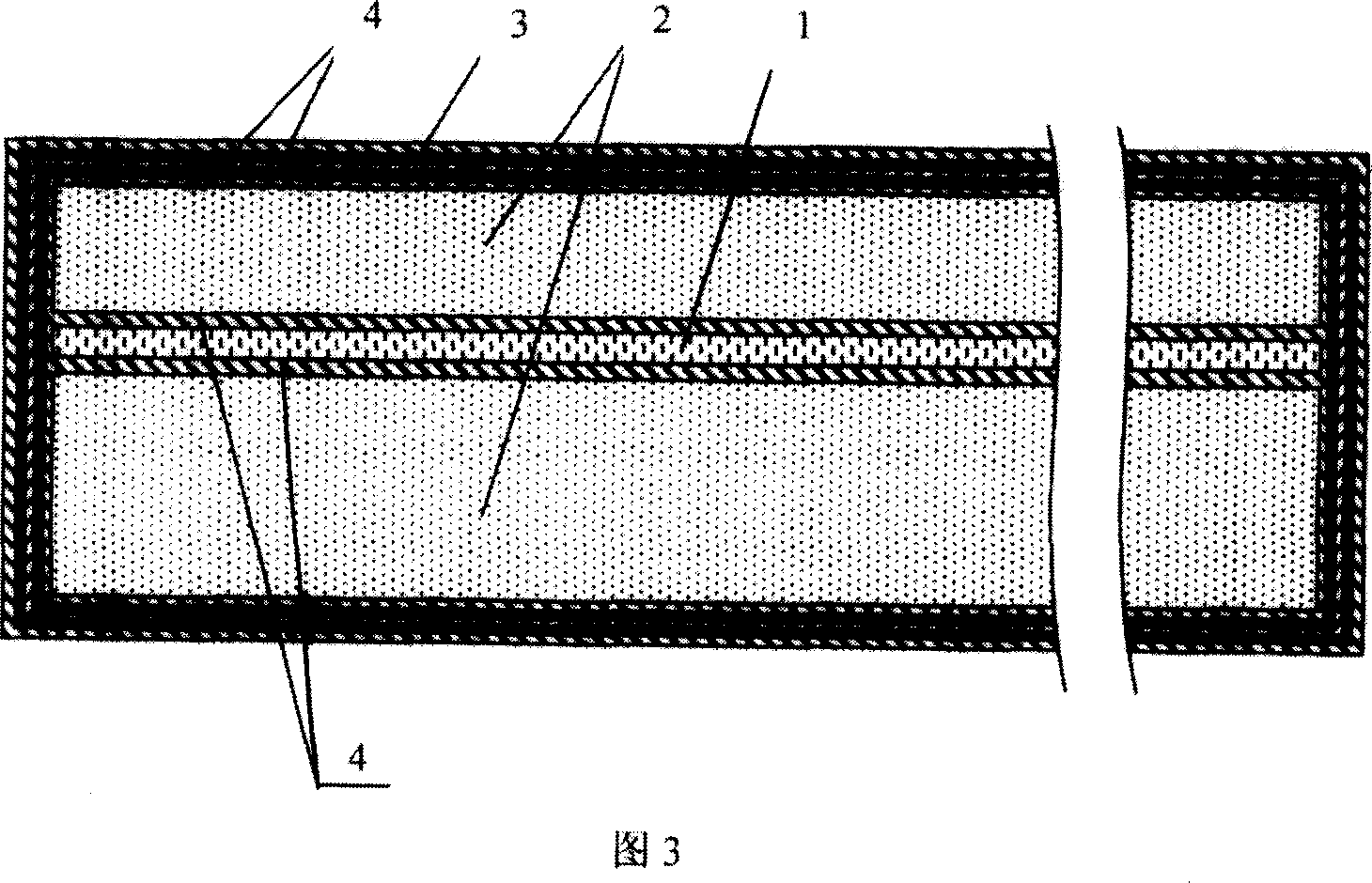

Composite wall panel with low thermal conductivity and sufficient strength for structural use

ActiveUS20130216802A1Improve insulation effectImprove barrier propertiesSolid waste managementWallsThermal insulationRebar

The present invention provides a composite wall panel with good thermal insulation and sufficient strength for structural use which is designed for the fabrication of energy efficient building. The composite wall panel of the present invention comprises a foamed concrete core with sufficient compressive strength and low thermal conductivity which is sandwiched between two lightweight ductile fiber reinforced cementitious composite (FRCC) protective layers with low thermal conductivity, good barrier resistance to moisture / chloride ion / gas, multiple cracking as well as certain amount of steel reinforcements. These composite wall panels are useful in a variety of buildings in both cold and hot regions.

