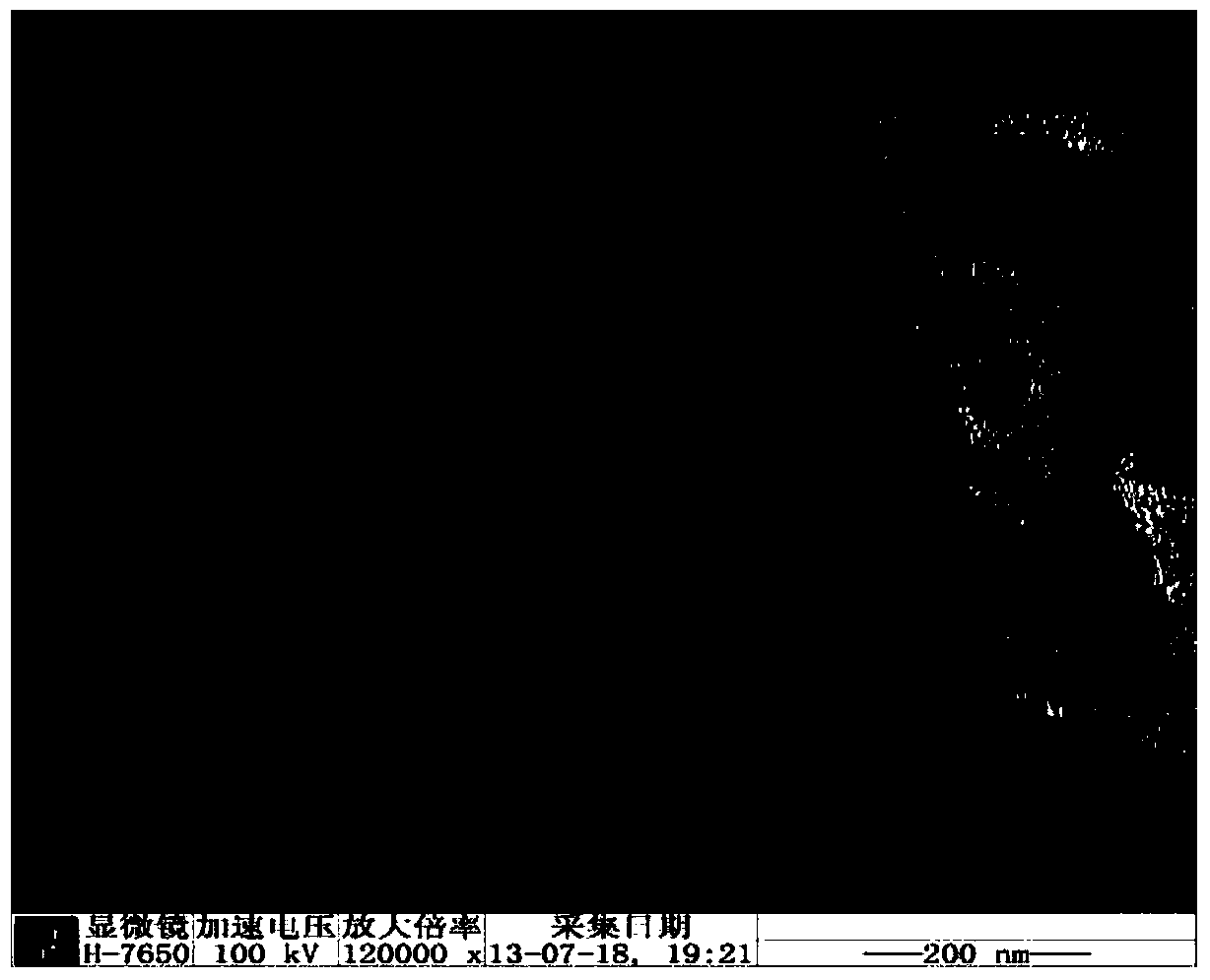

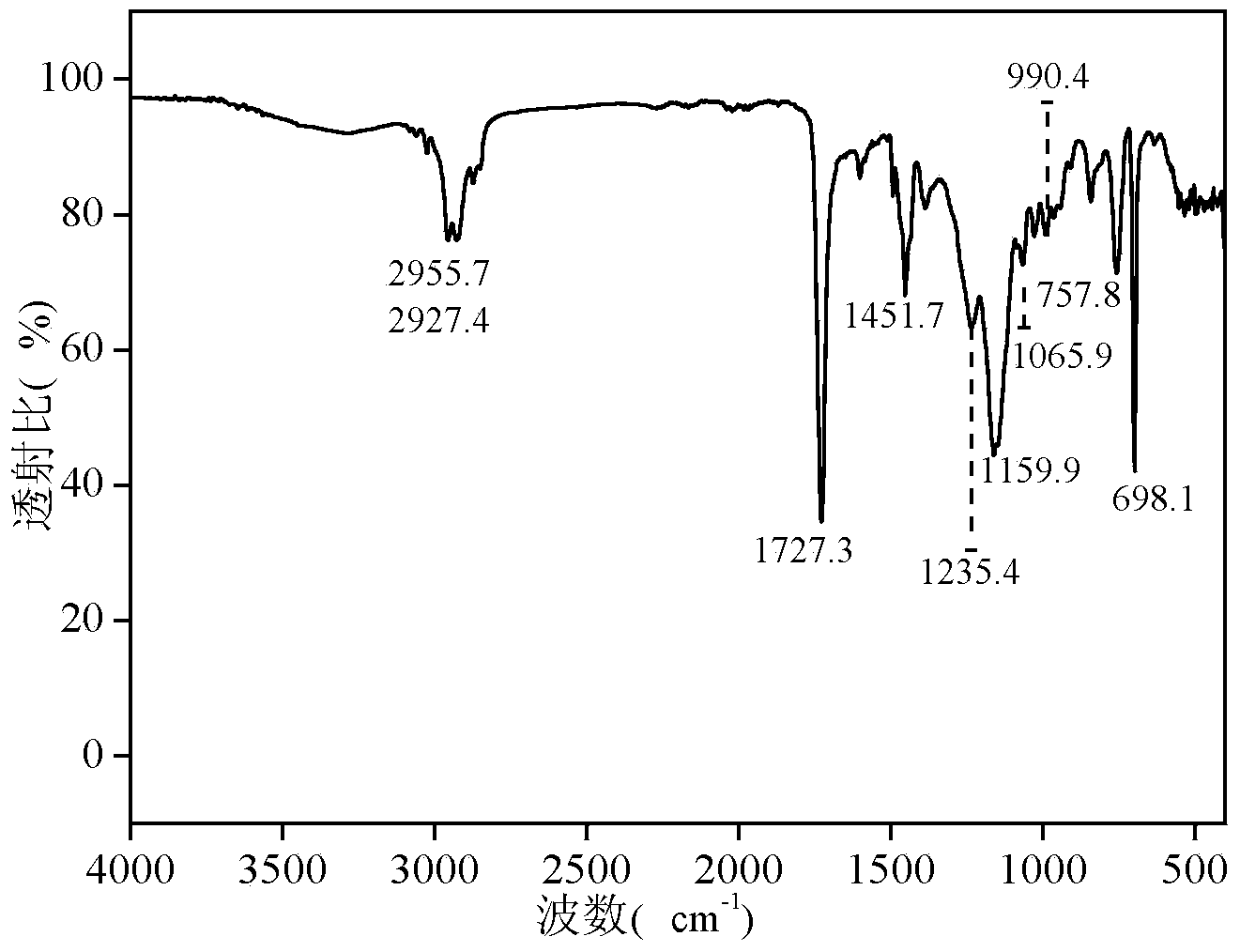

Preparation method of polystyrene-acrylate core-shell composite emulsion

A technology of acrylate and polystyrene, which is applied in the field of emulsion preparation, can solve the problems of anti-adhesion and poor heat resistance, and achieve the effect of transparent film formation, simple process and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Embodiment 1: In this embodiment, the polystyrene-acrylate core-shell composite emulsion is prepared as follows:

[0023] Step 1. Weighing by weight percentage: 72% distilled water, 17.7% vinyl mixed monomer, 8.8% acrylate mixed monomer, 1.0% composite emulsifier, 0.38% pH buffer and 0.12% initiator;

[0024] Among them, the vinyl mixed monomer is composed of 80% styrene and 20% butyl acrylate by weight; the acrylate mixed monomer is composed of 50% butyl acrylate, 46% methyl methacrylate and 4% methacrylic acid It is mixed; the compound emulsifier is a mixture of alkylphenol polyoxyethylene ether and sodium lauryl sulfate at a mass ratio of 2:1; the initiator is ammonium persulfate; the pH buffer is sodium carbonate.

[0025] Step 2. Add the distilled water weighed in step 1 into a four-necked bottle, raise the temperature to 55°C, add compound emulsifier and pH buffer, then add 20% of the vinyl mixed monomer weighed in step 1, stir and emulsify for 30 minutes , add 3...

specific Embodiment approach 2

[0028] Specific embodiment two: In this embodiment, polystyrene-acrylate core-shell composite emulsion is prepared according to the following method:

[0029] Step 1. Weigh respectively by weight percentage: 61.2% distilled water, 13.3% vinyl mixed monomer, 23.7% acrylic acid mixed monomer, 1.4% composite emulsifier, 0.32% pH buffer and 0.08% initiator;

