Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

159results about How to "Reduce molding pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low temperature and low pressure BMC (Bulk Molding Compound) material, preparation method thereof and purpose thereof

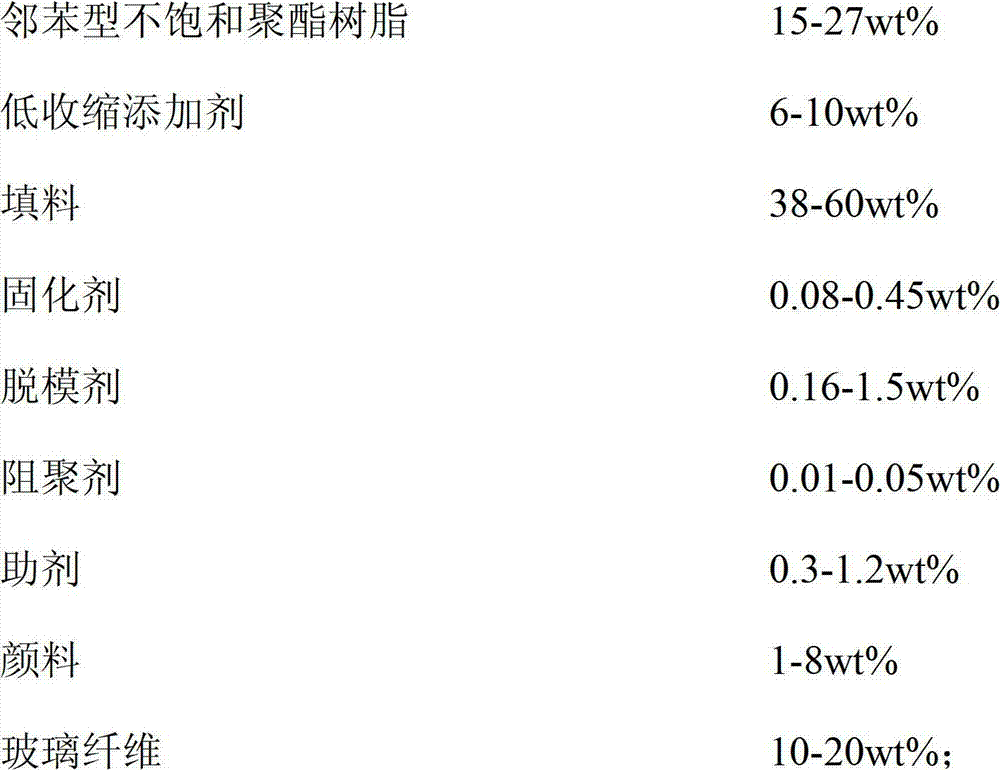

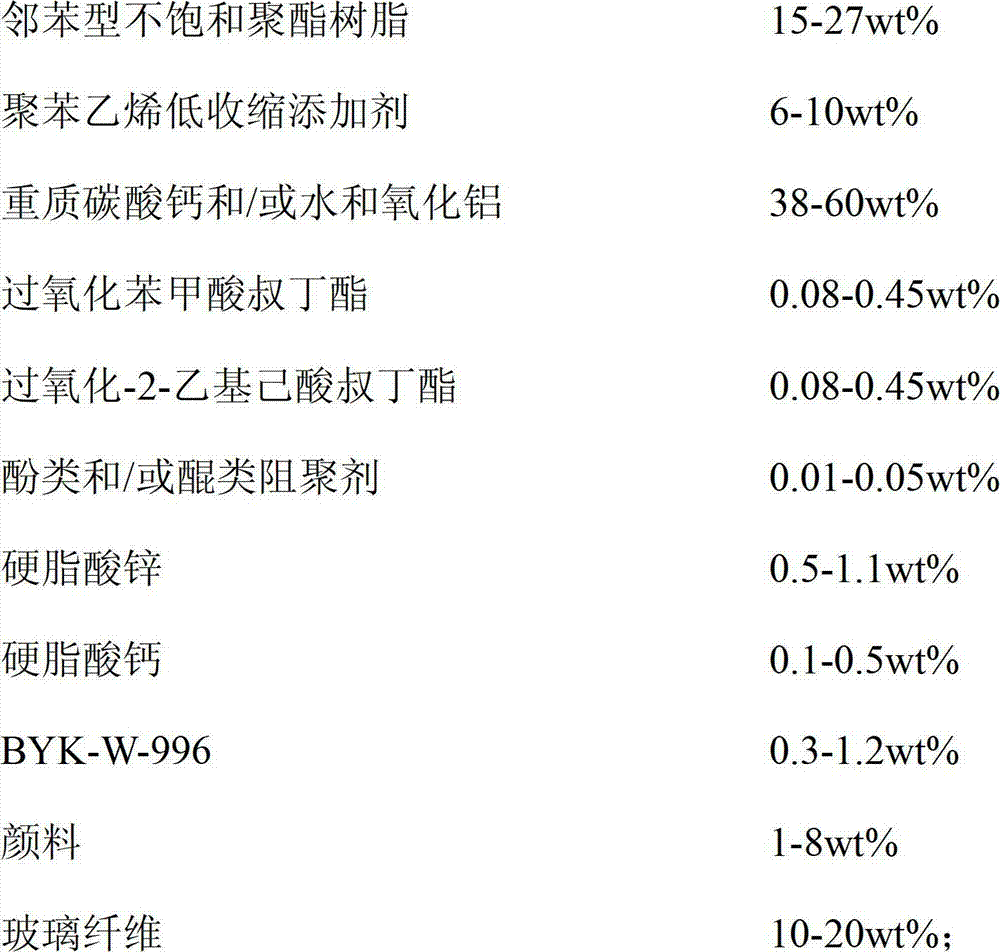

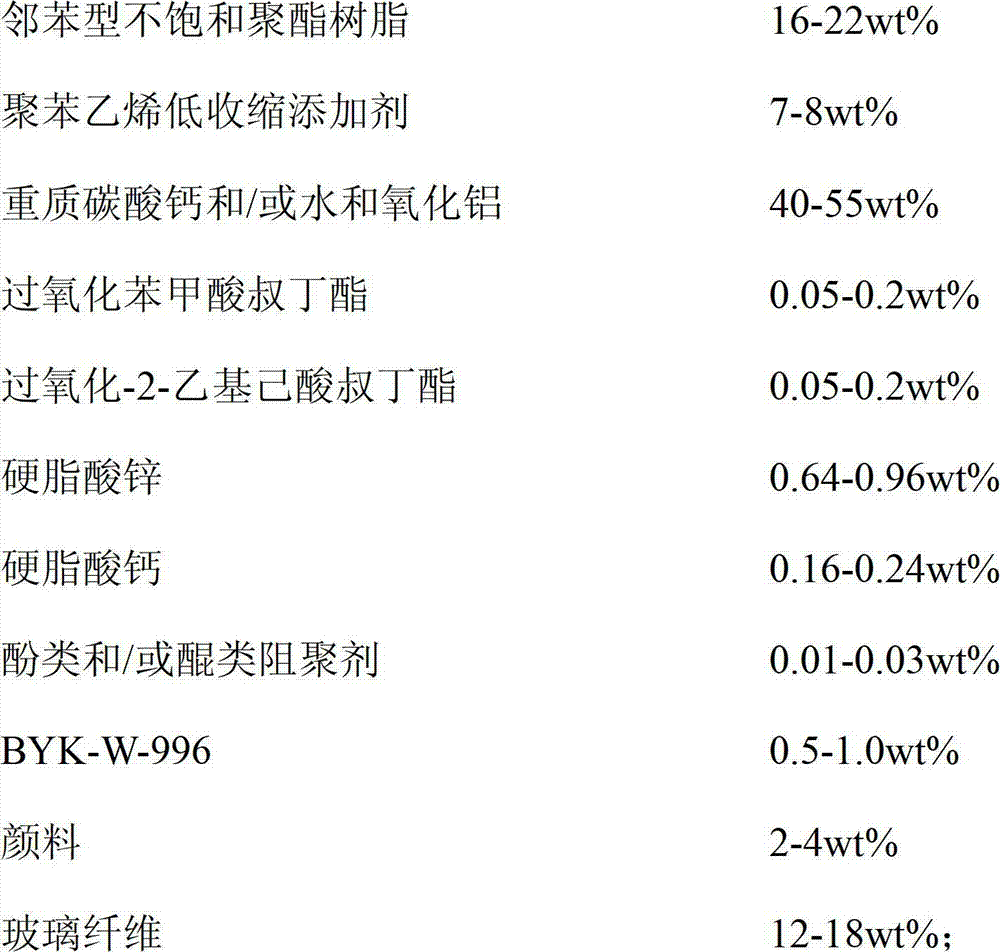

The invention relates to a low temperature and low pressure BMC (Bulk Molding Compound) material. The low temperature and low pressure BMC material comprises unsaturation resin, a low shrinkage additive, a filler, a curing agent, a mold release agent, a polymerization inhibitor, an auxiliary and glass fiber, wherein the mold release agent is a mixture of zinc stearate and calcium stearate. The molding temperature of the low temperature and low pressure BMC material provided by the invention is only 110-130 DEG C and is reduced by about 30% when compared with the molding temperature of the traditional BMC molding material; and the molding pressure of the low temperature and low pressure BMC material provided by the invention is only 70-100 kg / cm2 and is reduced by about 50% when compared with the molding pressure of the traditional BMC molding material.

Owner:WUXI XINHONGTAI ELECTRIC TECH CO LTD

Raw soil building material modification method and method for preparation of building block by use of modified raw soil

The invention discloses a raw soil building material modification method, belongs to the technical field of building materials, solves the technical problem that traditional raw soil building materials have low strength, high brittleness, poor resistance to water, and the like, first the performance of a raw soil material is improved by a chemical modification agent, a modified raw soil building block is prepared by physical pressure moulding technology, the performance of the raw soil material is improved significantly, especially aiming at vast raw soil resources in urgent need of development and utilization in Northern Shaanxi area, the method can largely use local raw soil materials, is convenient in material taking, economical and practical, strong in integrity, excellent in thermal processing property, simple in operation, easy in implementation and popularization, and to be more important, in line with the requirements of green building, and broad in application prospect.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

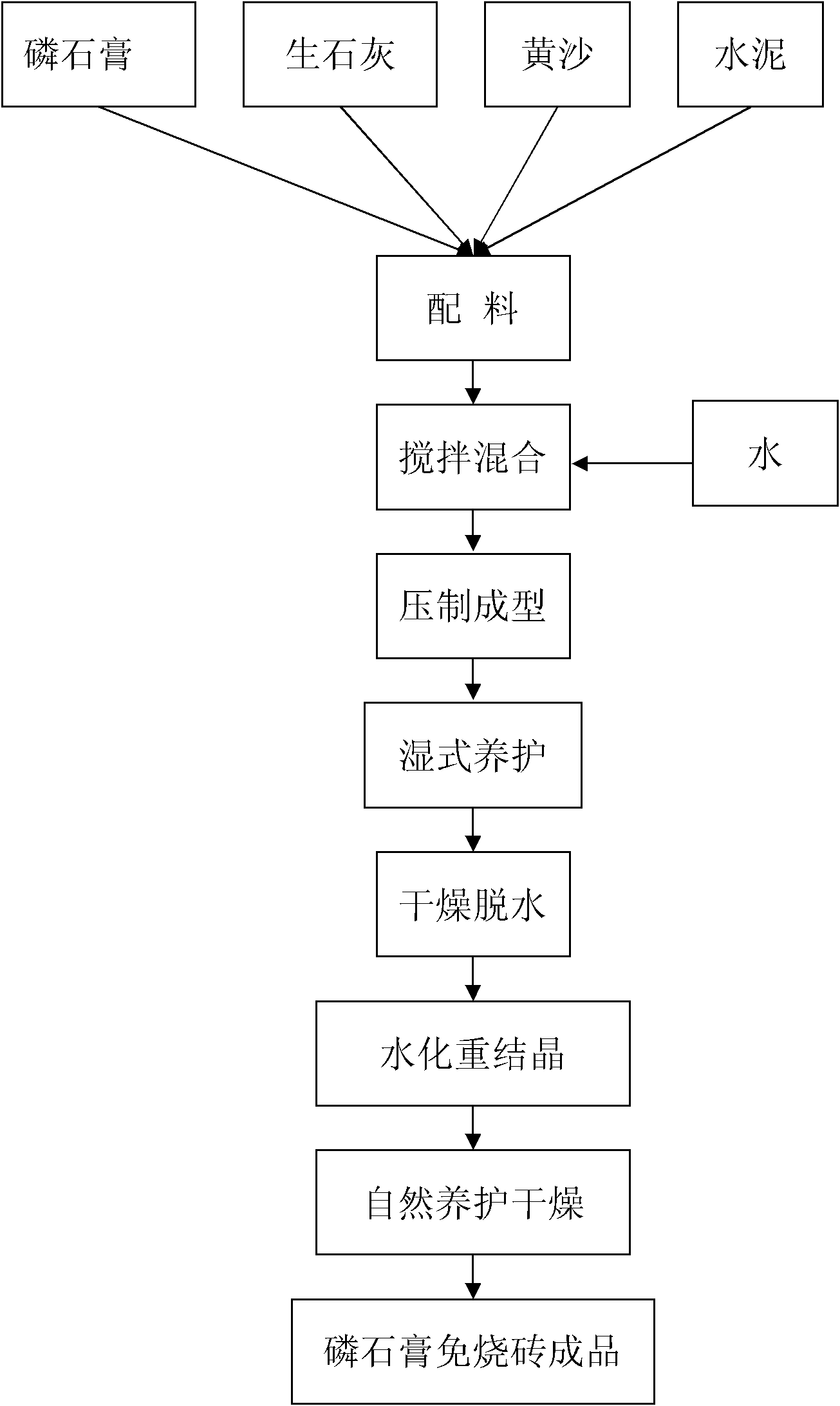

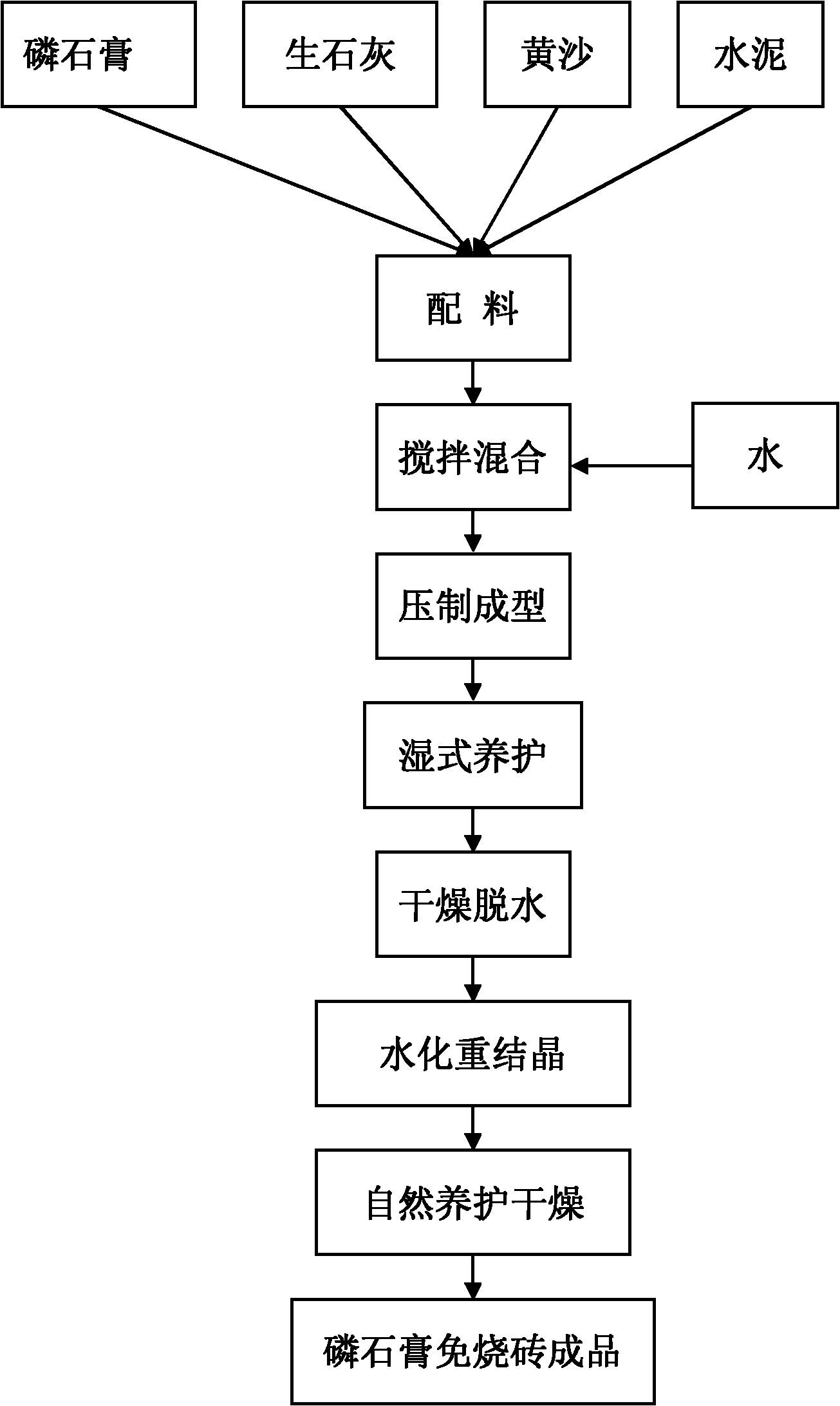

Process for producing high content phosphor-gypsum baking-free bricks

InactiveCN102172968ALow mechanical strengthLow recrystallization efficiencyCeramic shaping apparatusBrickPhosphor