Owner:NANO & ADVANCED MATERIALS INST

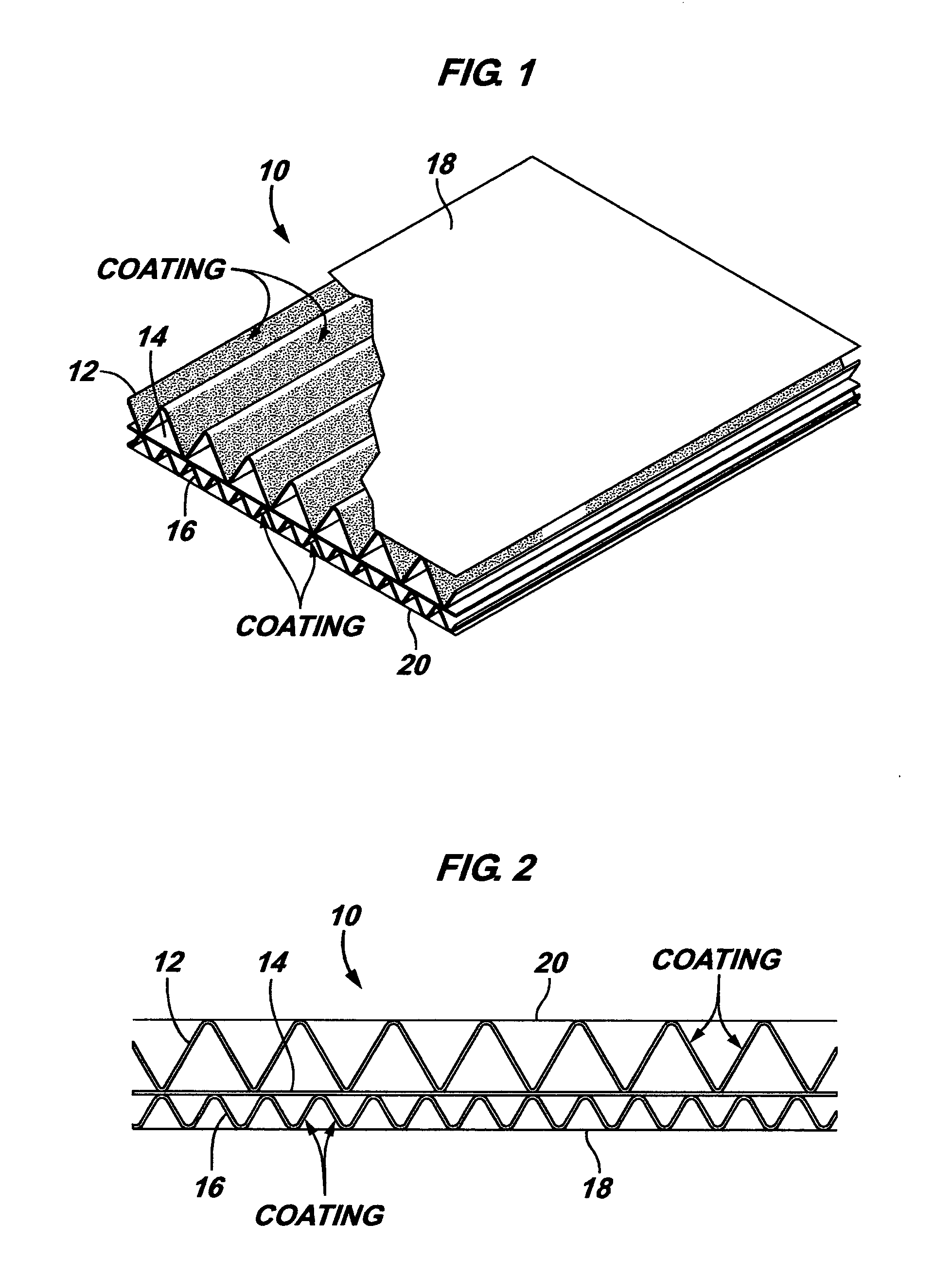

Building cladding panel

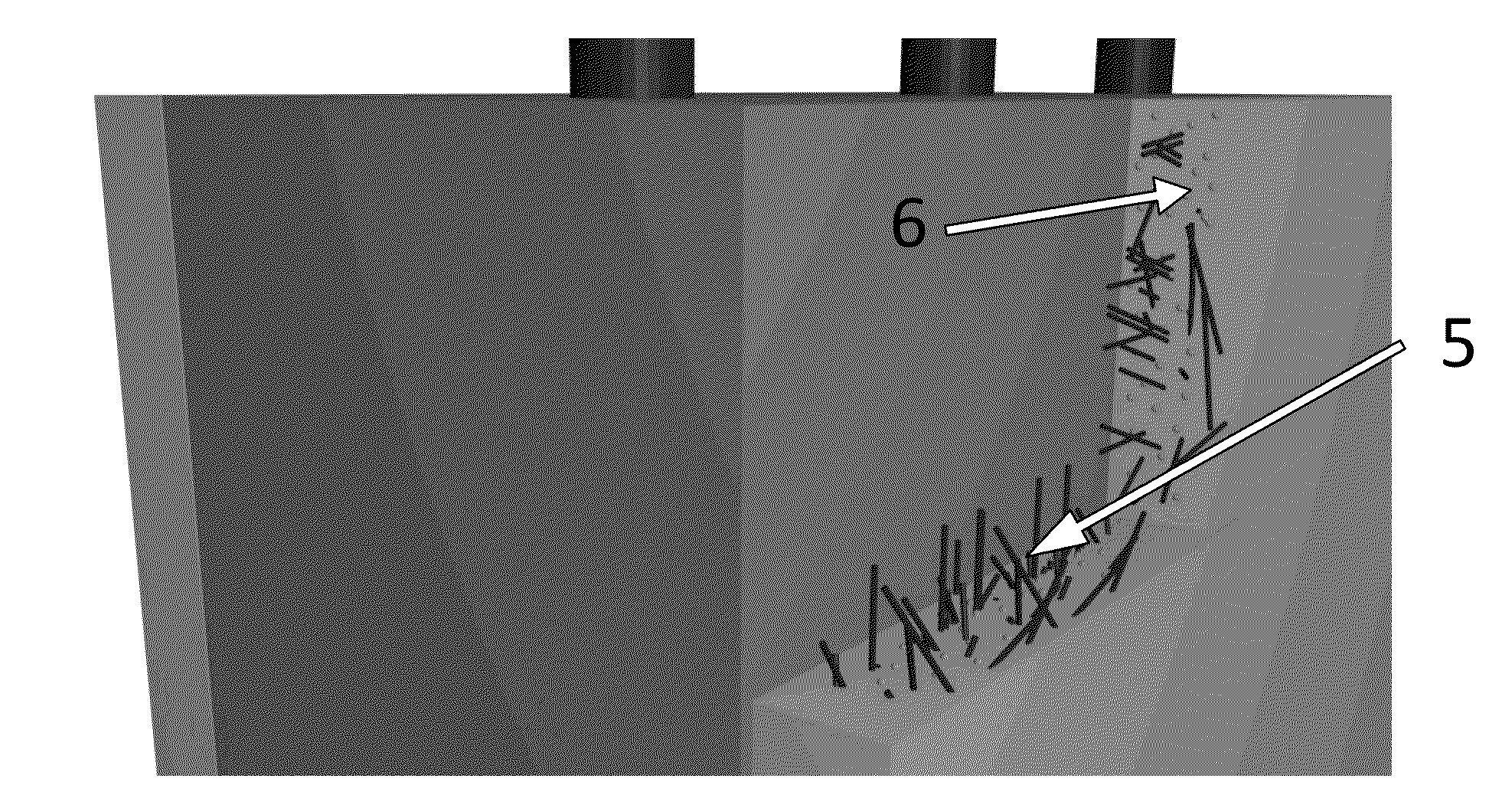

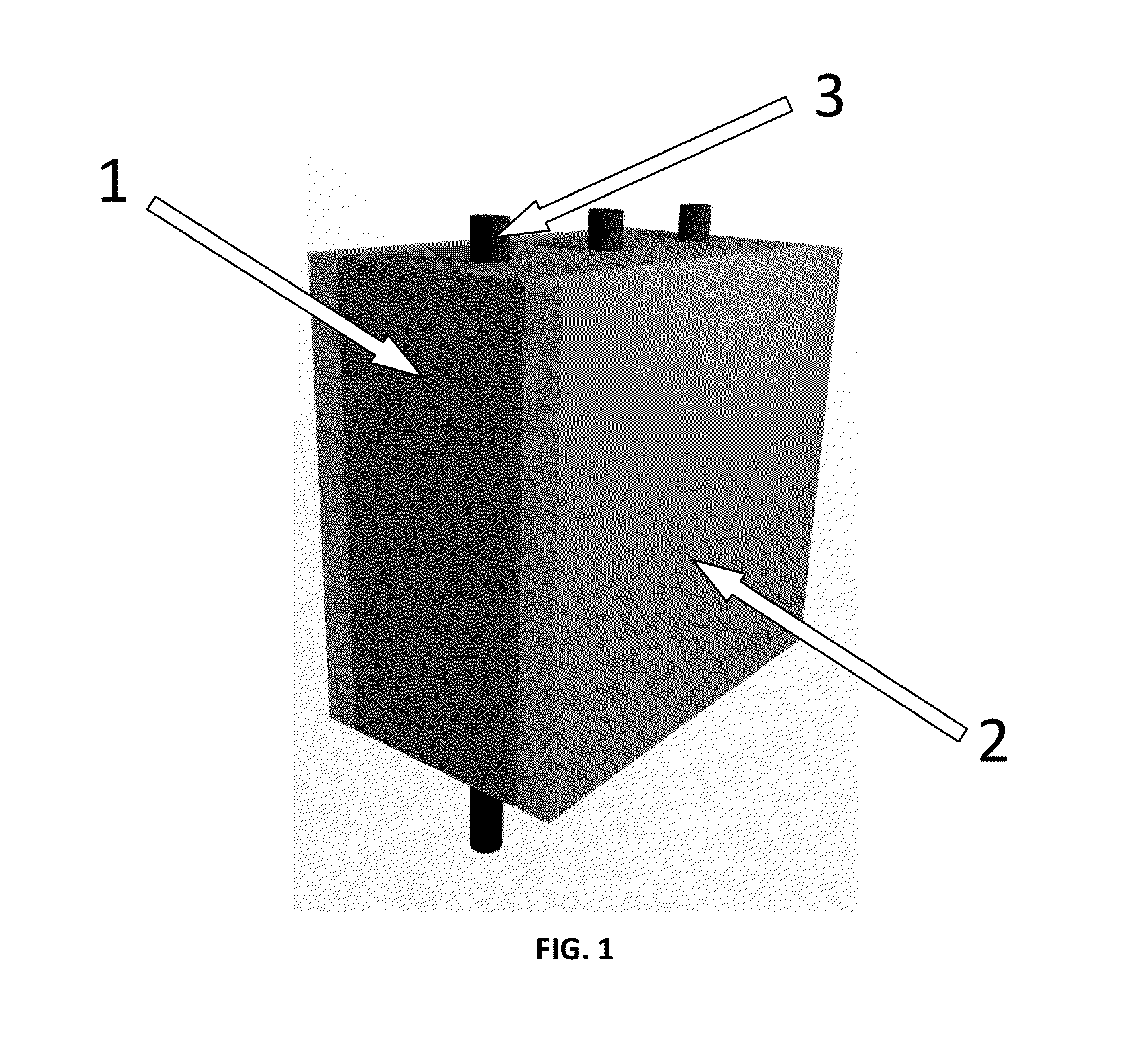

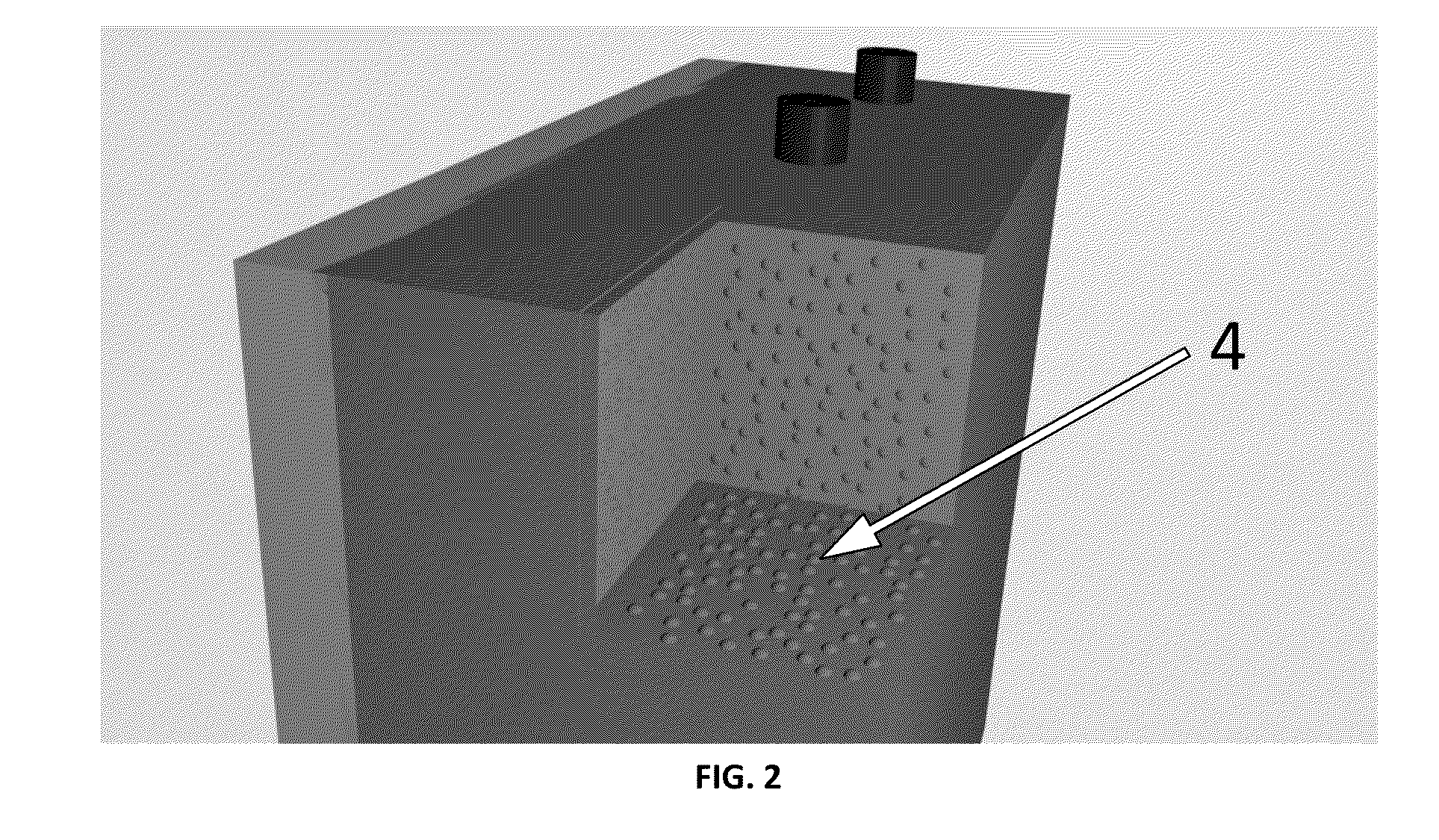

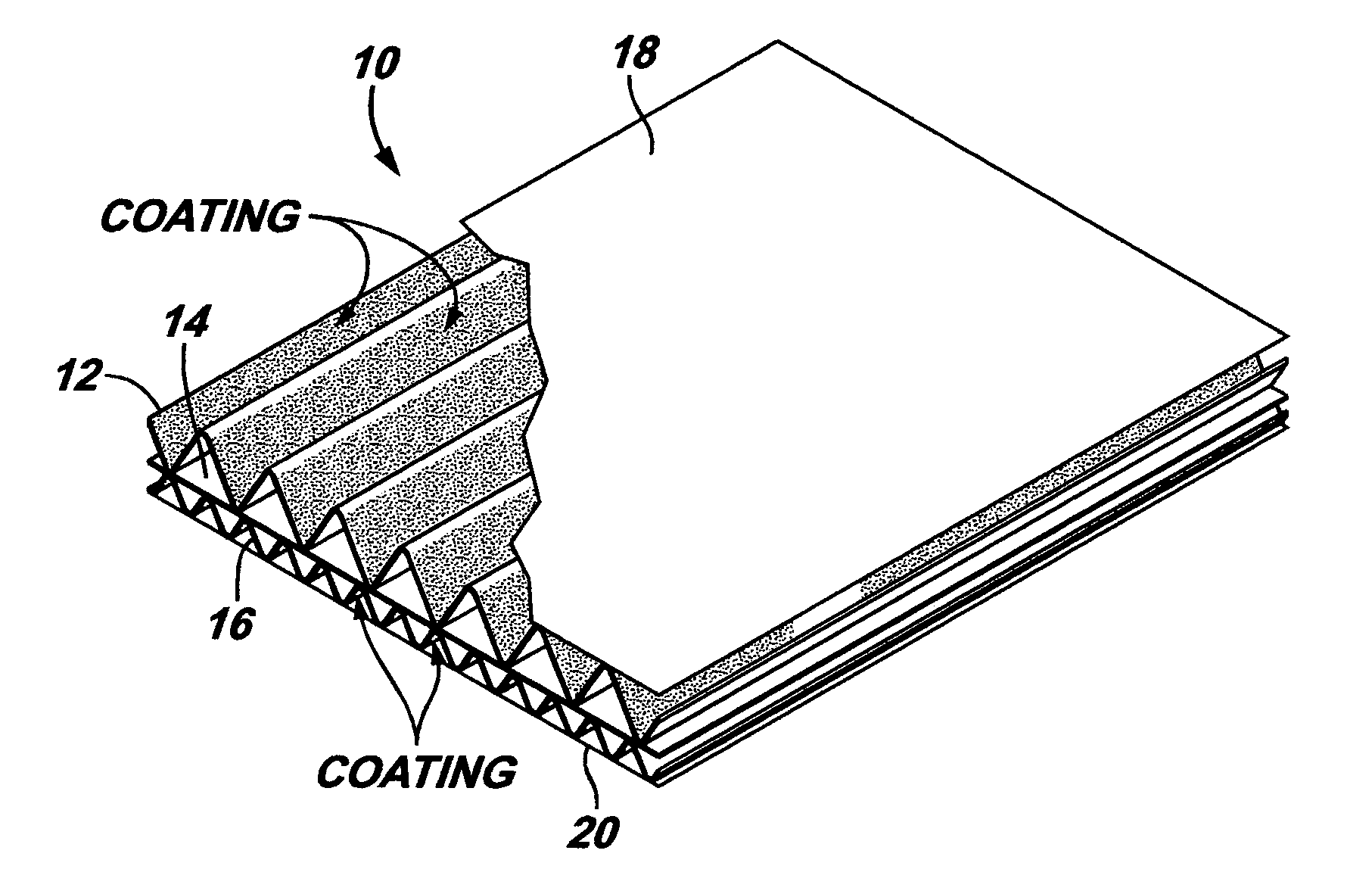

InactiveUS20050066619A1Protection from damageConstruction materialCovering/liningsArchitectural engineeringDamp proofing

An improved building construction panel used to protect the outside surfaces of a building from all forms of weather related damage is formed from two layers of corrugated members bonded to either side of an intermediate insulative sheet. The subject panel is treated to be moisture proof, weather resistant, fire resistant, not attractive to insets, fungus and / or mold and uses only environmentally friendly materials. The construction of the subject panel promotes the rebounding of objects striking its outer surface without damage to the panel.

Owner:MCDONALD MIKE

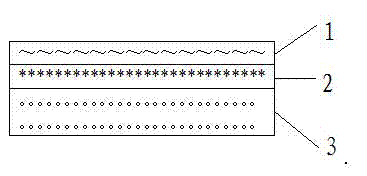

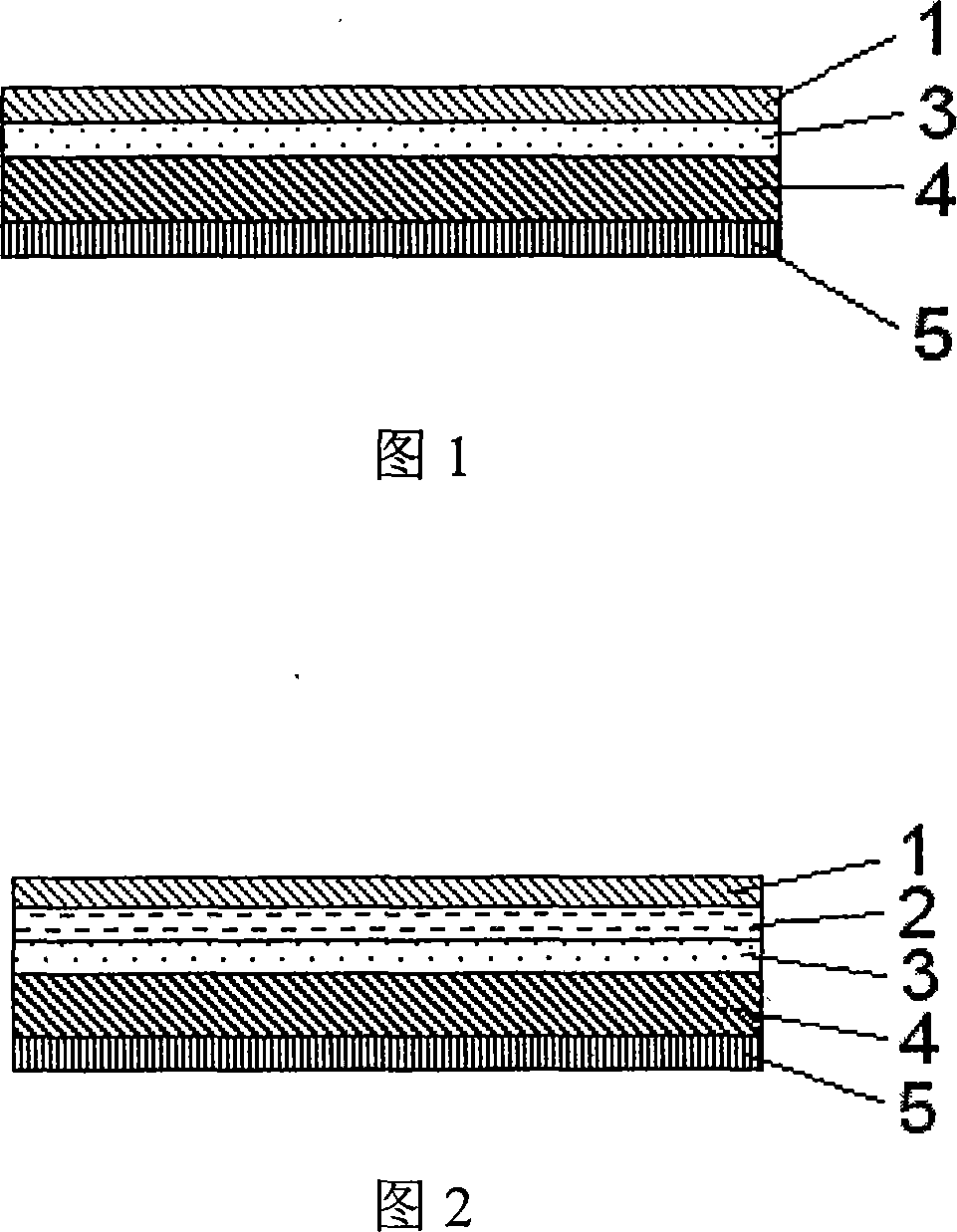

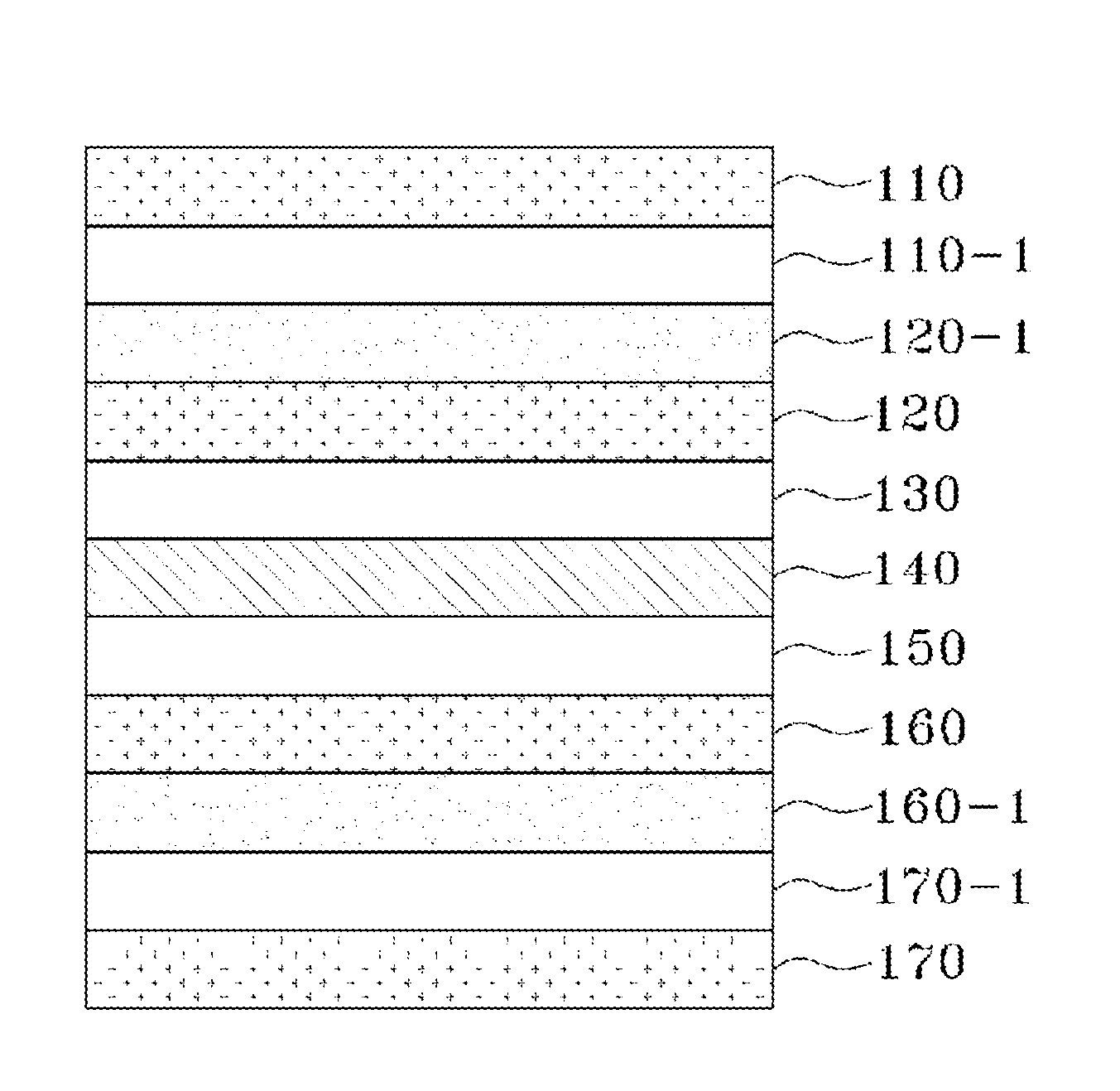

Flexible thermal-insulating decorative material for internal wall and method for producing flexible thermal-insulating decorative material

ActiveCN102505820ALow densityImprove the decorative effectCovering/liningsSynthetic resin layered productsAdhesive cementThermal insulation

The invention discloses a flexible thermal-insulating decorative material for an internal wall and a producing method for the flexible thermal-insulating decorative material. The flexible thermal-insulating decorative material is composed of a flexible inner decorative layer, an adhesive layer and a flexible foamed heat-insulating layer. The invention also provides a method for producing the flexible thermal-insulating decorative material. The flexible thermal-insulating decorative material for the internal wall has the advantages of low energy consumption, good benefit, simple construction and large market, and integrates thermal insulation, damp prevention, mold prevention, sound insulation and decoration; the combination of a flexible foamed heat-insulating material and a flexible decorative material for the internal wall to form the unique decorative material for the internal wall is a great breakthrough for emission reduction and energy conservation of a wall body; and the flexible thermal-insulating decorative material for the internal wall is particularly applicable to energy-saving reconstruction of old buildings.

