White covering film for flexible circuit board as well as preparation method and application for same

A flexible circuit board and cover film technology, which is applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problem that the ink surface is prone to cracks, it is difficult to meet the requirements of UL94V-0, and the surface brightness is easily affected by the environment. Influence and other issues, to achieve the effect of good surface brightness and reflectivity, excellent long-term weather resistance, and excellent yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

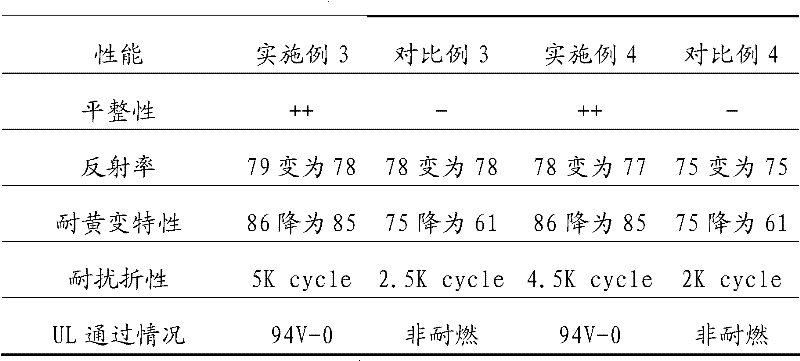

Examples

Embodiment 1

[0022] The method of preparing white cover film: Coat a 25um adhesive layer on a polyimide layer with a thickness of 25um, then attach a release paper layer, and then coat the other side of the polyimide layer with a thickness of 13um White ink layer. Among them, the polyimide layer adopts soluble polyimide with a number average molecular weight of 100,000, the adhesive adopts modified epoxy resin adhesive of HF Epoxy brand produced by Taihong Company, and the white ink adopts the product of DPR-55 brand of Asahi Company.

Embodiment 2

[0024] The method of preparing white cover film: Coat a 25um adhesive layer on a polyimide layer with a thickness of 25um, then attach a release paper layer, and then coat the other side of the polyimide layer with a thickness of 20um White ink layer. Among them, the polyimide layer adopts soluble polyimide with a number average molecular weight of 100,000, the adhesive adopts modified epoxy resin adhesive of HF Epoxy brand produced by Taihong Company, and the white ink adopts the product of DPR-55 brand of Asahi Company.

Embodiment 3

[0030] The method for preparing flexible circuit boards: tear off the bottom release paper of the white cover film prepared in Example 1, and heat the adhesive layer of the white cover film to the pre-treatment (that is, it has been cut and drilled). Hole, copper-plated and etched conductive layer) on the flexible copper clad board, the bonding temperature is 80℃, the pressure is 18 kg / cm2; then it is pressed with a hot press, the pressing temperature is 175℃, the pressure is 160 kg / cm, and the The heating time is 30s, and the pressing time is 5000s; the final baking is at 150°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com