Puncher pin auxiliary device suitable for self-piercing riveting and self-piercing riveting method

An auxiliary device, self-piercing riveting technology, applied in the field of basically no cutting or processing of bars or profiles, metal plates or tubes, it can solve the problems of poor mechanical properties of joints, difficult metal forming, and high welding temperature, so as to improve the quality, Simple structure and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

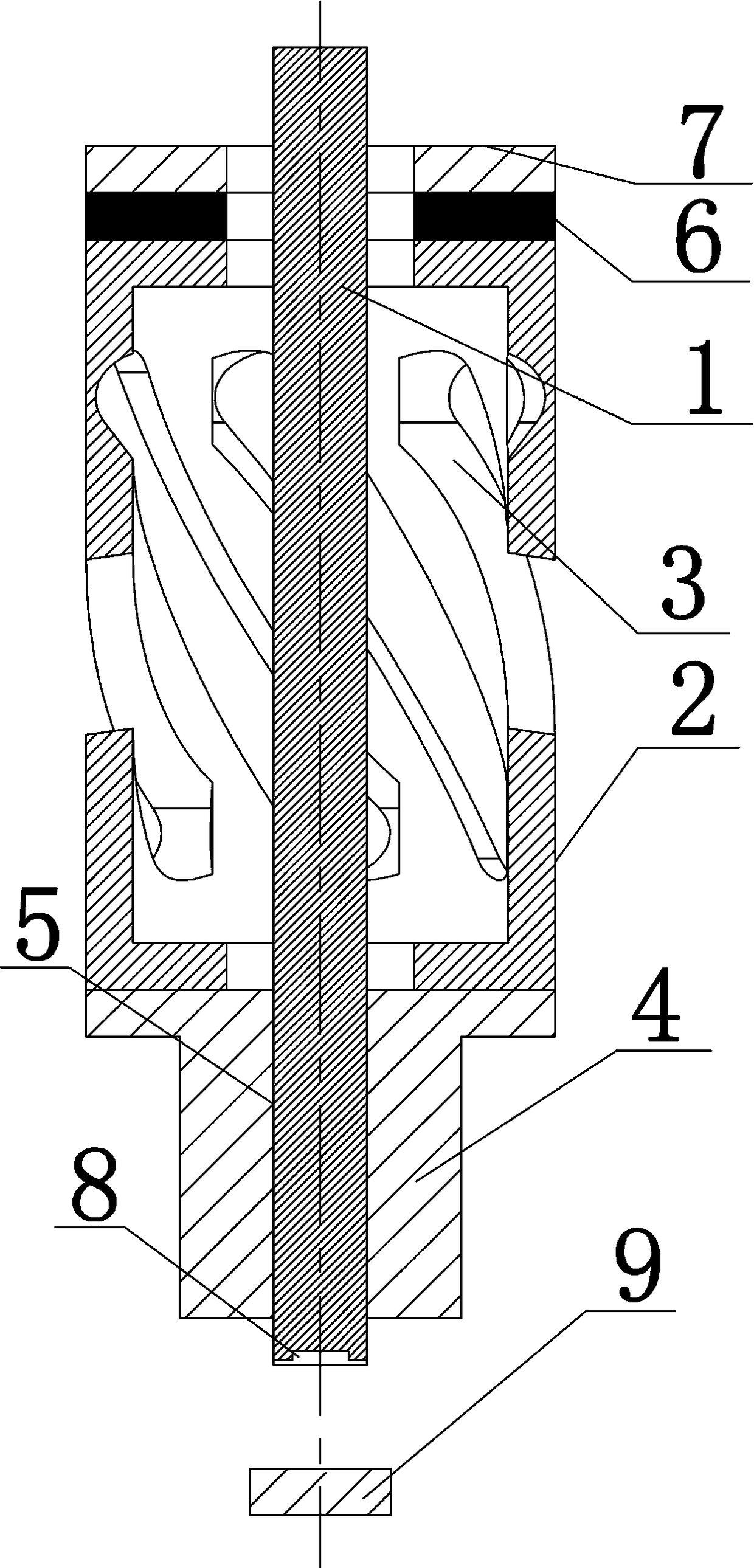

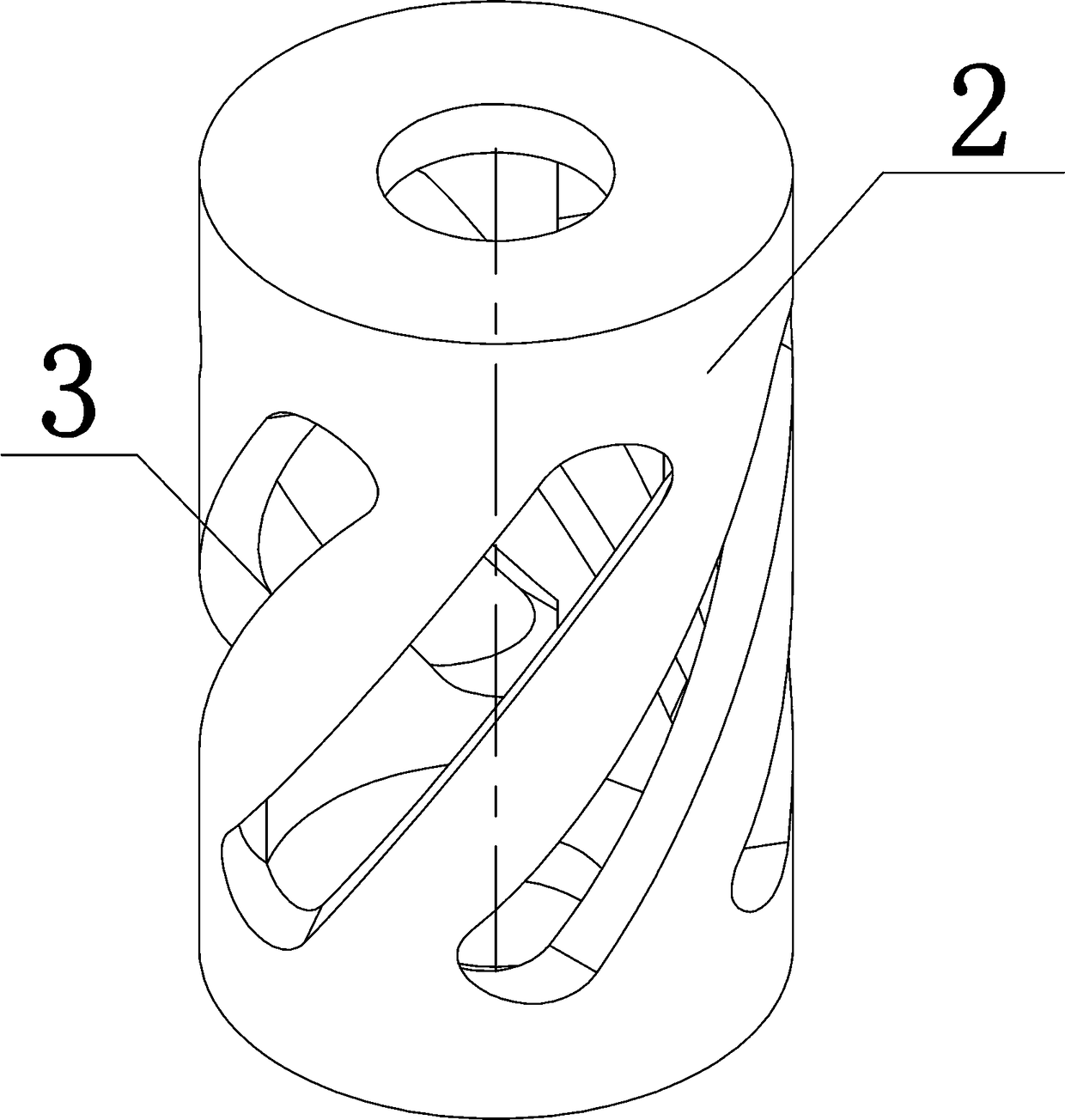

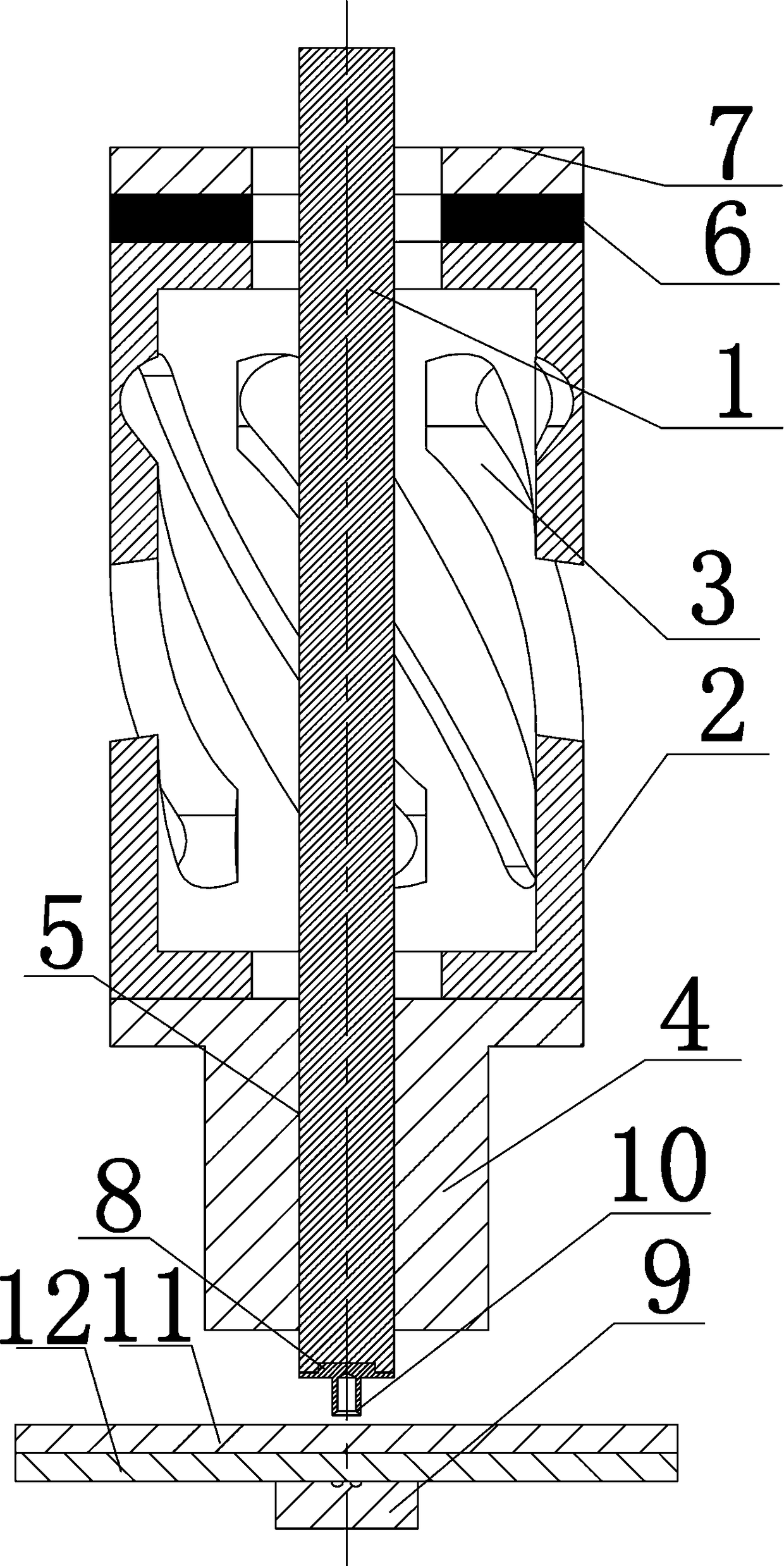

[0042] The invention relates to a punch auxiliary device suitable for self-piercing riveting. The punch auxiliary device is sleeved on the outside of the punch 1. The punch auxiliary device includes a hollow luffing mechanism, and the luffing mechanism cooperates with a There is a driving mechanism, and the amplitude-changing mechanism is screwed with the punch 1 .

[0043] In the present invention, the punch auxiliary device is sleeved on the outside of the punch 1. As a vibration aid for the punch 1, the driving mechanism drives the hollow luffing mechanism to perform the luffing vibration, and transmits the vibration of the luffing mechanism to the punch 1. Vibration assistance for the SPR process.

[0044] In the present invention, the luffing mechanism is threadedly connected with the punch 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com