Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

151results about How to "Good bonding properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

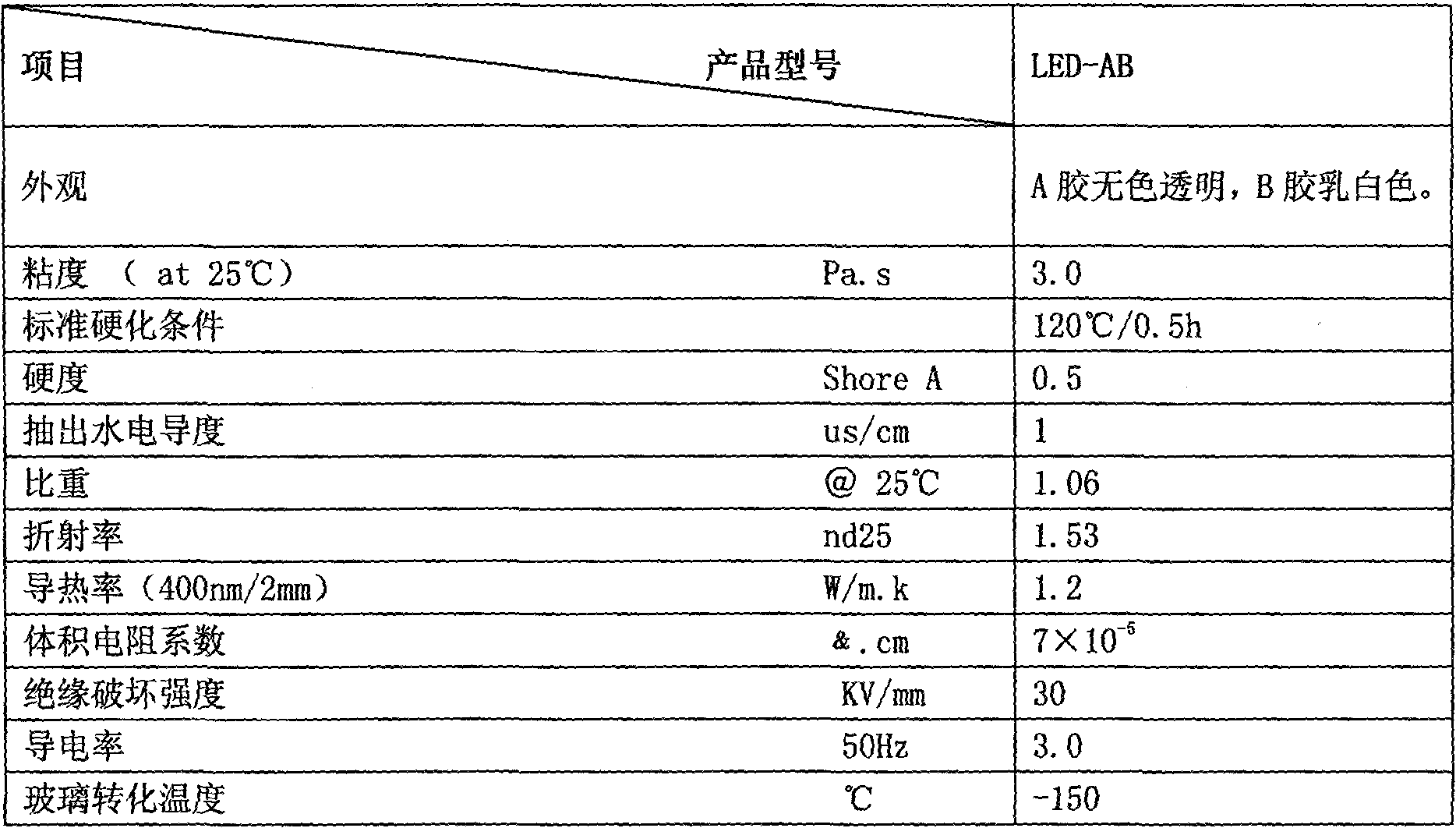

Light-emitting diode (LED) fluorescent glue

InactiveCN101787273AHigh Purity FeaturesDoes not absorb short wavelengthsLuminescent compositionsFluorescenceSilica gel

The invention discloses an LED fluorescent glue prepared from the following components (by the total weight of 100%): 3.10%-3.40% of OE-6450A (silica gel main agent), 2.60%-2.90% of OE-6450B (silica gel curing agents), 72.80%-75.54% of TO powder (dispersing agents), 6.3%-7.0% of silicon dioxide powder (SiO2), 10.6%-11.8% of aluminum oxide powder (Al2O3), 1.4%-1.7% of ST-11001 (silica gel), 0.28%-0.32% of JZ-520A (glue main agent) and 0.18%-0.22% of JZ-520B (glue curing agents). The invention can effectively excite the light spots of finished products and improve the confidence degree of finished products, has the advantages of low cost and convenient use, and can be used for preparing fluorescent powder for white-light LED elements.

Owner:ANHUI ZERUN OPTOELECTRONICS

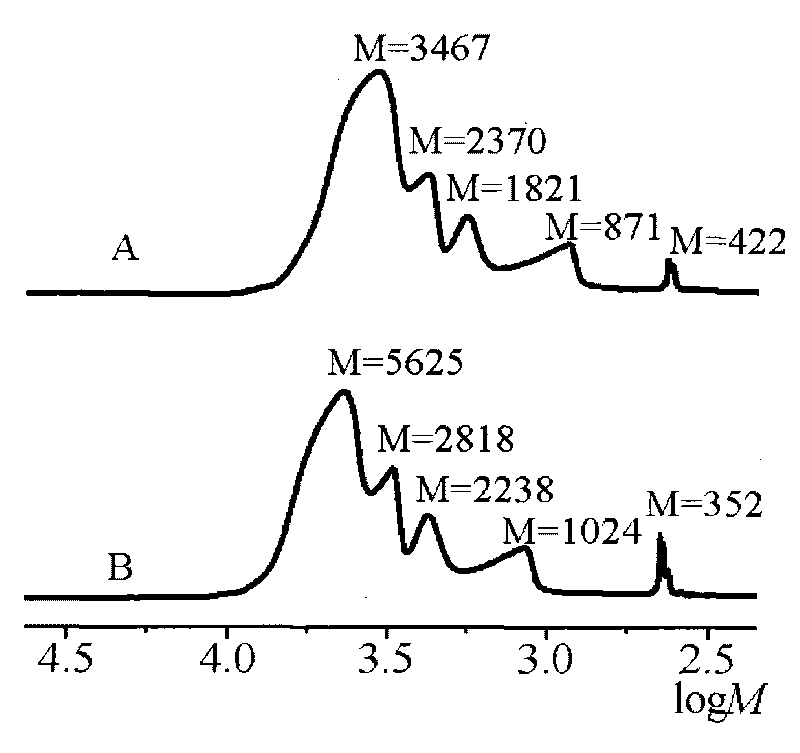

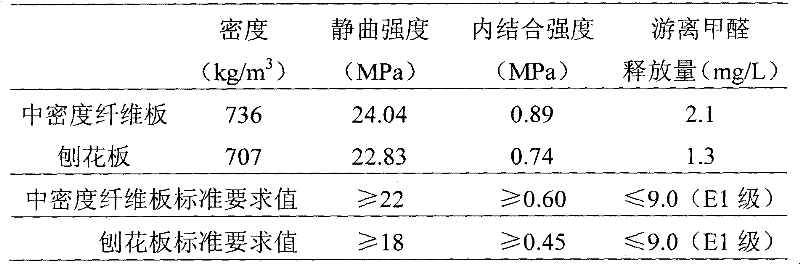

Wood adhesive prepared by degrading soybean protein by utilizing strong basicity and preparation method thereof

InactiveCN101724376AHigh viscosityImprove adsorption capacityProtein adhesivesGlue/gelatin preparationMedium densityAdhesive

The invention discloses a wood adhesive prepared by degrading soybean protein by utilizing strong basicity and a preparation method thereof, and relates to a soybean protein-based wood adhesive and a preparation method thereof. The invention solves the problems of low content of the soybean protein, high moisture content and large viscosity existing in conventional soybean adhesives or soybean protein adhesives. The product is prepared by performing a degradation reaction of defatted soybean protein powder or soybean protein isolate, strong base and water, then using strong phosphoric acid to adjust the pH value of the obtained solution, and then adding dialdehyde into the obtained solution to mix the solution evenly. The method comprises the steps of: 1, weighing; 2, preparing strong base solution, heating the strong base solution, adding the defatted soybean protein powder or the soybean protein isolate into the strong base solution under stirring, and then cooling the strong base solution to a room temperature after heating reflux; and 3, using the strong phosphoric acid to adjust the pH value, adding the dialdehyde into the solution, and stirring the solution evenly. The adhesive has the advantages of high content of the soybean protein, low moisture content and low viscosity, and can be used for preparing plywood, flakeboards and medium-density fiberboards.

Owner:NORTHEAST FORESTRY UNIVERSITY

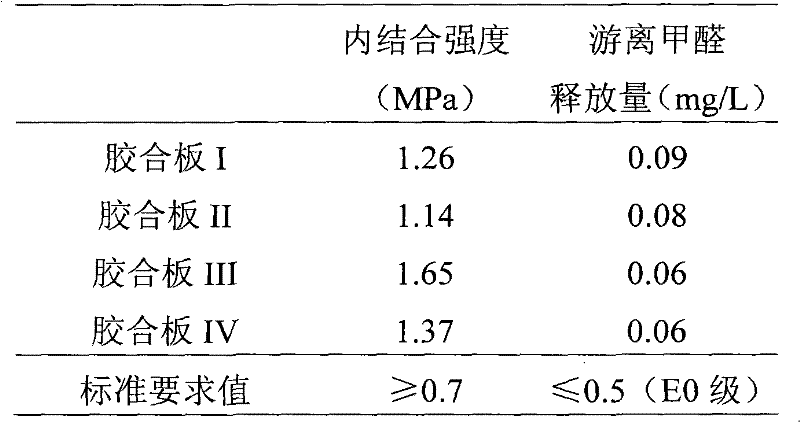

Geopolymer-based wood adhesive and preparation method and application thereof

ActiveCN109251682AWide variety of sourcesLow priceNon-macromolecular adhesive additivesMacromolecular adhesive additivesDopantAdhesive

The invention relates to an environmentally-friendly high-performance geopolymer-based wood adhesive and a preparation method and application thereof. The geopolymer-based wood adhesive is prepared from the following raw materials (by weight): 100 parts of a base material, 1-20 parts of an organic dopant, 87.5-280 parts of an alkali activator, 0.3-1 part of an initiator, 1-2.4 parts of a couplingagent, 1-2.4 parts of an emulsifier, 0.4-1.6 parts of an antifoaming agent and 50-200 parts of water. After the organic dopant is solidified, a chain or net structure can be formed. Thus, the chain ornet structure and the geopolymer form interpenetrating networks to achieve the toughening modification effect, and a mechanical locking effect with the wood material can also be achieved. The geopolymer-based wood adhesive is green and environmentally friendly; the sources of raw materials are wide; production cost is low; and the process is simple. The geopolymer-based wood adhesive is non-flammable, has no release of formaldehyde and has good bonding performance. The geopolymer-based wood adhesive is instant to use when prepared and the formula can be adjusted flexibly. The geopolymer-basedwood adhesive can be used to glue wooden raw materials such as wood, bamboo, straw and the like and to prepare wooden composite materials such as particle boards, fiberboards, plywoods, reconstitutedwood / bamboo and the like, and has industrial application value.

