Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Low water absorption thickness expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

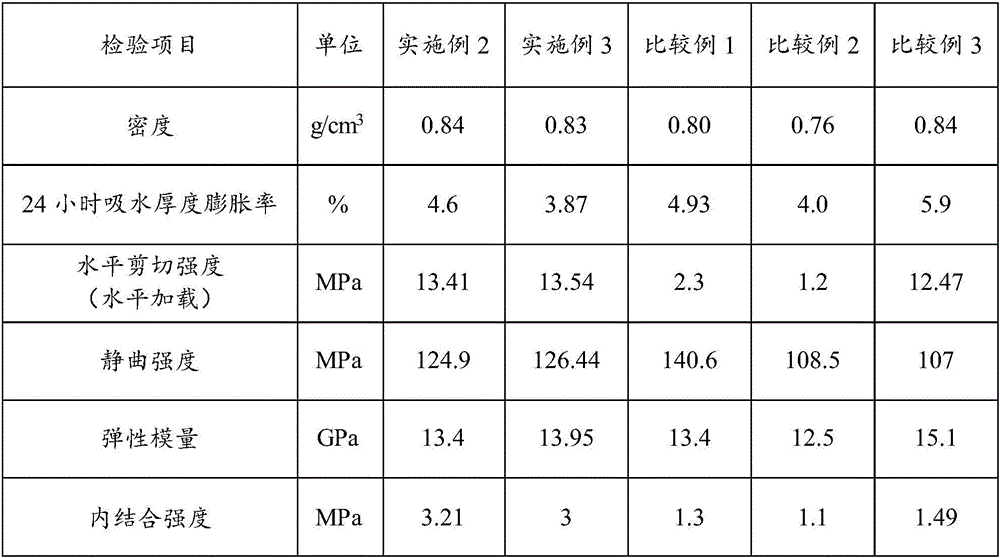

Method for using thin-wall bamboo materials to prepare bamboo scrimbers

PendingCN108127753AEnhance the ability to defuseEffective chemical attackWood compressionReed/straw treatmentWaxLiquid waste

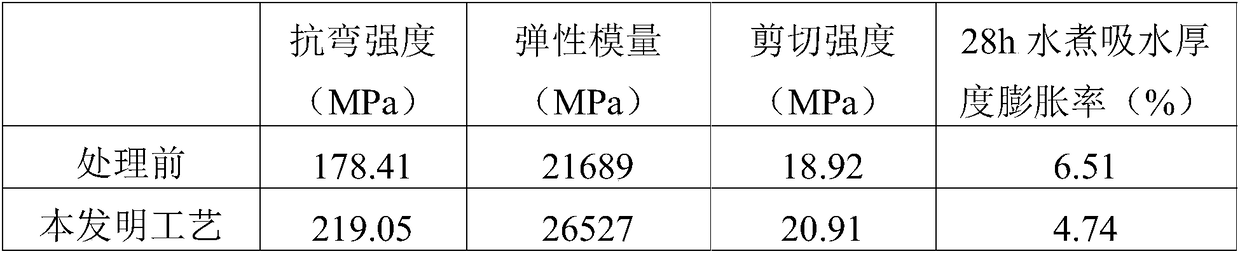

The invention discloses a method for using thin-wall bamboo materials to prepare bamboo scrimbers. The method includes the steps that alkali is adopted for stewing thin-wall bamboo sheets, and then defibering, gum dipping, laying and hot pressing are carried out in sequence; NaOH is used for stewing the bamboo sheets, and the bamboo sheets are processed by lipase and then subjected to defibering,wherein by means of the procedures above, the defibering effect of bamboo bundles is obviously improved by 35% or above, bamboo green and tabasheer on the surfaces of the bamboo materials are effectively subjected to chemical erosion, the purpose of breaking wax layers and silicon layers is achieved, and the effect of improving gluing is achieved. A waste liquid generated after stewing is used fordiluting a glum liquid, and the problem of discharging the waste liquid is solved; by adopting a vacuum pressurizing dipping mode, even permeation of an adhesive in the bamboo materials is achieved,consumption of the adhesive is reduced, the production cost is reduced, efficient utilization of the thin-wall bamboo materials is achieved, and the environment is protected. The physical and chemicalstrength of the scrimbers are obviously improved, the horizontal shearing strength is improved by 25% or above, the thickness swelling rate of water absorption is reduced by 100% or above, the bending strength is improved by 20% or above, and the elasticity modulus is increased by 15% or above.

Owner:GUANGDONG ACAD OF FORESTRY

Method for manufacturing weed wood and straw compounding medium density fiberboard with laminated structure

InactiveCN101659074ASave resourcesImprove flexural strengthFlat articlesDomestic articlesEcological environmentFlexural modulus

