Hollow plate and manufacturing method thereof

A manufacturing method and hollow technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve problems such as difficulty in lap jointing of overlapping profiles, poor vertical strength, and inability to be popularized, so as to improve competition. Force, short molding cycle, and the effect of reducing mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

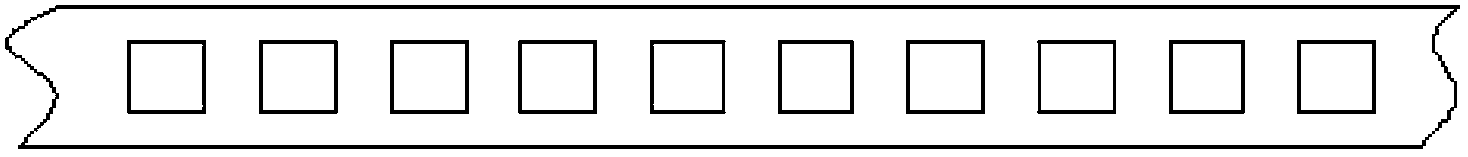

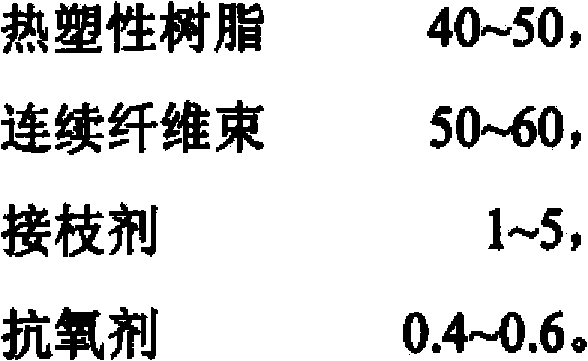

[0038] A continuous glass fiber reinforced polypropylene hollow board, the structure of which is as follows figure 1 shown. In this example, continuous glass fiber reinforced polypropylene is selected as raw material, 50 parts of polypropylene, 3 parts of grafting agent, and 0.5 parts of antioxidant are added to the extruder, and after stretching the fibers at the die head and through multiple mechanical rollers 50 parts of continuous glass fiber bundles are infiltrated and compounded, and then roll-formed to make a prepreg tape by roller winding and curling.

[0039] The specifications for making hollow boards are 2000mm*1500mm*10mm, and the preparation method is as follows:

[0040] (1) Cut the strip-shaped prepreg tape, and lay it in the direction of 0° / 90° according to the direction of the continuous fiber in the prepreg tape, and the laying thickness is 5mm;

[0041] (2) Evenly insert a 5mm diameter steel cylindrical core material sprayed with polytetrafluoroethylene in...

Embodiment 2

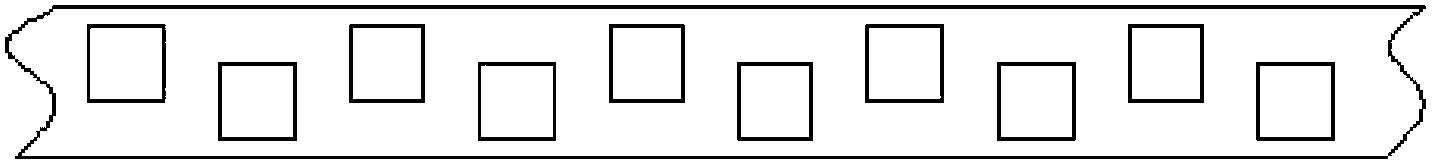

[0047] A continuous glass fiber reinforced polypropylene hollow board, the structure of which is as follows figure 2 shown. In this example, continuous glass fiber reinforced polypropylene is selected as raw material, 50 parts of polypropylene, 3 parts of grafting agent, and 0.5 parts of antioxidant are added to the extruder, and after stretching the fibers at the die head and through multiple mechanical rollers 50 parts of continuous glass fiber bundles are infiltrated and compounded, and then roll-formed to make a prepreg tape by roller winding and curling. The specifications for making hollow boards are 2000mm*1500mm*12mm, and the preparation method is as follows:

[0048] (1) Cut the strip-shaped prepreg tape, and lay it in the direction of 0° / 90° according to the direction of the continuous fiber in the prepreg tape, and the laying thickness is 5mm;

[0049] (2) After inserting a steel cylindrical core material with a diameter of 5mm wrapped by a PET film coated with a...

Embodiment 3

[0056] Continuous glass fiber reinforced polyamide hollow board. In this example, continuous glass fiber reinforced polyamide is selected as raw material. 50 parts of polyamide, 3 parts of grafting agent, and 0.5 parts of antioxidant are added to the extruder. The 50 parts of continuous glass fiber bundles after multiple mechanical rolling and stretching are subjected to impregnation and compounding, and then roll forming, and the prepreg tape is made by roller winding and curling. The specifications for making hollow boards are 2000mm*1500mm*10mm, and the preparation method is as follows:

[0057] (1) Cut the strip-shaped prepreg tape, and lay it in the direction of 0° / 90° according to the direction of the continuous fiber in the prepreg tape, and the laying thickness is 5mm;

[0058] (2) Evenly insert a steel square core material with a thickness of 5mm sprayed with polytetrafluoroethylene into the laid prepreg tape at a distance of 60mm, and then put it into the mold of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com