Owner:BEIJING FORESTRY UNIVERSITY

Moisture resistant oilproof electromagnetic wire epoxy self-bonding paint

ActiveCN101857764AImprove consistencyGood batch stabilityPolyurea/polyurethane coatingsInsulating bodiesPolyurethane elastomerEpoxy

The invention relates to a moisture resistant oilproof electromagnetic wire epoxy self-bonding paint meeting heat resisting requirement more than thermal level of 155 DEG C, applied to enamelled wire with high bonding strength and good surface quality. The moisture resistant oilproof electromagnetic wire epoxy self-bonding paint comprises the following components by parts by weight: 320-450 parts of methyl phenol, 350-480 parts of dimethyl benzene, 15-40 parts of polyurethane elastomer, 130-148 parts of epoxy resin, 10-30 parts of phenolic resion, 4.5-13 parts of amino resin, 0.8-1.2 parts of titanate coupling agent and 1-2 parts of flatting agent; wherein the weight-average molecular weight of the epoxy resin is 20000-30000. The main performance indexes of the manufactured product adopting the paint of the invention are as follows: 1, adhesiveness is good; 2, no cracking is produced when heat shock reaches 180 DEG C; 3, bonding strength is 11N / mm2, and the bonding strength in the JB / T6758.1-2007 standard is more than or equal to 5N / mm2.

Owner:江苏佳禾电子材料有限公司

Duplexer filter having film bulk acoustic resonator and semiconductor package thereof

InactiveCN1523754AGood bonding propertiesGood piezoelectric layer propertiesImpedence networksSemiconductor chipSemiconductor package

Owner:LG ELECTRONICS INC

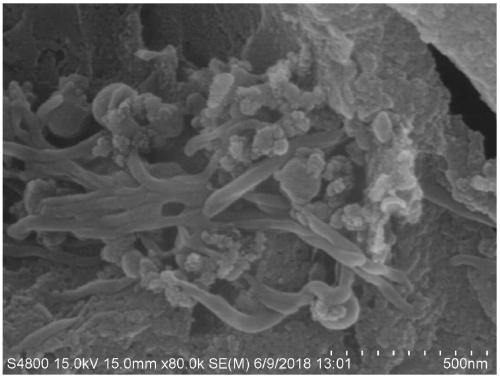

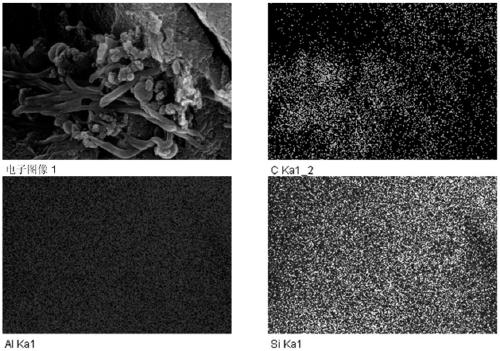

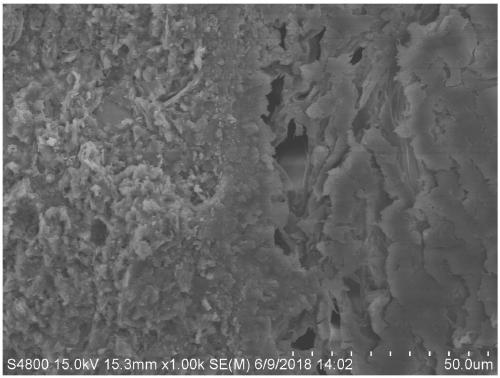

Plated copper wire structure used for ultrasonic bonding

InactiveCN104241237AAchieve expansionAvoid elevationSemiconductor/solid-state device detailsSolid-state devicesMaterial typeCopper wire

The invention provides a plated copper wire structure used for ultrasonic bonding, through which even if plating materials of plated copper wires or core material types and wire diameters are changed , ultrasonic bonding can be stably carried out with a broad process window when a bonding condition is not individually set. The structural characteristics of the plated copper wire structure used for the ultrasonic bonding are that the surface morphology is that a plurality of cirrus-cloud-shaped grooves along length direction of a bonding wire are molded in the surface of the core materials; the core materials are plated with plating materials composed of precious metal or alloy (which is briefly referred to as precious metal, etc. ) which are with better inoxidizability than the inoxidizability of the core materials.

Owner:TANAKA DENSHI KOGYO KK

Automatic tire patching agent

ActiveCN103031109AEnhanced bonding propertiesReduce condensation shrinkageOther chemical processesChemistryComposite material

The invention provides an automatic tire patching agent, which comprises an air pressure agent, an air pressure inhibiting agent, gels, rubber particles, fibers, solvents, additives and nanometer carbon powder. After the automatic tire patching agent provided by the invention is added with the nanometer carbon powder, the bonding characteristic is enhanced, the condensing shrinkage rate of the tire patching agent is reduced, and meanwhile, the friction resistance performance of tires is improved.

Owner:常熟市知识产权运营中心有限公司

Acrylic pressure-sensitive adhesive sheet

InactiveCN101831251AExcellent Adhesive PropertiesGood bonding propertiesFilm/foil adhesivesAmide/imide polymer adhesivesMeth-Hydrogen atom

The present invention relates to an acrylic pressure-sensitive adhesive sheet including: a viscoelastic material layer (X) containing hollow microspheres; and a pressure-sensitive adhesive layer (Y) provided on at least one face of the viscoelastic material layer (X) and formed from a pressure-sensitive adhesive composition including, as a main component, an acrylic copolymer which is constructed from the following monomers (m1) and (m2) as an essential monomer component, in which a content of the monomer (m1) is 50 to 99.9% by weight and a content of the monomer (m2) is 0.1 to 25% by weight based on a total amount of monomer components constituting the acrylic copolymer, (m1) an alkyl(meth)acrylate monomer including an alkyl group having 1 to 20 carbon atoms, which is represented by the following formula (1), [Chem. 1] CH2-C(R1)COOR2 (1) in which R1 represents a hydrogen atom or a methyl group, and R2 represents an alkyl group having 1 to 20 carbon atoms, (m2) an N-hydroxyalkyl(meth)acrylamide monomer including a hydroxyalkyl group having 1 to 4 carbon atoms, which is represented by the following formula (2), [Chem. 2] CH2-C(R3)CONHR4 (2) in which R3 represents a hydrogen atom or a methyl group, and R4 represents a hydroxyalkyl group having 1 to 4 carbon atoms.

Owner:NITTO DENKO CORP

Preparation method of polystyrene-acrylate core-shell composite emulsion

The invention discloses a preparation method of a polystyrene-acrylate core-shell composite emulsion, belongs to the emulsion preparation field, and solves the problems of adhesion resistance, poor heat resistance and the like of a thermoplastic polystyrene-acrylate random copolymer in the prior art. The preparation method is as follows: 1, weighing raw materials; 2, adding distilled water into a reactor, heating up, adding a compound emulsifier, a pH buffer and then part of a mixed vinyl monomer for emulsifying, adding part of an initiator, heating up to react until no reflux exists to obtain a seed emulsion; 3, continuing heating up, dripping off the rest of the mixed vinyl monomer, synchronously adding part of the initiator, after the dripping of the part of the initiator, keeping warm to obtain a core structure emulsion; 4, dripping a mixed acrylate monomer to the core structure emulsion, in the mixed monomer dripping process, adding part of the initiator, after dripping of the part of the initiator, adding the rest of the initiator, keeping warm, then cooling, adding ammonia water, stirring, further cooling, and filtering. The preparation method is applied in the fields of wood veneering, interior decoration, textiles and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