The invention relates to a process for producing high content phosphor-gypsum baking-free bricks. The process for producing the high content phosphor-gypsum baking-free bricks is characterized by comprising the following steps of: (1) proportioning: selecting the following raw materials in percentage by mass: 80.0 to 90.0 percent of phosphor-gypsum, 2.0 to 3.0 percent of lime, 0.0 to 15.0 percent of yellow sand, 3.0 to 10.0 percent of cement, and water in an amount which is 3 to 8 percent of that of the proportioned raw materials; (2) stirring and mixing; (3) pressing and molding; (4) wet curing; (5) drying and dehydrating: transferring the air-dried brick blanks to a dryer, and performing drying and dehydrating treatment for 2 to 6 hours at the temperature of between 125 and 180 DEG C under normal pressure to obtain dehydrated brick blanks; (6) hydrating and re-crystallizing: naturally cooling the dehydrated brick blanks to room temperature, soaking the brick blanks into room temperature water for 0.5 to 2 hours till the brick blanks are totally soaked, and obtaining hydrated and re-crystallized brick blanks; and (7) performing natural curing and drying to obtain the phosphor-gypsum baking-free bricks. The process has the characteristics of high phosphor-gypsum content, low production energy consumption, high product strength, simple production process and strong operability.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

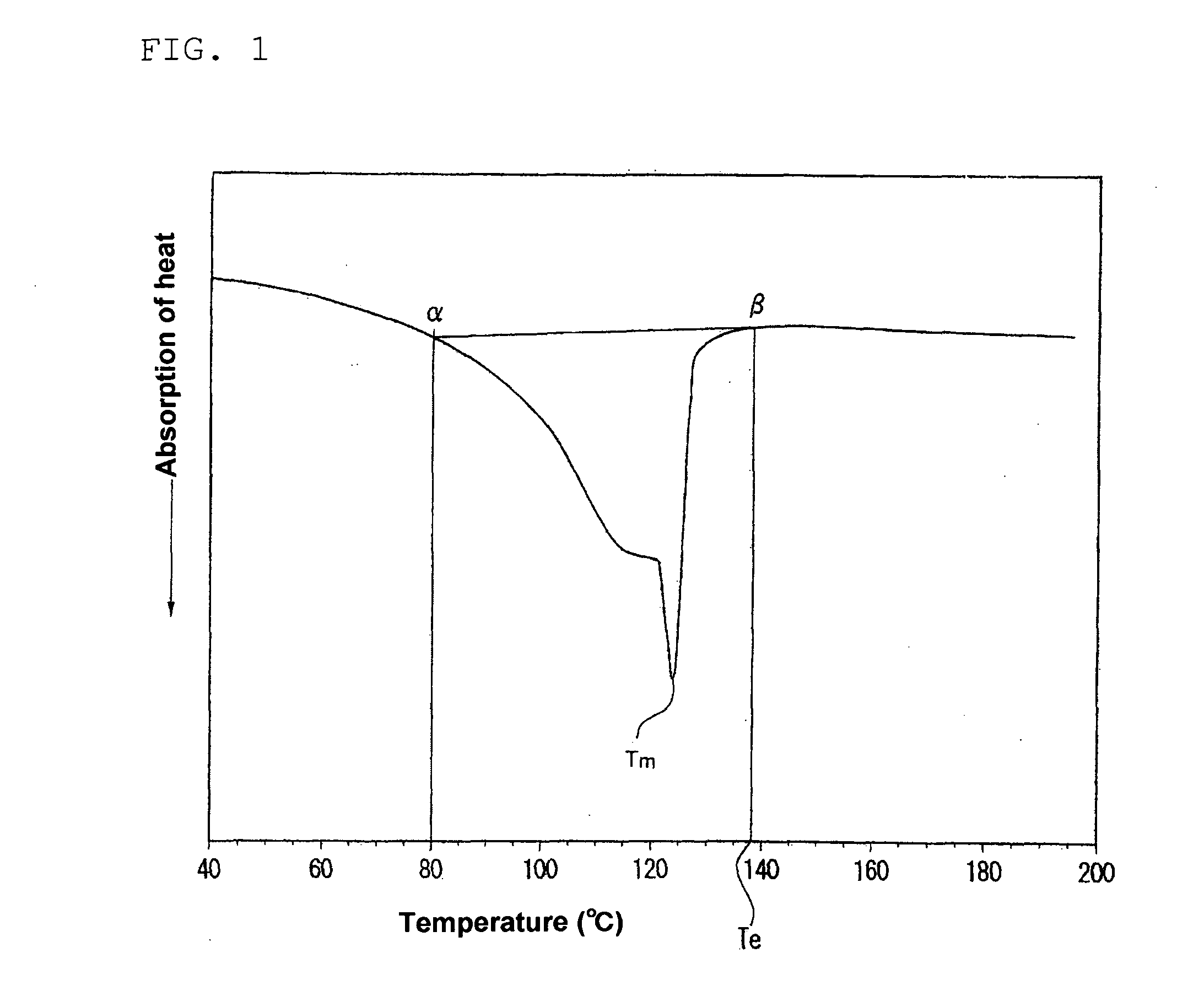

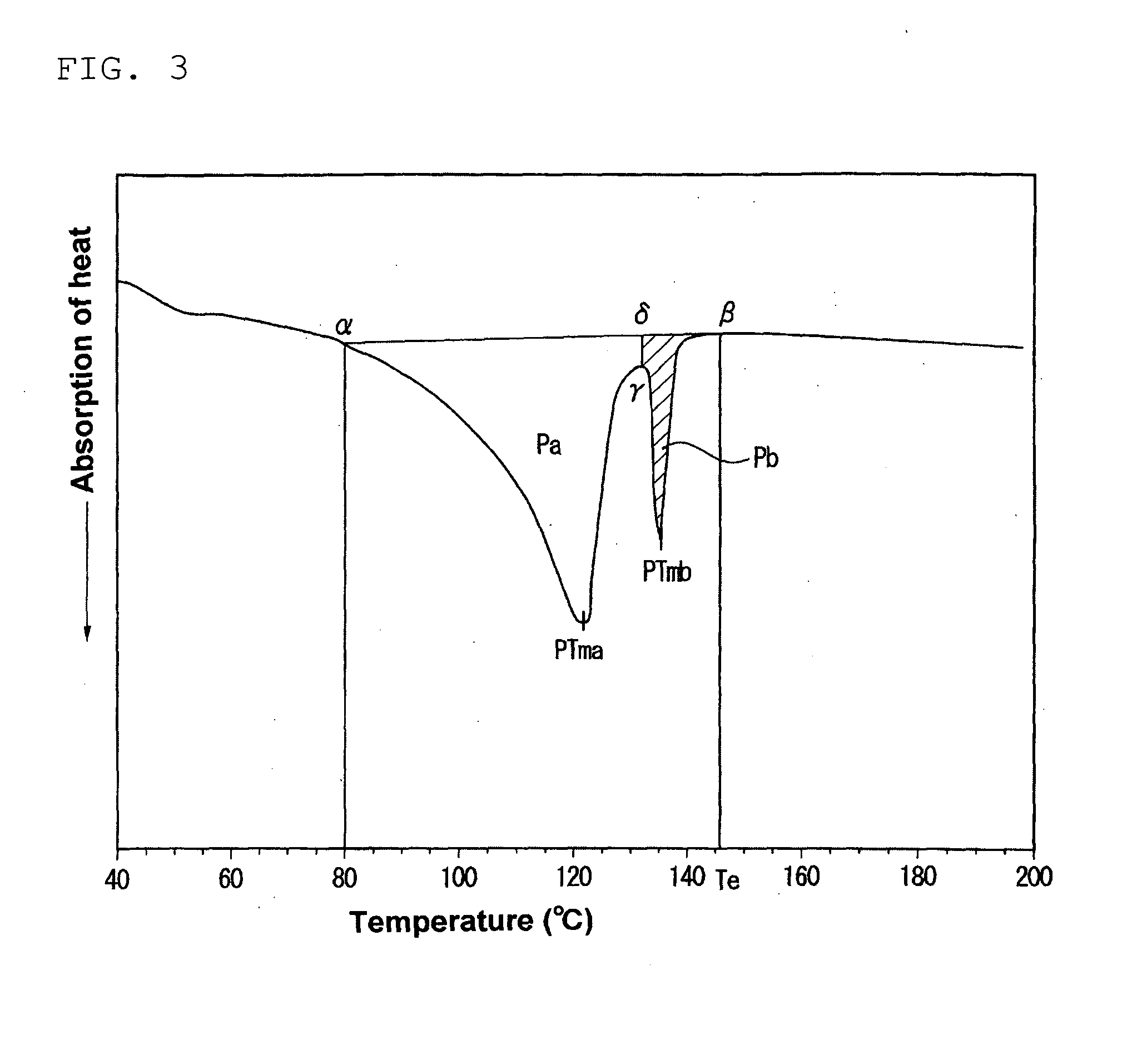

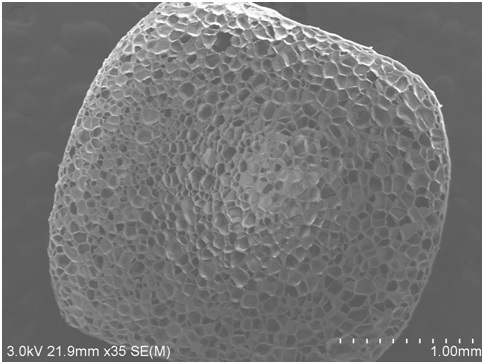

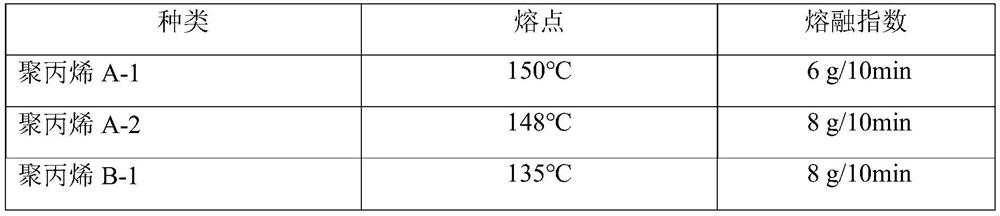

Polypropylene resin foamed bead and molded article thereform

Improved polypropylene resin foamed beads that without detriment to the excellence in properties, such as compression properties and heat resistance, characterizing the polypropylene resin foamed beads, can provide a polypropylene resin foamed bead molded article with equal properties by an molding conducted at low heating temperature. There are disclosed polypropylene resin foamed beads composed of a polypropylene resin of 115 to 135° C. melting point and 500 MPa or higher Olsen flexural modulus. The amount of ash at the surface of the foamed beads is 3000 wt. ppm or less (including 0). With respect to the foamed beads, in the first DSC curve obtained by heating 1 to 3 mg of polypropylene resin foamed beads from room temperature to 200° C. at a temperature elevation rate of 10° C. / min by the use of a differential scanning calorimeter, there appear not only one or more endothermic peak (Pa) having the peak temperature within a temperature zone not higher than the melting point of the resin but also one or more endothermic peak (Pb) having the peak temperature within a temperature zone exceeding the melting point of the resin and not lower than 130° C. The total calorific value of the endothermic peak (Pb) is in the range of 2 to 12 J / g. Further, there is disclosed a foamed bead molded article obtained by molding the above foamed beads.

Owner:JSP CORP

Method for preparing column-shaped active carbon

The invention relates to the activated carbon manufacturing field, in particular to a method of manufacturing columnar activated carbon, and solves the problems of high production cost, environmental pollution, low productivity, etc. caused by the addition of coal tar and hydraulic shaping devices required by the prior columnar activated carbon. A shaping device adopted by the invention when shaping is a feed granulation device manufactured by Fuji Seiki Equipment Manufacture Company, and the type of the shaping device is F-150. When coal is proportioned, coal powder is 72-78 percent, asphalt is 8-12 percent, water is 12-18 percent, the temperature of the coal powder is 18-20 DEG C, the temperature of water is 50-80DEG C, and the coal powder consists of 30-45 percent of soft coal, 25-35 percent of coke powder and 30-45 percent of coking coal. With the adoption of the shaping device, the method has the advantages of low shaping pressure, moderate operation conditions, improved productivity, simple process, reduced environmental pollution, saved heat energy, reduced production cost, and significantly improved the yield of products. The technical data of the prepared finished columnar activated carbon granules can be completely in accordance with the requirements. Furthermore, the method overcomes the technical prejudice of the technical field that only coal tar and the hydraulic shaping device can ensure the shaping of coal quality and the strength of activated carbon.

Owner:SHANXI XINHUA CHEM

Preparation method of prealloying matrix powder

The invention provides a preparation method of prealloying matrix powder. The preparation method comprises the following steps of: (a) mixing copper-clad iron powder, nickel powder, zinc powder, tin powder and cobalt powder to obtain mixed powder; (b) heating the mixed powder in three areas of a reducing furnace sequentially to obtain lump sinters, wherein the temperature of the first area is 550 DEG C-570 DEG C, the temperature of the second area is 600 DEG C-620 DEG C, and the temperature of the third area is 570 DEG C-590 DEG C; and (c) crushing and sieving the lump sinters to obtain the prealloying metal body powder. According to the method, the mixed powder is temperature-control heated in the three areas sequentially so as to be sintered, in the sintering process, the uniform prealloying matrix powder is obtained, and the apparent density of the prealloying metal body powder is reduced, so that the moulding pressure of the powder is reduced, and the prealloying metal body powder has better mouldability.

Owner:甘肃金川金顶汇新材料科技有限公司

Light forsterite heat insulating brick and method of manufacturing the same

InactiveCN101497527AReduce molding pressureHigh porosityGlass furnace apparatusBrickVolumetric Mass Density

The invention relates to a lightweight forsterite insulating brick and a manufacturing method thereof. The invention adopts a technical proposal that the insulating brick is prepared from the following raw materials in portion by weight: 60 to 70 portions of forsterite sand of 1 to 0.5 millimeter, 15 to 25 portions of magnesite of 1 to 0.5 millimeter, 5 to 15 portions of magnesite powder of less than or equal to 0.088 millimeter, and 5 to 10 portions of SiO2 micro powder of less than or equal to 2mu m; and the adding amount of a bonding agent is 5 to 15 percent of the gross weight of the raw materials. The lightweight forsterite insulating brick has the advantages of small volume weight, low heat conduction coefficient, good heat insulation effect, and high normal pressure strength. The manufacturing method adopts a hydraulic press to mold, not only can solve the problems such as difficult molding and uneven density of green bricks, is easy to strip a mold, does not need to cut a finished product, simultaneously reduces energy consumption, saves resource, reduces discharge of pollutants, and protects environment.

Owner:营口青花耐火材料股份有限公司

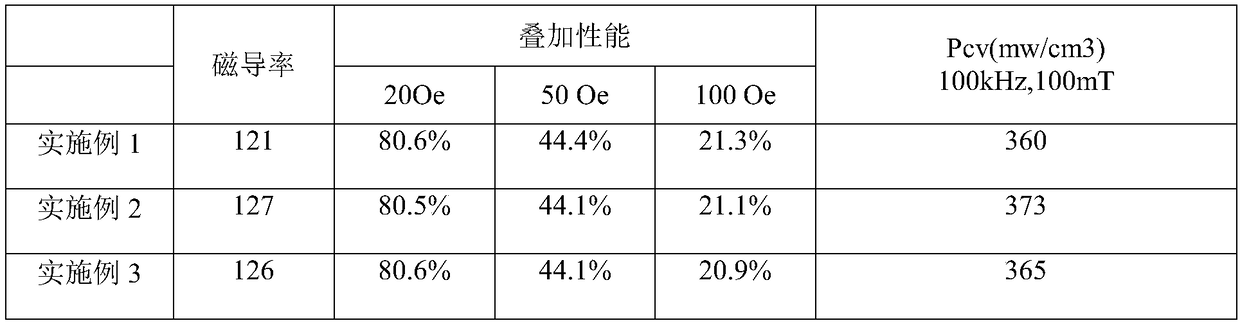

Preparation method of high-permeability aerosolized iron silicon aluminum magnetic powder core

ActiveCN109285685ASimple processReduce core breathTransportation and packagingMetal-working apparatusMagnetic coreMagnetic powder

The invention relates to the technical field of metal soft magnetic materials, and discloses a preparation method of a high-permeability aerosolized iron silicon aluminum magnetic powder core. The preparation method comprises the steps of 1) aerosolized powdering, 2) granularity combination, 3) powder thermal treatment, 4) insulating coating, 5) secondary coating, 6) pressing and molding, 7) magnetic core annealing and 8) impregnation spraying. The aerosolized iron silicon aluminum magnetic powder has the advantages of being good in formability and high in permeability.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Method for billow forming magnet alloy thin plate

The invention is a magnesium alloy sheet puffing shaping method relates to magnesium alloy puffing shaping production technique. The magnesium alloy sheets are puffing shaped in following steps: a. the sheets are heated to puffing shaping temperature 200 to 400 deg. C and keep the temperature for 10 to 60 minutes after brought into moulds; b: apply compressing load in axial direction in the moulds; c. aerate in the mould with air pressure 0.1 to 0.8 MPa and keep the pressure for 10 to 30 minutes; d. go on to increase the air pressure in the mould to 1 to 1.5 MPa and keep the pressure for 10 to 30 minutes to obtain a piece of the same moulding surface with the mould and finally the product after cooling and demoulding. By applying puffing shaping method to magnesium alloy piece production the invention provides the magnesium alloy material shaping with an economy, efficient and practical production technique which has advantages such as high thin wall shaping performance, high passing percent, high shaping accuracy, high material using ratio, lowering the piece weight, saving the cost, simple technique and so on.