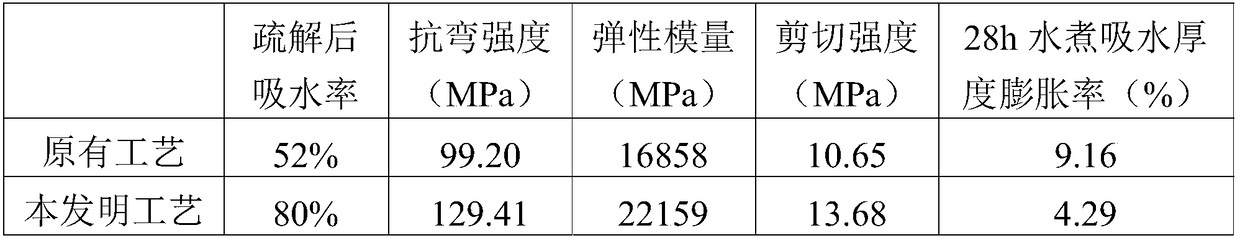

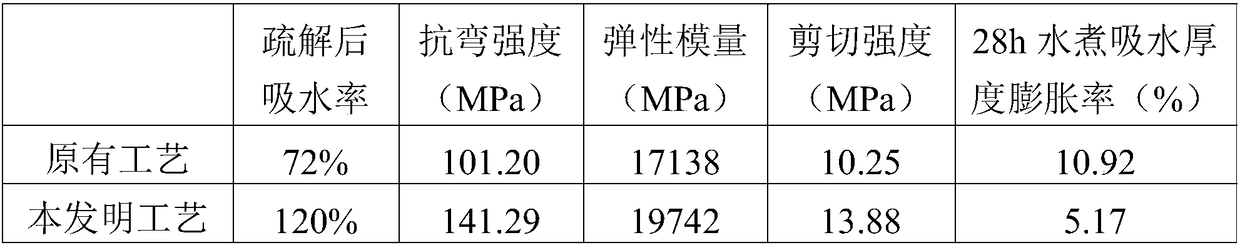

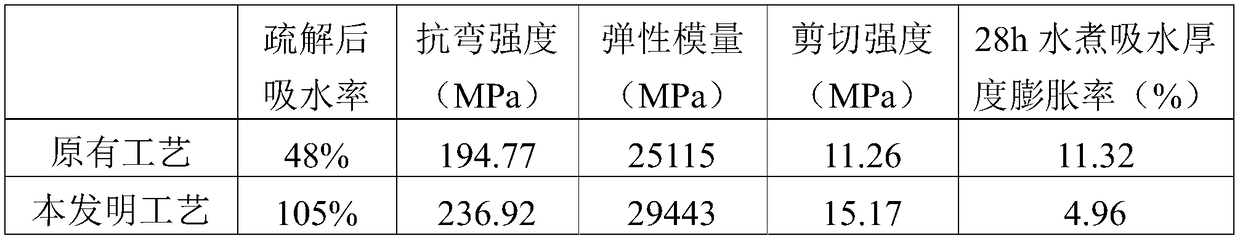

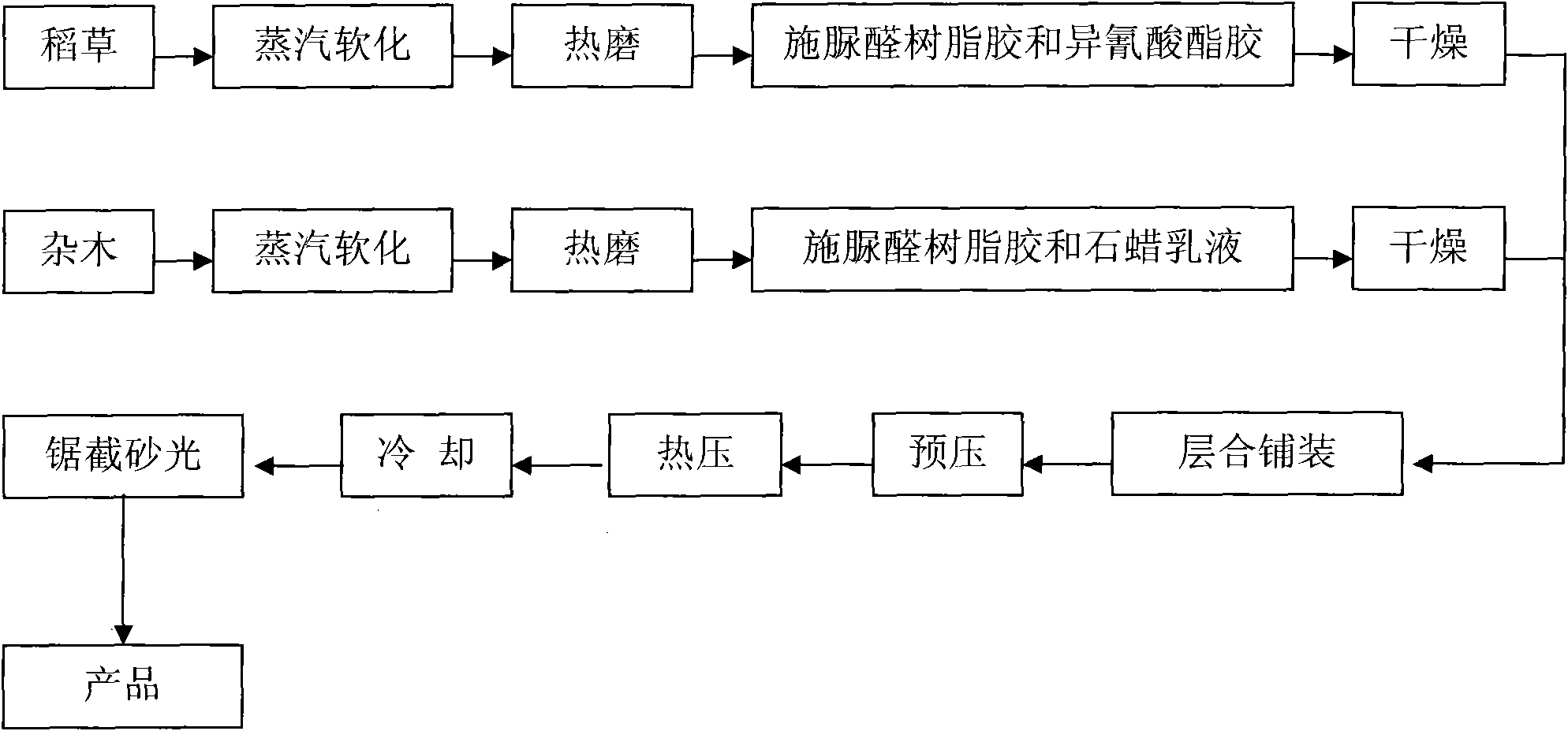

The invention relates to a method for manufacturing a weed wood and straw compounding medium density fiberboard with a laminated structure. The method adopts straw and weed wood as raw materials, andincludes the following steps: the straw and the weed wood are respectively processed by defibration, and urea formaldehyde resin adhesive and waterproof agent are added, and in the process of formation, straw fibres and wood fibres are proportionally assembled and laminated in the direction of thickness and then are processed by thermocompression to form boards. The method has the advantages thatproved by performance tests, the flexural modulus, the strength and the internal bonding strength of the medium density fiberboard, compared with a pure straw medium density fiberboard, are respectively and obviously increased under the same condition, and the expansion rate of water-absorbing thickness and the water absorption rate are lowered; and the relative performances of the compound material can be increased by changing the mode of lamination. The method efficiently and comprehensively utilizes the agricultural straws and saves wood resources, thereby protecting the ecological environment. The product can be applied to the occasions of furniture manufacturing and production, base materials for interior decoration, and the like.

Owner:NANJING FORESTRY UNIV

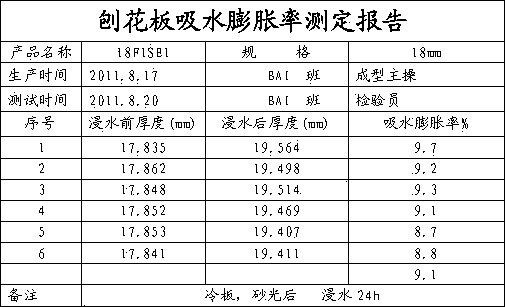

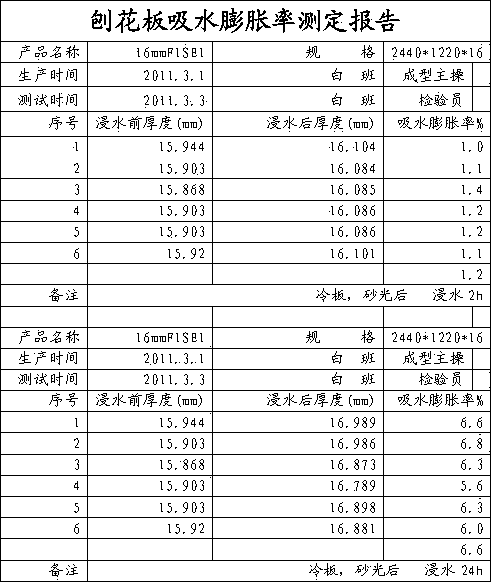

Method for producing uniform-density bamboo shaving board

InactiveCN102198685ALow costSave on energy costsWood working apparatusFlat articlesEngineeringVolumetric Mass Density

The invention relates to a machining process for an artificial board, in particular to a method for producing a uniform-density bamboo shaving board. The invention is realized through the following technical scheme: the method for producing the uniform-density bamboo shaving board is characterized by sequentially comprising the following steps of: (1) selecting materials; (2) first screening; (3) first drying; (4) second screening; (5) second drying; (6) sizing; (7) hot-pressing; and (8) refrigerating. The uniform-density bamboo shaving board has the advantages of density uniformity, high dimensional stability and high static bending strength.

Owner:浙江安吉强裕人造板有限公司

Preparation method of plant straw plate

InactiveCN104802276AReduce releaseStrong resistance to hydrolysisPolyureas/polyurethane adhesivesWood working apparatusAdhesivePlant stalk