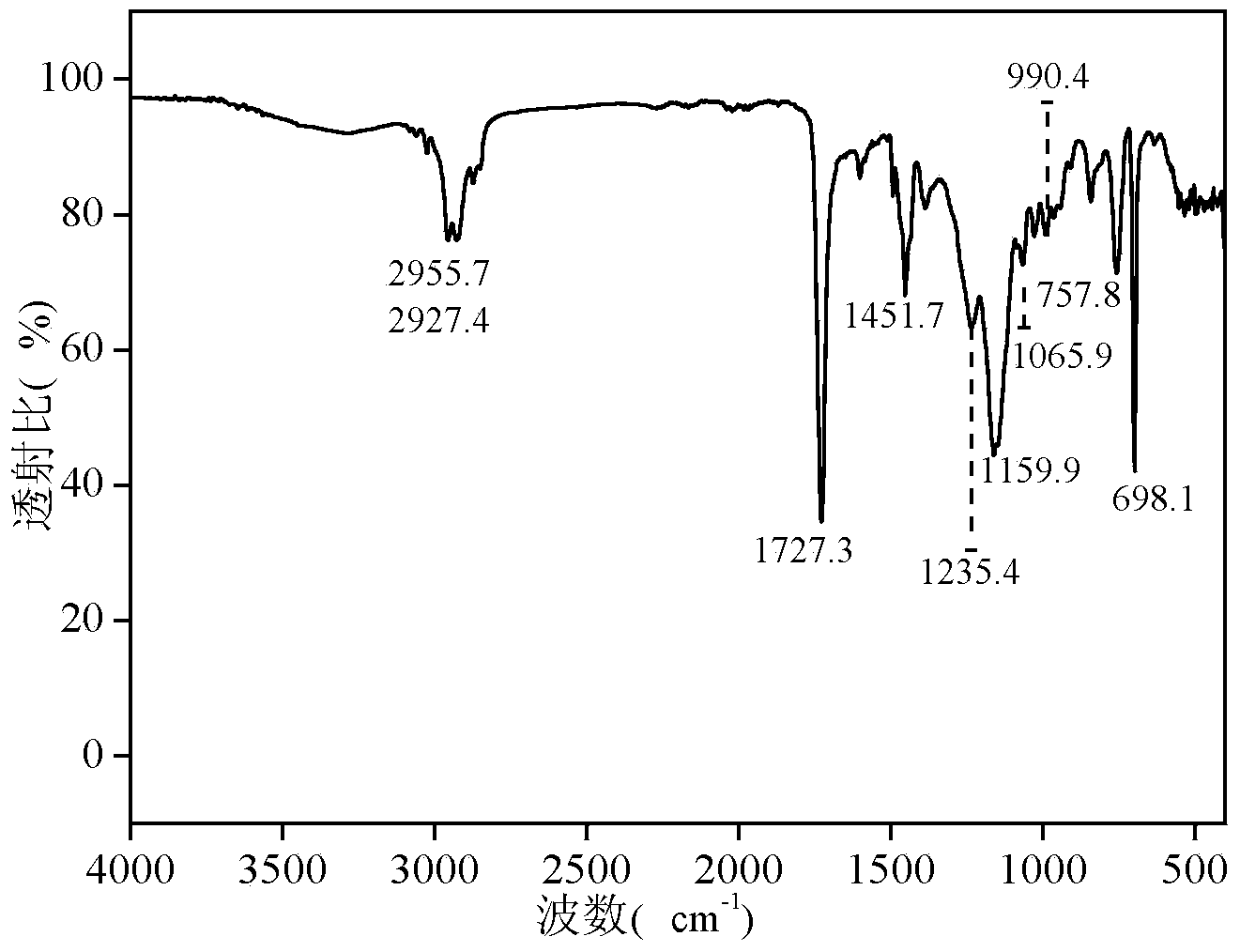

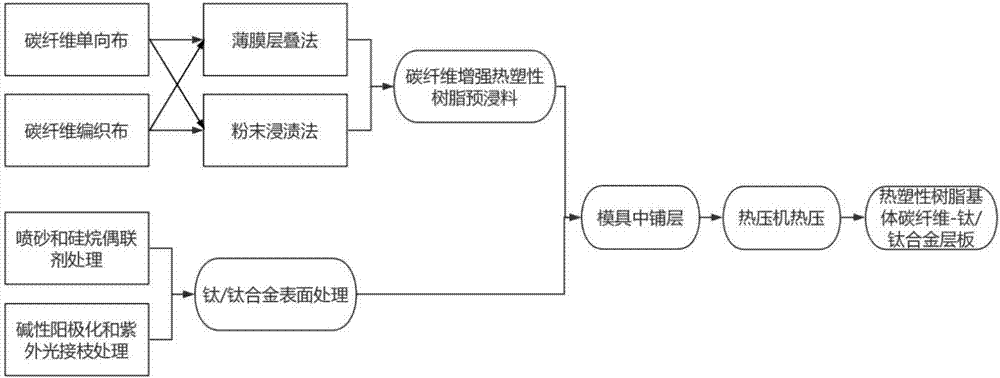

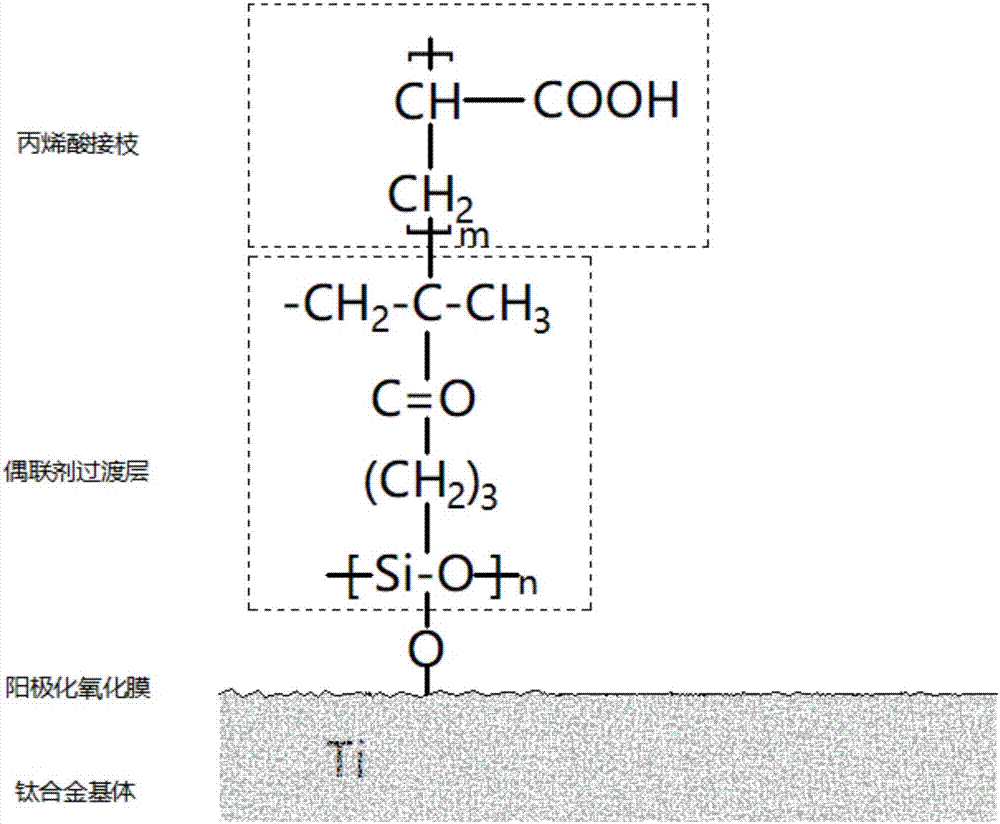

Preparing method of thermoplastic resin matrix carbon fiber-titanium/titanium alloy laminate plate

ActiveCN107283871AImprove impregnation effectHigh mechanical strengthCoatingsThermoplasticCarbon fibers

The invention discloses a preparing method of a thermoplastic resin matrix carbon fiber-titanium / titanium alloy laminate plate, and belongs to the field of light composite materials. The technical purpose is to solve the problem that currently the interface glue joint effect of titanium alloy of carbon fiber reinforcement titanium alloy laminate plate TiGr and a prepreg is poor. The thermoplastic resin comprises three kinds of high-performance thermoplastic resin including polyether-ether-ketone (PEEK), polyphenylene sulfide (PPS) and polyetherimid (PEI), with the coordination of a film laminating method and a powder impregnation method, the problem that the impregnation effect of the thermoplastic resin on carbon fiber is poor is solved.

Owner:HARBIN INST OF TECH

Acrylic pressure-sensitive adhesive sheet

InactiveCN101831252AExcellent Adhesive PropertiesGood bonding propertiesFilm/foil adhesivesAmide/imide polymer adhesivesMonomer compositionHydrogen atom

The present invention relates to an acrylic pressure-sensitive adhesive sheet, including: a viscoelastic material layer (X) containing hollow microspheres; and a pressure-sensitive adhesive layer (Y) provided on at least one face of the viscoelastic material layer (X) and formed from a monomer composition, in which the monomer composition includes the following monomers (m1), (m2) and (m3) as essential monomer components, in which a content of the monomer (m1) is 50 to 85% by weight, a content of the monomer (m2) is 0.1 to 20% by weight, and a content of the monomer (m3) is 2 to 40% by weight, based on a total amount of monomer components constituting the monomer composition, (m1) an alkyl(meth)acrylate monomer including an alkyl group having 1 to 20 carbon atoms, which is represented by the following formula (1), [Chem. 1] CH2-C(R1)COOR2 (1) in which R1 represents a hydrogen atom or a methyl group, and R2 represents an alkyl group having 1 to 20 carbon atoms, (m2) an N-hydroxyalkyl(meth)acrylamide monomer having a hydroxyalkyl group having 1 to 4 carbon atoms, which is represented by the following formula (2), [Chem. 2] CH2-C(R3)CONHR4 (2) in which R3 represents a hydrogen atom or a methyl group, and R4 represents a hydroxyalkyl group having 1 to 4 carbon atoms, (m3) a vinyl monomer having a nitrogen atom in a backbone thereof, except for the monomer (m2).