Owner:HARBIN UNIV OF SCI & TECH

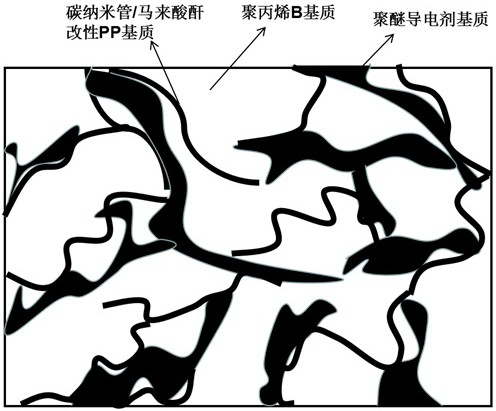

Gray antistatic polypropylene composite foamed beads with skin-core structure and molded product thereof

The invention discloses gray antistatic polypropylene composite foamed beads with a skin-core structure, which are composed of a foamed core layer and a non-foamed skin layer, and the foamed core layer is composed of polypropylene, a cell nucleating agent, an antioxidant, colored carbon black and a lubricant. The skin layer is prepared from polypropylene, a polyether block copolymer antistatic agent, maleic anhydride grafted modified polypropylene and multi-walled carbon nanotube; the composite foamed beads are obtained by extruding and granulating through a co-extrusion extruder and then foaming through a high-pressure foaming kettle. The skin layer contains the composite antistatic agent and the low-melting-point polypropylene, so that good fusion bonding, apparent quality and stable permanent antistatic property of the molded product are guaranteed; the foaming effect of the core layer is excellent, and the foaming ratio adjustability and the excellent mechanical property of a molded product are guaranteed. The molded product not only has permanent antistatic property, but also has good rigidity.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

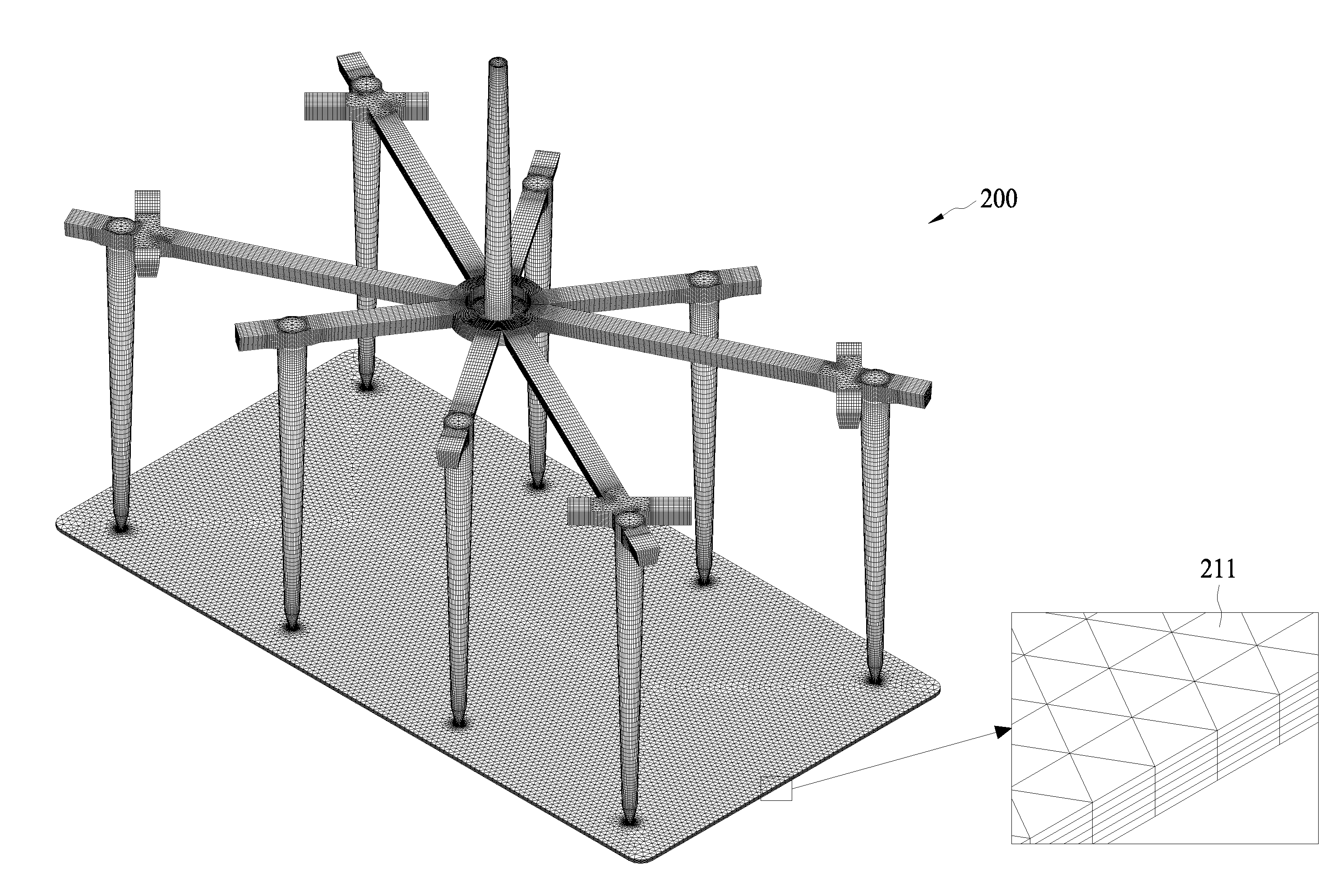

Inductor warm-pressing forming method and inductor prepared by using same

ActiveCN106409492AInductor with high permeabilityReduce DC resistanceTransformers/inductances detailsInductances/transformers/magnets manufactureCompression moldingHeating time

The invention relates to an inductor warm-pressing forming method and an inductor. The inductor warm-pressing forming method comprises the steps of heating magnetic powder in a molding cavity rapidly by utilizing a changeable magnetic field of lengthways AC or ripple wave containing DC generated at the center of a molding cavity by an electrified induction coil which is arranged at the periphery of the molding cavity; then transferring heat to a binder on the surface of the magnetic powder by the heated magnetic powder to soften the binder; and performing compression molding on granulation powder which is composed of the magnetic powder and the binder to form the inductor. The inductor has high magnetic conductivity, low DC resistance and few apparent defects; and the heating time of the inductor warm-pressing forming method is short; powder is heated based on an electromagnetic induction principle; and the inductor warm-pressing forming method has advantages of high production efficiency and low energy consumption.

