System for preparing laminated veneer lumber from wooden veneers and laminated veneer lumber preparation method

A technology of laminated veneer lumber and veneer, which is applied in the direction of wood processing appliances, flat products, household components, etc., and can solve problems such as the influence of strength of laminated lumber products, uneven distribution of glue, and substandard product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation system provided by the invention includes a roller press, first drying equipment, glue sizing equipment, second drying equipment, pressing molding equipment and thermal curing equipment. Wherein, the roller press includes two rollers arranged in parallel, and the roller gap is preferably 10-80% of the thickness of the wood veneer, more preferably 50-80%, most preferably 70-77%. In one embodiment provided by the present invention, the roller gap is 1-1.2 mm. In an embodiment provided by the present invention, the two pressure rollers arranged in parallel in the roller press are cylindrical cylinders, and the surface of the cylinders has no gears or threads.

[0030] In the present invention, the first drying device is arranged between the first double-pressing rollers and the sizing device, and is used for drying the veneer after being rolled by the first double-pressing rollers. The present invention does not specifically limit the specific structure of...

Embodiment 1

[0059] Laminated veneer lumber preparation system

[0060] The preparation system provided in this embodiment includes a roller press, first drying equipment, glue sizing equipment, second drying equipment, compression molding equipment and thermal curing equipment.

[0061] Among them, the roller press includes two rollers arranged in parallel. The roller gap is 77% of the thickness of the wood veneer. The two rollers are cylindrical cylinders with no teeth or threads on the surface of the cylinders. The diameter of the cylinders is 150mm. .

[0062] In this embodiment, the first drying equipment is arranged downstream of the roller press, specifically a mesh belt dryer.

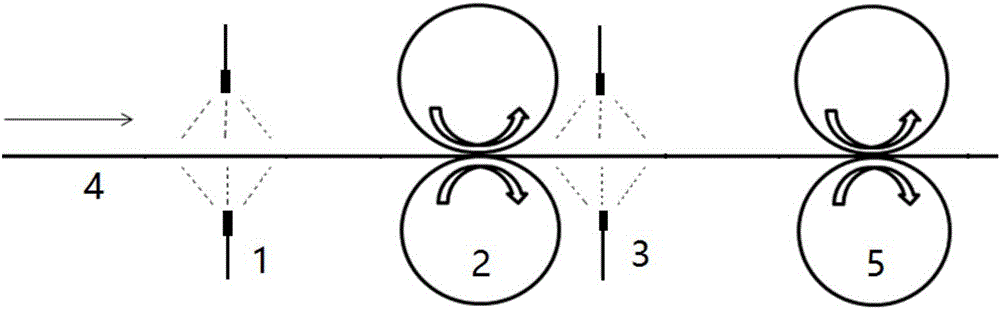

[0063] In this embodiment, the sizing equipment is arranged downstream of the first drying equipment, and its structure is as follows: figure 1 as shown, figure 1 Among them, 1 is the first glue spraying device, 2 is the first double pressure roller, 3 is the second glue spraying device, 4 is the conveyi...

Embodiment 2

[0072] Adopt the system that embodiment 1 provides to prepare laminated veneer lumber

[0073] 1) Rotary cutting: use a rotary cutting machine to cut Russian poplar into veneers, the thickness of the veneer is 1.3mm, the width is 250mm, the length is 650mm, and the moisture content is 130±10%.

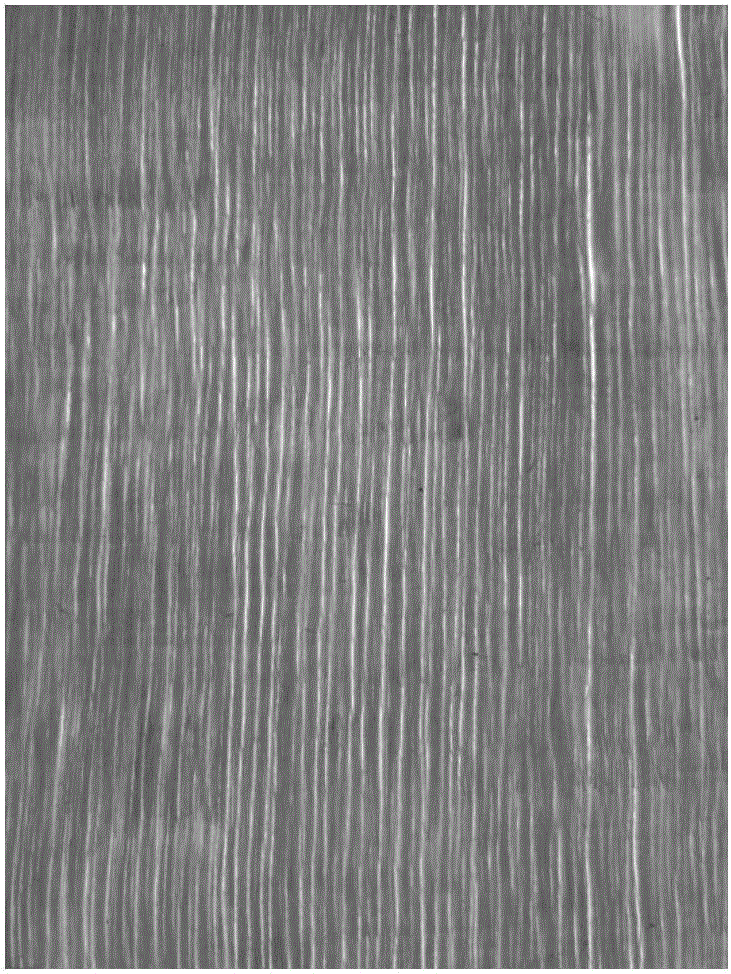

[0074] 2) One-time rolling: Put the rotary-cut wooden veneer into a rolling machine according to the direction of its fiber transverse grain for rolling. The rotating speed of the lower roller is 20r / min, and the rotating speed of the upper roller is 24r / min. After rolling, a rolled veneer is obtained. After rolling, the veneer is a broom-like mesh structure veneer that does not break in the longitudinal direction and is loose in the transverse direction, such as figure 2 as shown, figure 2 It is a digital photo of the veneer after being rolled by the first double pressure roller provided in Example 2 of the present invention.

[0075] 3) Drying of the veneer: After rolling, the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Static bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com