Owner:NITTO DENKO CORP

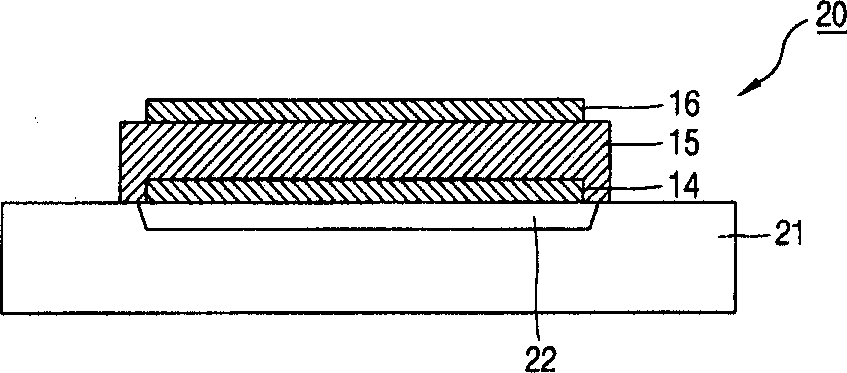

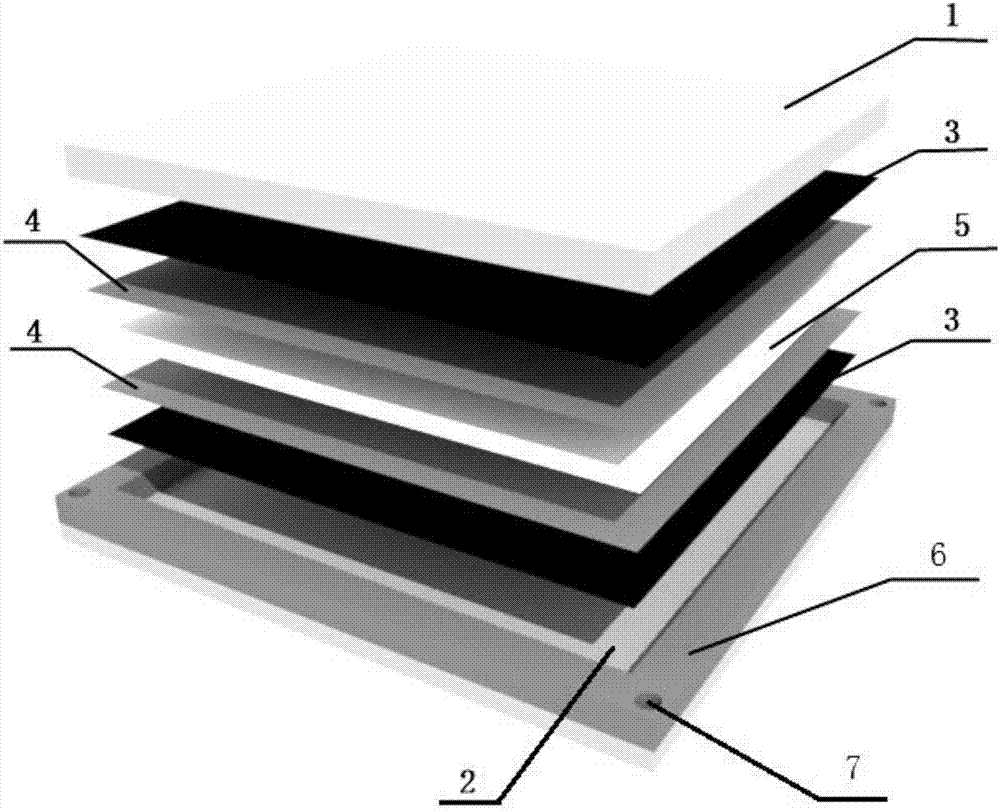

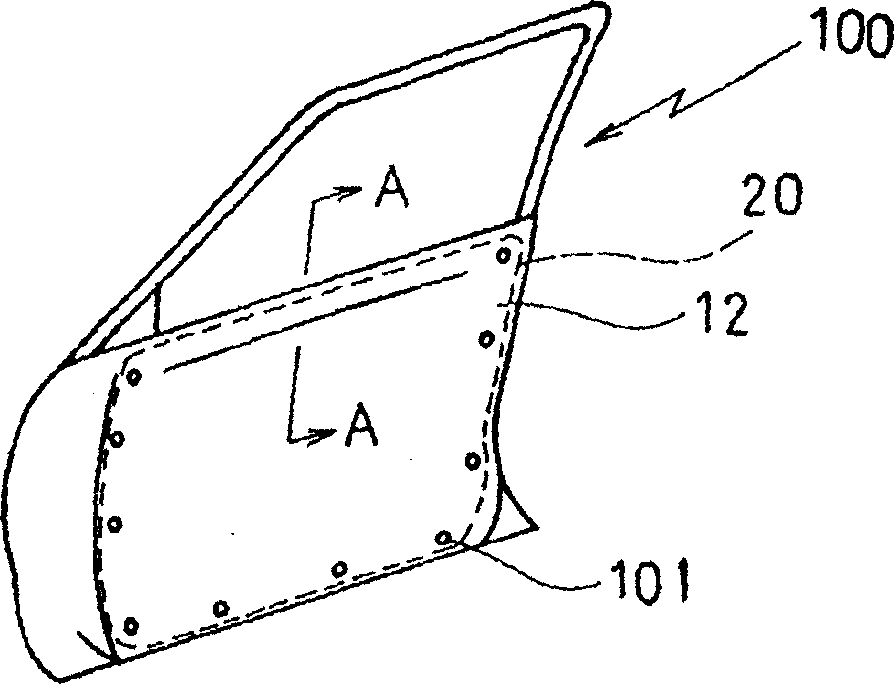

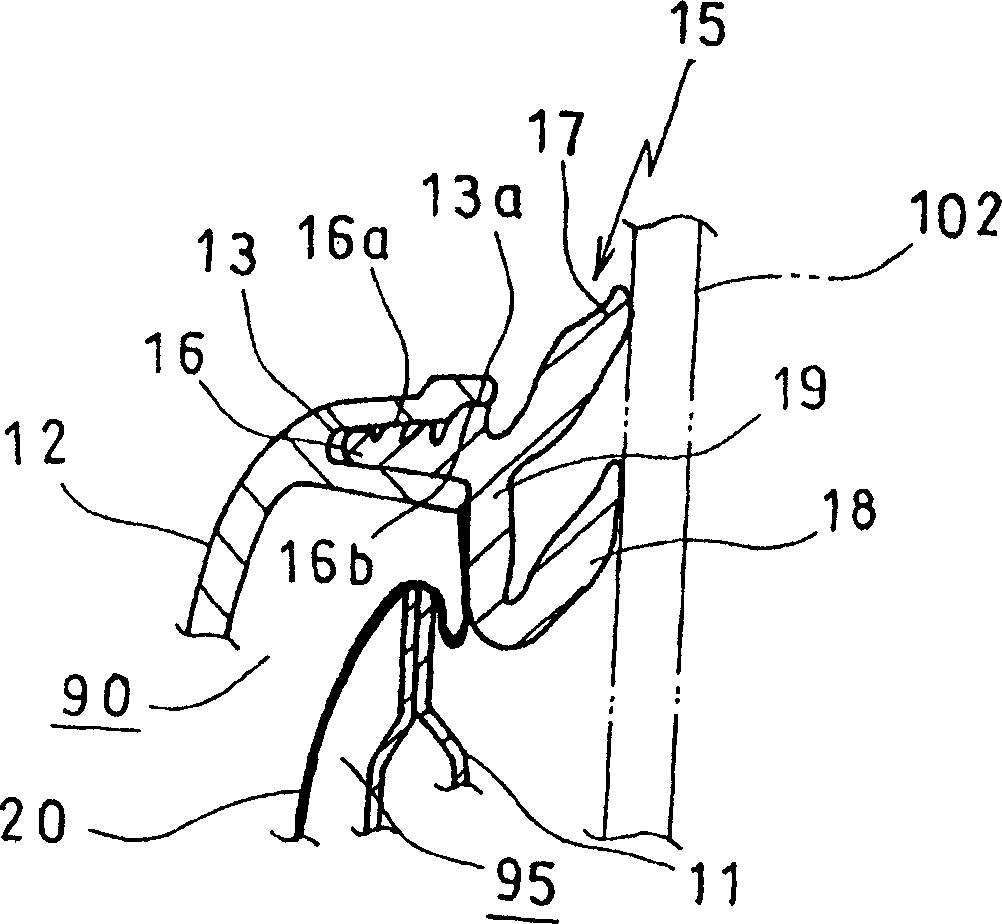

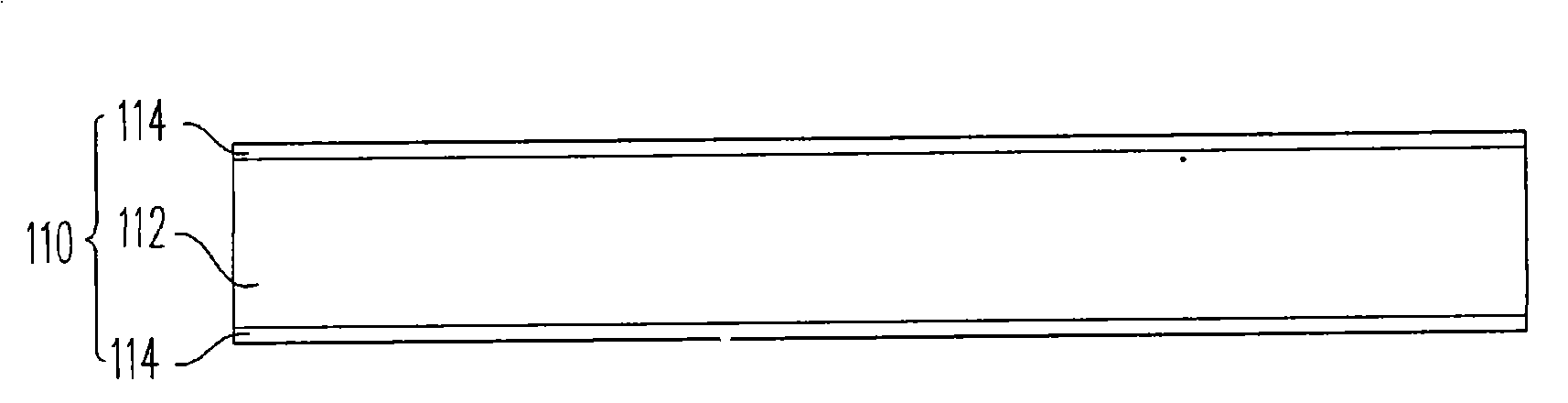

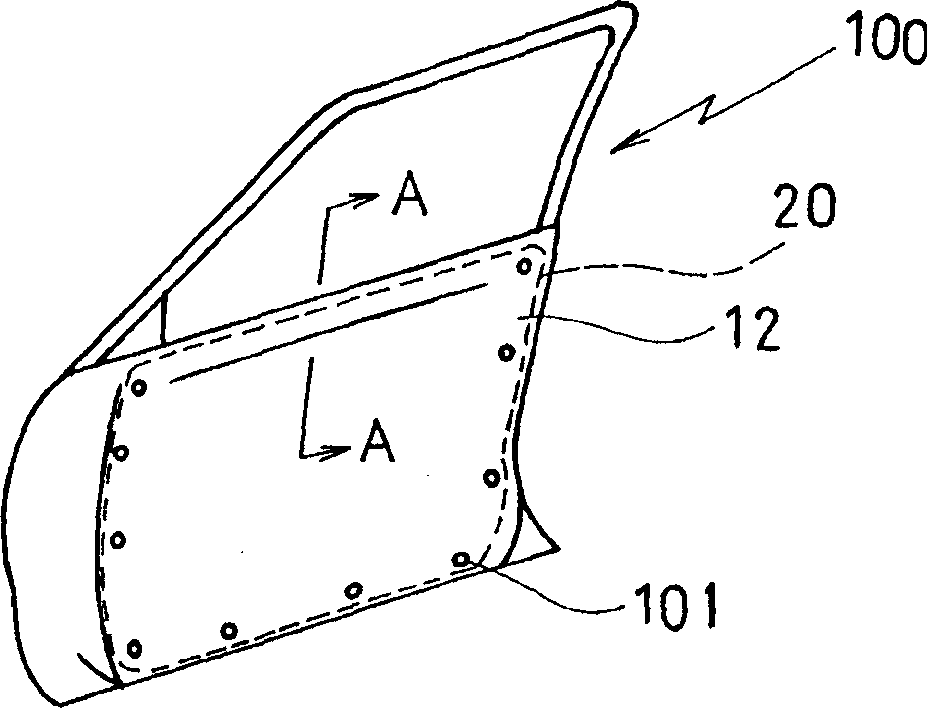

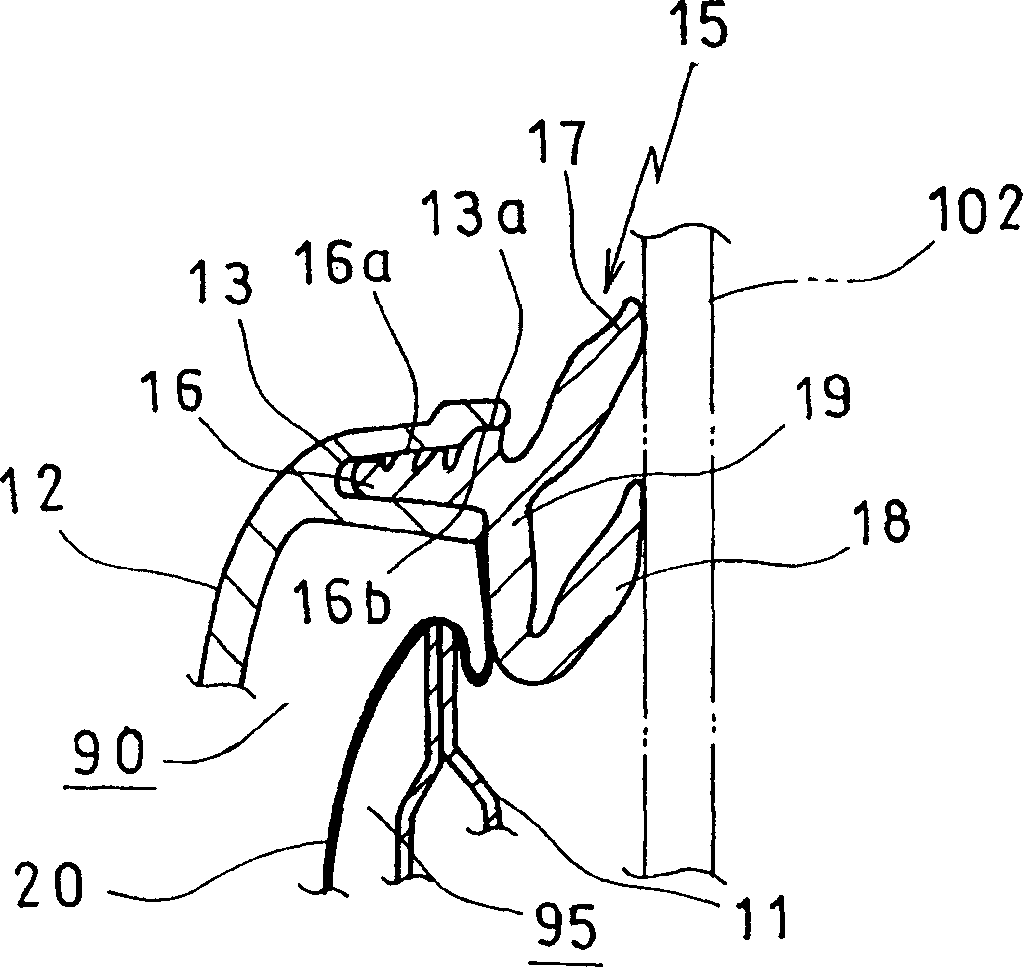

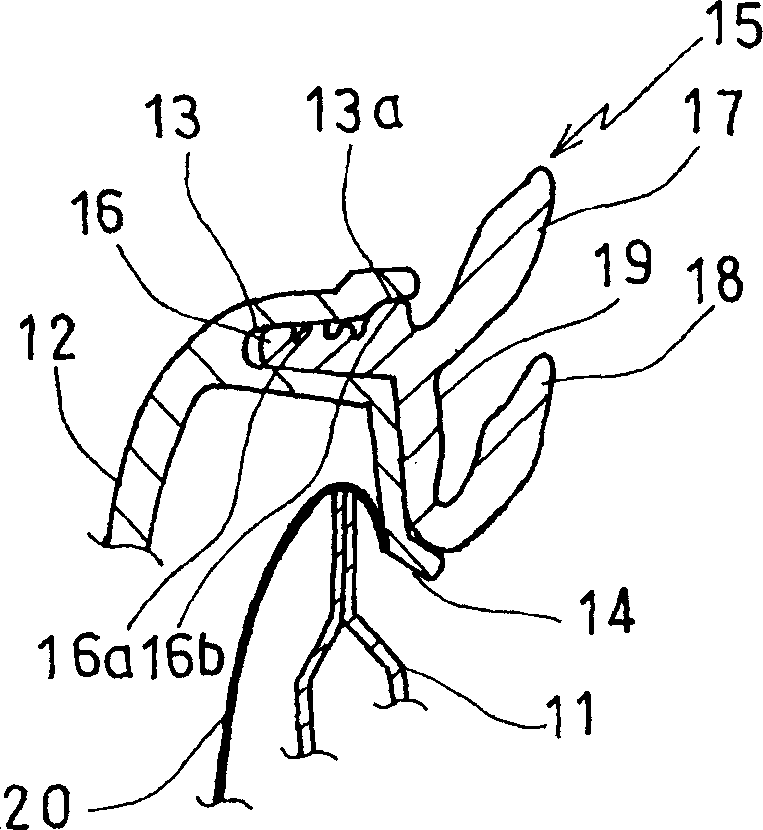

Car door structure and noise insulation sheet

InactiveCN1721649AImprove sound insulationReduce noiseDoor/window applicationsSealing arrangementsAcoustic boardElectrical and Electronics engineering

A car door structure comprises a door inner panel 11, an interior door trim 12 and a noise insulation sheet 20. The interior door trim 12 is installed in the interior side of the door inner panel 11. The noise insulation sheet 20 is provided between the door inner panel 11 and the door trim 12, where it is hung down from the upper side to the lower side of the door inner panel like a curtain. The noise insulation sheet 20 is fixed to either the door inner panel 11 or the door trim 12. The noise insulation sheet 20 is provided at about an upper half or a lower half of the door inner panel 11, or it is provided at a central part of the door inner panel 11 while dividing approximately into three sections in a vertical direction or a horizontal direction.

Owner:NISHIKAWA RUBBER

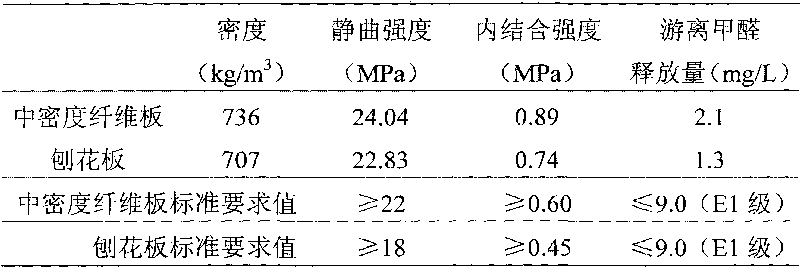

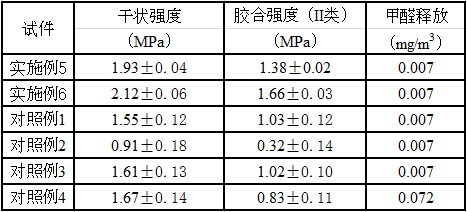

Modified urea-formaldehyde resin adhesive for outdoor fiberboard and preparation method thereof

InactiveCN108690541ALow costHigh bonding strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFiberPhenol

The invention relates to a urea-formaldehyde resin adhesive, especially to a modified urea-formaldehyde resin adhesive for an outdoor fiberboard and a preparation method thereof, belonging to the technical field of adhesives for artificial fiberboards. The adhesive disclosed in the invention comprises the following raw materials by mass: 85-95 parts of melamine-phenol modified urea-formaldehyde resin, 5-10 parts of an isocyanate prepolymer (EMDI), and 1.0-3.0 parts of ammonium sulfate. The invention also discloses a preparation method and application of the modified urea-formaldehyde resin adhesive for the outdoor fiberboard. The modified urea-formaldehyde resin adhesive for the outdoor fiberboard of the invention has good cementing performance and low cost. In the hot pressing process ofthe fiberboard, the modified urea-formaldehyde resin adhesive prepared through glue blending is sprayed onto fibers, stable chemical bonds are formed between the isocyanate prepolymer, the resin and the wood fibers, so the cementing strength, water resistance and aging resistance of the adhesive are further improved. With the adhesive, outdoor fiberboards meeting requirements prescribed in Standards GB / T 11718-2009 for Medium-Density Fiberboards can be produced.

Owner:DARE WOOD BASED PANEL GRP

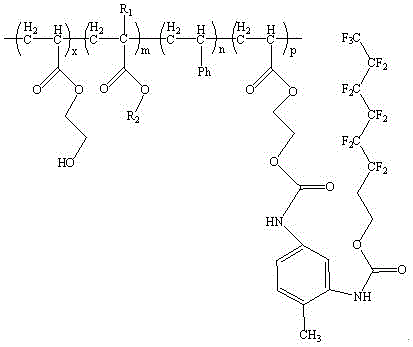

Fluoroalkyl modified acrylate-containing low-surface energy, drag reduction and fouling prevention coating and preparation method thereof

InactiveCN105542608ALower surface energyDurable stain resistanceAntifouling/underwater paintsRosin coatingsOrganic solventAcrylic resin

