Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

251results about How to "Low molding temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

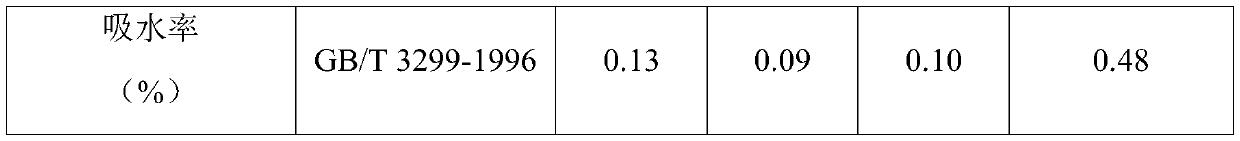

High strength glass fiber composition

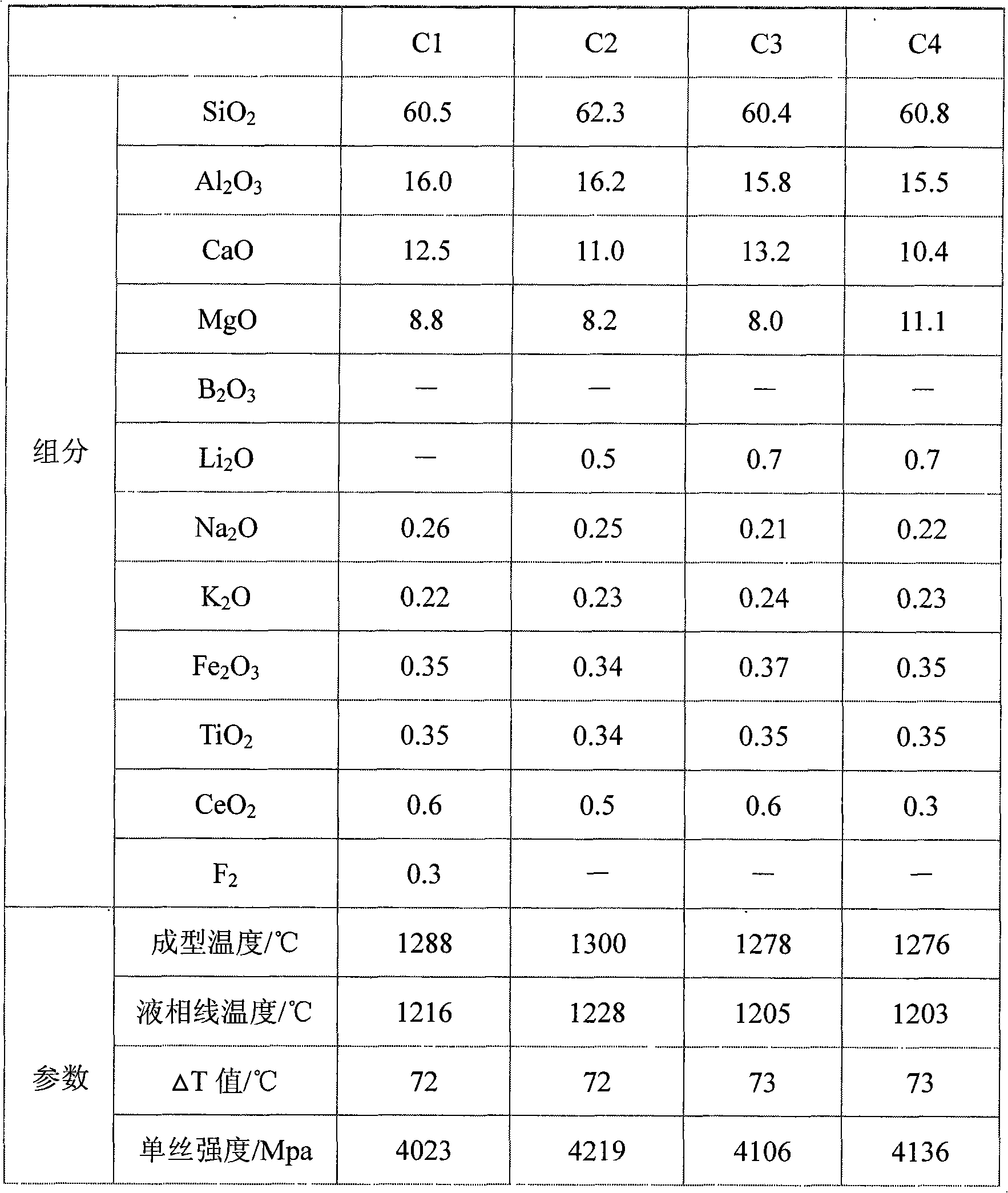

The invention discloses a high strength glass fiber composition which comprises the components with the weight percentage: 58-65% of SiO2, 14-20% of Al2O3, 15-25% of CaO+MgO, 0.05-1% of K2O+Na2O, 0.05-1% of Fe2O3 and 0.1-2% of CeO2; wherein, the proportional relation of the components is that CaO / MgO is more than 0.7 and less than 2.2. By preference and combination of the components, the high strength glass fiber composition not only can fully utilize rich raw mineral materials of China, but also can reduce mold temperature, liquidus temperature and clarification temperature and has lower total cost and easy large scale commercial process under the premise of ensuring the high strength of glass fiber.

Owner:JUSHI GRP CO

Glass fiber

InactiveCN103086605AHigh tensile modulusLow molding temperatureGlass fiberCrystallization temperature

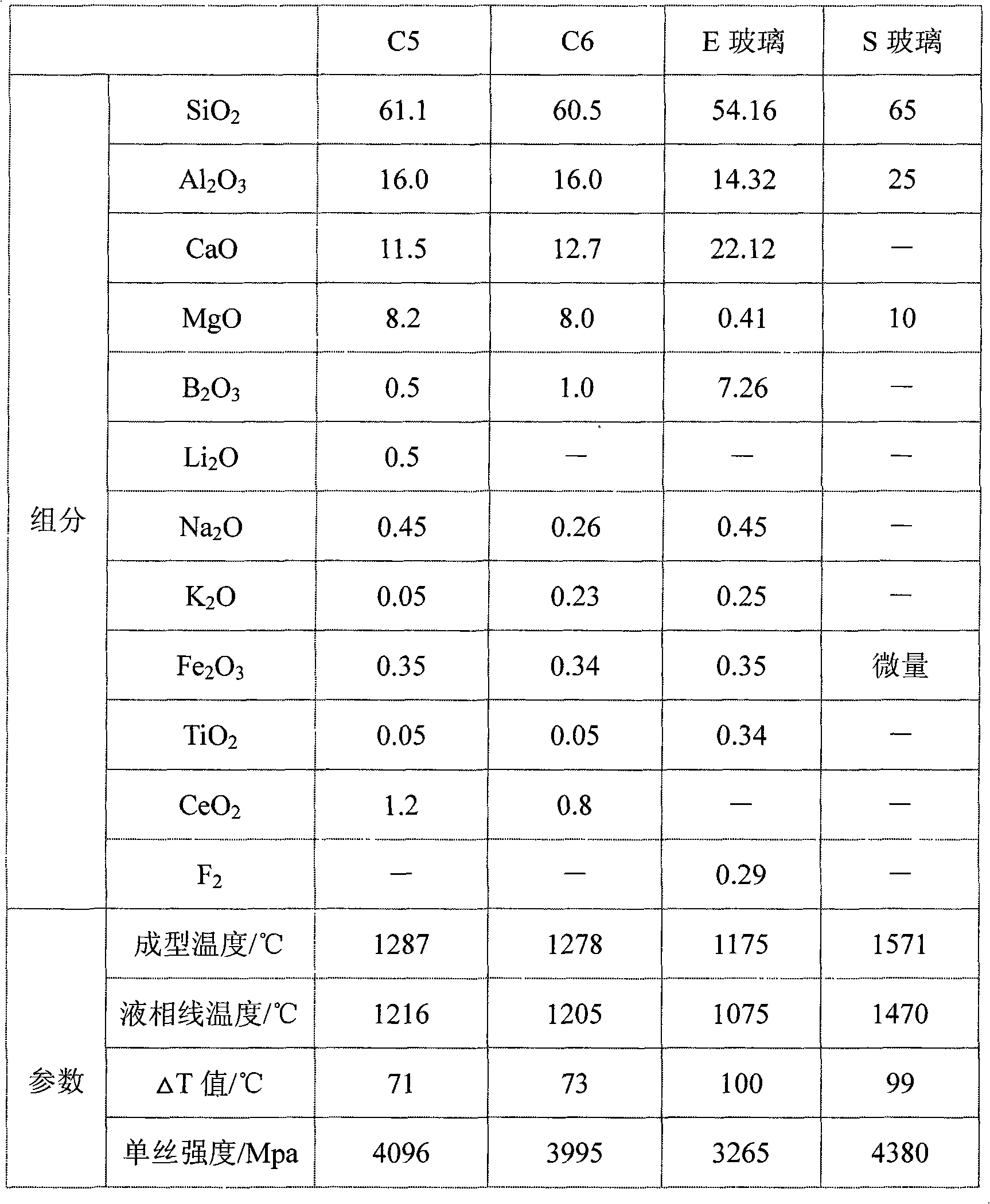

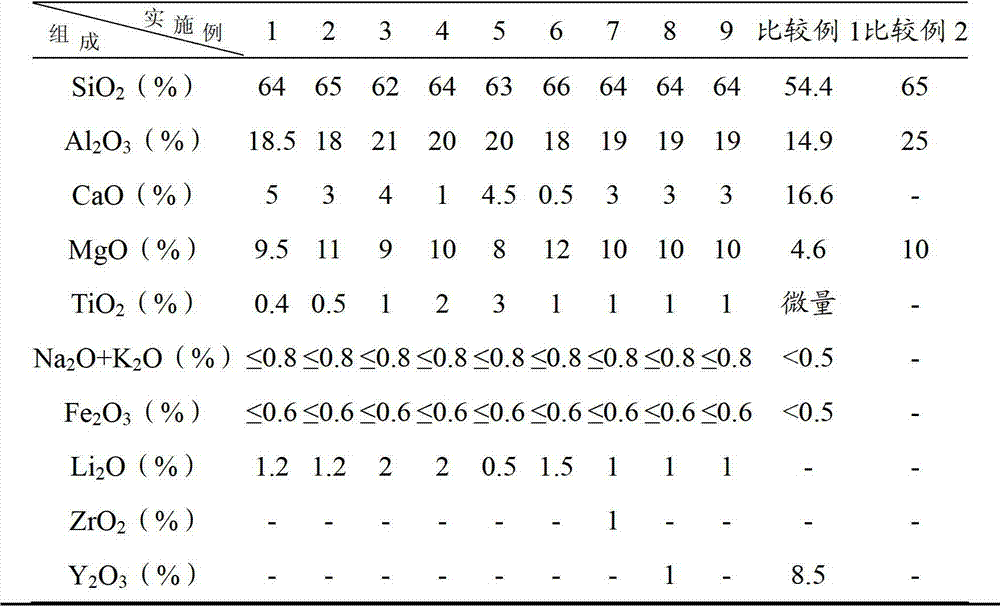

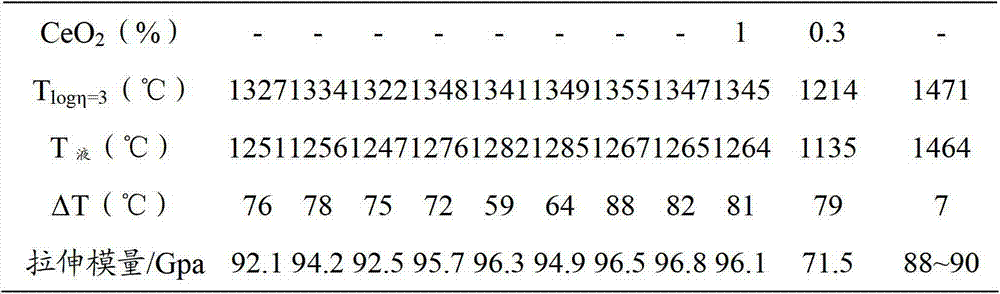

The invention provides a glass fiber which comprises 62-66 wt% of SiO2, 18-21 wt% of Al2O3, 0.5-5 wt% of CaO, 8-12 wt% of MgO, 0.5-2 wt% of Li2O, 0.4-3 wt% of TiO2, 0.1-0.6 wt% of Fe2O3 and 0.1-0.8 wt% of Na2O and K2O. The total mass content of the Na2O, K2O and Li2O is 0.5-3 wt%. Therefore, the glass fiber provided by the invention has low forming temperature and upper limit crystallization temperature on the premise of having high tensile modulus, so that the glass fiber is applicable to large-scale industrial production.

