Geopolymer-based wood adhesive and preparation method and application thereof

A technology of geopolymers and wood adhesives, applied in the directions of adhesives, inorganic adhesives, adhesive additives, etc., can solve the problems of poor interface compatibility of wood raw materials, high brittleness of geopolymers, and poor bonding strength, etc. The effect of bonding performance, low production cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

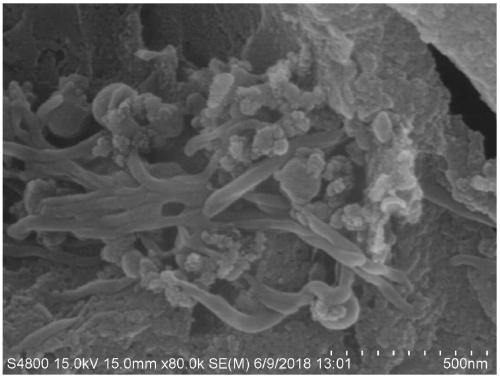

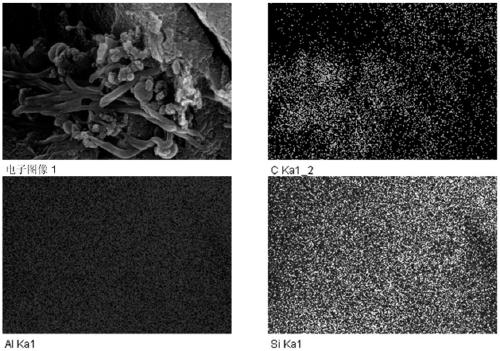

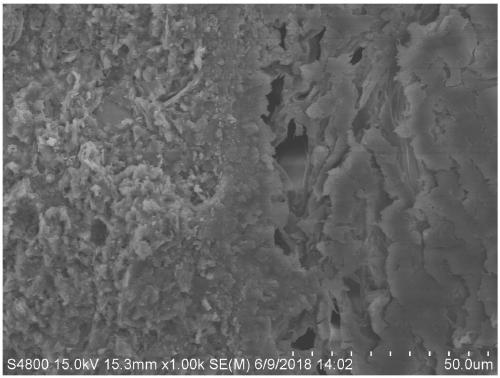

Image

Examples

Embodiment 1

[0055] A kind of environment-friendly high-performance geopolymer-based wood adhesive, its formula is calculated as:

[0056]

[0057] (1) Dissolve 40 parts of sodium hydroxide in 100 parts of distilled water and stir magnetically at 500 rpm for 30 min at a rotating speed. After cooling to room temperature, set the volume to a sodium hydroxide aqueous solution with a concentration of 10 mol / L;

[0058] (2) Mix the above 100mL aqueous sodium hydroxide solution with a concentration of 10mol / L and 250mL aqueous sodium silicate solution with a modulus of 1.5 at a speed of 1000rpm for 120min with magnetic stirring, and leave it at room temperature for 24h to obtain an alkali-excited solution with a modulus of 1.3. agent.

[0059] (3) Add 1 / 2 parts by mass of polyurethane to the alkali activator prepared in (2), and stir magnetically at a speed of 500 rpm for 30 minutes for mixing to form a stable solution.

[0060] (4) Mix the solution described in (3) with 1000 mesh metakaolin...

Embodiment 2

[0064] An environment-friendly high-performance geopolymer-based wood adhesive, the formula of which is calculated in parts by mass:

[0065]

[0066] (1) Dissolve 40 parts of sodium hydroxide in 100 parts of distilled water and stir magnetically at 500 rpm for 30 min at a rotating speed. After cooling to room temperature, set the volume to a sodium hydroxide aqueous solution with a concentration of 10 mol / L;

[0067] (2) Mix the above 100mL aqueous sodium hydroxide solution with a concentration of 10mol / L and 250mL aqueous sodium silicate solution with a modulus of 1.5 at a speed of 1000rpm for 120min with magnetic stirring, and leave it at room temperature for 24h to obtain an alkali-excited solution with a modulus of 1.3. agent.

[0068] (3) Add 1 / 2 parts by mass of polyurethane to the alkali activator prepared in (2), and stir magnetically at a speed of 500 rpm for 30 minutes for mixing to form a stable solution.

[0069] (4) Mix the solution described in (3) with 1000...

Embodiment 3

[0073] An environment-friendly high-performance geopolymer-based wood adhesive, the formula of which is calculated in parts by mass:

[0074]

[0075] (1) Dissolve 40 parts of sodium hydroxide in 100 parts of distilled water and stir magnetically at 500 rpm for 30 min at a rotating speed. After cooling to room temperature, set the volume to a sodium hydroxide aqueous solution with a concentration of 10 mol / L;

[0076] (2) Mix the above 100mL aqueous sodium hydroxide solution with a concentration of 10mol / L and 250mL aqueous sodium silicate solution with a modulus of 1.5 at a speed of 1000rpm for 120min with magnetic stirring, and leave it at room temperature for 24h to obtain an alkali-excited solution with a modulus of 1.3. agent.

[0077] (3) Add 1 / 2 parts by mass of polyurethane to the alkali activator prepared in (2), and stir magnetically at a speed of 500 rpm for 30 minutes for mixing to form a stable solution.

[0078] (4) Mix the solution described in (3) with 1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com