Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150results about How to "Improve surface brightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterborne shiny leather

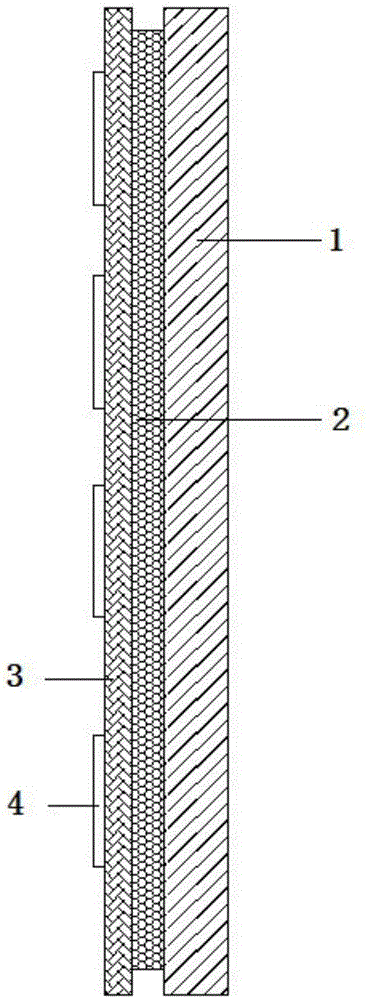

InactiveCN103422361AImprove surface brightnessNo creaseLamination ancillary operationsSynthetic resin layered productsPolymer sciencePolymer chemistry

The invention discloses waterborne shiny leather which is made in a dry-method film moving machining method. The method comprises the following steps that waterborne polyurethane resin slurry is arranged on release paper in a coating mode, the waterborne polyurethane resin slurry is divided into three layers, namely the face layer, the middle layer and the bottom adhesive layer, then a leather base cloth is bonded, paper and leather are separated, and the leather is detected and stored in a bin. The waterborne shiny leather has the advantages that besides the waterborne polyurethane resin utilization, the surface of the waterborne shiny leather is transparent, the surface brightness is high, and the surface has no crease line, the hydrolysis resistance of a synthetic leather product can be maintained for 5 years, the content of VOC is zero, no cell and needle eye exists in the surface of produced shiny synthetic leather, the surface is flat and smooth, similar products of other enterprises can not achieve the effect, and the waterborne shiny leather can be widely applied to various fields of sofas, automobile internal decoration, office appliances, and household walls.

Owner:ZHEJIANG WUZHOU IND

Film for suction plastic packaging of medical equipment and method for preparing same

InactiveCN101559854AGood heat sealing effectReduce production linksFlexible coversWrappersMaleic anhydrideMetal

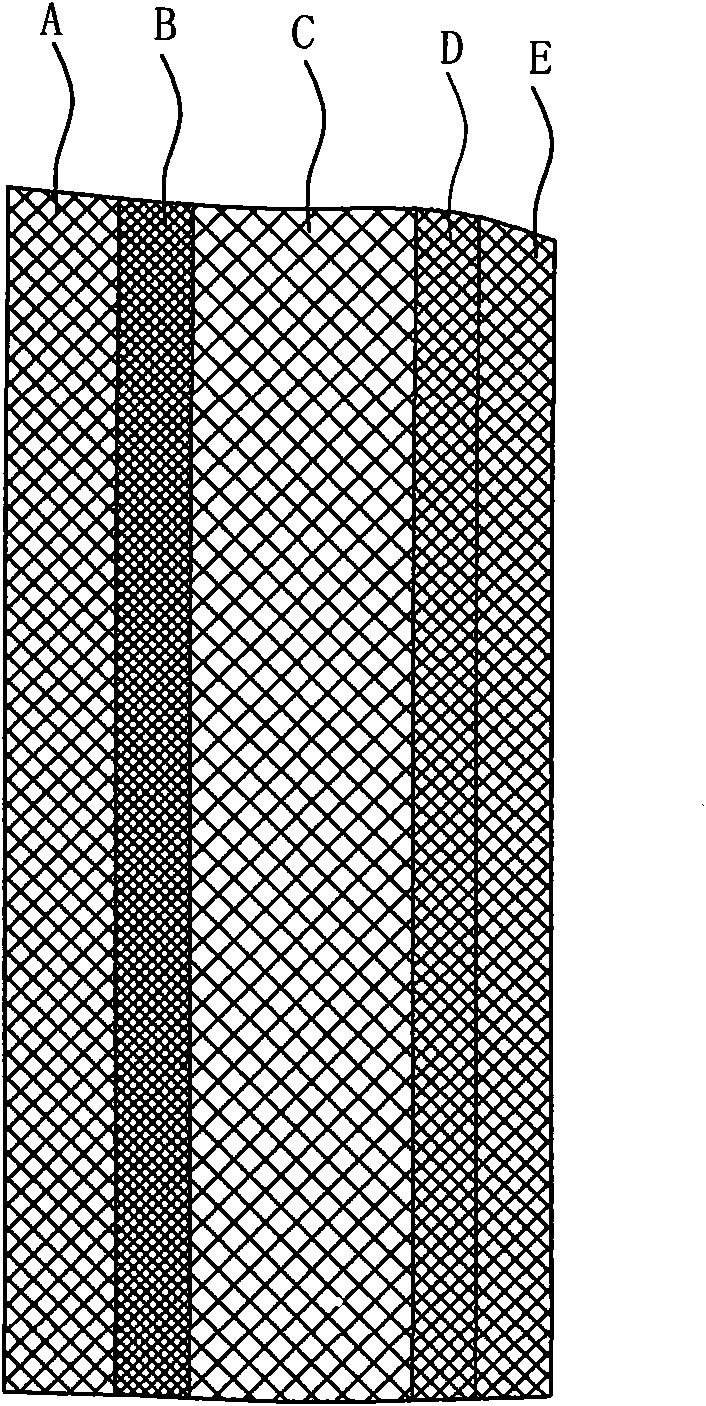

The invention relates to a film for suction plastic packaging of medical equipment and a method for preparing the same. The film adopts a five-layer structure; the first layer is a heat seal layer A, of which the component is co-mixing resin of linear low-density polyethylene and metallocene catalytic polyethylene taking octene as a comonomer, wherein the content of the metallocene catalytic polyethylene in the co-mixing resin is 20 to 40 weight percent; the second layer is an inner layer B, of which the component is linear low-density polyethylene containing a hexene comonomer; the third layer is a core layer, of which the component is linear low-density polyethylene containing a butene comonomer; the fourth layer is a bonding layer D, of which the component is maleic anhydride grafted polyethylene; and the fifth layer is a weathering resistant layer E, of which the component is nylon 6 or 66. The preparation method comprises the following steps that: the bottom blowing water cooling type co-extrusion process or flow casting method is adopted, and the plastics is subjected to fusion and die inflation or flow casting, and quick cooling at water temperature of between 15 and 18 DEG C. The film and the preparation method have the advantages that: the method is simple; the products have merits of various resins; the film can be thermally sealed with the dialyzing paper without glum spreading; and moreover, the method and the film also have the advantages of low film thickness, good comprehensive property and reutilization.

Owner:NINGBO HUAFENG PACKAGE

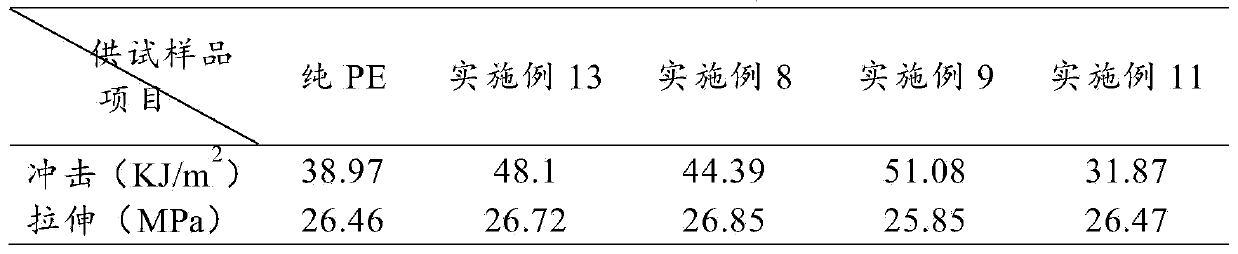

High glaze polypropylene material and preparation method thereof

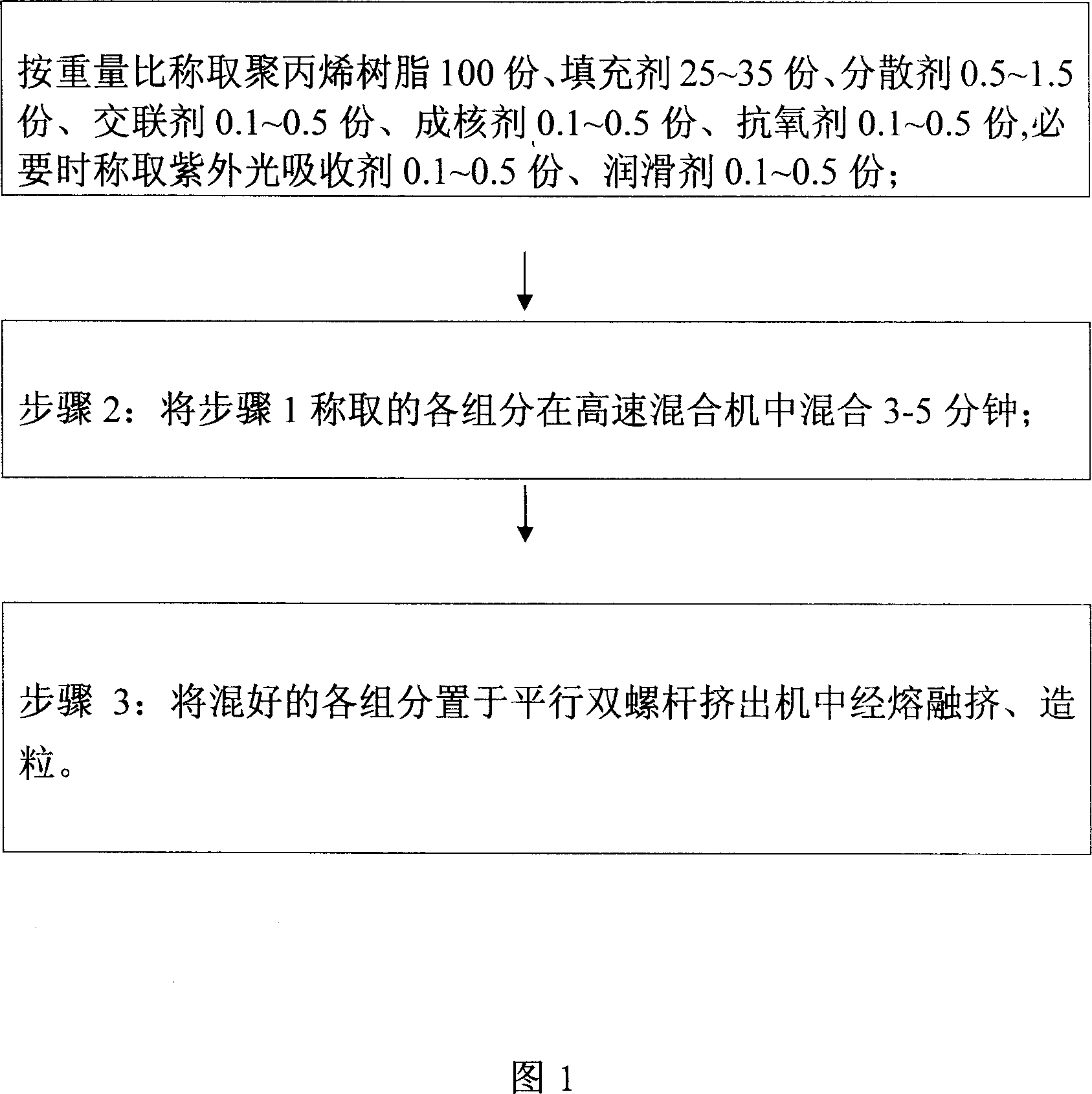

A high-lustre polypropylene material and its production are disclosed. The material consists of polypropylene resin 100 proportion, filler nanometer calcium carbonate 25-35 proportion, dispersant 0.5-1.5 proportion, cross-linking agent diisopropylzene 0.1-0.5 proportion, beta-crystal nucleation agent 0.1-0.5 proportion, and antioxidant 0.1-0.5 proportion. It costs low, has better toughness and surface brightness on surface.