Owner:CHONGQING POLYCOMP INT

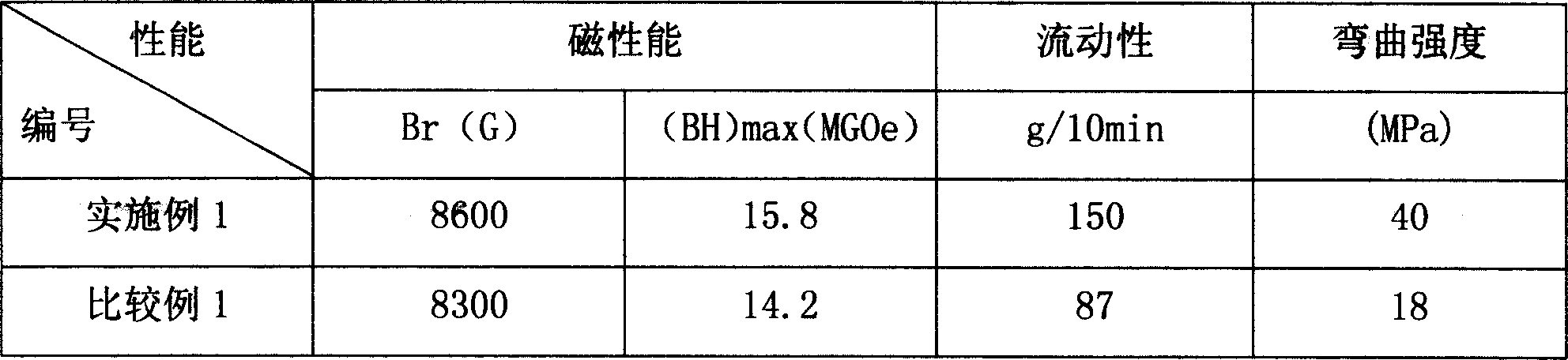

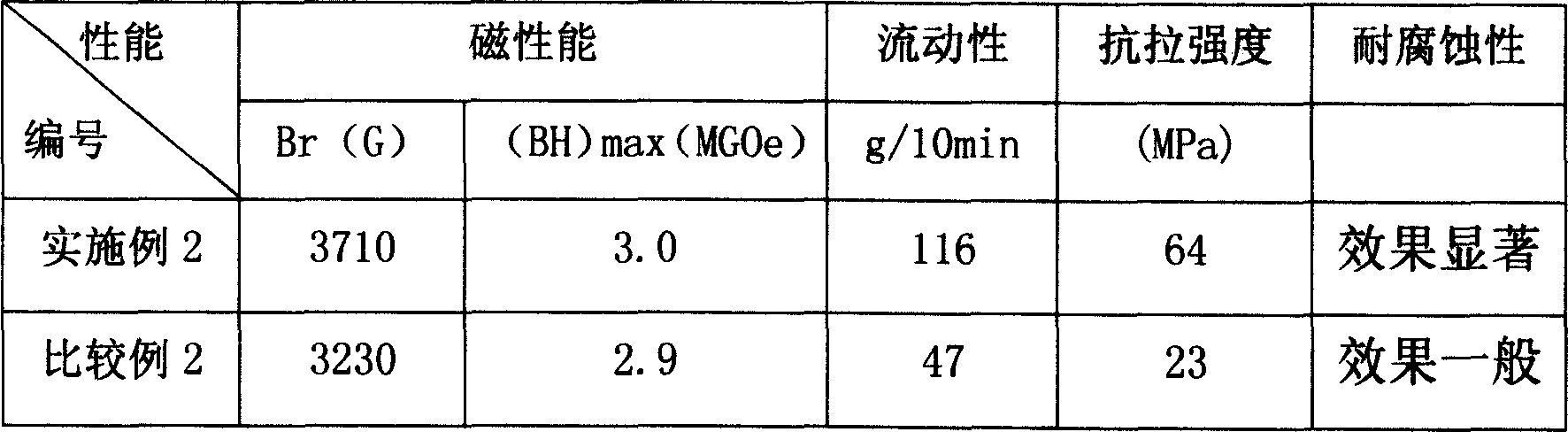

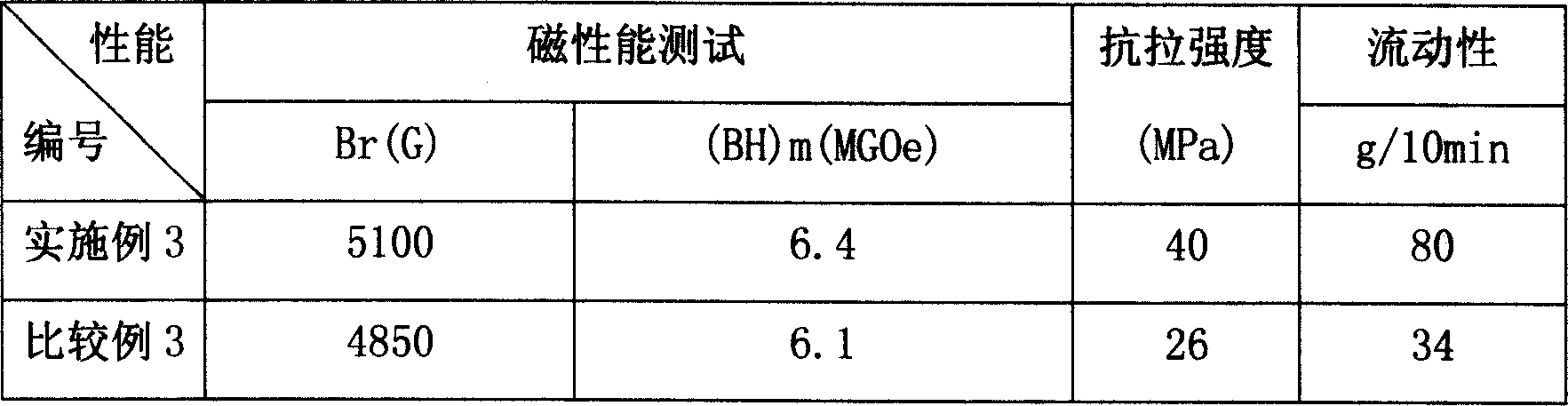

Formula of compoiste adhering magnet

ActiveCN1645525AImprove liquidityLow molding temperatureInorganic material magnetismMetallurgyAdditive ingredient

The invention is related to a permanent magnet consisting of more than two kinds of permanent magnetic powder, special binder, organic or inorganic lubricant, and other additives. The invention has following features: 1) the organic or inorganic lubricant makes the ingredient have good fluidity, low forming temperature, and high loading level of magnetic powder; 2) the production cost is low and the application of magnetic property is wide.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

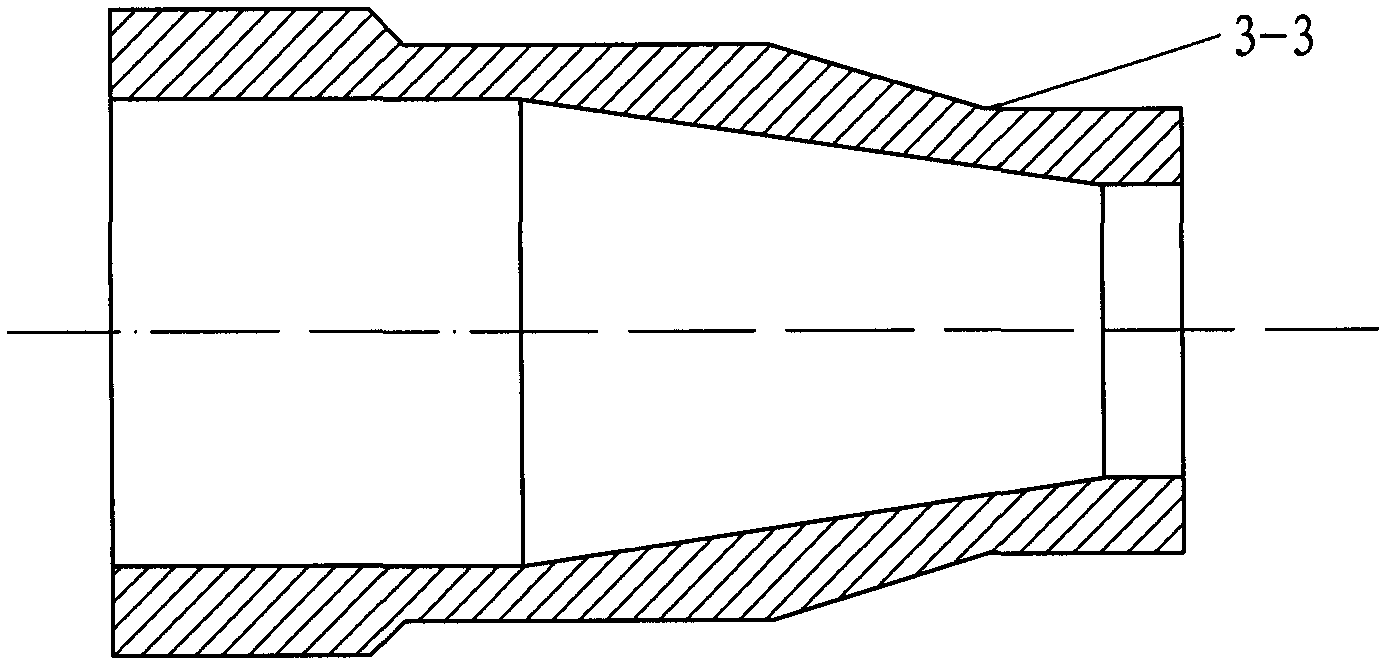

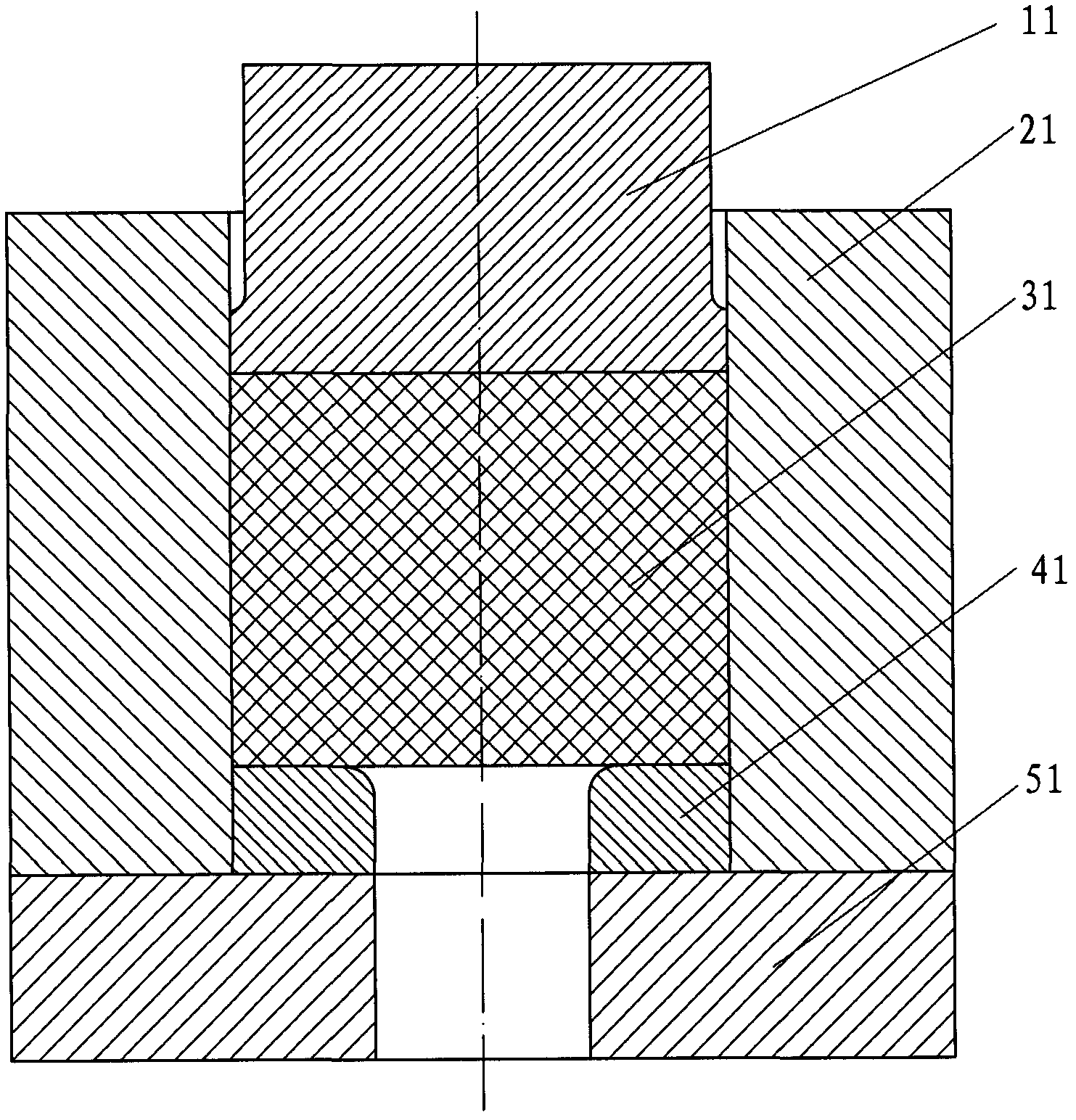

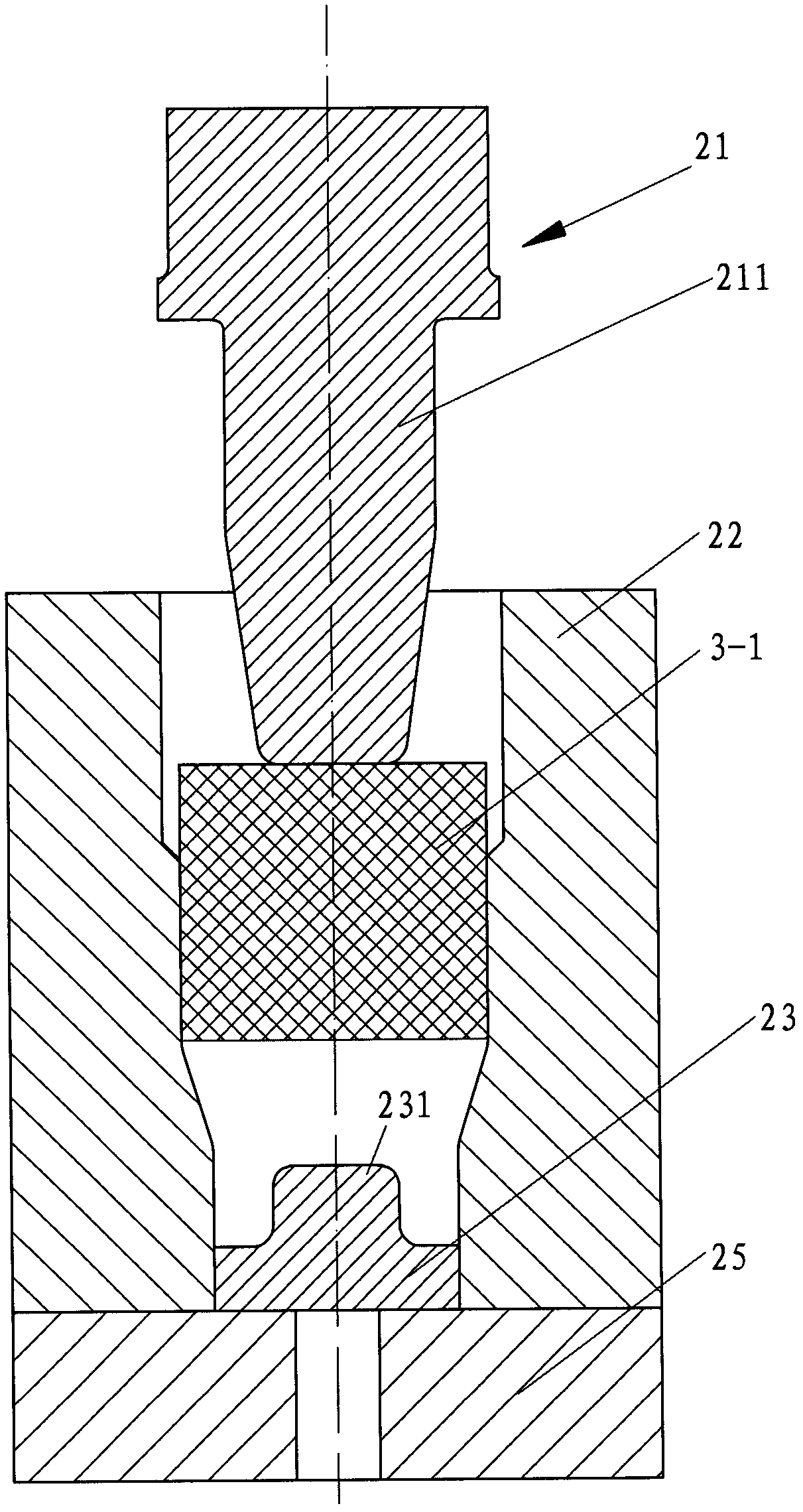

Preparation method of magnesium alloy variable-section cylindrical member by composite extrusion deformation

A preparation method of a magnesium alloy variable-section cylindrical member by composite extrusion deformation is characterized in that the method comprises the following steps: firstly, orderly performing homogenization pretreatment and hot extrusion deformation of an AZ80 magnesium alloy blank; preparing a variable-section cylindrical force-bearing member by forward and backward composite extrusion; finally performing turning and heat treatment to obtain a magnesium alloy variable-section cylindrical member. Compared with the prior art, the invention has the following advantages that the invention can prepare large-size cylindrical members; the material grain is fine; the mechanical properties are high; and the procedures are simple.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Method of semi-vitreous extrusion molding manufacturing for portiforium type millipore plastics extrusions

InactiveCN101229682ASolve technical problemsSimplify the molding processPlastic materialsMelt extrusion

The invention relates to a method for preparing opening micropore plastic material though slack-melting, extruding and molding. The method includes the processes: after reaching from a feeding device arranged on a double piston extruder to a heating material cylinder, preheating plastic powder with particle size of 40-1500 meshes is extruded by the piston driven by a hydraulic driver and compacted, transported and heated constantly; when the surface temperature of the plastic powder reaches the melt temperature of Tf plus or minus 20 DGE C, the power is extruded from a machine head and a die. Then, extruding matters are cooled and set by a cooling-traction device and the products are finished. By regulating the particle size of the powder, addictive and forming process conditions and so on, the invention can control opening rate, size and distribution of the aperture; the invention has simple process, short production cycle, low forming temperature and pressure as well as short forming time; besides, the invention can greatly reduce the production cost can not be degraded easily when the plastic is processed and can be widely applicable to molding of the opening micropore products of thermoplastic powders, thermosetting power and so on.

