Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1020 results about "Hydraulic machinery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurised according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, and/or pipes.

Transfer robot based on mobile mechanical arm

ActiveCN105500333AFlexible moving processImprove power densityProgramme-controlled manipulatorJointsMobile vehicleHydraulic machinery

The invention discloses a transfer robot based on a mobile mechanical arm, and relates to the field of robots. The transfer robot comprises MACNUM wheels, a vehicle body base, a revolving platform and the mechanical arm; the MACNUM wheels are arranged on the lower portion of the vehicle body base, the revolving platform is arranged on the upper portion of the vehicle body base through a revolving mechanism, and the mechanical arm is arranged on the revolving platform and comprises a first arm, a second arm, a third arm, a wrist joint and a mechanical grasper which are sequentially connected; the mechanical arm is further provided with a first oil cylinder, a second oil cylinder and a third oil cylinder which are used for driving the first arm, the second arm and the third arm respectively, and the portion, at the end of a screw, of the mechanical arm is provided with a revolving motor. According to the transfer robot, a mobile vehicle body based on the MACNUM wheels and the hydraulic mechanical arm are combined together, and the advantages that moving is flexible, the power density is high, and energy supply is convenient are achieved.

Owner:SHANDONG JIANZHU UNIV

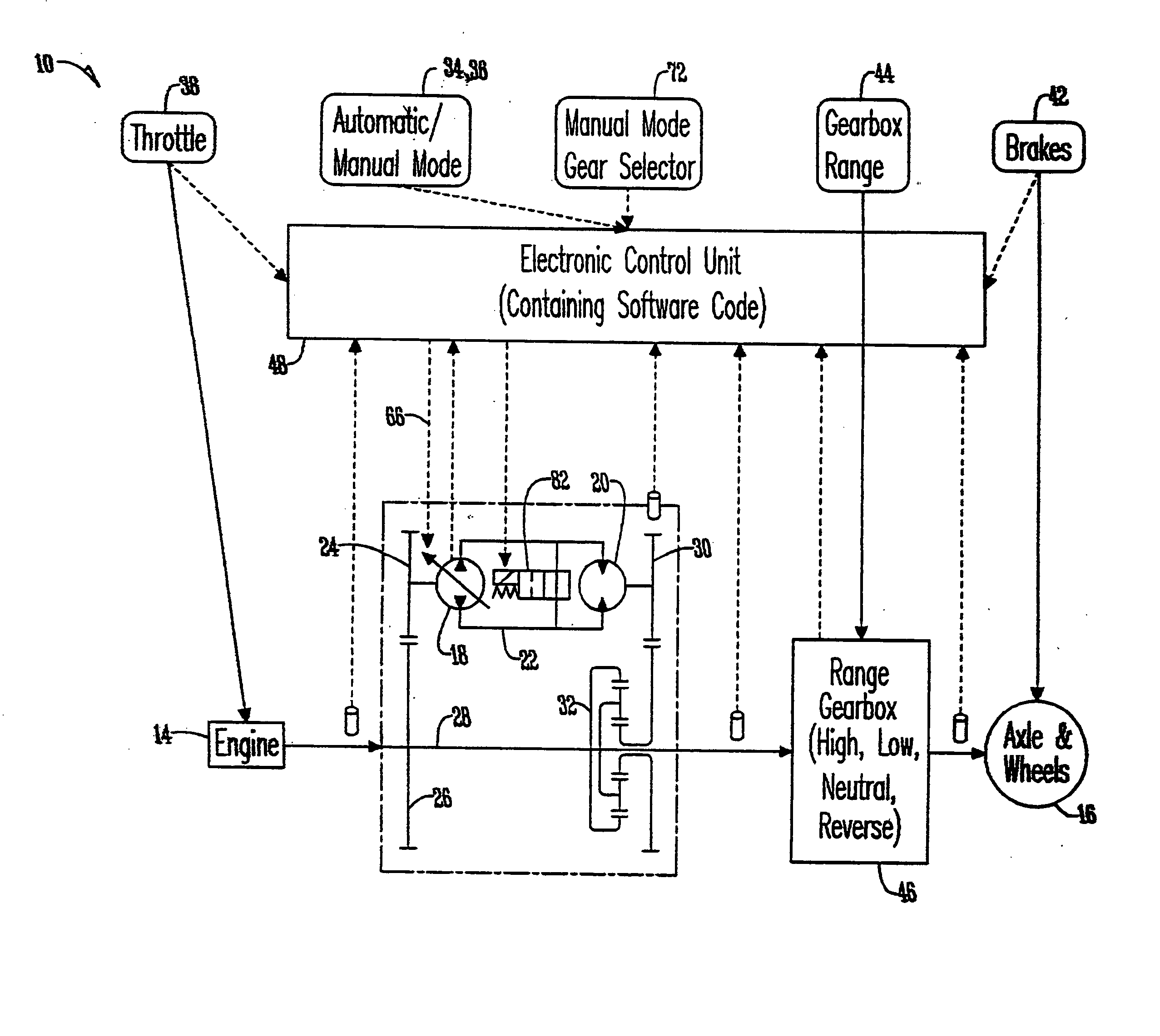

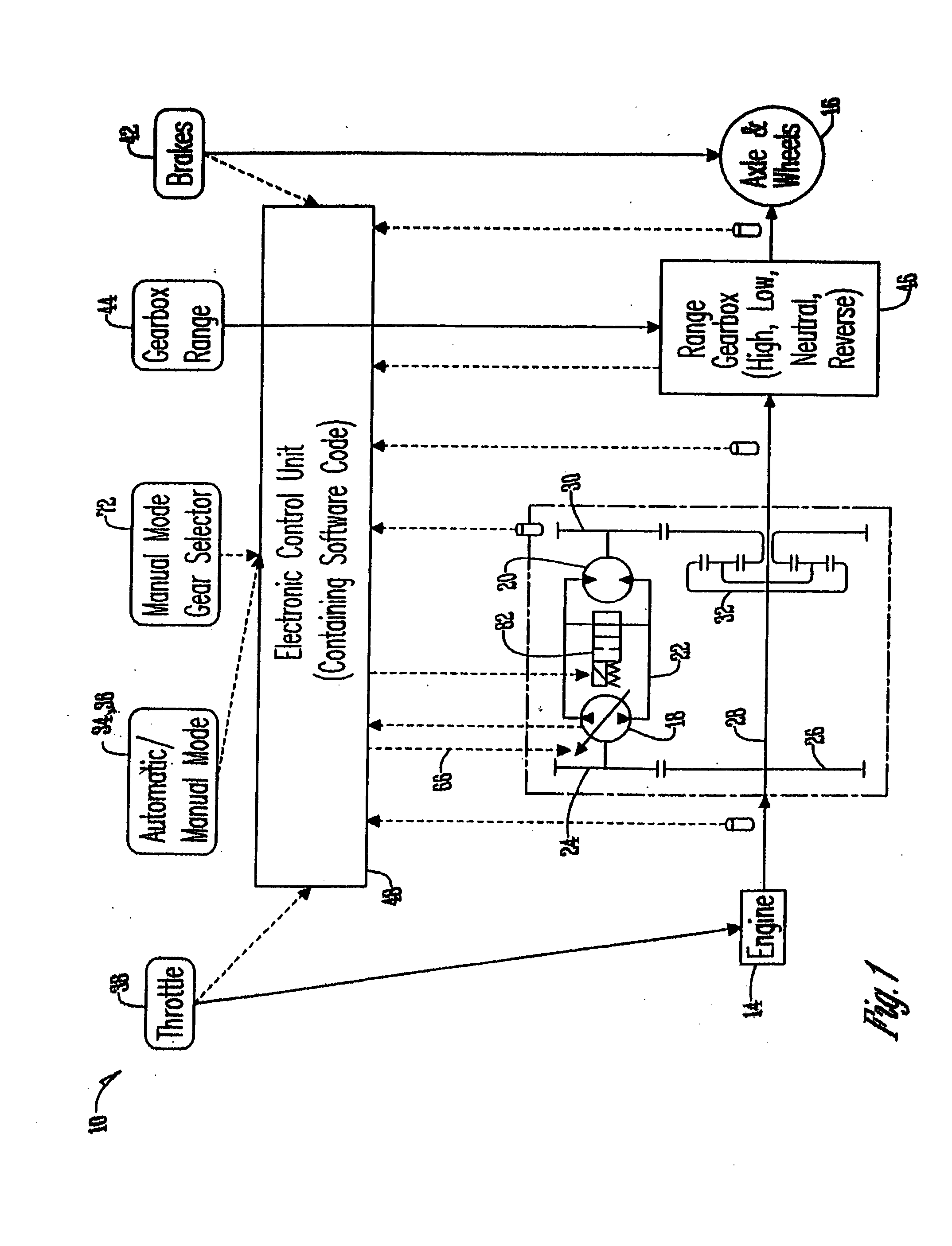

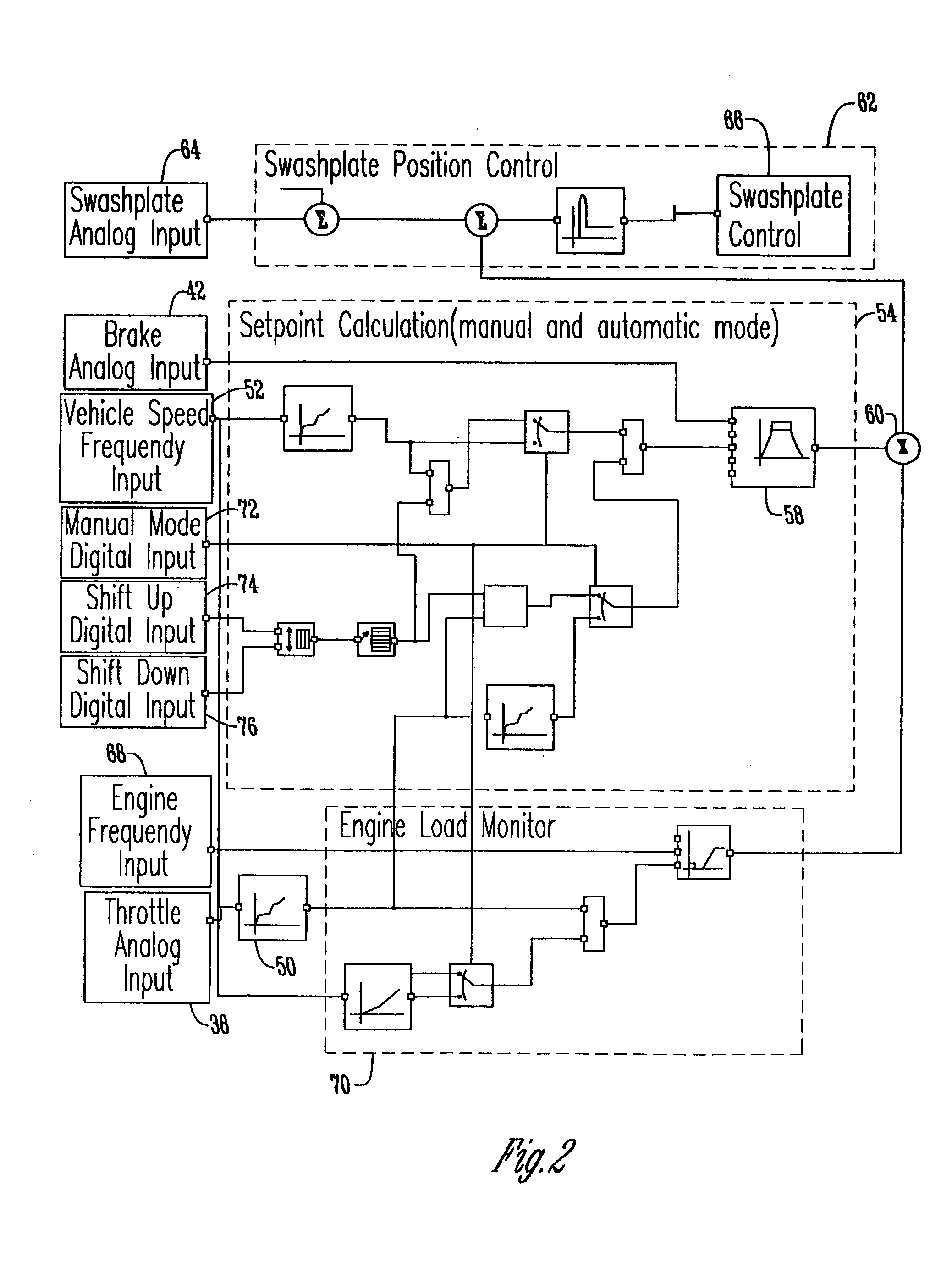

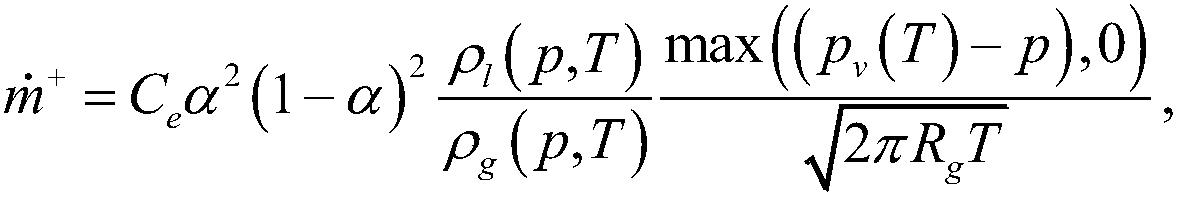

Hydromechanical transmission electronic control system for high speed vehicles

InactiveUS20050085979A1Quick changeSmooth conditionFluid couplingsVehicle fittingsElectronic transmissionElectronic control system

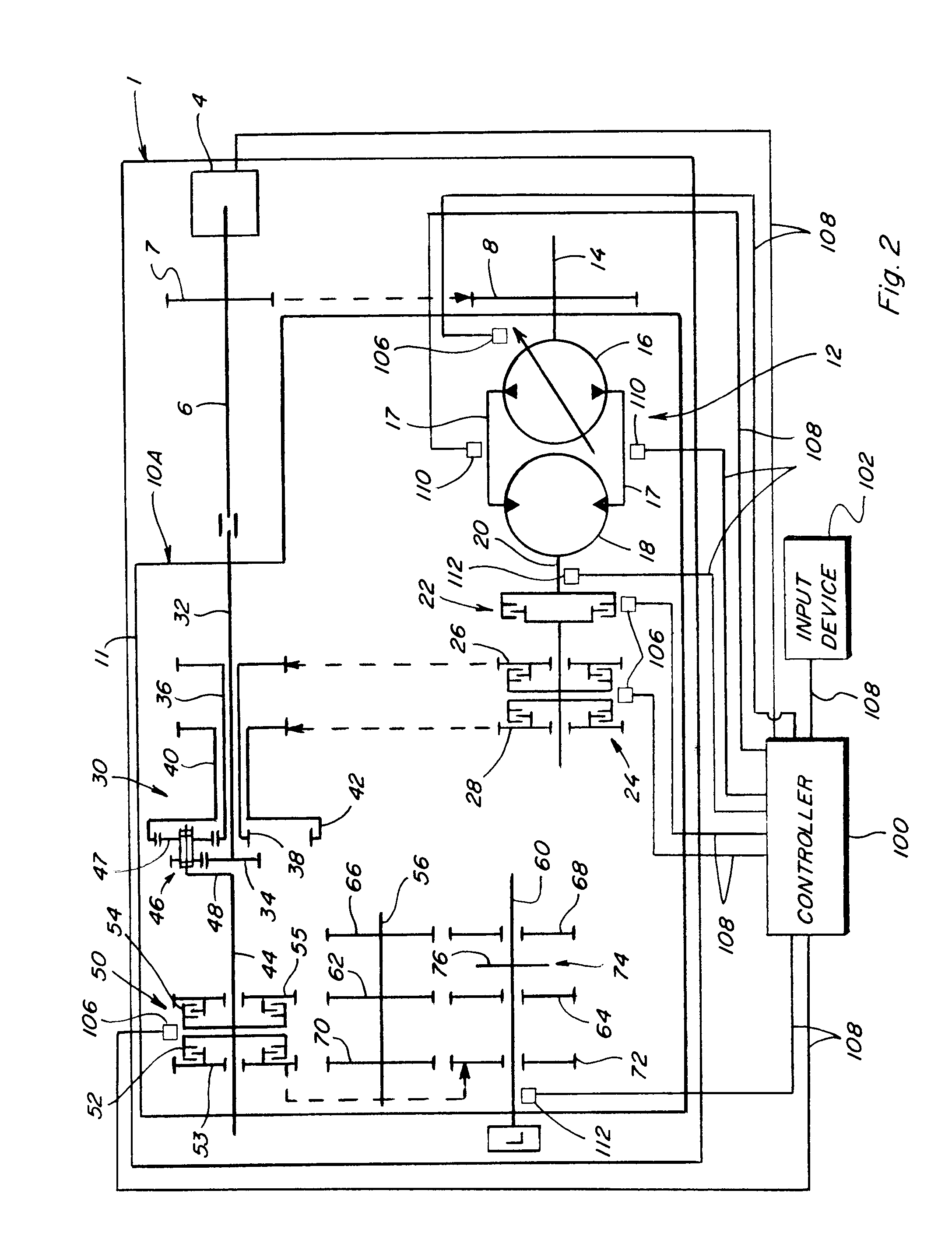

An electronic transmission control system is provided that can achieve a transmission ratio based on the operator inputs and the current vehicle operating conditions. The transmission constantly connects the engine to the load, and the transmission ratio is only varied by a change in command from the present invention. The transmission's mechanical function is solely to vary the ratio between its input and output. In using the present invention, an operator must select an operating mode, either automatic or manual, using a two-position switch. While in the automatic mode, the present invention determines the vehicle speed by considering the position of the throttle and the operator's use of brakes. In the manual mode, the present invention further considers the operator's selection of a gear condition.