Owner:SHENZHEN KEJU NEW MATERIAL

High temperature resistance film for blister package of medical equipment and preparation method thereof

InactiveCN101607616AChange the phenomenon of weak heat sealIncrease the effect of sterilization penetrationFlexible coversWrappersMedical equipmentEngineering

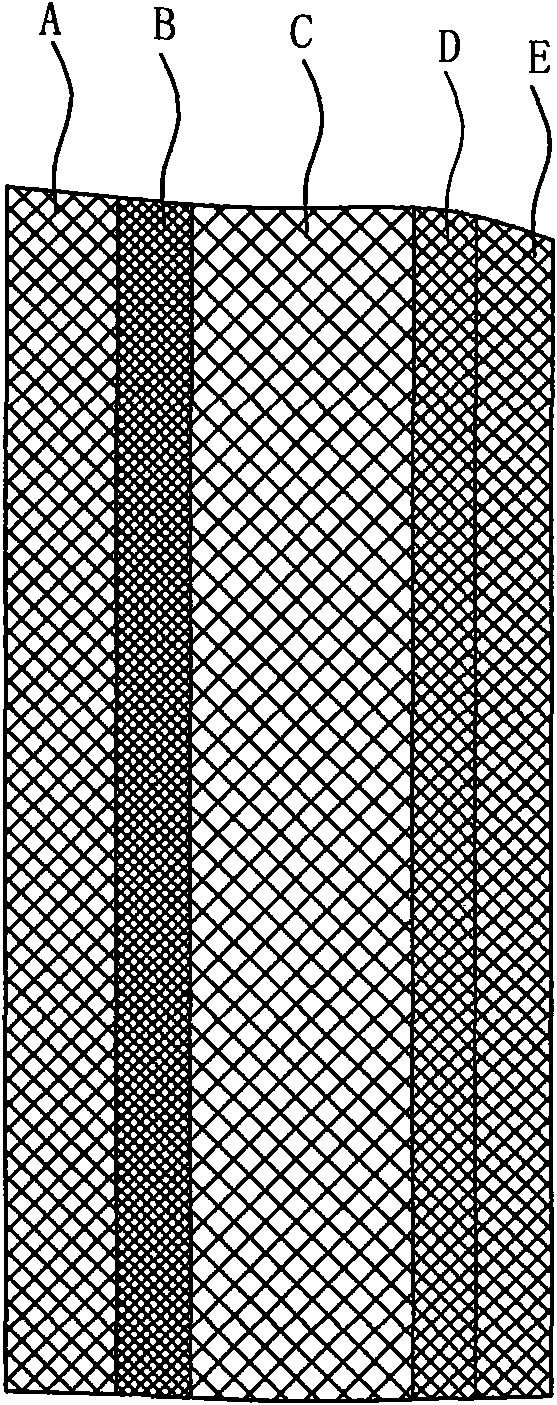

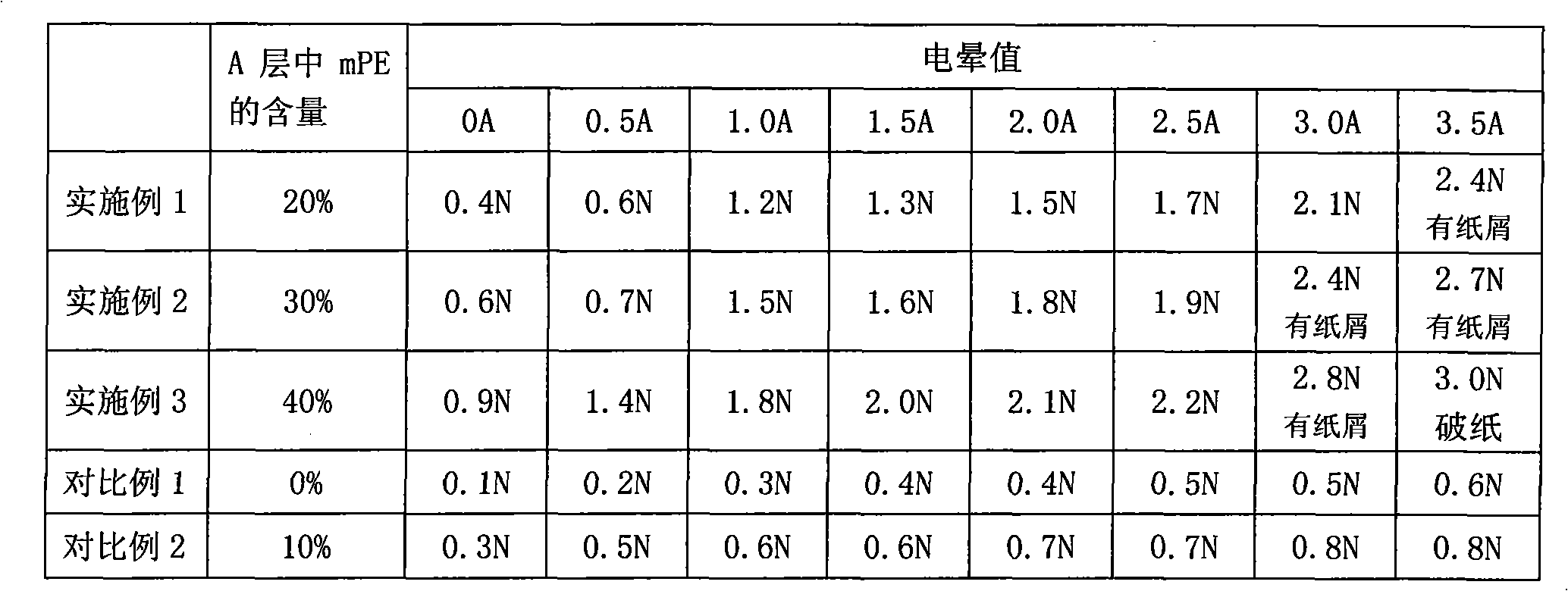

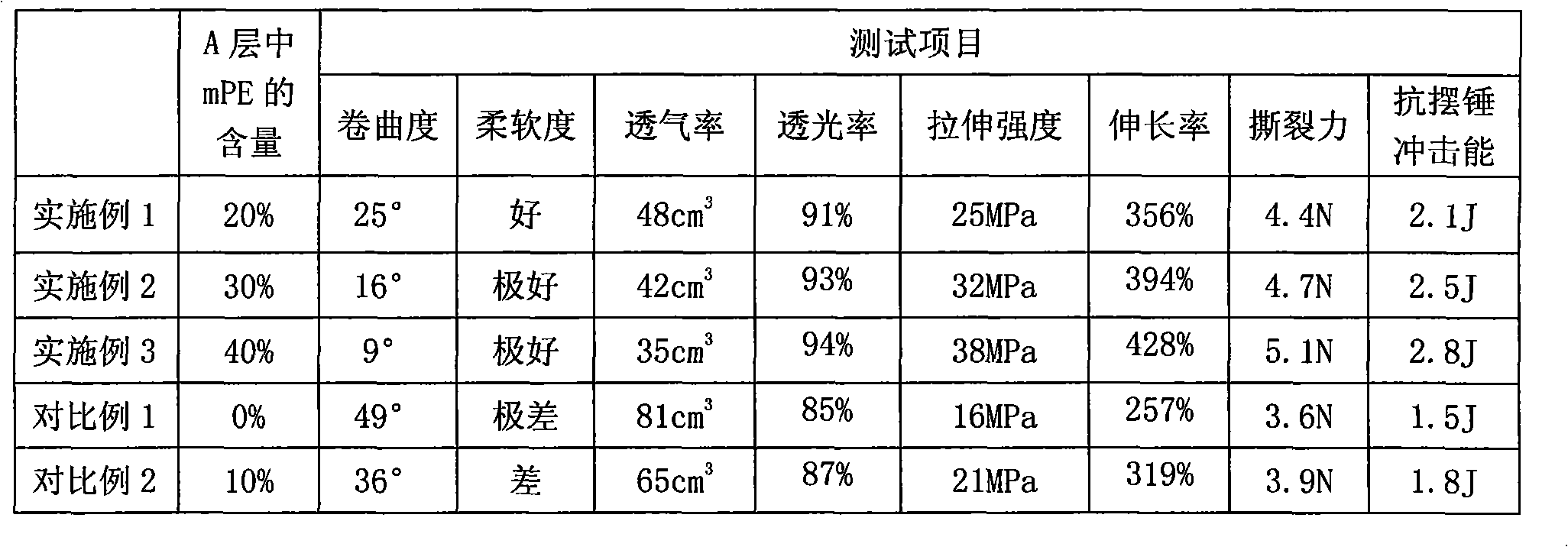

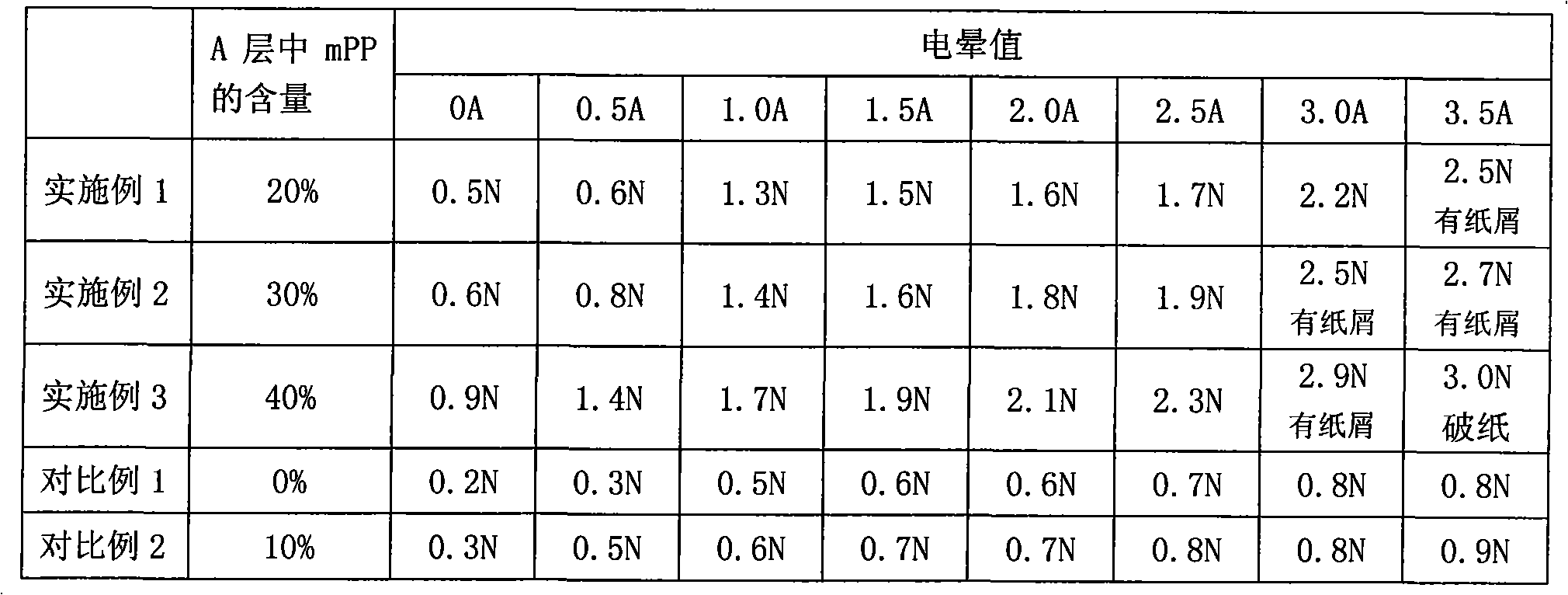

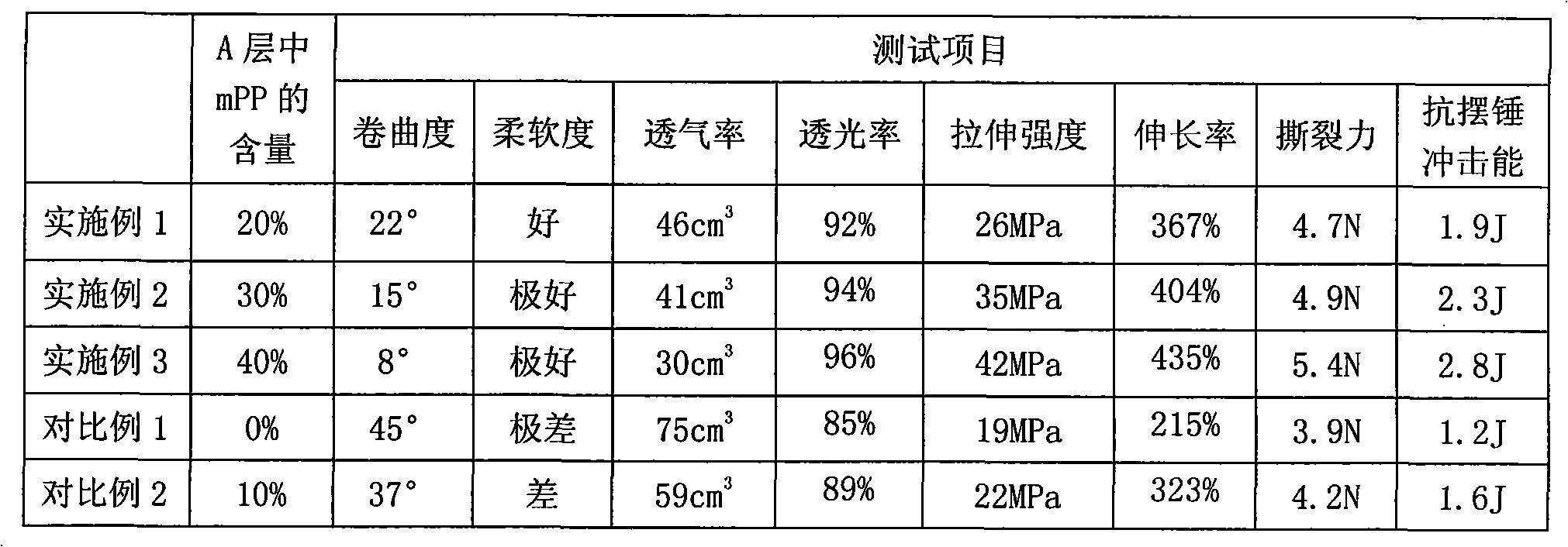

The invention relates to a high temperature resistance film for blister package of medical sterilization equipment and a preparation method thereof. The first layer of the film is a heat-sealing layer A, and comprises blending resin of block copolymerized polypropylene and metallocene catalyzed polypropylene (mPP), wherein, the melting point of the block copolymerized polypropylene is more than 131 DEG C; the dosage of the mPP accounts for 20 to 50 percent of the blending rein by weight; the second layer of the film is a secondary inner layer B, and comprises homopolymerized polypropylene; the third layer of the film is an intermediate layer C, and comprises homopolymerized polypropylene; the fourth layer of the film is a binding layer D, and comprises polypropylene grafted by maleic anhydride; and the fifth layer is a weather resistance layer E, and comprises nylon 6 or 66. The film is prepared by adopting a bottom blowing water cooling type co-extrusion process or a casting method, wherein, after plastic is sufficiently melted, is inflated or cast by a die, the plastic is cooled at water temperature of between 15 and 18 DEG C. The preparation method is simple, and the product can endure high temperature steam sterilization for long time, and has good heat-sealing performance of dialyzing paper.

Owner:NINGBO HUAFENG PACKAGE

Transparent polycarbonate alloy composite material and its prepn process

InactiveCN101089046ASmall transparency impactVigorous transesterification reactionPolyesterAlloy composite

The present invention relates to one kind of transparent polycarbonate alloy material and its preparation process. The transparent polycarbonate alloy material consists of polycarbonate 10-89 wt%, linear saturated polyester 10-89 wt%, alloy compatilizer 0.5-0.8 wt%, catalyst 0.01-0.05 wt%, and antioxidant 0.1-0.5 wt%. It is prepared through mixing the materials and pelletizing in a double screw extruder. The polycarbonate alloy material has high transparency, excellent hydrolysis resistance and wide use, and may be used in making cellphone cover, household appliance and automobile parts, etc.