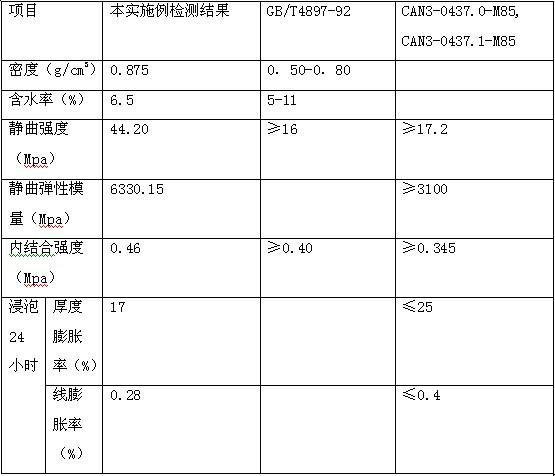

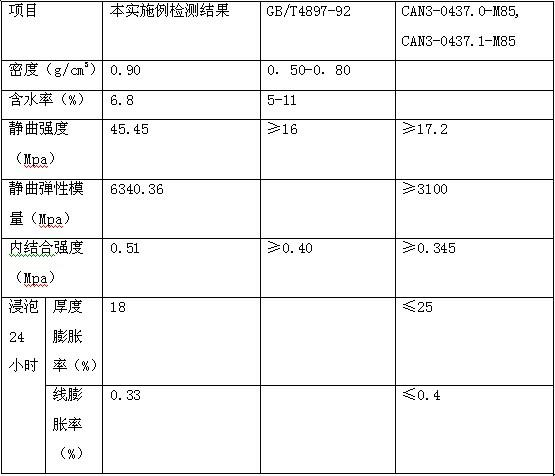

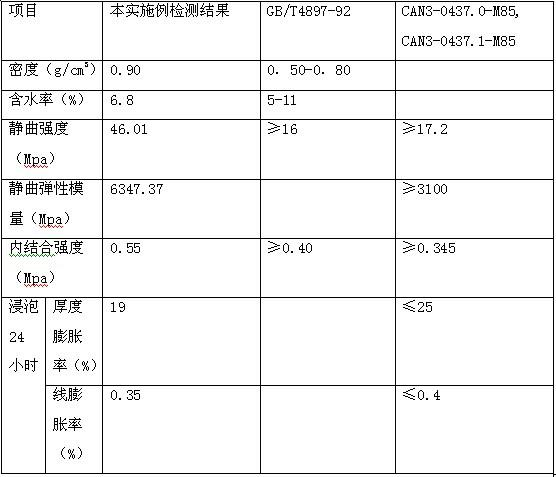

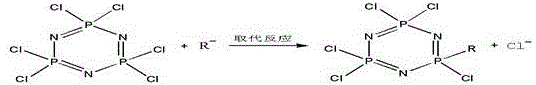

The invention provides a preparation method of a plant straw plate. The preparation method takes full components of dried corn straws, rice straws, wheat straws, sunflower straws, rapeseed straws and cotton straws as raw materials and utilizes a special adhesive of polyether polyol and a prepolymer of isocyanate, so that the water-resisting capability is strong, and the inner bonding intensity of a product is improved; the related indexes of the produced plant straw plate are equal to or better than quality standards of national standards (GB / T4897-92) of a wood artificial plate. The indexes including the inner bonding intensity, the static bending strength, the formaldehyde releasing amount, the water absorption thickness expansion rate and the like. The production process is simplified and the production cost is reduced.

Owner:CHANGCHUN YINGLONG MATERIAL TECH CO LTD

Aldehyde-free shaving board and production method and application thereof

ActiveCN104626329AIncrease incomeSimple production processWood working apparatusDomestic articlesEngineeringMechanical property

The invention relates to an aldehyde-free shaving board and a production method and application thereof. The aldehyde-free shaving board is prepared by conducting steam explosion pretreatment, sorting, additive mixing and hot pressing on a bamboo-based material and / or straw. The aldehyde-free shaving board prepared with the method is free of aldehyde, good in waterproof performance and mechanical property, stable in quality and capable of being applied to base materials, various kinds of furniture, decorations, building templates, kitchen cabinets and packaging boards.

Owner:四川中科板业有限公司

Method for preparing thick type shaving board through waste outdoor heat-treated wood and conventional wood and shaving board

ActiveCN105216089ALow hygroscopicityDimensionally stableLaminationLamination apparatusWood shavingsSurface layer

The invention provides a method for preparing a thick type shaving board through waste outdoor heat-treated wood and conventional wood. The thick type shaving board prepared through the method is small in hygroscopicity, stable in size and good in comprehensive mechanical property. According to the method, the waste outdoor heat-treated wood and the conventional wood are crushed into wood shavings respectively, and the two wood shavings are dried until the moisture content is 2%-4%, and then sizing and stirring are conducted; the wood shavings are made into a board blank through mat formation and are formed through hot pressing; when the mat formation is conducted, the wood shavings of the waste outdoor heat-treated wood are paved in a sandwich layer of the board blank, and the wood shavings of the conventional wood are paved in a surface layer of the board blank; in the sizing process, the adhesive is a urea-formaldehyde resin adhesive, or a phenolic resin adhesive, or a isocyanate adhesive; in the hot pressing process, the hot pressing pressure is 2.5-3.5 Mpa, the hot pressing time is 0.2-0.5 min / mm, and if the urea-formaldehyde resin adhesive is used, the hot pressing temperature is 110 DEG C to 160 DEG C; and if the phenolic resin adhesive or the isocyanate adhesive is used, then the hot pressing temperature is 150 DEG C to 200 DEG C.

Owner:广西东林木业有限公司

Impregnated paper finished OSB composite floor and preparation method

ActiveCN105464335ALow costGood value for moneyAldehyde/ketone condensation polymer adhesivesFlooringPulp and paper industryUltimate tensile strength

The invention relates to a plate, in particular to an impregnated paper finished OSB composite floor and a preparation method. The impregnated paper finished OSB composite floor sequentially comprises an OSB base material layer, a veneer layer, a buffer paper layer, a balance paper layer and a sprayed decorative paper layer from bottom to top. The longitudinal static bending intensity of the OSB base material layer is larger than or equal to 50 MPa, and the water absorption thickness swelling rate of the OSB base material layer is smaller than or equal to 12%. The veneer layer is a poplar bleached veneer, and the thickness ranges from 0.6 mm to 1.2 mm. The buffer paper layer is impregnated kraft paper with the thickness of 0.4 mm to 0.6 mm, and the glue quantity is 80% or above. The weight of the balance paper layer ranges from 70 g to 80 g, and the glue quantity ranges from 100% to 120%. The weight of the sprayed decorative paper ranges from 70 g to 80 g, and the glue quantity ranges from 100% to 120%. The impregnated paper finished OSB composite floor has high environment friendliness, stability and water resistance.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Production method for environment-friendly type middle-density board glue

InactiveCN101063028ASimple manufacturing processImprove performanceAldehyde/ketone condensation polymer adhesivesVolumetric Mass DensityMelamine

The invention discloses a preparing method of environment-friendly type density plate glue, which comprises the following steps: changing mole ratio of traditional urea-formaldehyde resin formaldehyde and aquacare; adding melamine into urea-formaldehyde resin; proceeding polycondensation; changing twice throwing aquacare to third throwing aquacare; allocating formaldehyde, caustic soda, aquacare, melamine, ammonia and PVA; checking the end product. This craft possesses simple craft and stable property, which increases the total quality to another stage.

Owner:SHANDONG HEYOU GROUP

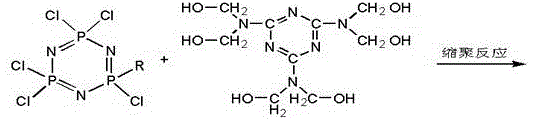

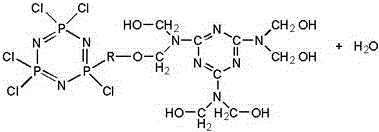

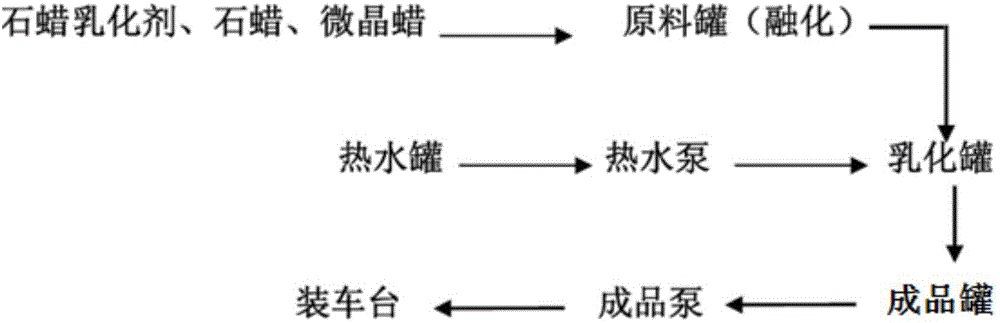

Emulsifying wax composition, preparation method and applications thereof

ActiveCN106032436ASmall particle sizeGood storage stabilityWax coatingsParaffin waxMicrocrystalline wax

The present invention relates to an emulsifying wax composition, a preparation method and applications thereof, wherein the emulsifying wax composition comprises 15-50 wt% of paraffin, 0.1-5 wt% of microcrystalline wax, 1-6 wt% of a paraffin emulsifying agent, and 40-80 wt% of water. According to the present invention, the emulsifying wax composition has advantages of small average particle size, and good storage stability, and the water absorbing thickness swelling rate of the product obtained by adopting the emulsifying wax composition as the water repellent agent is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