Owner:KUNSHAN CITONG NEW MATERIAL TECH CO LTD

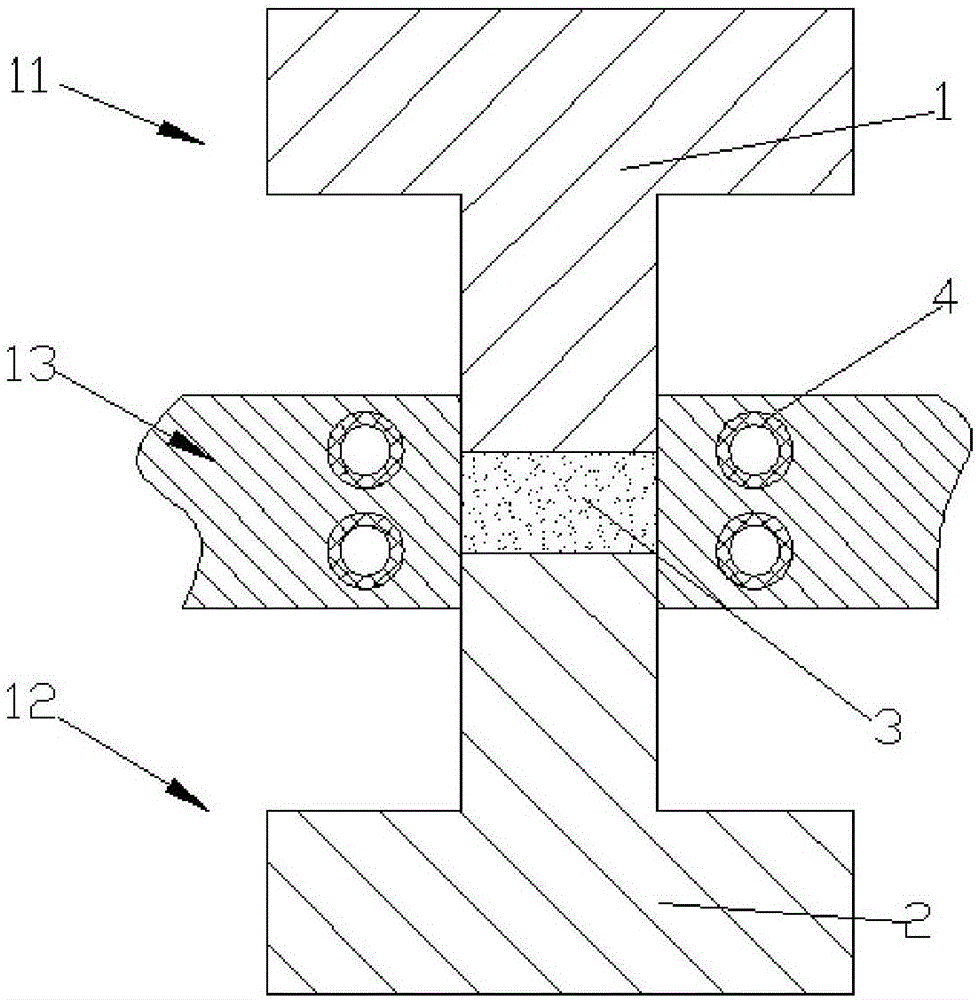

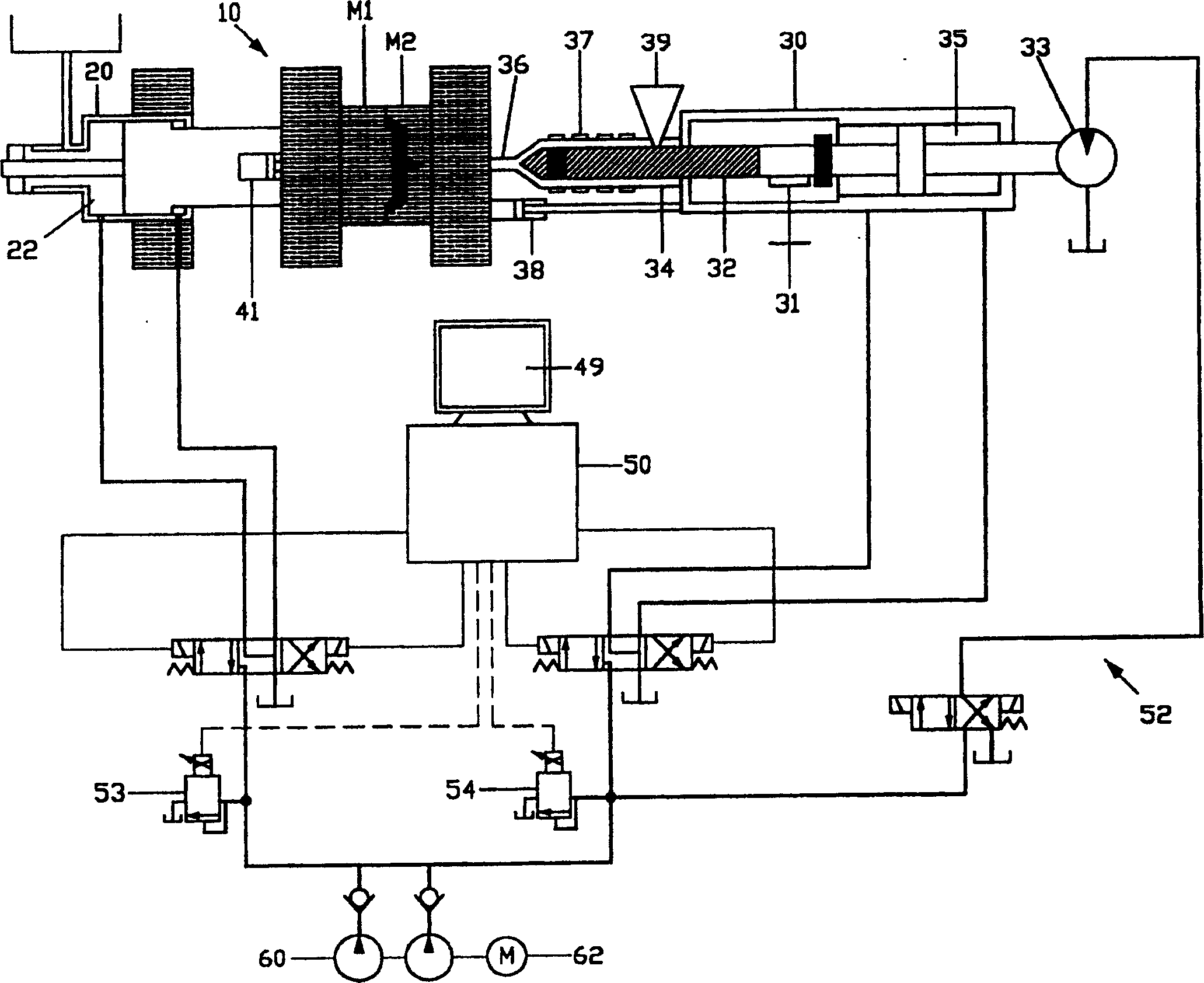

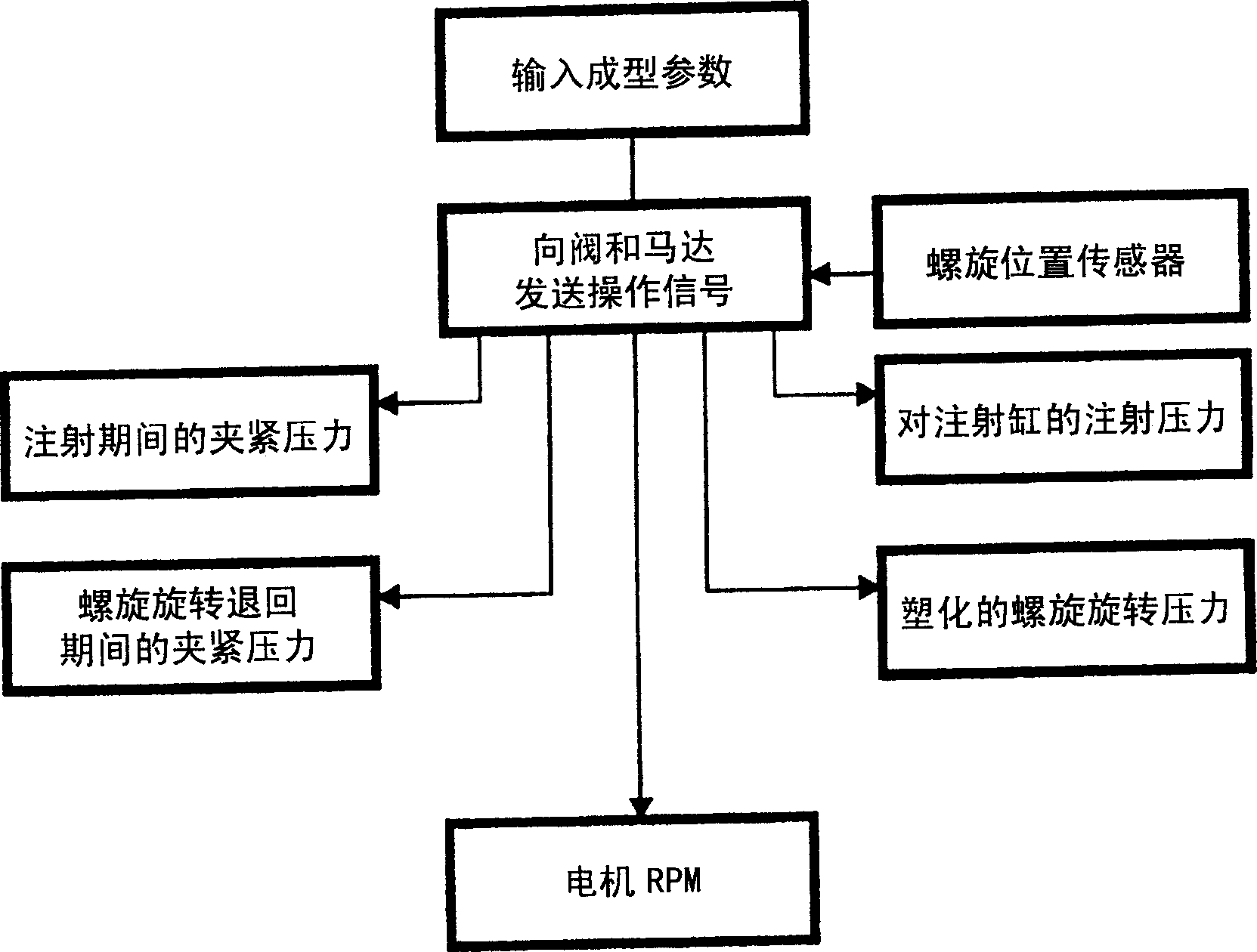

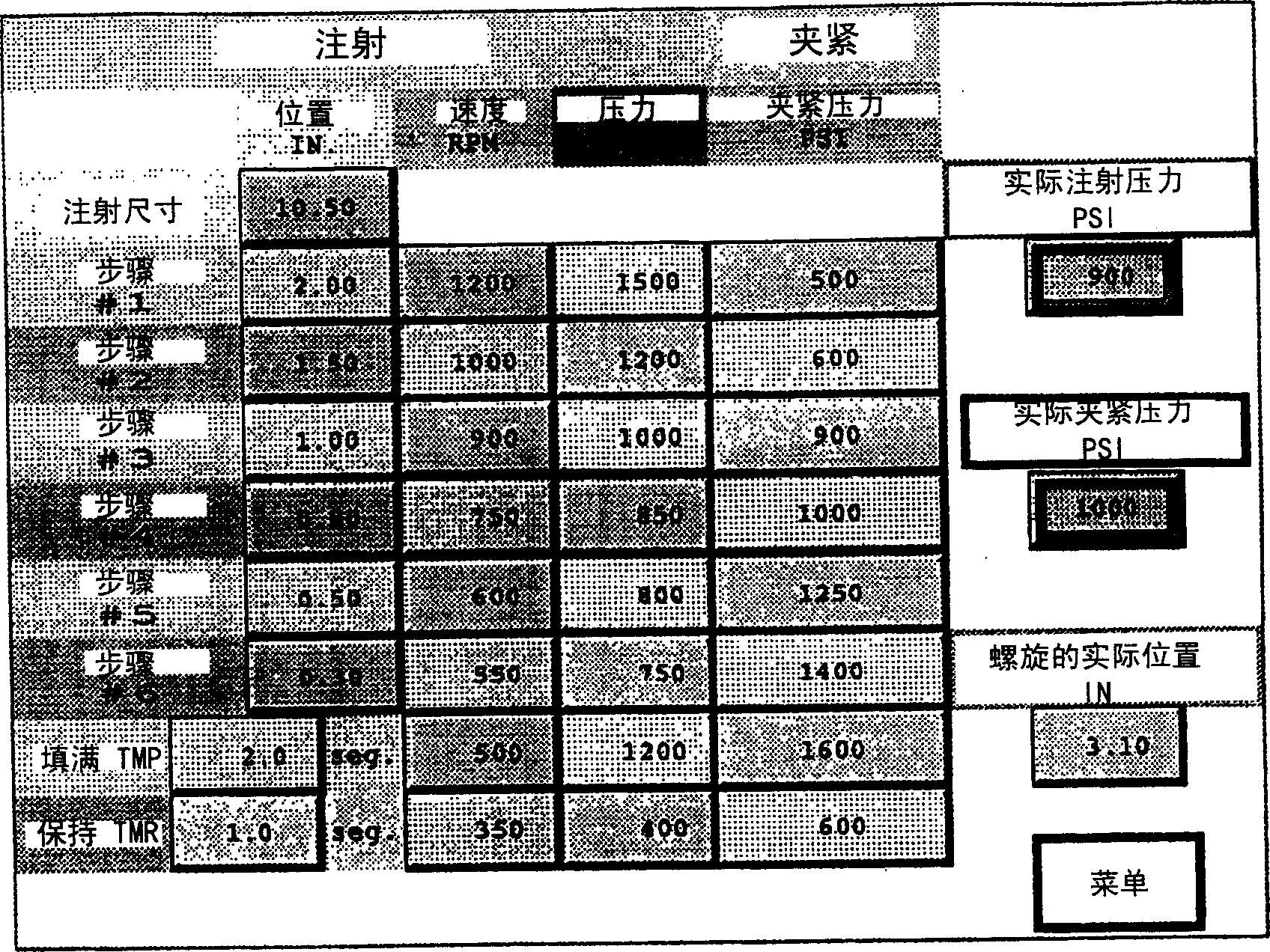

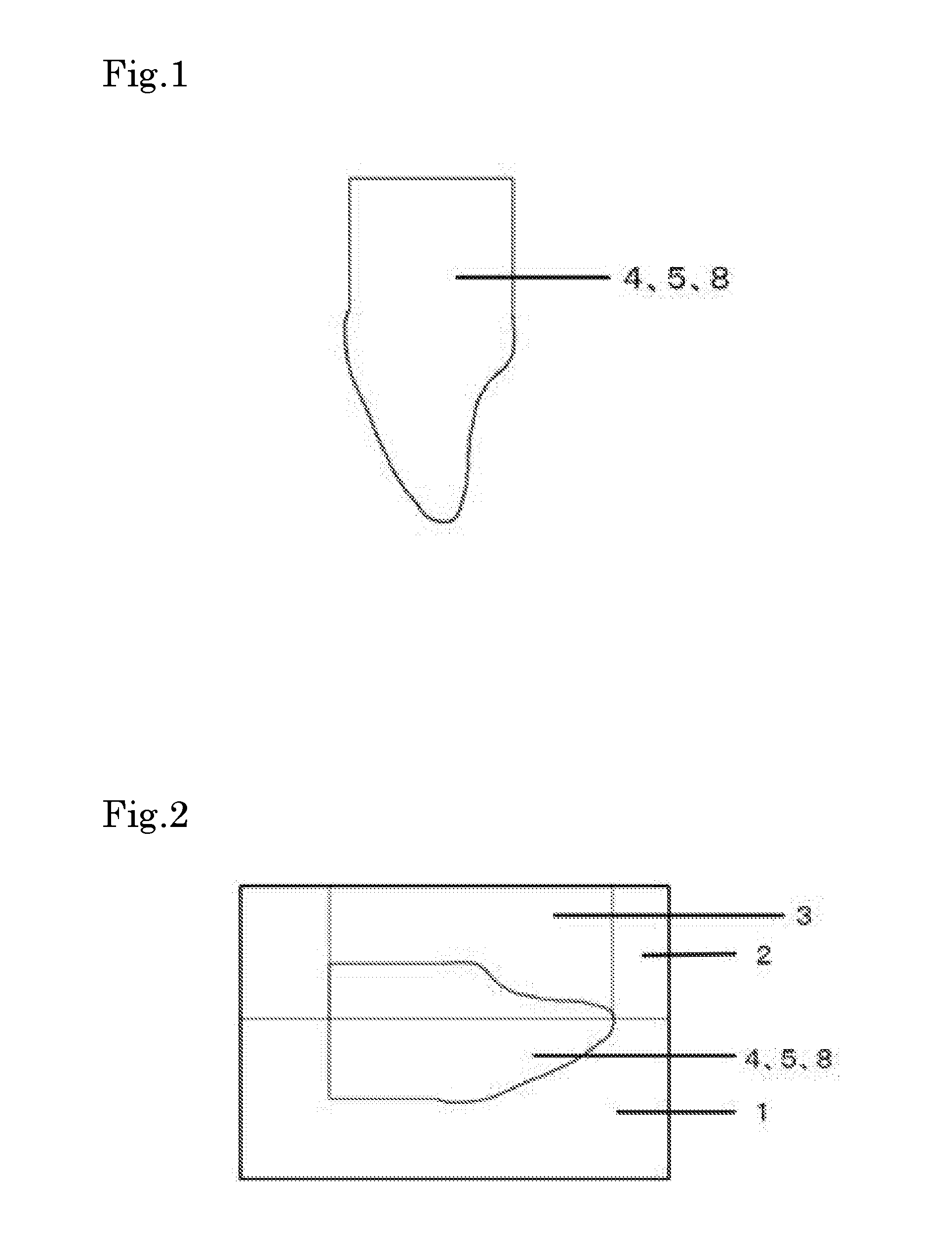

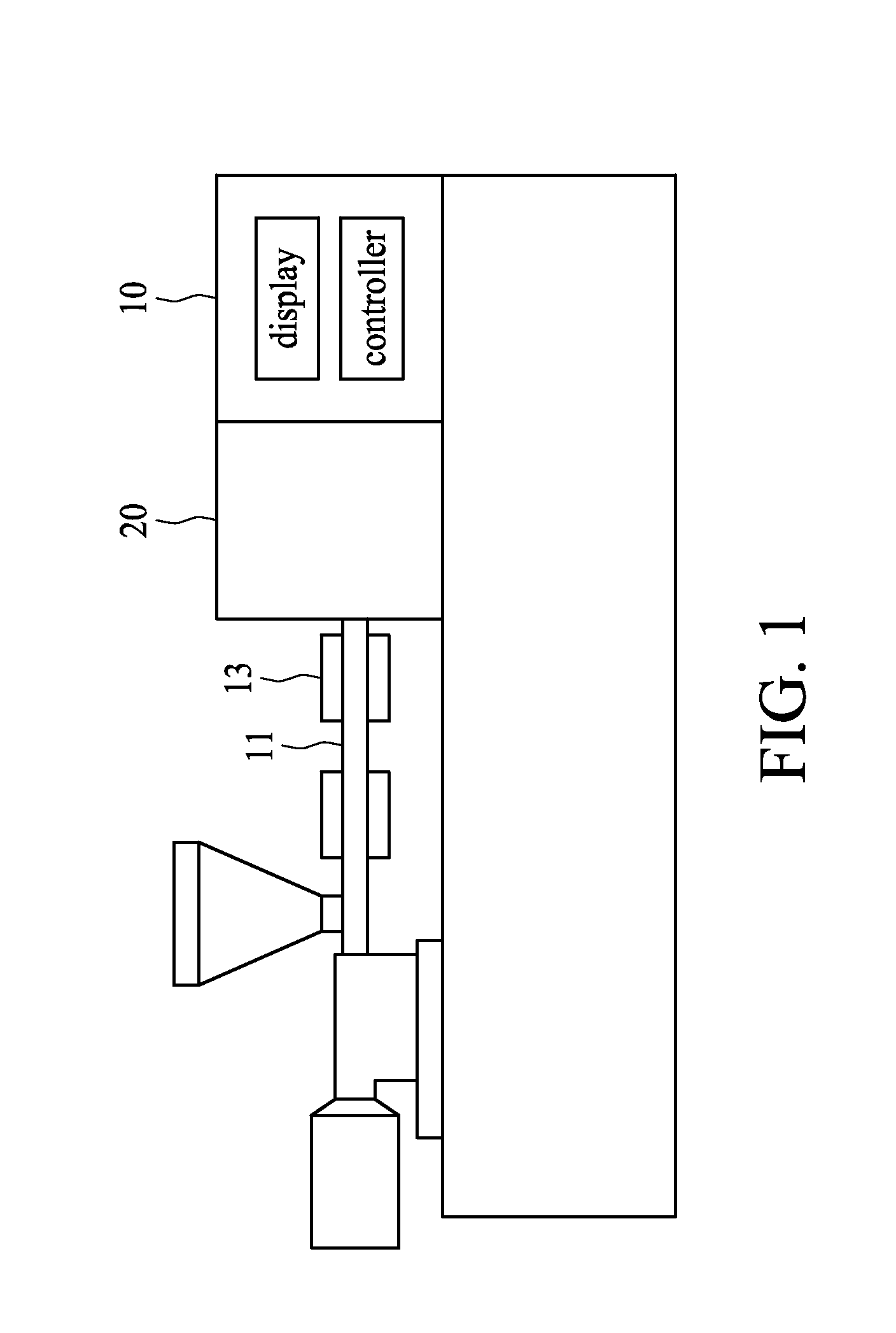

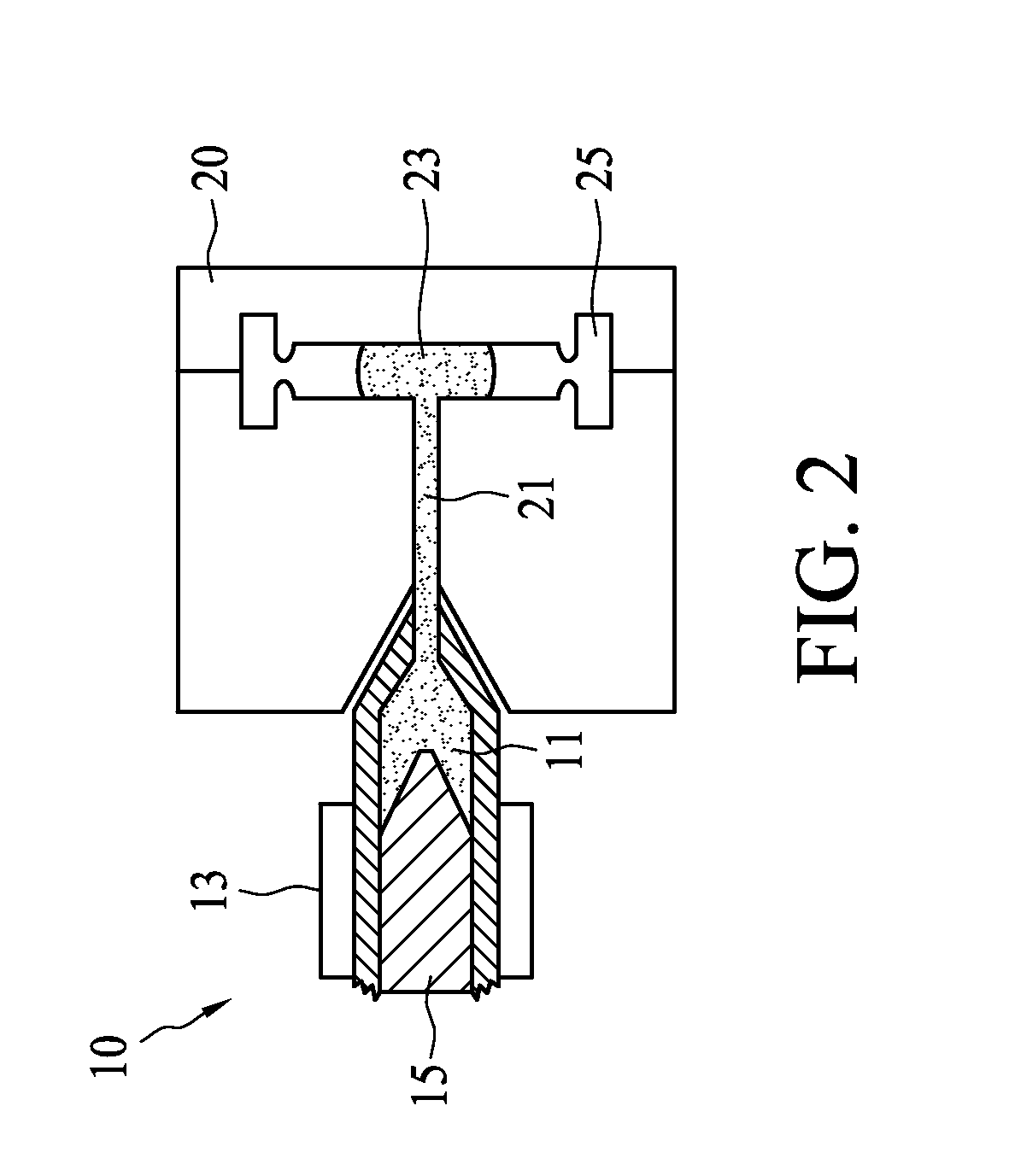

Injection molding machine and controller

An injection molding machine 10 utilizes a two part mold to produce a molded part. A machine includes a clamping mechanism 20 including one or more clamping cylinders 22 for applying a mold clamping force to the two part mold, an injection mechanism 30 for plasticizing material and injecting the plasticized material into the closed mold, and a controller 50 for powering the molding machine hydraulic system 52. In one embodiment, clamping pressure is automatically increased or decreased to allow air to escape as plasticized material flows into the mold cavity. In another embodiment, the controller provides a minimum clamp pressure to maintain the plasticized material within the mold as a function of fluid injection pressure to the screw member of the injection system.