Owner:DANFOSS POWER SOLUTIONS INC

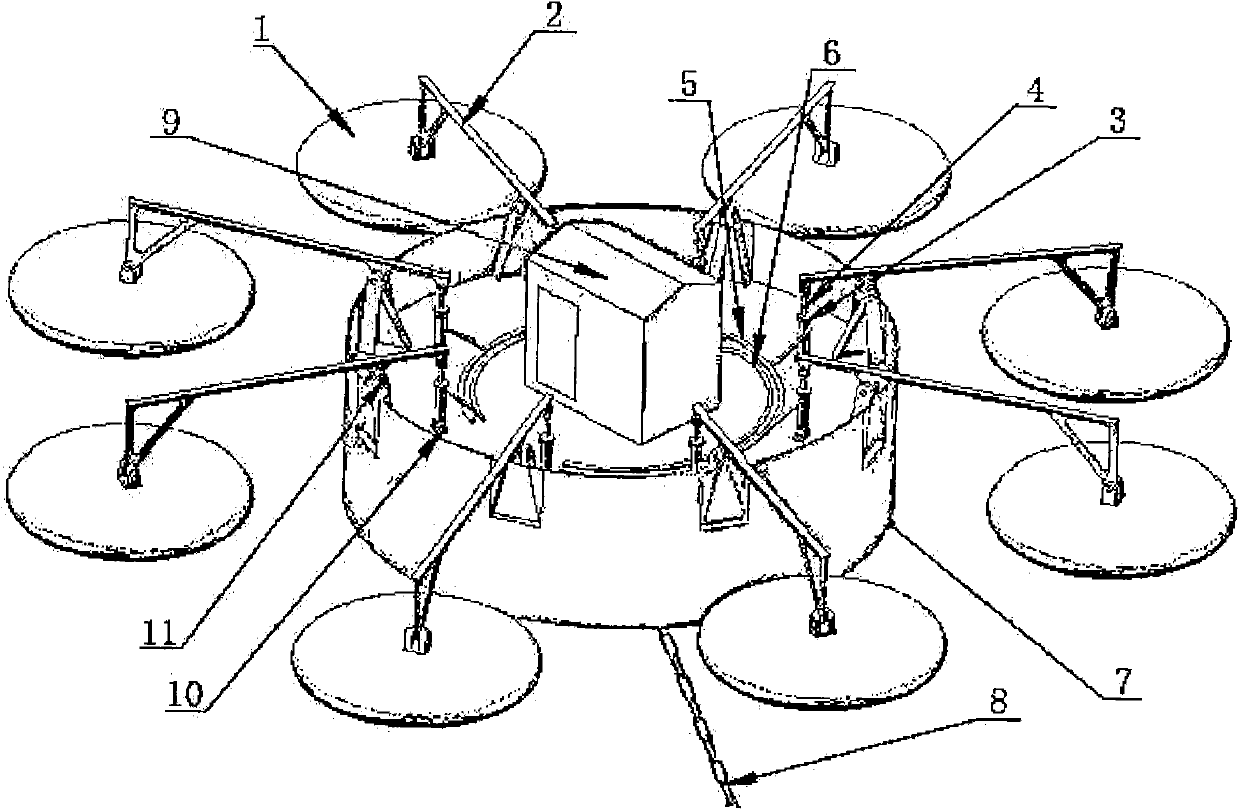

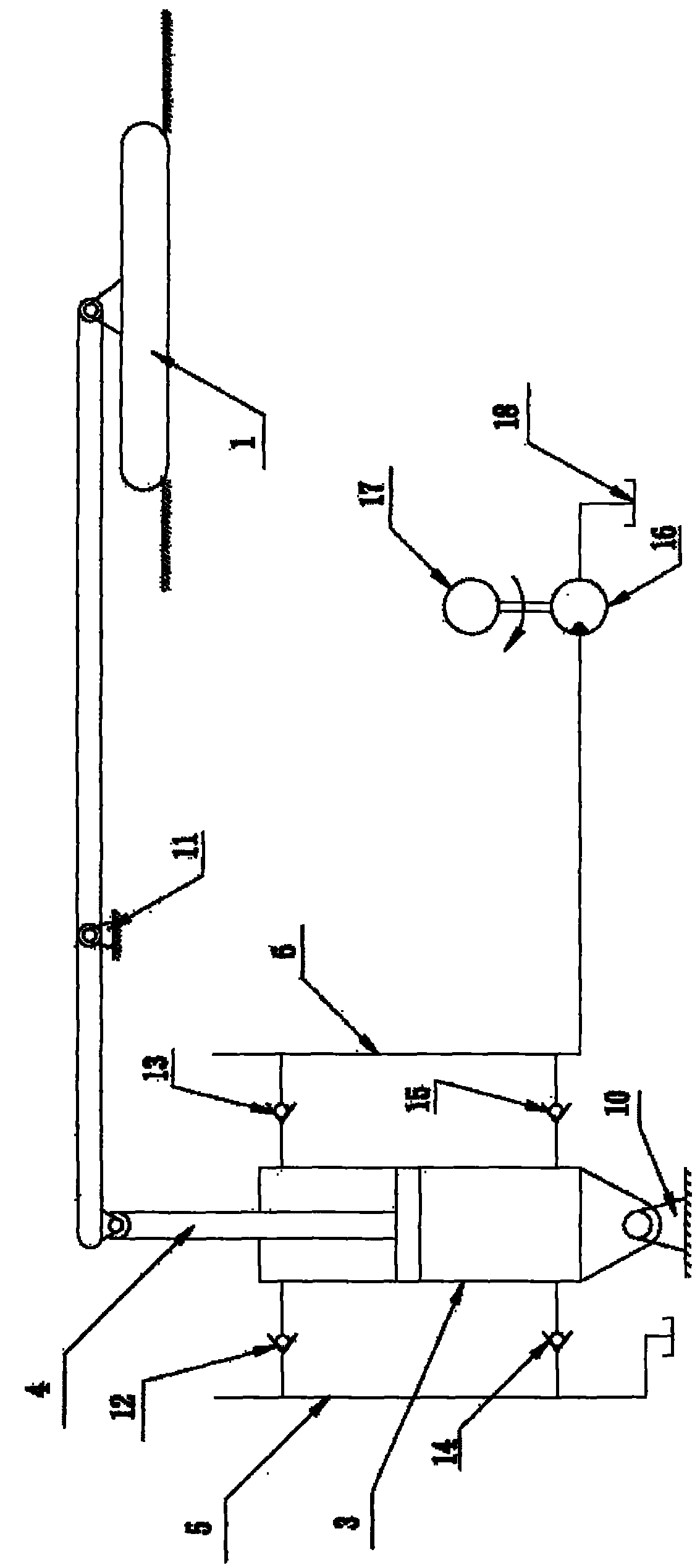

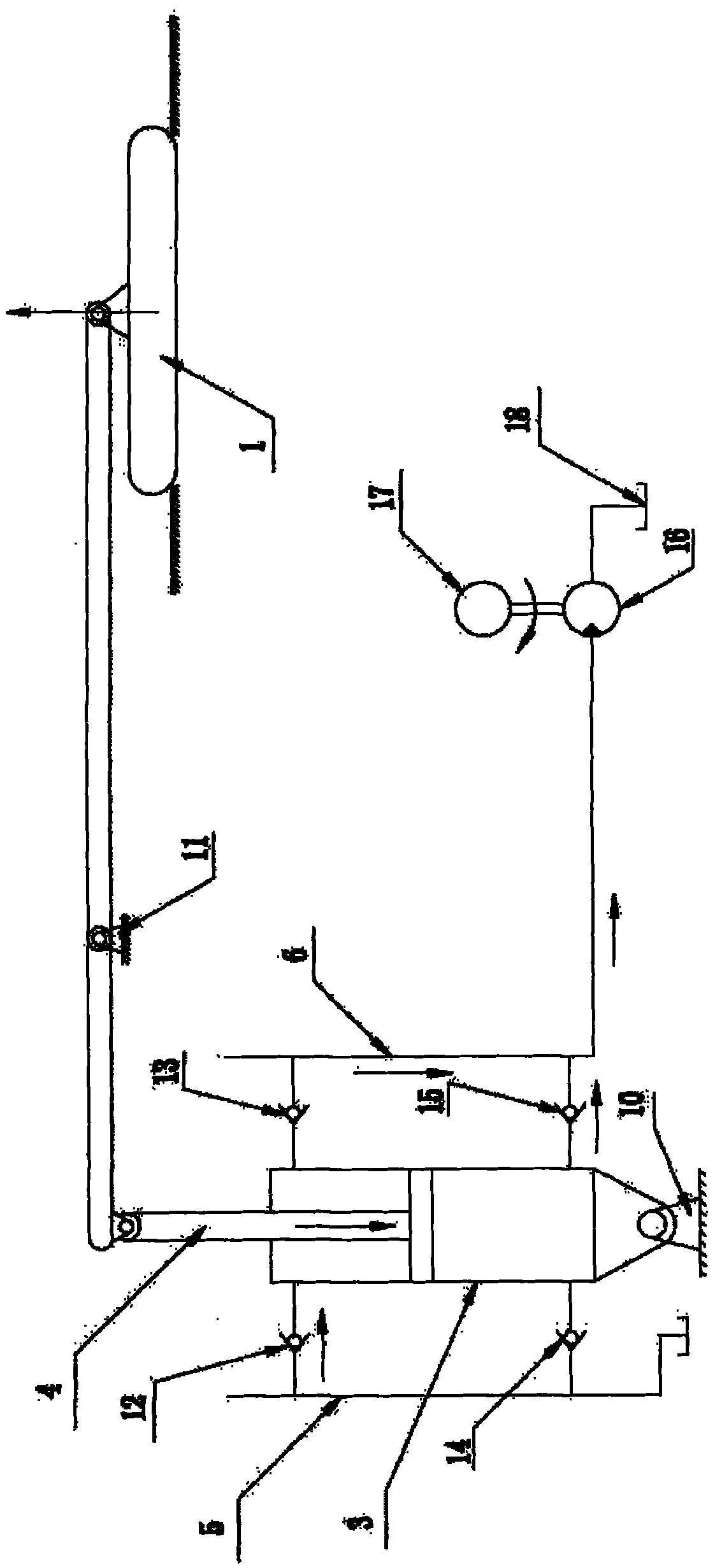

A floating type wave power generation system

InactiveCN102022248AEfficient captureControllable outputMachines/enginesEngine componentsWave power generationMechanical energy

A floating type wave power generation system is characterized in that the system consists of eight sets of lever-type floating bodies and a hydraulic energy accumulation converter with the hydraulic pump function. On a floating workbench 7, eight sets of levers 2 and a floating body 1 are connected through supporting hinge bearers 10 and 11; in this way, the highly undulating displacement caused by waves can be converted to relatively lesser displacement of a piston rod 4, and the minor force that the floating body bears can be converted through the lever to the major force on the piston rod. The piston rod drives a hydraulic tank 3 to switch and transmit the hydraulic energy through a connecting oil pipe5, a high-pressure oil pipe6, a hydraulic oil tank and four no-return valves of each set to a hydraulic motor in a hydraulic power generation control chamber 9; in this way the generator is driven to work. The present system can absorb, convert and accumulate the intermittent unstable wave energy in a highly effective way and can buffer the destructive effect of waves. The floating platform can be suitable to different marine space by adjusting the length of an anchor chain 8. And in various sea conditions, kinetic energy and potential energy possessed by waves in the sea surface can be converted and accumulated as hydraulic mechanical energy by utilization of the wave drop; thus the generator is driven to unremittingly provide electric power.

Owner:杨超

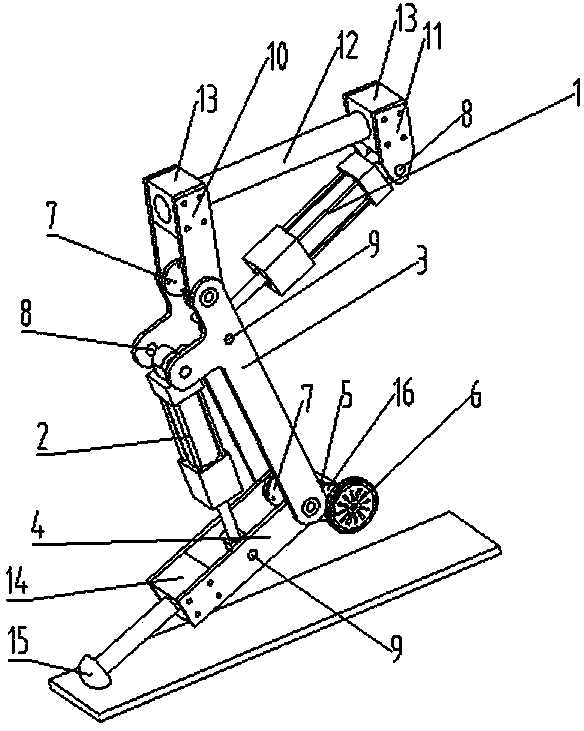

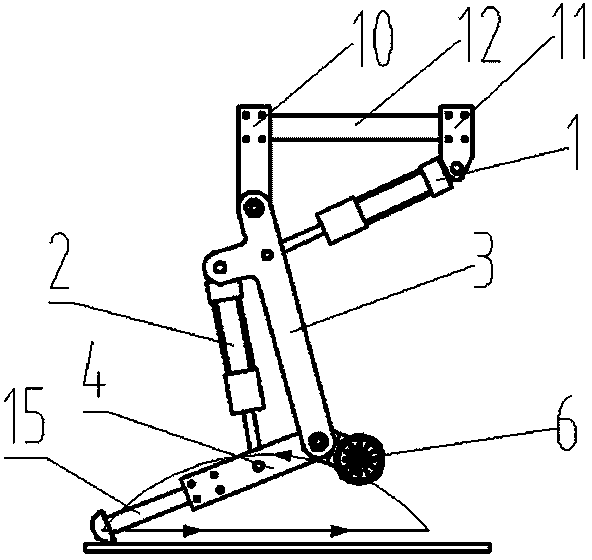

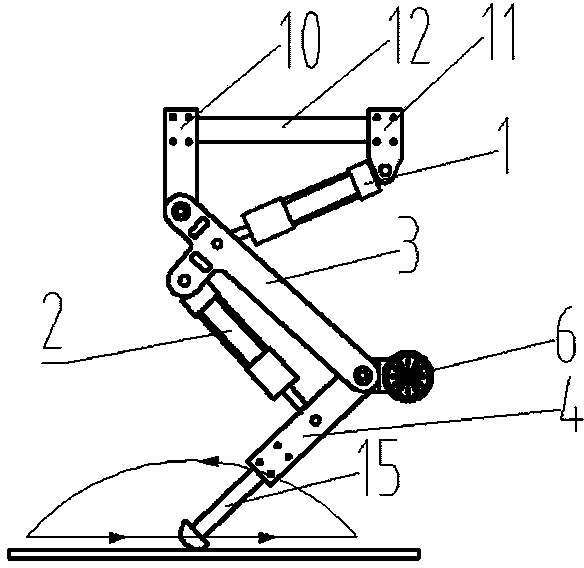

Leg and wheel hybrid type hydraulic mechanical leg

The invention discloses a leg and wheel hybrid type hydraulic mechanical leg. The leg and wheel hybrid type hydraulic mechanical leg comprises a thigh hydraulic cylinder, a shank hydraulic cylinder, thigh rod plates installed in parallel, shank rod plates installed in parallel, main body connecting plates installed in parallel and thigh hydraulic cylinder connecting plates installed in parallel. A main body cylinder connecting pillar is arranged between a square main body fixing block of the main body connecting plates and a square main body fixing block of the thigh hydraulic cylinder connecting plates. The two main body connecting plates are hinged to the two thigh rod plates respectively. The two thigh rod plates are hinged to the two shank rod plates respectively. A thigh tail end rod parallel to the shank rod plates is fixed between the two shank rod plates through a square shank fixing block. The two ends of the thigh hydraulic cylinder are hinged to the position between the upper portions of the two thigh rod plates and the position between the bottoms of the two thigh hydraulic cylinder connecting plates. The two ends of the shank hydraulic cylinder are hinged to the position between the middles of the two shank rod plates and a side arm plate extending from the two thigh rod plates. According to the leg and wheel hybrid type hydraulic mechanical leg, the structure is simple, control is convenient due to the two hydraulic cylinders, quick switching between two proceeding modes can be guaranteed due to a wheel installed at the knee joint position, and the leg and wheel hybrid type hydraulic mechanical leg can be applied to a four-foot or six-foot robot.

Owner:ZHEJIANG UNIV

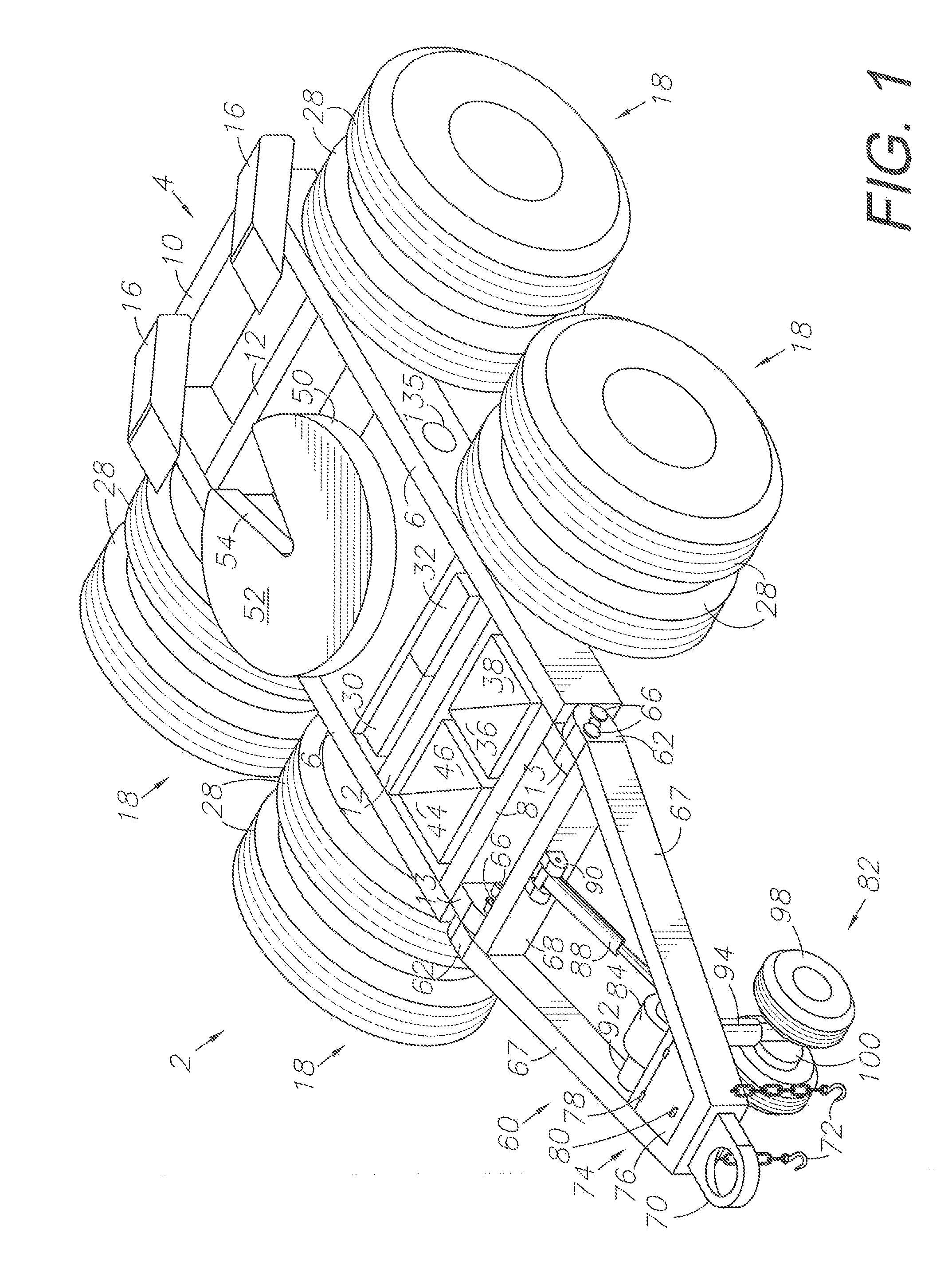

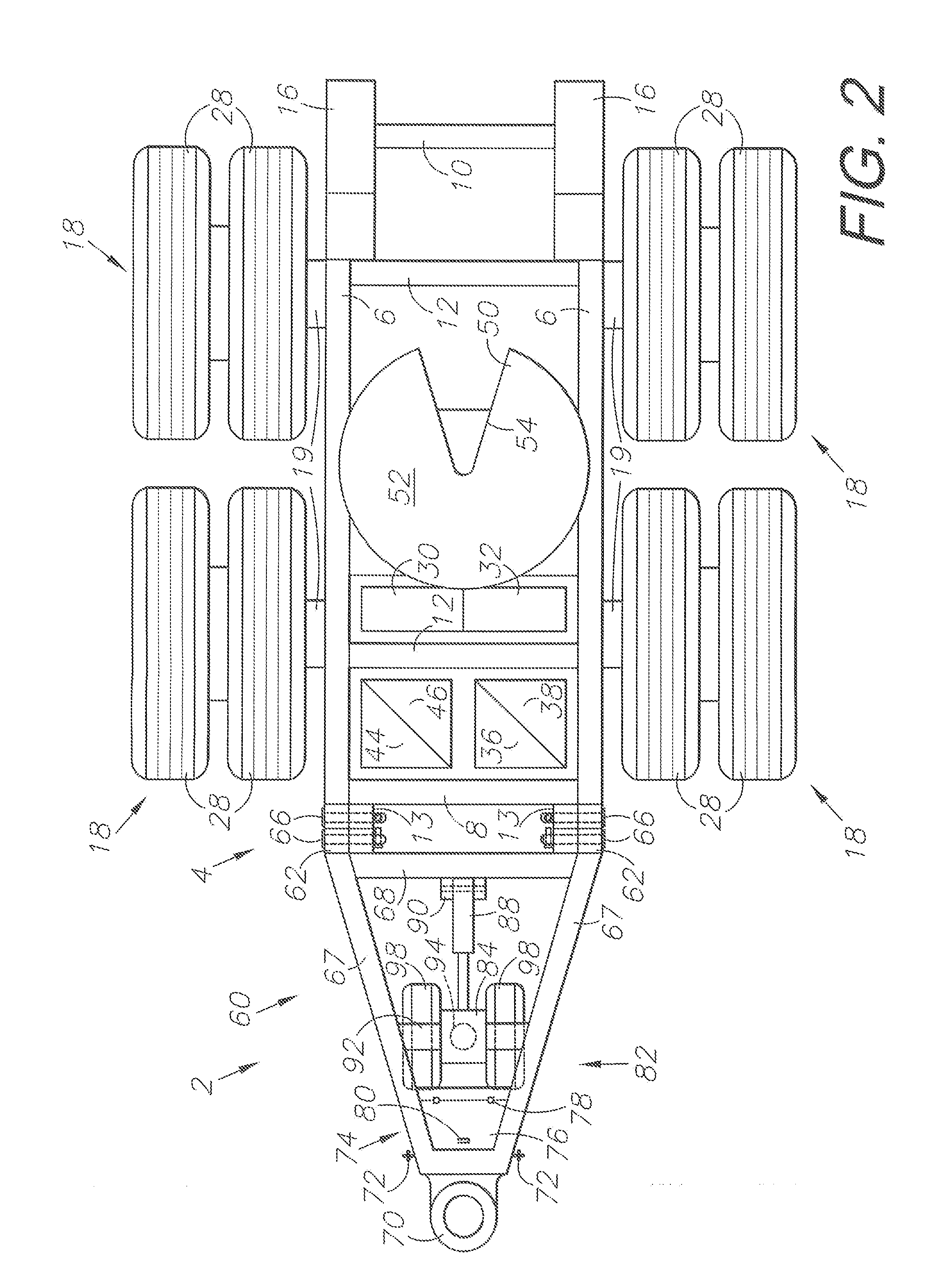

Powered converter dolly and securing device

ActiveUS20110074132A1Excessive injuryExcessive physical strainTractor-trailer combinationsWagons/vansGear wheelMotive power

A powered converter dolly for movement and attachment of trailers is provided. The dolly comprises a conventional converter dolly having a retractable landing gear assembly mounting wheels attached to the drawbar. The dolly has a power supply and operates as a towing device. The landing gear assembly provides steering for the dolly as well as motive power from a motor connected to the landing gear wheels. Alternatively, the wheels of the dolly may be powered for providing motion to the dolly. The dolly further comprises several attachment devices for securing the dolly to an intermodal railcar, including alternative hydraulic, mechanical, and electrically-powered tie down devices. A trolley movable along a railcar is provided for securing the dolly or trailer to the railcar and includes a hitch component for selectively interconnecting to a hitch component on the dolly or trailer.

