Injection molding machine and controller

An injection molding machine and controller technology, applied in the field of injection molding machines, can solve the problems of high energy consumption, uncontrolled, wasted energy, etc., and achieve the effects of low energy consumption, low clamping pressure, and fast air discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The injection molding process is a combination of art and science. It allows an experienced mold setter to properly run a particular mold on a particular molding machine. These individuals make the best possible part at the lowest possible cost through differential control of the machinery, molds, and other auxiliary equipment involved in the forming process. Thus, the molding machine preferably provides all the controls the setter needs to do his job.

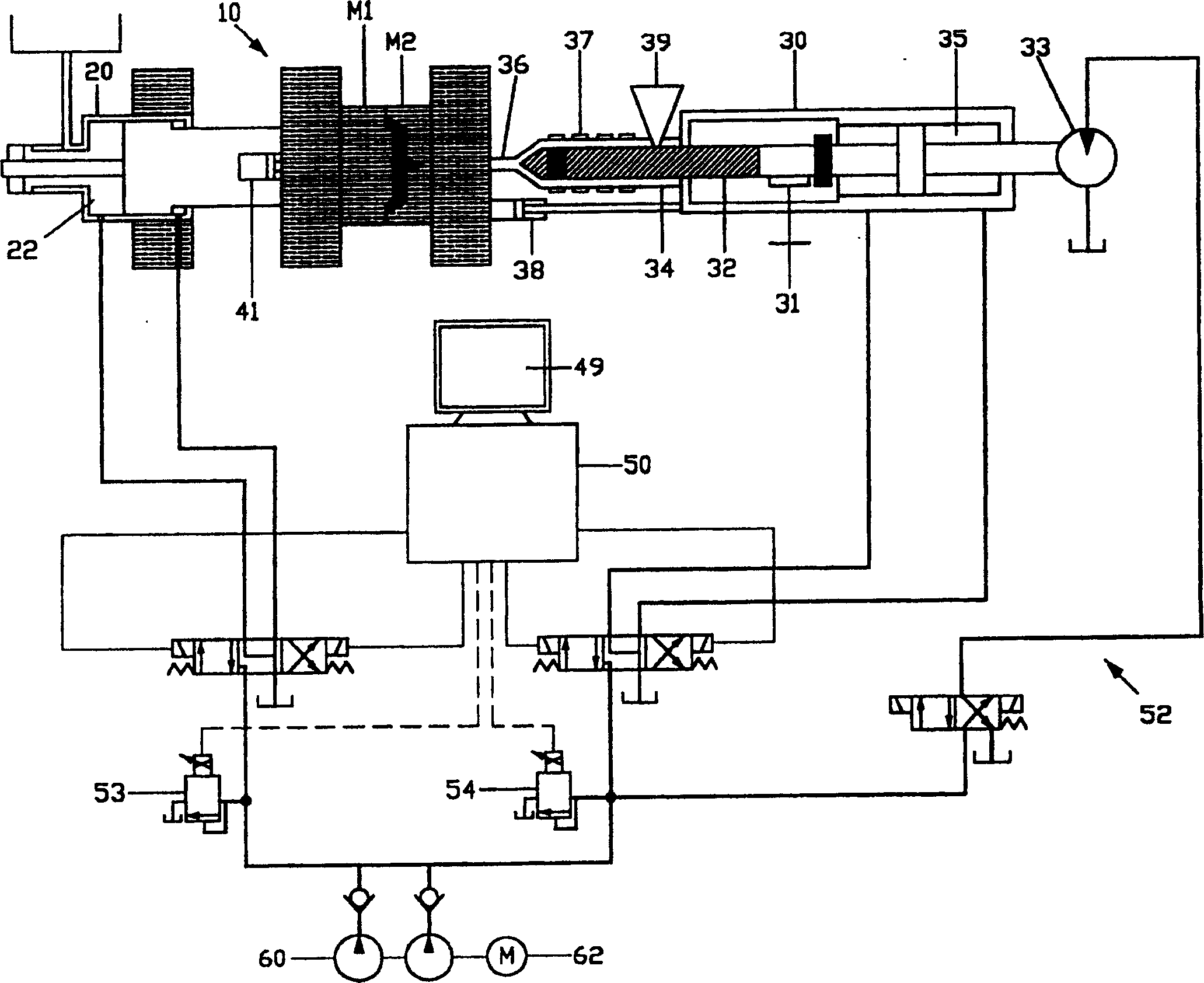

[0032] figure 1 An injection molding machine 10 is schematically shown, which manufactures molded parts by injecting material into a two-part mold shown M1 , M2 , the mold part. The mold can have more than two parts (multi-part mold), but two parts are required. The mold clamping mechanism includes at least one clamping cylinder 20 for applying mold clamping force to the two-part mold and for removing the mold parts to open the mold. An injection mechanism 30 is provided for plasticizing the material and injecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com