Post processing polishing process for hot galvanizing product

A technology of hot-dip galvanizing and products, applied in the field of polishing process, can solve the problems of difficult to meet the requirements of high-end equipment, insufficient polishing of workpieces, waste of water resources, etc., and achieve the effects of improving appearance quality, low cost, and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

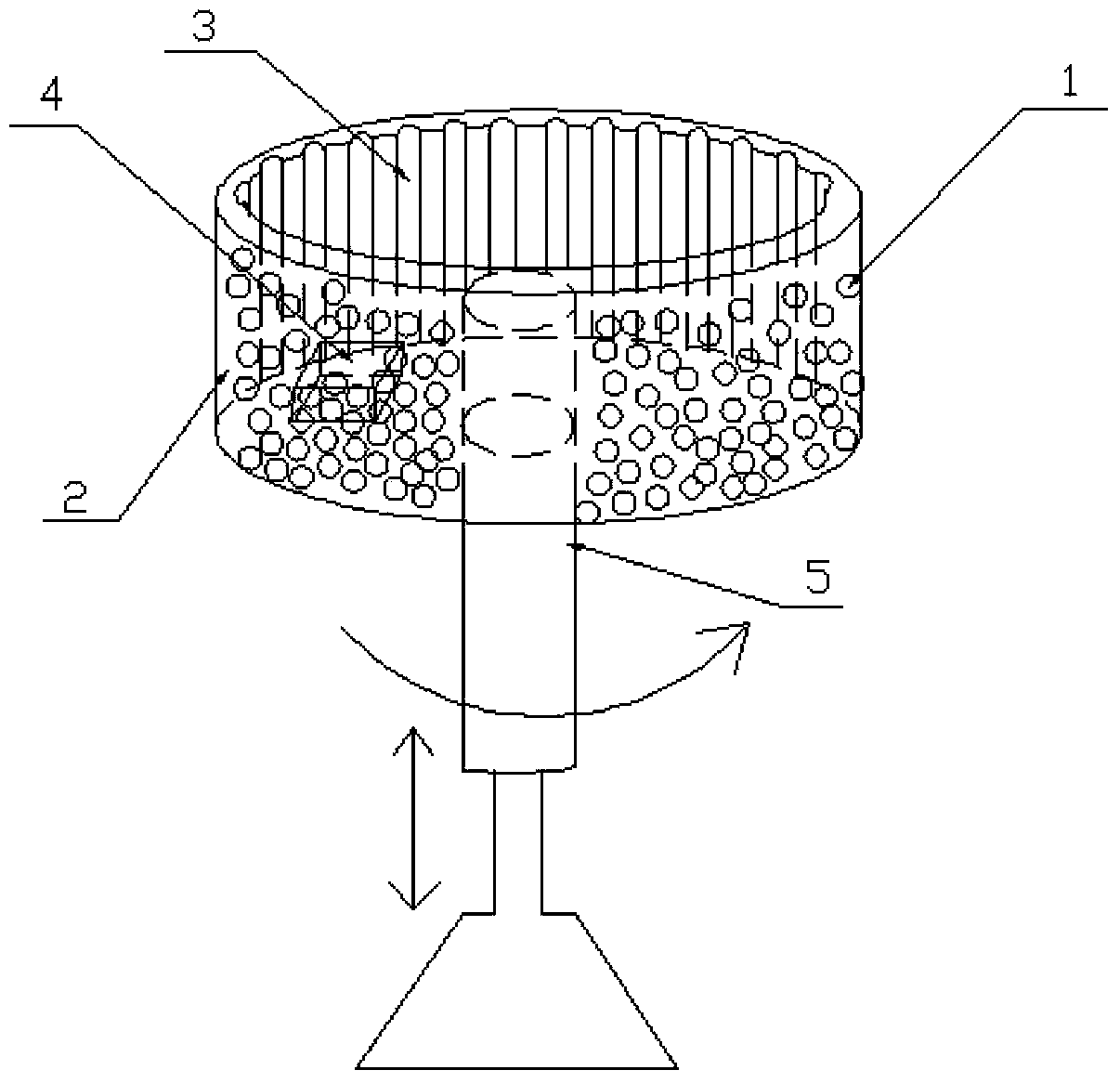

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings, making it easier to understand and grasp.

[0023] Such as figure 1 As shown, the present invention provides a polishing process for post-processing hot-dip galvanized products. A large number of steel balls 1 are placed in a rotatable and vertically vibrating accommodating chamber 2, and then the hot-dip galvanized products 4 to be processed are placed Put it into the steel ball pile, start the equipment, under the transmission of the moving rod 5, the accommodation chamber 2 rotates and vibrates up and down, which makes the hot-dip galvanized product 4 stored in it collide and rub against the steel ball 1, so that the hot-dip galvanized product 4 surface is polished.

[0024] In order to achieve a good polishing effect, vertical grooves 3 can be evenly arranged on the inner wall of the accommodation chamber 2, and the bottom of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com