Owner:TWENTY FIRST CENTURY TRANSPORT SYST INC

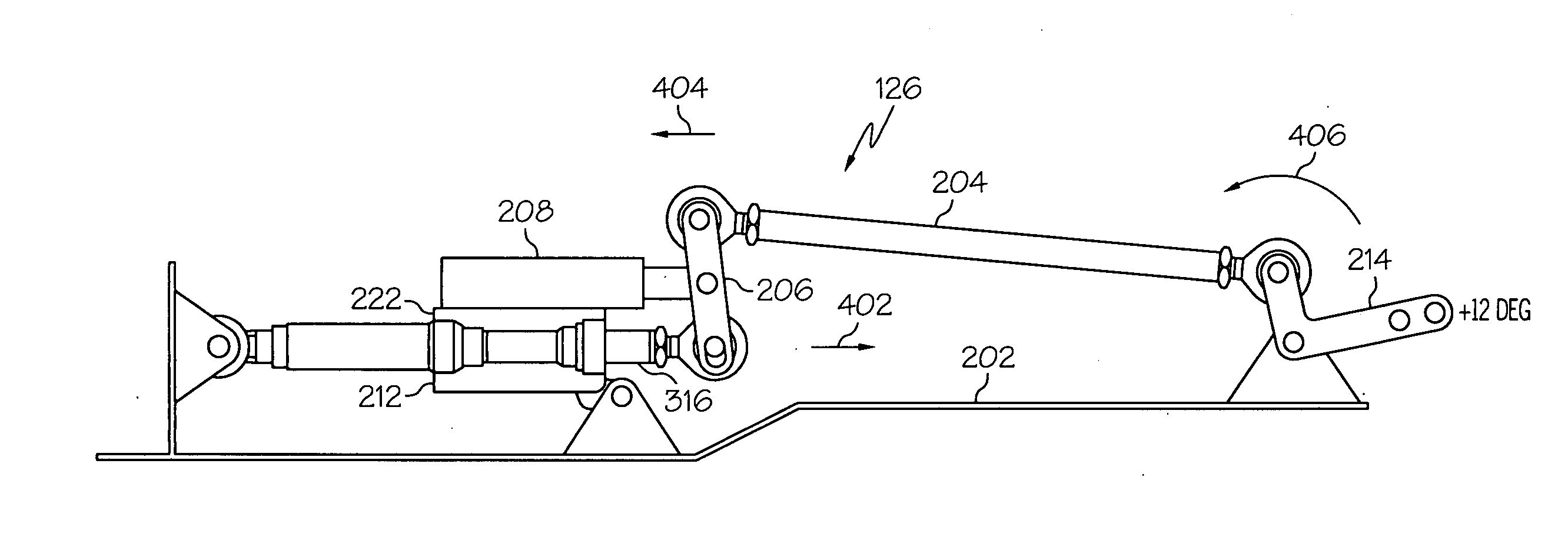

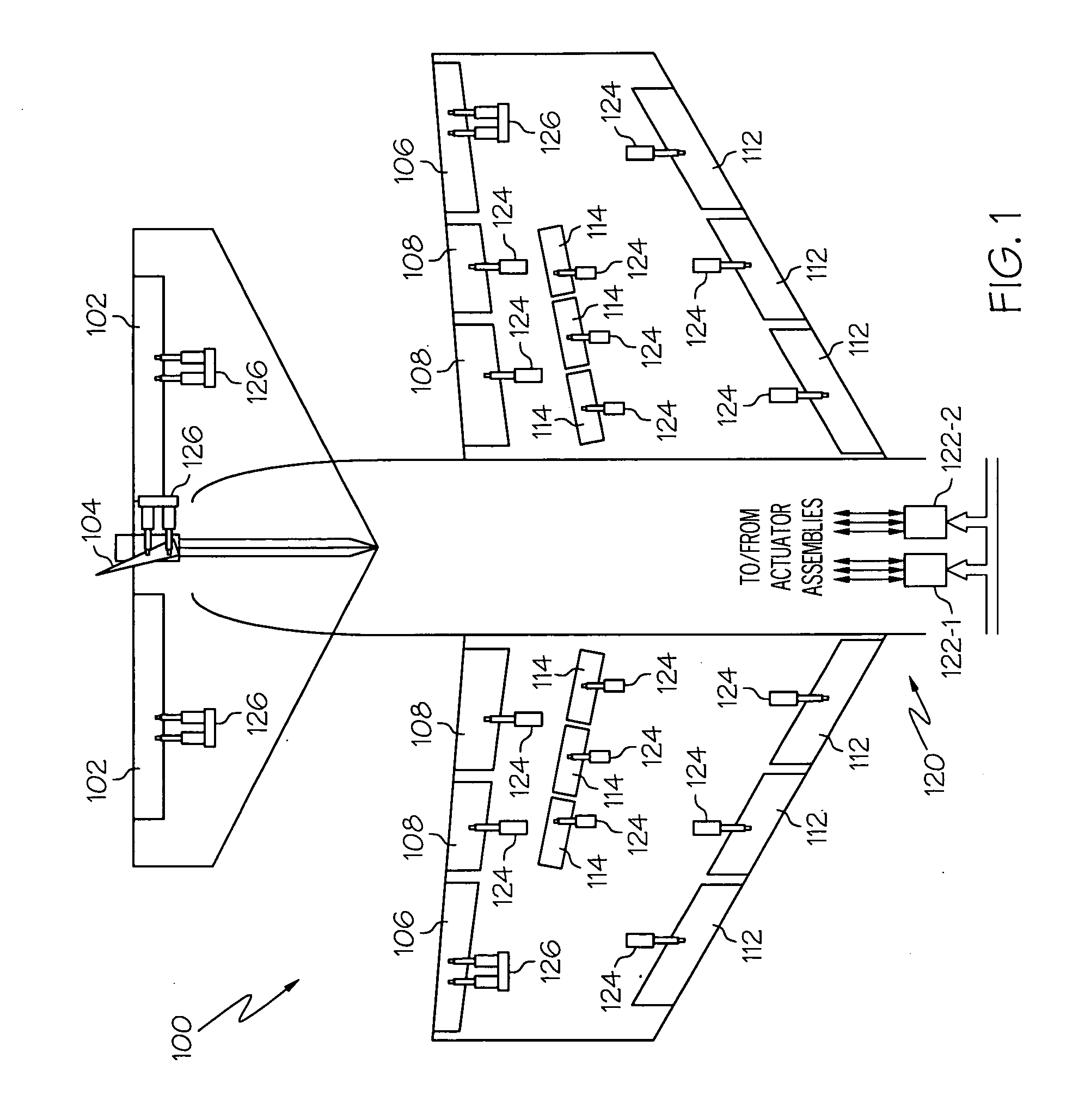

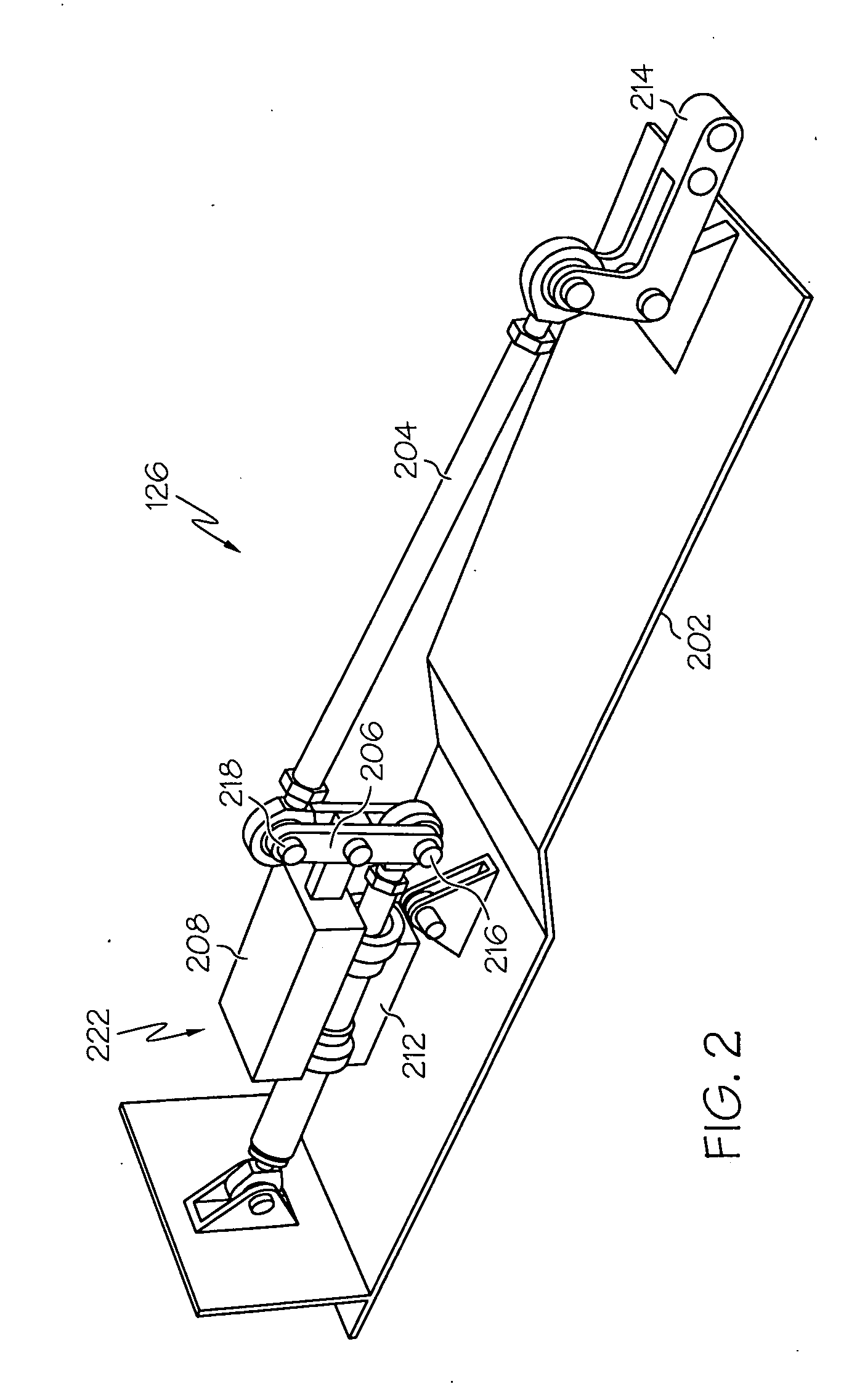

Hybrid electromechanical/hydromechanical actuator and actuation control system

A hybrid actuator assembly includes an actuator housing, an electromechanical actuator, and a hydraulic actuator. The electromechanical actuator is disposed at least partially within the actuator housing and is adapted to be controllably energized. The electromechanical actuator is configured, upon being controllably energized, to supply a first drive force. The hydraulic actuator is disposed at least partially within the actuator housing and is adapted to receive pressurized hydraulic fluid. The hydraulic actuator is configured, upon receipt of pressurized hydraulic fluid, to supply a second drive force.