Owner:乔斯・R・马拉齐塔

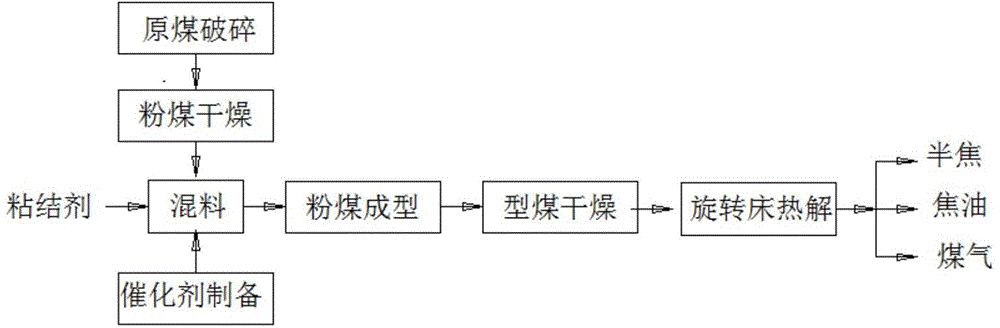

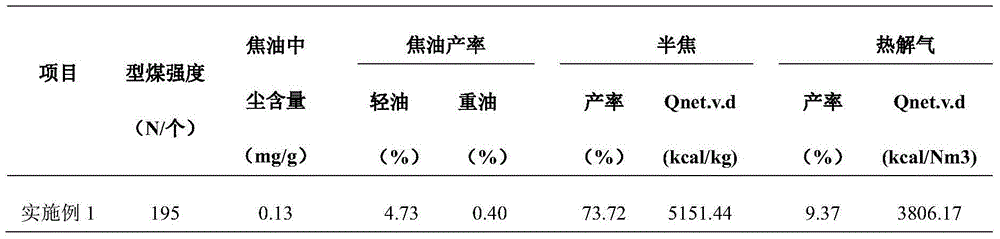

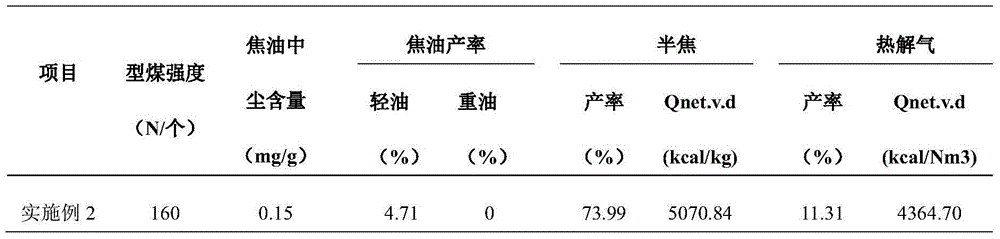

Revolving bed coal catalytic pyrolysis method

ActiveCN104910941AReduce intensityReduced strength requirementsIndirect heating destructive distillationSpecial form destructive distillationCatalytic pyrolysisTar

The invention provides a revolving bed coal catalytic pyrolysis method. The method comprises steps of raw coal pretreatment, catalyst preparation, powdered coal shaping with addition of the catalyst, catalyst briquette coal drying, and pyrolysis in a revolving bed thermal decomposition furnace, and the catalyst is a mixture of Fe2O3 and CaO. The method solves the problems that after powdered coal shaping with addition of the catalyst, the briquette coal is low in intensity, and is easy to pulverize during the pyrolysis process. The dust content in tar can be lowered, the tar yield is raised, and the tar quality is improved.

Owner:SHENWU TECH GRP CO LTD

Preparation method and application method of granular activated carbon for xylose decoloring

ActiveCN103754868AHave densityHas thermal conductivityOther chemical processesCarbon compoundsEmulsionPhosphoric acid

The invention discloses a preparation method and an application method of granular activated carbon for xylose decoloring, which belongs to the field of preparation methods and application methods of activated carbon. The preparation method comprises the following steps: (A) preparing raw materials, namely, weighing phosphoric acid method powder activated carbon made from saw dust, an acrylic emulsion and water according to a ratio of acrylic emulsion to phosphoric acid method powder activated carbon to water being (0.37-0.39):1:1; (B) mixing the raw materials, namely, mixing the weighed raw materials and sufficiently stirring till the granules are uniformly mixed; (C) forming granules, namely, extruding the uniformly mixed raw materials to form granules by using a pelletizing machine at the constant temperature of 90 DEG C, so as to make granules with the particle size of 2-5mm, cooling the granules to be 40-50 DEG C, and drying; (E) separating and cooling. The granular activated carbon prepared by using the method is good in adsorption property, high in strength, acid-alkali resisting, recyclable and reusable, the liquid adsorption amount of unit volume is equivalent to that of other granular activated carbons, and the production environment is improved.

Owner:HUNAN KAIFENG ACTIVE CARBON ENVIRONMENTAL PROTECTION SCI & TECH

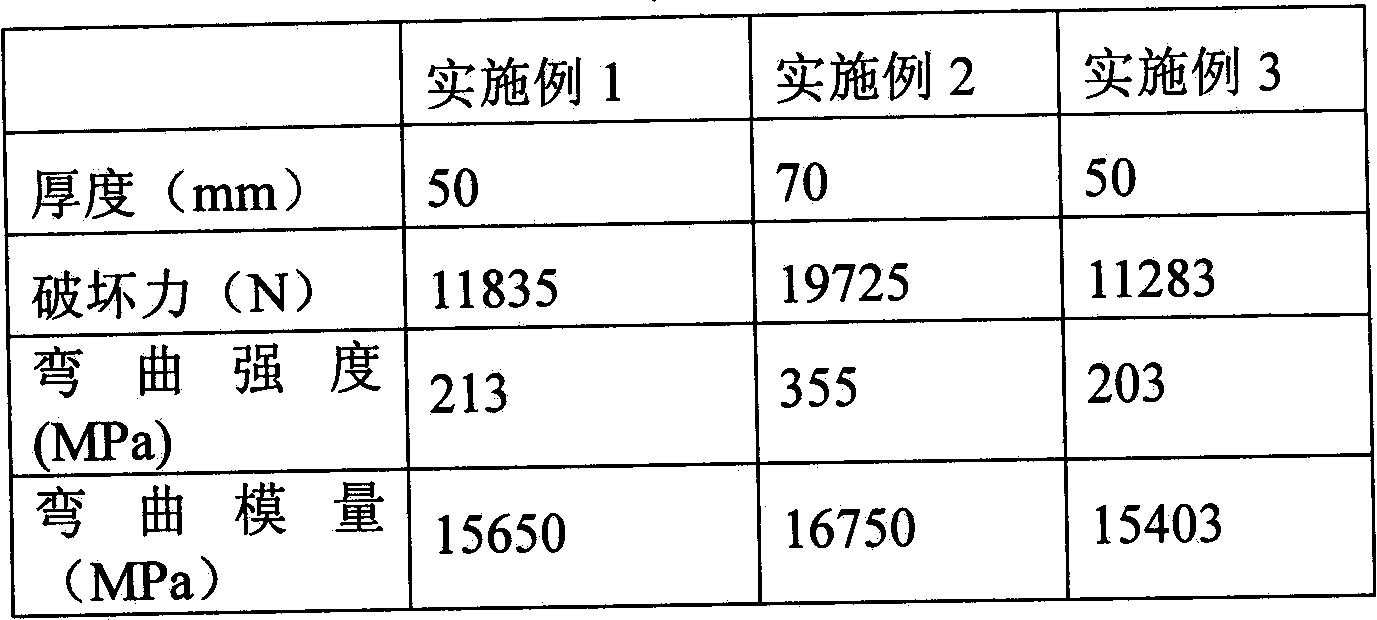

Low-density low-pressure sheet molding compound and preparation method thereof

The invention provides a low-density low-pressure sheet molding compound and a preparation method thereof. The invention discloses a low-density low-pressure sheet molding compound. The composite material is prepared from the following components in parts by weight: 55 to 65 parts of unsaturated polyester resin, 30 to 40 parts of low-shrinkage additive, 6 to 8 parts of styrene, 3.5 to 4.5 parts ofthickening agent, 1 to 2 parts of benzoyl peroxide tert-butyl ester, 4 to 6 parts of light zinc stearate, 70 to 80 parts of calcium carbonate, 20 to 30 parts of hollow glass beads and 45 to 55 partsof chopped glass fibers. According to the invention, a low-pressure sheet molding compound (LPMC) technology is adopted; mutual cooperation of components, therefore, the sheet molding compound prepared by the invention has lower density and the forming pressure can be greatly reduced; the magnesium oxide paste and the crystalline resin are used as a combined thickening system, so that the materialis formed under low pressure; the hollow glass beads are used as a filling material, so that the material density and the heat conductivity coefficient are reduced; the density of the sheet molding compound is 1.216-1.330 g / cm<3>, the heat conductivity coefficient of the sheet molding compound is 0.288-0.347 W / m.K, and the bending strength of the sheet molding compound is 59.15-82.39 Mpa.

Owner:WUHAN UNIV OF TECH

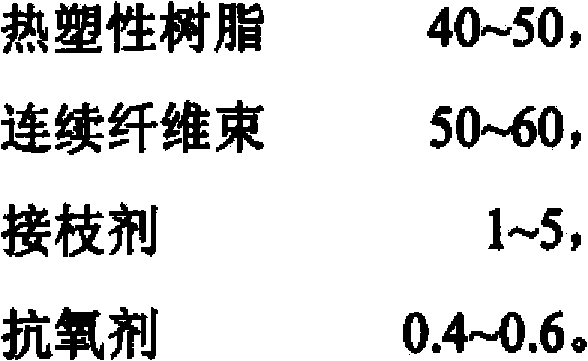

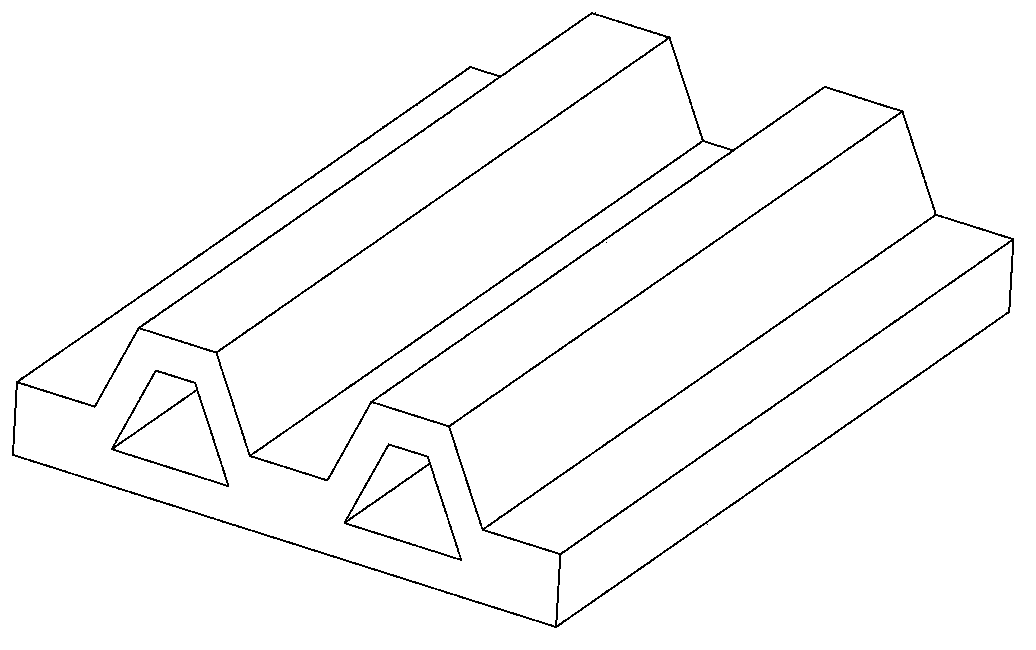

Hollow plate and manufacturing method thereof

The invention relates to a hollow plate and a manufacturing method thereof. The hollow plate is manufactured from the following components by weight: 40-50 parts of thermoplastic resin, 50-60 parts of a continuous fiber bundle, 1-5 parts of a grafting agent, and 0.4-0.6 part of an antioxidant. The manufacturing method includes: adopting a lamination process to lay a strip prepreg made from continuous fiber reinforced thermoplastic resin according to a mode of 0 degree-90 degrees, and placing the strip prepreg in a mold to conduct thermal forming, thus obtaining the hollow plate. By changing the hollow position and increasing the plate height, the plate strength can be enhanced, the sheet weight is reduced, and the cost is lowered. With the characteristics of high strength, high modulus, corrosion resistance, good water resistance, no conductivity and the like, the hollow plate is convenient to process and easy to clean, and has short forming cycle. The waste materials in production and the final product can all realize 100% recovery. Thus, the method belongs to a ''green'' product technology.

Owner:LIAONING LIAOJIE SCI & TECH

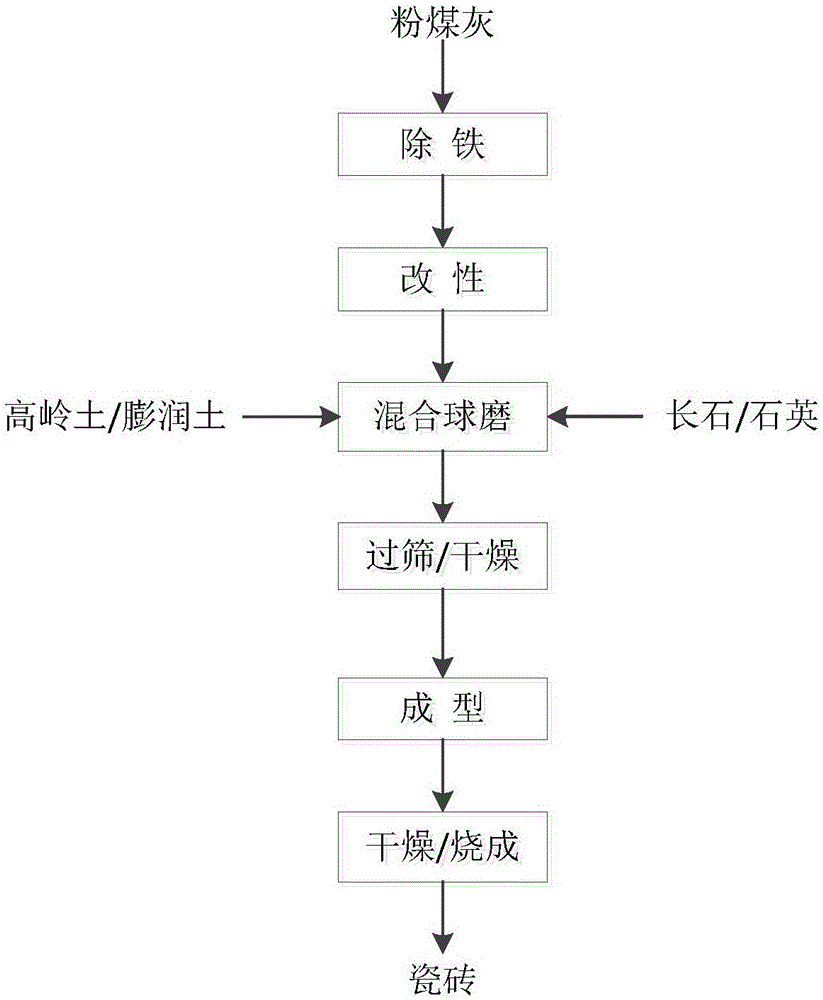

Fly ash-based porcelain brick preparation method

ActiveCN106365603AImprove plasticityBreak through the bottleneck problemCeramic materials productionClaywaresBrickSodium Bentonite

The invention discloses a fly ash-based porcelain brick preparation method, which comprises: 1) treating a raw material: carrying out iron removing on fly ash, mixing the obtained fly ash and an alkali liquid, carrying out a stirring reaction for 0.5-10 h at a temperature of 50-120 DEG C, carrying out solid-liquid separation on the obtained slurry, and drying to obtain modified fly ash; 2) mixing the modified fly ash obtained in the step 1), kaolin, bentonite, feldspar and quartz according to a certain ratio, adding water and electrolyte, adding into a ball mill, carrying out ball milling to obtain a uniform slurry, screening the obtained slurry, drying into a granular material, adding into a material bin, and aging for 1-3 days to obtain solid powder so as to be spare; 3) molding the solid powder obtained in the step 2) under a certain pressure, and drying the molded billet; and 4) firing the dried billet obtained in the step 3) at a high temperature, and cooling to obtain the porcelain brick. According to the present invention, the water absorption rate of the prepared porcelain brick is less than 0.5%, the flexural strength is much greater than 35 MPa, and the GB / T4100-2006 quality requirements are met.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Antioxidant for sintering neodymium iron boron jet mill, and use method of antioxidant

InactiveCN104449740AReduced oxidation resistanceLoss is good for compensationInorganic material magnetismChemical inhibitorsMetallurgyStearic acid

The invention discloses an antioxidant for a sintering neodymium iron boron jet mill, and a use method of the antioxidant. The antioxidant consists of an antioxidation agent and an antioxidation assistant, wherein the antioxidation agent consists of one or several of 1-cetyl alcohol, trityl alcohol and zinc stearate and alcohol; and the antioxidation assistant is a mixture of aviation gasoline and petroleum ether. The use method comprises the following steps that (1) 30-65% of the total amount of the antioxidation agent and neodymium iron boron magnetic powder are uniformly mixed and then crushed via the jet mill; (2) fine mixing is performed, and the antioxidation assistant and the rest antioxidation agent are added and uniformly mixed; and (3) compression molding is performed and then antioxidant removal treatment is performed. The antioxidant can improve the antioxidation property of the sintering neodymium iron boron magnetic powder, greatly improve the lubricating property and the orientation degree of the magnetic powder, and improve the magnet property. The use method can reduce loss of the antioxidation agent caused by volatilization, and can ensure continuous antioxidation property of the neodymium iron boron magnetic powder in each production stage.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