Owner:SICHUAN UNIV

SMC sheets and its prepn. method

InactiveCN1903563AShorten the curing timeLow molding temperatureSynthetic resin layered productsGlass/slag layered productsGlass fiberHigh surface

A SMC sheet with high surface quality and luster is composed of both surficial PE films and a core material prepared from glass fibers through immersing them in the resin paste which is proportionally from unsaturated polyester resin, low-shrinkage additive, internal demoulding agent, calcium carbonate, styrene, trigger and magnesium oxide.

Owner:北京玻钢院复合材料有限公司

High-dielectric-constant three-phase composite material containing modified graphene and preparation method thereof

Owner:UNIV OF SCI & TECH BEIJING

Low-temperature fabrication of glass optical components

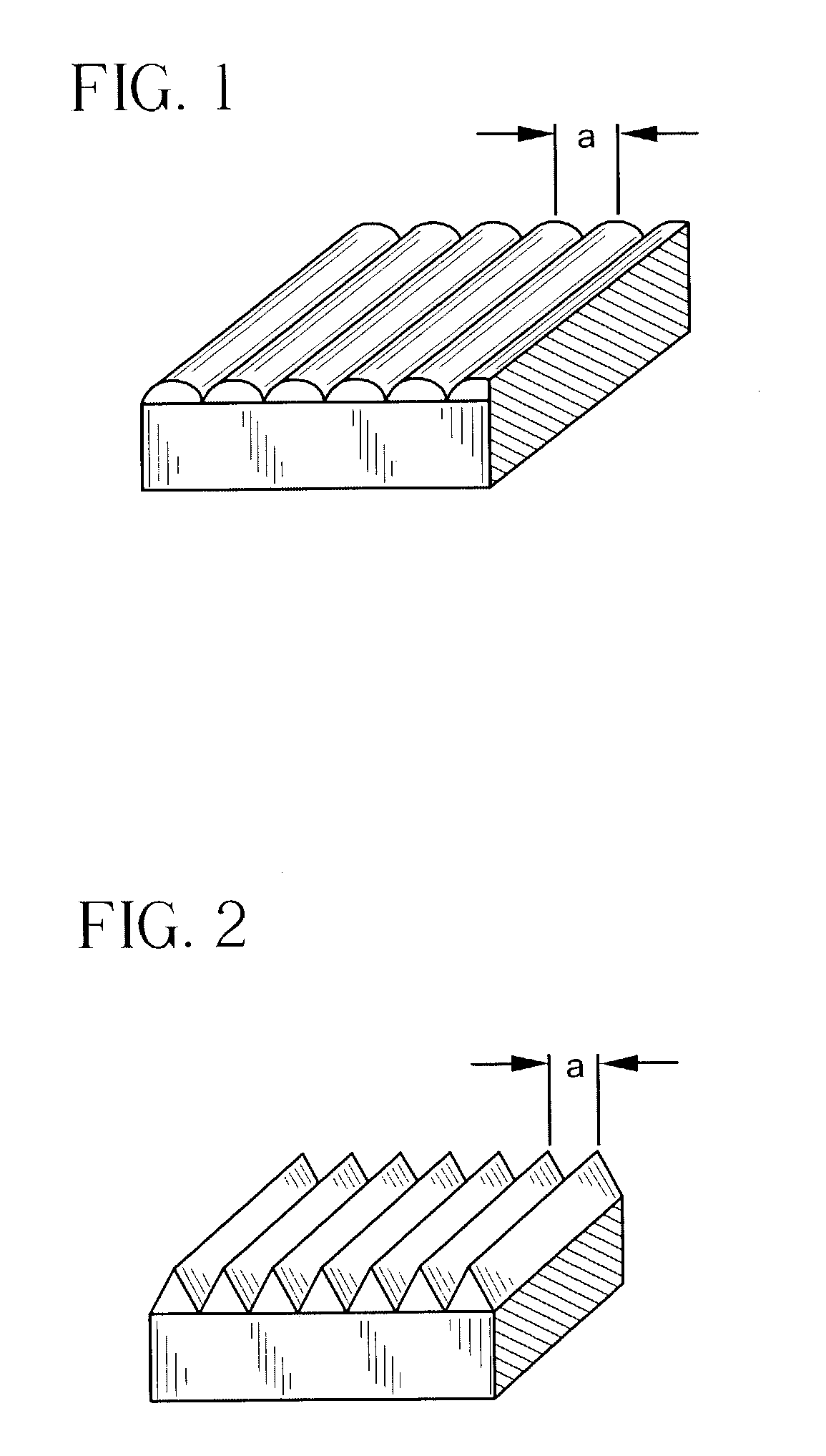

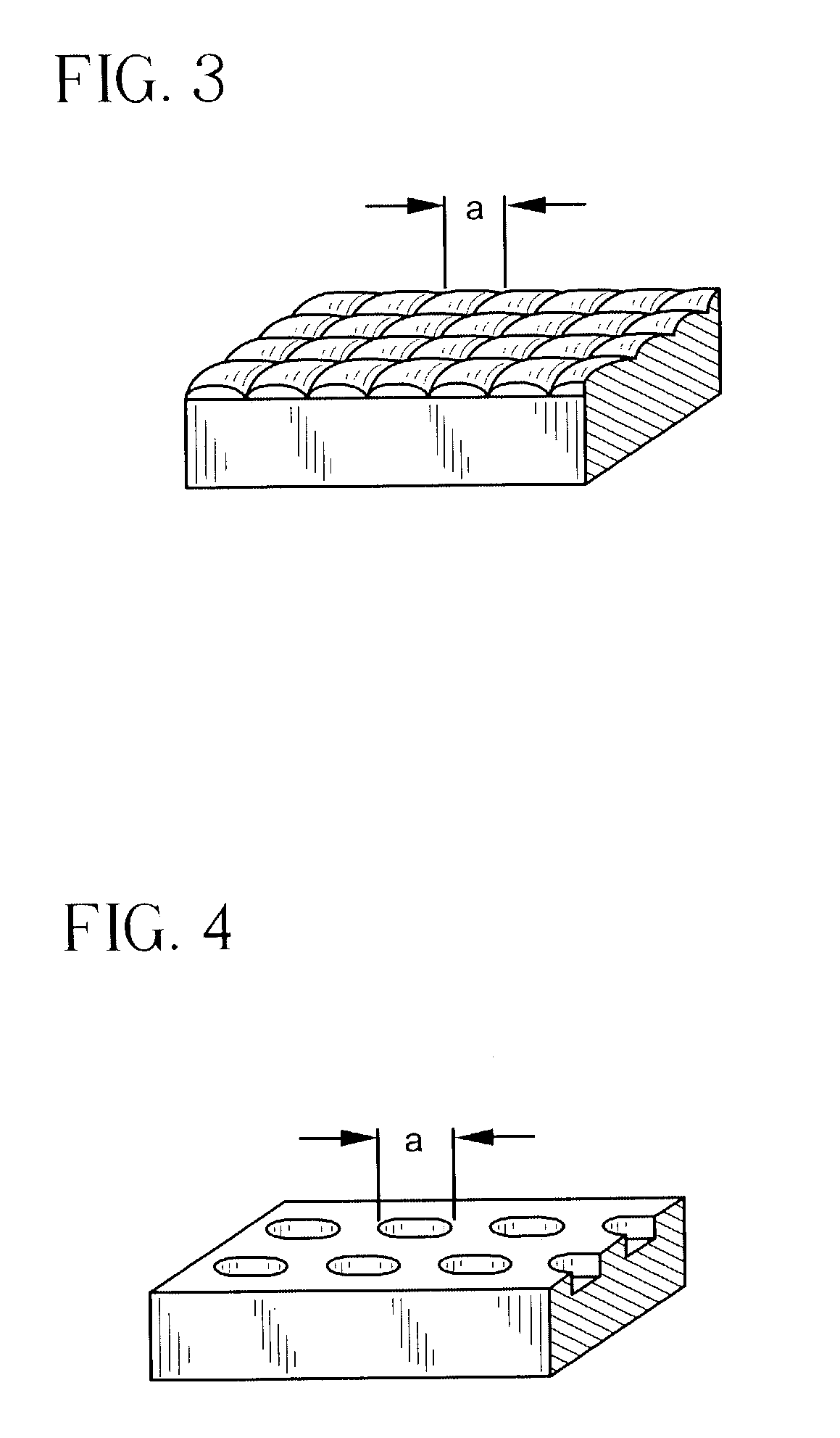

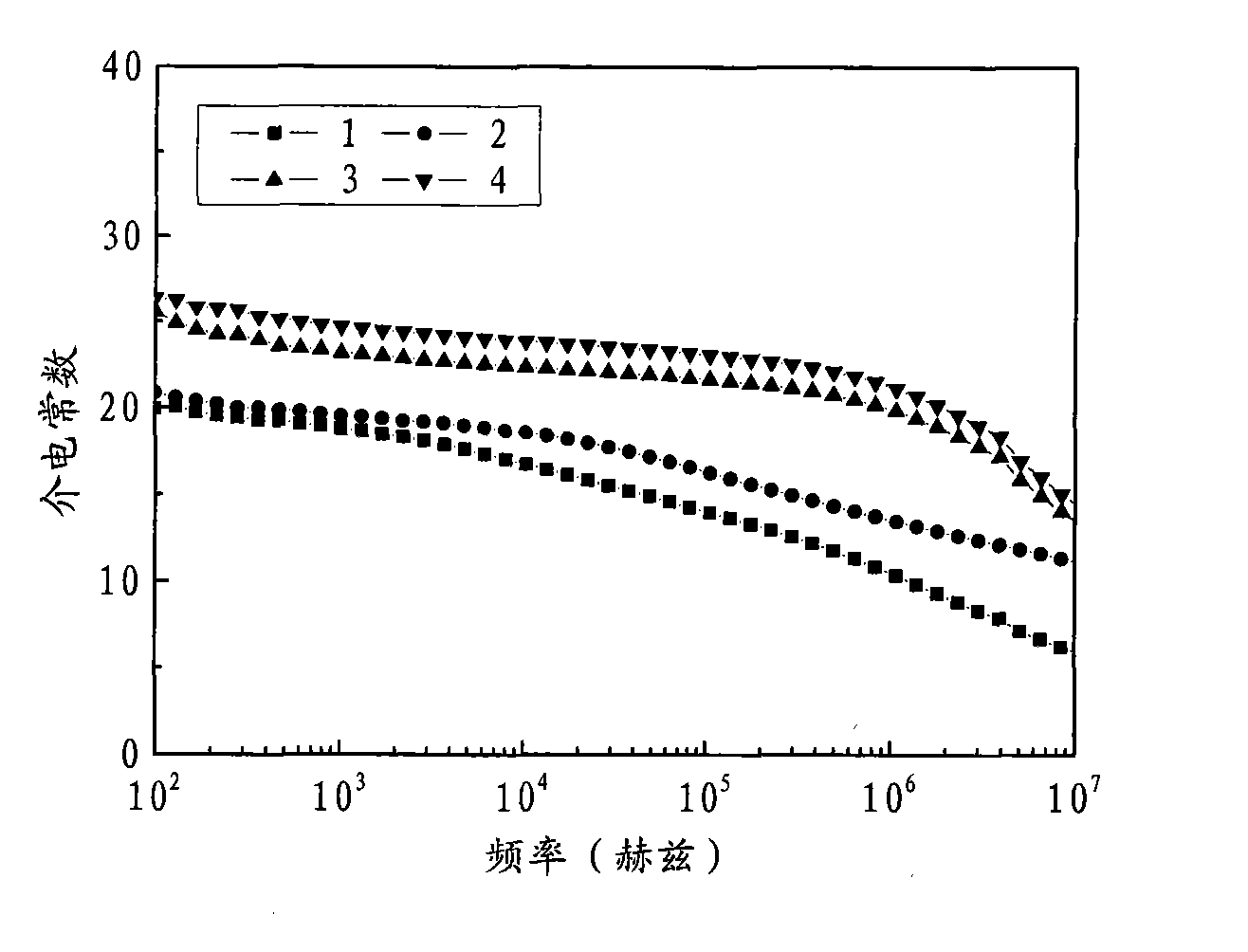

InactiveUS7143609B2High refractive indexLow molding temperatureGlass transportation apparatusGlass pressing apparatusGratingMetallic Nickel

A method is provided for molding from glass certain complex optical components, such as lenses, microlens, arrays of microlenses, and gratings or surface-relief diffusers having fine or hyperfine microstructures suitable for optical or electro-optical applications. Thereby, mold masters or patterns, which define the profile of the optical components, made on metal alloys, particularly titanium or nickel alloys, or refractory compositions, with or without a non-reactive coating are used. Given that molding optical components from oxide glasses has numerous drawbacks, it has been discovered in accordance with the invention that non-oxide glasses substantially eliminates these drawbacks. The non-oxide glasses, such as chalcogenide, chalcohalide, and halide glasses, may be used in the mold either in bulk, planar, or power forms. In the mold, the glass is heated to about 10–110° C., preferably about 50° C., above its transition temperature (Tg), at which temperature the glass has a viscosity that permits it to flow and conform exactly to the pattern of the mold.

Owner:CORNING INC

Multilayered structural polymer-based dielectric composite material and preparation method thereof

InactiveCN101882507AHigh dielectric constantImprove adhesionFixed capacitor dielectricSynthetic resin layered productsPolymer sciencePolymer

The invention relates to a multilayered structural polymer-based dielectric composite material and a preparation method thereof, which belong to the field of dielectric substance. The traditional polymer-based dielectric composite material can not take both dielectric constant and adhesive property into account and has complicated preparation process. The composite material provided by the invention comprises three layers of films which are superimposed together; the volume part of a polymer in an outer-layer film is 90 percent, and the volume part of inorganic ceramic particles is 10 percent; and the volume part of the polymer in a middle-layer film is 50 to 80 percent, and the volume part of the inorganic ceramic particles is 20 to 50 percent. In the invention, after the outer-layer film and the middle-layer film are respectively prepared by using the polymer as a basal body and the inorganic ceramic particles as a disperse phase and adopting a spin coating technology, the outer-layer film and the middle-layer film are combined together by adopting a hot pressing process to obtain the multilayered structural polymer-based dielectric composite material. The composite material provided by the invention has the advantages of high dielectric constant, good adhesive property, simple preparation process and the like.