Owner:SHENZHEN KEJU NEW MATERIAL

Preparation method for aluminum alloy shell and aluminum alloy shell

In order to overcome the problem that an aluminum alloy shell obtained by a method in the prior art is low in surface brightness, the invention provides a preparation method for the aluminum alloy shell. The preparation method comprises the following steps: S1, carrying out sand blasting treatment, wherein pressure intensity for sand blasting treatment is 0.18-0.25MPa, and the grain size of sand aggregates is 80-205 meshes; S2, carrying out chemical polishing treatment: at a temperature of 90-100 DEG C, adopting a polishing solution to polish for 15-20 seconds; S3, carrying out anodic oxidation treatment: carrying out the anodic oxidation treatment in an anodic oxidation electrolyte comprising 180-200g / L sulfuric acid at a temperature of 18-20 DEG C under a voltage of 13-16V, thereby obtaining an anode oxidation film with a thickness of 10-20 mu m; and S4: carrying out polishing treatment on the surface of the anodic oxidation film. The invention further discloses the aluminum alloy shell prepared by the method. The aluminum alloy shell prepared by the method is high in surface brightness, has various decorative effects, and is good in appearance quality.

Owner:BYD CO LTD

Flame-retardant glass fiber reinforced polypropylene composite material for manufacturing coil frame and preparation method thereof

The invention discloses a flame-retardant glass fiber reinforced polypropylene composite material for manufacturing a coil frame and a preparation method thereof. The composite material is mainly prepared from polypropylene, glass fiber, a fire retardant, a compatilizer, a nucleating agent, a dispersing agent and an antioxidant serving as raw materials. The preparation method comprises the following steps of: (1) uniformly mixing the polypropylene, the fire retardant, the compatilizer, the nucleating agent, the dispersing agent and the antioxidant; and (2) performing melt extrusion on the mixed raw materials obtained by the step (1) and the glass fiber in a melt extruder and pelleting to obtain a product. The invention provides the flame-retardant glass fiber reinforced polypropylene composite material for manufacturing the coil frame and the preparation method thereof.

Owner:ANHUI KEJU NEW MATERIALS

Post processing polishing process for hot galvanizing product

InactiveCN103481176AIncrease brightnessImprove appearance qualityEdge grinding machinesPolishing machinesMetallurgyBrightness perception