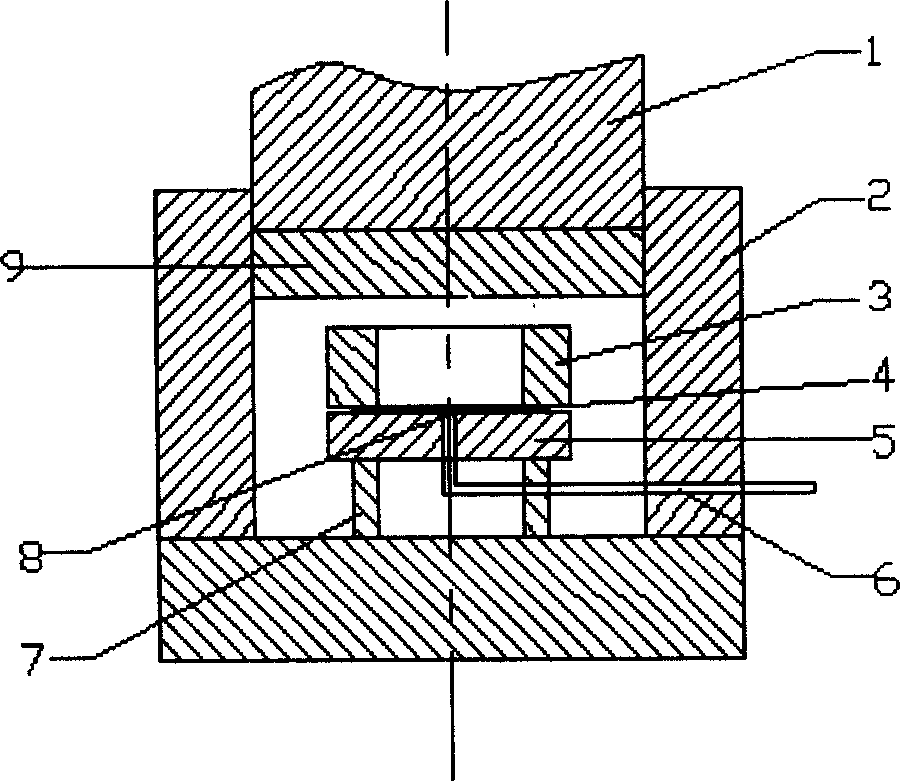

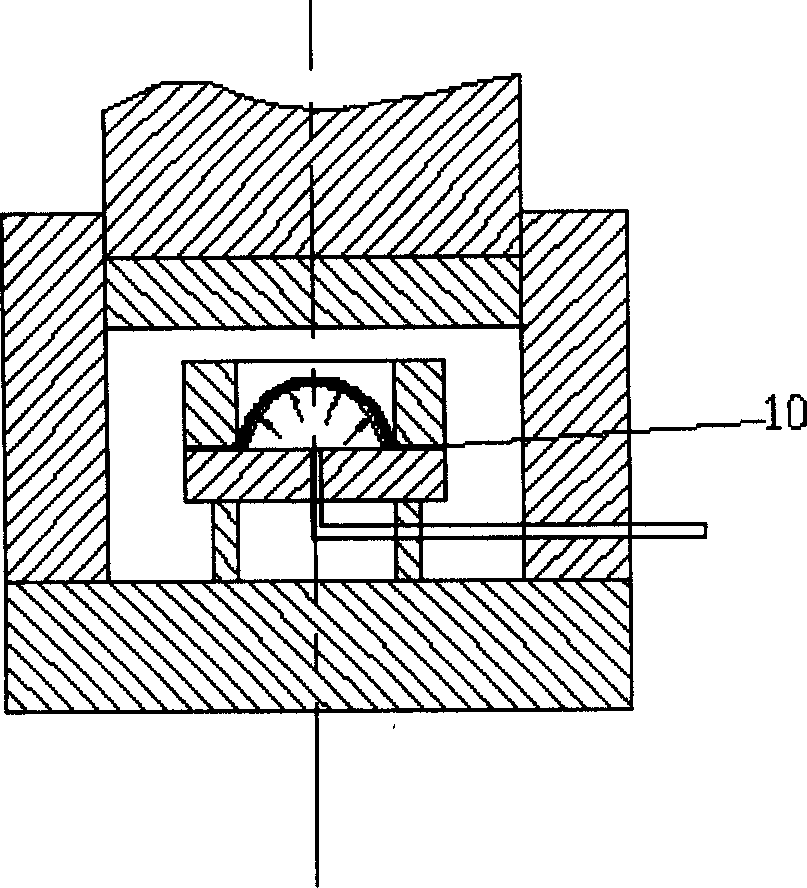

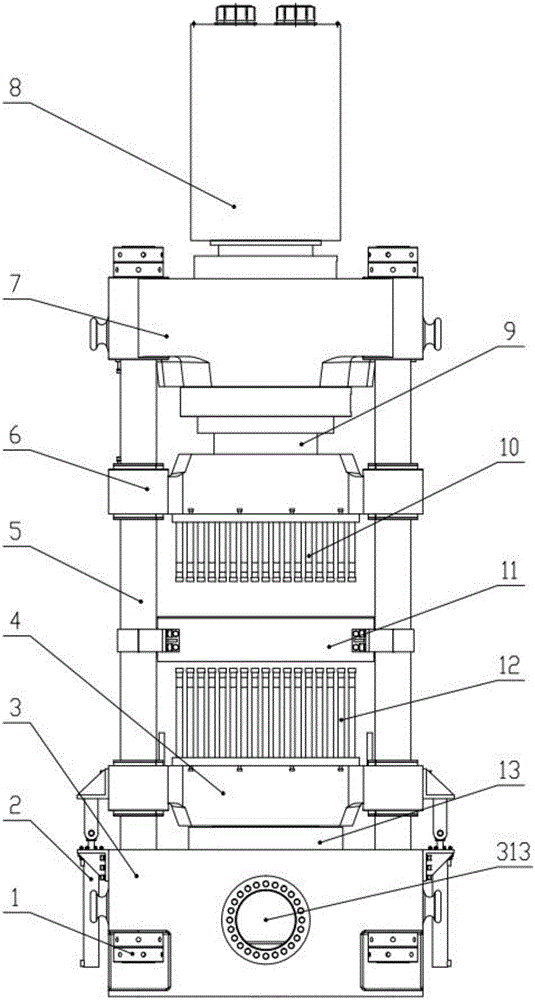

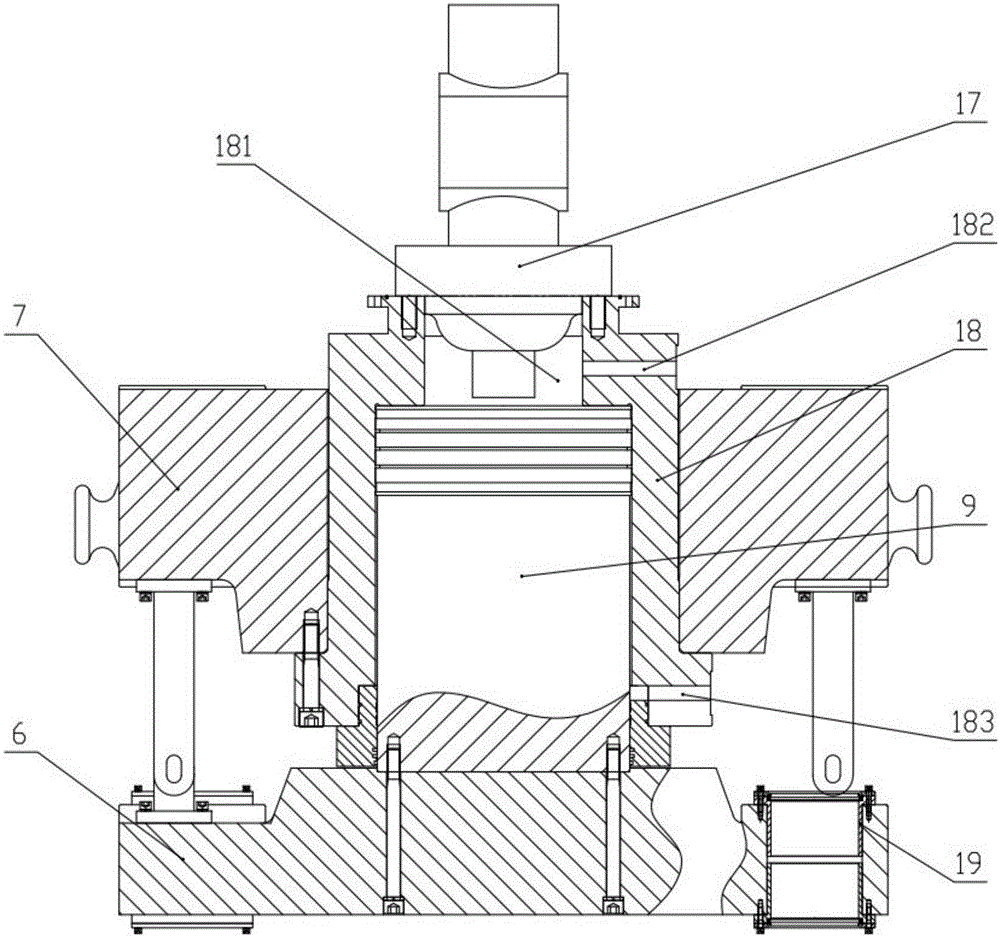

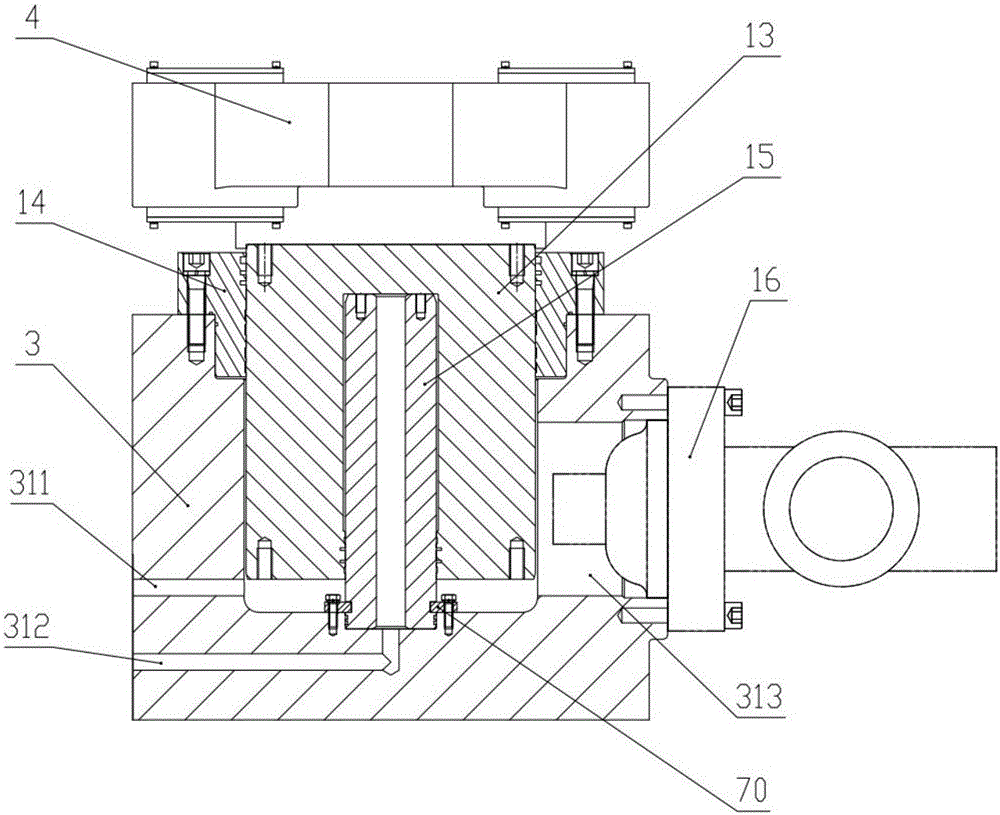

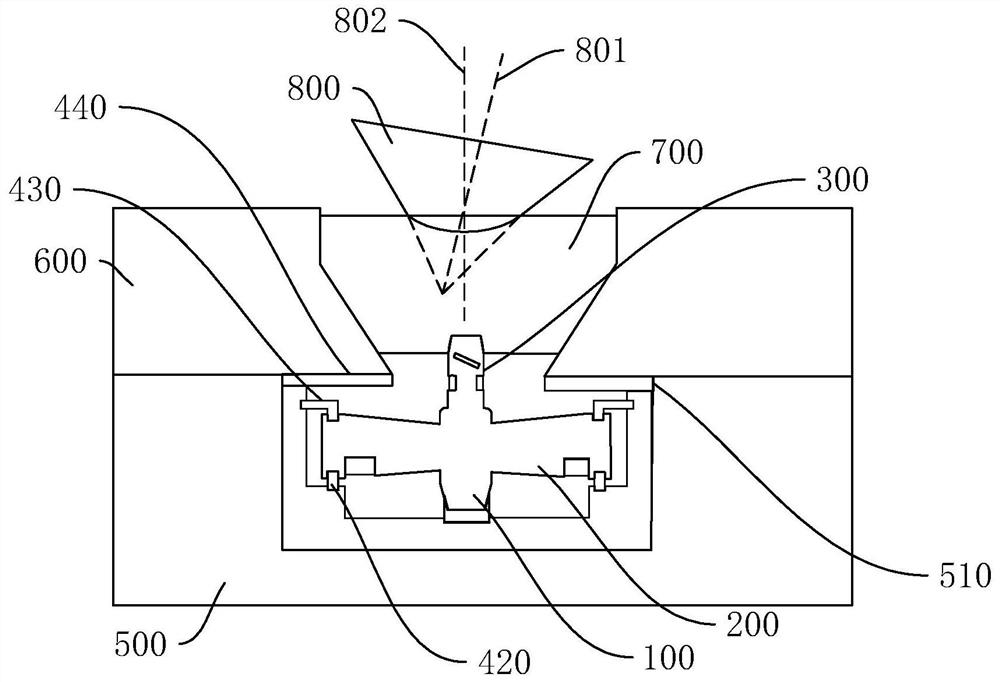

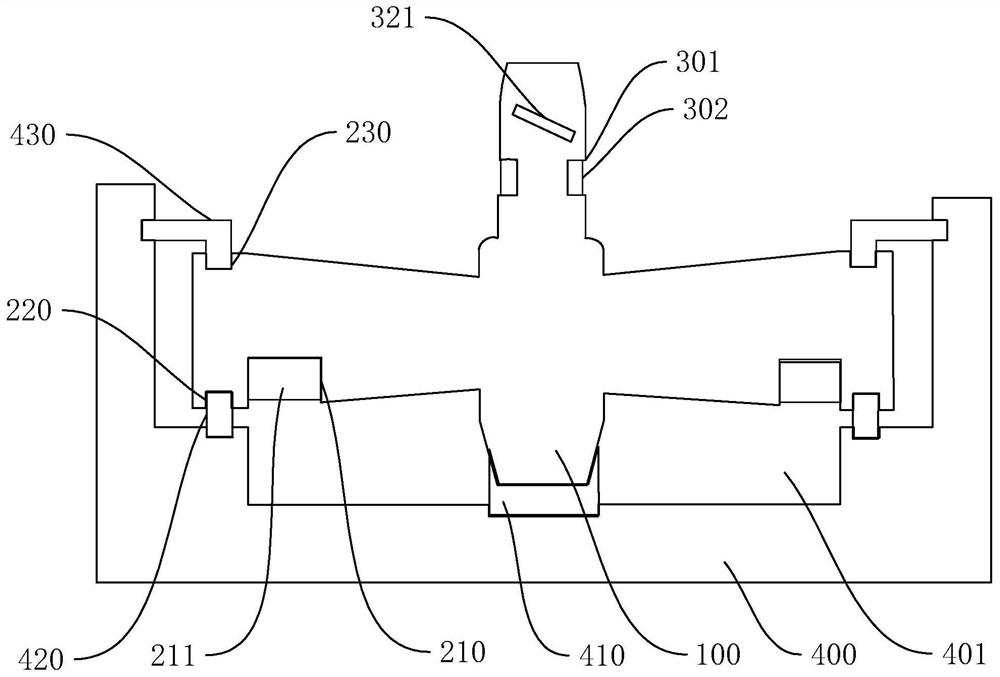

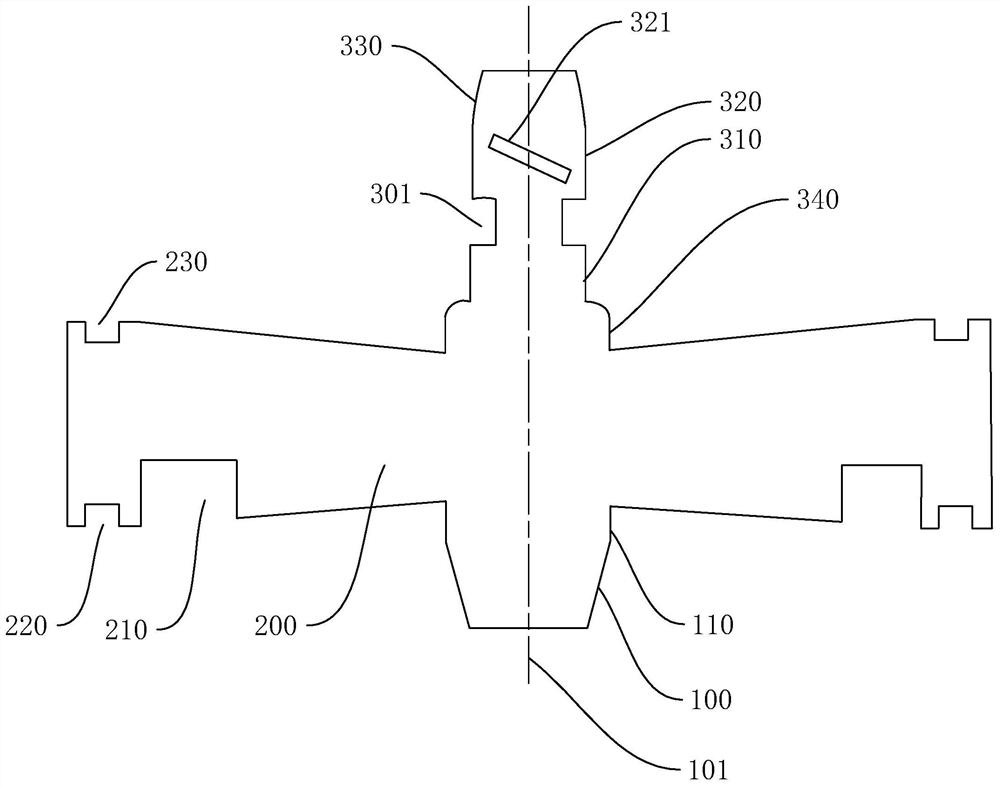

Oil cylinder assembly and full-automatic two-way pressurizing hydraulic brick press with same

InactiveCN105058554AImprove compactnessSimple structureAuxillary shaping apparatusFluid-pressure actuatorsBrickControl system

The invention discloses an oil cylinder assembly and a full-automatic two-way pressurizing hydraulic brick press with the same. The oil cylinder assembly is a lower oil cylinder used in cooperation with an upper oil cylinder. As part of a brick press body, the oil cylinder assembly and a hydraulic control system form the full-automatic two-way pressurizing hydraulic brick press. According to the oil cylinder assembly and the full-automatic two-way pressurizing hydraulic brick press provided with the same, the structure is simple, the performance is stable, and the production efficiency is high; the lower oil cylinder is of a large and small plunger structure, capable of achieving quick and slow control over a lower moving beam under the condition of small pressure oil supply amount by being provided with a filling valve, little in leakage and small in energy consumption; the lower oil cylinder drives a lower pressing head, so that powder in a middle mold frame can be pressurized from bottom to top, and compression-molded green bricks can be ejected from the middle mold frame.

