Oil cylinder assembly and full-automatic two-way pressurizing hydraulic brick press with same

A technology of two-way pressurization and brick press, applied in the direction of forming indenter, ceramic forming machine, fluid pressure actuating device, etc., can solve the problems of large hydraulic system, long pressing distance of upper die core and small flow demand, etc. Achieve the effect of high brick density, high production efficiency and less mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

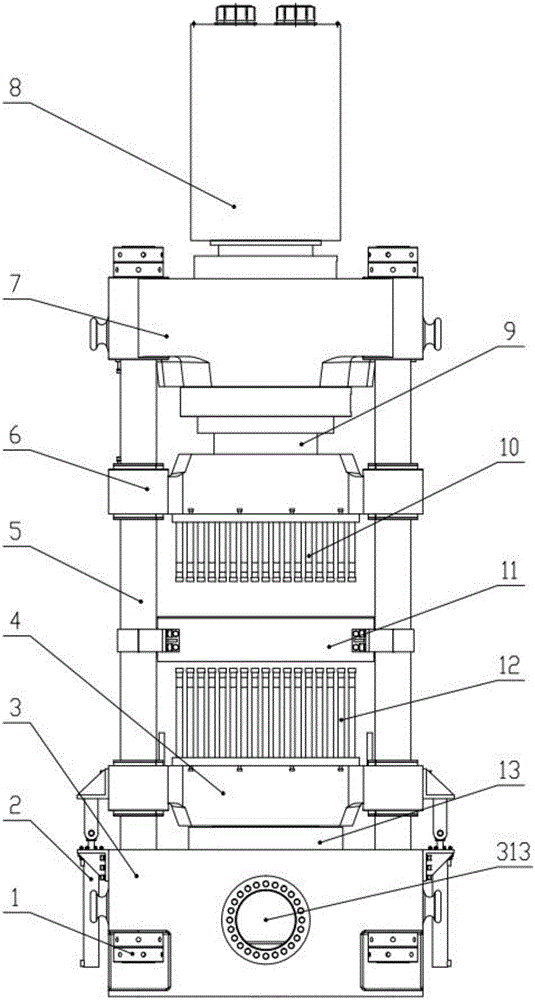

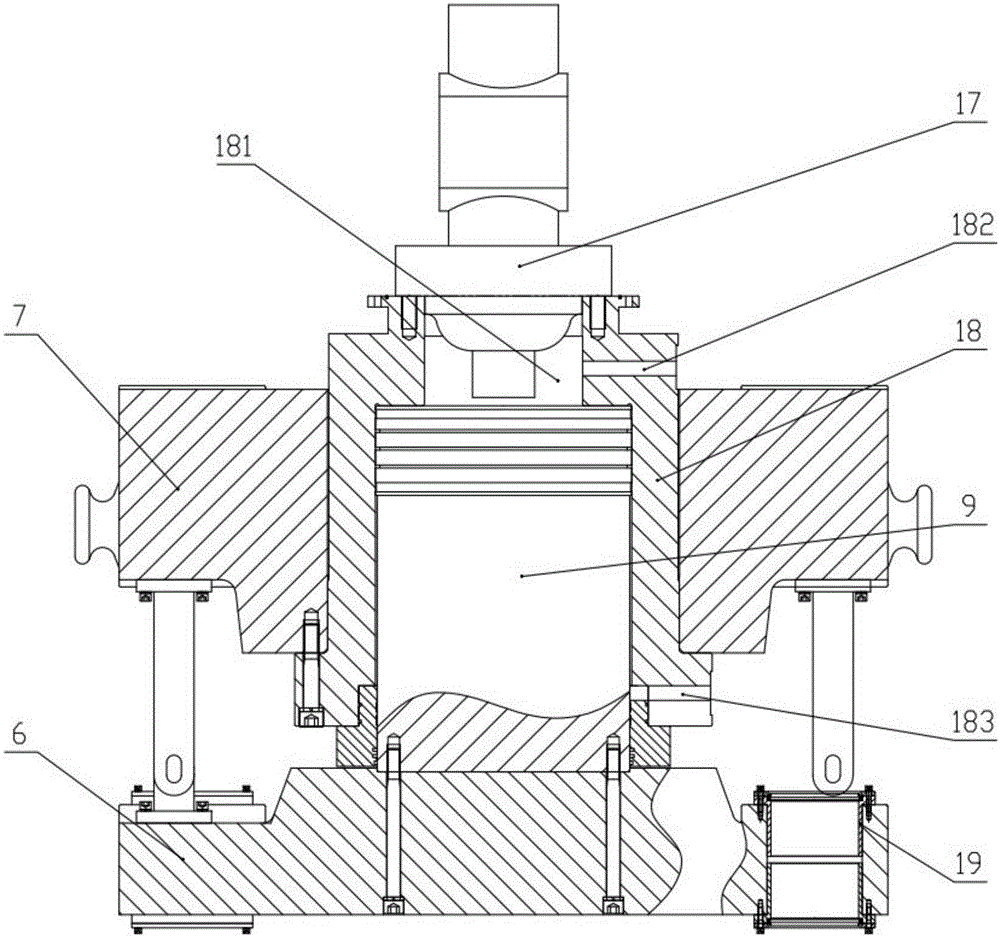

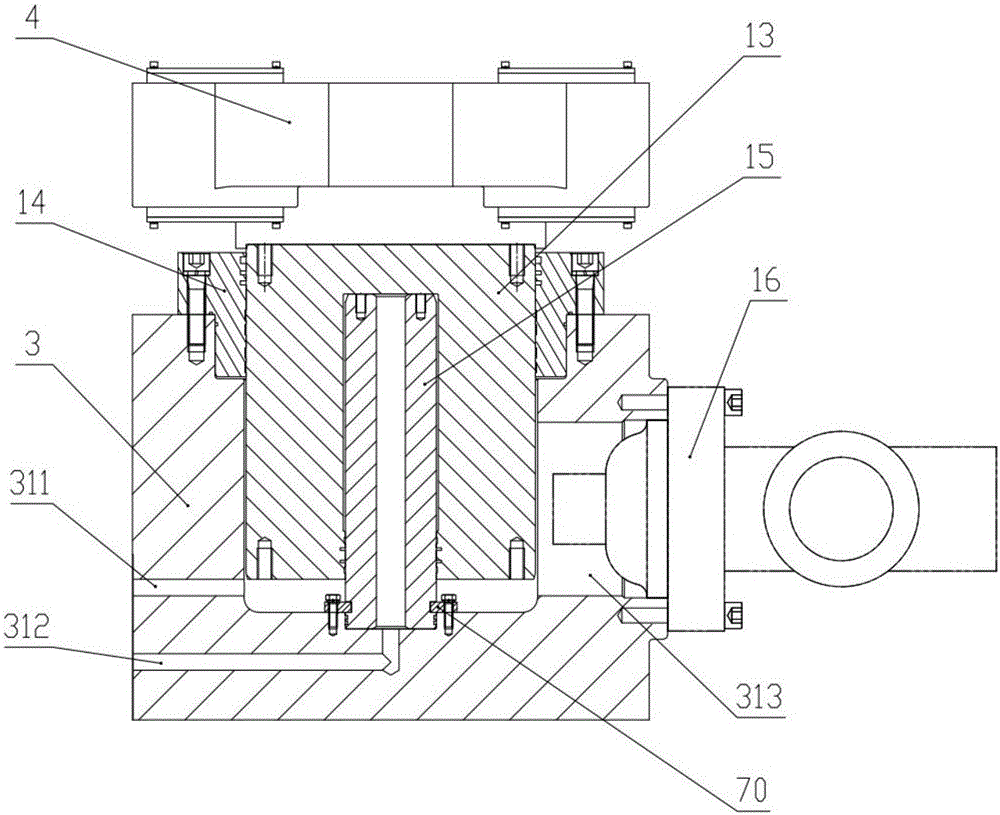

[0016] to combine figure 1 , the full-automatic two-way pressurized hydraulic brick press of the present invention includes a hydraulic control system (both the existing hydraulic system and the hydraulic control system of the present invention can be used) and a brick press main body, and the brick press main body includes an upper fixed Crossbeam 7, lower fixed crossbeam 3, upper movable beam 6, lower movable beam 4, middle mold frame 11, upper pressing head 10, lower pressing head 12, four guiding columns 5, upper oil cylinder, lower oil cylinder, the hydraulic control system Provide power for the movement of the upper oil cylinder and the lower oil cylinder, and drive the upper movable beam 6 and the lower movable beam 4 to move up and down along the guide column 5, so that the upper pressure head 10 and the lower pressure head fixed on the upper movable beam 6 and the lower movable beam 4 12 Carry out two-way pressurization and adobe ejection to the powder in the middle f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com