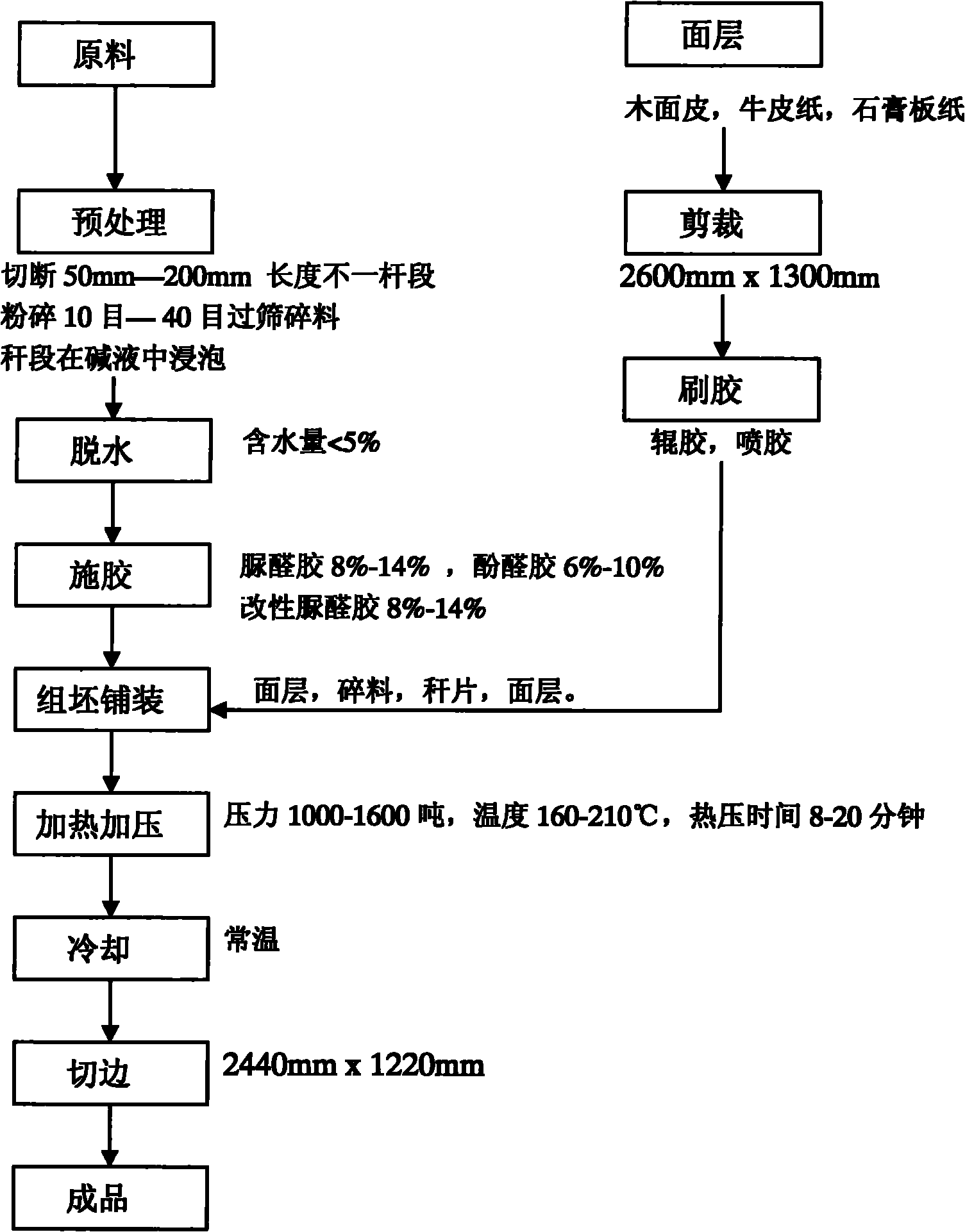

Process for pretreating raw materials of sunflower stalk composite boards and pressing assemblies

InactiveCN101941227AHigh strengthReduced process flowReed/straw treatmentAldehyde/ketone condensation polymer adhesivesPre treatmentPeanut hull

The invention provides a process for pretreating raw materials of sunflower stalk composite boards and pressing assemblies, which relates to the manufacturing industry of artificial boards of non-wood crop stalk hulls. In the process for pretreating raw materials and pressing assemblies, sunflower stalk is used as a main material of boards, and saw dust, rice hulls, peanut hulls, bean stalk, hemp stalk and cotton stalk are used for replacing wood to manufacture artificial boards. In the invention, the sunflower stalk is longitudinally broken and cut into stalk sections of which the lengths are 50-200mm to be used as main materials of the boards, thereby improving the strength of the boards; and the saw dust, the rice hulls, the peanut hulls, the bean stalk, the hemp stalk, the cotton stalk and part of broken materials of the sunflower stalk are used as auxiliary materials of the boards, thereby saving the wood. The concrete steps are described in the specification in detail.

Owner:刘金忠

Emulsion paraffin for producing waterproof fiberboard and preparation method thereof

ActiveCN103146204AImprove waterproof performanceImprove stabilityOther chemical processesParaffin waxEmulsion

The invention relates to emulsion paraffin for producing a waterproof fiberboard. The emulsion paraffin comprises solid paraffin, an emulsifier, a colloid stabilizer, a waterproof agent and water. The emulsion paraffin is obtained by self-emulsification in one step based on weakly hydrophilic polyether and / or phenolic ether as the emulsifier and polyvinyl formal as the colloid stabilizer. The preparation method comprises the following steps of: adding solid paraffin, the emulsifier, the waterproof agent and water; heating to 90-95 DEG C to completely dissolve solid paraffin; then, adding the colloid stabilizer polyvinyl formal aqueous solution to self-emulsify the mixed system to form a milk white emulsion; and cooling the emulsion to room temperature to obtain the target product. The reaction process is free from stirring, the mixed liquid is self-emulsified, and the average grain diameter of product particle is not greater than 300nm.

Owner:GUANGXI RES INST OF CHEM IND CO LTD +2

Edge banding agent for consolidated floor, preparation method and application thereof

InactiveCN102086347AImprove adhesionImprove permeabilityRosin coatingsPolyamide coatingsHydrocarbon solventsWax

The invention discloses an edge banding agent for consolidated floor, preparation method and application thereof, which belong to the field of waterproof coating for manmade plate. The edge banding agent for consolidated floor in the invention comprises the following ingredients of: wax, resin, esters solvent, and alkane hydrocarbon solvent. The edge banding agent for consolidated floor in the invention can be used for veneer consolidated fiber wood floor, and possesses characteristics of simple operation, excellent waterproof performance etc. Compared with blank floor without sealing and coating, when the coating amount of the edge banding agent for consolidated floor of the invention in side surface channel section of consolidated floor is 100-150 grams, the thickness expansion rate of the water absorption can be reduced to 21.4-45% of the original floor; and when compared with traditional waxing technology, the thickness expansion rate of the water absorption can be reduced to 24.7-51.9% of waxing floor. The edge banding agent for consolidated floor in the invention possesses characteristics of high adhesion, high-penetrability etc. The coating floor possesses quick-drying performance, no coating after the edge banding agent is dried, sub light, and low smell, and the agent belongs to environment-friendly waterproof coating.

Owner:EVERFIRST WISEFUND TECH BEIJING

Method for preparing melamine modified urea-formaldehyde resin adhesive

ActiveCN105623571AExtended shelf lifeImprove stabilityAldehyde/ketone condensation polymer adhesivesSolubilityPolymer science

The invention relates to the technical field of wood processing, in particular to a method for preparing a melamine modified urea-formaldehyde resin adhesive.The method for preparing the melamine modified urea-formaldehyde resin adhesive comprises the following steps of adding a first batch of urea and melamine, adding a second batch of urea, adding a third batch of urea and mixing adhesive.The melamine modified urea-formaldehyde resin adhesive obtained through the method is long in storage life, good in stability, high in bonding strength and good in waterproof performance, and the thickness swelling rate of water absorption of an artificial board can be effectively reduced; the melamine modified urea-formaldehyde resin adhesive can be used for manufacturing plywood and wet curtain paper and can also be used in the fields of fiberboard manufacturing, chipboard manufacturing and other water solubility resin application.

Owner:GUANGXI UNIV

A kind of preparation method of high moisture content particleboard

ActiveCN104493948BReduced activityGood storage stabilityMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPhysical healthPolymer science

The invention discloses a preparation method for a shaving board with high moisture content. The preparation method comprises the following specific steps: carrying out shaving screening on raw materials of different specifications and drying qualified shavings; weighing the shavings according to the density and the size of the to-be-manufactured shaving board and regulating the moisture content of each shaving to be 20-40 percent; enabling the sizing amount to be 5-8 percent by weight; uniformly laying the sized shavings in a mould, and hot-pressing for 8-10 minutes under the density of 700-800 g / cm<3> at the temperature of 130-140 DEG C so as to obtain the shaving board with high moisture content. The shaving board with high moisture content prepared by the method has high mechanical property and excellent size stability, such as lower water absorption and thickness swelling rate, reduces formaldehyde release quantity, and is beneficial to physical health.