Owner:BEIJING UNIV OF CHEM TECH

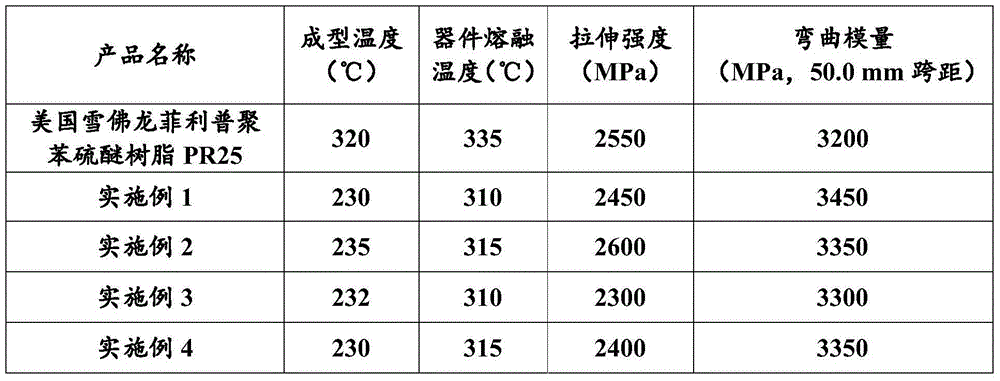

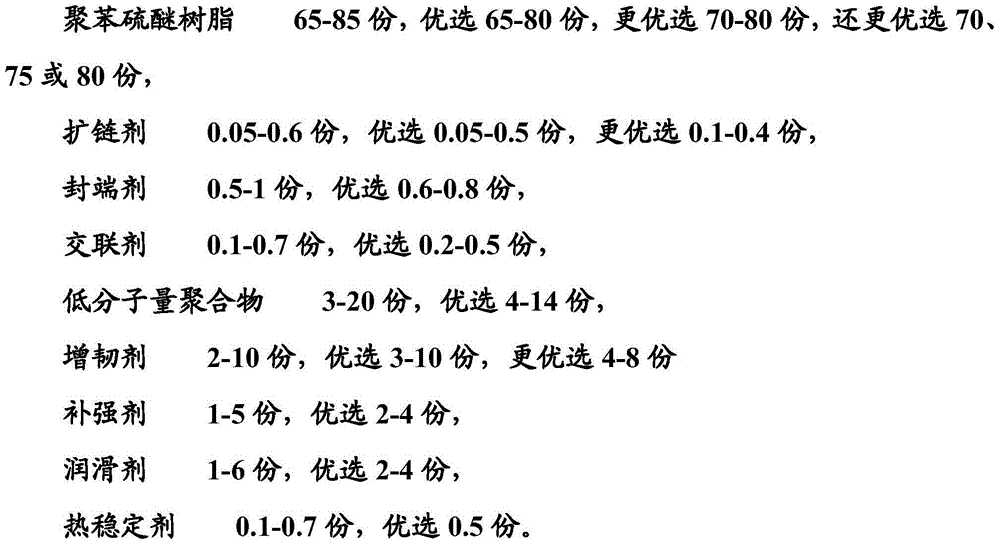

Modified polyphenylene sulfide resin suitable for 3D printing as well as preparation method and application of modified polyphenylene sulfide resin

ActiveCN104650587AIncrease profitImprove toughnessAdditive manufacturing apparatusDevice formToughness

The invention discloses modified polyphenylene sulfide resin suitable for 3D printing. The modified polyphenylene sulfide resin is a combination of the following components in parts by weight: 65-85 parts of polyphenylene sulfide resin, 0.05-0.6 part of a chain extender, 0.5-1 part of an end capping agent, 0.1-0.7 part of a crosslinking agent, 3-20 parts of low-molecular-weight polymer, 2-10 parts of a toughening agent, 1-5 parts of a reinforcing agent, 1-6 parts of a lubricating agent and 0.1-0.7 part of a heat stabilizer. The polyphenylene sulfide resin is modified by adopting the simple processes of mixing materials and extruding, and the processing temperature of the modified polyphenylene sulfide resin is reduced greatly. The melting temperature of the device formed by printing by adopting the modified polyphenylene sulfide resin is not reduced significantly, and the toughness is improved, and thus the polyphenylene sulfide resin can be widely applied to the field of 3D printing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

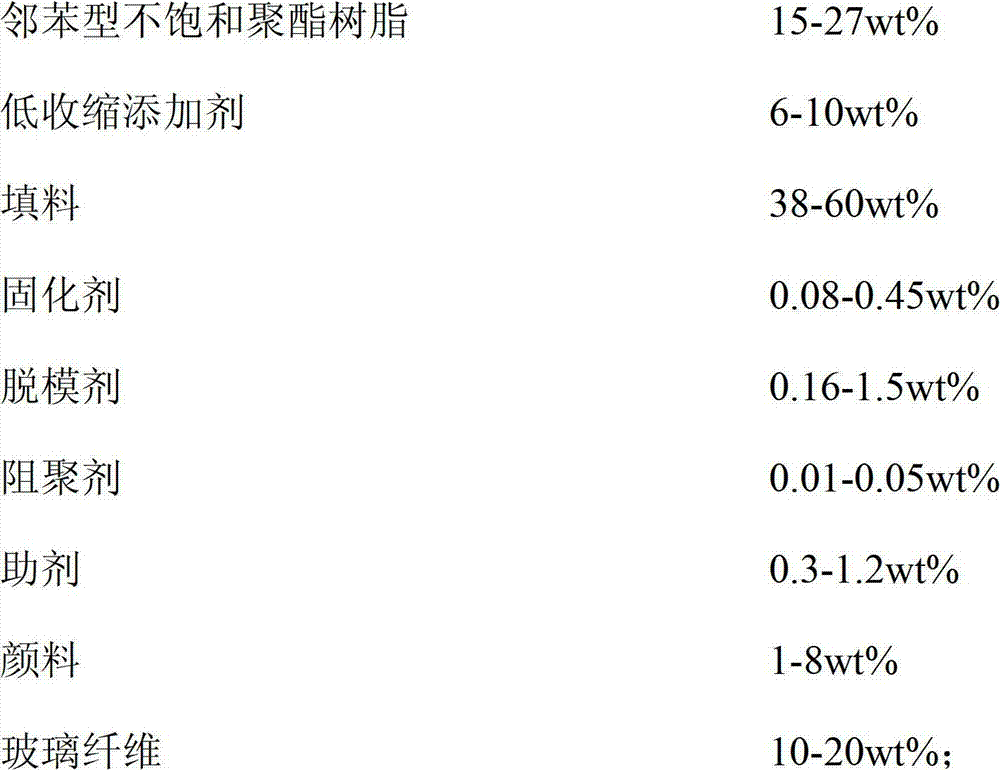

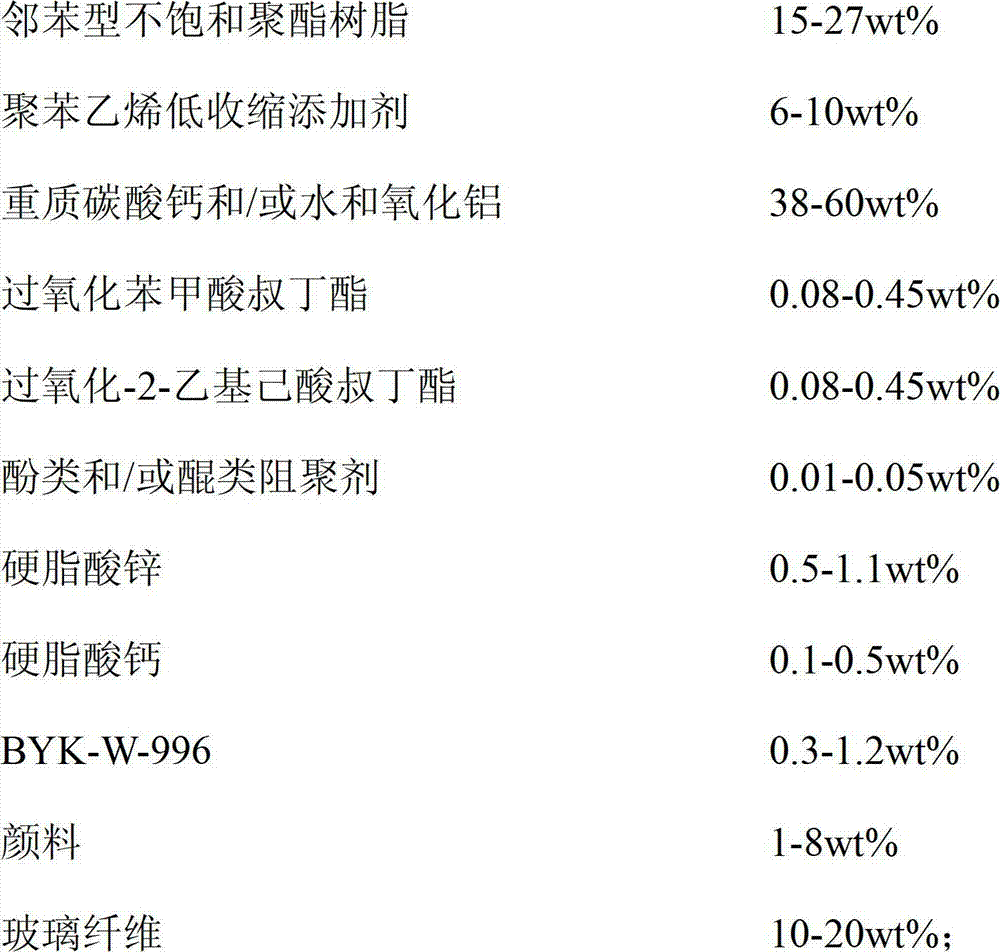

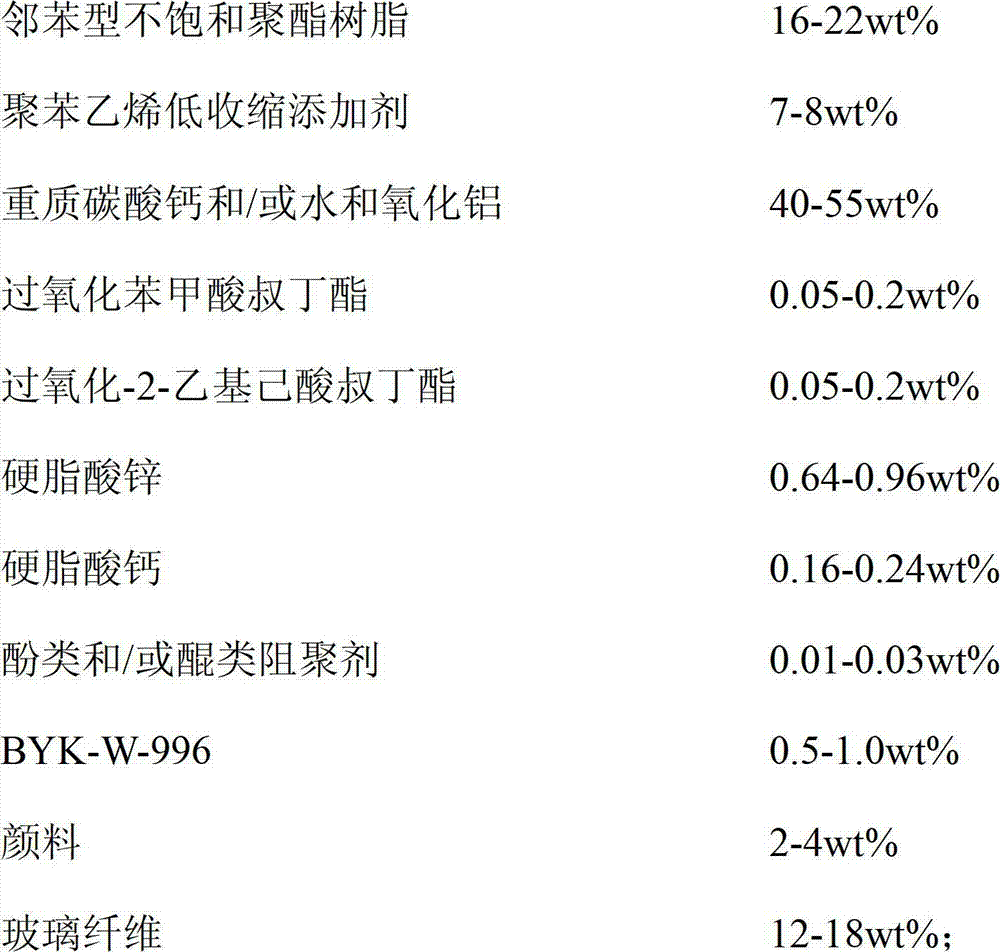

Low temperature and low pressure BMC (Bulk Molding Compound) material, preparation method thereof and purpose thereof

The invention relates to a low temperature and low pressure BMC (Bulk Molding Compound) material. The low temperature and low pressure BMC material comprises unsaturation resin, a low shrinkage additive, a filler, a curing agent, a mold release agent, a polymerization inhibitor, an auxiliary and glass fiber, wherein the mold release agent is a mixture of zinc stearate and calcium stearate. The molding temperature of the low temperature and low pressure BMC material provided by the invention is only 110-130 DEG C and is reduced by about 30% when compared with the molding temperature of the traditional BMC molding material; and the molding pressure of the low temperature and low pressure BMC material provided by the invention is only 70-100 kg / cm2 and is reduced by about 50% when compared with the molding pressure of the traditional BMC molding material.

Owner:WUXI XINHONGTAI ELECTRIC TECH CO LTD

Ultralow-expansion coefficient high transparent glass-ceramics and method for producing its product

The present invention relates to a Li2O-Al2O3-SiO2 system ultra-low expansion coefficient high-transparency glass-ceramic and production method of the products. Calculated by weight percentage, the ultra-low expansion coefficient high-transparency glass-ceramic is composed of 3.2 to 4.6 percent of Li2O, 18.0 to 23.6 percent of Al2O3, 64.1 to 69.4 percent of SiO2, 0.3 to 0.8 percent of MgO, 0.8 to 2.5 percent of BaO, 0.3 to 0.8 percent of R2O, 0.01 to 0.4 percent of Y2O3, 1.8 to 2.5 percent of TiO2, 1.6 to 2.4 percent of ZrO2, 1.1 to 1.8 percent of P2O5, 0.6 to 1.5 percent of Sb2O3, 0.3 to 1.0 percent of NaCl and 1.0 to 2.0 percent of NH4NO3. The heat-resistant glass plates and heat-resistant glass products can be manufactured by using the formula and the corresponding forming die. The present invention has the advantages that the production technique is simple, the produced products have low expansion coefficient, good transparency, high thermal impact temperature, high strength, have constant transparency when being used under the temperature of 700 Celsius system for a long time, the products have long service life, etc.