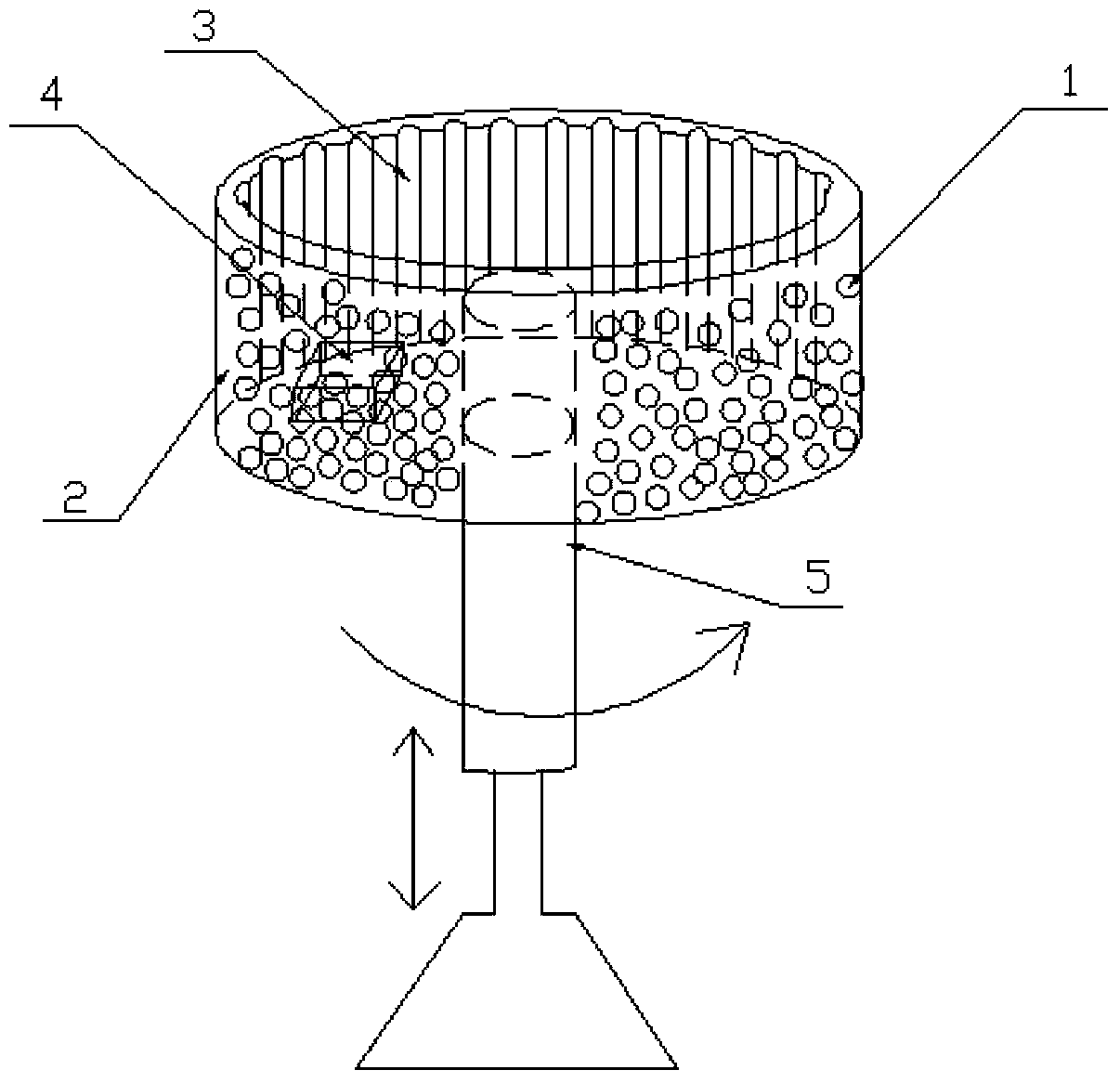

The invention relates to a post processing polishing process for a hot galvanizing product. The method comprises the steps of placing a large number of steel balls into a rotatable containing cavity capable of vibrating up and down, then placing the hot galvanizing product into the steel ball pile, starting equipment to rotate and vibrate the containing cavity up and down to promote the hot galvanizing product to be collided and rubbed with the steel balls, so the face of the hot galvanizing product is polished. The post processing polishing process for the hot galvanizing product can be implemented by adopting normal equipment, the operation is simple and convenient, the cost is very low, and the geometric dimension of a workpiece is not damaged in the treatment process. After the polishing, defects such bulges and uneven parts remaining at the face of the workpiece in a hot galvanized process can be removed, the face brightness of the workpiece is improved, the appearance quality of the workpiece is improved and the use demands of high-grade equipment are met.

Owner:DONGTAI JIANDONG MACHINERY MFG

Environment-protection flame-proof fiberglass reinforcing polyester alloy material and method for producing the same

The invention relates to an environmental-friendly flam retarding glass fiber reinforced polyester alloy material and a preparation method thereof. The polyester alloy material contains 50 to 70 percent makrolan, 10 to 40 percent of polyester, 3 to 5 percent compatilizer, 3 to 6wt percent of flame retarder, 0.1 to 1 percent of antioxidant, 0.3 to 1wt percent of lubricant and 3.5 to 10 percent of glass fiber. The preparation method is that: the makrolan and the linear saturated polyester are adopted as the matrix resin, and the compatilizer, the flame retarder, the antioxidant, the lubricant and the glass fiber are added in, and at last the pelleting process is carried out by a double screw extruder. The polyester alloy material has high surface brightness and excellent resistance to hydrolysis, thereby enlarging the application range of the polyester alloy and being widely used for fields of producing of three-phase electricity meter shells, home appliances and automobile parts, etc.

Owner:ANHUI KEJU NEW MATERIALS

Foaming silicone master batch as well as preparation method and application thereof

The invention relates to the field of high-molecular materials. The usage amount of silicone powder as an additive is generally lower than 5 parts by weight; in order to solve the problem that the silicone powder is unequally dispersed after being directly added and blended with a granular material base body, the invention provides a foaming silicone master batch. The foaming silicone master batch is prepared by blending the following components in parts by weight: 100 parts of thermoplastic high-molecular resin, 70-150 parts of the silicone powder, 0.5-1 part of foaming agents and 2-8 parts of an antioxidant. The foaming silicone master batch has the advantages of light weight and low density, and is easy to blend and disperse together with the granular thermoplastic high-molecular resin.

Owner:HUBEI HUIFU NANOMATERIAL CO LTD

Halogen-free low-smoke flame-retardant cable material and preparation method thereof

InactiveCN108727738AAvoid mechanical propertiesGood brightnessPlastic/resin/waxes insulatorsPlasticizerAntioxidant

The invention discloses a halogen-free low-smoke flame-retardant cable material, comprising, by weight, 75-90 parts of polyvinyl chloride, 0.5-4 parts of a smoke inhibitor, 5-10 parts of expansible graphite, 3-8 parts of a plasticizer, 16-20 parts of a filling agent, and 1-3 parts of an antioxidant. By modifying the various additives, especially using the expansible graphite, low-smoke property and flame retardance of the material herein are greatly improved, and mechanical strength of the material is partly improved.

Owner:ZHONGSHAN LVLANG ADDITIVES CO LTD

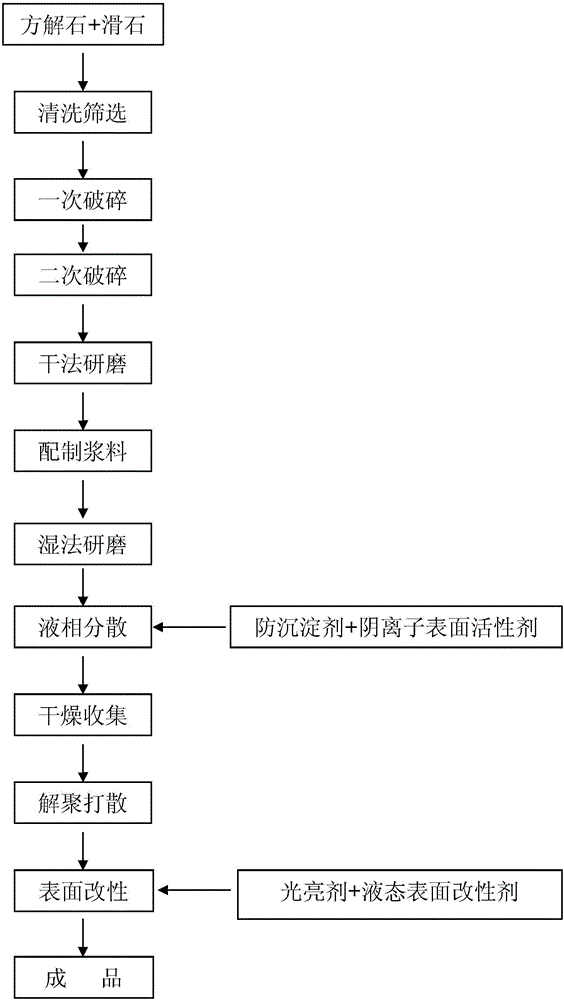

Preparation method of modified calcium carbonate

ActiveCN106317963AGood printabilityEvenly dispersedPigment treatment with organosilicon compoundsPigment physical treatmentDispersityCalcite

The invention provides a preparation method modified calcium carbonate. The preparation method includes: mixing and crushing calcite and talcum, performing dry grinding to obtain raw slurry with solid content being 70-75%, performing constant-temperature stirring and grinding to obtain processed slurry with average particle size being 0.9-1.1 micrometers, adding naphthalene sulfonate type anti-precipitation agent and anionic surfactant into the processed slurry to perform liquid-phase dispersing, drying, collecting, depolymerizing and dispersing, adding brightener and liquid surface modifier to perform wrapping treatment, and stirring to obtain the modified calcium carbonate. By the preparation method, the modified calcium carbonate which is good in printing performance, good in dispersity, good in surface brightness and applicable to films adhered to car bodies can be prepared.

Owner:JIANGXI GUANGYUAN CHEM

Halogen-free flame retardant high gloss polycarbonate (PC)/ acrylonitrile butadiene styrene (ABS) alloy and preparation method thereof

The invention belongs to the technical field of high molecular materials, and particularly relates to halogen-free flame retardant high gloss polycarbonate (PC) / acrylonitrile butadiene styrene (ABS) alloy and a preparation method thereof. The alloy comprises PC resin, ABS resin, polymethyl methacrylate (PMMA) resin, composition flame retardants, antioxidants and composite surface brighteners. The method for preparing the alloy includes the following steps: weighing, by weight, the PC resin, the ABS resin, the PMMA resin, the antioxidants and the composite surface brighteners; putting the PC resin, the ABS resin, the PMMA resin, the antioxidants and the composite surface brighteners in a high-speed mixer for dry-blending; throwing the polymer blends into a twin-screw extruder for melt extrusion and granulation, wherein the composition flame retardants are added from a side feed port and the addition is controlled by a metering pump; baking the produced particles to obtain the halogen-free flame retardant high gloss PC / ABC alloy. The obtained halogen-free flame retardant high gloss PC / ABC alloy is high in gloss, heat resisting and fluidity, simple in technology, low in cost, and capable of being suitable for the industrial areas of machinery, automobiles, electronics, instruments and apparatus, textile, constructions and the like.