Owner:NANJING FORESTRY UNIV

Preparation method for anti-aging composite materials of sleepers

The invention belongs to the technical field of track materials, and particularly relates to a preparation method for anti-aging composite materials of sleepers. According to the preparation method, bentonite, mica and titanium dioxide are mixed and ball-milled, dispersed into modified liquid and then stirred at a high speed to uniformly fill wood fiber cells subjected to enzymolysis treatment, the interiors of the wood fiber cells are fully swelled and filled, and therefore the effect of physically shielding ultraviolet light is achieved, the penetration rate of the ultraviolet light in the wood is effectively reduced, and the anti-aging performance of the wood material in an ultraviolet light environment is improved. Meanwhile, the wood material is subjected to hot pressing treatment, and due to high temperature and enzymolysis treatment, fibers of wood residues are fully hydrolyzed; and due to the fact that the internal cellulose cells are filled with the filler, the thickness swelling rate of water absorption is effectively reduced, redundant internal stress in the materials is released, and the aging resistance of the composite materials of the sleepers is greatly enhanced.

Owner:赖尚辉

Method for manufacturing ceramic recombined bamboo floor

ActiveCN104015242AIncrease productionImprove mildew resistance and corrosion resistanceWood treatment detailsWood impregnation detailsCasein hydrolysateCarbon source

The invention discloses a method for manufacturing a ceramic recombined bamboo floor. The method includes the steps of manufacturing and processing of thin bamboo strips, preparing of ceramic processing liquid, ceramic processing of the thin bamboo strips, heat processing of the ceramic thin bamboo strips, gumming of the ceramic thin bamboo strips and the like. According to the method, ceramic processing is conducted on the bamboo strips, mixed sugar serves as a carbon source and casein hydrolysate serves as a nitrogen source in the ceramic processing liquid, the yield of bacterial cellulose films is greatly improved, composite impregnation adhesives are adopted in gumming of the bamboo strips, the anti-mold property and the anti-corrosion grade of products are improved, and it is ensured that the thickness swelling rate of water absorption of the products is smaller than 5 percent.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for improving bonding performance of reconstituted bamboo

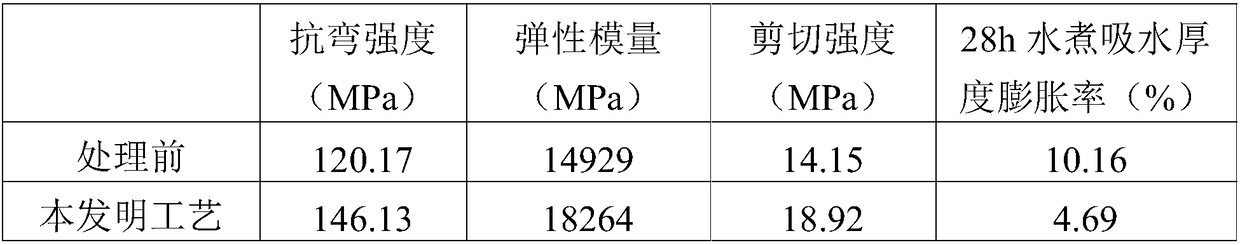

ActiveCN108162105AGood gluing propertiesEasy to operateWood treatment detailsCane mechanical workingWaxCarbonization

The invention discloses a method for improving bonding performance of reconstituted bamboo. The method includes the steps of bamboo defibering, bonding improvement treatment, drying, gum dipping, secondary drying of bamboo, reconstituting forming and the like. According to the method, the bamboo is subjected to mechanical defibering, then the bamboo is subjected to spraying treatment and high-temperature carbonization treatment with NaOH, and thus a silicon layer and a wax layer on the surface of the bamboo are effectively removed and damaged; and on the basis, gum dipping and secondary dryingare carried out, and finally reconstituting forming is carried out. According to the reconstituted bamboo prepared by the method, the bonding performance of the bamboo is improved, and in the processing progress, operation is simple, poison, harm and waste are avoided, and the physical mechanical strength is remarkably improved, wherein the horizontal shearing strength is improved by 10% or above, the water-absorbing thickness swelling rate is lowered by 26% or above, the bending strength is improved by 16% or above, and the elastic modulus is improved by 20% or above.

Owner:GUANGDONG ACAD OF FORESTRY

Polishing disc for polishing machine with good oxidation resistance and wear resistance, and preparation process thereof

ActiveCN108406619AImprove surface qualityNo poresAbrasion apparatusGrinding devicesMicrocrystalline waxOxidation resistant

The invention provides a polishing disc for a polishing machine with good oxidation resistance and wear resistance, and a preparation process thereof, and relates to the technical field of polishing discs. The polishing disc is prepared by taking asphalt, paraffin wax, microcrystalline wax, rosin, porous expanded perlite, silicon dioxide, abrasive material, hydrated magnesium silicate and petrolatum as raw materials. The preparation process of the polishing disc comprises the processes of asphalt extraction, solid-phase raw material crushing, stirring and mixing, pouring and curing, cooling and die release, and the like. The material of the polishing disc provided by the invention is high in surface quality, free from pores and impurities, and low in price; and the polishing disc product further has good oxidation resistance and wear resistance in addition to the traditional heat dispersion performance of the polishing disc.

Owner:宁国市顺鑫金属制品有限公司

High-moisture resistance urea-formaldehyde resin adhesive and preparation method thereof

ActiveCN104479601AGood bonding propertiesLow costNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSodium silicateAdhesive cement

The invention belongs to the technical field of adhesives for artificial fiber plates, relates to a urea-formaldehyde resin adhesive and especially relates to a high-moisture resistance urea-formaldehyde resin adhesive and a preparation method thereof. The high-moisture resistance urea-formaldehyde resin adhesive comprises, by weight, 45-55 parts of formaldehyde, 1-18 parts of water, 22-30 parts of urea, 8-30 parts of a composite assistant, and 0.1-0.5 parts of methanesiliconic acid sodium salt. The composite assistant is obtained by mixing of 0.1-1 part by weight of polyvinyl alcohol, 1-95 parts by weight of melamine and 1-10 parts by weight of glycol. The invention discloses a preparation method of the high-moisture resistance urea-formaldehyde resin adhesive. The high-moisture resistance urea-formaldehyde resin adhesive has good viscosity and a low cost. The preparation method has simple processes and high production efficiency. An artificial board with the high-moisture resistance urea-formaldehyde resin adhesive has high moisture resistance and a very low water absorption thickness swelling rate, greatly widens an artificial board use environment and range and prolongs a board service life.