The invention discloses a fluoroalkyl modified acrylate-containing low-surface energy, drag reduction and fouling prevention coating. The coating comprises a component A and a component B, wherein the component A comprises, by mass, 20-50% of fluoroalkyl modified acrylic resin, 2-15% of rosin, 15-25% of a composite antifouling agent, 5-15% of a pigment and filler, 1-5% of an assistant and 10-20% of an organic solvent; the component B is an N75 curing agent produced in the Bayer Company in Germany, and a mass ratio of the component A to the component B is 5:1-10:1; the structural formula of the fluoroalkyl modified acrylic resin is shown in the description; and in the structural formula, R1 is H or CH3, R2 represents a C1-4 alkyl group, and x, m, n and p are integers in a range of 1-9 respectively. The invention also discloses a preparation method of the coating. A film formed by using the coating has good bonding ability with a substrate, keeps lasting brightness, and also has the characteristics of excellent static / dynamic fouling prevention, low surface energy and drag reduction.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Novel acrylic pressure-sensitive adhesive protective film

ActiveCN108219702ATimely exclusionSimple recipePressure sensitive film/foil adhesivesAntioxidantSolvent

The invention relates to a novel acrylic pressure-sensitive adhesive protective film. The novel acrylic pressure-sensitive adhesive protective film is at least prepared from the raw materials as follows: an acrylic acid monomer, an acrylate monomer, a solvent and an initiator. A reticular structure can be formed when the acrylic pressure-sensitive adhesive protective film is applied to the surfaceof a product, and bubbles are eliminated timely. The acrylic pressure-sensitive adhesive protective film has a simple formula, and additives such as antioxidants, tackifying resin, softeners and thelike are not added. The pressure-sensitive adhesive can be recycled and can still maintain good adhesive characteristic after being adhered and peeled off many times, and the peeling strength cannot be reduced significantly; the peeling strength cannot be improved remarkably after the acrylic pressure-sensitive adhesive is adhered for a long period of time or subjected to higher pressure, and thepressure-sensitive adhesive can be easily separated from an adhered substance without transfer of an adhesion layer.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

Glued sample manufacturing equipment and method

ActiveCN110470523AEasy to slideMeet needsPreparing sample for investigationBiomedical engineeringPressure sensor

The embodiment of the invention provides a piece of glued sample manufacturing equipment and method. The equipment comprises a first clamp, a second clamp, a first displacement sensor, a pressure sensor, a sliding device, and a control device. The second clamp is connected with the sliding device, and can slide in the vertical direction along with the sliding device. The pressure sensor is connected with the first clamp. The first displacement sensor is used for monitoring the first clamp or a gluing piece. The control device is connected with the first displacement sensor, the pressure sensorand the sliding device. In the embodiment of the invention, the controller makes the gluing piece move towards a glued piece through the sliding device, the thickness of a glue layer of a glued sample is determined through the displacement sensor, and whether the glue layer between the glued piece and the glued piece is filled or not is judged according to the pressure, monitored by the pressuresensor, borne by the first clamp. The precision of the obtained glued sample is higher, and the gluing effect of the glued sample is better. It is guaranteed that a test can be smoothly conducted.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