Owner:东莞市松燊塑料科技有限公司

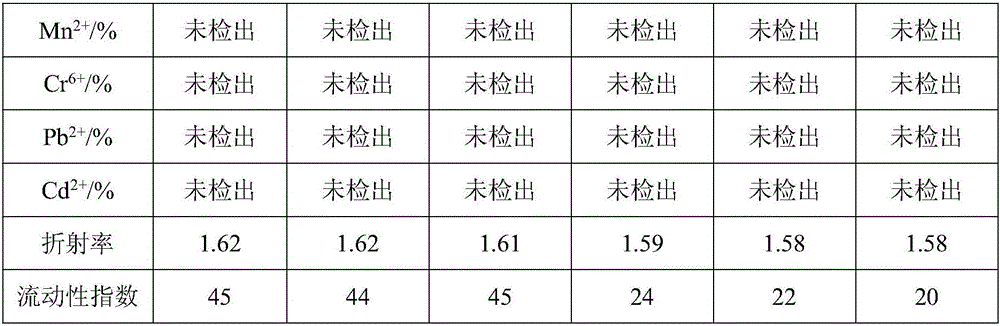

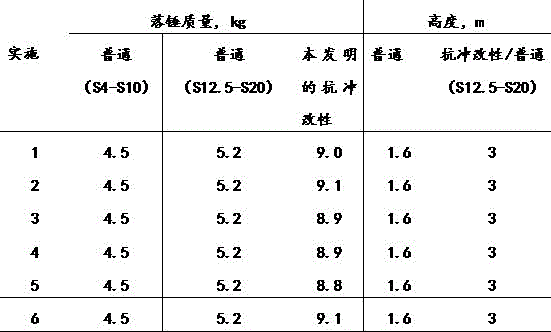

Low-density anti-impact modified polyvinyl chloride pipe and production process thereof

The invention discloses a low-density anti-impact modified polyvinyl chloride pipe, which is produced from the following components in parts by weight: 100 parts of polyvinyl chloride resin, 0.4 to 4.0 parts of stabilizer, 2 to 8 parts of flexibilizer, 2 to 8 parts of rigid particles, 0.5 to 3.0 parts of processing agent, 1.1 to 2.5 parts of lubricant, 0.05 to 0.5 parts of antioxidant, 0.03 to 3 parts of colorant and 0 to 5 parts of filling agent. A production process of the low-density anti-impact modified polyvinyl chloride pipe is as follows: all the components are uniformly mixed in a high-speed mixer, a pipe is extruded out by a double-main unit single-screw extruder after uniform mixing in the cold mixer, and after vacuum sizing and cooling formation, the pipe is cut according to fixed length and packaged. Because the flexibilizer and rigid particle synergistic toughening method is used by the anti-impact modified polyvinyl chloride pipe disclosed by the invention, the problem that rigidity-toughness balance of the PVC pipes is hard to realize is solved, and thereby the toughness of the pipe is notably increased while the pipe keeps the rigidity of hard PVC pipes.

Owner:LINYI DONGLI PLASTIC BUILDING MATERIAL CO LTD

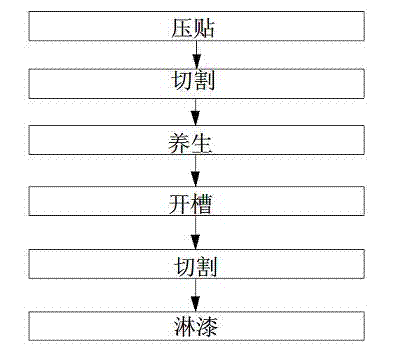

Laminated wooden floor with paint facing layer and production process

ActiveCN102852313AHigh saturationImprove surface brightnessWood working apparatusFlooringFiberAdhesion force

The invention provides a laminated wooden floor with a paint facing layer. The laminated wooden floor comprises a UV (Ultra Violet) paint wear resistance layer, a decoration layer, a base material layer and a balance layer, which are sequentially arranged from top to bottom. The base material layer is a high-density fiber board; a decoration layer is adhered to the base material layer; a UV paint wear resistant layer is coated on the decoration layer; the decoration layer is a pitted surface board with a pitted surface; and the moisture-proof balance layer is adhered below the substrate layer. A production process of the laminated wooden floor comprises the following steps of pressing, cutting, preserving, grooving, and packaging to be in stock after coating in a qualified manner. The laminated wooden floor provided by the invention has the advantages of better waterproof property, and thick and comfortable foot sense. The laminated wooden floor is coated after the preservation time of 5-10 days and has the better film adhesion force; the four edges of a notch are sealed with wax, so that the product waterproof property is improved, and the release of mail compound VOC (Volatile Organic Compounds) is reduced. The wear-resistant component of aluminum trioxide is added on finish paint, so that not only can the adhesion force of the film be increased, but also the wear resistance of the surface can be effectively increased.

Owner:JIANGSU KENTIER WOOD

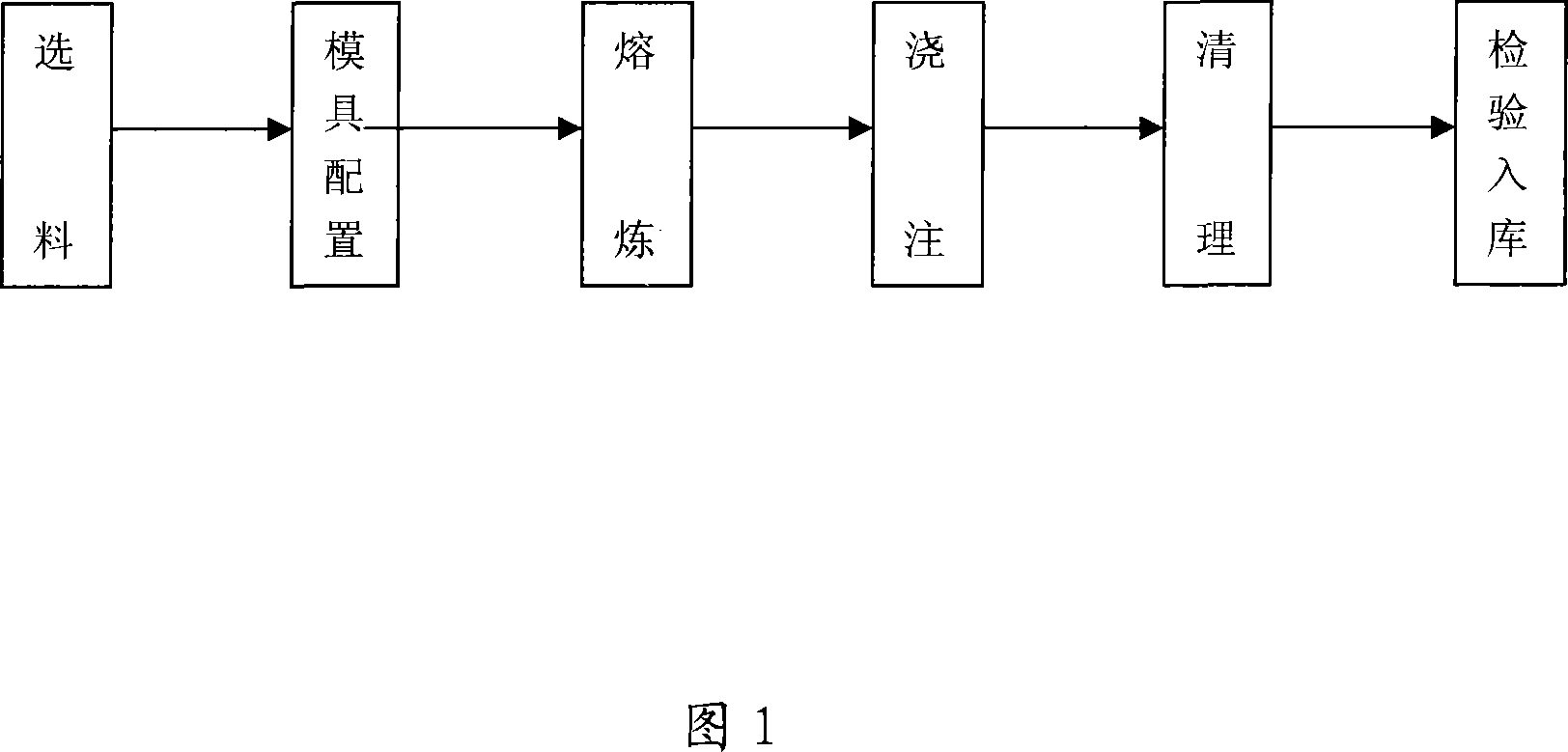

Waste copper recasting process

InactiveCN101054633AImprove surface brightnessDense internal organizationFoundryIntermediate frequency

The present invention discloses a re-foundry technique and method of waste copper used for producing copper alloy cast formed parts by utilizing waste copper. The main method in accordance with the present invention comprises selecting waste and old copper scrap such as red copper and brass and right amount of rare-earth alloy elements; heating them to 1100-1200 DEG C at an intermediate frequency electric stove, adding alloy element and rare earth of 0.03%-0.5% after a thoroughly stirring, performing an affinage and deterioration processing, straring casting after achieving the preceptive casting temperature, and finally, warehousing after a cleaning and check-up. Casting parts produced by adopting said technological process exhibit high surface brightness, compact internal organizing, without gas cavities, inclusion and abscess air holes therein, which all data entirety achieve performance levels of casting parts of the same breed variety, in china and overseas.

Owner:安徽威龙再制造科技股份有限公司

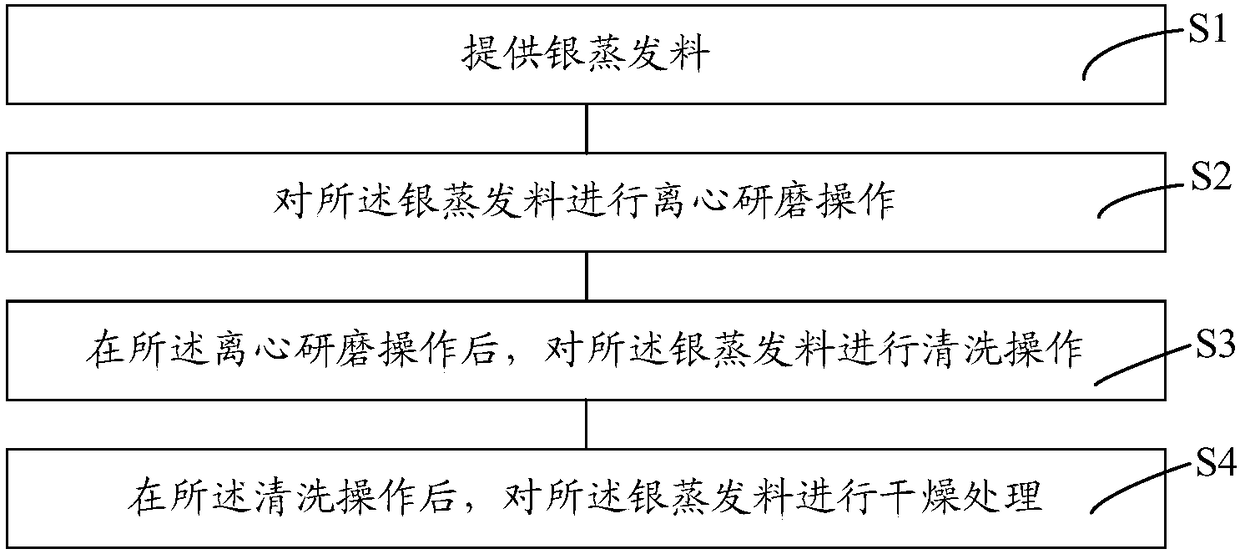

Surface treatment method of silver evaporating material

InactiveCN108987273AImprove surface brightnessImprove smoothnessSemiconductor/solid-state device manufacturingNanotechnologySurface processing