Owner:四川金路高新材料有限公司

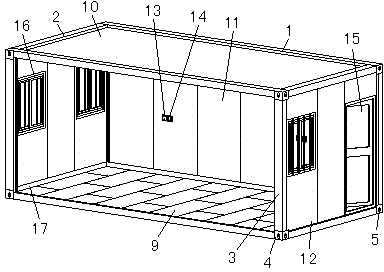

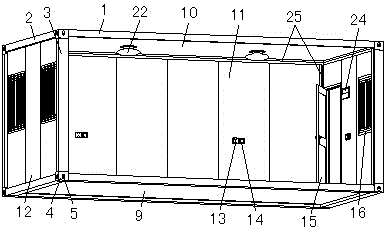

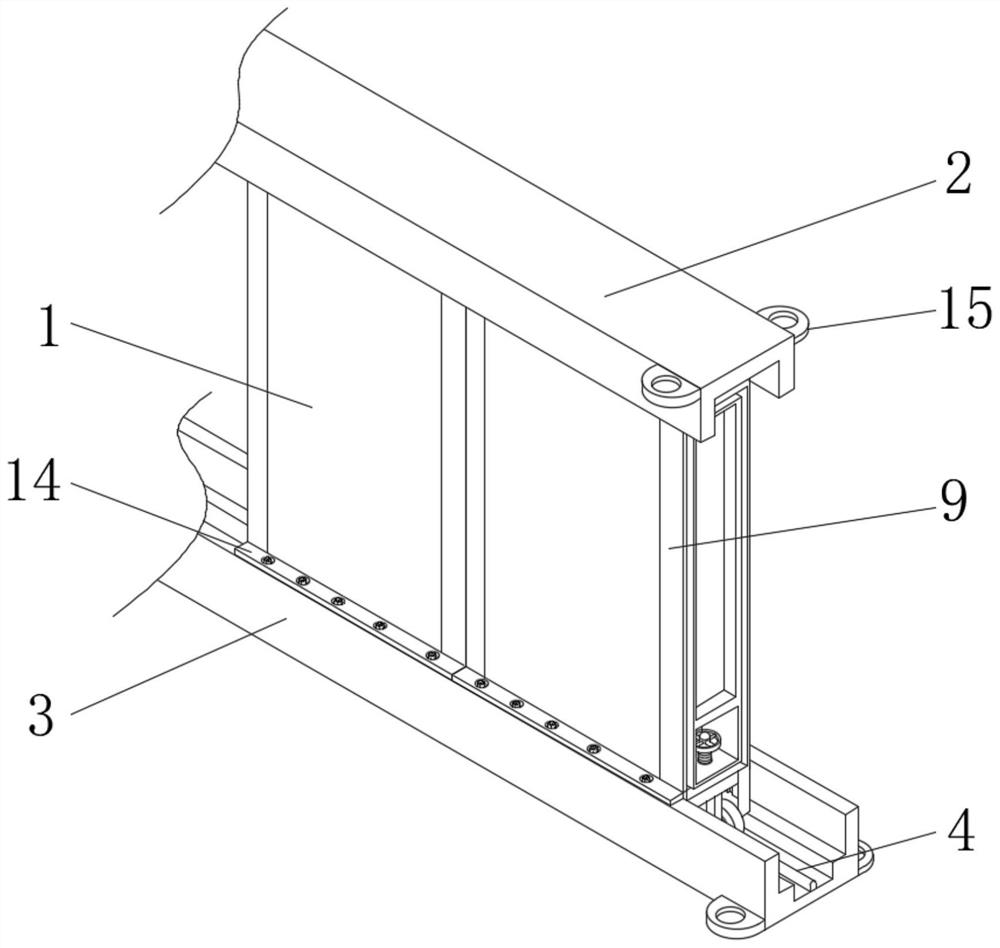

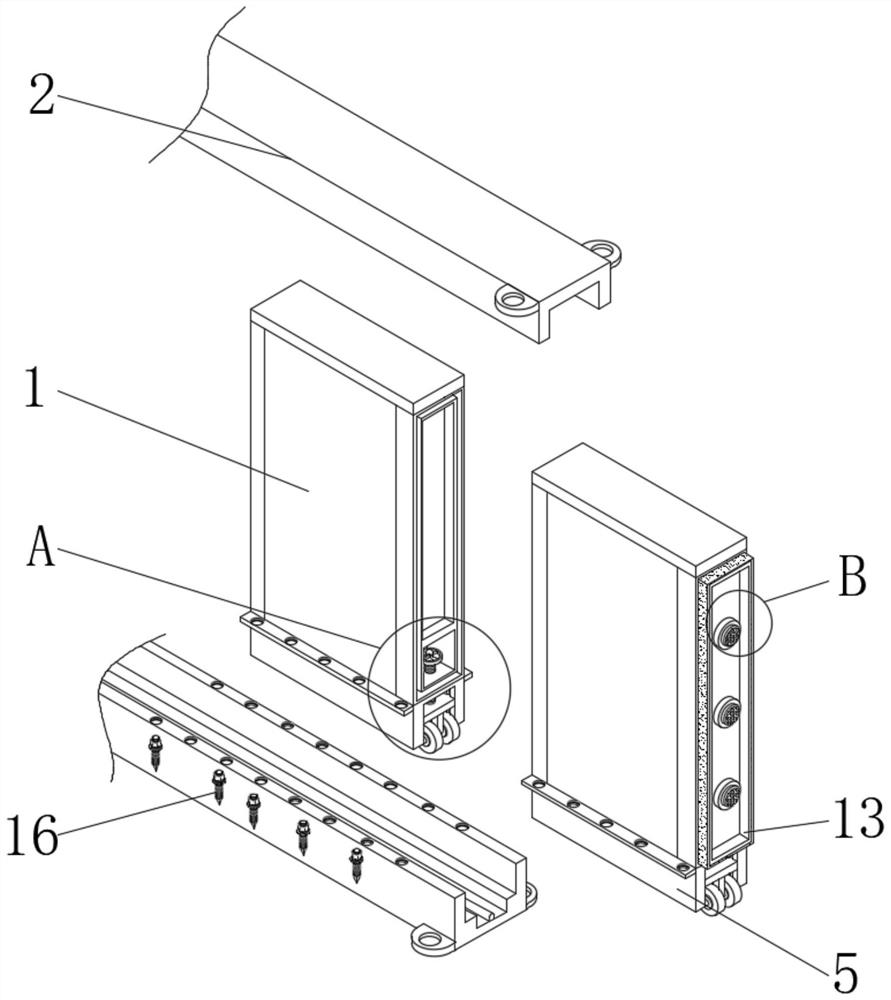

Construction method and structure of spliced type standard temporary houses

ActiveCN105649207AHigh dimensional accuracyImprove interchangeabilityClimate change adaptationBuilding material handlingBolt connectionElectric wire

The invention discloses a construction method and structure of spliced type standard temporary houses. The construction method adopts a standard manufacturing mode, in the splicing process, only a framework adopts bolts for connection, other parts are all connected in a clamping or plugging mode, and the whole splicing process does not need welding. The framework is formed by bending and forming Q235 galvanized steel plates 3 mm thick overall, is high in strength and is not prone to rusting, thereby improving the circulation rate. All components are high in size accuracy and good in interchangeability, only galvanized bolts are adopted for connection in the splicing process, assembling and disassembling are simple, convenient and rapid, and the construction period is short. Combination is flexible, and office rooms, temporary meeting rooms, dormitories, dining rooms, bathrooms, toilets, standard rooms, power distribution rooms, water pump rooms and the like with different areas and different purposes can be obtained in a freely spliced mode. All wires are pre-buried in wall boards at a time when processed in a factory and do not need to be arranged on site. The construction method and structure of the spliced type standard temporary houses further have the characteristics of firmness, durability, dampproofness, wind resistance, fireproofness, corrosion resistance, heat insulation, sound insulation and heat preservation.

Owner:CHINA CONSTR FOURTH ENG DIV

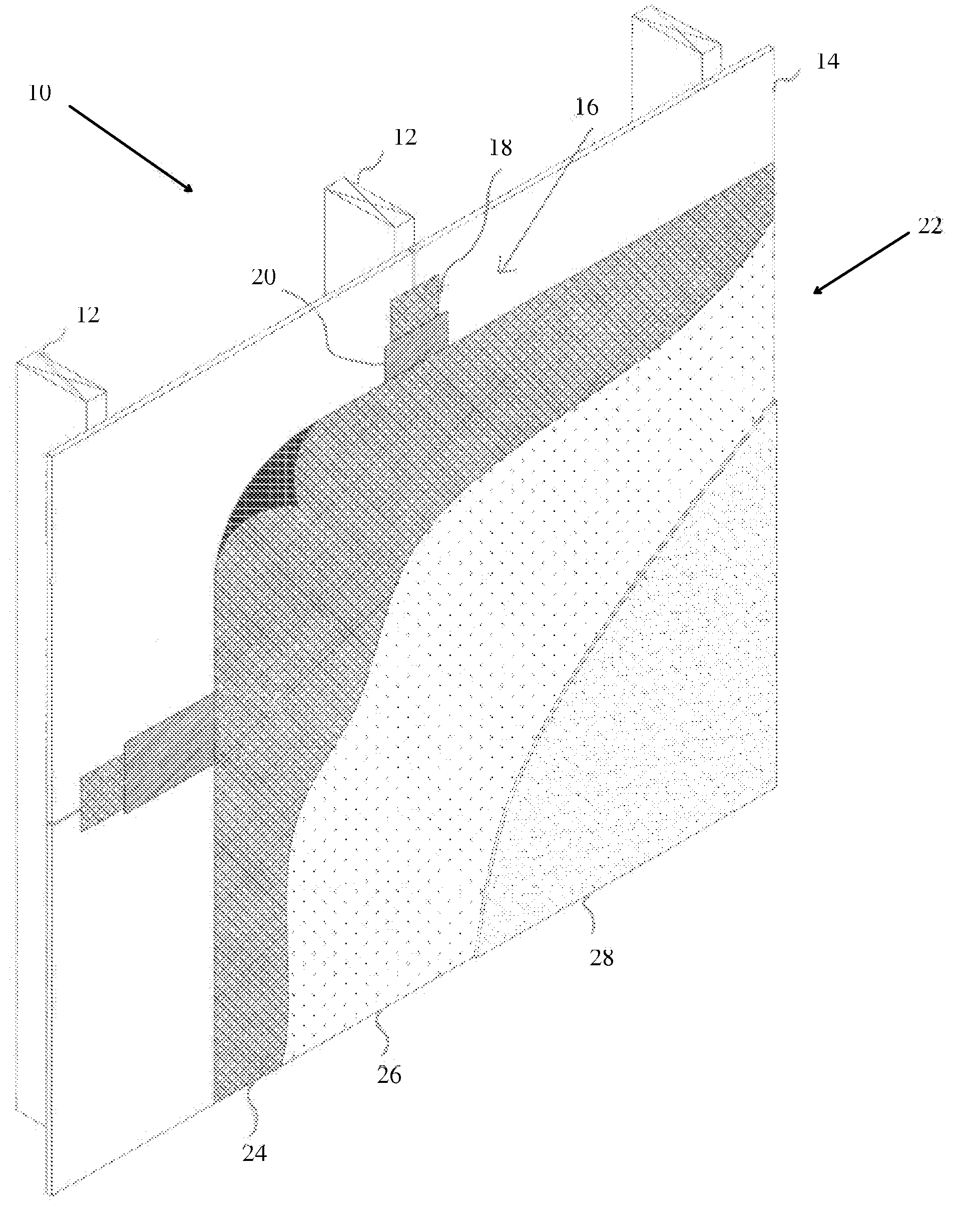

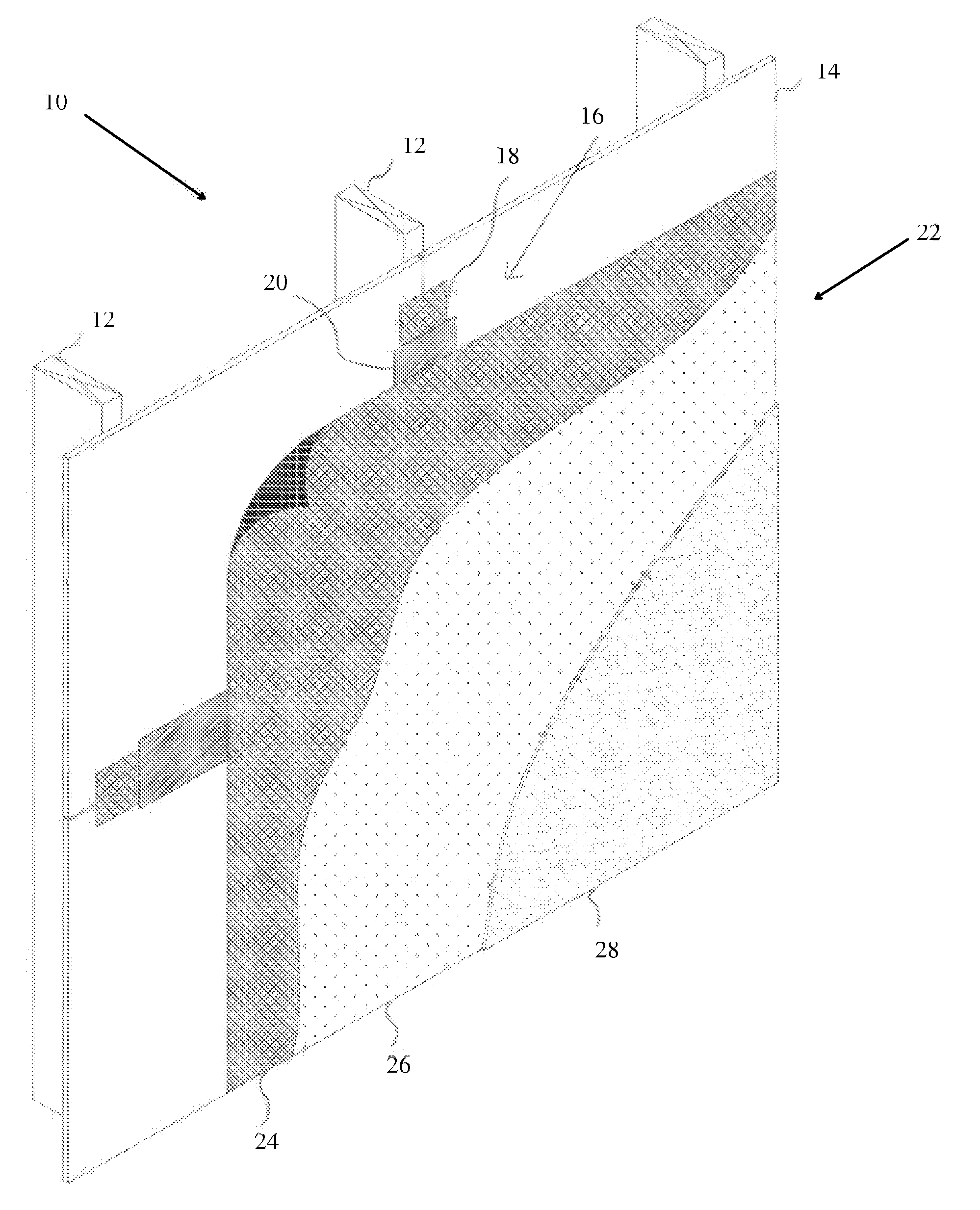

Compositions and methods for coating surfaces

An exterior building cladding system and methods of applying the building cladding system are described. The system is a weather resistive barrier and decorative system that is particularly effective as a covering system for buildings having an exterior wood substrate. The system includes a flexible waterproof base layer of acrylic and rubber that is adhered directly to a wood substrate, a mesh embedded in the flexible waterproof base layer and an acrylic stucco outer layer adhering directly to the flexible waterproof base layer. The system eliminates the need for building wrap while providing a moisture resistant and vapour permeable layer.

Owner:CANO COATINGS

Light inorganic silicate fiber reinforcing fireproof paint and preparation method thereof

The invention relates to a fireproof heat-insulation paint, in particular to a light inorganic silicate fiber reinforcing fireproof paint which is characterized by comprising the following materials in percentage by weight: 10%-30% of building gypsum powder, 5%-15% of silica sol, 15%-30% of soft clay, 5%-15% of cenospheres, 5%-20% of diatomite, 5%-15% of expanded vermiculites, 2%-10% of silicate fibers, 0.5%-5% of gypsum retarders and 0.5%-2% of damp-proofing agents. The light inorganic silicate fiber reinforcing fireproof paint is respectively packaged into a solid material and a liquid material and is the fireproof heat-insulation paint which has the advantages of environmental protection, acid-alkali resistance, light weight, noninflammability, heat insulation and sound absorption function.