Owner:广东科迪微晶玻璃实业有限公司 +1

Nano silicon dioxide microporous heat insulator and preparation method thereof

The invention discloses a nano silicon dioxide microporous heat insulator, which is characterized by consisting of 55 to 85 percent of nano silicon dioxide, 10 to 35 percent of opaquer, 3 to 10 percent of inorganic fibers and 2 to 12 percent of reaction activator. In the invention, the nano silicon dioxide is used as a basic raw material, added with carborundum and titanium dioxide serving as an opaquer, reinforced by basalt fibers or aluminium silicate fibers and subjected to a chemical reaction at a low sintering temperature of 200 to 450 DEG C in the presence of the reaction activator consisting of activator sodium fluoride and aluminium dihydrogen phosphate, so that compounds such as fluosilicate and phosphosilicate are formed on the contact surfaces of the particles of the raw materials to connect the particles of the raw materials into a whole. When the technique disclosed by the invention is used for preparing the nano silicon dioxide microporous heat insulator, the process is simple and the manufacturing is convenient; and the prepared product has high heat insulating performance, and the coefficient of heat conductivity at the average temperature of 500 DEG C is less thanor equal to 0.038w / m.k.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

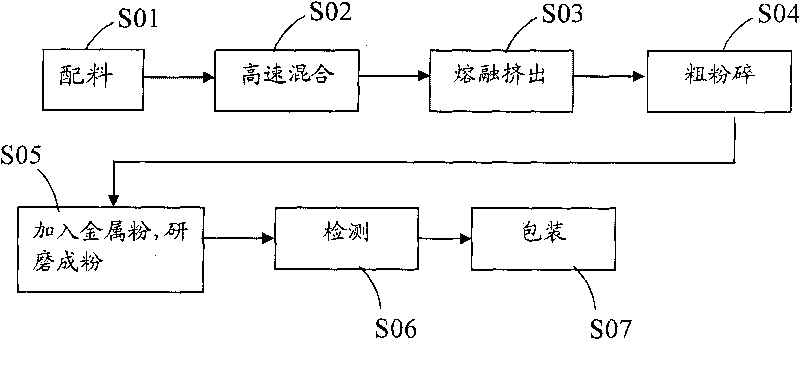

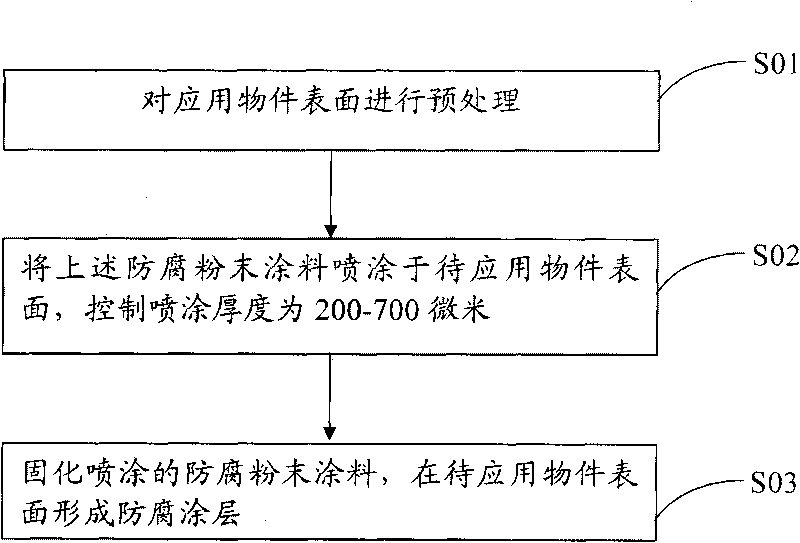

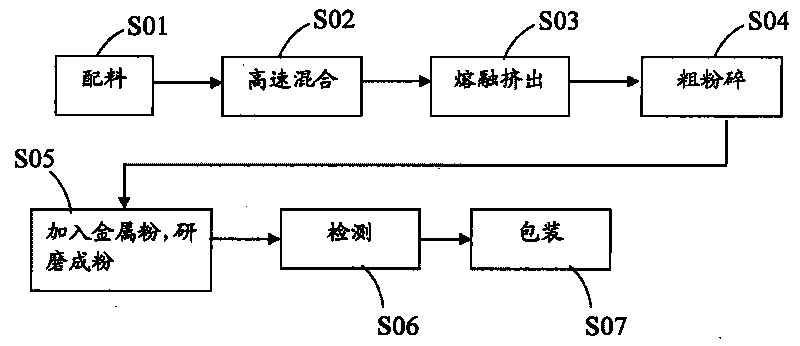

Antiseptic powder coating, manufacturing method and applying method thereof

The invention provides an antiseptic powder coating which comprises the following components by weight percent: 30-60% of bisphenol A-epoxy resin matrix, 10-20% of polyester resin, 20-40% of filler, 1-10% of additive, 0.2-2% of carbon powder and 1-9% of metal powder, wherein the metal powder is zinc powder, aluminum powder or zinc aluminum powder. The invention further provides a manufacturing method and an applying method of the antiseptic powder coating. Bisphenol A-epoxy resin is adopted as a matrix in the antiseptic powder coating, thereby being characterized by no toxicity, abrasion resistance and the like through polyester resin curing and realizing strong adhesive to metal. The carbon powder can improve the temperature resistant performance of the coating, and the metal power containing zinc / aluminum powder can play the roles of seawater resistance and salt fog resistance. The antiseptic powder coating has the advantages of easy obtainment of preparation raw materials and low manufacturing cost, when in application, the antiseptic powder coating is directly sprayed on the surface of an object at one time, and the coating is thicker, thereby simplifying the construction process, reducing the construction cost, and having broad application prospects.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

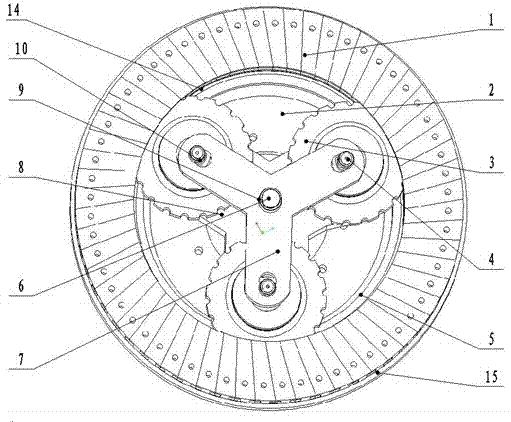

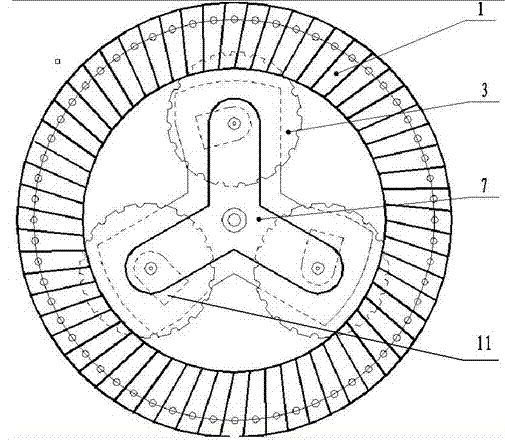

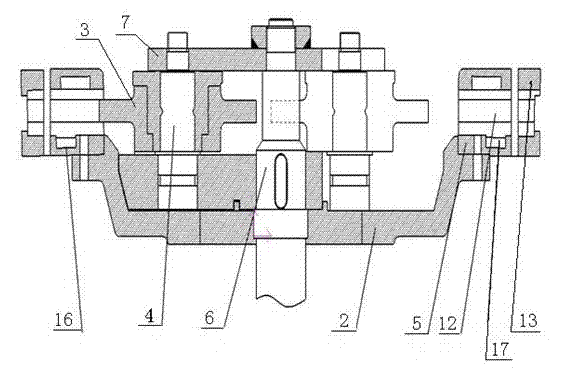

Straw briquetting machine

InactiveCN102873899AIncrease productivityExtended service lifeShaping pressPulp and paper industryBriquette

The invention relates to a straw briquetting machine. The straw briquetting machine comprises a ring die (1), a base (2), a pressing roller (3), an eccentric shaft (4), a pressure cover (5), a main shaft (6), an abrasive disk (8) and an upper pressure plate (13), wherein the central hole of the base (2) is provided with a central main shaft (6); the straw briquetting machine is characterized in that the main shaft (6) drives the abrasive disk (8) to rotate; the abrasive disk (8) drives the eccentric shaft (4) to rotate; and the pressing roller (3) rotates around the main shaft (6) on the eccentric shaft (4). Straw fed from a feeding port (14) of the ring die (1) is continuously compressed in the space of an abrasive cavity and extruded from a discharge port (15) to prepare finished products, and the straw briquettes are formed. By adopting the straw briquetting machine, the production efficiency of the straw briquette is improved, the power consumption is reduced, the production cost is lowered; and a roller is connected with the abrasive disk through the eccentric shaft, so that the gap between the roller and an extrusion die can be adjusted, the production efficiency is improved, the service lives of the extrusion die and the roller are prolonged, and the safety is enhanced.

Owner:JIANGSU YUANTONG AGRI MACHINERY TECH

Heatproof anticorrosion wear resistant powdery paint, preparation method and application

ActiveCN103073972AImprove anti-corrosion performanceHigh temperature resistanceLiquid surface applicatorsAnti-corrosive paintsPotassium perfluorobutanesulfonatePolyvinyl butyral

The invention relates to a heatproof anticorrosion wear resistant powdery paint, a preparation method and an application. The powdery paint comprises the following raw materials by weight: 80-100 parts of phenol novolac epoxy, 25-35 parts of bisphenol A-epoxy resin matrix, 4.0-5.5 parts of dicyandiamide, 80-120 parts of cast stone powder, 10-40 partsof polypropylene, 5-8 parts of graphite, 5-8 parts of component A, 2-5 parts of aluminum hydroxide, 1-3 parts of magnesium oxide, 5-7 parts of ethyl lactate, 1-3 parts of polyvinyl butyral, 5-8 parts of copper oxide, 1-5 parts of carbon nanotube, 0.1-2 parts of 2,4,5-trichlorobenzene sulfonate, 0.2-1 part of potassium perfluorobutanesulfonate and 0.1-0.4 parts of phenylsulfonyl benzene sulfonic acid potassium. According to the invention, phenol novolac epoxy is taken as a base, the bisphenol A-epoxy resin matrix is added, the carbon nanotube is added in the anticorrosion paint, the heatproof and anticorrosion performances of the paint can be enhanced, and the coating process is simple.

Owner:BEIJING SINOPERM TECH

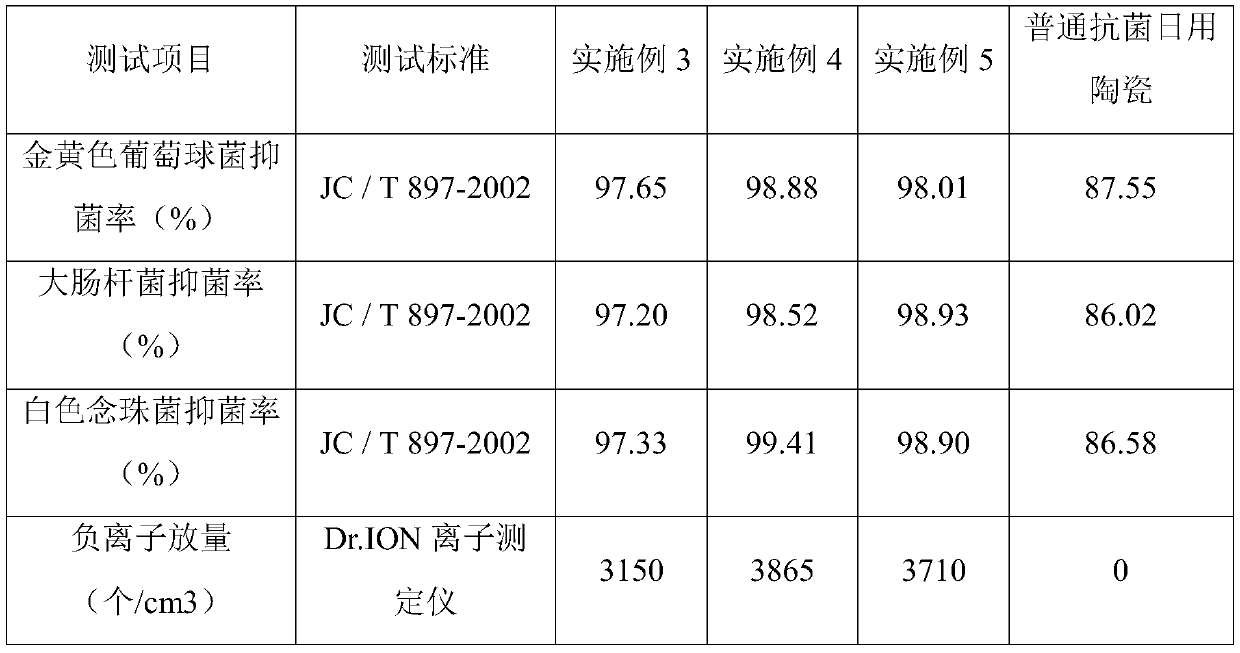

Antibacterial environment-friendly daily ceramic and preparation method thereof

InactiveCN110015884AImprove antibacterial propertiesIncrease the release of negative ionsClaywaresPotassiumCalcite

The invention discloses antibacterial environment-friendly daily ceramic and a preparation method thereof. The blank body of the ceramic comprises the following raw materials: in parts by weight, 30-45 parts of kaolin, 20-25 parts of clay, 12-15 parts of potassium feldspar, 14-18 parts of Songshui feldspar, 8-11 parts of cooked talcum powder, 5-8 parts of tourmaline, 2-5 parts of opal, 3-6 parts of microcline, 0.8-1.2 parts of a nano-zirconium phosphate sliver-loaded antibacterial agent, 1.5-2.5 parts of nano titanium dioxide and 4-7 parts of shell powder, and a glaze layer includes the following raw materials: in parts by weight, 30-45 parts of kaolin, 15-20 parts of albite, 12-15 parts of quartz, 10-15 parts of calcite, 2-4 parts of zinc oxide, 7-10 parts of tourmaline, 3-5 parts of opal, 3-5 parts of microcline, 1.2-1.8 parts of a nano-zirconium phosphate sliver-loaded antibacterial agent, 2-4 parts of nano-titanium dioxide and 8-12 parts of shell powder. The daily ceramic has a good antibacterial effect, large release amount of negative ions, low sintering temperature and energy saving.

Owner:FUJIAN PROVINCE DEHUA COUNTY GRANGTOP CERAMICS CO LTD

Method for improving thermoplastic plastics shaping manufacturability and capability

InactiveCN101245179AExcellent performance retentionLow viscosityPowdery paintsPolyamide coatingsThermoplasticEngineering

The invention relates to a method for improving thermoplastics forming manufacturability and property, in particular to that: a relatively small amount of light-cured crosslinking monomers, oligomers, photoinitiators and photosensitizers are utilized for being blended with a large amount of thermoplastics so as to lower the viscosity of a bending system to improve the forming manufacturability and the property of the thermoplastics and the composite materials; the thermoplastics and the composite materials are made by the following raw materials calculated by weight portion: thermoplastics: 60 to 95 portions; light-cured crosslinking monomers which are acrylic monomers: 5 to 20 portions; oligomers which are epoxy oligomers: 5 to 20 portions; photoinitiators: 1 to 4 portions and photosensitizers: 0.5 to 2 portions. The method for improving thermoplastics forming manufacturability and property can improve and increase the property of the thermoplastics and the composite materials, and the technology can lead the thermoplastics and the rotational mode products, composite materials products, powder coating and injection and extrusion products to have key breakthrough in property and application, which can promote the development of new composite materials.