The invention provides a surface treatment method of silver evaporating material, comprising: providing silver evaporating material; Performing a centrifugal grinding operation on the silver evaporating material; Performing a cleaning operation on the silver evaporating material after the centrifugal grinding operation; Drying the silver evaporating material after the cleaning operation. A centrifugal grin operation is performed on that sil evaporating material, to remove an oxide layer on the surface of the silver vaporizer, so that that effect of surface polis is achieved, compared to a scheme employing an acid pickling operation to remove an oxide layer, The invention can avoid the problem that the pickling solution consumes the silver evaporating material, thereby improving the surfacebrightness and smoothness of the silver evaporating material, improving the purity of the silver evaporating material, reducing the consumption of the silver evaporating material, and further reducing the preparation cost of the silver evaporating material.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

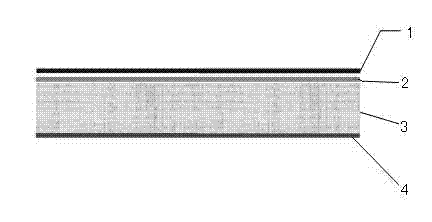

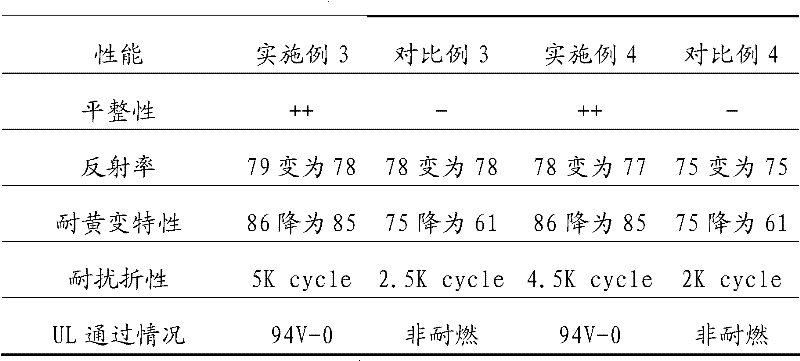

White covering film for flexible circuit board as well as preparation method and application for same

InactiveCN102501499ASolve the flatnessHigh reflective brightnessLamination ancillary operationsSynthetic resin layered productsSurface brightnessFlexible circuits

The invention provides a white covering film for a flexible circuit board, comprising an outmost white ink layer, a middle polyimide layer, an inner adhesive layer and release paper on a bottom layer. The invention further provides a method for preparing a flexible circuit board by using the white covering film, comprising the following steps of: removing the release paper on the bottom layer of the white covering film, thermally bonding the adhesive layer of the white covering film on a pre-treated flexible copper-clad plate primarily, pressing-fitting by a hot press, and finally roasting. The flexible circuit board prepared by using the white covering film provided by the invention is good in smoothness, remarkably increased in the reflecting brightness of LED (light-emitting diode), excellent in anti-yellowing characteristic, great in flexibility, as well as good in surface brightness and reflectivity.

Owner:欣兴同泰科技(昆山)有限公司

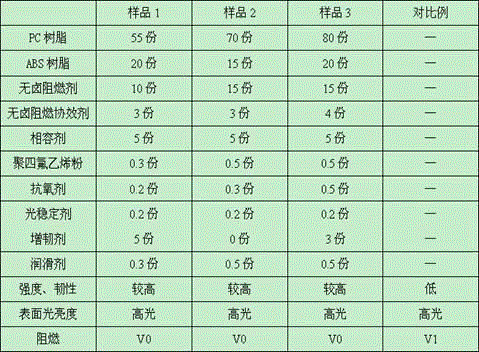

Highlight halogen-free flame-retardant PC/ABS composite material for electric appliance shell

The invention relates to a highlight halogen-free flame-retardant PC / ABS composite material for an electric appliance shell. The material is mainly composed of, by weight, 50-80 parts of PC resin, 10-30 parts of ABS resin, 5-20 parts of halogen-free flame retardant, 1-5 parts of halogen-free flame retardant synergist, 3-8 parts of compatilizer, 0.3-0.8 part of polytetrafluoroethylene powder, 0.1-0.5 part of antioxygen and 0.1-0.5 part of light stabilizer. A preparation method of the material includes the steps of raw material mixing, squeezing and granulating. The material is easy to prepare, good in appearance, safe to use and high in brightness, heat resistance and mobility, can be widely applied to the electric appliance shell of the home appliance field and has wide application prospects on the aspects of high-end television set shells and cell phone components.

Owner:JIANGSU BOILN PLASTICS CO LTD

Environment-friendly fluorescent anti-counterfeiting aluminum-foil paper and manufacturing technology thereof

InactiveCN105619954AImprove structural strengthImprove surface brightnessLamination ancillary operationsLaminationFluorescenceEnvironmental resistance

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

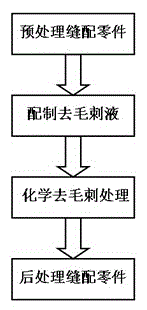

Deburring method for joint accessories

The invention provides a deburring method for joint accessories. The joint accessories are made of high-carbon steel materials. The deburring method includes the following steps of (a) pre-treatment of the joint accessories, (b) preparation of deburring liquid, (c) chemical deburring treatment and (d) post-treatment of the joint accessories. The deburring method is easy and convenient to operate, environmentally friendly and efficient, obviously lowers the surface roughness of the accessories, improves the surface brightness of the accessories, and greatly improves the mechanical strength of the accessories.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

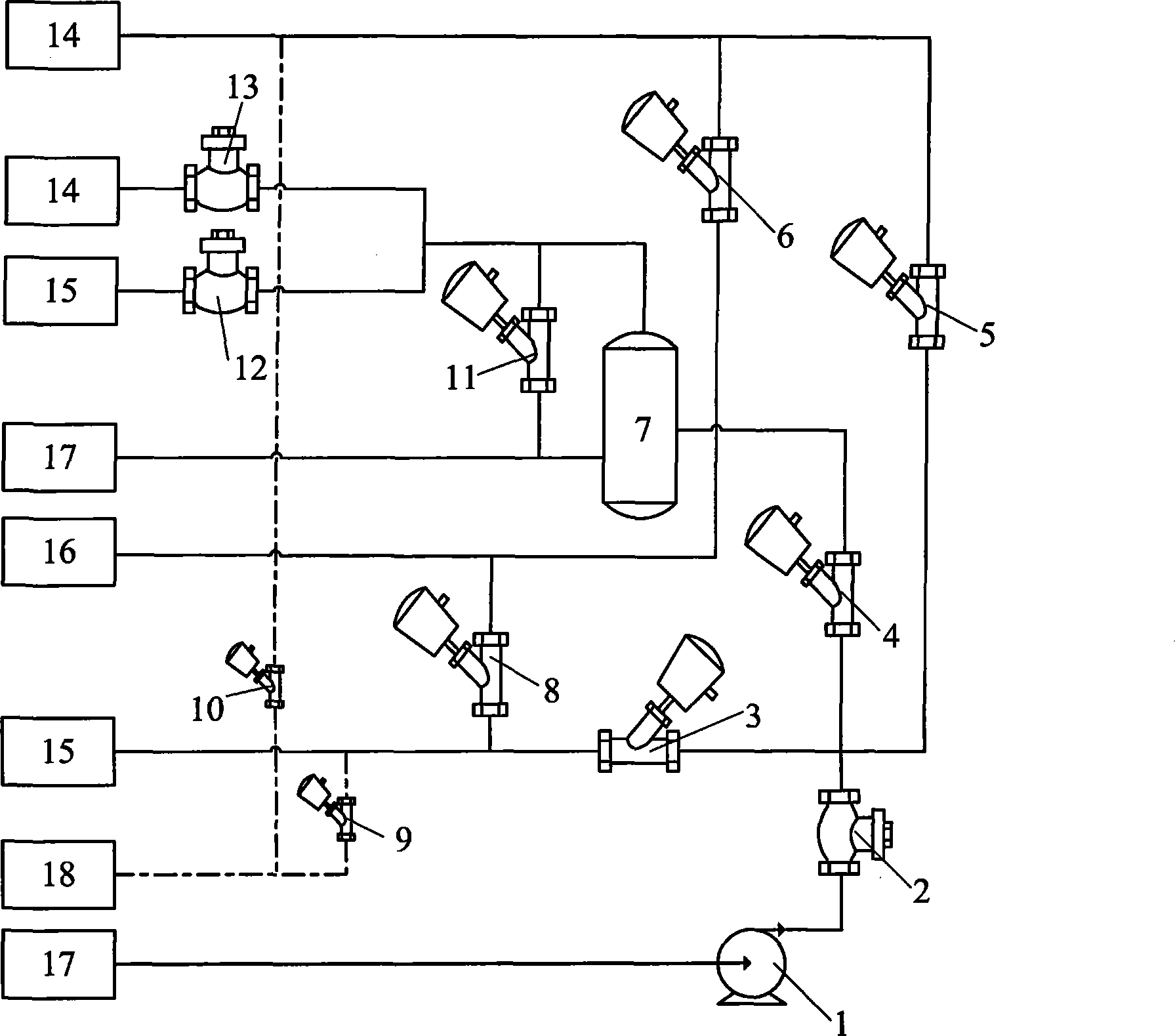

Multifeed mould temperature control system of high light weld mark free shooting technique

InactiveCN101229678AHigh temperature control accuracyGuaranteed injectionTemperature controlControl system

The invention provides a temperature control system of a multi-point die for a high light injection process without melt traces, which essentially comprises a heating boiler, a cooling pool, a pump, an air compressor, a mixer and a control unit. The heating boiler is connected with a steam pipeline; the cooling pool is connected with an cooling pipeline through the pump; the air compressor is connected with an air compressing pipeline; an outlet of the mixer is connected with the cooling pool; at least two branch pipelines are respectively connected with a set of die are arranged on the steam pipeline; the cooling pipeline has at least three branch pipelines and one of the branch pipeline is connected with an inlet of the mixer and the other branch pipelines are provided with the control valves and respectively connected with one set of die; at least two branch pipelines respectively connected with one set of die are arranged on the air compressing pipeline. By adopting the invention, one set of temperature control system can realize temperature control of a plurality of dies simultaneously; besides, the invention simplifies the structure, reduces the cost and occupied area of the system as well as enlarges operation space of technicians.

Owner:SHANDONG UNIV

Hot galvanizing furnace hearth composite alloy and implementation process

InactiveCN105803371AImprove surface brightnessPromote wettingHot-dipping/immersion processesManganeseCerium

The invention provides hot galvanizing furnace hearth composite alloy and an implementation process. The hot galvanizing furnace hearth composite alloy comprises, by weight, 96.9%-99.85% of zinc, 0.08%-1.0% of aluminum, 0-0.14% of nickel, 0-1.0% of manganese, 0-0.12% of silicon, 0-2.0% of magnesium, 0-0.5% of rare earth lanthanum and 0-1.0% of rare earth cerium. The implementation process includes the steps of burdening, smelting, plating part treatment, hot galvanizing and the like. According to the hot galvanizing furnace hearth composite alloy, the materials have excellent corrosion resistance and comprehensive mechanical property, the structure and performance are stable, and the quality can be guaranteed to meet the requirements for current national standard; the preparation method is simple, the cost can be effectively controlled, and the market prospect is good.

