Process for pretreating raw materials of sunflower stalk composite boards and pressing assemblies

A sunflower stalk and pretreatment technology, which is applied in the pretreatment of molding materials, manufacturing tools, reed/straw treatment, etc., can solve the problems of limited board strength, environmental protection, and low product strength, so as to improve strength and reduce production costs , The effect of reducing the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

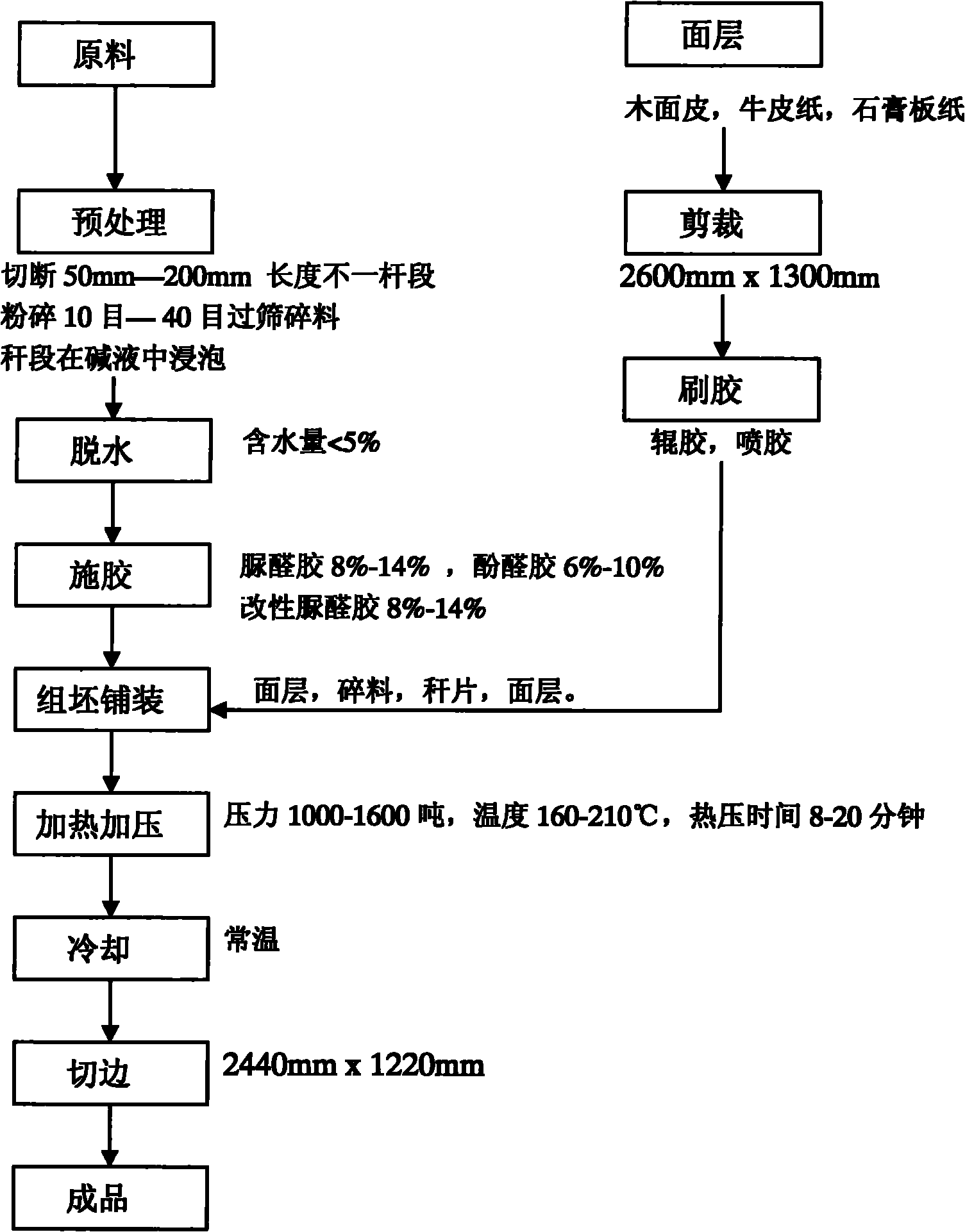

Method used

Image

Examples

Embodiment 1

[0016]First of all, sunflower stalks, sawdust, rice husks, peanut shells, bean stalks, hemp stalks, and cotton stalks should be dehydrated (natural drying and artificial drying) to make the water content <5%, and the sunflower stalks should be broken longitudinally from root to tip. , break it into two halves, three halves, four halves, and five halves, then remove the outer skin and pith on special equipment, and then use a cutting machine to cut the stalks into 50mm-200mm lengths of stalks, and then cut the stalks Put it into a immersion tank with an alkali content of 1%-1.5%, the water temperature is 20-30°C, and the immersion time is 30-60 minutes, then it is taken out and sent to a roller machine for rolling and dehydration, and then dried. If the water content is less than 5%, grind sawdust or rice husks, peanut shells, bean stalks, hemp stalks, cotton stalks and some sunflower stalks into 10-40 mesh sieves and put them in the mixer Carry out glue sizing and stirring for...

Embodiment 2

[0018] The raw materials are dried so that the water content is less than 5%, so as to ensure the quality of the board. First, a part of the sunflower stalk is broken from the root to the tip, and more than two halves are removed, and then the outer skin and pith are removed. Wait for the stalk section, and then send it to a soaking pool with an alkali concentration of 1%-1.5% for 30-60 minutes, and the water temperature is 20-30 degrees, take it out and send it to a roller machine for rolling and dehydration, and after drying For sizing, crush a part of the sunflower stalks into 10-40 mesh sieved fragments and send them to the mixer for sizing and mixing. After cutting and gluing the 0.5mm thick wood dough, lay it on the formwork, and then lay the sunflower stalk fragments The thickness of each layer on the surface layer is 6mm, and then it enters the stalk sheet assembly process, that is, the 50mm-200mm length stalk sheets after sizing are randomly laid on the scraps accordin...

Embodiment 3

[0020] Firstly, lay 120 grams of kraft paper that has been cut and glued on the template, and then the rice husk that has been crushed into 10-40 meshes and passed through the sieve is laid on the surface layer after being glued and stirred. The thickness of each layer is 4mm. Lay the crushed and dried 50mm-1200mm long stalk segments on the crushed material in parallel longitudinal arrangement, then lay a layer of 4mm thick rice husk crushed material, and then lay the second layer of horizontally parallel arranged stalk pieces, The vertical and horizontal layers should be laid staggered and vertically, that is, one layer of scraps and one layer of stalks can be laid crisscross and staggered repeatedly for 10 layers, and then a layer of 120 grams of kraft paper is laid on top of it, and then transferred to the press, which can be pressed 12 times each time. Sheet material, pressure 1200 tons, temperature 160 degree, hot pressing time 8 minutes, can suppress the plate material of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com