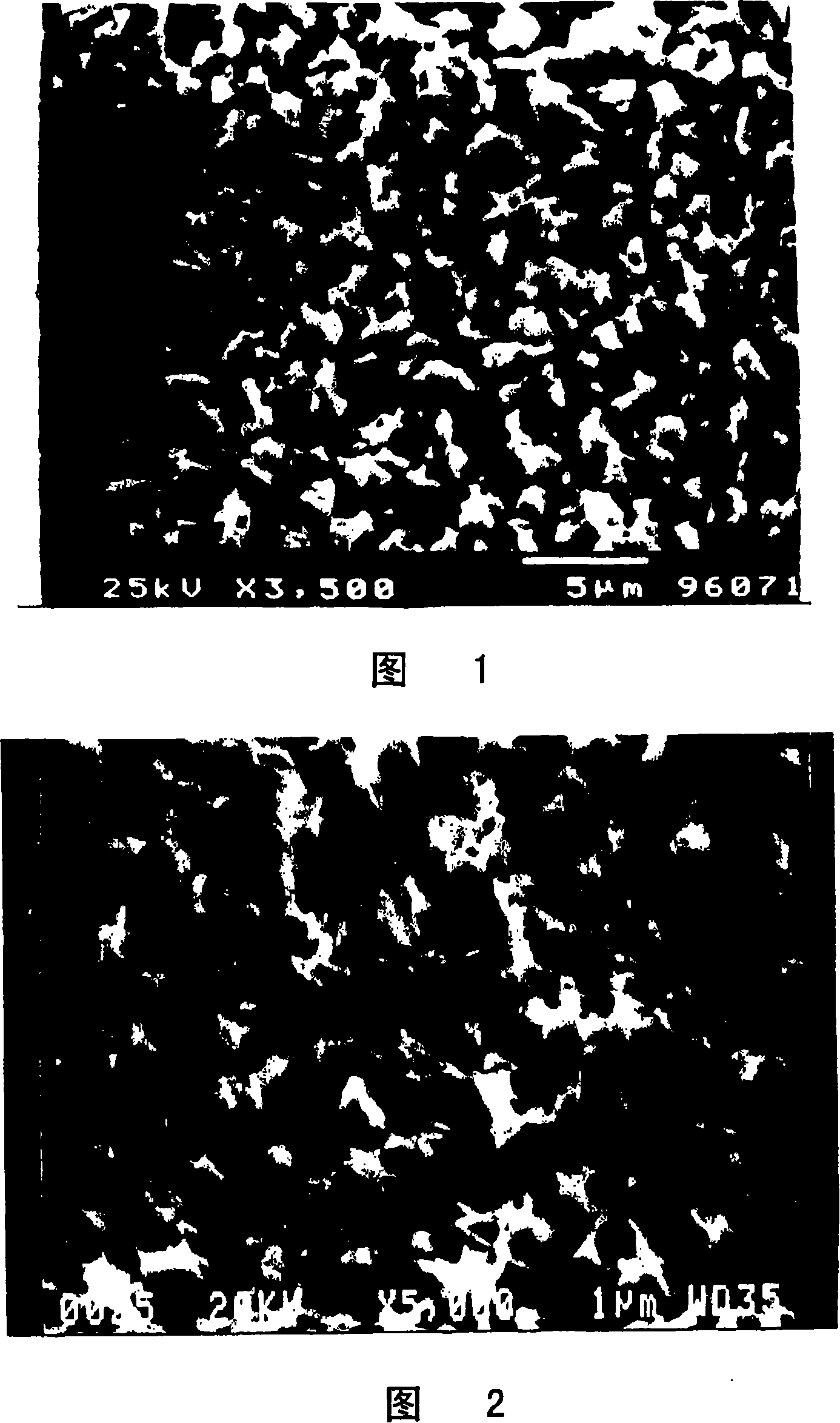

Method for preparing spherical ultrafine nickel powder at room temperature

The invention relates to a method for preparing spherical ultrafine nickel powder at a room temperature, which belongs to the technical field of the preparation of function powder materials, and solves the problems of the prior art that the ultrafine nickel powder cannot be prepared at the room temperature. The method comprises the following steps of (1) placing surface active agent into aqueous solution of nickelous salt at the temperature of 20DEG C to 25DEG C to prepare nickel salt active solution; (2) placing aqueous alkali into hydrazine or hydrazine hydrate at the temperature of 20DEG C to 25DEG C, and adjusting the pH value to 12 to 14 to prepare the alkali reducing agent; (3) slowly adding the nickel salt active solution into the alkali reducing agent during the intense agitation process at the temperature of 20DEG C to 25DEG C to be reacted for 30min, and obtaining reaction mixture; and (4) pumping and filtering the reaction mixture at the temperature of 20DEG C to 25DEG C to obtain solids, washing the obtained solids to be neutral through the deionized water, washing the solids for three times through acetone, and then placing the solids into a drying box at the temperature of 60DEG C to be dried, and thus preparing the spherical ultrafine nickel powder. Due to the adoption of the method, the spherical ultrafine nickel powder can be prepared at the room temperature, the cost is low, and convenience in operation can be realized.

Owner:KUNMING SHUYANG TECH

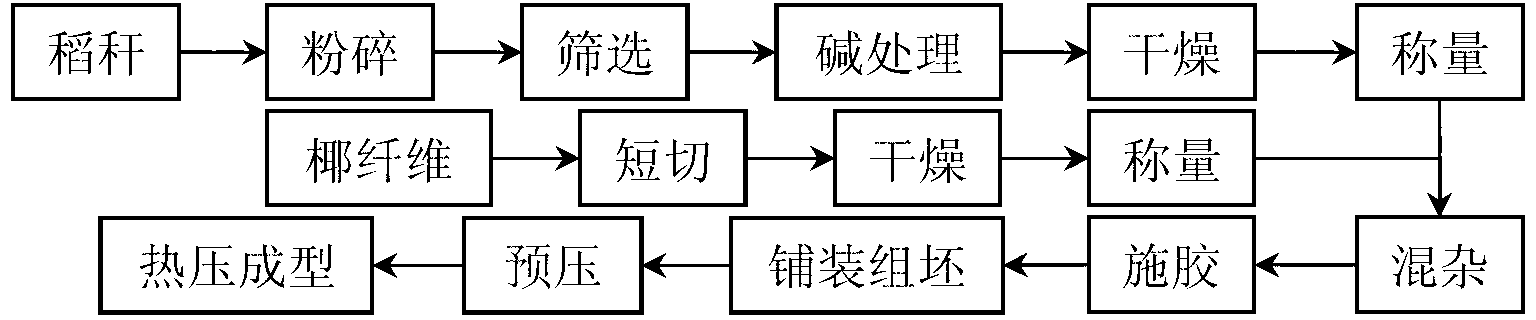

Coconut-fiber-reinforced crop straw composite material and manufacture method thereof

InactiveCN103072174ASimple preparation processImprove mechanical propertiesWood working apparatusFlat articlesAdhesiveToughness

The invention discloses a coconut-fiber-reinforced crop straw composite material and a manufacture method thereof, aiming to provide the strong-toughness and environment-friendly biomass composite material having good mechanical property, gluing property, toughness and vibration damping property. The coconut-fiber-reinforced crop straw composite material is formed by adding coconut fibers in crop straw units and uniformly dispersing as well as crossing and interconnecting the coconut fibers in a composite material system to form a bulky mesh structure, wherein the mass fraction of the coconut fibers in the system is 10-50%. The manufacture method comprises the following steps of: preparing and preprocessing of the straw units, preparing of the coconut fibers, unit mixing, gluing, paving and billet assembling, prepressing, hot-press or cold-press molding, postprocessing and the like. The coconut-fiber-reinforced crop straw composite material is free from isocyanate adhesives, so that the preparation cost of an artificial board can be reduced; and the coconut-fiber-reinforced crop straw composite material can be used as a structure material and a damping material and applied to bearing structures and in rigid use environments with frequent vibration fatigue actions and easily occurring impulse loads so as to play roles of bearing, supporting, damping and denoising, and thus, the application field of the crop straw artificial board is enlarged.

Owner:NORTHEAST FORESTRY UNIVERSITY

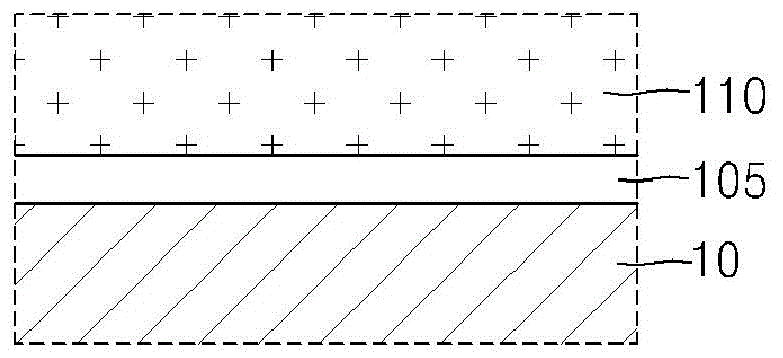

Solid electrolyte composition, electrode sheet for all-solid state secondary battery, all-solid state secondary battery, and methods for manufacturing electrode sheet for all-solid state secondary battery and all-solid state secondary battery

InactiveUS20190088949A1Improve adhesionHigh voltageSolid electrolytesFinal product manufactureAll solid stateElectrolyte composition

Provided are a solid electrolyte composition containing an inorganic solid electrolyte, a binder, and a dispersion medium (C) containing a dispersion medium (C1) below and a dispersion medium (C2) below at a specific mass ratio, an electrode sheet for an all-solid state secondary battery having an active material layer, a primer layer, and a collector which are formed of the solid electrolyte composition, an all-solid state secondary battery, and methods for manufacturing an electrode sheet for an all-solid state secondary battery and an all-solid state secondary battery.dispersion medium (C1): a saturated aliphatic compound or alicyclic compound having a boiling point of 80° C. or higher and lower than 200° C., anddispersion medium (C2): an aromatic compound having a boiling point of 100° C. or higher and lower than 220° C.

Owner:FUJIFILM CORP

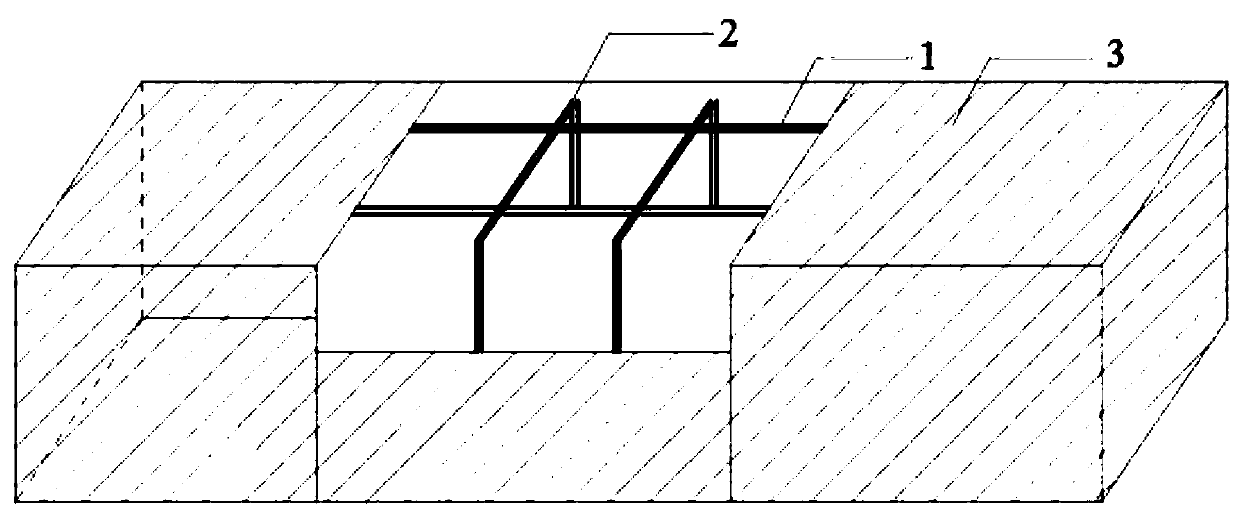

Inside imbedded type line board technique with conductive hole

ActiveCN101351092ALine Width EffectImprove qualityMultilayer circuit manufacturePrinted element electric connection formationEngineeringDielectric layer

The invention discloses an embedded circuit board technology with conducting holes which comprises the following steps: firstly, an embedded circuit base plate is provided and the embedded circuit board comprises a dielectric layer, a first circuit layer and a second circuit layer, wherein, the dielectric layer comprises a first surface and a second surface, the first circuit layer is embedded in the first surface, the lateral surface of the first circuit layer has the same surface with the first surface, while the second circuit layer is embedded in the second surface and the lateral surface of the second circuit layer has the same surface with the second surface. Then an open hole forms in the embedded circuit base plate, and subsequently conducting layers form on the first surface, the second surface and the inner wall of the open hole. Finally, the conducting layers on the first surface, the second surface and the lateral side of the open hole are removed to form a conducting hole.