Owner:新疆鲁阳陶瓷纤维有限公司

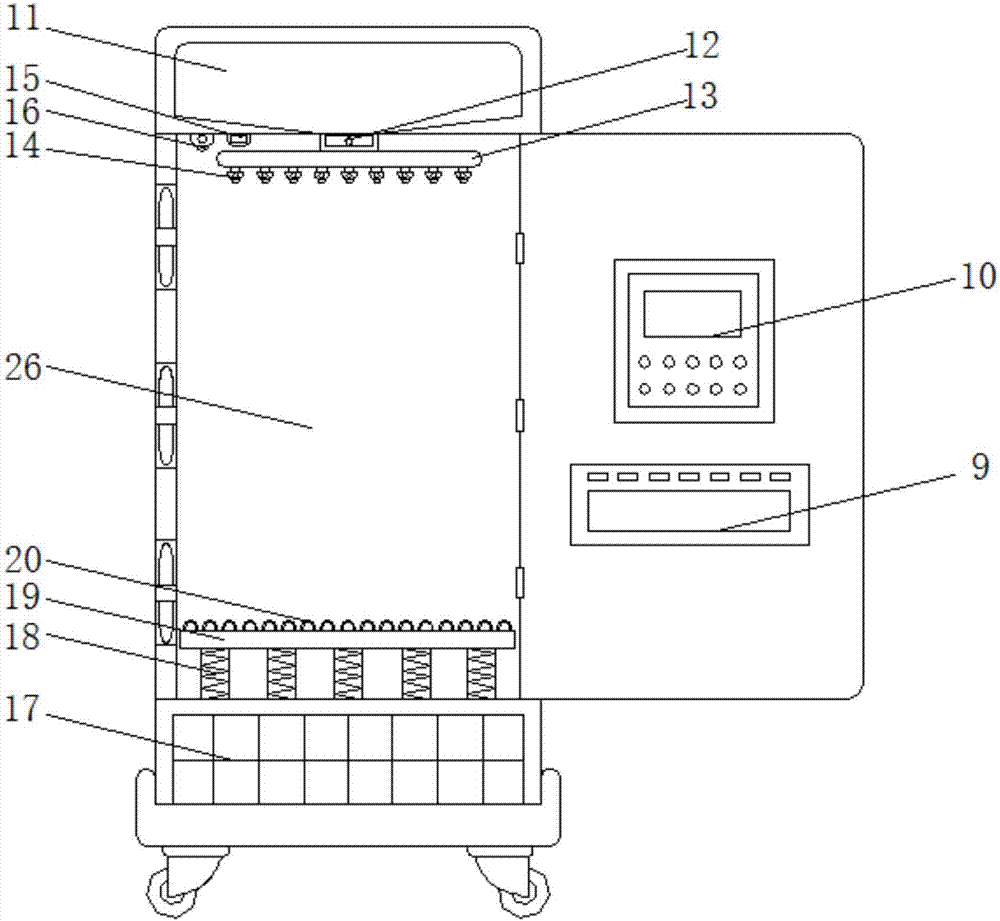

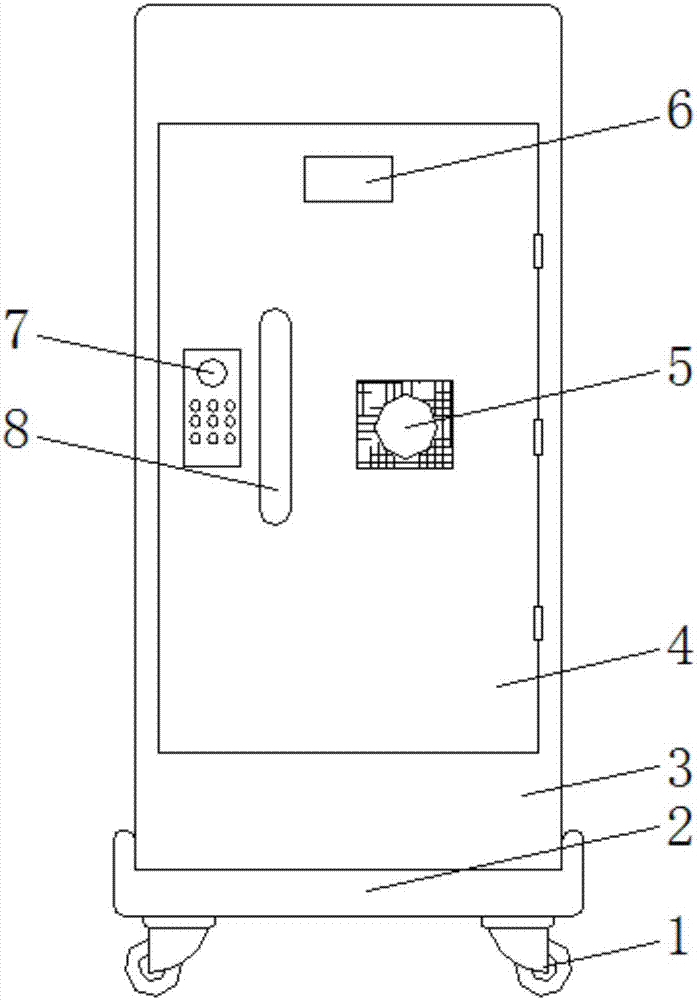

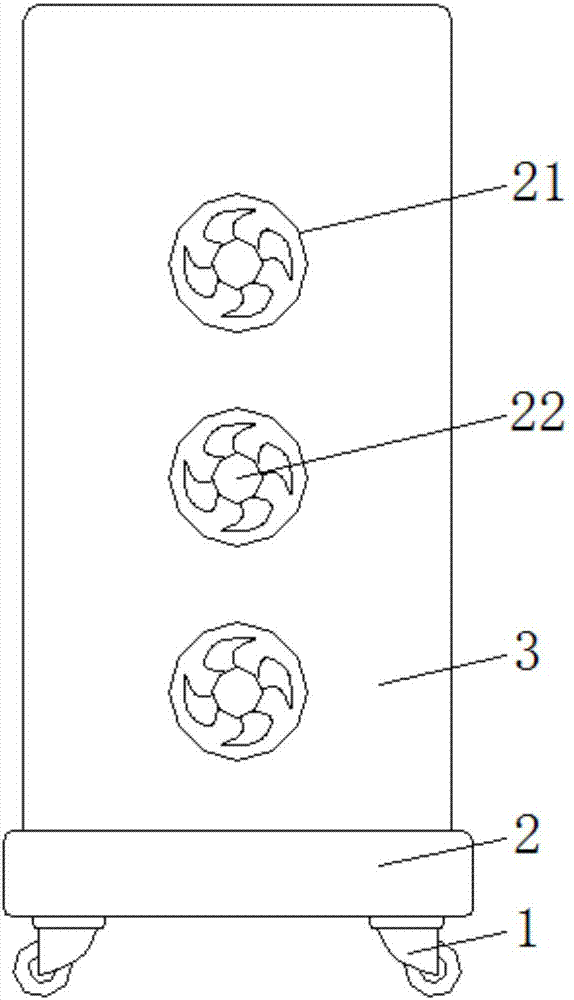

Highly safe high-tension switch cabinet

PendingCN106992441AMovableImprove securityBus-bar/wiring layoutsBoards/switchyards circuit arrangementsSolenoid valveFire - disasters

The invention discloses a highly safe high-tension switch cabinet. The high-tension switch cabinet comprises a universal wheel, a cabinet body, a cabinet door and an installation cavity. A moisture-proof plate is installed at the bottom of the cabinet body. The universal wheel is installed at the bottom of the moisture-proof plate. A sound-light alarm and an electronic coded lock are installed on the surface of the cabinet door under a temperature digital display screen. A power supply controller and a controller are installed on the inner surface of the cabinet door. A filtering fence is installed in an installation through hole in the outer side of a heat dissipation fan. A storage battery is installed on the lower end of the interior of the cabinet body. An installation plate is installed at the bottom of the installation cavity through a damping spring. A fire disaster sensor and a temperature sensor are installed on the top end of the interior of the installation cavity. A solenoid valve is installed on the output end of the fire extinguisher. Spraying heads are uniformly arranged on a spraying cloth rod. According to the invention, by installing a series of structures, the use safety performance of the high-tension switch cabinet is quite high.

Owner:CHINA SCI TIANGONG ELECTRICAL HLDG

Water-based expoxy antiquing coating, preparation method and application as well as using method thereof

The invention relates to a water-based expoxy antiquing coating, a preparation method and application as well as using method thereof. The antiquing coating is composed of a water-based sealing primer, a middle coating, a coloring agent and a water-based finishing coat, wherein the water-based sealing primer, the middle coating and the water-based finishing coat are composed of two components; the antiquing coating is suitable for various new and old cement floors and new and old wall surfaces; pain films have the performances such as water resistance, medicine resistance, solvent resistance, corrosion resistance and moisture proofing; the water-based expoxy antiquing coating can meet the requirements of modern industrial terraces and has the advantages which a solvent type expoxy terrace coating does not have; the coating effect and the color of the water-based expoxy antiquing coating are three-dimensional; the flower color of the water-based expoxy antiquing coating is various; and the water-based expoxy antiquing coating is safe, non-toxic and pollution-free in the construction process, breaks through the situation that a solvent based coating occupies the leading market, broadens and meets the market requirement.

Owner:刘娜

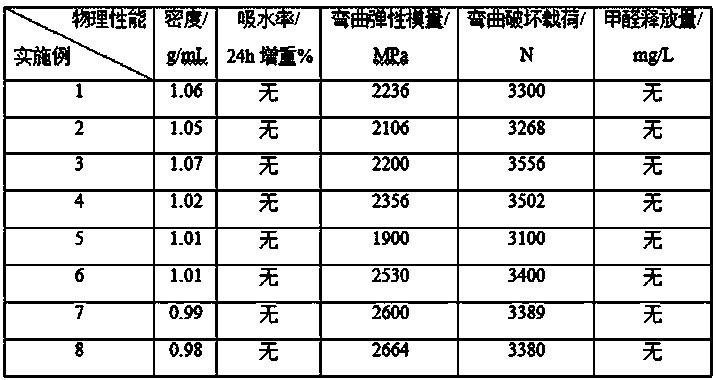

Super-low-temperature-resistant weather-resistant low-smoke halogen-free flame-retarding PC material and preparation method thereof

InactiveCN108102328AExcellent light resistance and moisture resistanceImprove impact performanceWeather resistanceVolumetric Mass Density

Owner:上海日之升科技有限公司

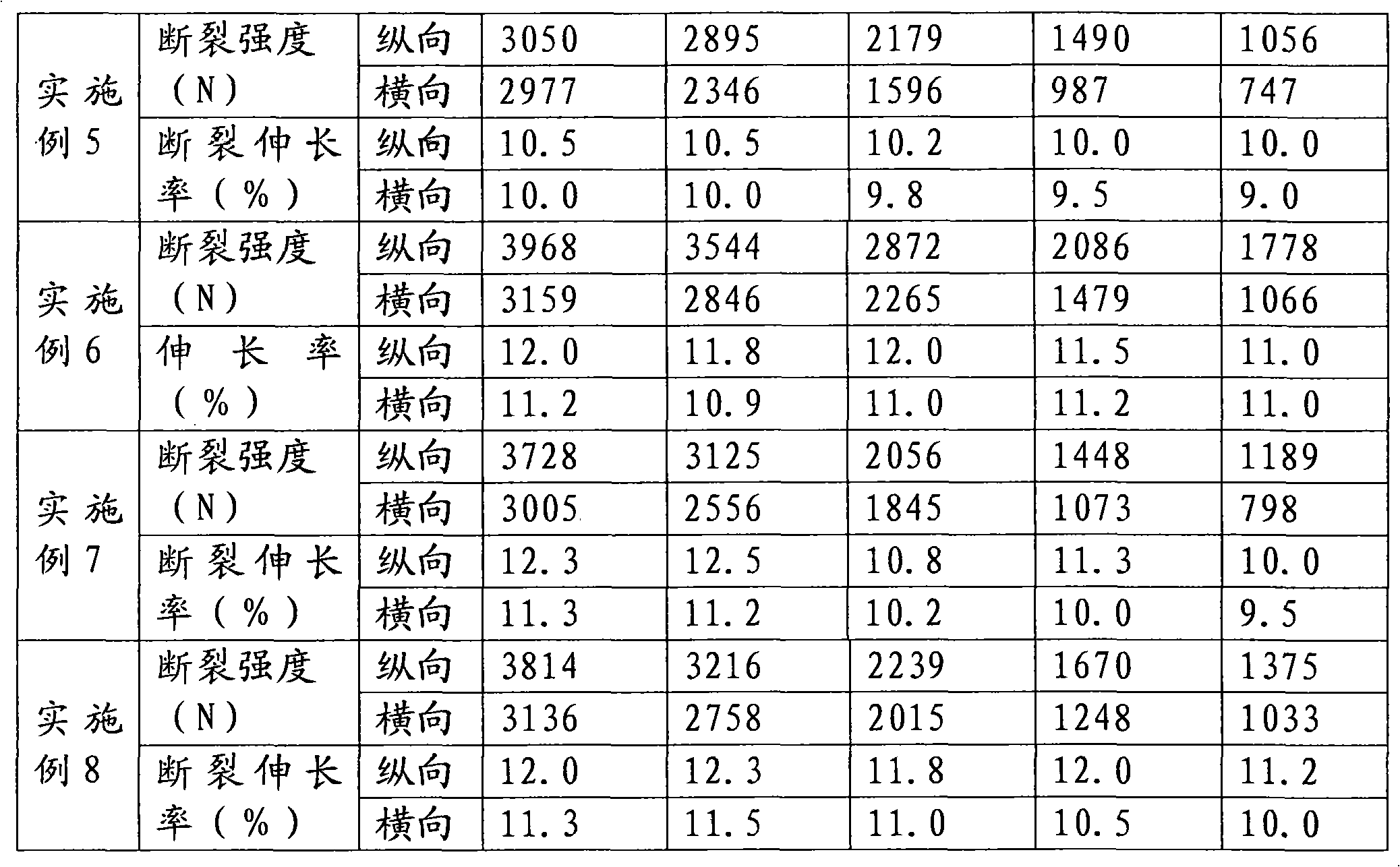

Fibrilia wall cloth

InactiveCN101935917AAchieve deformation factorRealization of longitudinal and transverse fracture strengthNon-woven fabricsAdhesiveNonwoven fabric

The invention discloses fibrilia wall cloth, which consists of a single fibrilia non-woven layer. The fibrilia non-woven wall cloth has the gram weight of 80 to 300 g / m<2>, and comprises the following components in percentage by weight: 5 to 100 percent of fibrilia and 0 to 95 percent of other fibers except the fibrilia, wherein the other fibers at least comprise tacky fibers. The fibrilia wall cloth solves the problem of environmental unfriendliness caused by the need of bonding between fibrilia and a substrate which needs arranging in the fibrilia wall cloth in the prior art in a great number of adhesives. In the invention, the fibrilia wall cloth capable of being used without the substrate is obtained by properly selecting the gram weight of the fibrilia wall cloth, and has the characteristics of rot resistance, damp proofing and environmental friendliness.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