[0030] Among them, the vinyl mixed monomer is mixed by 85.7% styrene and 14.3% butyl acrylate by weight percentage; the acrylate mixed monomer is mixed by 54% butyl acrylate, 44% methyl methacrylate and 2% acrylic acid The composite emulsifier is a mixture of alkylphenol polyoxyethylene ether and sodium dodecylsulfonate in a mass ratio of 1:4; the initiator is potassium persulfate; the pH buffer is sodium bicarbonate.

[0031] Step 2. Add the distilled water weighed in step 1 into a four-necked bottle, raise the temperature to 50°C, add compound emulsifier and pH buffer, then add 15% of the vinyl mixed monomer weighed in step...

specific Embodiment approach 3

[0034] Specific embodiment three: In this embodiment, polystyrene-acrylate core-shell composite emulsion is prepared according to the following method:

[0035] Step 1. Weigh respectively by weight percentage: 61% distilled water, 9.1% vinyl mixed monomer, 28% acrylate mixed monomer, 1.5% composite emulsifier, 0.25% pH buffer and 0.15% initiator;

[0036] Among them, the vinyl mixed monomer is composed of 70.6% styrene and 29.4% butyl acrylate by weight; the acrylate mixed monomer is composed of 50% butyl acrylate, 46% ethyl methacrylate and 4% methacrylic acid It is made by mixing; the compound emulsifier is a mixture of alkylphenol polyoxyethylene ether and sodium lauryl sulfate at a mass ratio of 2:3; the initiator is ammonium persulfate; the pH buffer is dipotassium hydrogen phosphate.

[0037] Step 2. Add the distilled water weighed in step 1 into a four-necked bottle, raise the temperature to 58°C, add compound emulsifier and pH buffer, then add 20% of the vinyl mixed mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com