Owner:HONEYWELL INT INC

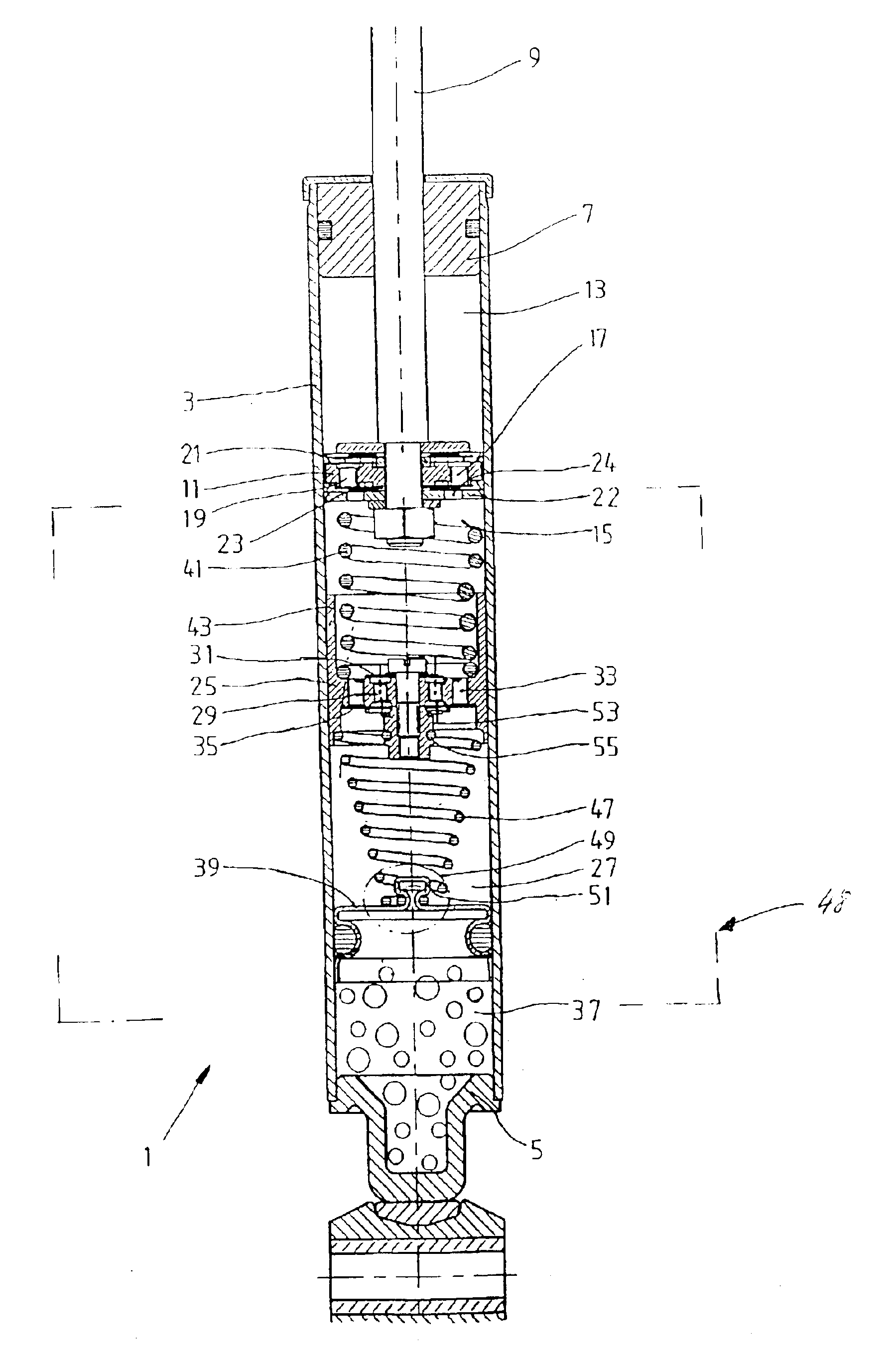

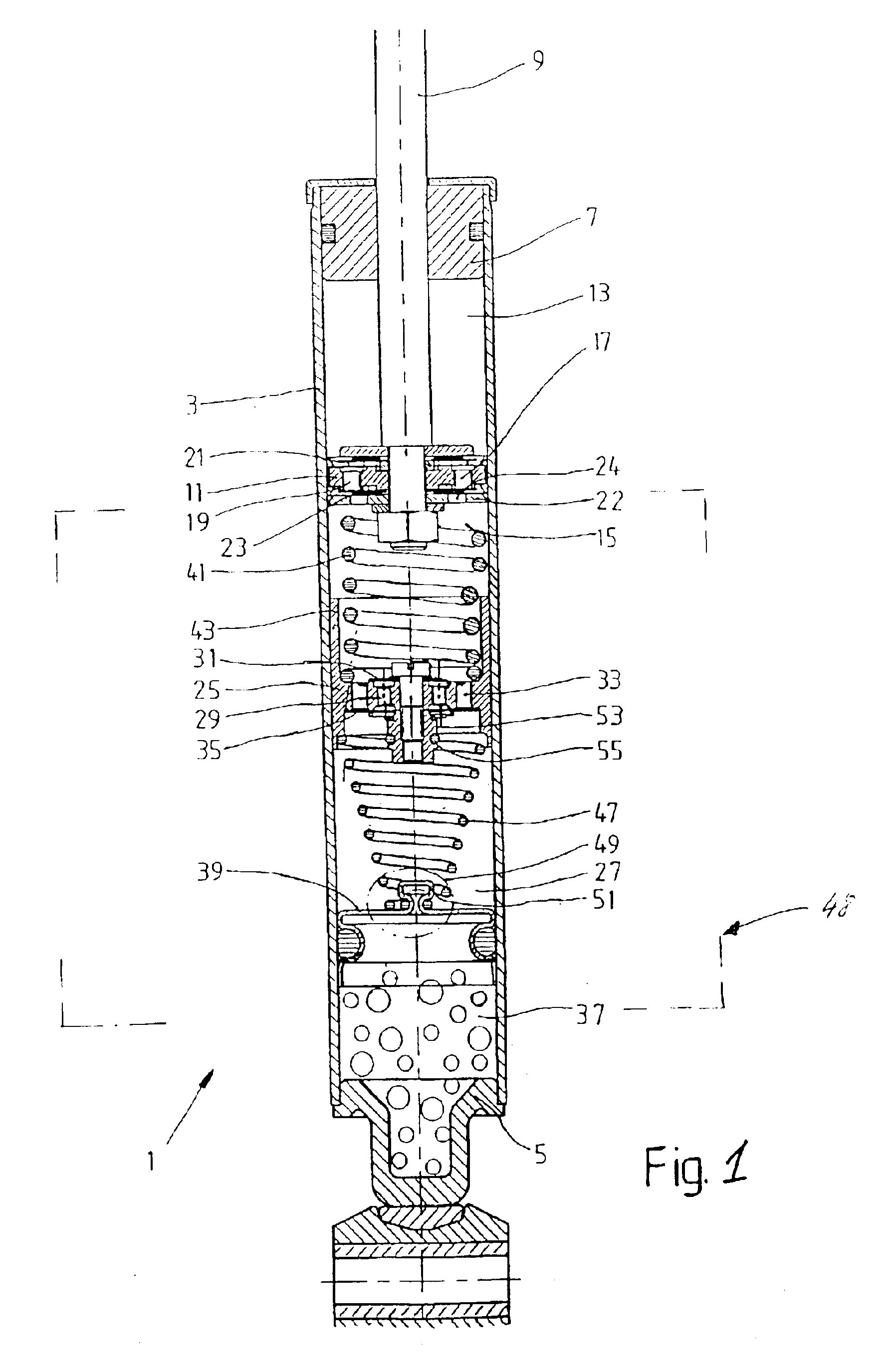

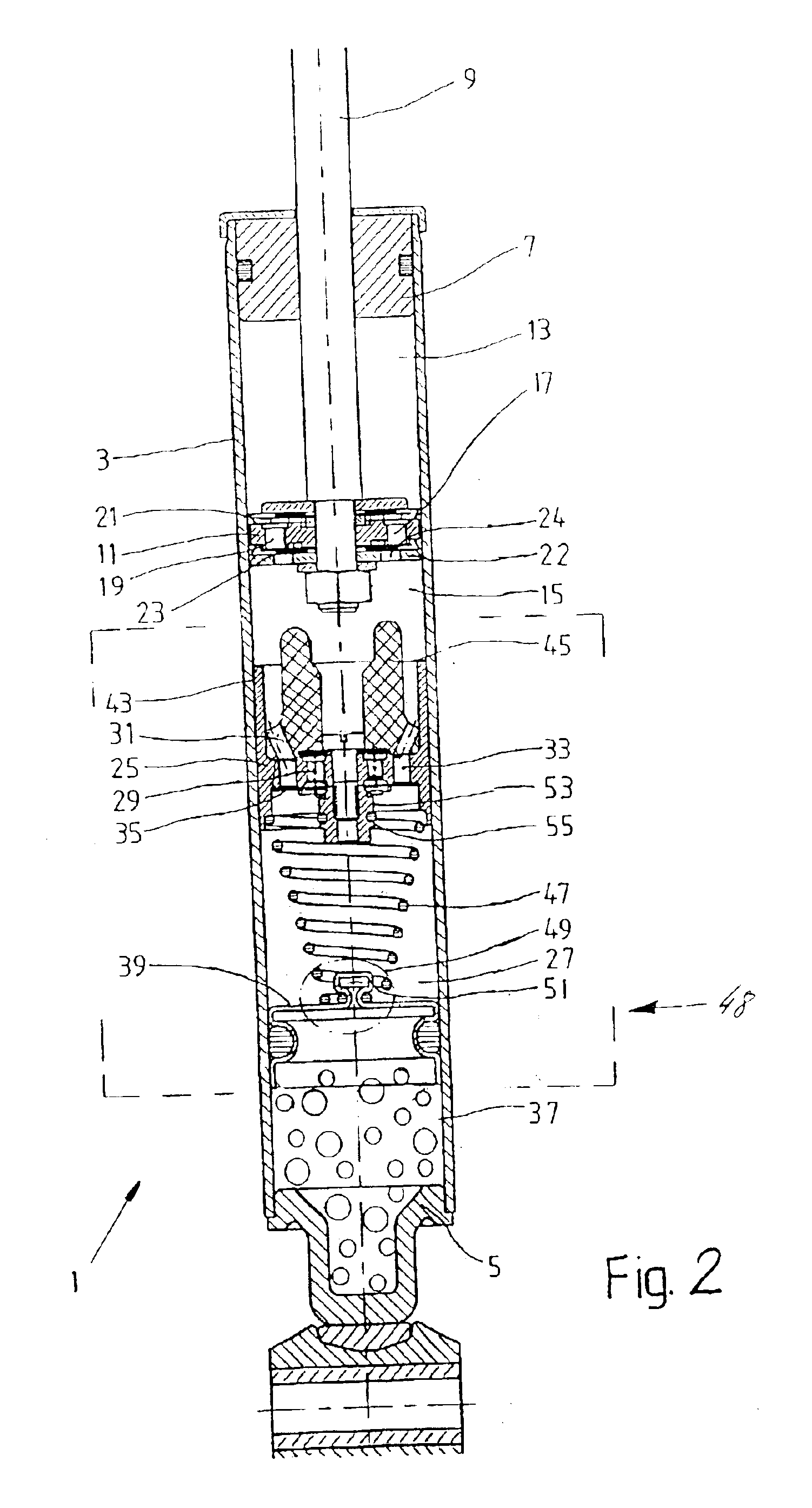

Vibration damper with a hydraulic pressure stop

A vibration damper with a hydraulic-mechanical pressure stop includes a cylinder filled with damping medium; a piston rod movable in and out of the cylinder, a first piston fixed to the piston rod with freedom of axial movement, a second piston spaced from the first piston, a transfer spring in the second working space for moving the second piston toward the third working space in response to movement of the first piston toward the second working space; and a disk valve which allows damping medium to flow from the third working space through the second piston to the second working space as the second piston moves toward the third working space. The first piston divides the cylinder into a first and a second working space where the piston rod extends through the first working space. The second piston separates the second working space from a third working space.

Owner:ZF SACHS AG

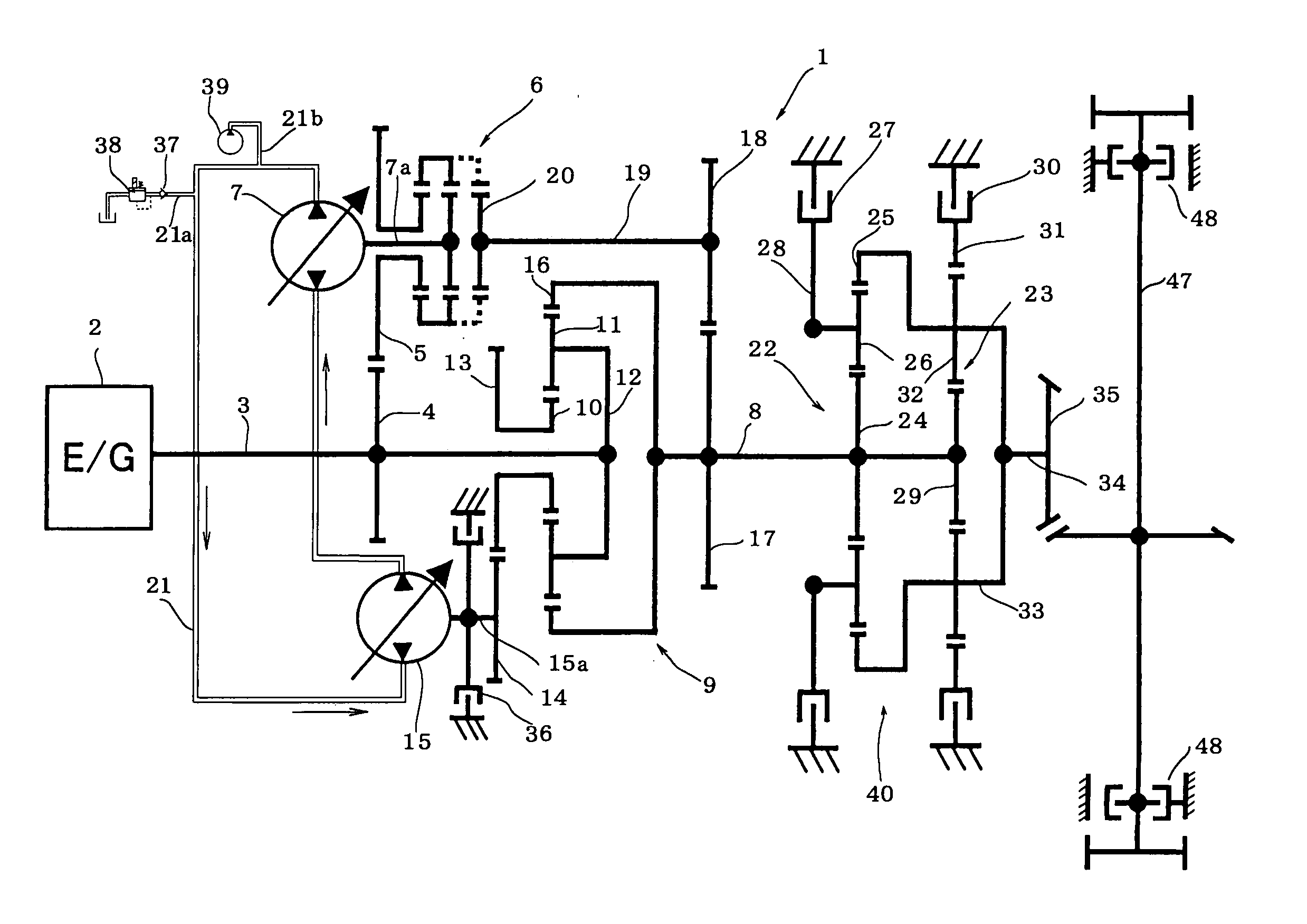

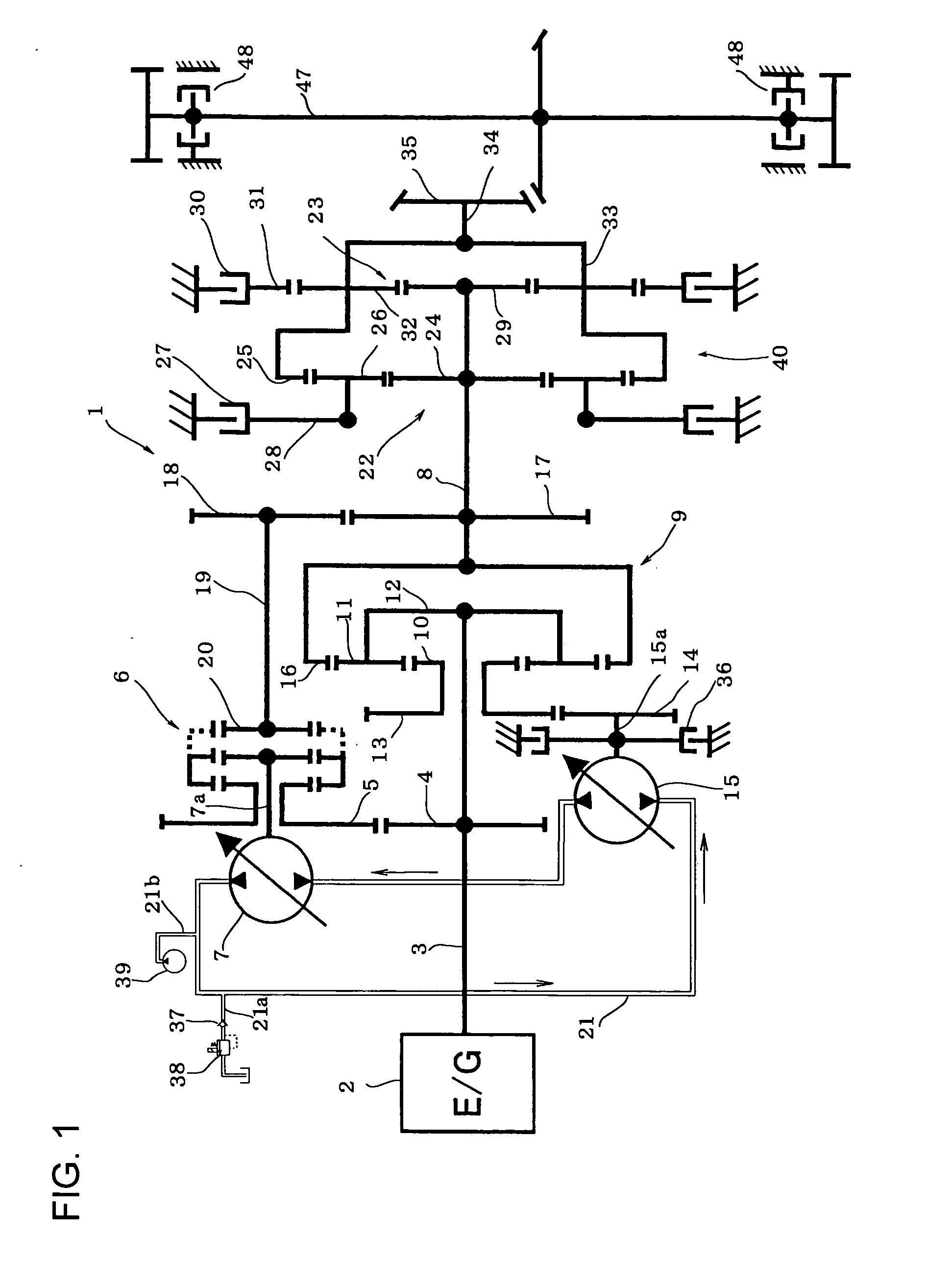

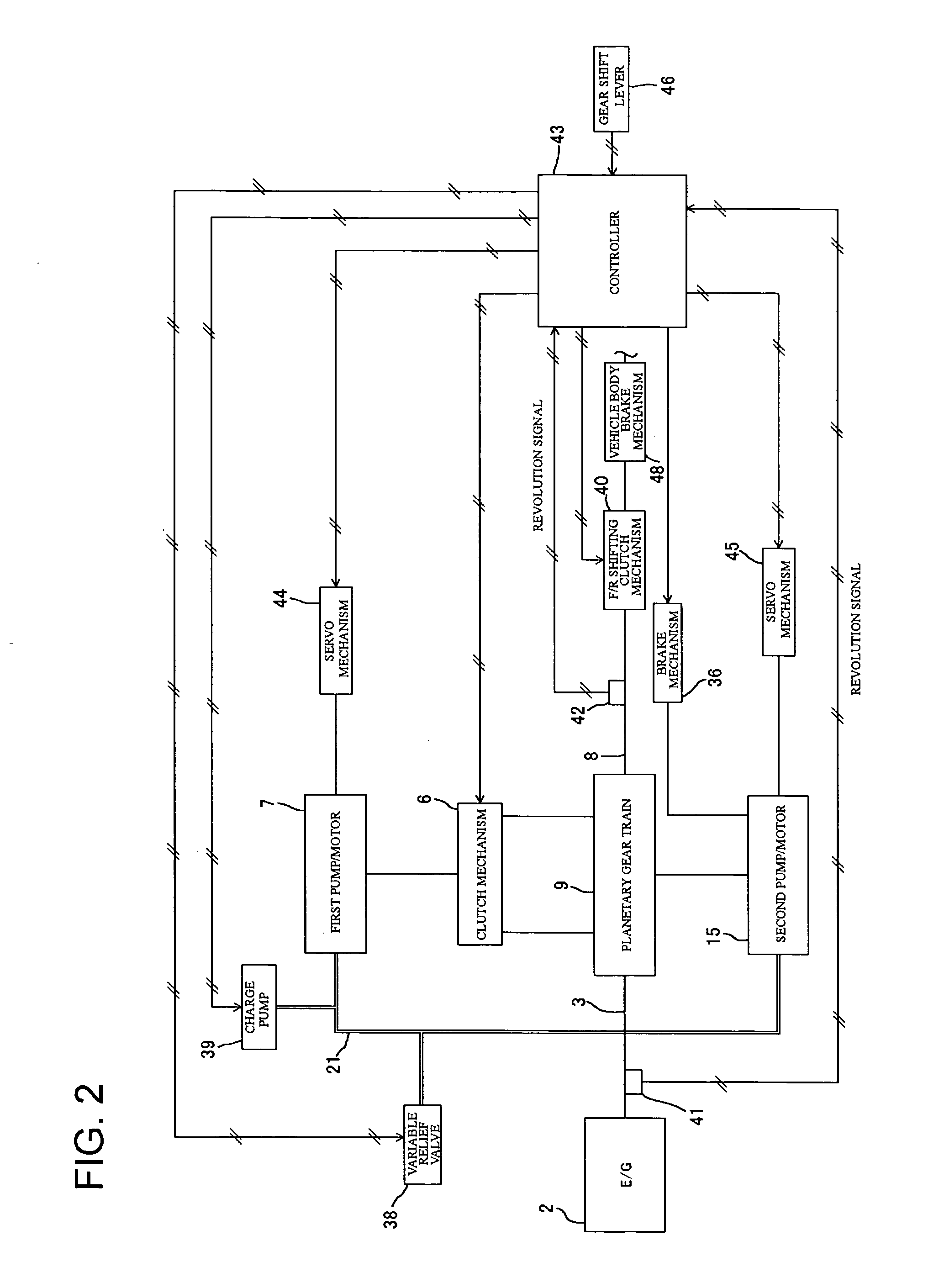

Control system for a hydro-mechanical transmission

InactiveUS20050059521A1Increase pressureReduce heat loadFluid couplingsGearing controlControl systemHydraulic machinery