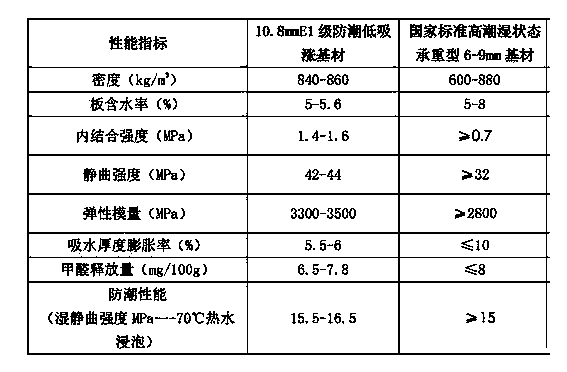

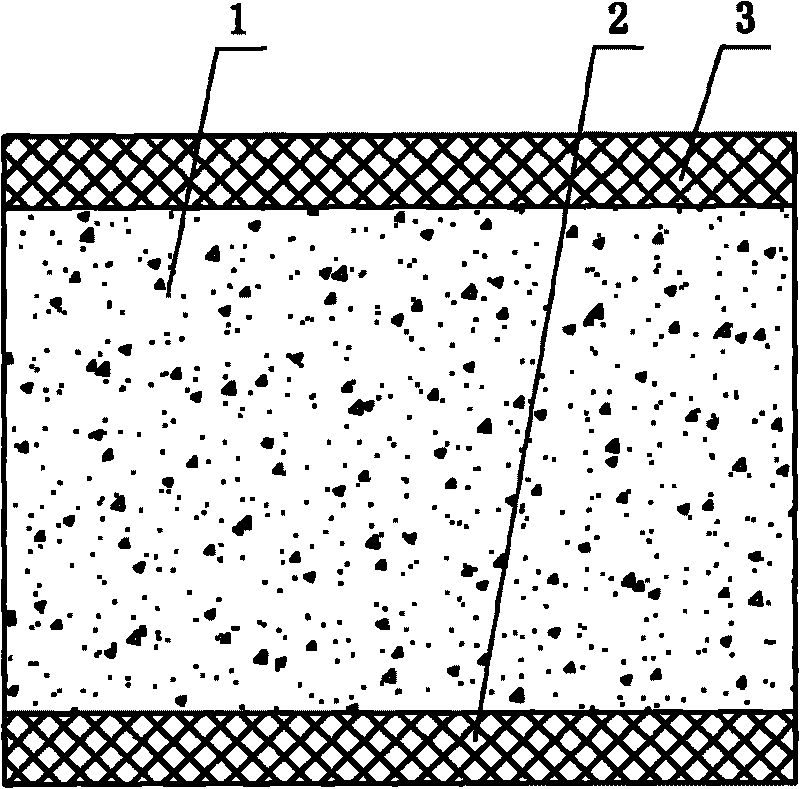

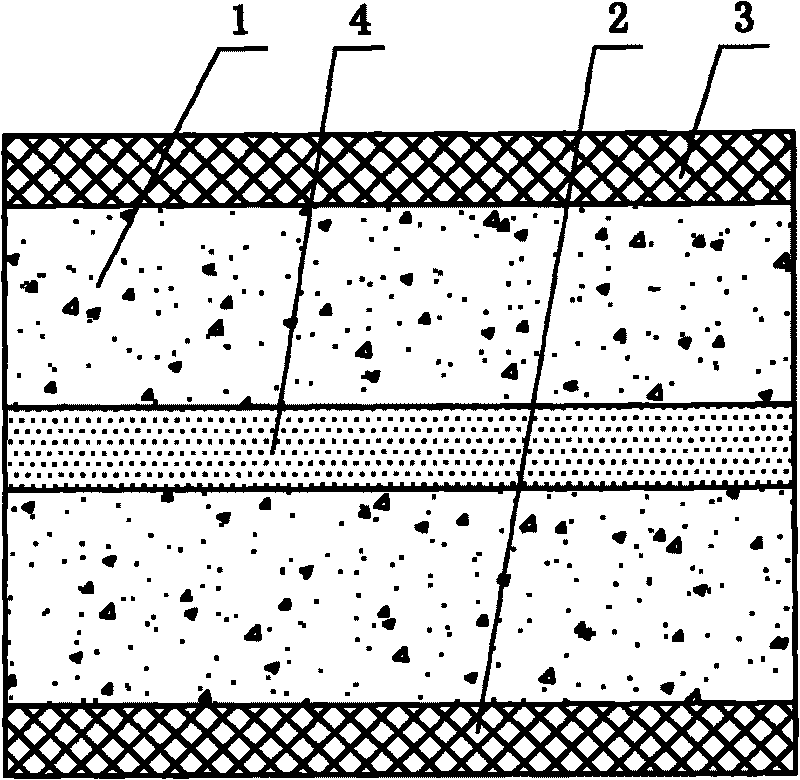

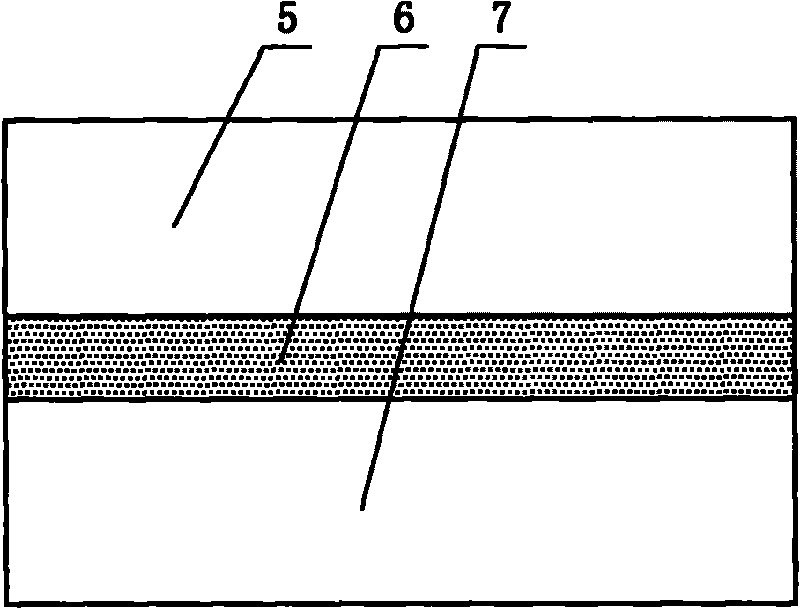

Process for manufacturing damp-proof low-water-swelling floor base material and method for manufacturing adhesive

ActiveCN103628362ALow water absorption thickness expansionHigh water absorption thickness expansionFibreboardAldehyde/ketone condensation polymer adhesivesAdhesive cementFiber

The invention belongs to the technical field of wood processing, and relates to a process for manufacturing a floor base material, in particular to a process for manufacturing a damp-proof low-water-swelling floor base material and a method for manufacturing adhesive. The process for manufacturing the damp-proof low-water-swelling floor base material includes the following steps of wood peeling, chipping, screening, washing, cooking, fiber separating, glue mixing and applying, drying and sorting, paving and forming, prepressing, hot pressing, cooling, sanding, inspecting and grading, and packaging and storage entering. According to the special requirements of the damp-proof low-water-swelling floor base material, the melamine modified urea resin damp-proof adhesive is adopted, and the floor base material with the high waterproof and damp-proof performance is developed according to the low thickness swelling rate of water absorption and damp-proof requirements and based on the production process of a common floor base material. The floor base material manufactured through the method is low in cost and high in quality and has the damp-proof function, the low thickness swelling rate of water absorption of a floor made of the base material is low, and the floor has the damp-proof function and is suitable for home service environments in a high damp state.

Owner:DARE WOOD BASED PANEL GRP

Cement-based decoration material, decoration plate and production method thereof

InactiveCN101693609AImprove general performanceAnti-agingCovering/liningsMixing operation control apparatusCelluloseWeather resistance

The invention relates to a cement-based decoration material which comprises cement flour, emulsion and cellulose in following component relations: when the emulsion is liquid emulsion, the ratio of the cement lour to the emulsion is 100: 40-100, and the ratio of the cement to the cellulose is 100:0.1-0.5; and when the emulsion is dispersible emulsion, the ratio of the cement lour to the emulsion is 100:1.5-2.4, and the ratio of the cement to the cellulose is 100:0.1-0.5. The decoration plate provided by the invention can be directly applied to internal and external walls and floors of buildings, also can be used as waterproof materials of roofs, underground structures, washrooms, or kitchens, can realize the protection against water, fire, damp, crack and falling off, and has good aging resistance and weather resistance and same service life with buildings and is a novel poisonless, tasteless, environment-friendly and energy-saving product with convenient use, low production cost and long service life.

Owner:陈友增

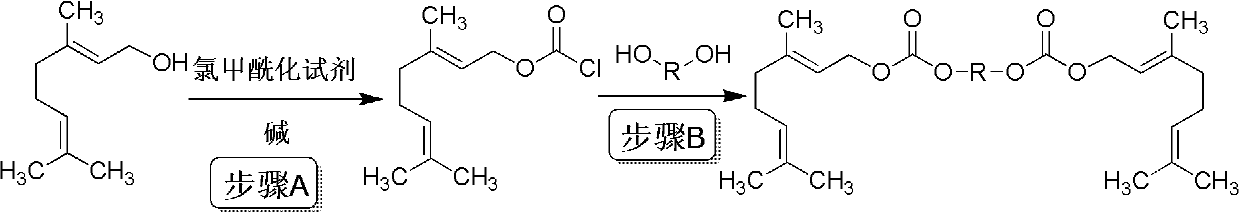

Monosaccharide geraniol carbonate diester compound, preparation method and use thereof

InactiveCN102304155AWater solubleFat solubleEsterified saccharide compoundsTobacco treatmentGeraniolStructural unit

The invention relates to a tobacco humectant, discloses a monosaccharide geraniol carbonate diester compound, and further discloses a preparation method for the monosaccharide geraniol carbonate diester compound. According to the present invention, the effects of humidity preserving, damp proofing, slow perfume releasing and sensory evaluation of the monosaccharide geraniol carbonate diester compound adopted as the tobacco humectant are tested. The test results show that: the monosaccharide geraniol carbonate diester compound provides the humidity preserving property for the tobacco, and has effects of aroma increasing, uniform aroma releasing and improvement of organoleptic quality of the tobacco. In the formula provided by the present invention, O-R-O represents a residue of five-carbon or six-carbon monosaccharide, the two geraniol carbonate structure units are positioned on any two possible locations of the five-carbon or six-carbon monosaccharide.

Owner:CHINA TOBACCO CHUANYU IND +1

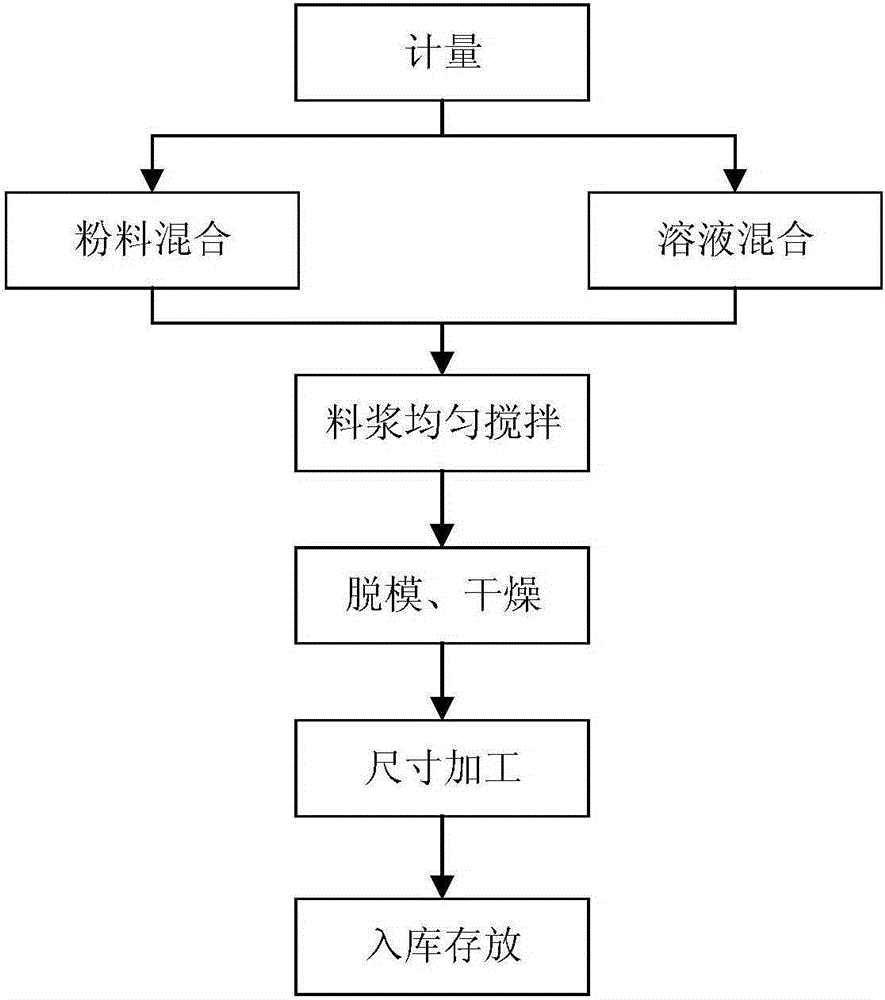

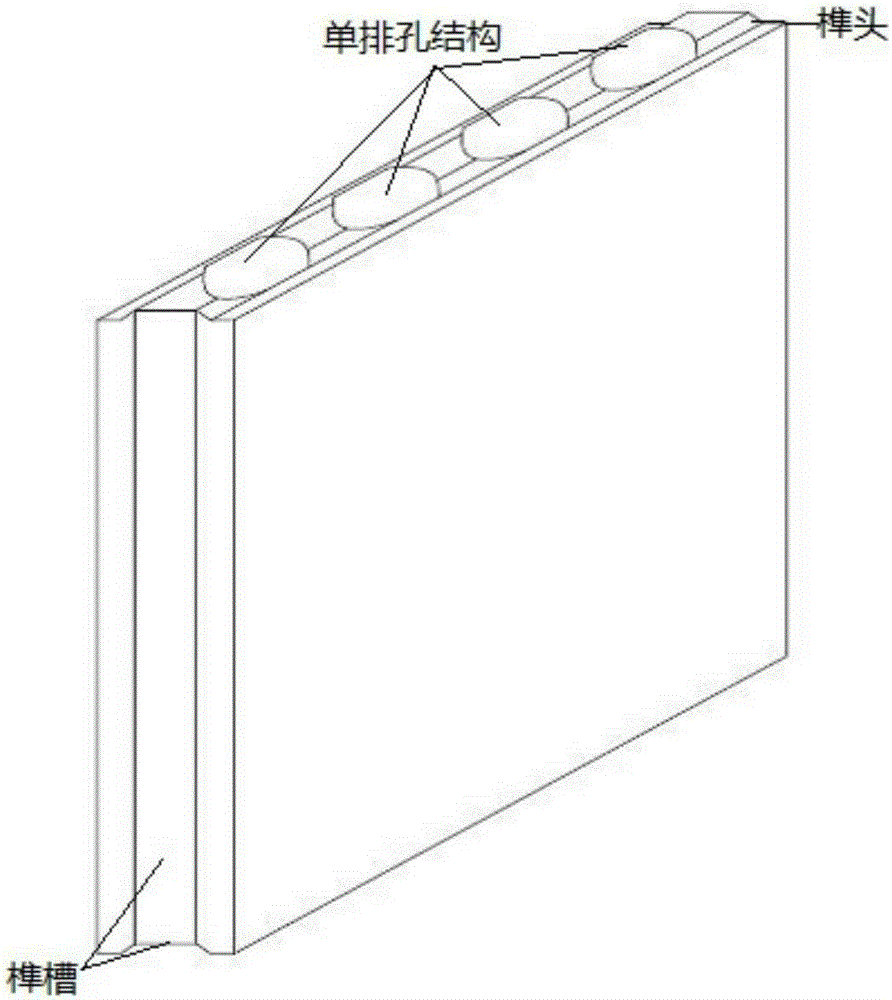

Full-body high-strength damp-proof gypsum block and preparation method

The invention discloses a full-body high-strength damp-proof gypsum block and a preparation method. The full-body high-strength damp-proof gypsum block is prepared from the following materials in percentage by weight: 50-55% of building gypsum, 42-45% of water, 1-3% of cement, 0.2-1.5% of fiber, 0.2-1.0% of wood powder, 0.2-0.5% of a water reducing agent, 0.05-0.4% of a water proofing agent, and 0.005-0.02% of paint. According to the full-body high-strength damp-proof gypsum block prepared by adopting the uniform stirring technology, adding the waterproof component and strengthening the toughening component, the uniformity of the full body of a wall body material is improved, and the strength, the humidity resistance, the shock resistance, the permeation resistance, the crack resistance and the fireproof performance of the wall body material are improved; various performance indexes are superior to that of the conventional wall body material and the common gypsum block, cracking and permeation of the built wall body are avoided, and the engineering quality is ensured.

