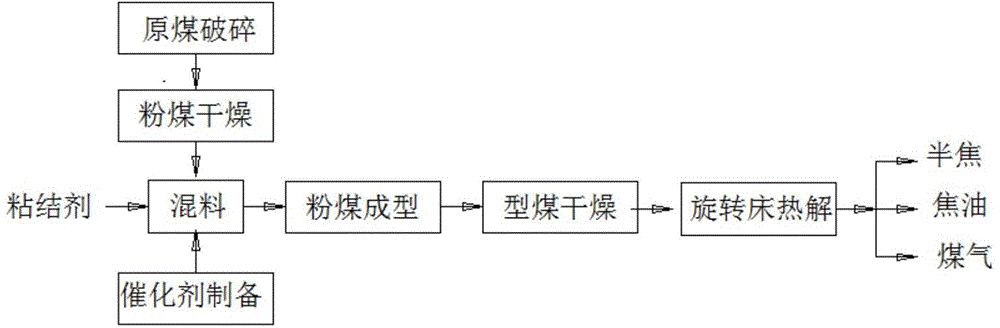

Revolving bed coal catalytic pyrolysis method

A rotary bed, coal catalysis technology, applied in the direction of indirect heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems of easy pulverization and low coal strength, so as to prolong the service life, reduce the energy consumption of forming, and reduce the forming The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

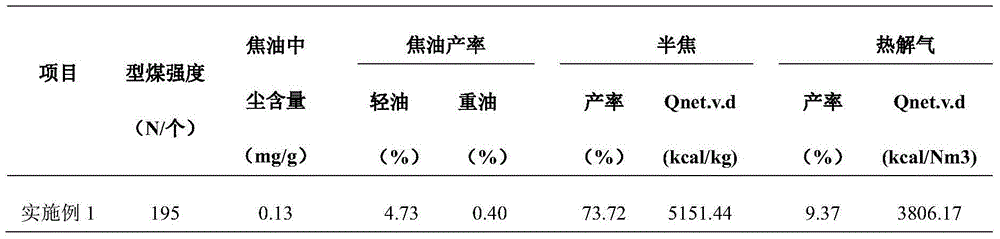

Embodiment 1

[0041] The catalyst of this embodiment is Fe 2 o 3 and CaO; the weight percent of pulverized coal molding is: pulverized coal: Fe 2 o 3 : CaO: binder = 79%: 5%: 1%: 15%; molding pressure is 21MPa / piece, drying temperature is 110°C, rotating bed pyrolysis temperature is 500°C, rotating bed processing capacity is 1 million tons / year. The catalytic pyrolysis results are shown in Table 1.

[0042] Table 1 Catalytic pyrolysis results (dry basis)

[0043]

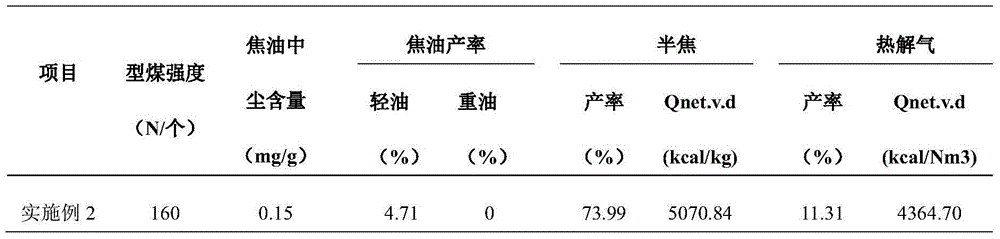

Embodiment 2

[0045] The catalyst of this embodiment is Fe 2 o 3 and CaO; the weight percent of pulverized coal molding is: pulverized coal: Fe 2 o 3 : CaO: binder = 75%: 6%: 2%: 17%; the molding pressure is 22MPa / piece, the drying temperature is 115°C, the pyrolysis temperature of the rotating bed is 550°C, and the processing capacity of the rotating bed is 1 million tons / year. The catalytic pyrolysis results are shown in Table 2.

[0046] Table 2 Catalytic pyrolysis results (dry basis)

[0047]

Embodiment 3

[0049] The weight percent of the pulverized coal molding of the present embodiment is: pulverized coal: Fe 2 o 3 : CaO: binder=74%:4%:3%:19%; molding pressure is 24MPa / piece, drying temperature is 105°C, rotary bed pyrolysis temperature is 550°C, rotary bed processing capacity is 1,000,000 tons / year. The catalytic pyrolysis results are shown in Table 3.

[0050] Table 3 Catalytic pyrolysis results (dry basis)

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com