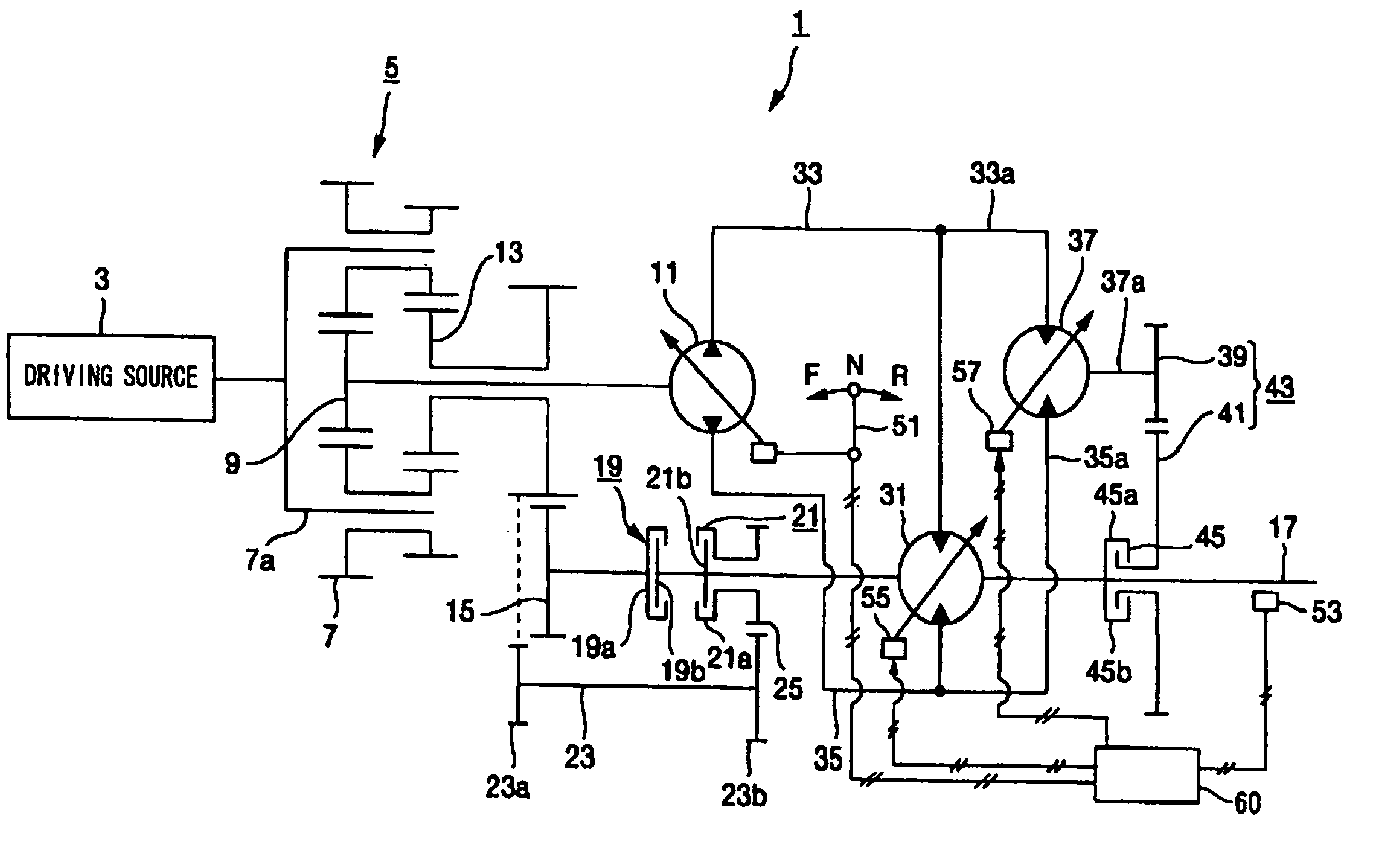

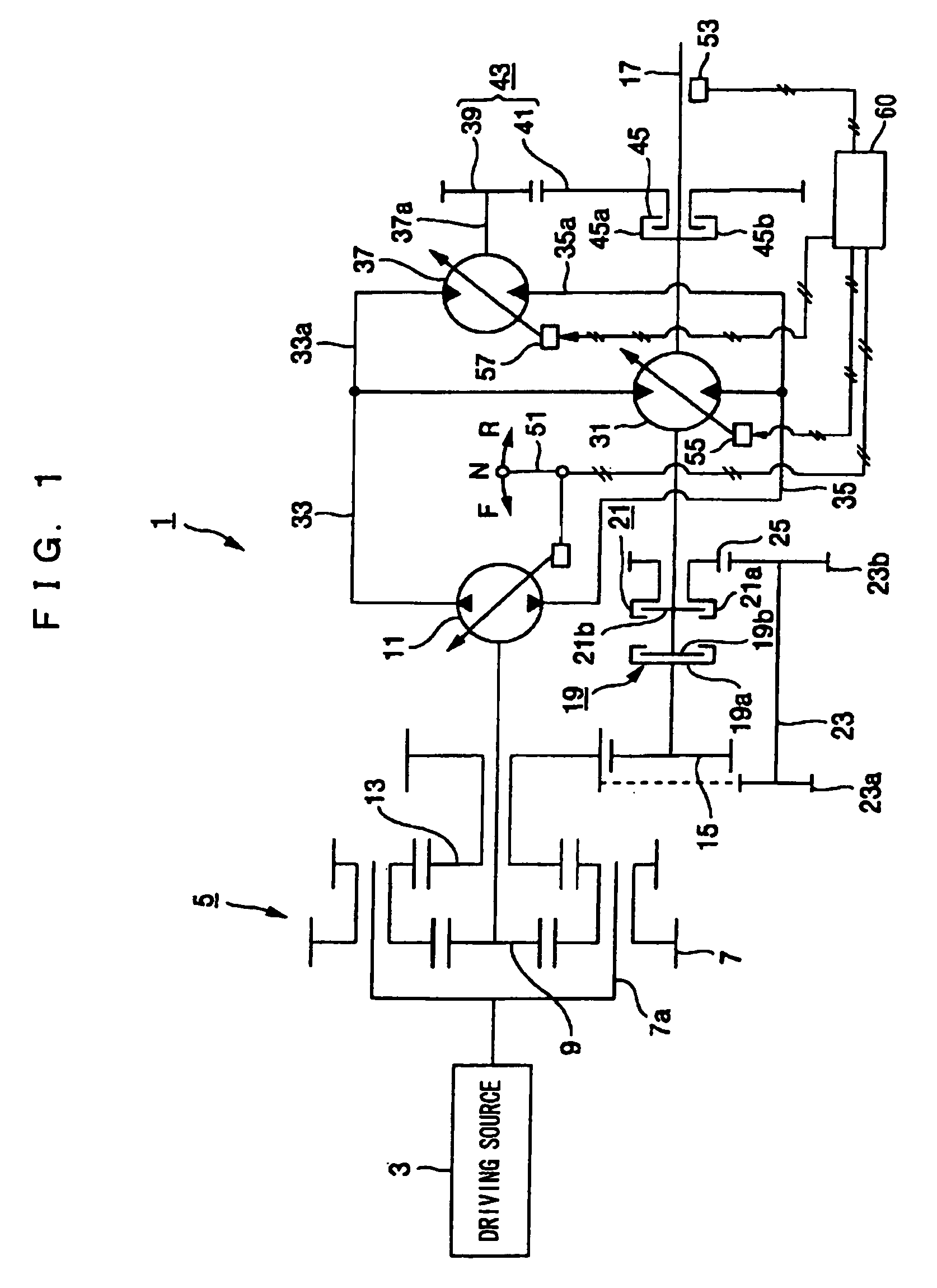

A variable relief valve is inserted in a hydraulic piping for connecting a first pump / motor to a second pump / motor. The variable relief valve is controlled such that when shifting the transmission from forward to reverse or vice versa, a relief set pressure of the variable relief valve is reduced in response to switching of a forward / reverse shifting clutch mechanism and after completion of the switching of the forward / reverse shifting clutch mechanism, the relief set value is increased.

Owner:KOMATSU LTD

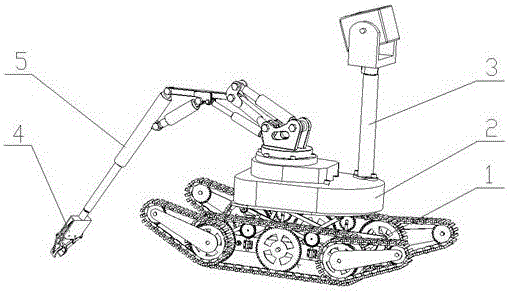

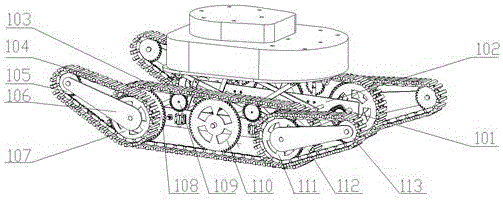

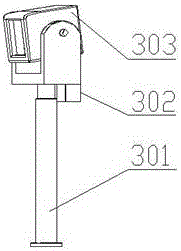

Explosive-handling robot

InactiveCN106428264AAll-round crawlingEndless track vehiclesManipulatorHydraulic machineryRoad surface

The invention provides an explosive-handling robot which comprises a base plate, a detecting unit, a box, a hydraulic mechanical arm and a manipulator. A swinging arm type crawler mechanism is adopted for the base plate so that the explosive-handling robot can run fast on the flat road and surmount various barriers, and can be particularly suitable for moving in dangerous and complicated road surface environments. A high-definition camera detection device is installed on the box, and a camera can identify explosives. In addition, a rotation device is installed on the box so that the mechanical arm can rotate by any angle. The hydraulic mechanical arm is adopted as the main body of the mechanical arm body and provided with a hydraulic drive pitching cylinder, two hydraulic driven pitching cylinders and a hydraulic drive telescopic cylinder in total. The manipulator is installed at the tail end of the mechanical arm, and used for clamping explosives through driving of a servo motor, transmission of a lead screw and adoption of a four-rod mechanism. The explosive-handling robot has the characteristics of rapid moving, accurate grabbing, simple structure and good performance.

Owner:SHANGHAI UNIV

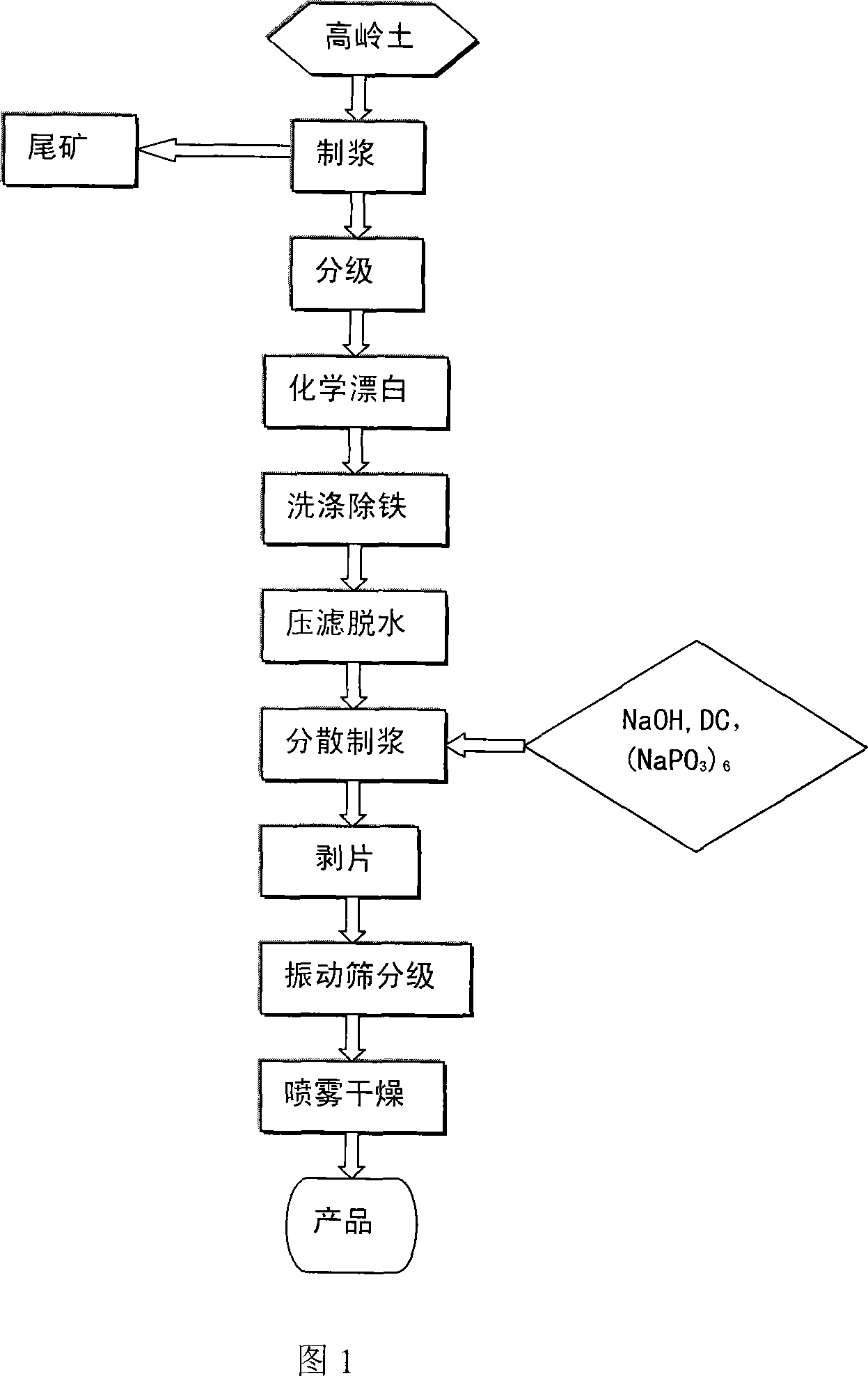

Production technology of high

InactiveCN101117004AImprove performancePerformance impactClay processing apparatusThermal insulationKaolin clay

The present invention relates to a manufacturing technique of kaolin with high viscosity and concentration. A manufacturing technique of kaolin with high viscosity and concentration is characterized by comprising following procedures: 1) manufacturing kaolin slurry J with kaolin extracted by hydraulic machinery method undergoing pulping, classification, chemical bleaching, iron removal by washing, dehydrating through pressure filters, dispersed pulping, exfoliation, vibration screen classification ; 2) spray drying and intercalation which is accomplished by a) firstly, improving product lines of a spray drying equipment, that is, adding a thermal insulation layer to a packing auger, a lift pot and a storage hopper of the spray drying equipment, and then arranging a variable frequency feeding machine communicated with a urea crusher through pipelines on the packing auger of the bottom of a spray drying mouth of the spray drying equipment; b) spray drying to achieve kaolin powder; c) intercalating intercalation agent urea with the kaolin powder through the variable frequency feeding machine with parameter of a fresh feed pump between 2 HZ and 8 HZ and with additional of mass of the intercalation agent urea between 2 percent and 10 percent of the mass of the kaolin powder; thereby getting final kaolin products with viscosity and concentration between 72 percent and 73.7 percent. The manufacturing technique can produce kaolin with high viscosity and concentration.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

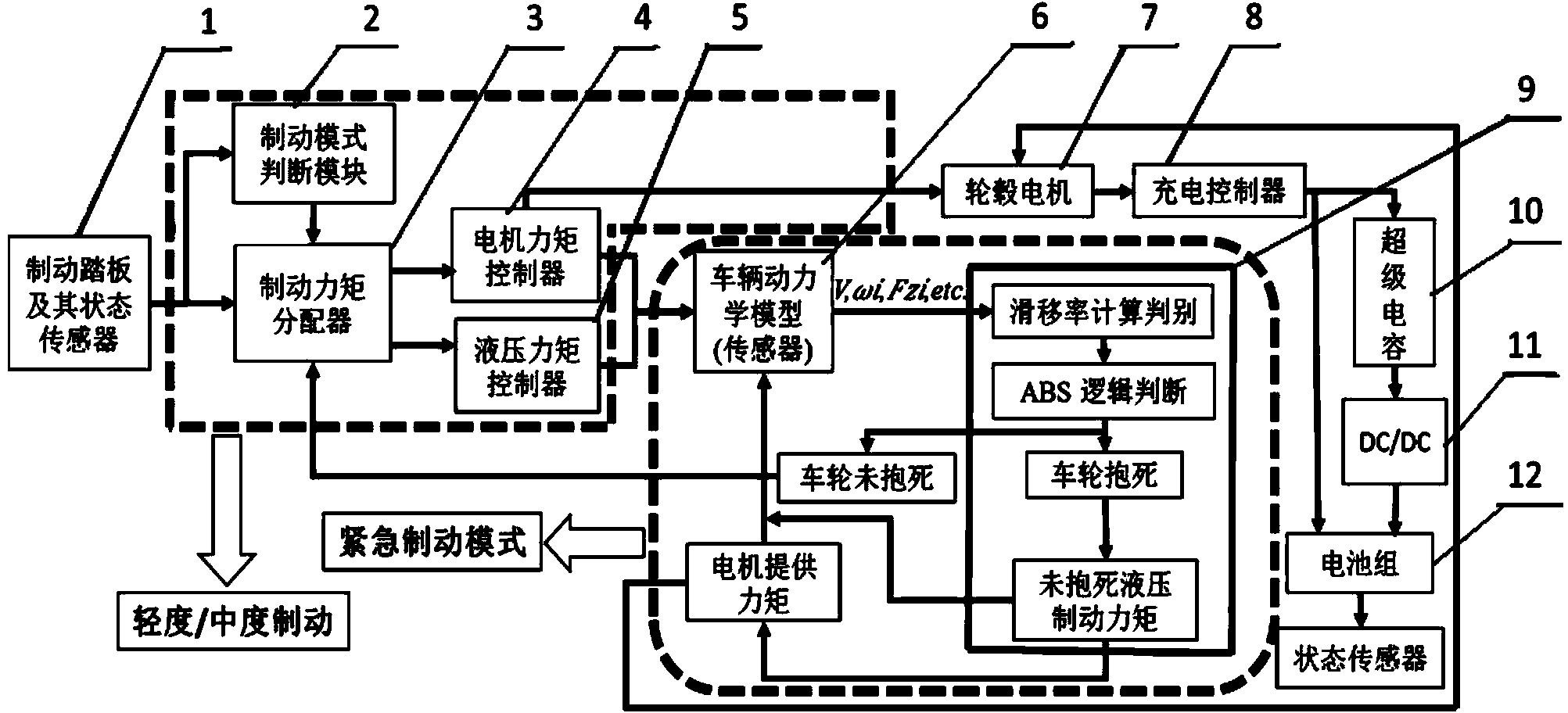

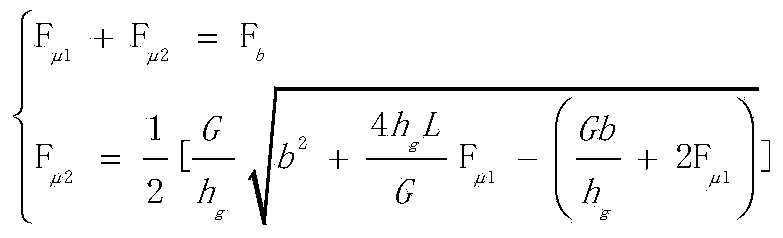

Electrohydraulic-combined brake control method of battery electric vehicle

ActiveCN104108316AIncrease mileageGuaranteed stabilityElectrodynamic brake systemsEnergy recoveryKinetic energy

The invention discloses an electrohydraulic-combined brake control method of a battery electric vehicle and belongs to the technical field of electric vehicle control. During braking of an electric vehicle, stability of a vehicle body is guaranteed, part of braking energy can be recycled during braking by the aid of reversible power characteristics of a wheel hub motor, charging strategy can be optimized according to the size of electric current generated, kinetic energy consumed during braking can be converted into electric energy to be stored, and the purpose of increasing continuous driving range can be achieved. Relevant signals measured by a sensor and about a brake pedal, travel speed, wheel speed, brake cylinder pressure, battery end voltage, battery charging current, torque of a motor and the like are transmitted to a control system, the status of the vehicle body, wheels and a battery are monitored in real time by a controller, different barking requirements, energy recycling process braking security maintenance are realized by adjusting motor electromagnetic braking torque and hydraulic mechanical braking torque through an electrohydraulic-combined system, and higher efficiency can be achieved in utilization of energy of the electric vehicle.

Owner:嘉兴智德睿控新能源有限公司

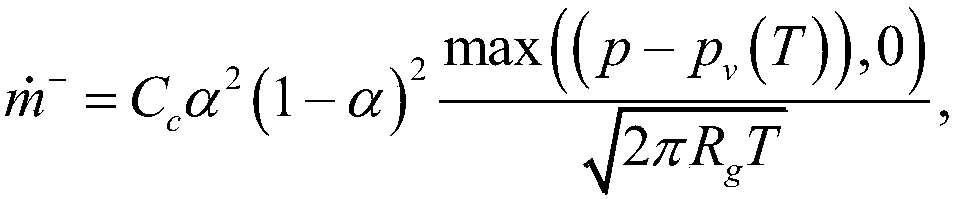

Numerical simulation method for cavitation compressible flow shock wave dynamics

ActiveCN108763800ARealize simulationHelp in in-depth researchSustainable transportationDesign optimisation/simulationShock waveAviation

The invention discloses a numerical simulation method for cavitation compressible flow shock wave dynamics and belongs to the field of numerical simulation of cavitation compressible flow and shock wave dynamics. A three-dimensional computing watershed based on three-dimensional geometric modeling software is established; a three-dimensional computing watershed mesh is divided based on mesh generation software; a cavitation compressible flow computational fluid dynamics model is established; an initial boundary condition is set to perform a three-dimensional computational domain flow field numerical computation; based on flow field post-processing software, the computational result is post-processed to obtain the unsteady evolution process of a multi-phase bubble structure. The numerical simulation method for cavitation compressible flow shock wave dynamics in the invention facilitates in-depth study of the cavitation physical mechanism, can be applied to the field of cavitation compressible flow and shock dynamics numerical simulation and solves related engineering problems. The cavitation compressible flow and shock dynamics numerical simulation engineering application area comprises hydraulic machinery, marine propellers, aviation turbo pump induction wheels, underwater supercavitation weapon applications.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for estimating and controlling driveline torque in a continuously variable hydro-mechanical transmission

ActiveUS20110166752A1Reduce torqueReducing engine speedAnalogue computers for trafficGearing controlHydraulic machineryControl theory

The method of estimating and controlling driveline torque in a continuously variable hydro-mechanical transmission uses pressure data and other metrics of a hydrostatic power unit of the transmission in lieu of actual driveline torque data. A mechanical efficiency of the transmission is determined as a function of whether the power unit is operating in a power generation or regeneration mode, and the torque output of the power unit is estimated from that and other hydrostatic parameters. This is used to estimate a torque output of a planetary power unit of the transmission, and the torque on an output member of the driveline is then estimated using that value, and appropriate corrective action taken.