Owner:DARE WOOD BASED PANEL GRP

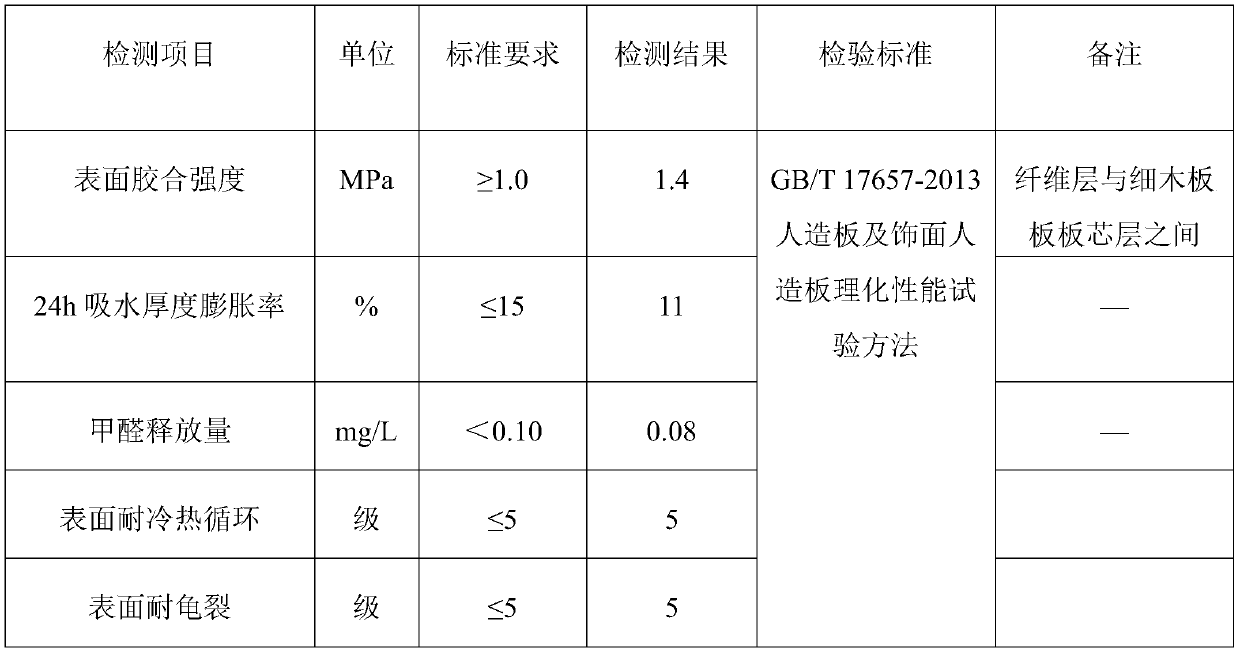

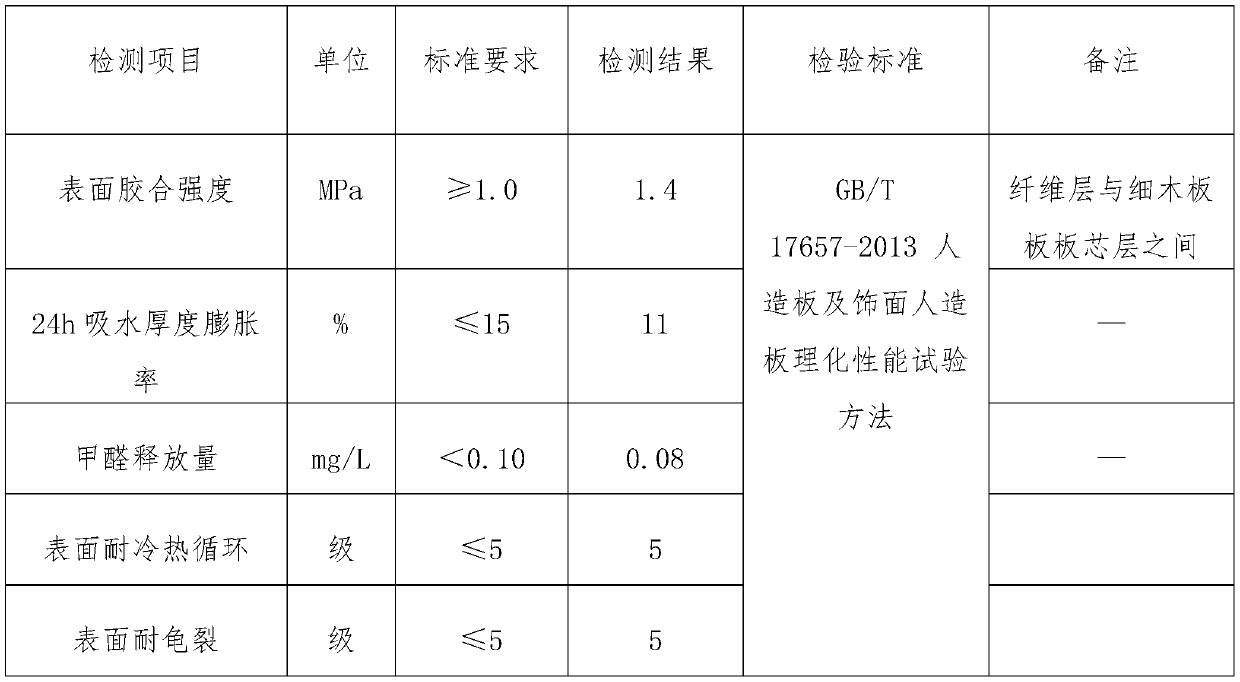

Wood fiber composite facing ecological board and manufacturing method thereof

InactiveCN110962192AImprove flatnessHigh surface bonding strengthWood veneer joiningFlat articlesFiberAdhesive

The invention discloses a wood fiber composite facing ecological board and a manufacturing method thereof. Wood fibers are selected, and the thickness of the wood fibers ranges from 0.2 mm to 0.6 mm;the moisture content of the wood fibers is 0-9%; an adhesive is adopted for adhesion, and is applied and stirred in the fibers; the adhesive application amount is 7-35% of the weight of the wood fibers; 0.3-0.6% of waterproof agent and 0.1-0.4% of mildew preventive are added; after the application, the moisture content of the fibers is dried to 3 to 15 percent; upper and lower surfaces of a laminated wood board core or a plywood core in the thickness of 5-21 mm, length of 2450 mm to 2750 mm and width of 1230 mm to 1310 mm are coated with the adhesive, and the coating weight of a single surfaceis 100-120g / m2; the uniformly stirred wood fibers is uniformly laid on the upper and lower surfaces of the facing board core for hot pressing at the hot pressing temperature of 100-150 DEG C; the actual unit pressure and time are divided into three sections for hot pressing, then board collecting, and then stacking and natural curing are conducted for more than 7 days, edge sawing and sanding thickness determination are conducted, and the wood fiber composite facing ecological board is manufactured by conducting high-temperature hot pressing on the two faces and impregnating adhesive film paper. The wood fiber composite facing ecological board is high in flatness, high in surface bonding strength, low in water content, stable in size, resistant to cracking and good in cold and hot cycle resistance.

Owner:NANNING KETIAN NEW MATERIAL TECH CO LTD

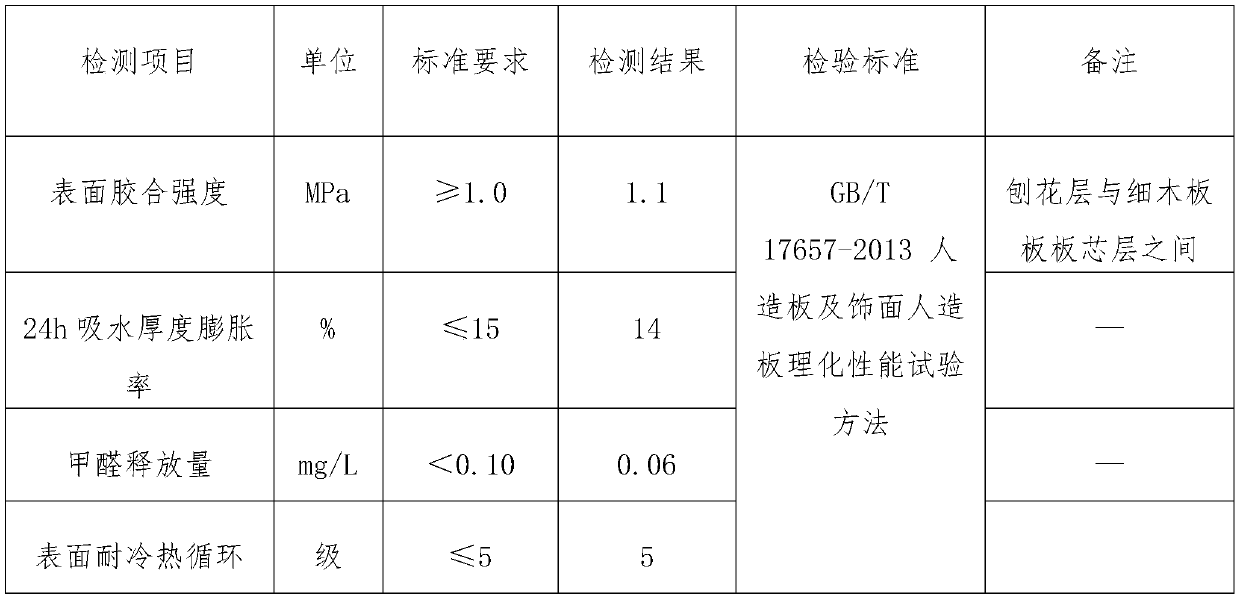

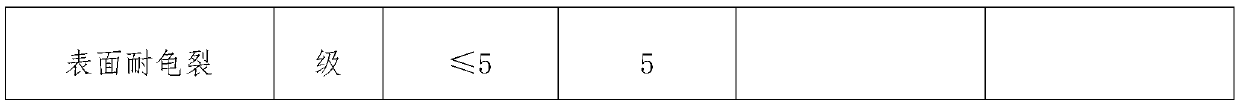

Composite plywood and manufacturing method thereof

InactiveCN110900775AImprove flatnessHigh bonding strengthFlat articlesDomestic articlesFiberAdhesive cement

The invention discloses composite plywood and a manufacturing method thereof. The manufacturing method comprises the following steps of: the step 1, uniformly stirring wood shavings or wood fibers with an adhesive; the step 2, paving the stirred wood shavings or wood fibers on the two board surfaces of the plywood, and carrying out high-temperature hot pressing to prepare the wood shaving composite plywood or wood fiber composite plywood; the step 3, after hot pressing is completed, allowing the composite plywood to be subjected to air blowing cooling for 5 min or above, and then collecting and stacking the plywood, and naturally curing the wood fiber composite plywood for more than 7 days, then performing edge sawing, sanding and thickness determining, and controlling the plate surface thickness error to be + / -0.1 mm. The composite core-board prepared by the method is good in flatness, high in surface bonding strength, low in water content, good in size stability, cracking resistanceand cold and hot cycle resistance, and capable of reducing the production cost.