Owner:UNIMICRON TECH CORP

Ballastless track base plate exposed reinforcement repairing material and application thereof

InactiveCN109734389AIncreased durabilityImprove stress resistanceRailway track constructionRepair materialSlurry

The invention belongs to the field of maintenance of ballastless track maintenance and particularly relates to a ballastless track base plate exposed reinforcement repairing material and application thereof. The ballastless track base plate exposed reinforcement repairing material is made from, by mass, 21-52 parts of cement, 22-62 parts of broken stone, 10-20 parts of quartz sand, 4-18 parts of an enhancer, 2-10 parts of an anti-cracking agent, 0.5-9 parts of a water reducer, 1-2 parts of a toughener, 0-4 parts of a setting time regulator, and 0.5-1 part of a color regulator. The enhancer andthe toughener cooperate with the other components such that a ballastless track base plate repaired with the repairing material herein gains high compressive strength and good durability. The resultsof embodiments show that hardened slurry of the repairing material herein has 28-day compressive strength of 36.8-44.2 MPa, 28-day splitting adhesive strength of 1.8-3.1 MPa, and 28-day dry shrinkageof only -0.01% to 0.02%.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

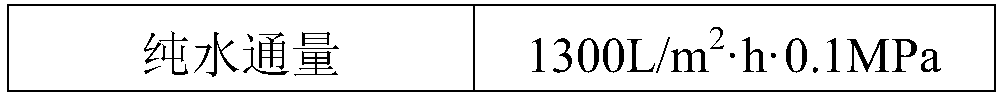

Surface hydrophilic modified membrane and preparation method thereof

ActiveCN108559124AGood wetting hydrophilicityGood bonding propertiesLiquid repellent fibresCoatingsSurface layerPorous membrane

The invention provides a surface hydrophilic modified membrane and a preparation method thereof. The preparation method includes the steps of providing a base membrane structure and performing unwinding corona treatment on the structure of the base membrane; preparing a mixed liquid containing a hydrophilic sticking substance which coats on at least one surface of the treated base membrane structure; drying the structure to obtain a surface hydrophilic modified membrane which consists of a base membrane structure and a hydrophilic surface bonding layer. According to the surface hydrophilic modified membrane and the preparation method, a solution containing the hydrophilic sticking substance is utilized to treat the base membrane to form a hydrophilic bonding layer, which has a good wettability and a fine bonding property. The coating can be limited to the surface of the base membrane structure to prevent blockage; the micro porous pore size and the porosity of the base membrane structure can be maintained, so that the porous membrane has a permanent hydrophilic surface layer on the basis of keeping the original pore diameter and the porosity, maintaining a large amount of pure water flux.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD +1

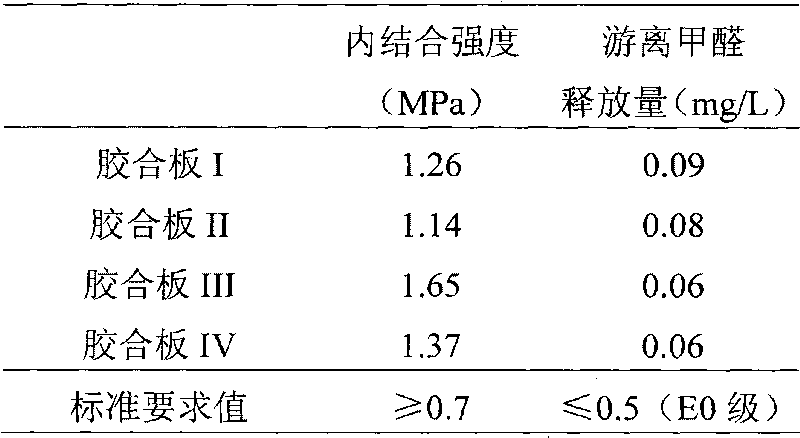

Wood adhesive prepared by degrading soybean protein by utilizing strong basicity and preparation method thereof

InactiveCN101724376BHigh viscosityThe damage is not obviousProtein adhesivesGlue/gelatin preparationO-Phosphoric AcidMedium density fiberboard

The invention discloses a wood adhesive prepared by degrading soybean protein by utilizing strong basicity and a preparation method thereof, and relates to a soybean protein-based wood adhesive and a preparation method thereof. The invention solves the problems of low content of the soybean protein, high moisture content and large viscosity existing in conventional soybean adhesives or soybean protein adhesives. The product is prepared by performing a degradation reaction of defatted soybean protein powder or soybean protein isolate, strong base and water, then using strong phosphoric acid toadjust the pH value of the obtained solution, and then adding dialdehyde into the obtained solution to mix the solution evenly. The method comprises the steps of: 1, weighing; 2, preparing strong base solution, heating the strong base solution, adding the defatted soybean protein powder or the soybean protein isolate into the strong base solution under stirring, and then cooling the strong base solution to a room temperature after heating reflux; and 3, using the strong phosphoric acid to adjust the pH value, adding the dialdehyde into the solution, and stirring the solution evenly. The adhesive has the advantages of high content of the soybean protein, low moisture content and low viscosity, and can be used for preparing plywood, flakeboards and medium-density fiberboards.

Owner:NORTHEAST FORESTRY UNIVERSITY

High-moisture resistance urea-formaldehyde resin adhesive and preparation method thereof

ActiveCN104479601AGood bonding propertiesLow costNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSodium silicateAdhesive cement

The invention belongs to the technical field of adhesives for artificial fiber plates, relates to a urea-formaldehyde resin adhesive and especially relates to a high-moisture resistance urea-formaldehyde resin adhesive and a preparation method thereof. The high-moisture resistance urea-formaldehyde resin adhesive comprises, by weight, 45-55 parts of formaldehyde, 1-18 parts of water, 22-30 parts of urea, 8-30 parts of a composite assistant, and 0.1-0.5 parts of methanesiliconic acid sodium salt. The composite assistant is obtained by mixing of 0.1-1 part by weight of polyvinyl alcohol, 1-95 parts by weight of melamine and 1-10 parts by weight of glycol. The invention discloses a preparation method of the high-moisture resistance urea-formaldehyde resin adhesive. The high-moisture resistance urea-formaldehyde resin adhesive has good viscosity and a low cost. The preparation method has simple processes and high production efficiency. An artificial board with the high-moisture resistance urea-formaldehyde resin adhesive has high moisture resistance and a very low water absorption thickness swelling rate, greatly widens an artificial board use environment and range and prolongs a board service life.

Owner:DARE WOOD BASED PANEL GRP

Bus door structure and sound insulating plate

InactiveCN1442326AImprove sound insulationReduce noiseEngine sealsVehicle sealing arrangementsEngineeringAcoustic board

A car door structure, which includes a door inner protection panel 11 , an inner door lining 12 and a sound insulation board 20 . The inner door liner 12 is installed inside the door inner panel 11 . The sound insulation panel 20 is provided between the door inner panel 11 and the door liner 12 , wherein the sound insulation panel hangs like a door curtain from the upper side of the door inner panel to the lower side thereof. The sound insulation panel 20 is fixed to both the door inner panel 11 and the door liner 12 . The sound insulation panel 20 is arranged on the upper half or the lower half of the door inner panel 11, or when the door inner panel 11 is divided into three parts in the vertical or horizontal direction, it is arranged on the door inner panel Middle part of 11.

Owner:NISHIKAWA RUBBER

Soybean meal adhesive for blockboards, and preparation method thereof

ActiveCN111675998AImprove bonding performanceReduce usageNon-macromolecular adhesive additivesProtein adhesivesPhosphoric acidPlasma treatment

The invention discloses a soybean meal adhesive for blockboards, and a preparation method thereof. The adhesive comprises, by mass, 22-26 parts of soybean meal powder, 86 parts of a dispersing agent,2-3 parts of trypsin, 1-2 parts of a composite viscosity regulator, 2-3 parts of a branched polymer cross-linking agent and 0.04-0.04 part of calcium phosphate. The preparation method comprises the following steps: K1, performing plasma treatment on the soybean meal powder in a nitrogen atmosphere, then adding calcium chloride and the dispersing agent, performing ultrasonic treatment, adding trypsin, performing treatment at 50-60 DEG C for 20 minutes, cooling, adding phosphoric acid, and performing uniform stirring to obtain a first mixture; and K2, adding calcium phosphate and the branched polymer cross-linking agent into the first mixture, uniformly stirring, adding the composite viscosity regulator, mixing, and regulating the pH value to 9.0 to obtain the soybean meal adhesive for the blockboards. The adhesive is good in water-resistant adhesive property, and ensures the practical performance of the adhesive and the durability of the blockboards.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD +1

Printed wiring board and method of producing the same

InactiveCN101106872AReduce bond strengthDoes not cause poor continuity in partsInsulating substrate metal adhesion improvementElectrical connection printed elementsOrganic acidElectrical conductor

A multilayer printed wiring board (52) provided with a lower layer conductor circuit (26), an interlayer resin insulating layer (37) formed on the lower layer conductor circuit (26), an upper layer conductor circuit (44) formed on the interlayer resin insulating layer (37) and via-holes (51) connecting the lower layer conductor circuit (26) to the upper layer conductor circuit (44), wherein the lower layer conductor circuit (26) has a roughed surface (35) formed with an etchant containing a cupric complex and an organic acid, and the via-holes (51) are connected to the lower layer conductor circuit (26) through the roughed surface (35). Tight adhesion between the lower layer conductor circuit and the interlayer resin insulating layer and between the lower layer conductor circuit and the via-hole conductors can be improved and the high connection reliability of the via-hole parts is ensured even during heating or through heat cycle.