Owner:BLUE LEAF I P

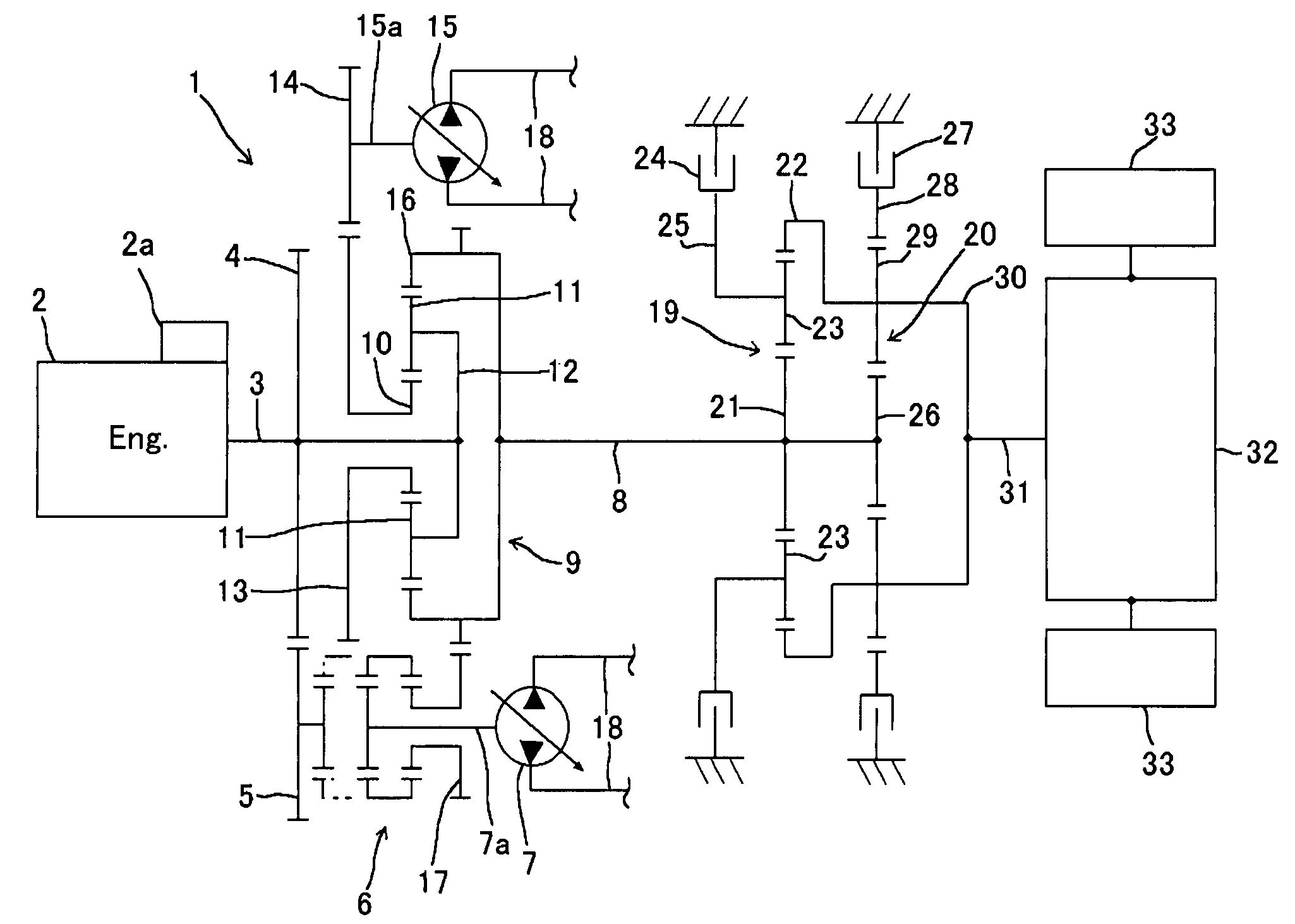

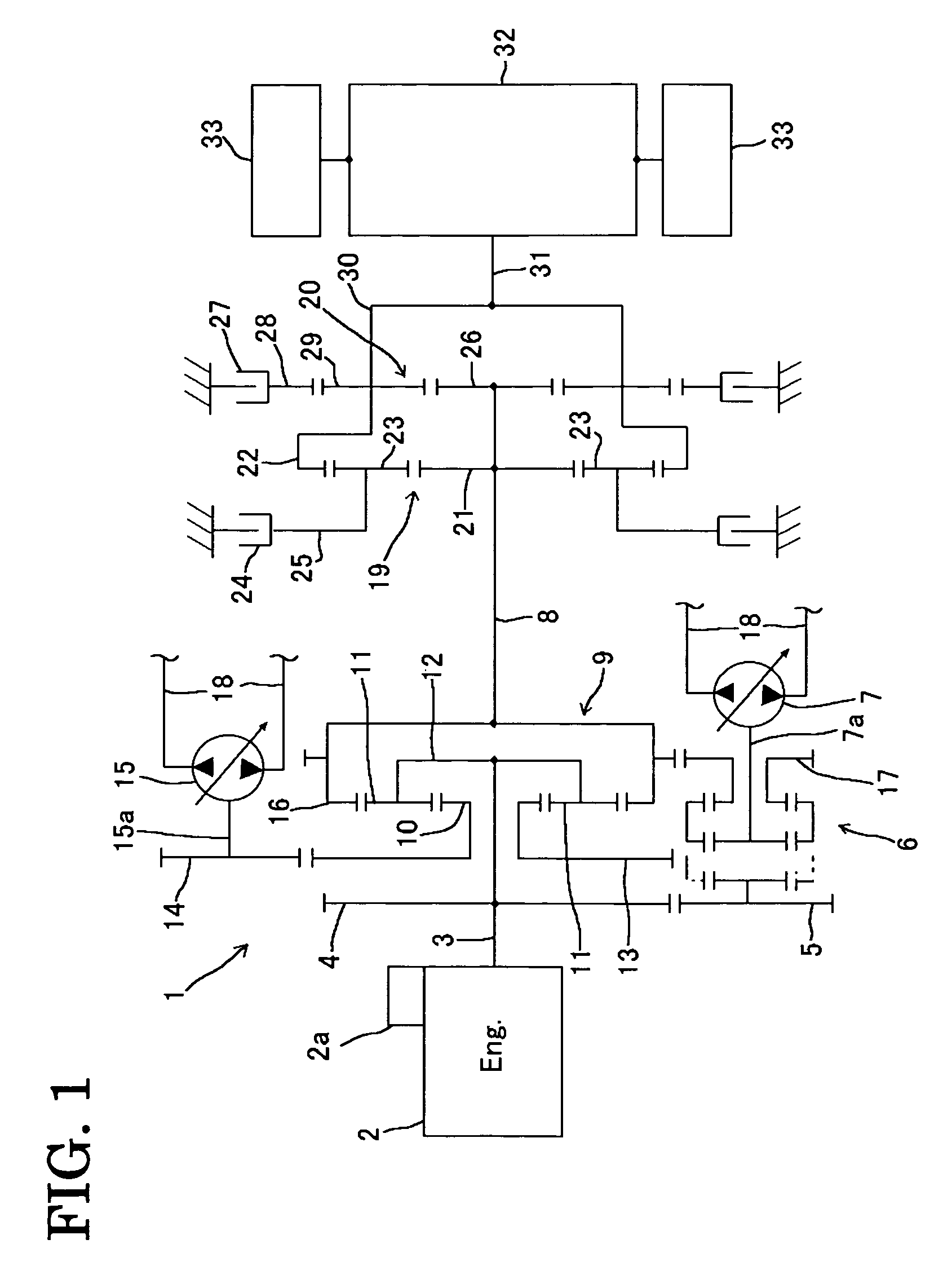

Hydromechanical transmission

InactiveUS7070531B2High outputSpeed reduction ratio is made largeFluid gearingsHydraulic motorHydraulic machinery

Owner:KOMATSU LTD

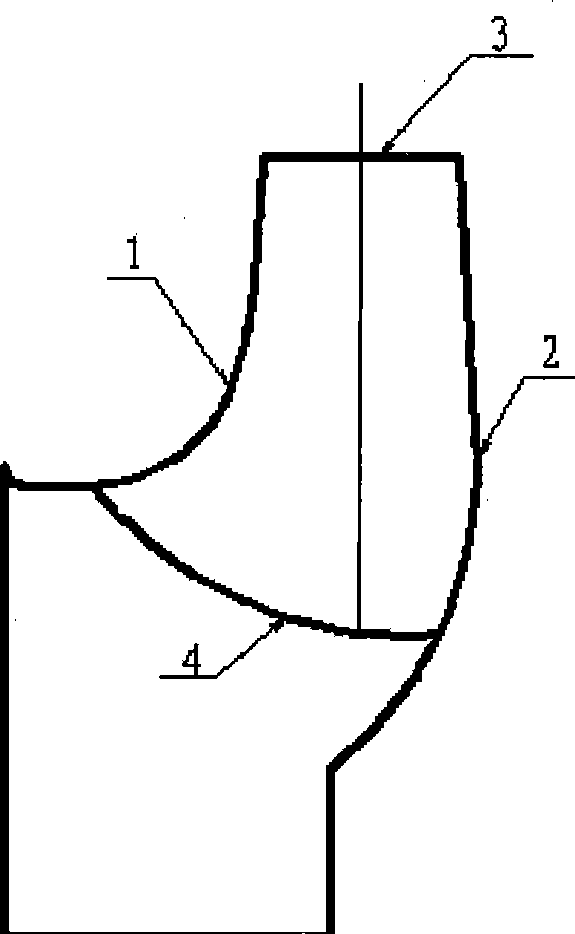

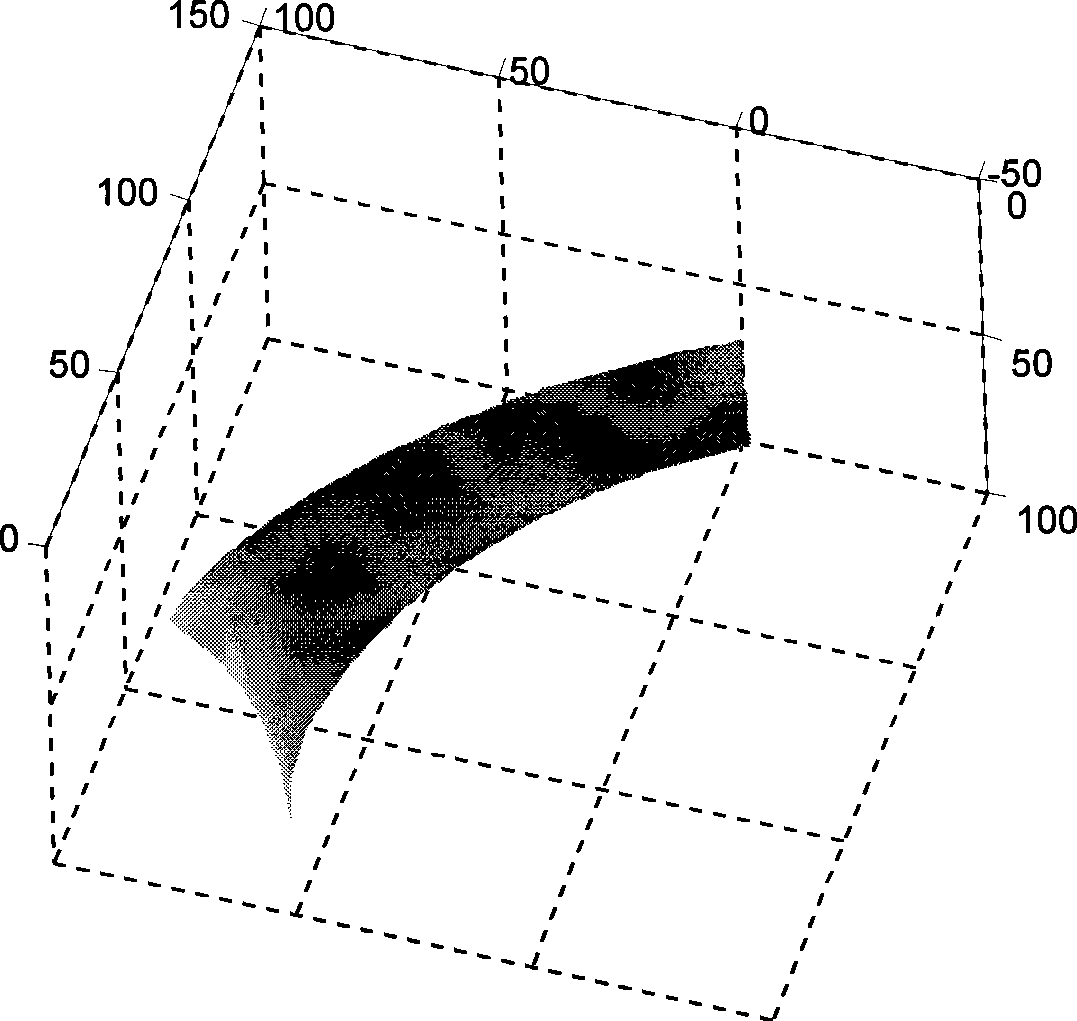

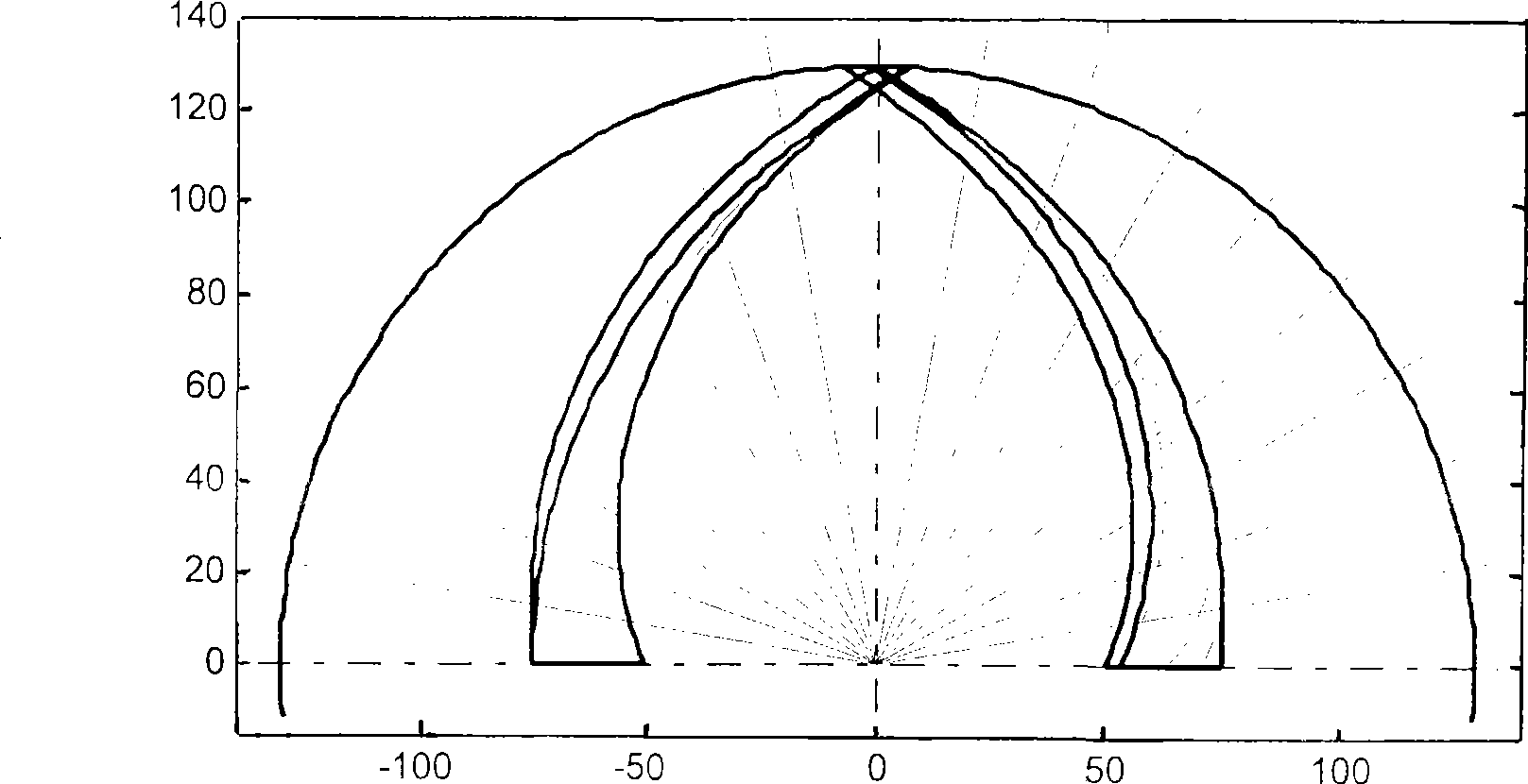

Reverse design method for impeller of centrifugal pump

InactiveCN101520052AOvercoming the Definition of GeometryOvercome many inconveniences such as modificationPump componentsPumpsBoundary value problemThree-dimensional space

The invention discloses a reverse design method for an impeller of a centrifugal pump, which comprises the following steps: according to a given impeller axial plane, a blade in a three-dimensional space can be actually expressed as X=X(z(u, v), r(u, v), theta(u, v)), the (z(u, v), r(u, v)) has been determined when a streamline of the impeller axial plane is given, and the space modeling of the blade can be determined by determining the theta(u, v) on the impeller axial plane. The reverse design method is characterized in that the reverse design method transforms a geometric design problem of the blade of the centrifugal pump into a boundary value problem of a partial differential equation to solve under the condition of the given impeller axial plane of the centrifugal pump. The reverse design method overcomes a lot of disadvantages such as the definition and modification of geometrical shape of the blade in the prior design method, can realize the parametric design of the blade, overcome the defects existing when a fussy two-dimensional form drawing is used for showing three-dimensional twisted blades in the prior method, can closely combine the hydraulic design of hydraulic machinery, three-dimensional solid modeling and the CFD analysis of flow field, and realize the quick and accurate solving of the reverse problem of the blade.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

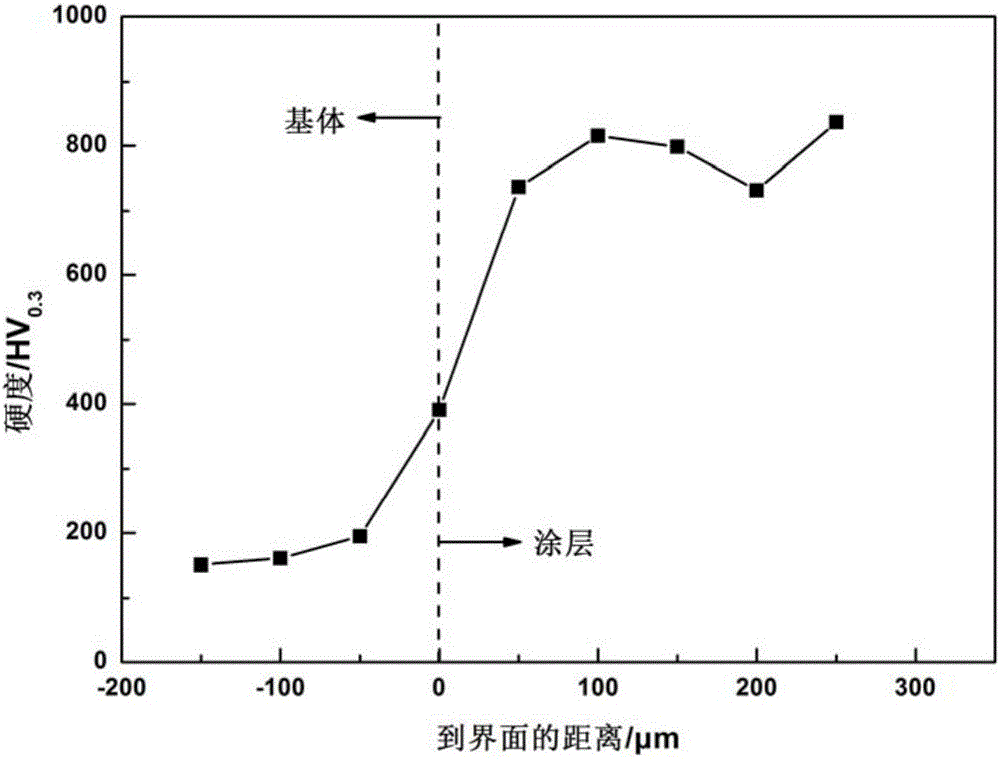

Iron-based amorphous powder and preparation method and application thereof

The invention discloses iron-based amorphous powder and a preparation method and application thereof. The powder comprises the following elements in percentages by weight: 17-23wt% of Cr, 2.7-4.5wt% of B, 0.3-1wt% of C, 0.5-2.5wt% of Si, 2-3wt% of Cu, 3-8wt% of Ni, 12-18wt% of Mo, 2-4wt% of Co and the balance of Fe. The preparation method comprises the following steps: adding raw materials in an induction electromagnetic furnace, heating and melting; and carrying out water atomization on molten metal, then drying, and screening powder. According to the application of the iron-based amorphous powder in preparation of an anti-cavitation and corrosion-resistant iron-based amorphous powder coating, the coating is prepared by a supersonic flame spraying technology, and the surface of a matrix is subjected to oil removal and rust removal treatment, and then is subjected to pretreatment such as sand blasting. The coating which is low in porosity, high in hardness, excellent in anti-cavitation property and excellent in corrosion resistance can be obtained. The iron-based amorphous powder is suitable for demanding components such as marine hydraulic machinery, key components of nuclear submarines, parts of engines of airplanes, and bosses of blades of aviation engines, particularly has advantages in a severe marine environment, facilitates industrialization, and is wide in application prospect.

