Low temperature and low pressure BMC (Bulk Molding Compound) material, preparation method thereof and purpose thereof

A low-temperature, low-pressure, low-shrinkage additive technology, applied in the field of BMC materials, low-temperature and low-pressure BMC materials, preparation, can solve the problems of harsh molding conditions, cost waste, energy waste, etc., to shorten the curing time and maintain the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

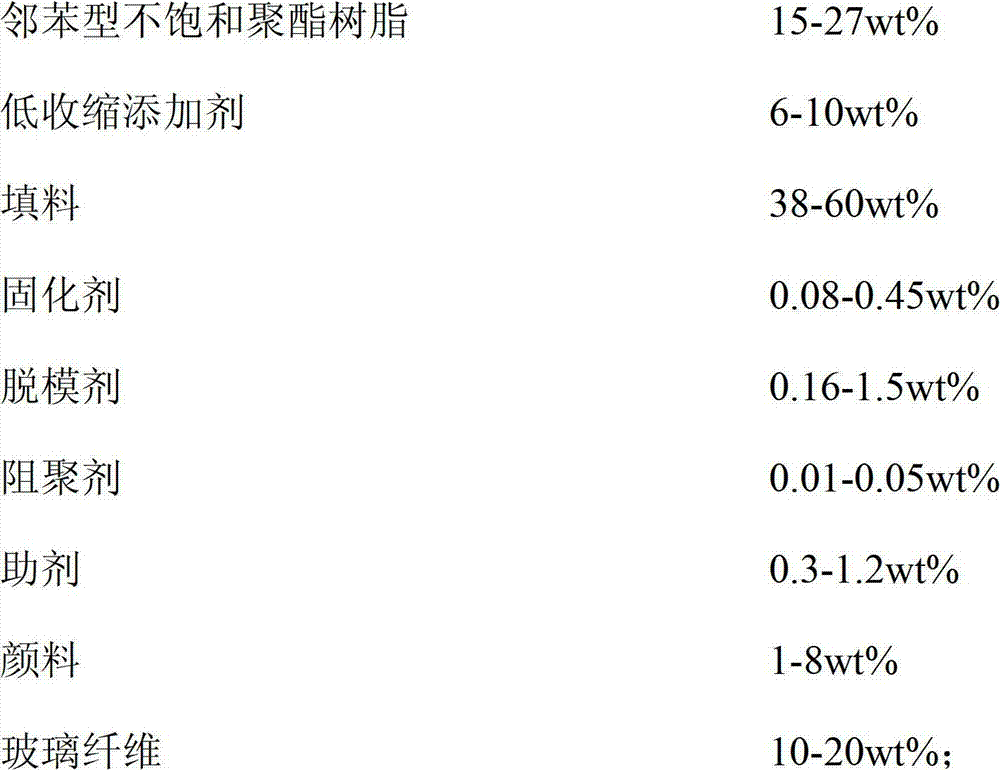

[0080] A BMC material comprises the following components by mass percentage:

[0081]

[0082] The preparation method is:

[0083] (1) Stir the unsaturated resin, low shrinkage additive, auxiliary agent, curing agent and polymerization inhibitor in the disperser for 20 minutes;

[0084] (2) Add release agent and pigment to the mixture obtained in step (1) and stir for 20 minutes at a speed of 1000 rpm to obtain a resin paste;

[0085] (3) Put the filler into the kneader, stir for 3 minutes, and the speed is 3000 rpm;

[0086] (4) Add the resin paste obtained in step (2) into the kneader described in step (3), and stir for 3 minutes; then add 10% of the glass fiber in the formula and stir together, and then add the remaining glass fiber to stir and disperse, the material manufacture complete.

