Polypropylene thermoplastic elastomer composite material and preparation method thereof

A technology of thermoplastic elastomer and composite materials, which is applied in the field of polypropylene thermoplastic elastomer composite materials and its preparation, and polypropylene composite materials, which can solve the problems of low tensile strength, low low-temperature impact resistance, and large surface friction resistance of products and other problems, to achieve the effect of low water absorption thickness expansion rate, improve low-temperature impact resistance, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

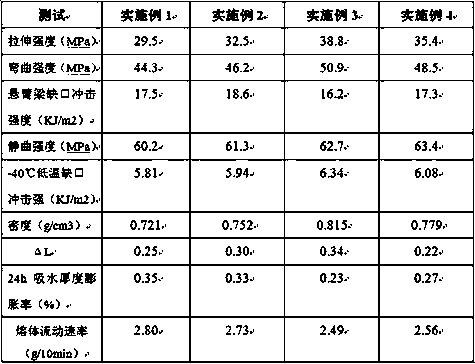

Examples

Embodiment 1

[0032] Embodiment 1 A kind of polypropylene / thermoplastic elastomer composite material

[0033] The polypropylene / thermoplastic elastomer composite material includes the following components in parts by weight:

[0034] 40 parts of polypropylene, 8 parts of elastomer POE, 5 parts of liquid silicone rubber, 2 parts of nano-cerium oxide powder, 1.5 parts of nano-ceramic powder, 13 parts of carboxylated nitrile latex, 0.6 parts of cross-linking agent, 3 parts of compatibilizer, 1.2 parts of oxidizing agent, 1.5 parts of coupling agent, 2.5 parts of filler;

[0035] Described polypropylene is the mixing of isotactic polypropylene and syndiotactic polypropylene, both mixing mass ratios are 8.3:2; Isotactic polypropylene, isotacticity 95%;

[0036] The elastomer POE is an ethylene-octene copolymer, and its melt flow rate is 13g / 10min under the test condition of 230°C×2.16kg;

[0037] The liquid silicone rubber is methyl vinyl silicone rubber:

Embodiment 2

[0053] Embodiment 2 A kind of polypropylene / thermoplastic elastomer composite material

[0054] The polypropylene / thermoplastic elastomer composite material includes the following components in parts by weight:

[0055] 55 parts of polypropylene, 10 parts of elastomer POE, 6 parts of liquid silicone rubber, 2 parts of nano-cerium oxide powder, 1.5 parts of nano-ceramic powder, 16 parts of carboxylated nitrile latex, 1 part of crosslinking agent, 6 parts of compatibilizer, antioxidant 1.5 parts, 1.5 parts of coupling agent, 2.5 parts of filler;

[0056] Described polypropylene is the mixing of isotactic polypropylene and syndiotactic polypropylene, both mixing mass ratios are 8.5:2; Isotactic polypropylene, isotacticity 95%;

[0057] The elastomer POE is an ethylene-octene copolymer, and its melt flow rate is 13g / 10min under the test condition of 230°C×2.16kg;

[0058] The liquid silicone rubber is methyl vinyl phenyl silicone rubber:

[0059] The nano cerium oxide powder ha...

Embodiment 3

[0074] Embodiment 3 a kind of polypropylene / thermoplastic elastomer composite material

[0075] The polypropylene / thermoplastic elastomer composite material includes the following components in parts by weight:

[0076] 70 parts of polypropylene, 15 parts of elastomer POE, 8 parts of liquid silicone rubber, 3 parts of nano-cerium oxide powder, 3.2 parts of nano-ceramic powder, 20 parts of carboxylated nitrile latex, 1.3 parts of crosslinking agent, 9 parts of compatibilizer, antioxidant 3.1 parts, 2 parts of coupling agent, 3 parts of filler;

[0077] Described polypropylene is the mixing of isotactic polypropylene and syndiotactic polypropylene, both mixing mass ratios are 9:2; Isotactic polypropylene, isotacticity 98%;

[0078] The elastomer POE is an ethylene-octene copolymer, and its melt flow rate is 15g / 10min under the test condition of 230°C×2.16kg;

[0079] The liquid silicone rubber is methyl vinyl silicone rubber:

[0080] The nano cerium oxide powder has a partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com