Owner:HOHAI UNIV

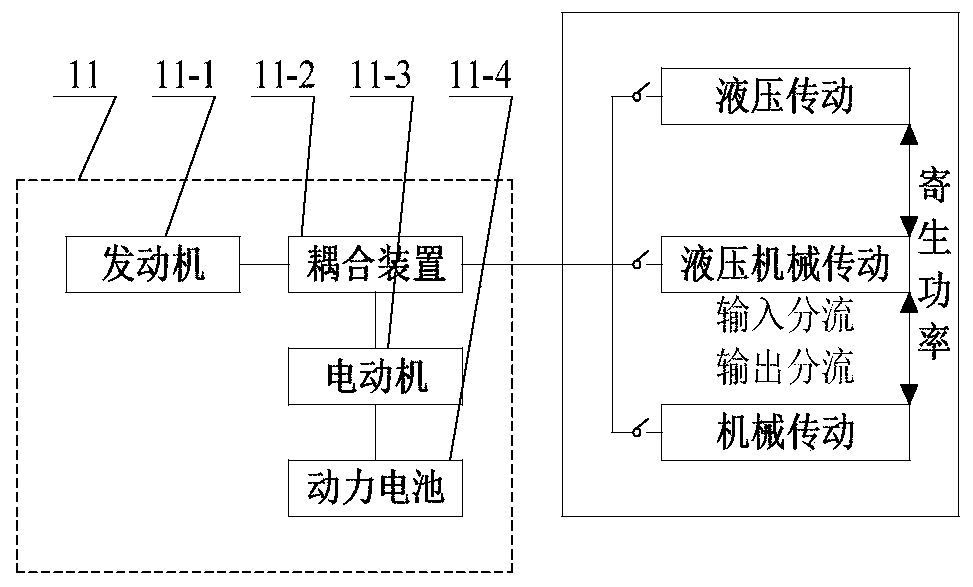

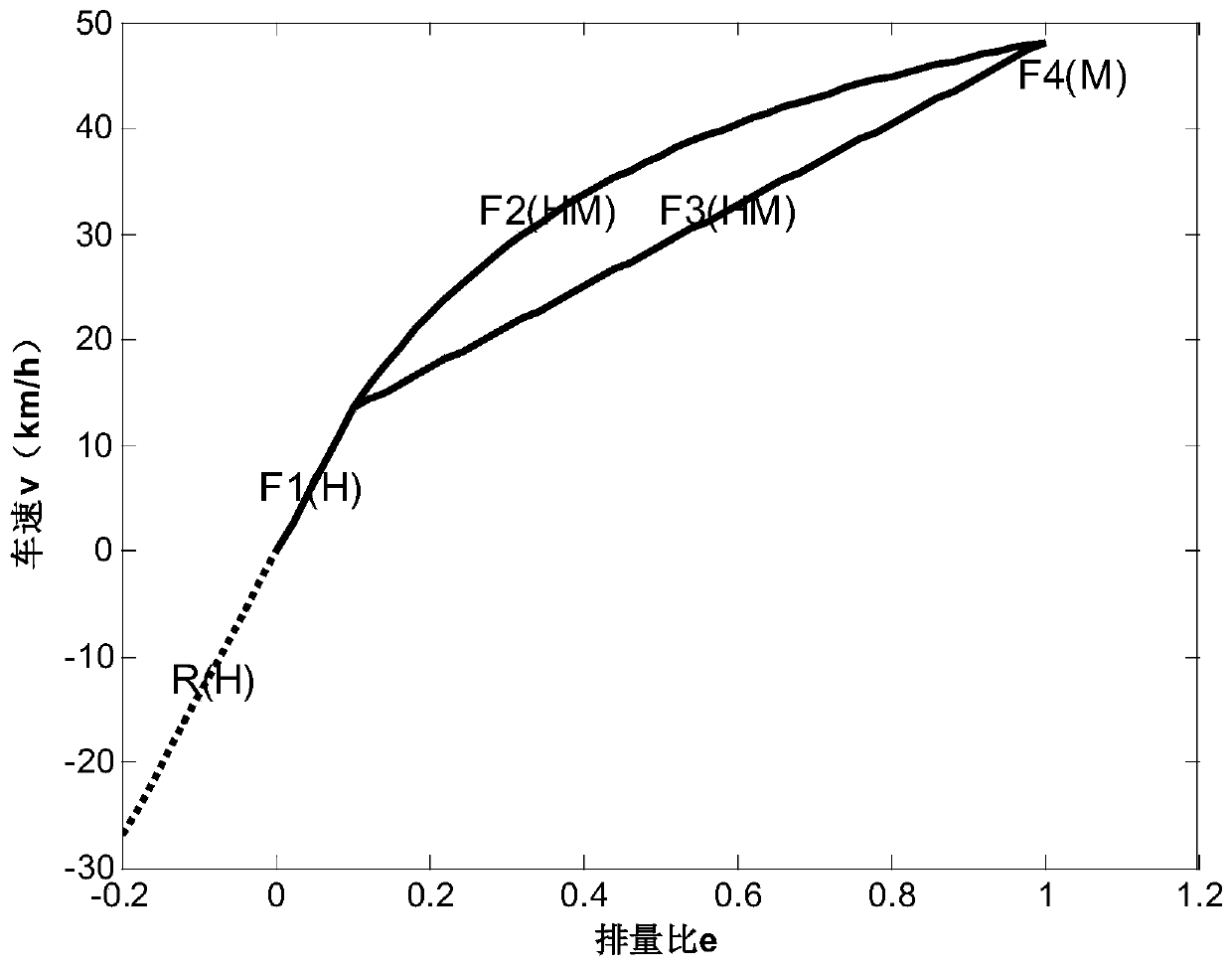

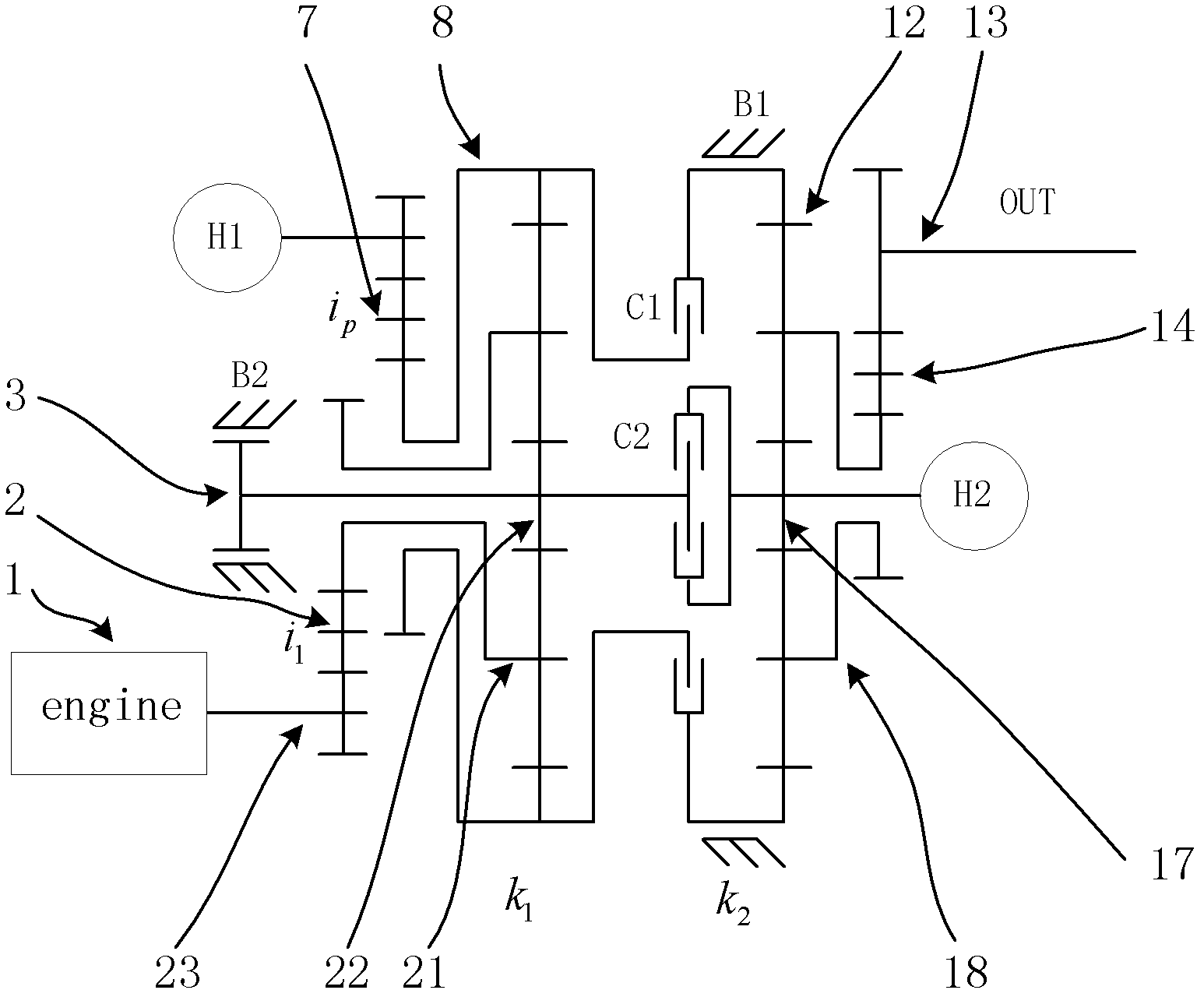

Continuously variable transmission system achieving multi-mode switching of hybrid power

ActiveCN109723789ARealize stepless speed changeCompact structureFluid gearingsQ-switchingMode switching

The invention provides a continuously variable transmission system achieving multi-mode switching of hybrid power. The continuously variable transmission system comprises an input component, an outputcomponent, a clutch assembly, a brake, a hydraulic transmission assembly and a planetary gear assembly. The input component is connected with the hydraulic transmission assembly. The output componentis connected with the planetary gear assembly. The clutch assembly connects the input component and the hydraulic transmission assembly to the planetary gear assembly. The brake and the clutch assembly provides the transmission ratio of continuous advancing or retreating between the input component and the output component. Through linear increase or non-linear increase of the displacement ratioof the hydraulic transmission assembly, hydraulic-mechanical transmission is converted into mechanical transmission. Integrated control can be carried out through a dual power source adopting an engine and an electromotor as power and the transmission and composite transmission adopting hydraulic transmission, mechanical transmission and hydraulic-mechanical transmission as the transmission manner, the statistical method based on test data is used, and matched energy management strategies are provided.

Owner:JIANGSU UNIV

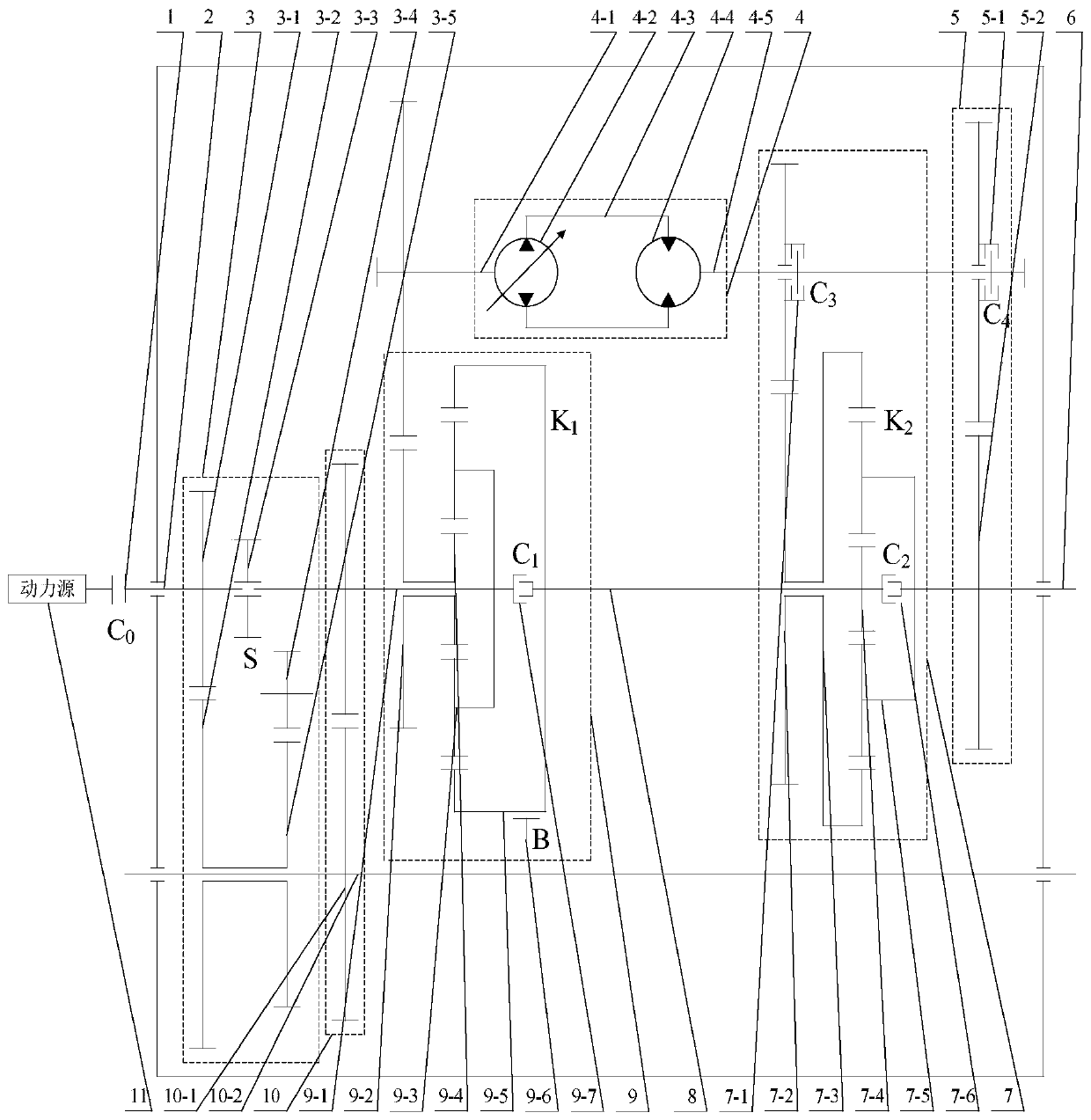

Hydraulic mechanical continuously variable transmission for loader

The invention relates to a hydraulic mechanical continuously variable transmission for a loader and belongs to the technical field of mechanical transmission. The transmission comprises a planet gear a1, a planet gear a2, a planet gear a3, a planet gear a4, a closed transmission hydraulic unit, a high / low gear pair and a combined clutch, wherein the planet gear a1, the planet gear a2, the planet gear a3 and the planet gear a4 are arranged inside a box, the pure hydraulic transmission low gear starting or loader heap operation through the planet gear a1 and a clutch C1, the hydraulic mechanical power dividing, confluence and middle / low gear driving through the planet gear a2 and a clutch C2, the reverse gear is achieved through the planet gear a3 and an arrester B1, and the forward gear is achieved through the planet gear a4 and an arrester B2. A microcomputer control system controls the joint state of clutches and the discharge capacity of a variable pump, the forward reverse multistage continuous hydraulic mechanical continuously variable transmission which is in wide in range and high in efficiency is achieved, and the transmission is suitable to engineering vehicles such as wheel loaders.