Owner:江苏腾宇机械制造有限公司 +1

Preparing method of tungsten copper powder for perforating bullet type cover

The invention discloses a preparing method of tungsten copper powder for a perforating bullet type cover, and relates to the technical field of manufacturing of petroleum perforating devices. According to the preparation method, copper acetate is selected as copper salt for wrapping tungsten powder particles, after being mixed, the copper acetate and the tungsten powder particles are calcinated in a hydrogen environment and are reduced to obtain copper-coated tungsten powder, then, the copper-coated tungsten powder is mixed with electrolytic copper powder, and therefore the tungsten copper powder is obtained. Based on the surface features of tungsten copper powder particles and a powder particle segregation mechanism that powder particles with different components have the phenomenon of segregation under the joint function of particles proportions and particle internal friction force, the preparing method solves the problems of increase of production costs and the low production efficiency caused by a degreasing presintering process on the bases of solving the problem of segregation in the processes of mixing and rotary pressing of tungsten powder and copper powder and guaranteeing the perforating performance of perforating bullets.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

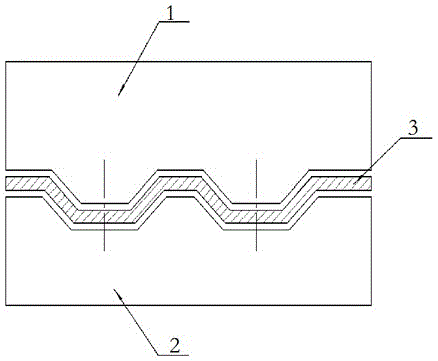

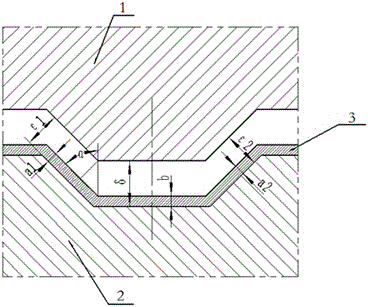

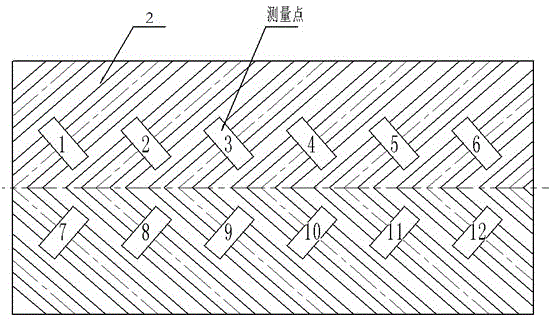

Measuring method for mold clearance of plate molding of plate type heat exchanger

ActiveCN105115464AReduce hardnessImprove liquidityMeasurement devicesHardnessPlate fin heat exchanger

The invention relates to the technical field of production auxiliary equipment detection of plate type heat exchangers, and discloses a measuring method for the mold clearance of plate molding of a plate type heat exchanger. According to the method, characteristics of low hardness of soft metal materials, good liquidity during extrusion, and extremely small resilience after molding are employed, lead wires or tin wires of the soft metal materials are cut into a plurality of sections and prepared to soft metal samples arranged on the internal surface of a lower mold of mold test points, the test points are uniformly, comprehensively, and symmetrically distributed on the internal surface of the lower mold, a proper pressure is applied to the samples on a hydraulic press for pressing, the mold clearance is filled by the soft metal materials, the mold clearance is calculated by employing the thickness of the molded soft metal, and the actual mold clearance of a calendaring mold can be accurately detected. The test method is simple, the precision of the measuring result is high, the consumption of the soft metal materials is low, and the detection cost is lowered; besides, the hardness of the soft metal materials is low so that the molding pressure is low, the damage to the internal surface of the mold is prevented, and the service lifetime of the mold is extended.

Owner:LANZHOU LS GRP

Corrugated hollow plate and manufacturing method thereof

ActiveCN103507279ALow priceReduce processing requirementsSheets/panelsFlat articlesHigh intensityEngineering

The invention relates to a corrugated hollow plate and a manufacturing method thereof. The corrugated hollow plate is manufactured by cutting prepreg prepared by continuous fiber enhanced thermoplastic resin, laying the prepreg in a forming machine, locking a die after placing an inflation core, thermally forming, finally maintaining pressure and cooling. Compared with the prior art, the corrugated hollow plate has advantages of low cost, not high technology requirement, greening, environmental protection, high intensity, high modulus, good corrosion resistance, good water tolerance, inertia to a plurality of acids and alkalis, non-conduction, high dielectric strength, simple processing, easy cleaning, no need of special storage condition and long storage life, can be 100% recovered, and belongs to a green product technology.

Owner:LIAONING LIAOJIE SCI & TECH

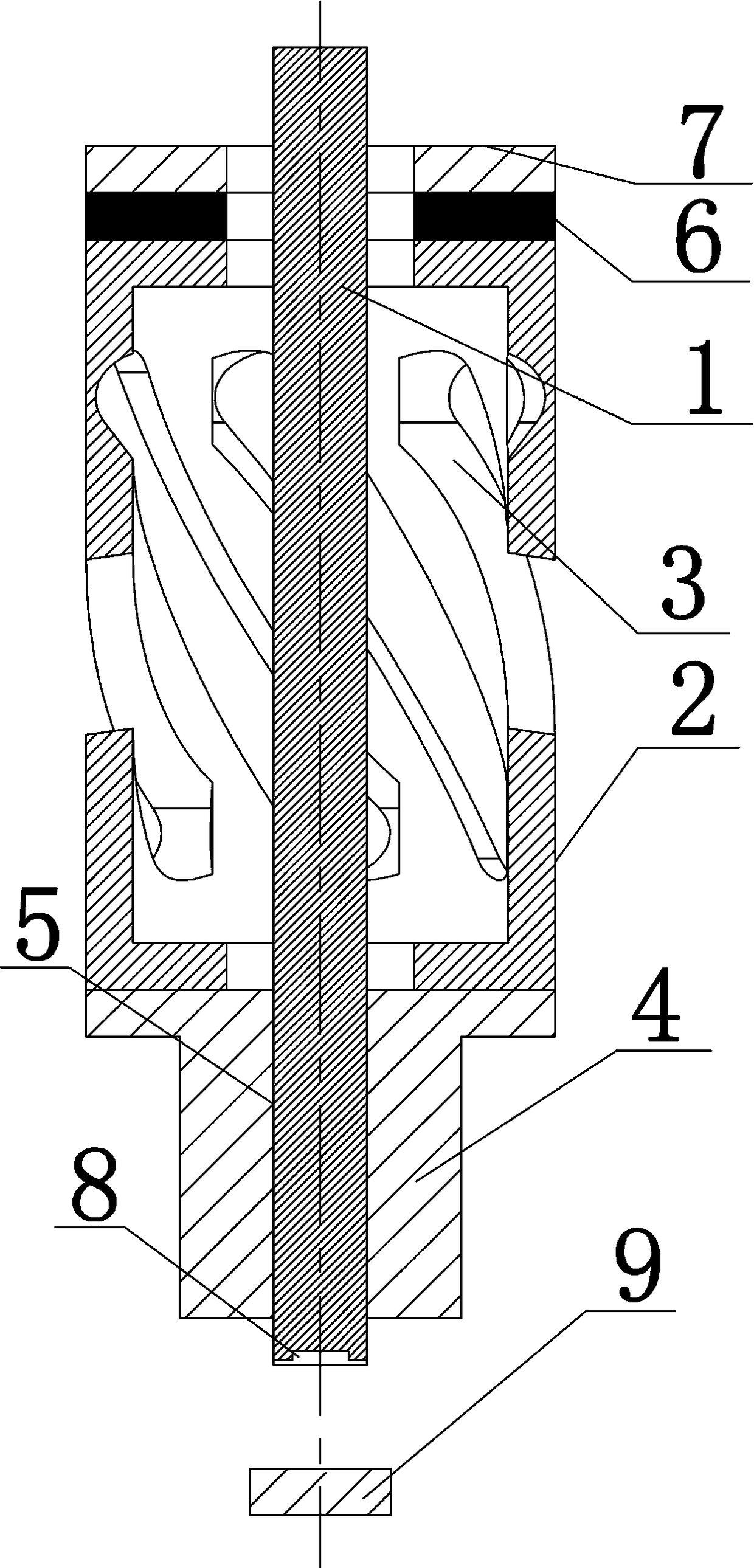

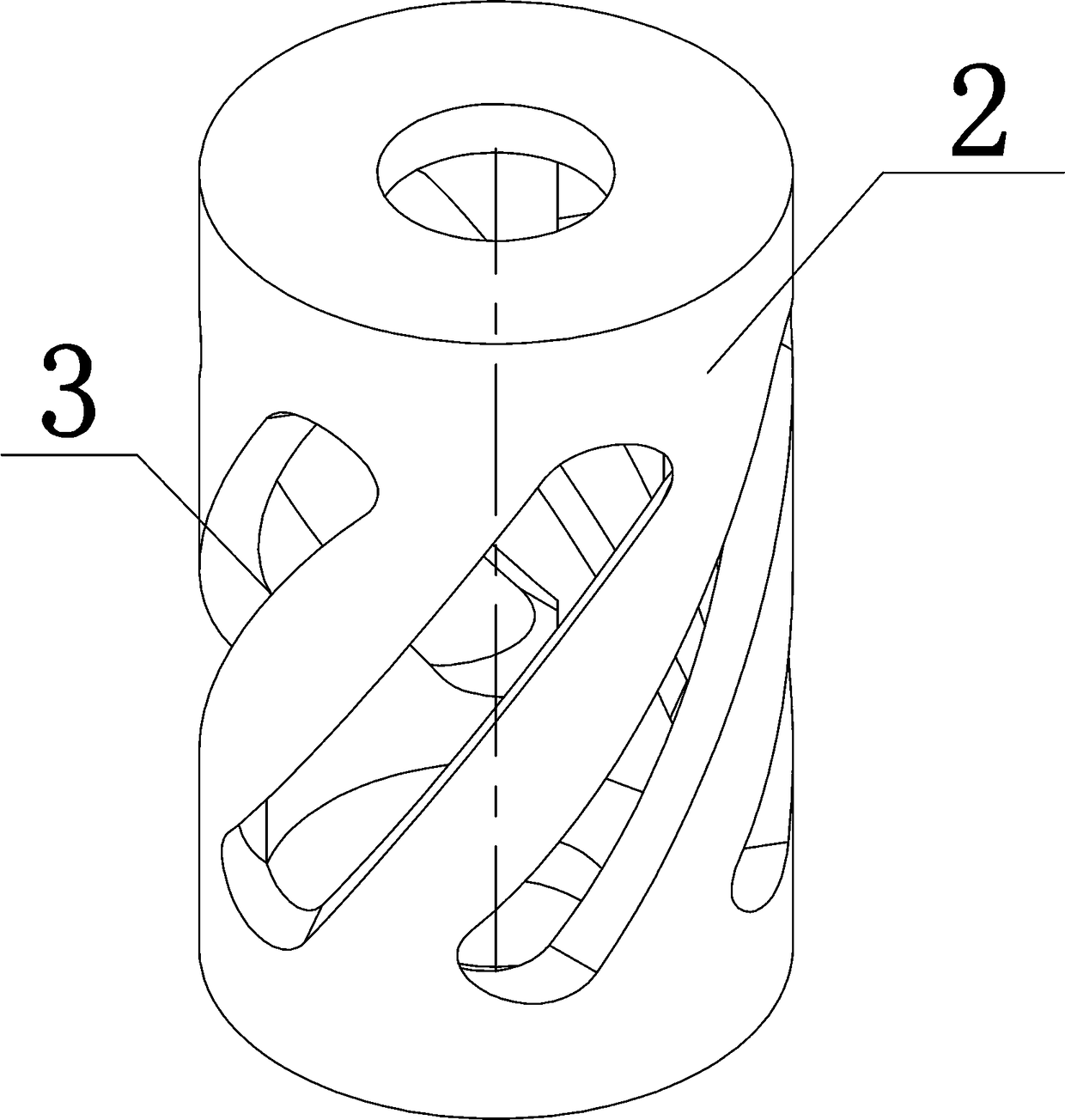

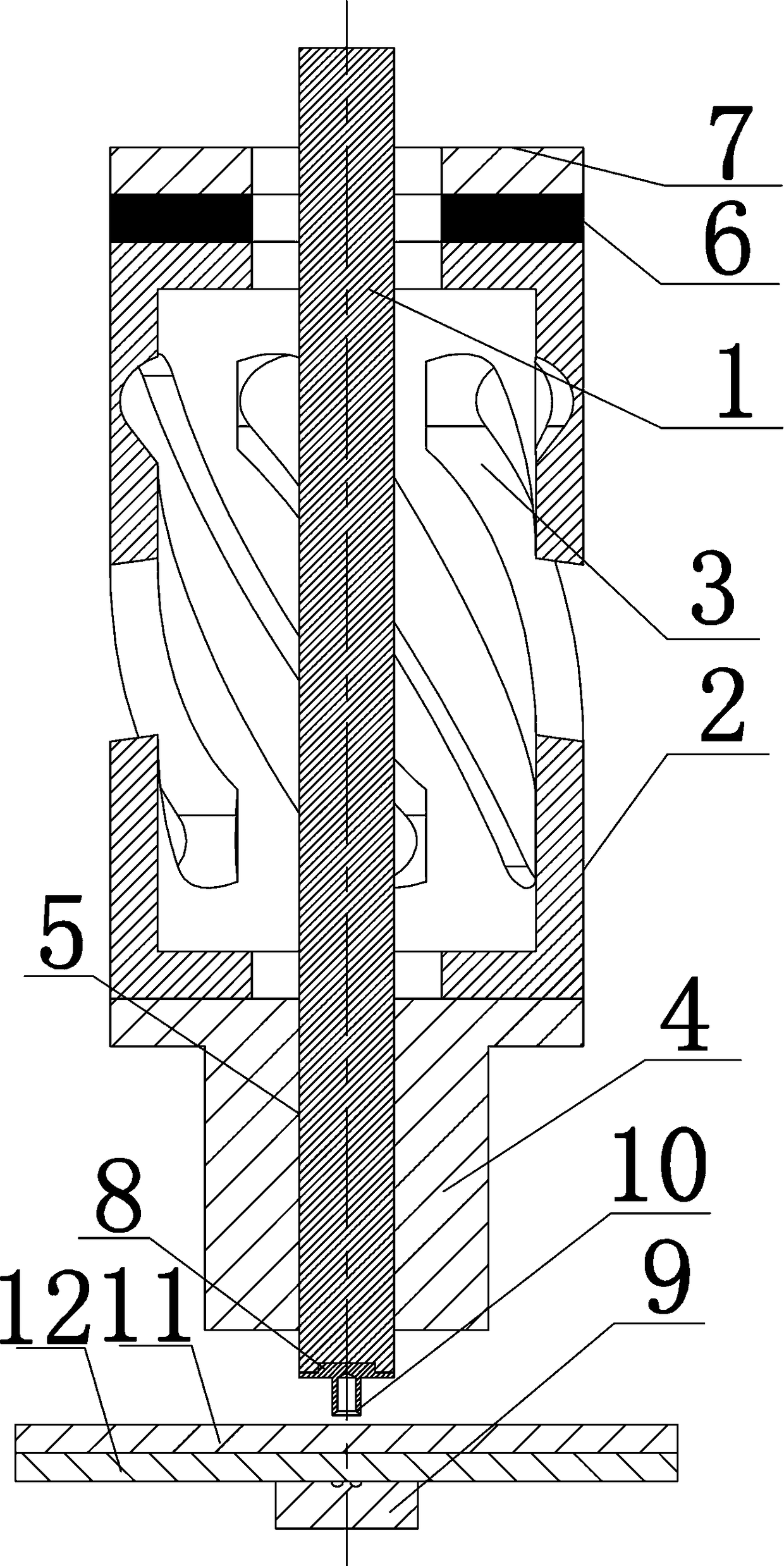

Compression molded tooth

InactiveUS20160293056A1Easy to produceAccurate shapeArtificial teethDentistry preparationsDentistryPolysaccharide

The compression molded tooth used for practicing dental cutting treatment of the present invention comprises a composition containing a powder or powders of saccharide, polysaccharide, protein, and / or glycoprotein each having a particle size of 1 to 100 μm.

