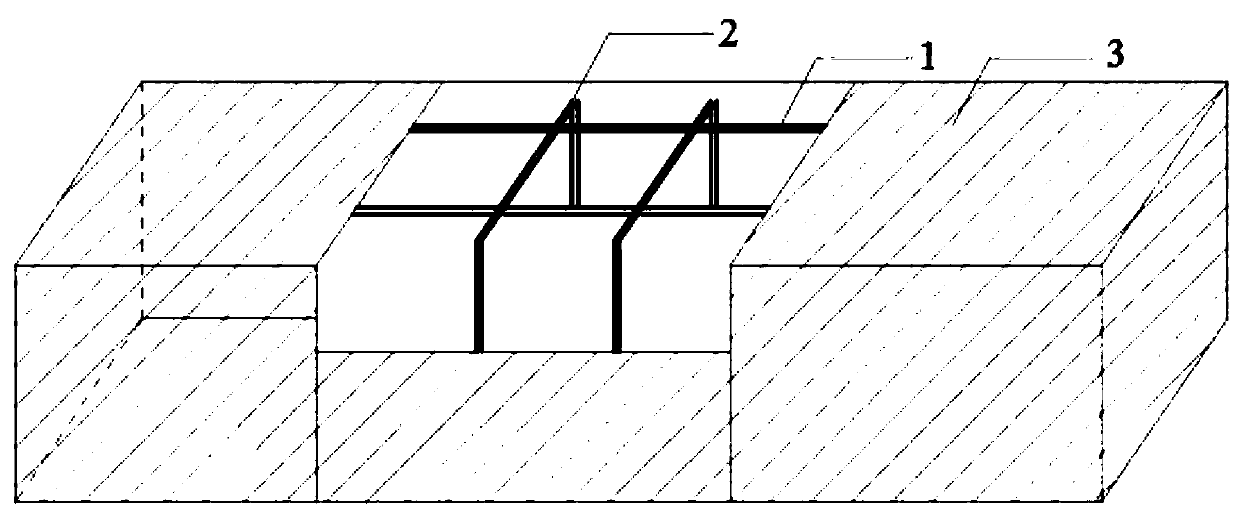

Ballastless track base plate exposed reinforcement repairing material and application thereof

A ballastless track and repair material technology, which is applied in the direction of track, track maintenance, track laying, etc., can solve the problems of secondary cracking, long setting time, high dry shrinkage rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Weigh 23kg of 52.5-grade aluminate cement, 52kg of 5-20mm natural clean gravel (mud content 0.2wt.%, needle flake particle content 3.0wt.%), 20-70 mesh quartz sand 10kg, silica fume 5kg, 6kg of expansion agent, 2kg of alkali-resistant glass fiber, 1kg of polycarboxylate powdered water reducing agent, 0.2kg of lithium carbonate, 0.3kg of citric acid and 0.5kg of black iron oxide were mixed to obtain the repair material for exposed reinforcement of ballastless track base plate.

[0077] Water was weighed according to the water-to-material ratio of 0.13 and the obtained ballastless track base plate exposed reinforcement repair material was mixed with a forced concrete mixer for 180 seconds to obtain repair concrete slurry.

Embodiment 2

[0079] Weigh 32kg of 52.5-grade sulphoaluminate cement, 31kg of 5-20mm natural clean gravel (0.3wt.% mud content, 2.7wt.% needle-like particle content), 13kg of 20-70 mesh quartz sand, and 6kg of metakaolin , silica fume 1.4kg, expansion agent 7kg, polypropylene fiber 0.4kg, carbon fiber 0.8kg, powdered naphthalene-based superplasticizer 6kg, sodium hydroxide lithium 0.3kg, tartaric acid 0.3kg, boric acid 1kg, iron oxide black 0.3kg and chrome green 0.5kg of copper was mixed to obtain the repair material for the exposed reinforcement of the ballastless track base plate.

[0080] Weigh water and the obtained ballastless track base plate exposed reinforcement repair material according to the water-material ratio of 0.15, and use a forced concrete mixer to stir for 180 seconds to obtain repair concrete slurry.

Embodiment 3

[0082]Weigh 47kg of 42.5-grade sulphoaluminate cement, 22kg of 5-20mm natural clean gravel (mud content 0.4wt.%, needle-like particle content 1.8wt.%), 20-70 mesh quartz sand 19kg, nano-dioxide Mix 4kg of silicon, 2kg of gypsum, 2kg of steel fiber, 2kg of powdered polycarboxylate superplasticizer, 1kg of lithium chloride, 0.5kg of tartaric acid, 0.3kg of chrome black, and 0.2kg of cobalt green to obtain a repair material for exposed reinforcement of the ballastless track base plate.

[0083] Weigh water and the obtained ballastless track base plate exposed reinforcement repair material according to the water-material ratio of 0.17, and use a forced concrete mixer to mix for 180 seconds to obtain repair concrete slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com