Coconut-fiber-reinforced crop straw composite material and manufacture method thereof

A technology for crop straws and composite materials, applied in the field of biomass composite materials and its manufacturing, can solve the problems of increasing capital investment in equipment, single performance of composite materials, and rising prices, and achieves easy processing and preparation, simple preparation process, and low cost. The effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

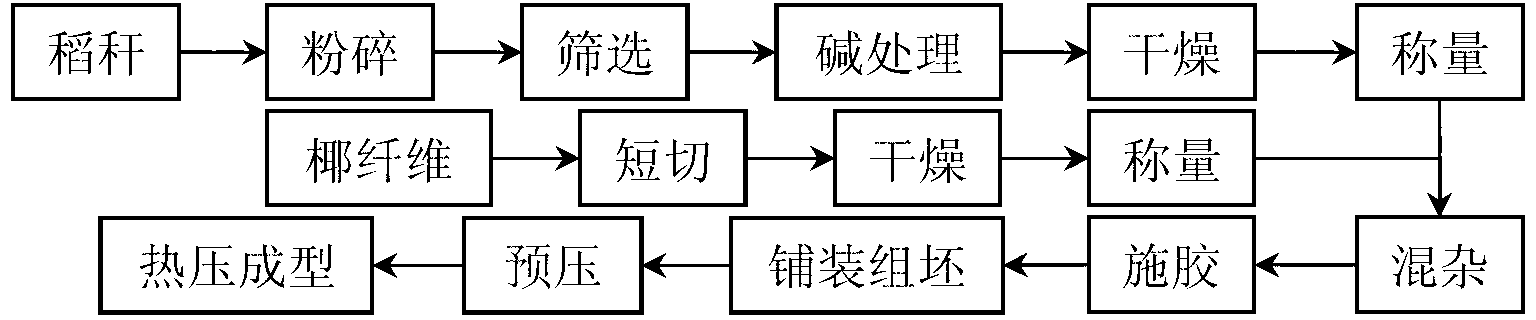

Image

Examples

preparation example Construction

[0018] Preparation and alkali treatment of straw shavings: The harvested and air-dried rice stalks are first sprayed with water to a moisture content of 30% to 40%, and then the rice stalks are pulverized in a plant rubbing machine so that they can be Obtain filament long flakes and retain the mechanical properties of straw; the crushed straw, first use a wire mesh with a mesh size of 10mm × 10mm to screen out large-sized straw scraps for re-grinding, and then use 8-mesh sieves are used for screening, and the straw scraps on the screen are used as the main raw materials for board making; the straw scraps are sprayed with a dilute sodium hydroxide solution, the lye concentration (mass fraction) is 1.5%, and the material-to-liquid ratio is 10. : 50 (g:ml), the treatment time is 8~12h, and the drying temperature is 90 ℃, and the moisture content is 3% ± 1%; The weight percentage is as follows: 40 mesh accounts for 10%, and the length of the straw shavings is 1~4cm. After alkali ...

Embodiment

[0027] In the above-mentioned preparation process parameters and attached figure 1Under the preparation technological process, preparation is added with coconut fiber but does not apply the composite straw board of isocyanate adhesive, wherein coconut fiber quality accounts for 40% of the total weight of coconut fiber and straw scraps, detects its performance according to the standard, the test that draws The results are as follows: the static bending strength is 25.31MPa, the flexural elastic modulus is 2.84GPa, the internal bonding strength is 0.54MPa, the 24h water absorption thickness expansion rate is 14.05%, and the impact toughness is 24.48KJ / m 2 , the bending toughness is 1802.04N·mm, and the damping ratio is 3.773%. It can be seen that the properties of the coconut fiber reinforced straw composite material also meet the requirements of the standard, and the toughness and damping performance of the composite material have been greatly improved. Compared with Comparativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com