Owner:ZHANGZHOU ZHENGBA BUILDING MATERIAL TECH

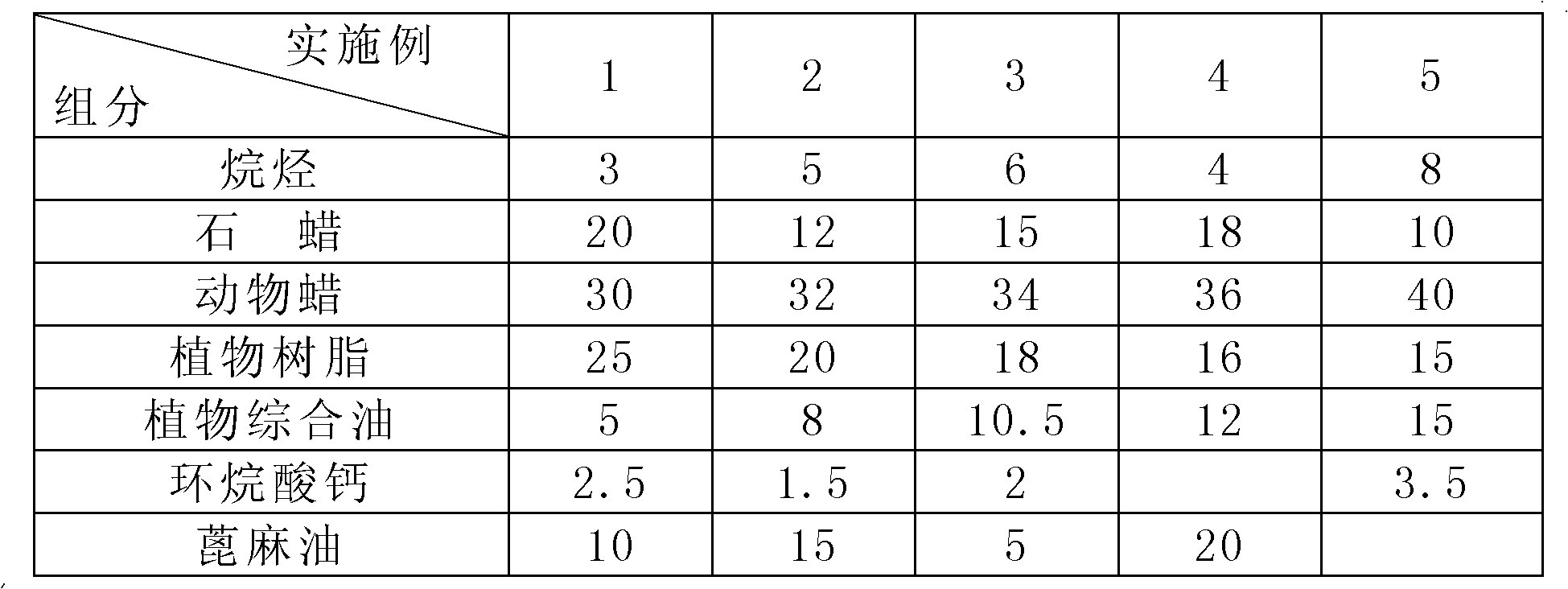

Environment-friendly wood wax oil and preparation method thereof

The invention provides an environment-friendly wood wax oil and a preparation method thereof, which belong to the technical field of products of chemical industry. The environment-friendly wood wax oil is prepared by the following components in part by weight: 3 to 8 parts of alkane, 10 to 20 parts of wax, 30 to 40 parts of animal wax, 15 to 25 parts of plant resin and 5 to 15 parts of plant synthetic oil, wherein the general formula for the alkane is CnH2n+2 and n is more than or equal to 6 and less than or equal to 16. The preparation method is characterized by simple process flow, less steps, wide source for the raw material and low cost; and the prepared product has high uniformity, no toxicity and no pollution and has the functions of mildew resistance, damp proofing, moisture protection, moth proofing, surface maintenance, beautification and the like after use.

Owner:王增平

Wood-emulating floor and its manufacture method

The invention relates to imitated solid wood floor, the surface and the back of a density fibrous material core layer structure are respectively covered with a surface structure layer and a damp-proof balanced structure layer, wherein the surface structure layer at least contains a surface anti-wear lacquer coat and a decorative bottom layer. When in manufacture, firstly, the frontal area of a density fibrous material core layer plate blank whose back is covered with the damp-proof balanced structure layer is covered with the decorative bottom layer, then, the surface is firstly covered with a water-based or oily lacquer coat and dried, and then the surface is covered with an oily anti-wear lacquer coat or UV lacquer coat and dried. The imitated solid wood floor can effectively solves the problems of strengthening floor at present that the surface glossiness of laminated floor is bad, the articulation of decorative patterns is not ideal, decorative wood grains are not true and natural enough compared with solid wood floor, and the like.

Owner:SICHUAN SHENGDA FORESTRY IND

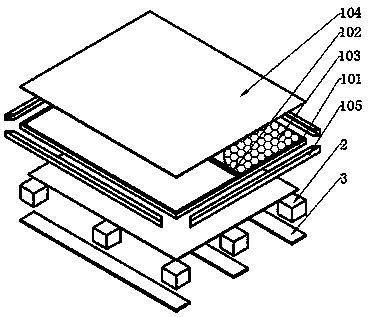

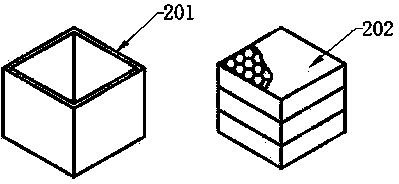

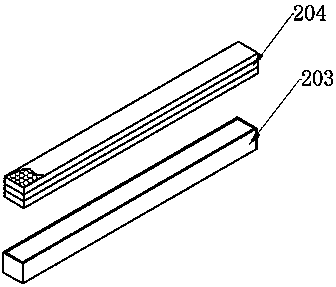

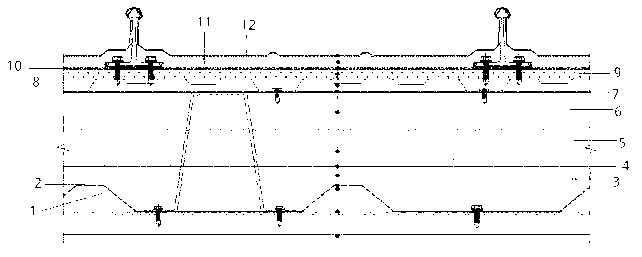

Sound insulation floor with micro-foaming plate as sound insulation cushion layer and construction method of sound insulation floor

The invention discloses a sound insulation floor with a micro-foaming plate as a sound insulation cushion layer. The sound insulation floor is composed of a reinforced-concrete-structure floor body, the micro-foaming plate sound insulation cushion layer, a cement mortar protecting layer and a surface layer material in an overlapping mode. The reinforced-concrete-structure floor body serves as the base layer, the micro-foaming plate sound insulation cushion layer and the cement mortar protecting layer serve as the middle layer, the cement mortar protecting layer is located on the micro-foaming plate sound insulation cushion layer, and the surface layer material serves as the upper layer. The invention further discloses a construction method of the sound insulation floor. The method includes the steps of firstly, cleaning the reinforced-concrete-structure floor body serving as the base layer to ensure the flatness of the base layer; secondly, laying the micro-foaming plate sound insulation cushion layer; finally, laying the dry and hard cement mortar protecting layer and the surface layer material on the micro-foaming plate sound insulation cushion layer. According to the sound insulation floor, the defect that a traditional floating sound insulation floor needs an armored concrete protecting layer 40 mm to 50 mm thick is overcome; the sound insulation floor is small in thickness, light in weight, resistant to moisture and mould and free of pollution, the sound insulation improving amount of crashing sound ranges from about 8 dB to 20 dB, and the requirement of housing construction for sound insulation is met. Meanwhile, the sound insulation floor of the structure can be constructed without any special construction machine or tool, laying can be quite conveniently conducted, and the sound insulation floor is economical and remarkable in effect.

Owner:广东建科节能环保科技有限公司

Slidable assembly type wall

PendingCN112112310AEasy to move and installPrevent movementWallsSound proofingEngineeringSlide plate

The invention relates to the technical field of assembly, and discloses a slidable assembly type wall. The slidable assembly type wall comprises a wallboard, an upper fixing plate is clamped to the upper surface of the wallboard, a lower fixing plate is clamped to the lower surface of the wallboard, a sliding groove is formed in the inner bottom wall of the lower fixing plate, a fixing base is fixedly connected to the lower surface of the wallboard, and the inner side wall of the fixing base is slidably connected with a sliding plate through a sliding groove. According to the slidable assemblytype wall, through the arrangement of the wallboard, a sliding block, the sliding groove, the fixing base, the sliding plate, a supporting column, a adjusting device and other structures, moving, splicing and installing of the wallboard are convenient, meanwhile, after moving and installing, a rotary disc is rotated to drive a threaded rod to rotate, rolling wheels are retracted into the fixing base, moving of the wallboard can be avoided, and thus the stability of the wallboard after installation is improved; and through cooperative use of a damp-proof plate, a sound insulation plate and a fireproof plate, the wallboard can have the fireproof, dustproof and sound insulation effects, and the practicability of the slidable assembly type wall is improved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Paper tray and manufacturing method of paper tray

ActiveCN103863654ACompact structureImprove carrying capacityPaper/cardboard articlesBio-packagingMaterials preparationPaperboard

The invention discloses a paper tray, which comprises a panel, a bottom foot, a tearing plate and a waterproof and damp-proof layer, wherein a rectangular reinforcing frame is manufactured on the periphery of the panel by high-intensity and high-modulus materials, according to the bending resistance requirement of the tray during the erected placement, one to three reinforcing ribs are parallelly and fixedly arranged in the reinforcing frame at equal intervals in the transverse direction, vertical direction or inclined direction, single-layer or multi-layer bonded honeycomb paper boards are embedded in small lattices surrounded by the reinforcing frame and the reinforcing ribs, industrial paper boards are pasted on the two sides of the reinforcing frame, in addition, U-shaped paper grooves are used for covering the edges, the bottom foot is formed by filling a round paper pipe or a honeycomb paper board into a square paper pipe or a U-shaped groove, and the tearing plate is made of high-intensity and high-modulus materials. The invention also discloses a manufacturing method of the paper tray. The manufacturing method mainly comprises the following steps including material preparation and blanking, panel manufacturing, bottom foot manufacturing, tearing plate manufacturing, assembling, and waterproof and damp-proof layer coating and brushing. The paper tray has the advantages that the appearance is attractive, the weight is light, the cost is low, and the like. In addition, the bending resistance intensity is high, the impact resistance, the waterproof and damp-proof effects can be realized, the paper tray can replace a wood tray, and the application field is wider.

Owner:HUNAN HUAWANG TECH

Constructional light wall partition slab material and producing method thereof

The present invention is light partition wall plate for building, and features that the light partition wall plate has one central layer comprising one middle wood sheet and two foamed plastic plates adhered together with adhesive layer, and glass fiber cloth layers adhered with adhesive to the periphery of the central layer. The present invention has high waterproof performance, high surface hardness, high strength, light weight, high heat and sound isolating performance and other features.