Owner:WUHAN UNIV OF TECH

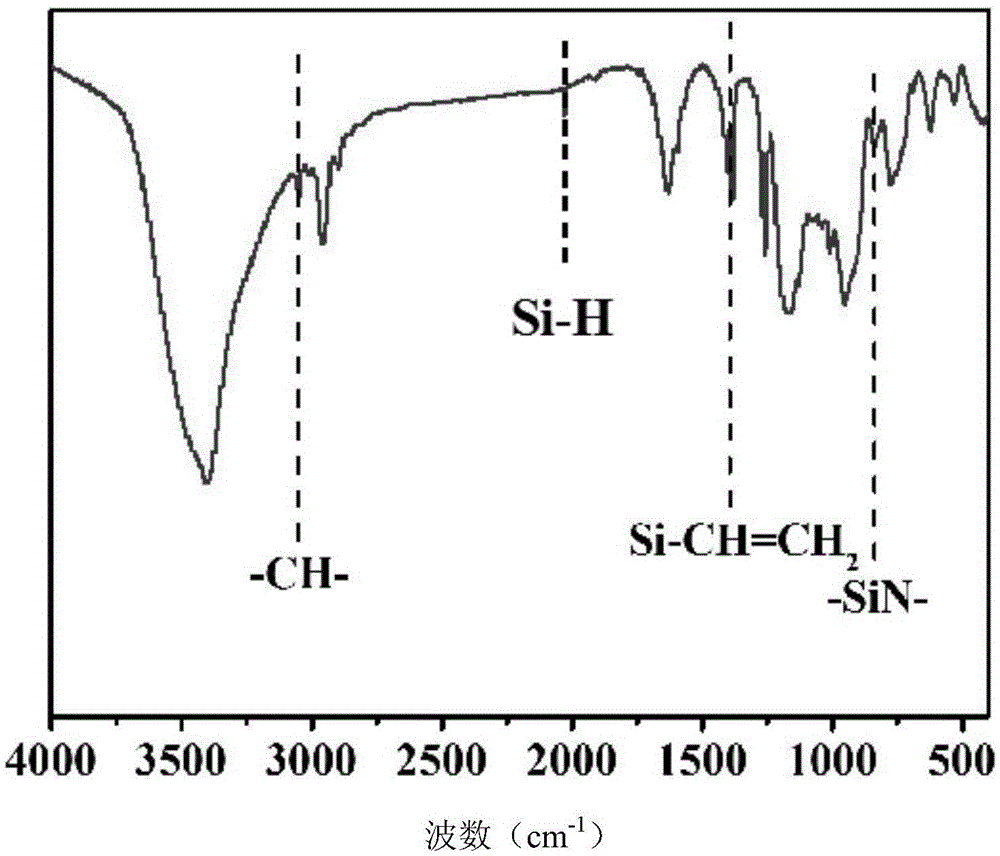

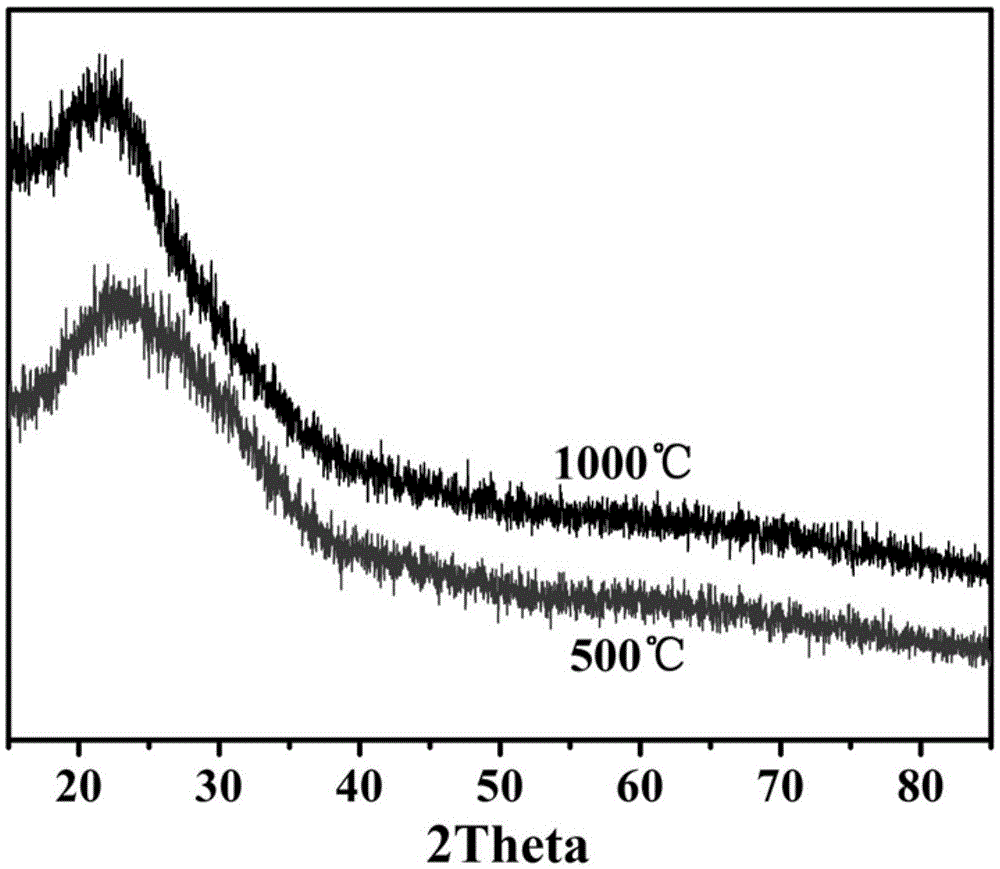

SiCN aerogel and preparation method thereof

The invention discloses a SiCN aerogel. The raw materials comprise polyvinyl silazane containing -CH=CH2 bond or also containing both -Si-H bond in the molecular structure, and divinylbenzene / dicumyl peroxide. A polymer precursor conversion ceramic preparation method and an aerogel preparation method are conduced to prepare the SiCN aerogel with specific surface area of 100-200 m<2> / g, porosity of 80-90% and density of 0.05-0.15 g / mL. The SiCN aerogel of the invention is a novel nano-porous ceramic material with extremely high porosity and specific surface area, and low density.

Owner:厦门纳美特新材料科技有限公司

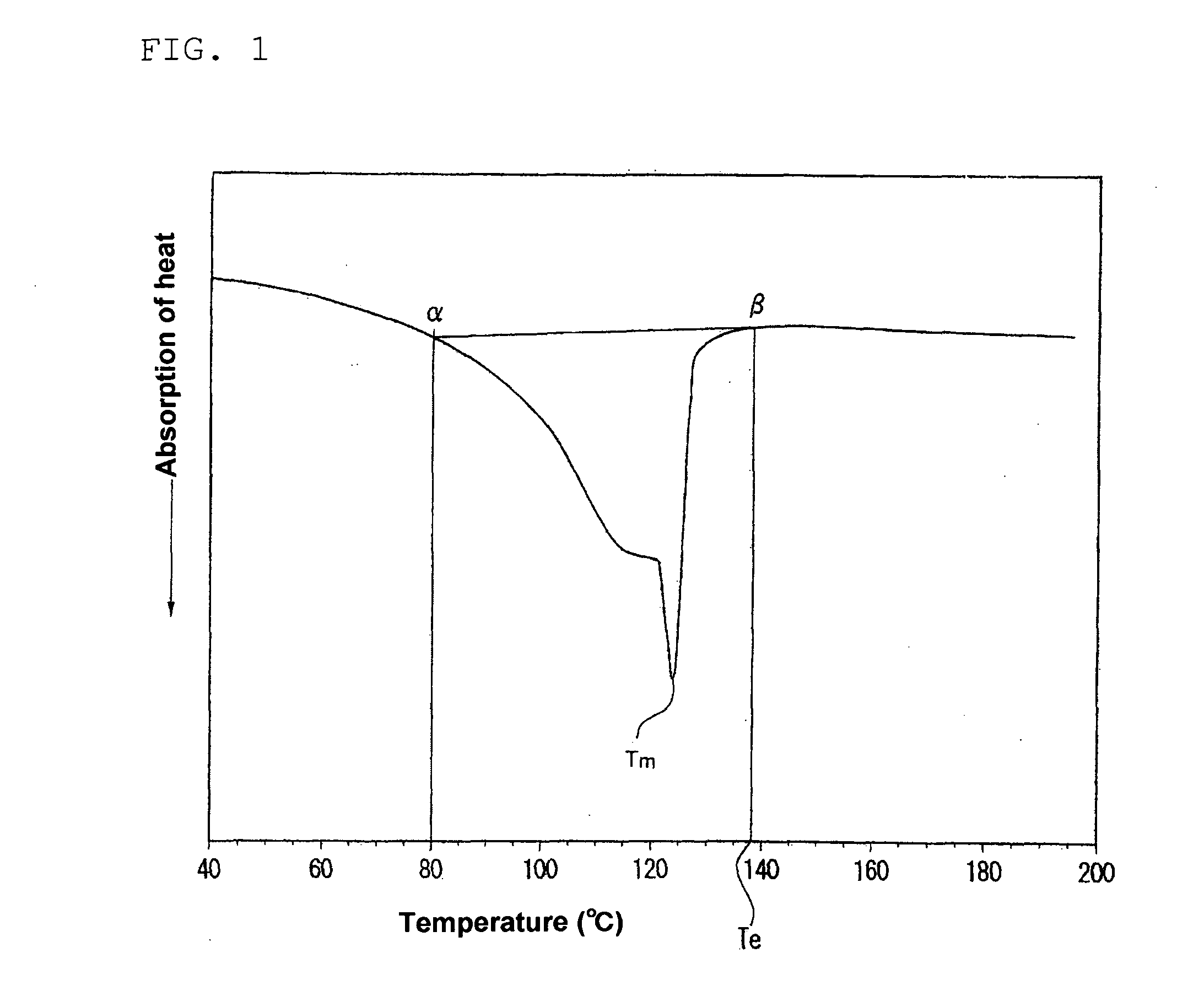

Polypropylene resin foamed bead and molded article thereform

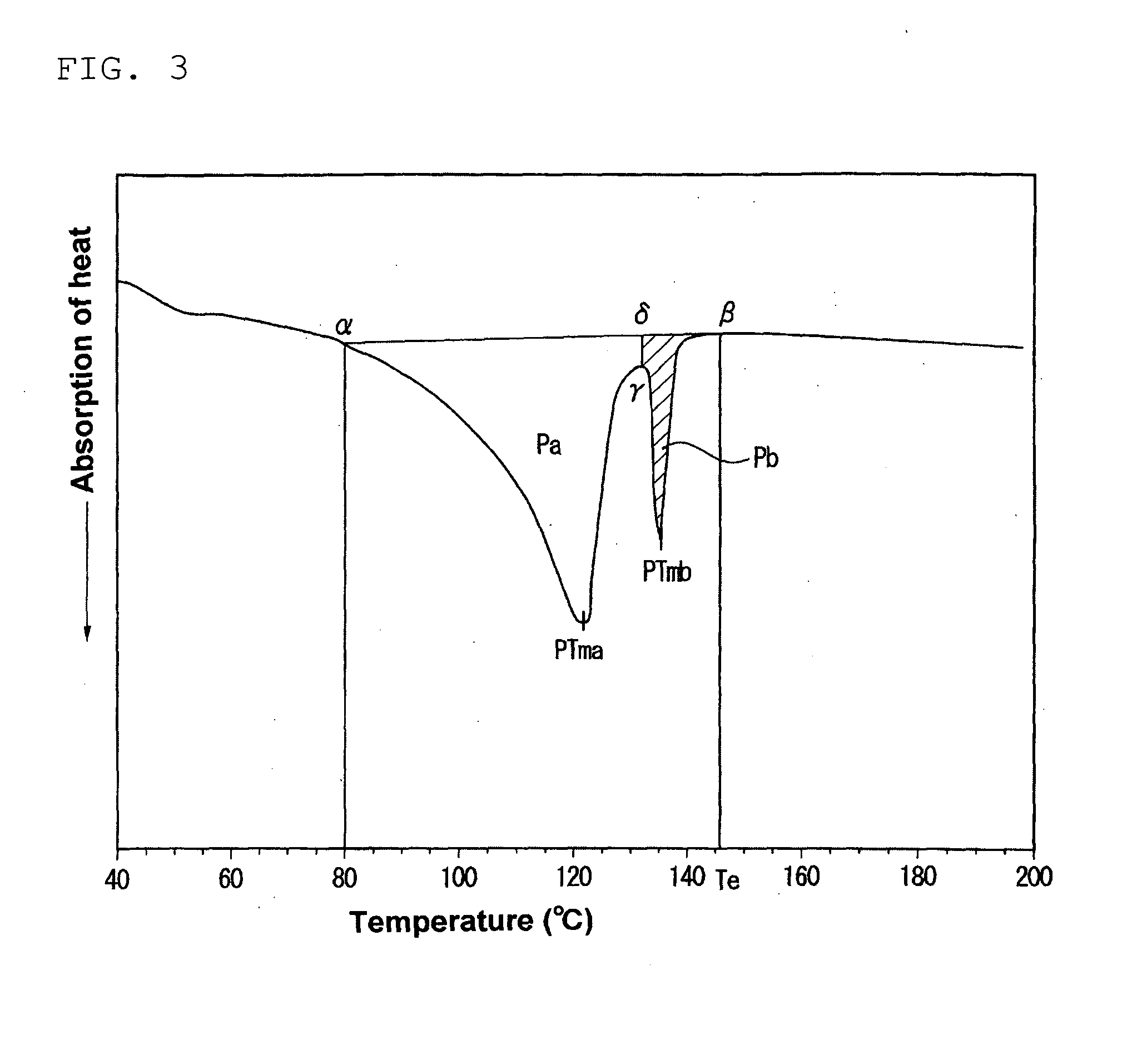

Improved polypropylene resin foamed beads that without detriment to the excellence in properties, such as compression properties and heat resistance, characterizing the polypropylene resin foamed beads, can provide a polypropylene resin foamed bead molded article with equal properties by an molding conducted at low heating temperature. There are disclosed polypropylene resin foamed beads composed of a polypropylene resin of 115 to 135° C. melting point and 500 MPa or higher Olsen flexural modulus. The amount of ash at the surface of the foamed beads is 3000 wt. ppm or less (including 0). With respect to the foamed beads, in the first DSC curve obtained by heating 1 to 3 mg of polypropylene resin foamed beads from room temperature to 200° C. at a temperature elevation rate of 10° C. / min by the use of a differential scanning calorimeter, there appear not only one or more endothermic peak (Pa) having the peak temperature within a temperature zone not higher than the melting point of the resin but also one or more endothermic peak (Pb) having the peak temperature within a temperature zone exceeding the melting point of the resin and not lower than 130° C. The total calorific value of the endothermic peak (Pb) is in the range of 2 to 12 J / g. Further, there is disclosed a foamed bead molded article obtained by molding the above foamed beads.