Owner:SHOFU INC

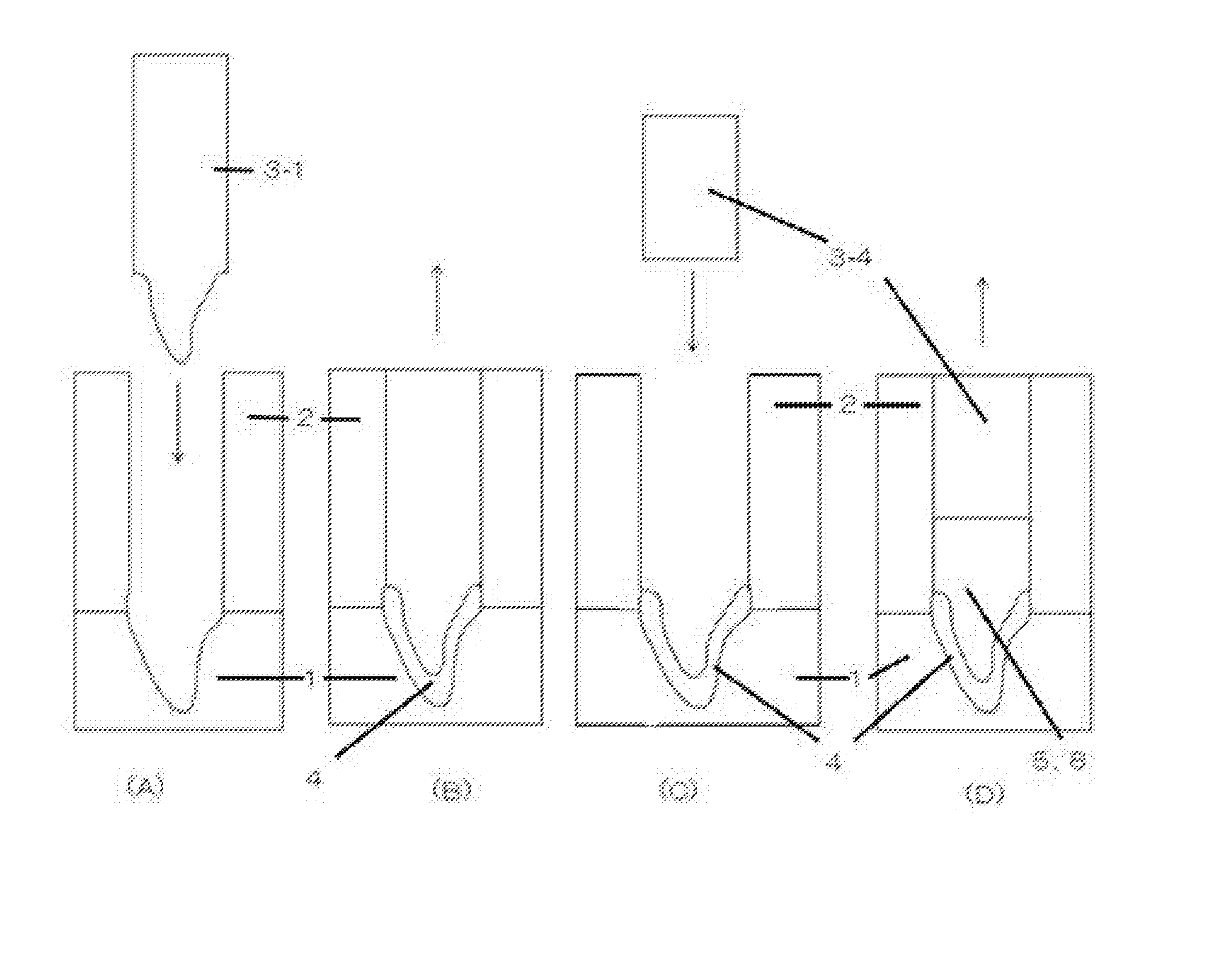

Forming method of lignite lump coal facilitating container transport

The invention discloses a forming method of a lignite lump coal facilitating container transport, which comprises the following steps of: (1) treating raw materials: adjusting the temperature of lignite powder to between 95 and 105 DEG C and the water content to between 12 and 14 percent (weight) by using a drying device; (2) pressing and forming: pressing the lignite powder by using a hydraulic machinery, controlling the pressing pressure to more than 35 MPa, and pressing for three to four times; and (3) cooling: naturally cooling the pressed lump coal by standing. The forming method of lignite lump coal facilitating the container transport has the advantages of simple processing technology, high water resistance and stability of the formed lump coal, contribution to the container transport by sea and land, low dust pollution of coal during use, contribution to environmental protection and great promotion of mining and use of Australian lignite and other lignite.

Owner:ANHUI KEDA IND CO LTD +1

Puncher pin auxiliary device suitable for self-piercing riveting and self-piercing riveting method

PendingCN109365713ASpeed up the flowFully contactedEngineeringElectrical and Electronics engineering

The invention relates to a puncher pin auxiliary device suitable for self-piercing riveting and a self-piercing riveting method. The puncher pin auxiliary device is arranged on the outer side of a puncher pin in a sleeving manner, a hollow amplitude variation mechanism of the puncher pin auxiliary device is driven by a drive mechanism for amplitude variation vibration, and vibration of the amplitude variation mechanism is transmitted to the puncher pin in threaded connection with the amplitude variation mechanism for vibration assistance. In the puncher pin auxiliary device, vibration is transmitted to to-be-connected parts through rivets, and the to-be-connected parts are promoted to be in full contact; metal plates are prevented from cracking, and the pressure needed for riveting is reduced; equipment light weight operation is promoted, the rivets, the plates and concave dies are promoted to be in full contact, the riveting quality is improved, connecting reliability is improved, andstacking can be achieved on traditional self-piercing riveting equipment; and the advantages that the structure is simple, and operability is high are achieved. On the basis of the traditional SPR process, longitrorse composite vibration with controllable amplitude is added for assisting in stimulation, the application range of the SPR process is widened, and connecting reliability between the to-be-connected parts is improved; and the structure is simple, operability is high, the manufacturing process is improved, and the quality of finished products is improved.

Owner:杭州捷能科技有限公司

Preparation method of biomass granular fuel

The invention relates to the field of preparation of biomass granular fuel and specifically relates to a preparation method of biomass granular fuel. According to the preparation method provided by the invention, sorghum straw and cotton stalks are adopted as raw materials which are mixed with ammonium nitrate; in a high-pressure state, a gap appears in the joint between cellulose and lignin in the straw; then, the gap is expanded by ammonium nitrate and soaked in an ethanol oxalate solution; lithium chloride is adopted for catalysis; the cellulose is softened to reduce the forming pressure offorming particles from the fuel; meanwhile, after the cellulose is softened, part of the cellulose is separated from the lignin, and lithium ions are loaded in the formed gap; during combustion, thefuel combustion is more sufficient through catalysis of lithium ions; the softened cellulose can release more heat to promote complete combustion of the lignin; the problems of easy slag formation, ash accumulation and insufficient combustion are reduced in the combustion process; cracks in the fuel are increased, a ventilation channel is added, and combustion is accelerated.

Owner:常州蓝旗亚纺织品有限公司

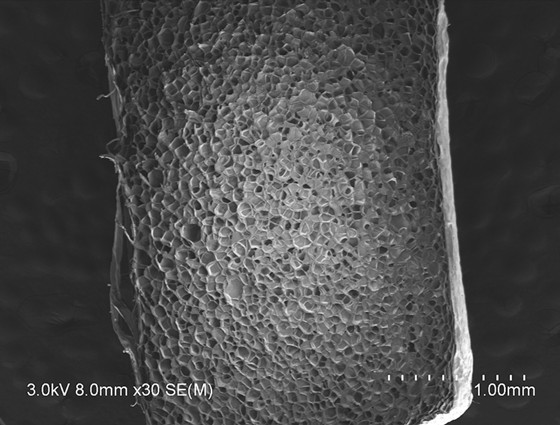

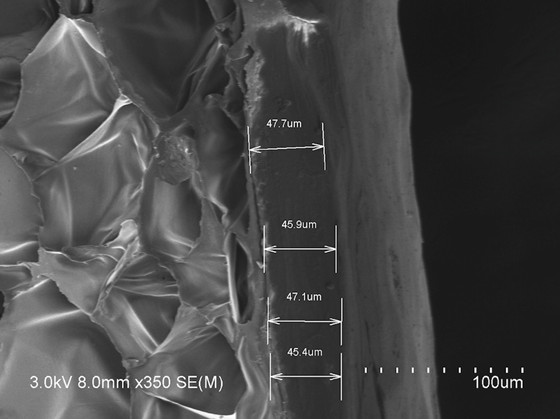

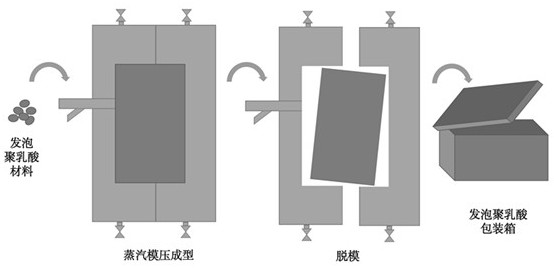

Expandable polylactic acid composite micro-particle with core-shell structure, foamed bead and preparation method of molded piece of expandable polylactic acid composite micro-particle

ActiveCN113372605AImprove flame retardant performanceGood dimensional stabilityElastomerPolymer science

The invention provides an expandable polylactic acid composite micro-particle with a core-shell structure, a foamed bead and a molded piece thereof through structural design and an efficient co-extrusion technology. According to the invention, the outer layer of the composite foamed bead is a biodegradable elastic polyester skin layer, the main component is a biodegradable high-toughness thermoplastic copolyester elastomer, and good rebound resilience and impact resistance are provided for the composite foamed bead; the inner layer of the composite foamed bead is a biodegradable polylactic acid foaming core layer, and the composite foaming bead is high in compression strength, small in shrinkage rate and good in size stability; and the molded piece prepared by using the biodegradable polylactic acid composite foamed bead has the advantage of low molding energy consumption, excellent rebound resilience, impact resistance and dimensional stability, and is an ideal green packaging material for large-size pieces such as large liquid crystal screens of more than 100 inches, large precise electronic devices and the like, which have strict requirements on the size and also have buffering protection requirements.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

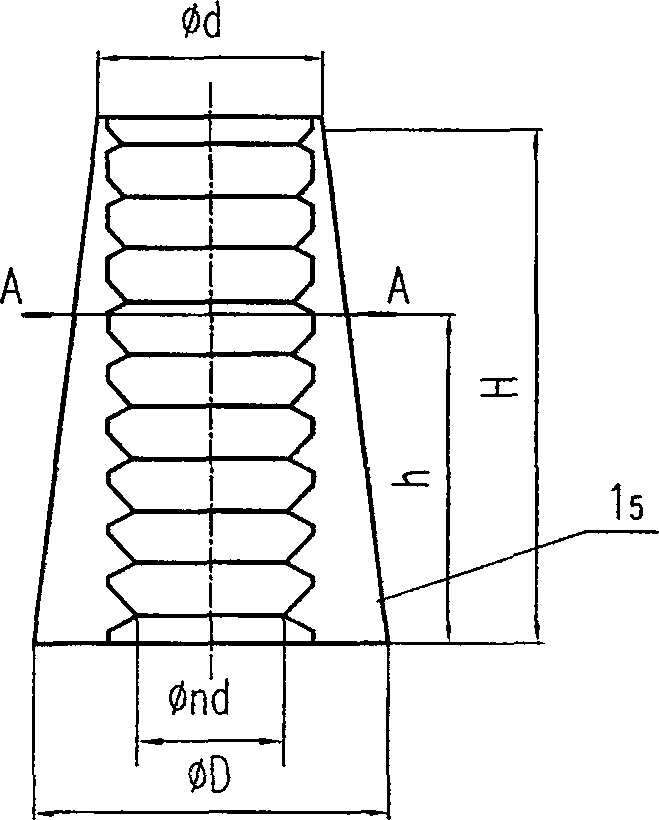

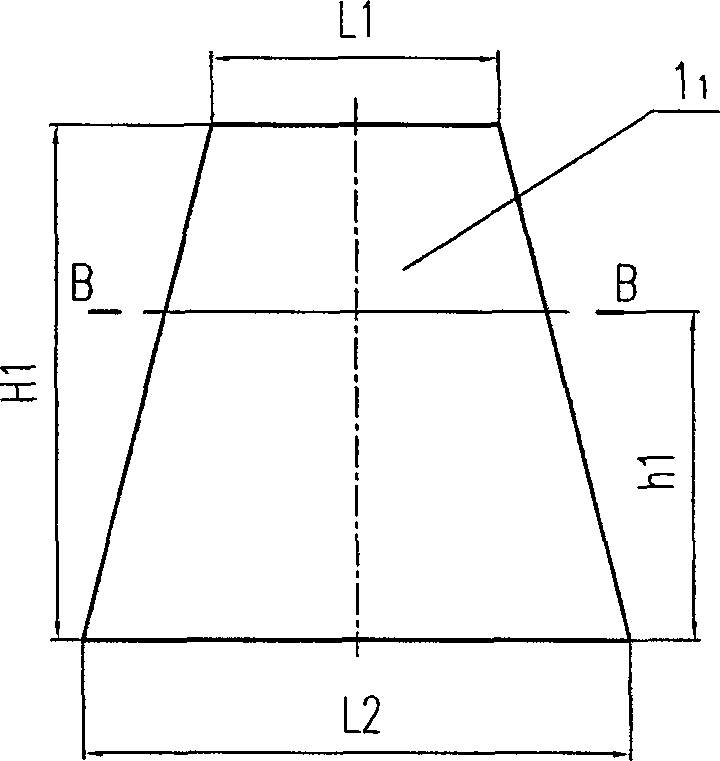

Method for manufacturing single clamping piece of anchorage, and dedicated mould

ActiveCN1872489AIncrease profitReduce processing stepsShaping toolsExtrusion diesEngineeringMechanical engineering

A method for manufacturing the clamping plat of anchor device includes such steps as providing a plate with needed thickness, blanking to obtain an isosceles trapezoidal plate, punching with a bending die set to obtain an arc plate, pre-shaping with the shaping die sets A and B, fine shaping with the shaping die set C, and machining internal teeth by squeezing or milling. The said all die sets are composed of male die and female die.

Owner:LIUZHOU OVM MASCH CO LTD

Predicting Shrinkage of Injection Molded Products with Viscoelastic Characteristic

ActiveUS20140156237A1Increase shear viscosityReduce shear rateComputation using non-denominational number representationDesign optimisation/simulationShear rateSpecific volume

A computer-implemented method and non-transitory computer medium for calculating a shrinkage of a molding product comprises a step of using a computer processor to calculate a molding pressure of a molding fluid in a molding cavity by taking into consideration an increase of a shear viscosity of the molding fluid by a decrease of a shear rate, and a step of calculating the shrinkage of the molding products by taking into consideration a variation of a specific volume of the molding fluid as the molding pressure and a molding temperature decrease.

Owner:CORETECH SYST

Device for forming bevel gear through ultrasonic-assisted cold-rocking-rolling and machining method

ActiveCN112756708AIncrease vibrational energyMeet processing needsGear teethPiezoelectric actuatorsEngineering

The invention discloses a device for forming a bevel gear through ultrasonic-assisted cold-rocking-rolling. The device comprises a base, a lower die and an ultrasonic horn, wherein the base has an accommodating cavity with an upward opening; the lower die is used for clamping a workpiece; the ultrasonic horn is mounted in the accommodating cavity and comprises a positioning section, a first vibration mounting section and a vibration conversion output section which are sequentially and coaxially arranged along a vertical axis; the positioning section is connected with the base and is positioned in the circumferential direction; a first piezoelectric actuator is mounted on the first vibration mounting section; a second piezoelectric actuator is mounted on the vibration conversion output section; ultrasonic vibration generated by the first piezoelectric actuator and ultrasonic vibration generated by the second piezoelectric actuator are superposed; and the vibration conversion output section makes contact with the workpiece and is used for transferring the ultrasonic vibration to the workpiece. The accommodating cavity is used for accommodating the ultrasonic horn, and ultrasonic vibration with larger vibration energy is generated after the ultrasonic vibration generated by the first piezoelectric actuator and the second piezoelectric actuator on the ultrasonic horn is utilized and superposed, so that the machining requirement is met.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com