Owner:梁永威 +1

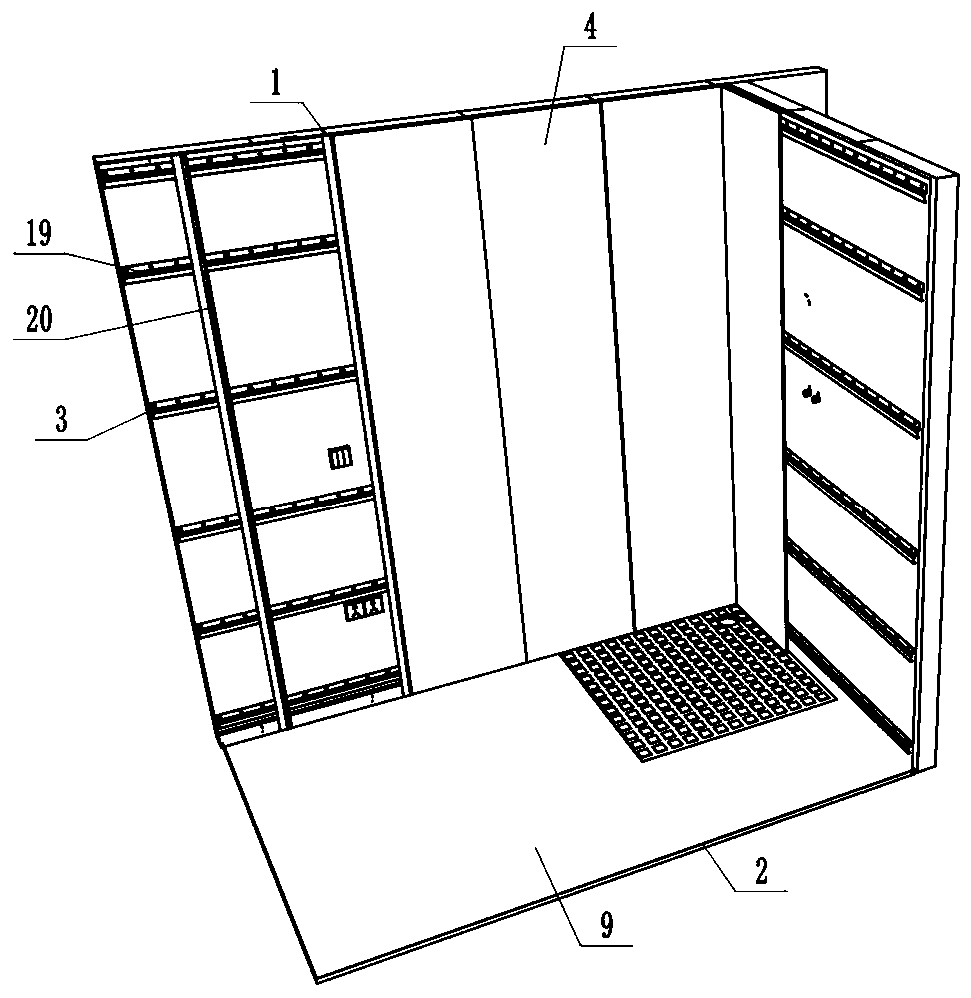

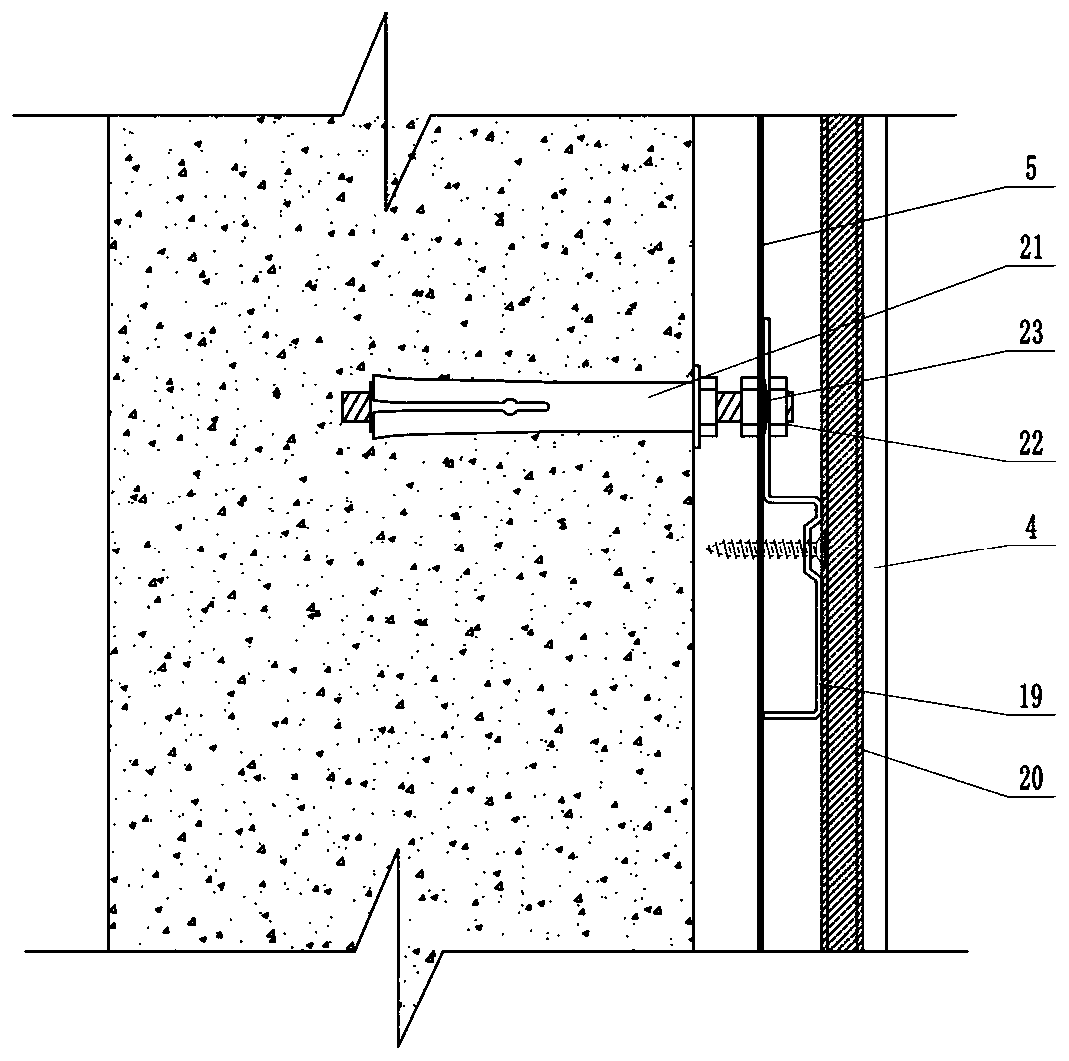

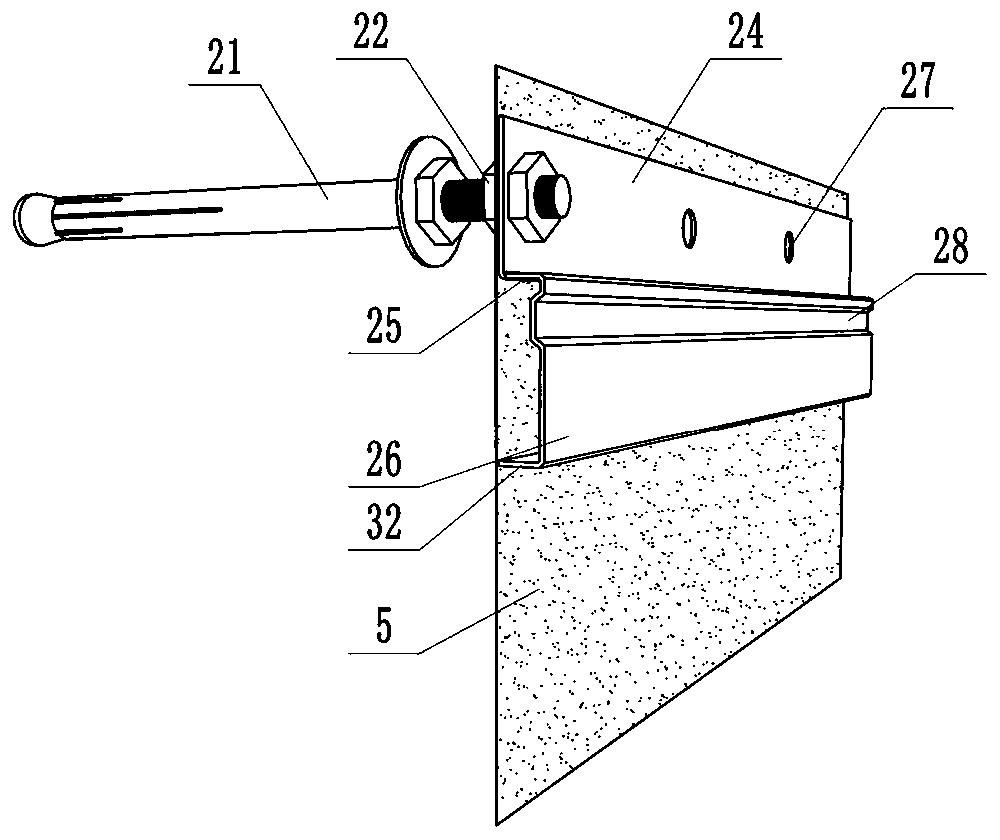

Assembled toilet system

PendingCN111485737AWith waterproof functionSolve the waterproof problemFatty/oily/floating substances removal devicesCovering/liningsCalcium silicateStructural engineering

The invention relates to an assembled toilet system, and belongs to the technical field of assembled decoration. The assembled toilet system specifically comprises an assembled wall panel and an assembled floor, wherein the assembled wall panel comprises a wall surface keel fixed to a wall body, and a wall panel installed on the wall surface keel, a moisture-proof film is further arranged on the rear part of the wall panel, and the moisture-proof film is fixed to the wall surface keel; the assembled floor comprises an overhead module and a support leveling assembly supported on the bottom of the overhead module, a waterproof chassis is laid on the overhead module, the wall panel is located in the waterproof chassis, a decoration panel is laid on the waterproof chassis, and a drainage floordrain is further installed on the waterproof chassis; and the overhead module comprises a base body made of a galvanized steel plate and a calcium silicate plate installed on the base box. The assembled toilet system is simple and convenient to install, and high in construction efficiency.

Owner:山西建投装饰产业有限公司

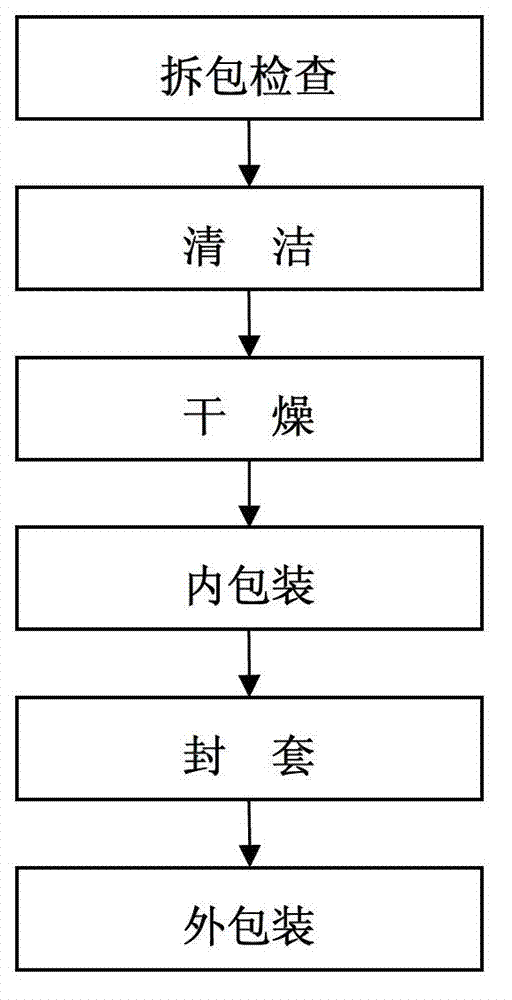

High-reliability hermetical packaging method for precise instruments

InactiveCN102815462AChange the internal environment of the packageFor long-term storageShock-sensitive articlesLiquid dispensingEngineeringAntistatic Materials

The invention discloses a high-reliability hermetical packaging method for precise instruments, and belongs to the technical field of packaging. The method includes: unpacking and checking a to-be-packaged instrument, replacing overdue oil in the to-be-packaged instrument, cleaning oil stains and dirt outside the to-be-packaged instrument, and drying; and performing interior packaging, envelope sealing treatment and exterior packaging and boxing. By controlling the interior packaging environment, taking protective measures such as envelope sealing, damping and buffering, and adopting novel packaging materials such as high-penetration-resistance materials, reinforced pierce preventing materials and antistatic materials, sealing reliability can be improved, various packaging protective effects can be achieved, and the requirements on sealing protection of various types of precise instruments can be met. The high-reliability hermetical packaging method for precise instruments has the advantages that the interior packaging environment of the precise instruments is changed, protective functions such as water proofing, damp proofing, shock proofing and oil proofing are realized, and stored articles can be protected from being damaged by severe environments to realize long-term storage.

Owner:中国人民解放军空军勤务学院

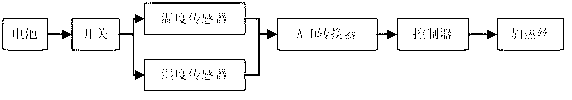

Intelligent insole

InactiveCN103315454ARealize functionImprove practicalityInsolesSimultaneous control of multiple variablesElectrical batteryEngineering

The invention discloses an intelligent insole and belongs to the technical field of daily necessities. The intelligent insole comprises a main cushion layer and an auxiliary cushion layer, an sensing device is arranged between the main cushion layer and the auxiliary cushion layer and comprises a battery for power supply, a switch, a temperature sensor, a humidity sensor, an A / D (analog / digital) converter, a controller and a heating wire, the battery is connected with the switch, the switch is connected with the temperature sensor and the humidity sensor respectively, the temperature sensor and the humidity sensor are connected with the A / D converter, and the A / D converter is connected with the controller and the heating wire respectively. Since the sensing device is arranged between the main cushion layer and the auxiliary cushion layer, humidity and temperature of the insole can be sensed immediately, automatic monitoring of the temperature, the humidity and a heating process is realized, functions of heat insulating and damp proofing are provided for people, the problems about cold feet, sweating and the like of people using the insole are well solved, and functions of the insole are realized better.

Owner:WUXI INST OF COMMERCE

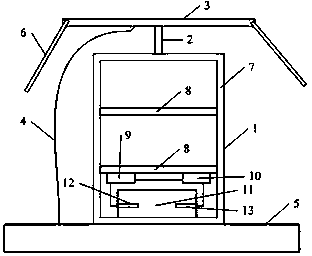

Waterproof control box

InactiveCN104300388ATroubleshoot broken tech issuesAvoid soakingSubstation/switching arrangement casingsEngineeringStructural engineering

The invention discloses a waterproof control box. The control box comprises a control box shell, a cuboid rain-proof cover is connected above the control box shell through a support; the upper end face of the rain-proof cover is concave; the concave bottom of the rain-proof cover is connected with a flow guide pipe; the other end of the flow guide pipe is connected with a water collection box embedded underground; the four side faces of the rain-proof cover are each connected with a rain blocking plate; a side opening door is arranged on the front face of the control box shell; a sealing ring is arranged at the connecting position of the side opening door and the shell; partition plates are arranged on the periphery of the side opening door and are semi-cylindrical; a drying layer is arranged on the inner wall of the control box shell; drying agents are arranged in the drying layer; N dampproof plates are arranged in the control box shell; the interior of the control box shell is divided into N+1 containing areas through the N dampproof plates. The technical effects that the waterproof control box is reasonable in structural design and good in rainproof effect, and safety of internal devices and circuits of the control box is ensured are achieved.

Owner:CHENGDU FENGDA TECH

Wear-resisting solid wood core floor and production technology thereof

InactiveCN106437084AReinforce cracking damageImprove fastnessLaminationLamination apparatusEnvironmentally friendlySolid wood

The invention discloses a wear-resisting solid wood core floor which comprises a paint layer, a wear-resisting layer, a decorative layer, a base material layer and a core layer. The upper surface of the decorative layer is connected with the lower surface of the wear-resisting layer. The upper surface of the wear-resisting layer is coated with the paint layer. The lower surface of the wear-resisting layer is connected with the upper surface of the decorative layer. The lower surface of the decorative layer is connected with the upper surface of the base material layer. The lower surface of the base material layer is connected with the core layer. A fixing groove is formed in one side of the base material layer, a convex block matched with the fixing groove is arranged on the other side of the base material layer, and a steel tank is arranged between the base material layer and the core layer, and filled with damp-proof silicone rubber. The wear-resisting solid wood core floor improves the utilization rate, is environmentally friendly and meets the requirement of lives of modern people.

Owner:JIANGSU OUSHENG WOOD

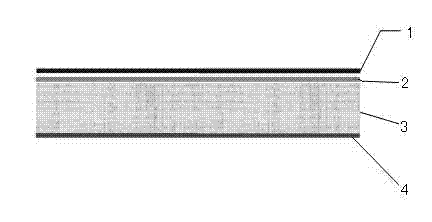

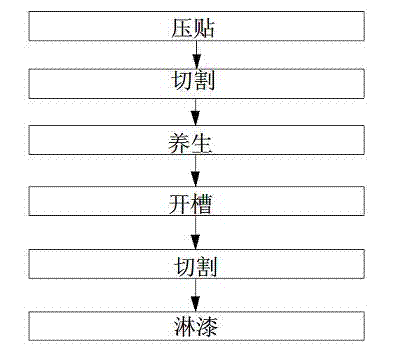

Laminated wooden floor with paint facing layer and production process

ActiveCN102852313AHigh saturationImprove surface brightnessWood working apparatusFlooringFiberAdhesion force

The invention provides a laminated wooden floor with a paint facing layer. The laminated wooden floor comprises a UV (Ultra Violet) paint wear resistance layer, a decoration layer, a base material layer and a balance layer, which are sequentially arranged from top to bottom. The base material layer is a high-density fiber board; a decoration layer is adhered to the base material layer; a UV paint wear resistant layer is coated on the decoration layer; the decoration layer is a pitted surface board with a pitted surface; and the moisture-proof balance layer is adhered below the substrate layer. A production process of the laminated wooden floor comprises the following steps of pressing, cutting, preserving, grooving, and packaging to be in stock after coating in a qualified manner. The laminated wooden floor provided by the invention has the advantages of better waterproof property, and thick and comfortable foot sense. The laminated wooden floor is coated after the preservation time of 5-10 days and has the better film adhesion force; the four edges of a notch are sealed with wax, so that the product waterproof property is improved, and the release of mail compound VOC (Volatile Organic Compounds) is reduced. The wear-resistant component of aluminum trioxide is added on finish paint, so that not only can the adhesion force of the film be increased, but also the wear resistance of the surface can be effectively increased.

Owner:JIANGSU KENTIER WOOD

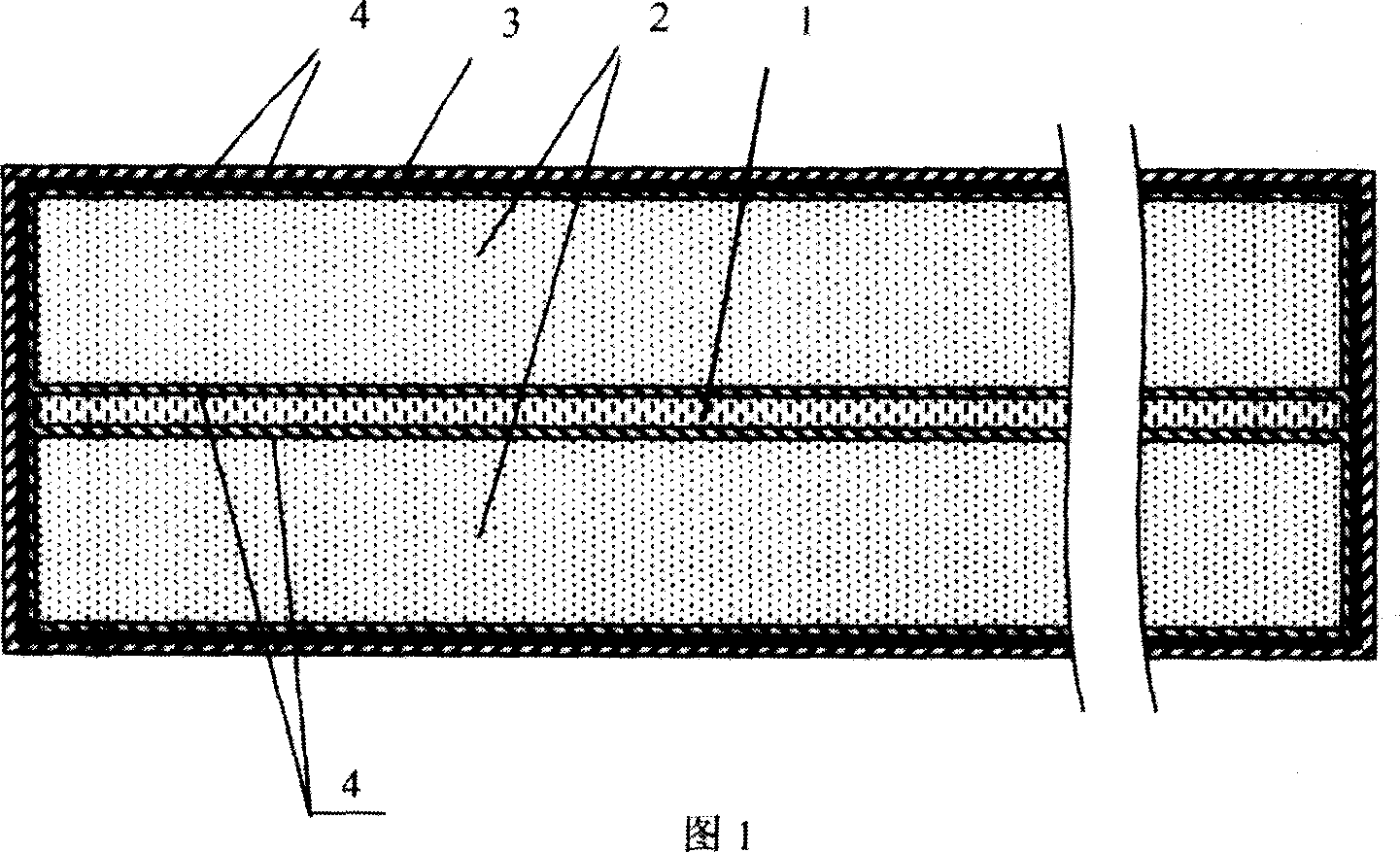

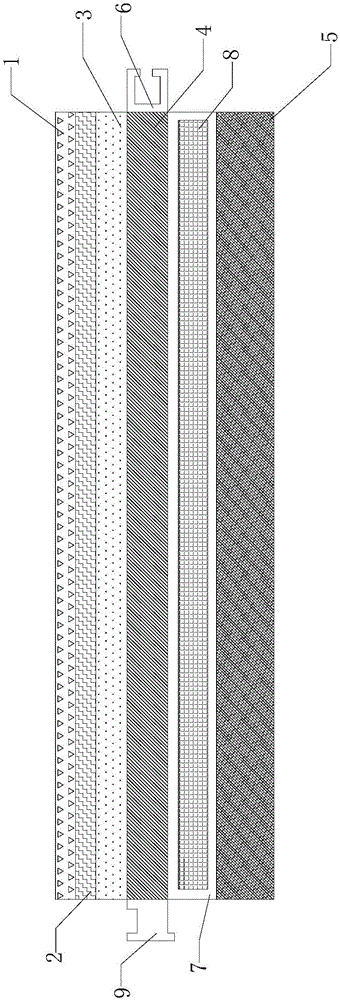

Metal roof structure

InactiveCN103291014AMeet waterproofDoes not hinder ventilationBuild-up roofsRoof covering insulationsFiberVapor barrier