Owner:GUANGXI UNIV FOR NATITIES

Active calcium silicate, and preparation method and application thereof

InactiveCN104194404AActivity hasGood dispersionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsCalcium silicateBlow molding

The invention discloses an active calcium silicate, and a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing a coupling agent and water to prepare a dispersion solution; (2) adding calcium silicate into the dispersion solution prepared in the step (1), and stirring; carrying out vacuum filtration to obtain modified active calcium silicate; and (3) drying the active calcium silicate prepared in the step (2). The invention also discloses a plastic stuffing which comprises the active calcium silicate, a lubricant, polymers and a compatilizer. The invention also discloses a method for preparing the plastic stuffing. When being used in blow molding, running, injection molding and other plastic products, the active calcium silicate or plastic stuffing has favorable dispersion effect and toughening effect.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT +1

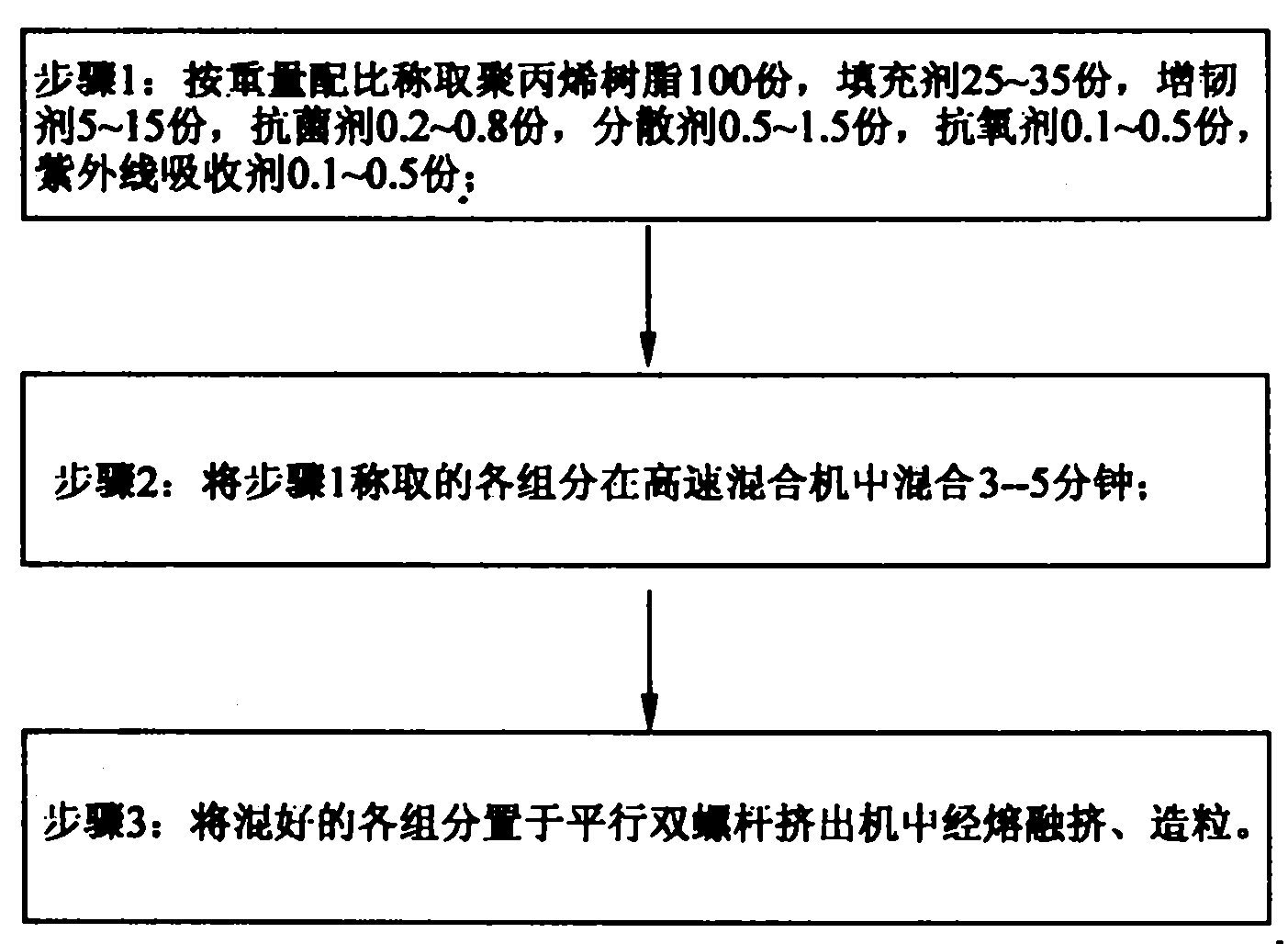

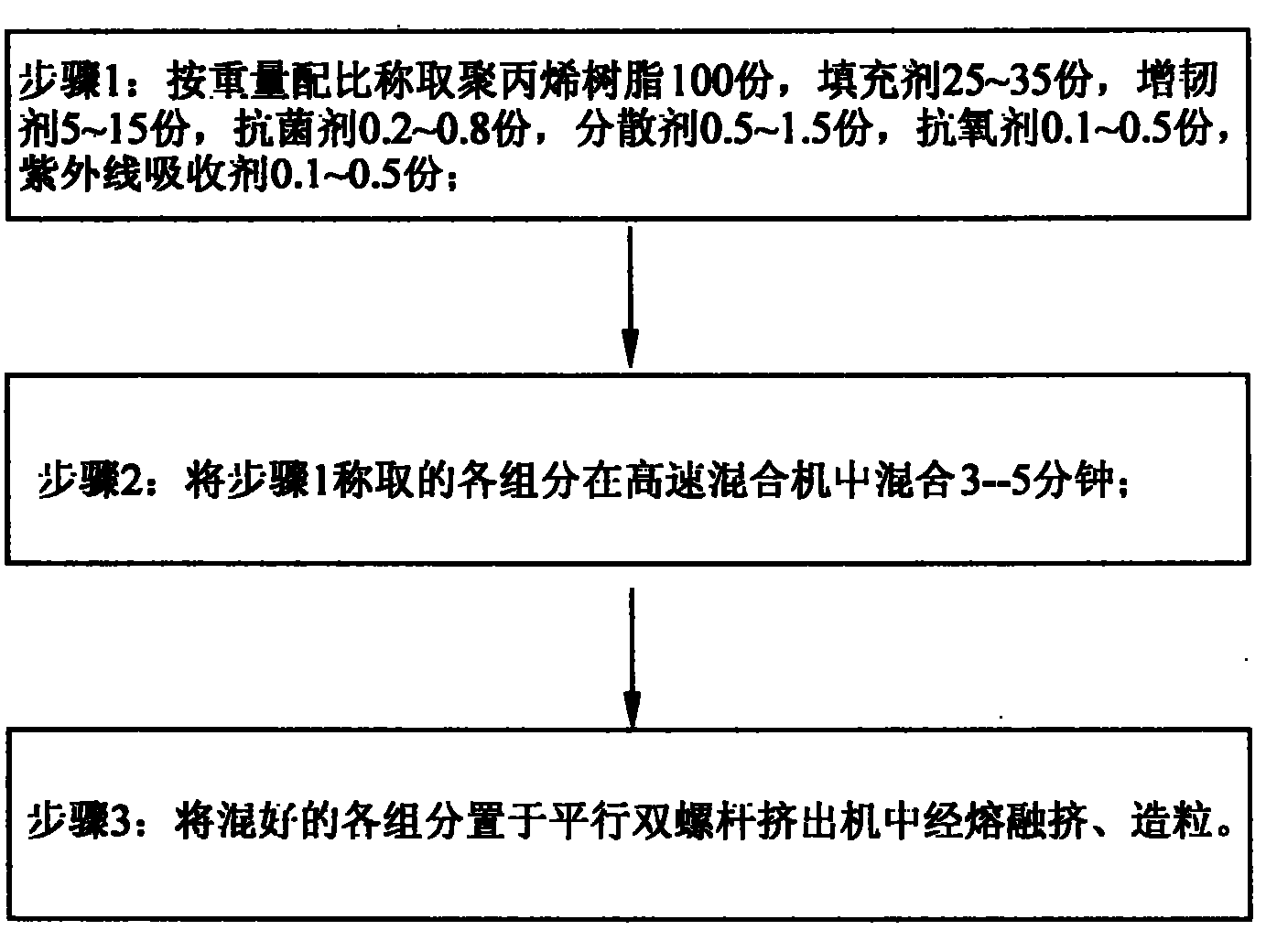

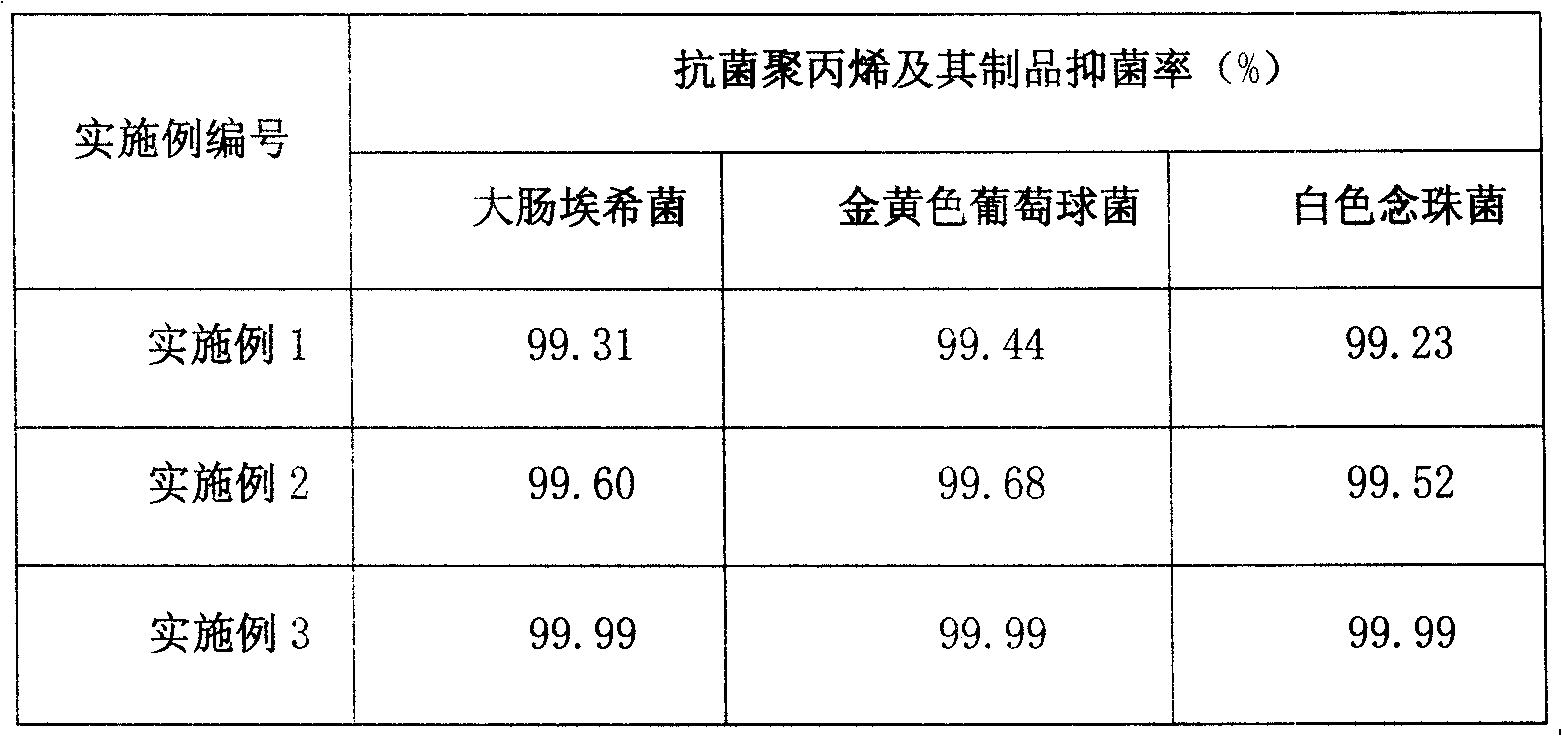

Antibacterial polypropylene material and its preparation process

InactiveCN101089038BReduce manufacturing costHigh surface glossBiocideAnimal repellantsUltravioletPolypropylene

The antibacterial polypropylene material consists of polypropylene resin 100 weight portions, stuffing 25-35 weight portions, toughening agent 5-15 weight portions, antiseptic 0.2-0.8 weight portion, dispersant 0.5-1.5 weight portions, antioxidant 0.1-0.5 weight portion and ultraviolet absorber 0.1-0.5 weight portion. The polypropylene resin is homopolypropylene, and the antiseptic is compounded with nanometer silver and organosilicon antiseptic. The present invention also provides the preparation process of the antibacterial polypropylene material with low production cost, excellent antiseptic performance.

Owner:SHENZHEN KEJU NEW MATERIAL

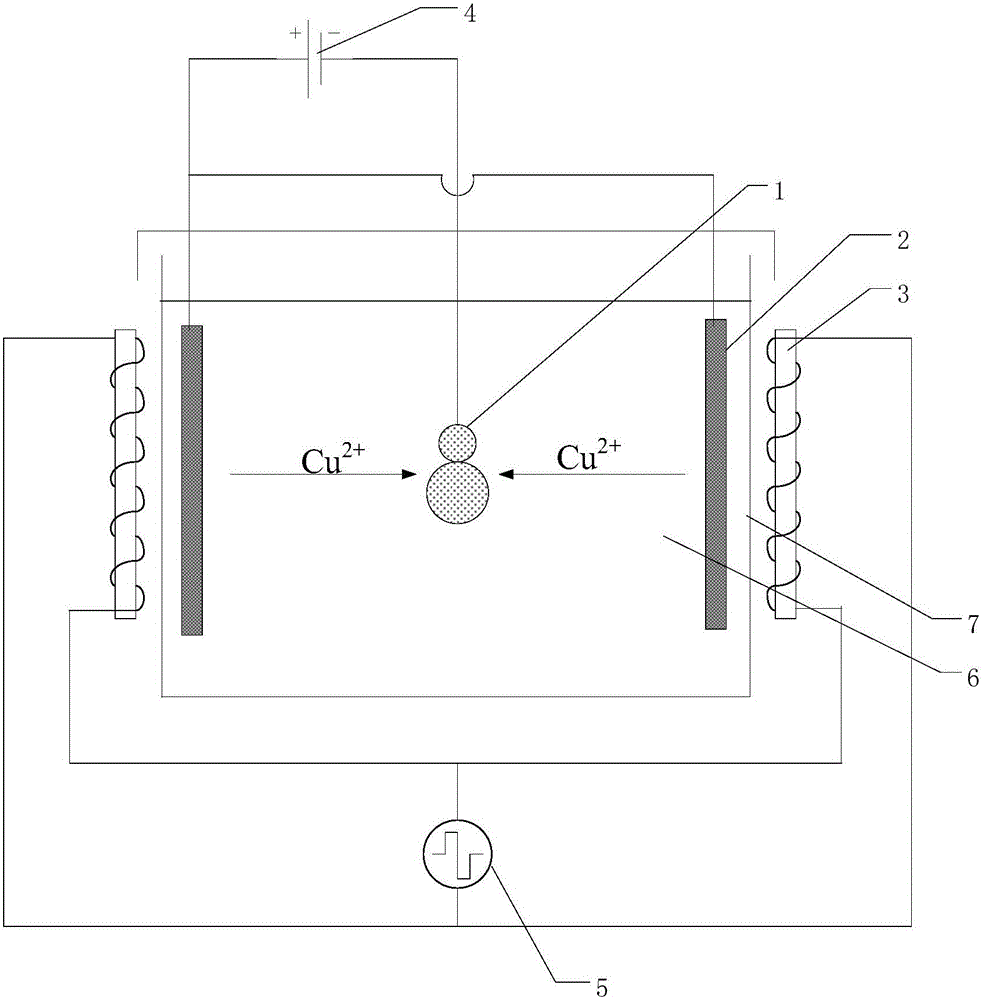

Steel piece cyanide-free copper plating method adopting applied magnetic field

The invention discloses a steel piece cyanide-free copper plating method which comprises the following steps: step 1, carrying out treatment including polishing, oil removing, cleaning, activating and the like on a plated steel piece; step 2, putting the plated steel piece and a pure copper plate into an electroplating liquid by taking the pretreated plated steel piece as a cathode and the pure copper plate as an anode, applying voltage at two sides of the cathode and the anode, applying a pulse magnetic field to an electroplating bath, and carrying out electroplating by ensuring that the direction of the magnetic field is vertical to the movement direction of copper ions in the electroplating liquid; and step 3, carrying out treatment including cleaning, passivation, drying and the like on the electroplated steel piece. By adopting the method disclosed by the invention to plate copper for a steel statue, the deposition rate of a clad layer is high, the surface is bright and smooth, and the technology is easy to control.

Owner:NANJING CHENGUANG ART ENG CO LTD

PBT (polybutylene terephthalate) enhanced flame-retardant laser printing material and preparation method thereof

ActiveCN104448735AGuaranteed mechanical propertiesMeet high temperature resistancePolytetramethylene terephthalateGlass fiber

The invention relates to a PBT (polybutylene terephthalate) enhanced flame-retardant laser printing material. The PBT enhanced flame-retardant laser printing material comprises the following raw materials: PBT resin, PBT laser powder, a flame retardant, an antioxidant, a flow aid, a demolding agent, 5%-8% of a toughening agent and glass fibers. The PBT enhanced flame-retardant laser printing material is prepared by the steps of feeding dried PBT into a double-screw extruder from the first section of a cylinder body, mixing the flame retardant, the PBT laser powder, the antioxidant, the flow aid, the demolding agent and the toughening agent by virtue of a high-speed mixer, adding the mixture into the double-screw extruder from the fourth section of the cylinder body by virtue of a proportioning feeding machine, simultaneously adding the glass fibers, and after blending materials by virtue of the double-screw extruder, carrying out extruding, cooling, particle dicing and measurement packing. The PBT enhanced flame-retardant laser printing material can resist high temperature and can be used for printing white fonts on a black substrate by virtue of laser, and the fonts are clear.