Owner:NANNING KETIAN NEW MATERIAL TECH CO LTD

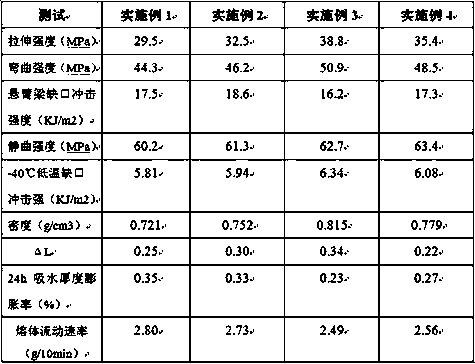

Polypropylene thermoplastic elastomer composite material and preparation method thereof

InactiveCN110498968AImprove mechanical propertiesImprove low temperature impact resistanceElastomerCross-link

The invention provides a polypropylene thermoplastic elastomer composite material. Raw materials of the composite material comprises, by weight, 40-70 parts of polypropylene, 8-15 parts of an elastomer POE, 5-10 parts of a liquid silicone rubber, 2-3 parts of nanometer cerium oxide powder, 1.5-3.2 parts of nano-ceramic powder, 13-20 parts of carboxylated nitrile rubber, 0.6-1.3 parts of a cross-linking agent, 3-9 parts of a compatibilizer, 1.2-3.1 parts of an antioxidant, 1.5-2.5 parts of a coupling agent and 2.5-3 parts of a filler. The prepared polypropylene thermoplastic elastomer compositematerial has a high mechanical strength and an excellent low-temperature impact resistance, the low-temperature notch impact strength at -40 DEG C reaches 5.81-6.34 KJ / m<2>, and the product has a smooth surface and a good scratch resistance.

Owner:山东寿光健元春化工有限公司 +1

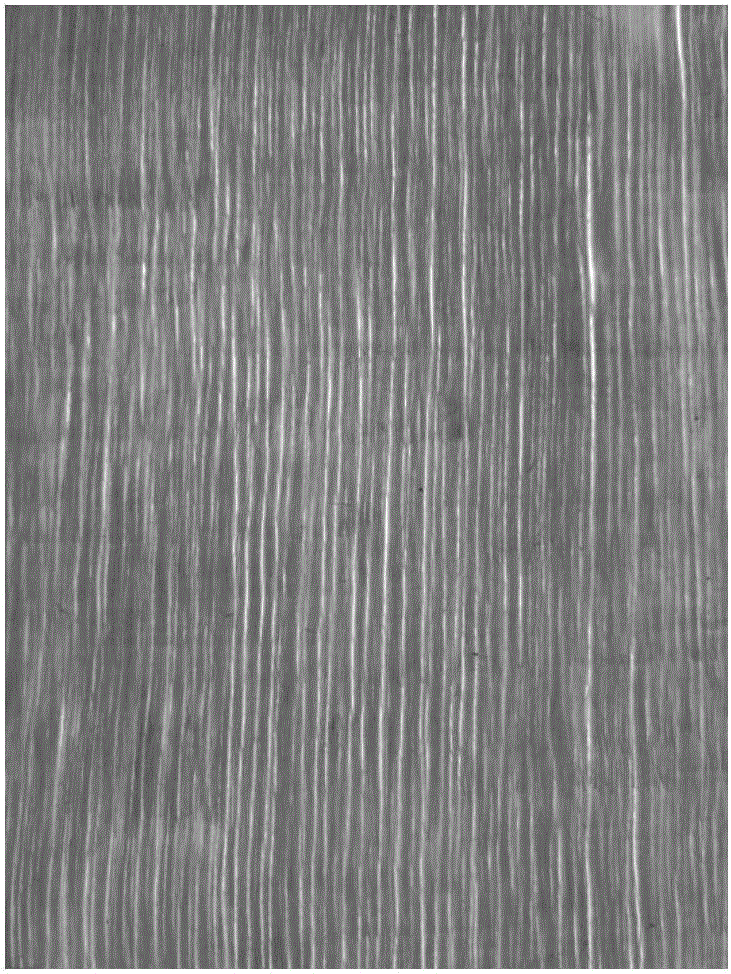

Manufacturing method of reorganized solid board

InactiveCN103817750ARich sourcesImprove permeabilityWood treatment detailsWood veneer joiningPulp and paper industryVolumetric Mass Density

The invention discloses a manufacturing method of a reorganized solid board. The method comprises the following steps of selecting wood processing corner waste, rotationally cutting or planing rest logs into wood chips of 0.01-0.03cm by rotary, drying and flattening; printing the wood chips into thin wood chips with various tree textures by a 3D (three-dimensional) printing technology; dipping into environment-friendly glue with well adjusted color, soaking for 5-10 minutes to enable glue color to fully dye into the thin wood chips, and dehydrating by placing in a dehydrator to obtain colored wood chips; further arraying by a 3D technology, and overlapping according to the sequence of various textures during arraying to obtain wood blanks; performing hot-pressing molding by hot-pressing equipment to obtain the reorganized wood. The reorganized solid board is lifelike, clear in wood grain, high in density and not deformed, and belongs to the optimal material of high-class furniture and office appliances, forest resources are saved, and the utilization rate of edge and corner wastes in timber machining and log raw materials is increased.

Owner:程进华

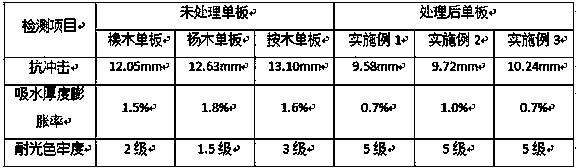

Preparation method of functional impact-resistant veneer

InactiveCN110883893AAvoid overexpansionReduces changes in internal stressWood treatment detailsPressure impregnationColour fastnessHindered amine light stabilizers

The invention discloses a preparation method of a functional impact-resistant veneer; the veneer is processed through dyeing and drying, resin preparation, resin impregnation and drying balance, so that the veneer has good and lasting impact resistance and attractiveness, and the service life of the veneer is prolonged. Specifically, the problems of cracking, warping deformation and the like are avoided by controlling the moisture content of the veneer in the technological process, the strength of the veneer is kept, on the basis, the veneer is coated with modified resin with modified PAE as amain raw material, a vacuum impregnation technology is combined, and thus the impact strength, the size stability and the waterproofness of the veneer are improved; a specific compound dye composed of a hindered amine light stabilizer and a bisazo acid dye is combined with a vertical dip dyeing process, so that the dyeing effect is attractive and lasting, meanwhile, the modified resin isolates the environment, and the color fastness of the veneer is further improved.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Tannin-based adhesive shaving board and preparation method thereof

InactiveCN108393999AHigh strengthImprove water resistanceDomestic articlesFlat articlesCelluloseWood shavings

The invention discloses a tannin-based adhesive shaving board. The tannin-based adhesive shaving board is formed by carrying out hot pressing after applying a tannin-based adhesive modified by cellulose nanofibers grafted with hyperbranched polyamide to wood shavings, the adhesive applying amount is 8%-14%, and the content of the cellulose nanofibers grafted with the hyperbranched polyamide is 0.5-3%wt of the solid tannin content in the tannin-based adhesive modified by cellulose nanofibers grafted with hyperbranched polyamide. The cellulose nanofibers with the high specific surface area, highcrystallinity degree, high strength and other characteristics are used as modifying materials, meanwhile the crosslinking degree between the cellulose nanofibers and tannin molecules is improved through the surface grafted hyperbranched polyamide, and the effect of improving the physical mechanics strength and water resistance of the tannin-based adhesive shaving board is achieved. According to the tannin-based adhesive shaving board, the internal binding strength can be improved by 27.0% or above, the elasticity modulus can be improved by 22.2% or above, the static bending intensity can be improved by 25.3% or above, and 2h water absorption thickness expansion rate can be reduced by 23.6% or above.