The invention discloses a metal roof structure. A steel lining plate is arranged on the bottommost layer of the roof structure, an aluminum-magnesium-manganese alloy roof panel is arranged on the topmost layer of the roof structure, a support steel plate and a gypsum fiber plate are arranged between the aluminum-magnesium-manganese alloy roof panel and the lining plate, the support steel plate is supported at the bottom of the gypsum fiber plate, a superfine glass cotton noise proofing layer is filled between the aluminum-magnesium-manganese alloy roof panel and the gypsum fiber plate, support purlines are arranged at the bottom of the support steel plate, a non-woven fabric dustproof layer is paved on the lining plate, a glass cotton sound-absorbing layer is arranged on the non-woven dustproof layer, heat-preserving cotton is filled among the glass cotton sound-absorbing layer and the support purlines, a vapor barrier layer is arranged between the heat preservation cotton and the glass cotton sound-absorbing layer, and a water-proofing and vapor-permeating layer is arranged between the superfine glass cotton noise proofing layer and the gypsum fiber plate. Waterproof effect of a metal roof is improved, outdoor noise is prevented from being transmitted into a room, and a heat preserving, a damp proofing effect and a vapor permeating of the metal roof are improved.

Owner:ZHONGTIAN CONSTR GROUP

Water-ingress label using a double coating capsule structure

ActiveUS20140224170A1Accurately knowAvoid changeStampsMeasured value indication by color changeDouble coatingWater soluble

A water-ingress label using a double coating capsule structure includes a water absorbent layer which is formed from any one of paper, synthetic paper, non-woven fabric, synthetic non-woven fabric, Korean paper or an absorbent coating for absorbing water; an ink layer which is formed on the back surface of the water absorbent layer as an ink having a double coating capsule structure including a colourant selected from any one or a plurality of water-soluble dyes, pigments, metallic silica, metallic oxides and mica together with a hydrophilic / water-absorbing halogen-free resin; and an ink barrier layer having a damp-proofing and water-proofing function, which is formed on the back surface of the ink layer and prevents leaking, into the back surface of the ink layer, of the colourant selected from any one or more of water-soluble dyes, pigments, metallic silica, metallic oxides and mica.

Owner:QL CO LTD

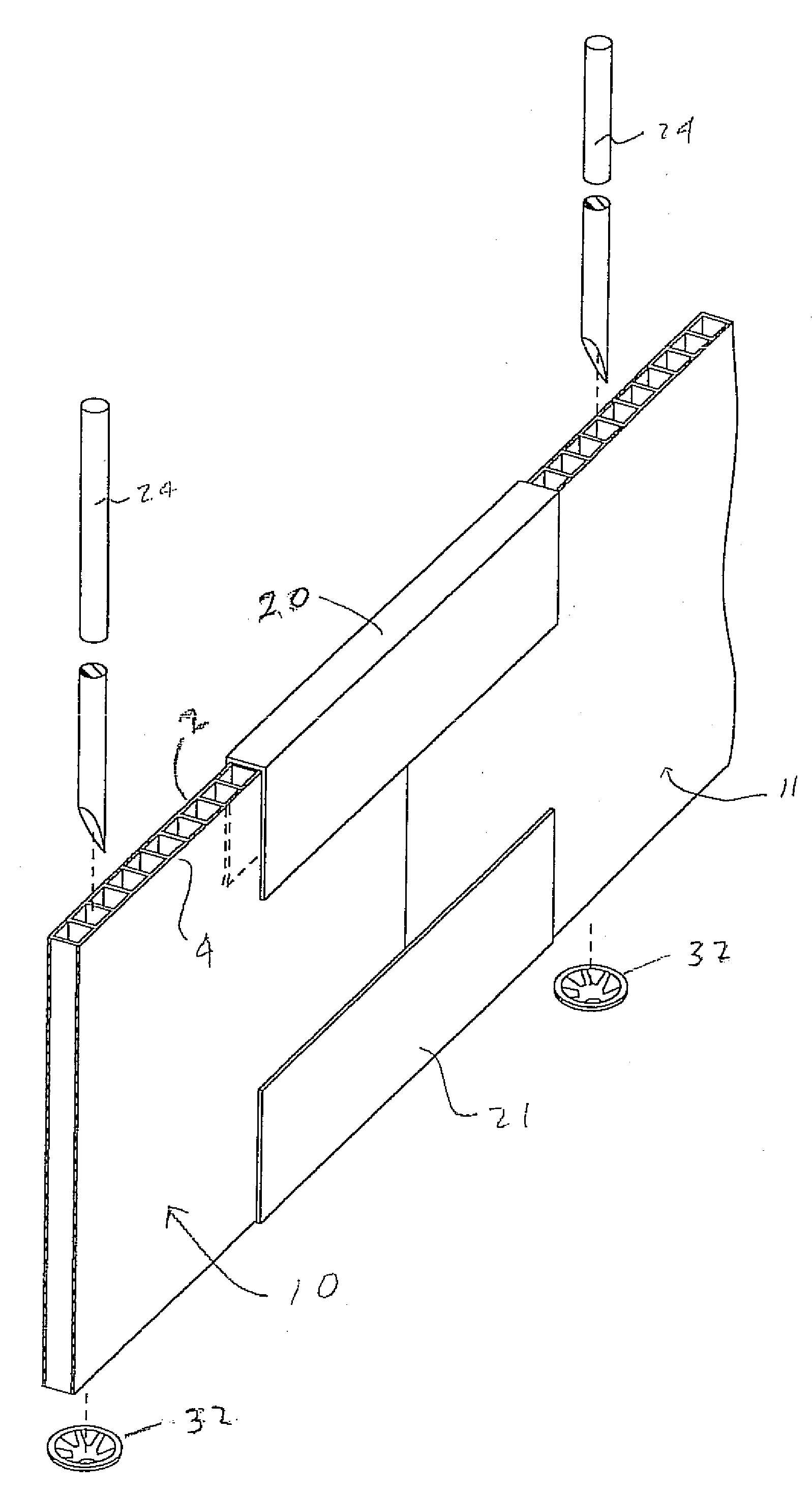

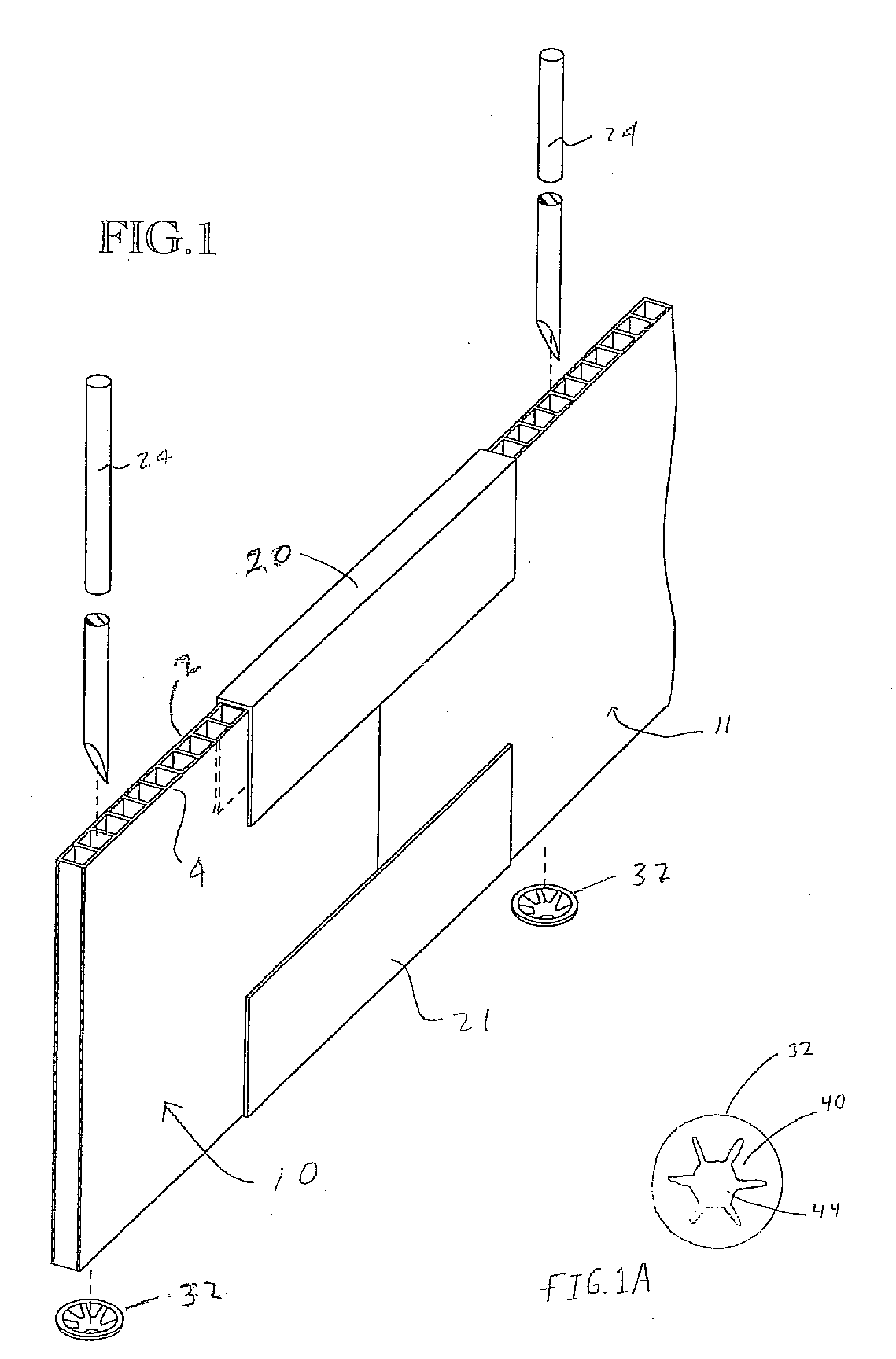

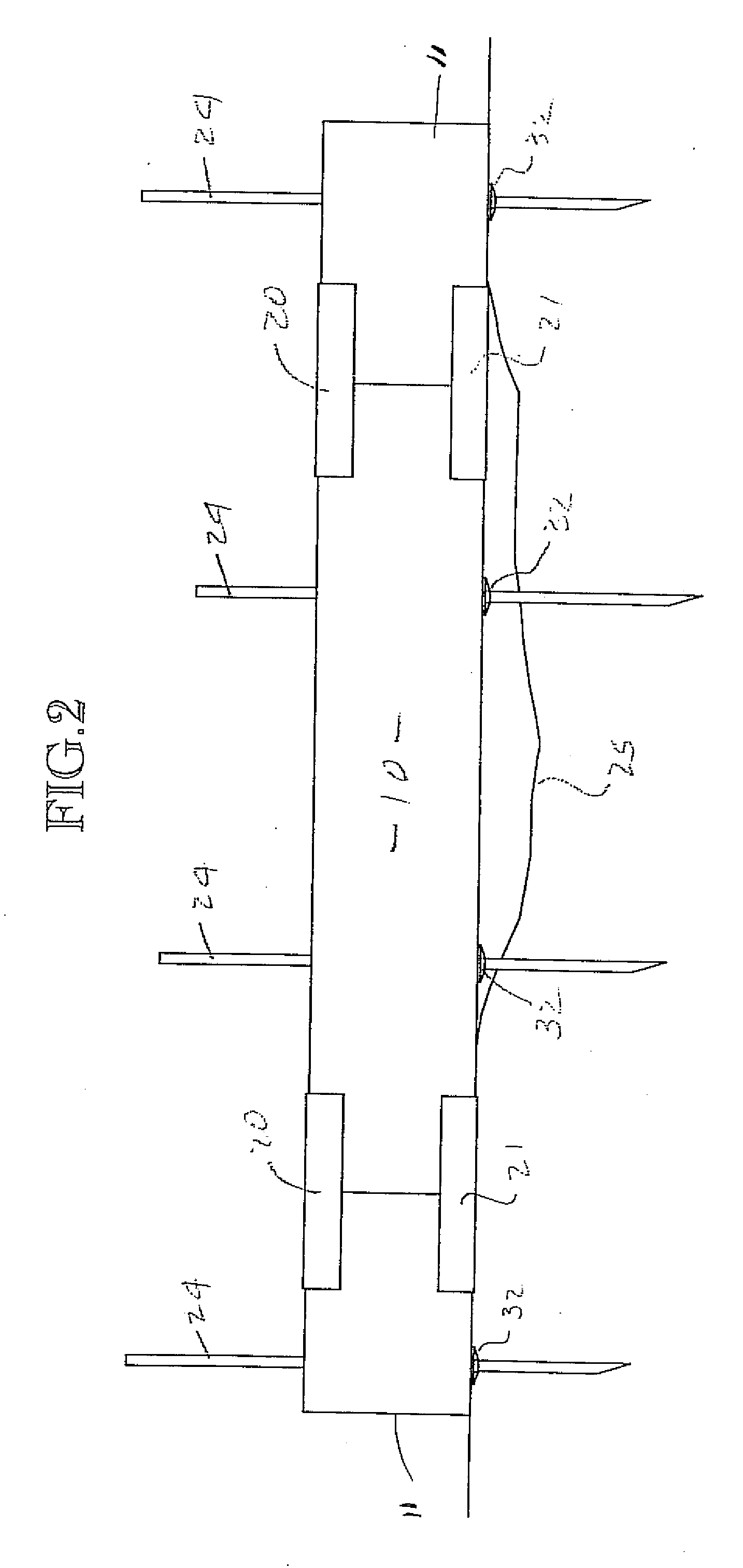

Concrete forms

InactiveUS20070193192A1Light weightEasily placed in positionFoundation engineeringForms/shuttering/falseworksEngineeringSteel bar

Moisture resistant foundation footing form sections constructed from corrugated plastic are disclosed. Supports for holding sections of reinforcing bar, and connecting the side walls of the form sections are included. The form sections can be secured in position with stakes, and leveling devices for leveling the form once it is secured in position are disclosed. The form sections disclosed herein can be reused, but they do not attract insects and therefore they do not have to be removed from finished foundation footings.

Owner:QUICK FORMZ

Microlite PVC foam floor

The invention relates to a microlite PVC (Poly Vinyl Chloride) foam floor and belongs to the technical field of chemical building materials. The microlite PVC foam floor is prepared from the following raw materials in parts by weight: 100-150 parts of PVC, 200-300 parts of microlite powder, 0.5-0.7 part of stabilizer, 0.6-1.0 part of foaming agent, 0.2-0.3 part of plasticizer, 0.5-0.7 part of lubricant and 0.5-0.7 part of flame retardant. The microlite PVC foam floor is extrusion-molded by using a plastic extruding machine; the obtained microlite PVC foam floor is low in density, wear-resistant, impact-resistant, high in elastic strength, natural in texture, and beautiful and elegant; the microlite PVC foam floor is also environment-friendly, non-toxic, tasteless and formaldehyde-free; the microlite PVC foam floor is further waterproof, damp-proof, skid-proof, wear-resistant, corrosion-resistant, fire-resistant, and recyclable.

Owner:HENAN LEISEN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com