Owner:JIANGYIN JIHUA NEW MATERIAL

Hastelloy electrolytic polishing process

The invention provides a hastelloy electrolytic polishing process, and belongs to the technical field of a polishing process. The specific steps are as follows: carrying out drying and cleaning pretreatments on a hastelloy electrolytic polishing workpiece to ensure that no redundant moisture is left on the surface of the workpiece; directly carrying out an electrolytic polishing treatment on the dry and clean workpiece; hanging the dry workpiece on a titanium alloy fixture, putting the titanium alloy fixture in an electric polishing groove, immediately electrifying constant voltage direct current, carrying out electrolytic polishing for 60-120 seconds, and controlling the current density at 5-7 A / dm<2>; cleaning the electrolytically polished workpiece in hot water of 38-42 DEG C for 2 minutes and drying the workpiece. According to the invention, a universal electrolytic polishing liquid reagent is adopted, and the pretreatment manner and the control process are adjusted, so that the appearance of the electrolytically polished surface of the hastelloy workpiece is good, the surface brightness is increased, the hastelloy workpiece has obvious metallic luster and has no spot corrosion, and the processing quality is effectively guaranteed.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

Glass fiber enhanced polycarbonate (PC) and preparation method thereof

The invention discloses a glass fiber enhanced polycarbonate (PC) and a preparation method thereof. The glass fiber enhanced polycarbonate comprises the following ingredients according to mass percentage: 50-90% of polycarbonate, 10-30% of glass fiber, 5-15% of flexibilizer, 2-6% of compatilizer, 0.1-1% of anti-oxidant and 0.3-1.5% of TAF bright lubricant. The glass fiber enhanced polycarbonate (PC) has the beneficial effect that compared with prior art, The prepared glass fiber enhanced polycarbonate (PC) has high strength, good appearance, and excellent processing performance and electrical property, the TAF bright lubricant can prevent glass fiber exposition, the surface-brightening degree of the products can be simultaneously enhanced, processing temperature of the products can be produced, and wearing effect of machinery equipment is reduced.

Owner:QINGDAO XINZHAN PLASTIC

Small melon and fruit leaf removing device

InactiveCN107259610ADefoliation effect is goodLow removal rateFruit and vegetables preservationFood treatmentBristleWater flow

The invention relates to a small melon and fruit leaf removing device and belongs to the technical field of melon and fruit processing devices. Firstly, melons and fruits are fed into a machine body from a small melon and fruit inlet and fall onto a rotary drum, then a motor drives a large belt wheel through a belt to make the rotary drum roll forwards, a fan for downward blowing is configured above the rotary drum, part of withered leaves on small melon and fruit branches and leaves are blown off, then melons and fruits are driven to roll through a parallel bristle brush zone provided with a high-pressure spray nozzle at the upper portion and by using a bristle brush after being flushed by water sprayed by the high-pressure spray nozzle, meanwhile the axial flow fan at the upper portion blows the small melon and fruit branches and leaves and cooperates with brush bristles to remove dead twigs and withered leaves, the dead twigs and withered leaves fall into a branch and leaf collecting groove at the lower portion, and finally the melons and fruits roll into a discharging port and enter a collecting bag. The small melon and fruit leaf removing device is good in leaf removing effect and high in removal speed and has a wide application prospect.

Owner:常州凯奥机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com