Embodiment 2

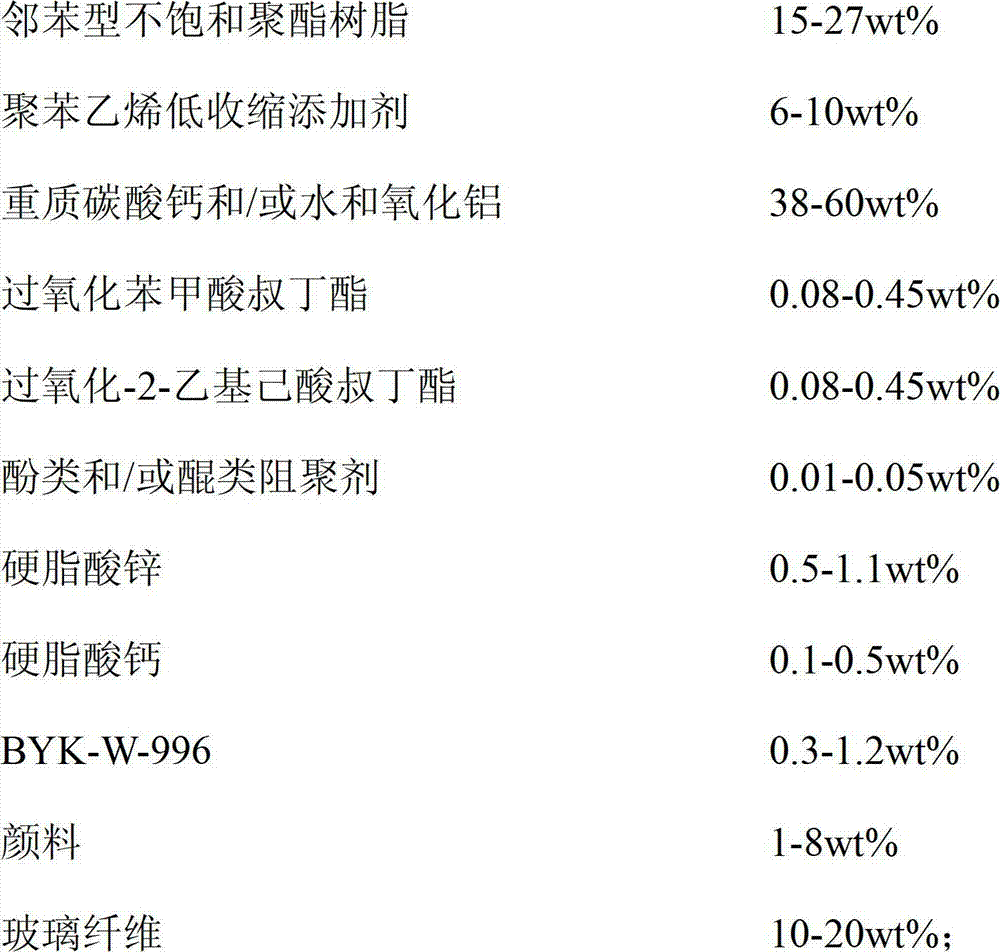

[0088] A BMC material comprises the following components by mass percentage:

[0089]

[0090] The preparation method is:

[0091] (1) Stir the unsaturated resin, low shrinkage additive, auxiliary agent, curing agent and polymerization inhibitor in the disperser for 3 minutes;

[0092] (2) Add release agent and pigment to the mixture obtained in step (1) and stir for 3 minutes at a speed of 3000 rpm to obtain a resin paste;

[0093] (3) Add the filler into the kneader, stir for 20 minutes, and rotate at 1000 rpm;

[0094] (4) Add the resin paste obtained in step (2) into the kneader described in step (3), and stir for 20 minutes; then add 10% of the glass fiber in the formula and stir together, and then add the remaining glass fiber to stir and disperse, the material manufacture complete.

Embodiment 3

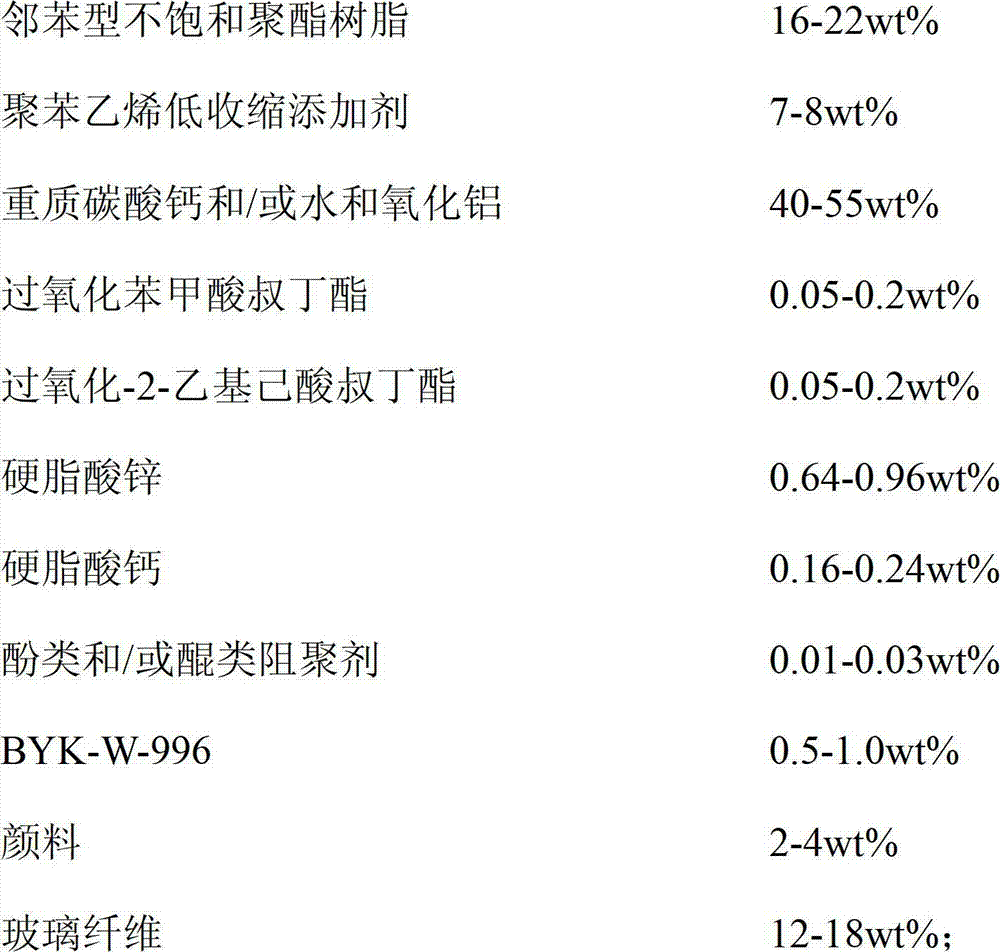

[0096] A low-temperature and low-pressure BMC material includes the following components by mass percentage:

[0097]

[0098] The preparation method is:

[0099] (1) Stir the unsaturated resin, low-shrinkage additive, auxiliary agent, curing agent, and polymerization inhibitor in the disperser for 6 minutes;

[0100] (2) Add release agent and pigment to the mixture obtained in step (1) and stir for 4 minutes at a speed of 1800 rpm to obtain a resin paste;

[0101] (3) Add the filler into the kneader, stir for 5 minutes, and rotate at 2000 rpm;

[0102] (4) Add the resin paste obtained in step (2) into the kneader described in step (3), and stir for 12 minutes; then add 10% of the glass fiber in the formula and stir together, and then add the remaining glass fiber to stir and disperse, the material manufacture complete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com