Gray antistatic polypropylene composite foamed beads with skin-core structure and molded product thereof

A skin-core structure and composite foaming technology, which is applied in the field of polymer material processing, can solve the problems of large temperature changes in antistatic performance, weakening EPP foaming performance, and damaging the surface of electronic devices, etc., to achieve low inorganic filling and reduce re-use Agglomeration phenomenon, the effect of excellent appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

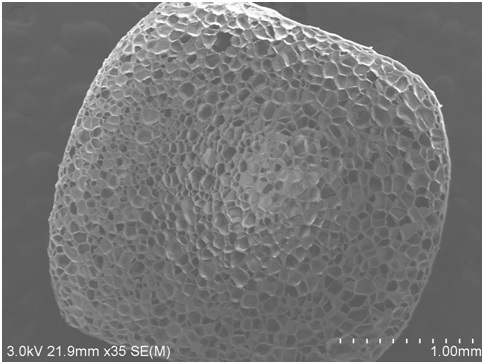

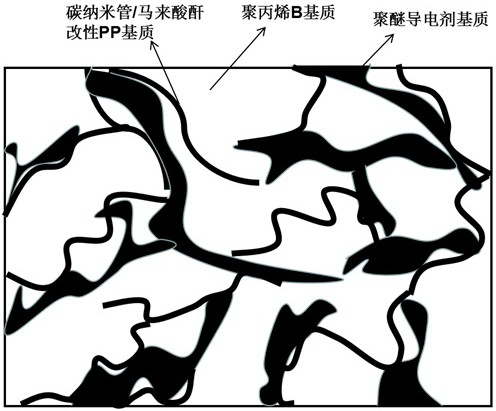

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

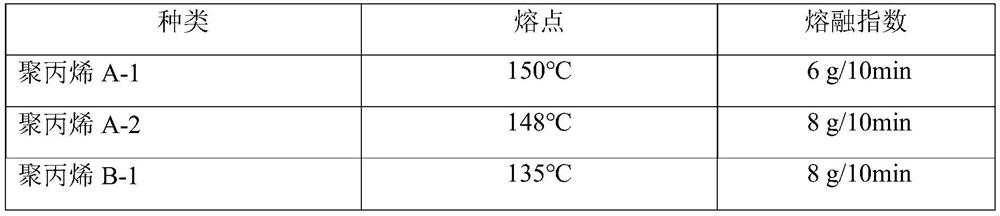

[0028] The main raw materials used in the present invention are shown in Table 1.

[0029] Table 1

[0030]

[0031]

[0032] The antioxidant is a commercially available general-purpose 1076 antioxidant, and the lubricant is a commercially available general-purpose 7001 lubricant.

[0033] The production method of masterbatch F is: after mechanically mixing maleic anhydride branched modified polypropylene D and multi-walled carbon nanotubes (5-10% by we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com