Owner:NANJING FORESTRY UNIV +1

Wood fiber composite new material veneer plywood and manufacturing method thereof

InactiveCN111002400AImprove flatnessHigh surface bonding strengthLaminationLamination apparatusSolid woodFiber

The invention discloses a wood fiber composite new material veneer plywood and a manufacturing method thereof. Solid wood veneers or technical veneers in the thickness ranging from 0.10 mm to 3.2 mm and wood fibers in the thickness ranges from 0.2 mm to 0.6 mm are selected; the moisture content of the wood fibers is 0-9%; an adhesive is adopted for adhesion and is applied to the fibers and stirredwith the fibers; the sizing amount is 7-35% of the weight of the wood fibers; 0.1 to 0.9 percent of a waterproof agent and 0.05-0.8% of a mildew inhibitor are added, after application, the fiber moisture content is dried to 3-15%; the uniformly stirred wood fibers are laid on the surface of the single plate, a pre-pressed plate blank is hot-pressed at the temperature of 110-210 DEG C, the actualunit pressure and time are divided into four sections for hot pressing, the single-sided plate and the common plywood are adhered by the adhesive, and after the composite adhered plate blank is cooled, the wood fiber composite new material veneer plywood is prepared by high-temperature hot pressing. The wood fiber composite new material veneer plywood is high in flatness, high in surface bonding strength, low in water content, stable in size, resistant to cracking and high in cold and hot cycle resistance.

Owner:NANNING KETIAN SHUIXING TECH LTD CO

Preparation method of composite floor

InactiveCN108081417AHigh bonding strengthImprove the index of resistance to cold and heat cyclesOther plywood/veneer working apparatusWood veneer joiningWood shavingsSurface layer

The invention discloses a preparation method of a composite floor, and belongs to the technical field of building materials. The preparation method of the composite floor comprises the following stepsof preparing wood shavings, drying the wood shavings, screening the wood shavings, sizing the wood shavings, carrying out paving, carrying out hot pressing, sanding, distributing glue, carrying out cold pressing, carrying out hot pressing, cutting edges, pasting paper, carrying out hot pressing, guiding edges, carrying out multi-piece sawing, carrying out double-end milling and inspecting and packaging and storing. Compared with the preparation method of a traditional decorative plate, the preparation method of the composite floor is scientific, the surface layer is refined, the density of the surface layer is large, the proper sizing amount is applied, so that the internal bonding strength of plates is improved, groove milling is facilitated, the water absorption thickness expansion rateis small, and the service life of the plates is prolonged; and moreover, the formaldehyde release amount is low, due to the fact that the transverse strength is increased, the cold and hot circulation resistant index and the cracking performance of the surfaces of the plates are improved.

Owner:安徽信耀玻璃有限公司

Building wood planking recycling method

InactiveCN102528879ALow water absorption thickness expansionWood working apparatusFlat articlesChemical agentExpansion rate

The invention discloses a building wood planking recycling method which comprises the following steps: firstly, waste building wood planking is soaked in a clean water tank for 3 to 5 days; then chemical agent for modest degradation treatment is added for appropriate degradation process, then the waste building wood planking is placed into a steaming plant with the temperature higher than 105 DEG C for stewing for 36 to 48 hour, and then the waste building wood planking is layered and peeled off, so as to form a veneer; and after peeling off, the water content of the veneer is dried to 8 to 12 percent, the veneer is taken as a core plate and used together with the whole veneer of a novel rotary cutter, then is sent into a cold press machine for cold pressing for 30 min through sizing and assembling, and then is sent to a hot press, and finished product is formed through edge cutting, sanding and checking. The water absorption thickness expansion ratio is lower than 12 percent, the static bending strength is 28.3MP, and the elastic modulus is 3.62 103MPa, which is larger than or equal to 0.7 Mpa (national standard) and is 0.82 MPa. The operating requirements of concrete template plywood are all met.

Owner:SICHUAN AGRI UNIV

Damp-proof shaving board low in absorbent thickness expansion rate and manufacturing method thereof

InactiveCN103419263ALow water absorption thickness expansionNo deformationDomestic articlesFlat articlesWood shavingsSurface layer

The invention discloses a damp-proof shaving board low in absorbent thickness expansion rate and a manufacturing method thereof. The manufacturing method comprises the specific steps of wood shaving preparation, glue mixing, hot pressing, cooling and product forming. In the step of glue mixing, glue mixing is respectively conducted on surface layer materials and core layer materials, the surface layer materials comprise wood shavings, 10-13% of glue, 0.5-1% of curing agents and 3-4 kg / m<3> of water-proofing agents, and the wood shavings, the 10-13% of glue, the 0.5-1% of curing agents and the 3-4 kg / m<3> of water-proofing agent are mixed after a moderate amount of water is added; the core layer materials comprise wood shavings, 8-10% of glue, 1.3-2% of curing agents and 2-3 kg / m<3> of water-proofing agents, and the wood shavings, the 8-10% of glue, the 1.3-2% of curing agents and the 2-3 kg / m<3> of water-proofing agents are mixed after a moderate amount of water is added. In the hot pressing step, the hot pressing speed is 270-450mm / s, and a partition hot pressing mode is adopted. The damp-proof shaving board low in absorbent thickness expansion rate is suitable for being used in the damp environment, produces no deformation, and is long in service life.

Owner:大亚木业(福建)有限公司 +1

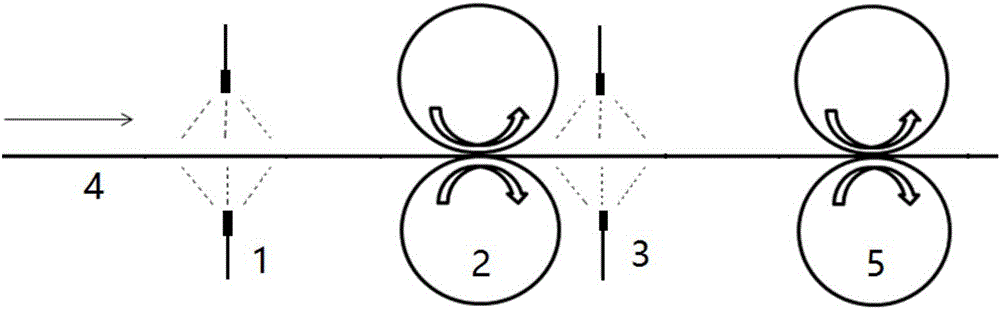

System for preparing laminated veneer lumber from wooden veneers and laminated veneer lumber preparation method

InactiveCN106827162AHigh strengthImprove performanceWood working apparatusFlat articlesLaminated veneer lumberControllability

The invention belongs to the field of laminated veneer lumber and particularly relates to a system for preparing laminated veneer lumber from wooden veneers and a laminated veneer lumber preparation method. The system comprises a first double press roller, first drying equipment, gluing equipment, second drying equipment, compression moulding equipment and thermocuring equipment. The first drying equipment and the gluing equipment are arranged at the downstream position of the first double press roller, and the second drying equipment, the compression moulding equipment and the thermocuring equipment are arranged at the downstream position of the gluing equipment. The gluing equipment comprises a first glue spraying device, a rolling and glue spraying device and a conveying device, wherein the rolling and glue spraying device is arranged at the downstream position of the first glue spraying device and comprises the first double press roller and a second glue spraying device arranged at a discharging end of the first double press roller, and the conveying device is used for allowing the wooden veneers dried by the first drying equipment to pass through the first glue spraying device and the rolling and glue spraying device sequentially. The system has advantages that controllability and uniformity in gluing of the wooden veneers can be realized, and accordingly high-strength laminated veneer lumber can be prepared.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com