Owner:IBIDEN CO LTD

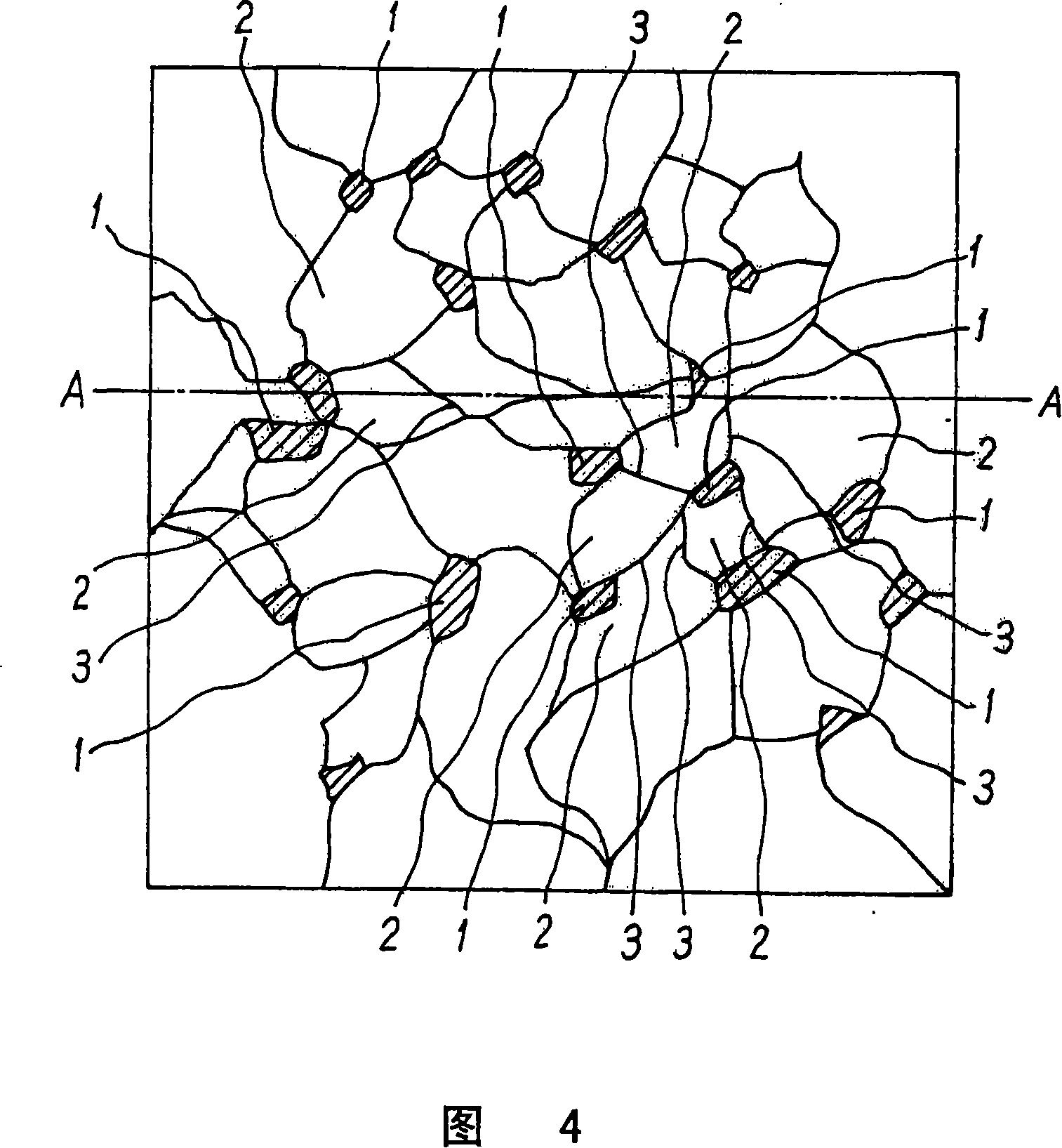

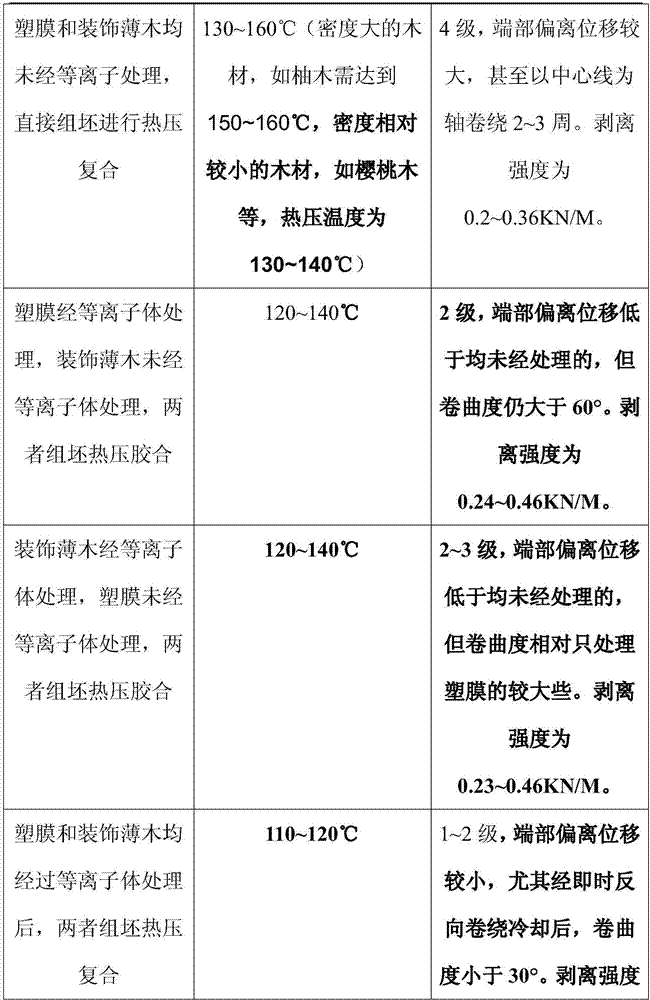

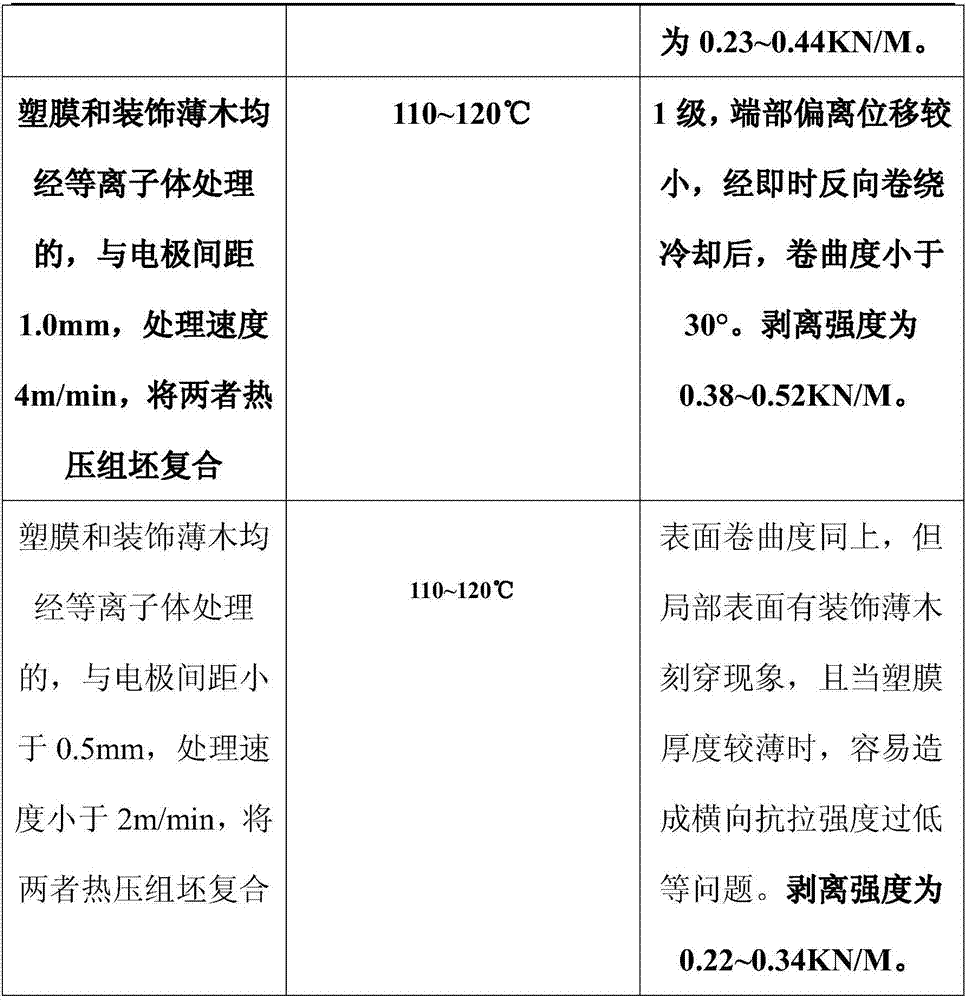

Method for improving interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification

ActiveCN107030802AResolve curlSolve discolorationLayered product treatmentElectric wood treatmentAdhesiveEngineering

The invention discloses a method for improving the interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification. The method sequentially comprises the following technology steps that surface pretreatment of the decorative veneer, low-temperature plasma treatment of the surface of the decorative veneer, low-temperature plasma treatment of the surface of a plastic film, assembly and hot pressing of the decorative veneer and the plastic film, and facing hot-pressing of the plastic-film-reinforced flexible decorative veneer. By the adoption of the method for improving the interface bonding performance between the composite flexible decorative veneer and the surface facing through plasma modification, woodwork surface facing is conducted through the plastic-film-reinforced flexible decorative veneer manufactured through plasma modification treatment, an adhesive is not needed, the procedure of applying the adhesive can be omitted, the bonding strength of the facing surface of the product can be improved by 10%-70%, the adhesive force of a paint film can be improved by 20%-40%, the production cost can be reduced by 10%-50%, energy is saved, environmental friendliness is achieved, operation is easy and convenient, and efficiency is high.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Synthesis method of lithium battery binder carboxymethyl cellulose salt

ActiveCN111423518AGood bonding propertiesImproved supplenessCell electrodesSodium carboxymethylcelluloseElectrochemistry

The invention belongs to the field of natural polymer chemical modification, and discloses a synthesis method of a lithium battery binder carboxymethyl cellulose salt. Raw materials such as cotton orcellulose powder, 10%-40% of a sodium hydroxide solution and lithium hydroxide a solvent and chloroacetic acid and the lick are subjected to strict condition control in a reaction kettle, so that a mixture product of sodium carboxymethyl cellulose and lithium carboxymethyl cellulose is prepared, and the ratio of sodium carboxymethyl cellulose to lithium carboxymethyl cellulose randomly ranges from10% to 90%. A slurry method is adopted for preparation, so the product flexibility is better, substituent distribution more uniform; in the pulping and coating process of the lithium battery, the flexibility of the binder is improved, the processability of the electrode plate is better, and a certain amount of lithium ions are doped in the binder, so that the total amount of the lithium ions in the whole lithium battery system can be additionally increased, the electrochemical performance of the lithium battery is improved, and the performances are incomparable better to those of sodium carboxymethyl cellulose produced by a kneading machine method.

Owner:眉山晶瑞电子材料有限公司

Nitride semiconductor light emitting device and method of manufacturing the same

InactiveCN103915539AGood bonding propertiesImprove light scattering propertiesSemiconductor devicesPower flowLong term durability

The present invention provides a nitride semiconductor light emitting device which can improve long term durability by securing excellent light scattering capabilities while enhancing adhesion of a p-electrode pad and a current blocking pattern, and a method of manufacturing the same. The nitride semiconductor light emitting device includes an n-type nitride layer; an active layer formed on the n-type nitride layer; a p-type nitride layer formed on the active layer; a current blocking pattern formed on the p-type nitride layer; a transparent conductive pattern formed to cover upper sides of the p-type nitride layer and the current blocking pattern, and having a contact hole through which a portion of the current blocking pattern is exposed; and a p-electrode pad formed on the current blocking pattern and the transparent conductive pattern, and directly connected to the current blocking pattern.

Owner:ILJIN LED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com