Owner:JSP CORP

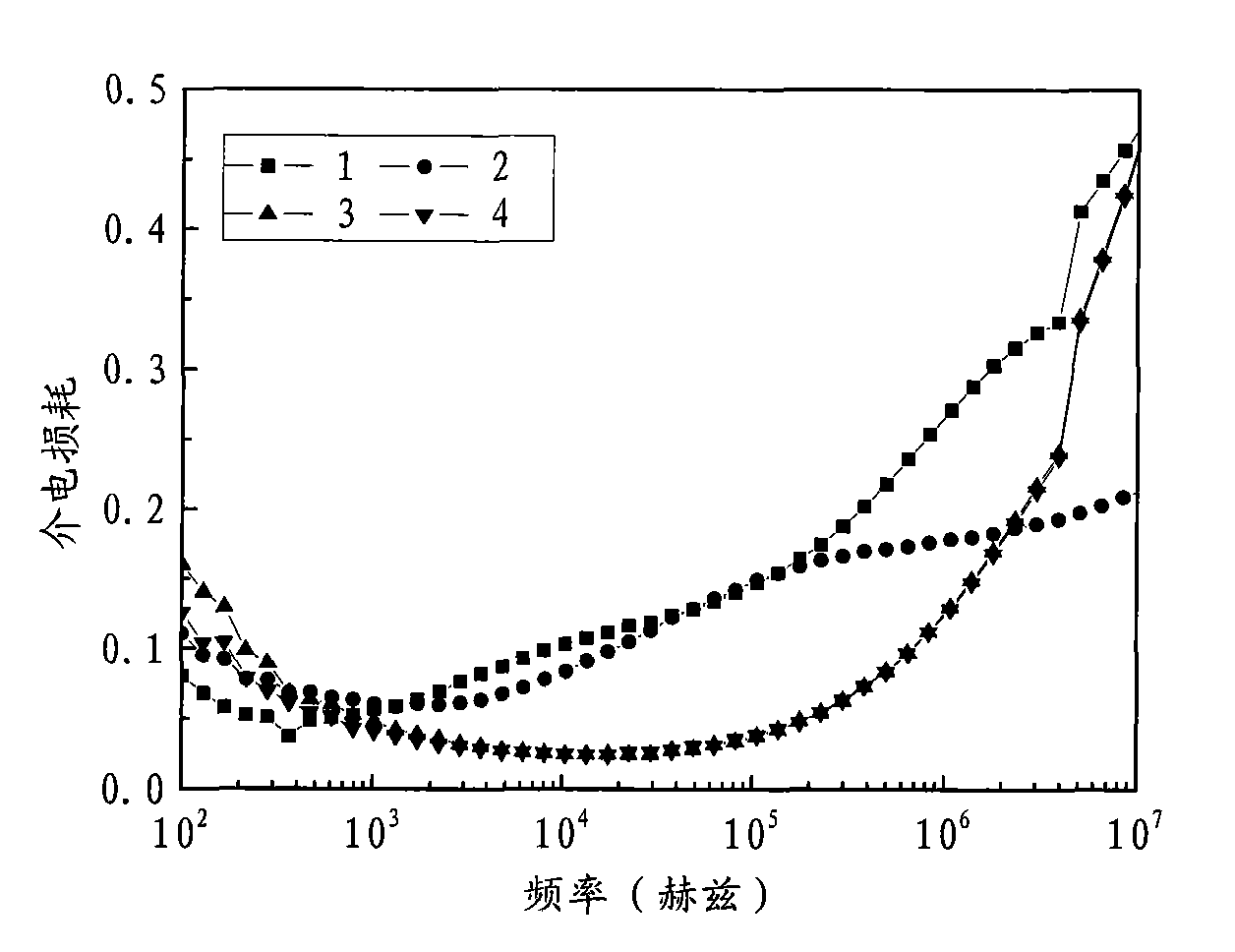

Three-phase composite high-dielectric-property material, manufacturing method and processing method

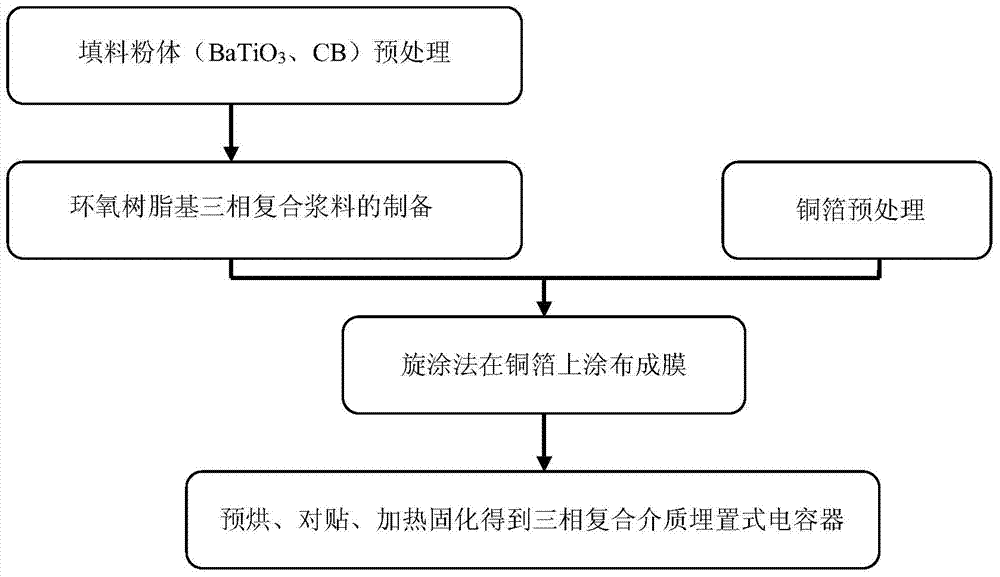

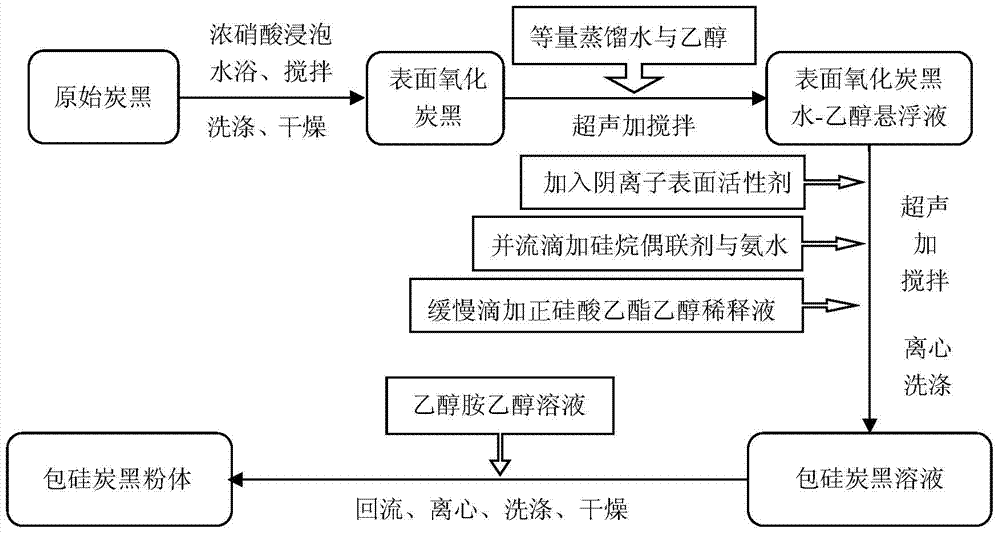

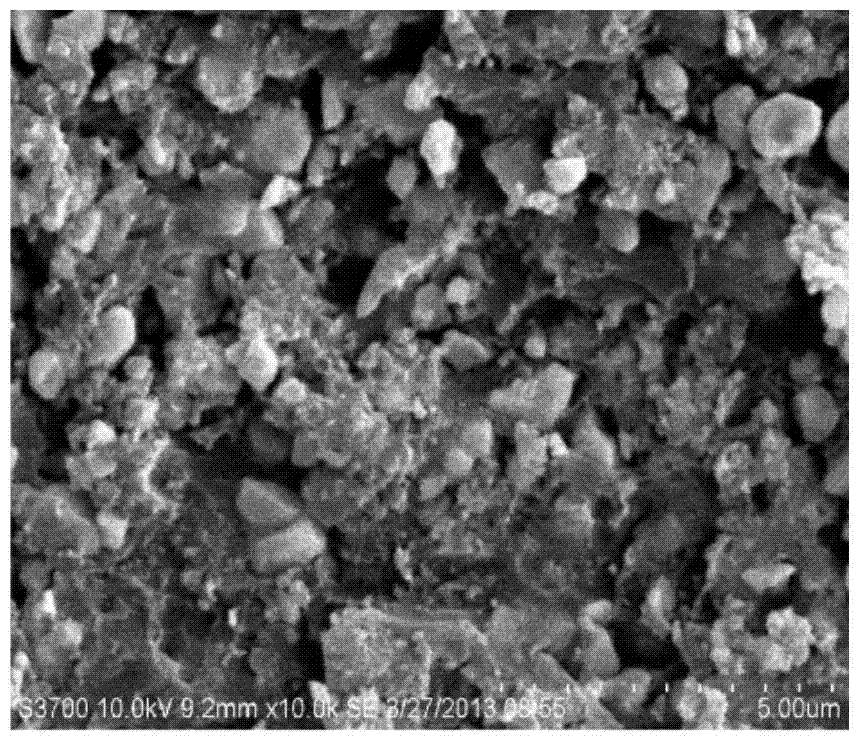

The invention provides a three-phase composite high-dielectric-property material, a manufacturing method and a processing method. The three-phase composite high-dielectric-property material comprises surface-activated barium titanate, silicon package carbon blank and epoxy resin. The three-phase composite high-dielectric-property material is manufactured according to the following steps of (1) preprocessing barium titanate, (2) preprocessing carbon blank, (3) reprocessing powdery surface-oxidized carbon blank, (4) preprocessing epoxy resin and (5) taking and adding surface-activated barium titanate and silicon package carbon blank into a epoxy resin butanone solution. The processing method includes the following steps of (1) material preprocessing, (2) curing agent preprocessing, (3) copper foil preprocessing, (4) surface coating and (5) solidifying. According to the three-phase composite high-dielectric-property material, the manufacturing method and the processing method, under the premise that dielectric loss is controlled, conductive particles are used for replacing a part of ferroelectric ceramics to manufacture a conductor / ceramics / a polymer three-phase composite dielectric material, wherein the conductor / the ceramics / the polymer three-phase composite dielectric material can effectively improve the dielectric constant of a polymer matrix composite material. Meanwhile, the problems that carbon blank is difficult to disperse in a polymer and dielectric loss is increased due to the fact that a conductive path is formed after the content of the carbon blank rises are effectively solved.

Owner:SOUTH CHINA UNIV OF TECH +1

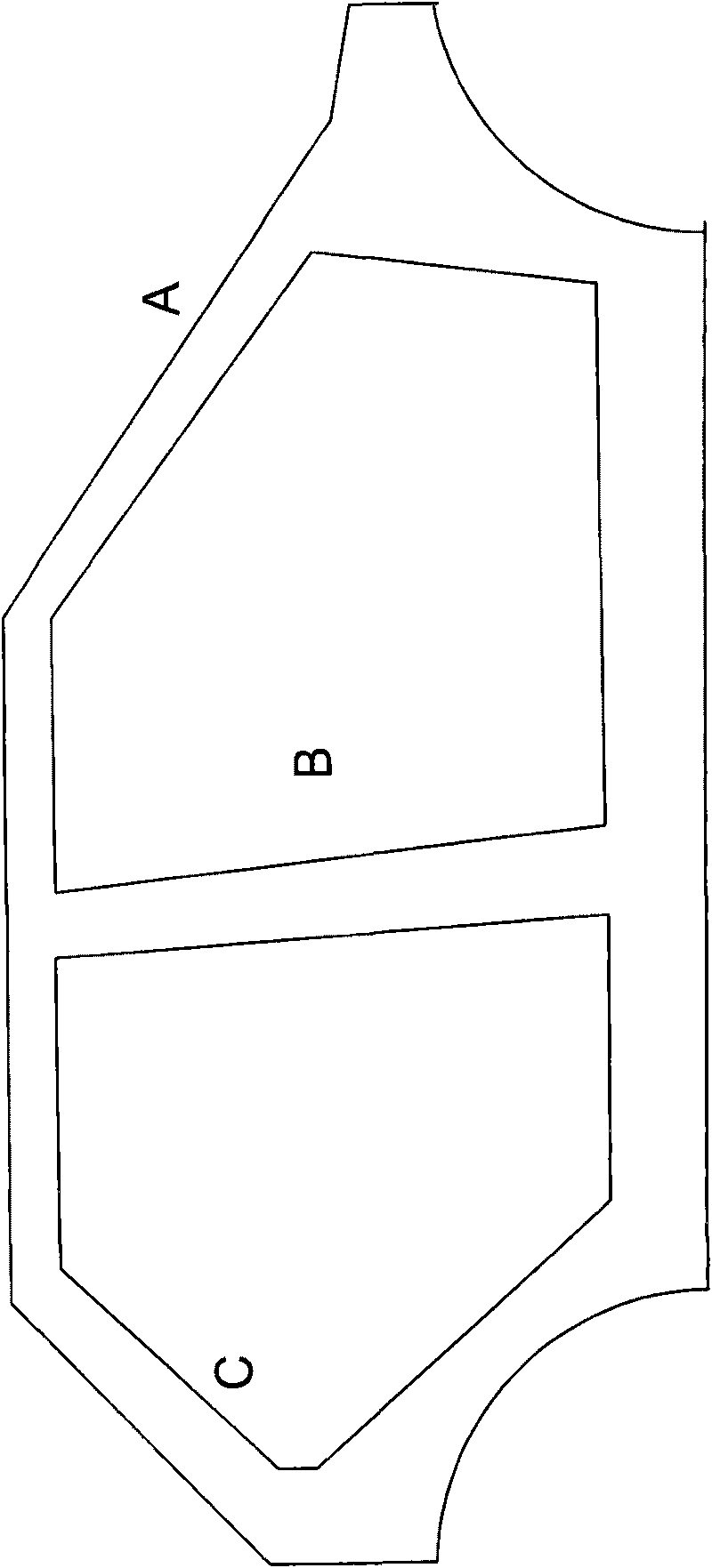

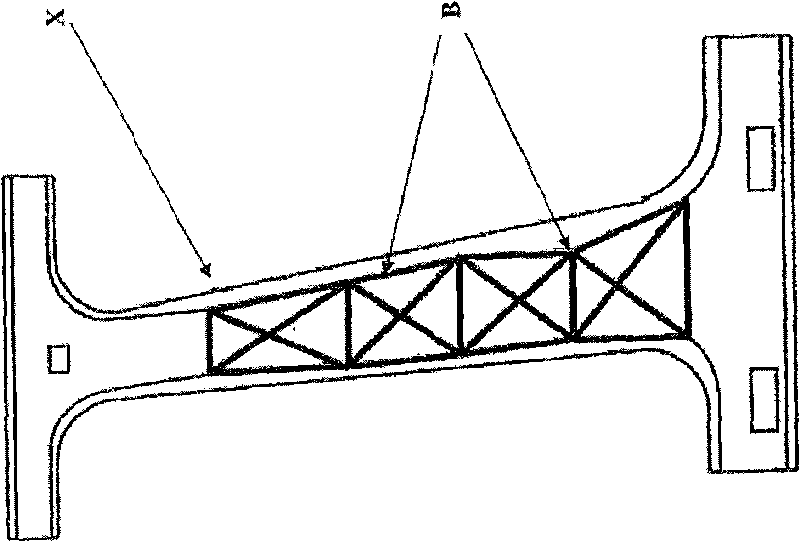

Lightweight component in hybrid construction

InactiveCN101735602AImprove bending abilityHigh torsional stabilitySeat framesSuperstructure subunitsThermoplasticEngineering

The present invention relates to lightweight components in hybrid construction, also referred to as hybrid components or hollow-chamber lightweight components, comprising a base body which is made by aluminum of which the surface is preprocessed and is reinforced by means of thermoplastics and is suitable for the transmission of high mechanical loads, wherein, the thermoplastics is added with a special glidant for improving physical property.

Owner:LANXESS DEUTDCHLAND GMBH

Method of preparing apertured micropore plastic product semifusion mould press shaping method

A semi-fusing and die-pressing method for preparing the milliporous plastic product with open pores includes such steps as mixing the synthetic resin particles with at least one of plasticizer, viscosity increaser, foaming agent and disperser, preheating, storing in a temp and humidity constant container, filling in preheated die, hot die pressing, and cooling while holding the pressure.

Owner:SICHUAN UNIV

Method for producing black transparent microcrystal glass and its products

The invention provides a method for producing black transparent microcrystal glass and its products, wherein the base glass comprises Li2O, RO, Al2O3 and SiO2, the coloring agent comprises NiO, V2O5 and Fe2O3, the crystal nucleus agent comprises TiO2, Zr2O5 and P2O5, the weight percentage of each component being, Li2O: 2.5-4.7%, RO: 2-3%, Al2O3: 17-26%, SiO2: 62-72%, NiO: 0.05-0.1%, V2O5: 0.1-0.2%, Fe2O3: 0.05-0.1%, TiO2: 2-2.5%, ZrO2: 1.5-2.5%, P2O5: 1-2%. The formulation and related die arrangement can be used for making electromagnetic oven plate, disc, microwave oven disc, roasting and grilling plate, baking oven cloche, frying pan and various pots.

Owner:广东科迪微晶玻璃实业有限公司 +1

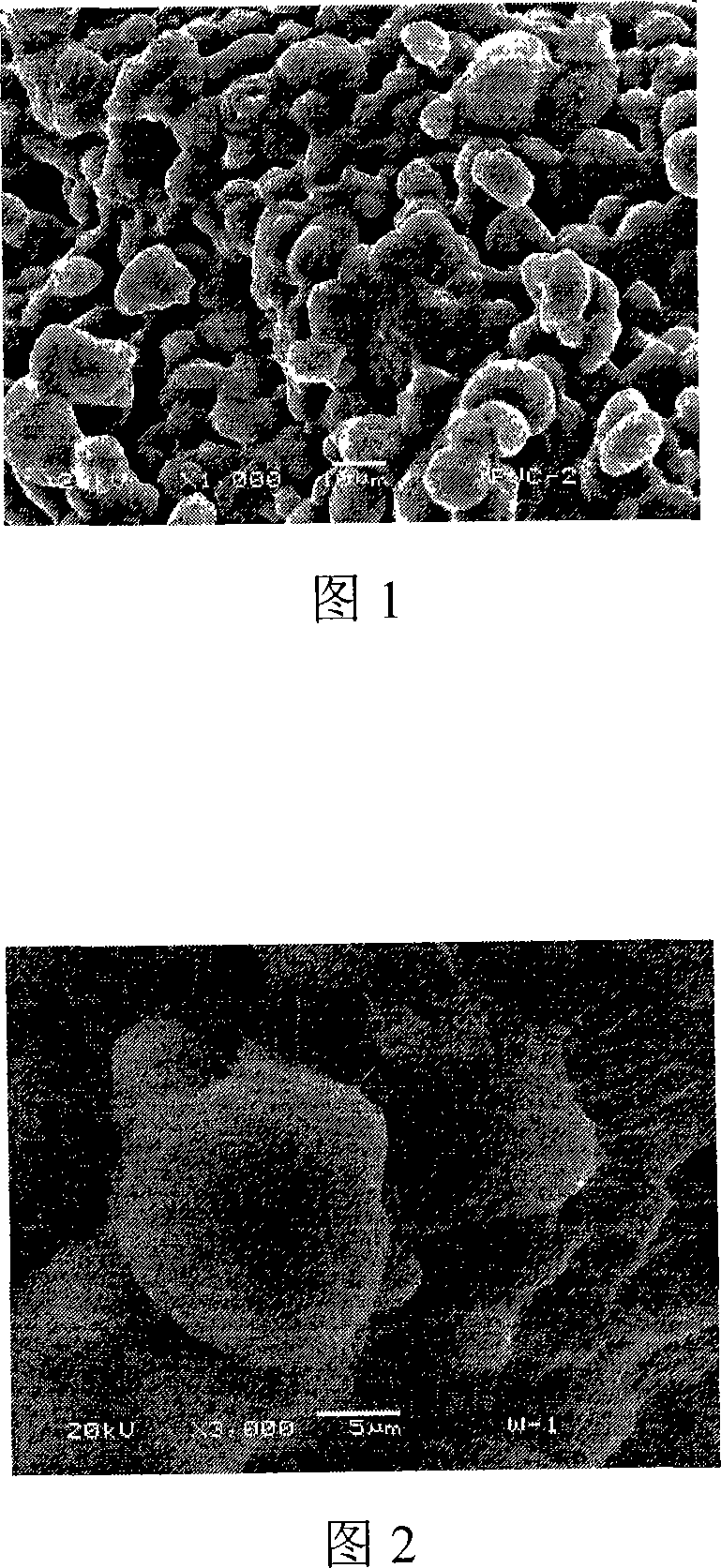

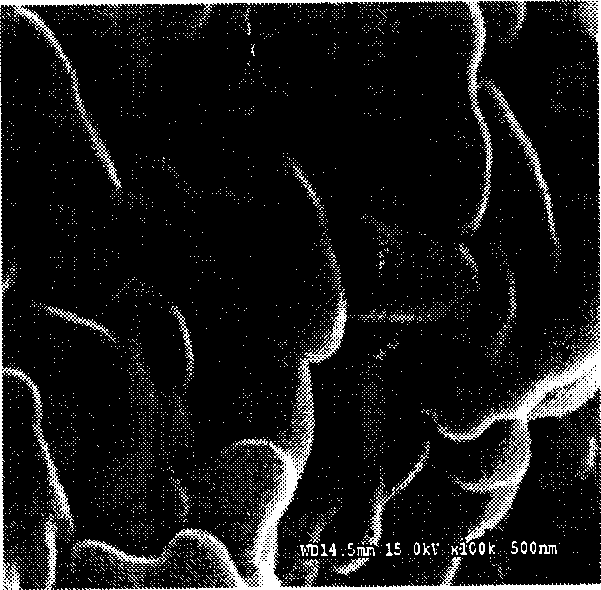

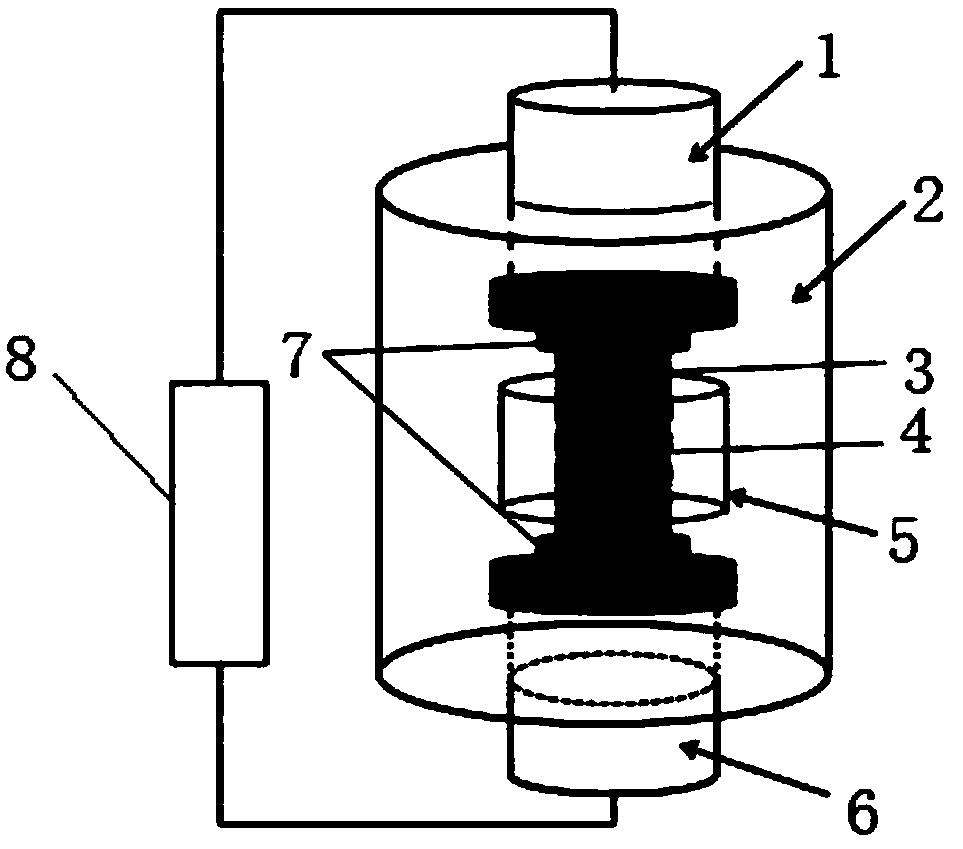

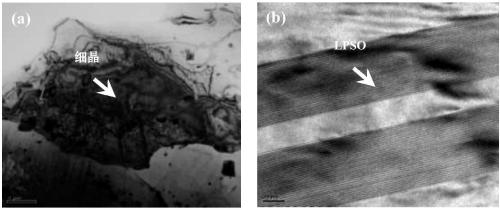

Preparation method for adjusting and controlling high-toughness magnesium alloy containing fine LPSO structure through spark plasma sintering

The invention provides a preparation method for adjusting and controlling a high-toughness magnesium alloy containing a fine LPSO structure through spark plasma sintering. The preparation method comprises the following steps: A, Mg-RE-Zn-Zr / Mn alloy powder is prepared through atomizing powder; B, the Mg-RE-Zn-Zr / Mn alloy powder is subject to the spark plasma sintering to obtain the high-toughnessmagnesium alloy with the fine LPSO structure; and C, aging treatment is carried out on the magnesium alloy prepared in the step B. According to the preparation method, the pressure, temperature, timeand heating rate of the spark plasma sintering are regulated and controlled, the tissue of the alloy is regulated and controlled, and compared with an existing magnesium alloy forming mode, the forming temperature of the method is low, the forming speed is high, the tissue of products can be regulated and controlled, the crystal grain is small, the LPSO structure is fine, and therefore the mechanical property is improved.

Owner:SHANGHAI JIAO TONG UNIV +1

Modified nylon material with high smooth surface level, and preparation method

This invention discloses a modified nylon material with high surface smoothness and luster. The modified nylon material is composed of: PA66 resin 61-67 wt.%, PA6 resin 3-8 wt.%, long glass fibers 5-10 wt.%, calcium silicate 20-25 wt.%, antioxidant 0.2-0.4 wt.%, and lubricant 0.1-0.3 wt.%. Compared with solely PA66-filled modified nylon materials, the modified nylon material in this invention has such advantages as high surface smoothness and luster, good mechanical performance, and can be used in production of plastic shells such as electric appliance shell, motor shell, and automobile wheel shell.

Owner:ANHUI KEJU NEW MATERIALS

Amorphous copolyester and preparation method thereof

The invention discloses amorphous copolyester and a preparation method thereof. The preparation method of the amorphous copolyester comprises the following steps: (1) in an inert atmosphere, carrying out an esterification reaction of at least two diacids and at least two diols under a condition of the presence of a catalyst; and (2) adding a stabilizer and a catalyst into the system after the esterification reaction in the step (1), and carrying out a polycondensation reaction under a vacuum condition to obtain the amorphous copolyester. The amorphous copolyester has the characteristic of low molding temperature; the amorphous copolyester has no melting point, the molding temperature is decided by the softening temperature, and the highest molding temperature is only about 100 DEG C. The amorphous copolyester has the characteristics of small product shrinkage percentage and good dimensional stability; and since the copolyester is amorphous, no product shrinkage problem exists, and the product dimensional stability is good.

Owner:TSINGHUA UNIV

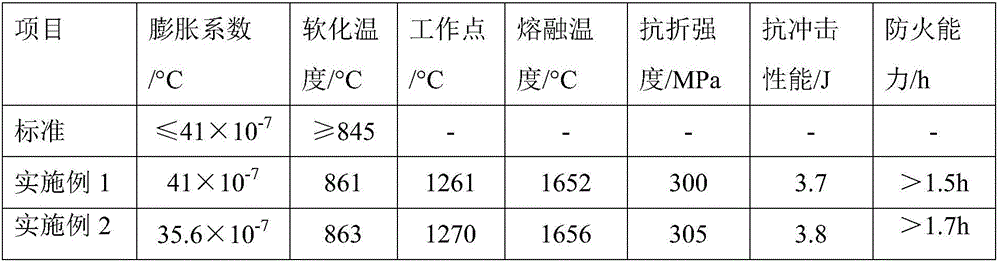

Heat-resistant borosilicate flat glass and preparation method thereof

ActiveCN106587604AEffective control of air bubblesEffective control of striaeFlat glassFire protection

The invention provides heat-resistant borosilicate flat glass and belongs to the technical field of fireproof glass. The heat-resistant borosilicate flat glass is prepared from, by weight, 78.1-82% of SiO2, 1-5% of Al2O3, 9-14% of B2O3, 3-6% of Na2O, 1-5% of CaO, 0.5-2% of K2O, 0.1-3% of ZrO2 and 0.01-2% of GeO2, wherein the total content of SiO2 and B2O3 accounts for 87.1-92% of the total content of all the materials, and the weight ratio of SiO2 to B2O3 is 5.5 to 8.6. The invention further provides a preparation method of the heat-resistant borosilicate flat glass; compared with current borosilicate flat glass in the market, the heat-resistant borosilicate flat glass has a higher glass softening point and a lower linear expansion coefficient, at the same time, the melting temperature and the molding temperature are relatively low; the glass is easy to manufacture and can serve as the fireproof glass applied in the fire protection field after being tempered.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

Optical glass

InactiveUS20100304950A1Not require time-consuming operationIncrease production capacityRefractive indexGlass transition point

The present invention relates to an optical glass containing, in terms of mass % on the basis of oxides, B2O3: 10 to 20%, SiO2: 0.5 to 12%, ZnO: 5 to 19%, Ta2O5: 2.5 to 17%, Li2O: 0.2 to 3%, ZrO2: 0.6 to 4.9%, WO3: 1 to 20%, La2O3: 25 to 50%, Gd2O3: 0 to 13%, and Y2O3: 0.2 to 20%, provided that La2O3+Gd2O3+Y2O3 is 35 to 60%, in which the optical glass does not substantially contain Nb2O5, and has a refractive index (nd) of 1.82 to 1.86, an Abbe's number (νd) of 37 to 44 and a glass transition point (Tg) of 630° C. or lower.

Owner:ASAHI GLASS CO LTD

Glass fiber composition and glass fiber and composite material thereof

ActiveUS20160362327A1Low molding temperatureHigh liquidus temperatureGlass/slag layered productsGlass fiberRefractive index

The present invention provides a glass fiber composition, a glass fiber and a composite material therefrom. The glass fiber composition comprises the following components expressed as percentage by weight: 58-64% SiO2, 14-19% Al203, ≧8.8% and <11.8% CaO, 7.5-11% MgO, 0.2-2.7% SrO, 0.1-2% Na2O+K2O, 0.05-0.9% Li2O, 0.05-1% Fe2O3, 0.05-1.1% TiO2 and <0.5% F2, wherein the range of the weight percentage ratio C1=(MgO+SrO) / CaO is 0.75-1.1, and the range of the weight percentage ratio C2=CaO / MgO is less than 1.4. Said composition can effectively inhibit the crystallization tendency of glass, significantly decrease the liquidus temperature and crystallization degree of glass and also has an outstanding glass refractive index and outstanding modulus.

Owner:JUSHI GRP CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com