Owner:TIANJIN ENG MACHINERY INST

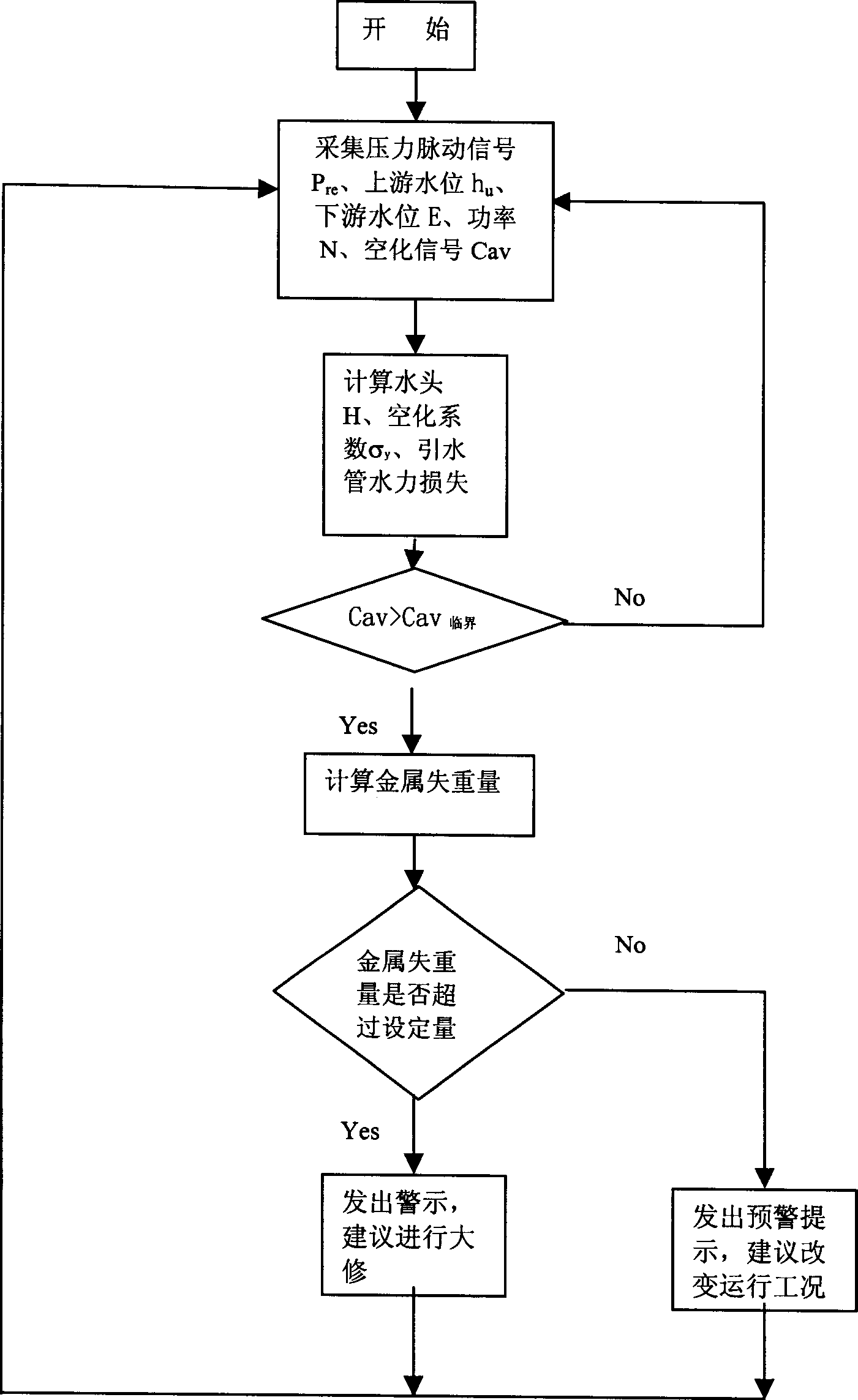

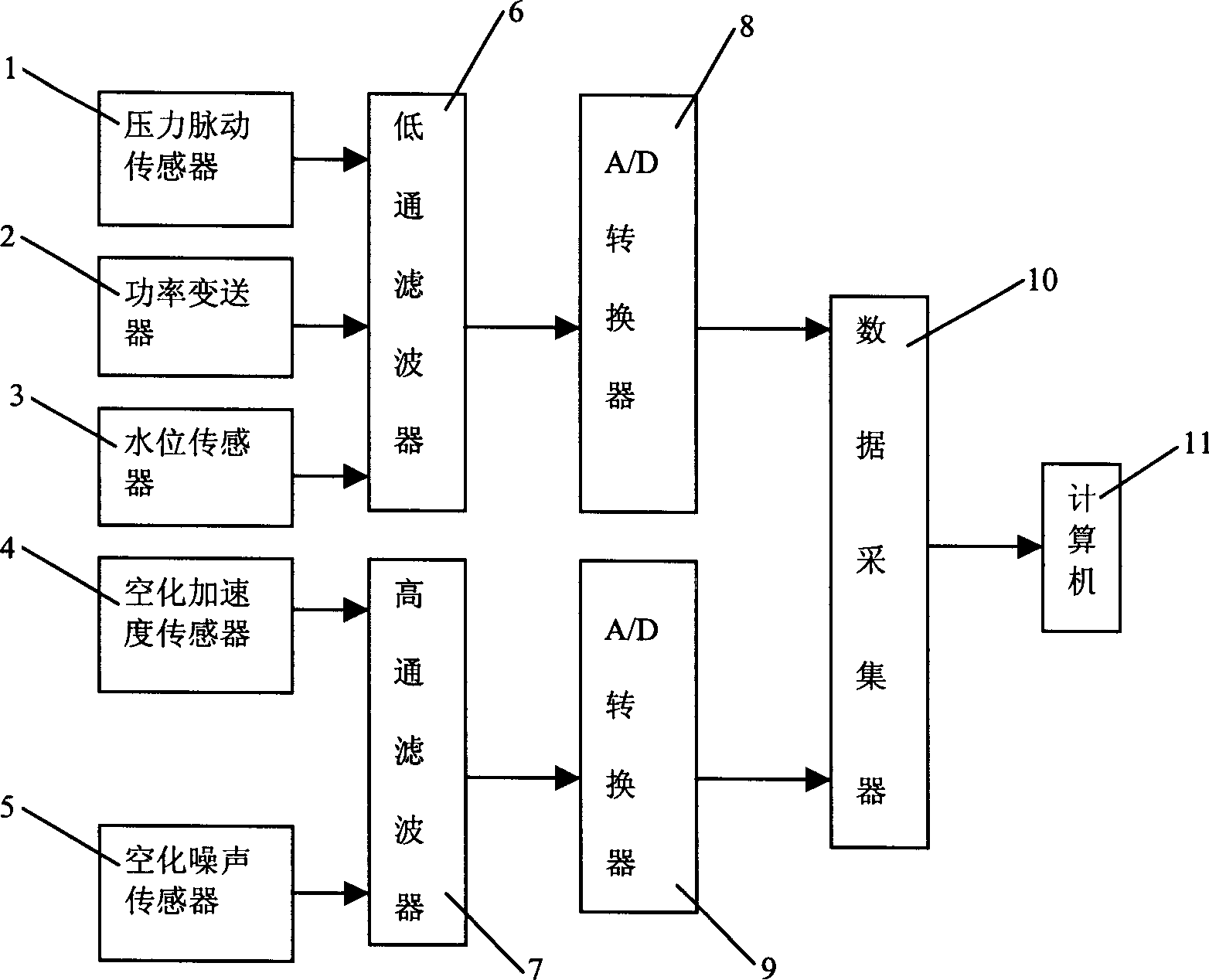

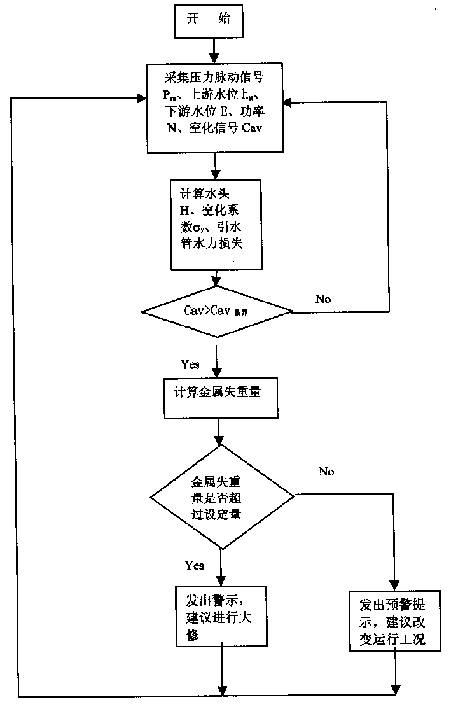

Hydraulic machinery cavitation destruction on-line monitoring method and diagnosis apparatus

InactiveCN1401986AImprove securityExtended service lifeStructural/machines measurementHydro energy generationHydraulic machineryEngineering

An in-line monitor method and diagnosing apparatus for the damage of cavitation and cavitation erosion of hydraulic machinery is characterized by that the cavitation coefficient, pressure pulse, energy characteristics of hydraulic machinery, working water head, and the cavitation impact signals are measured, the lost metal weight is calculated out and the intensity of cavitation and cavitation erosion and damaged legree are analyzed.

Owner:TSINGHUA UNIV

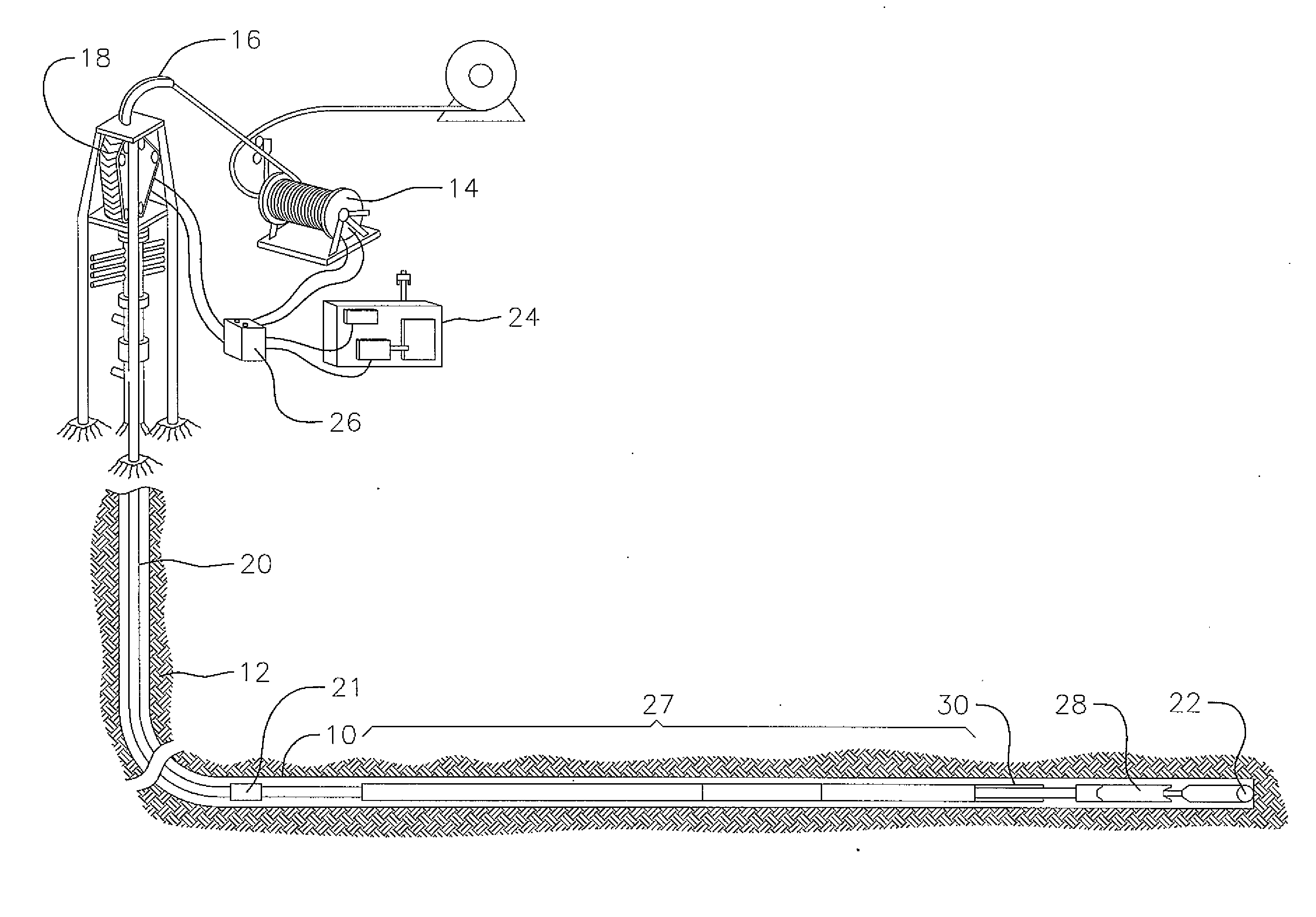

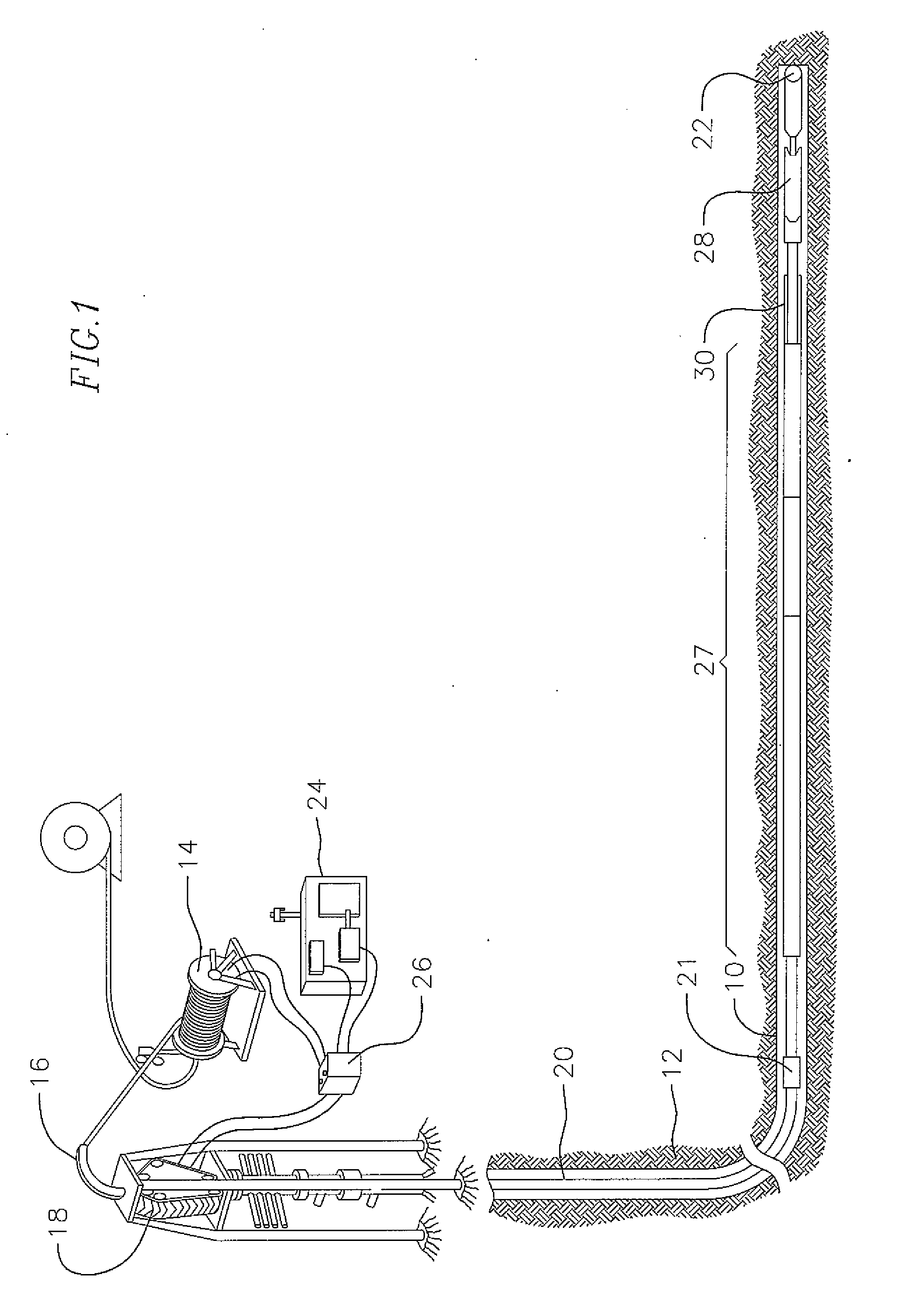

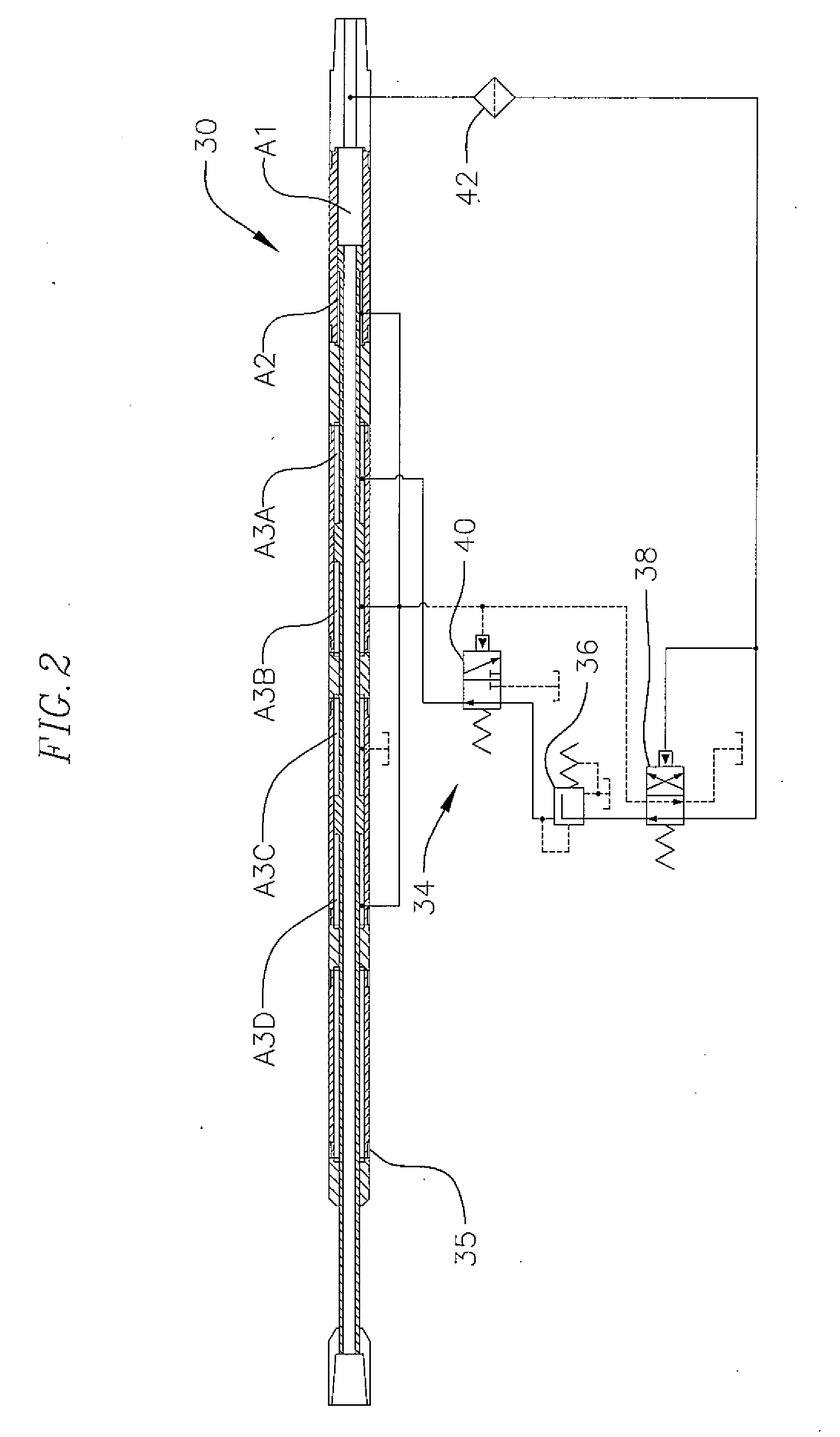

Electrical controller for Anti-stall tools for downhole drilling assemblies and method of drilling optimization by downhole devices

InactiveUS20160090832A1Maintaining WOBIncreasing WOBDrilling rodsConstructionsWell drillingHydraulic machinery

A method of operating a bottom hole assembly having a drill pipe, an anti-stall tool, a motor and a drill bit in real-time including entering an upper torque threshold and a lower torque threshold as operating parameters for the bottom hole assembly into the anti-stall tool, continuously sensing torque of the bottom hole assembly by a torque sensor in the bottom hole assembly, electronically determining if the sensed torque has exceeded the upper torque threshold or the lower torque threshold for a specified duration of time requiring an intervention by the anti-stall tool, and communicating instructions to the anti-stall tool for proper hydro-mechanical adjustment of the anti-stall tool.

Owner:WWT NORTH AMERICA HLDG

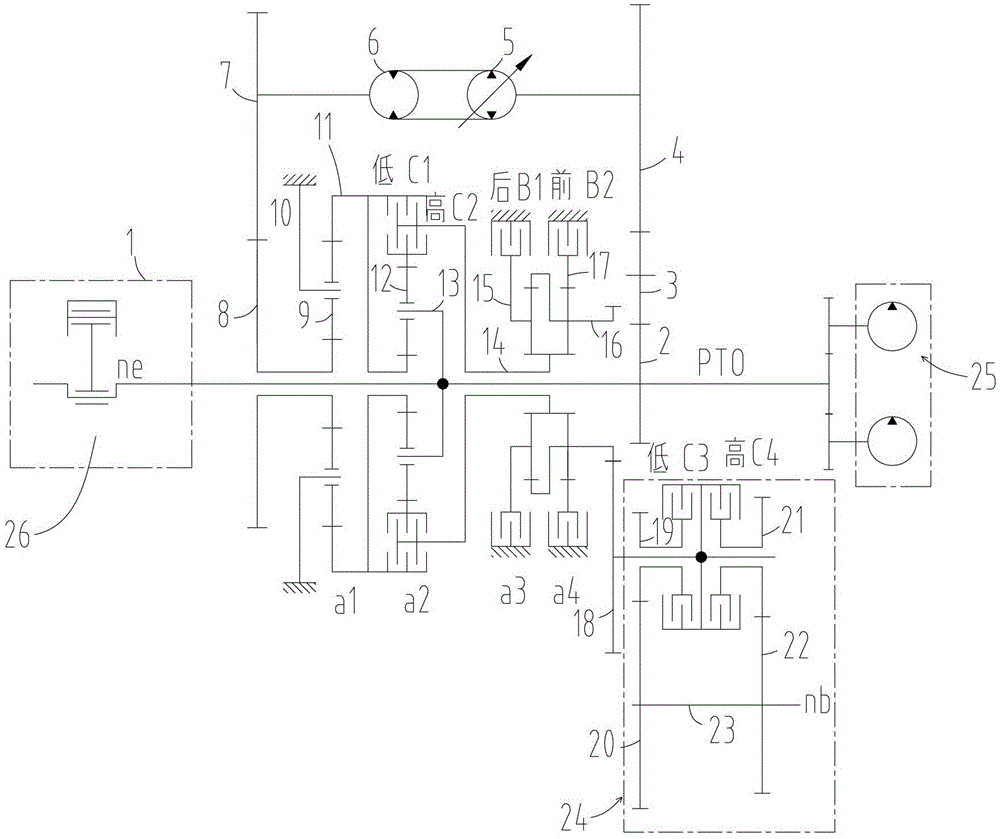

Three-section hydraulic mechanical continuous stageless transmission device and method thereof

ActiveCN102537269ARealize stepless speed changeSimple structureFluid gearingsFully developedHydraulic machinery

The invention discloses a three-section hydraulic mechanical continuous stageless transmission device and a method thereof. The three-section hydraulic mechanical continuous stageless transmission device comprises a planet transmission part, a hydraulic speed regulation part and a section change operation part. The whole device uses two planet rows as basis to reasonably control reunion or separation of the section change operation part and smoothly join a speed-division moment-converge flow-split mode, a speed-division speed-converge flow-split mode and a moment-division speed-converge flow-split mode to fully develop performance advantages of all flow-split modes. In addition, the transmission device can achieve a reverse-gear pure hydraulic work condition and pure mechanical transmission work condition of two fixed gears. The transmission device has the advantages of being simple in structure, continuous in stepless speed change, good in starting characteristics, small in system volume, small in mass and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Master-slave hydraulic mechanical arm system of high-voltage hot-line operation robot

ActiveCN102615638AMeet the requirements of high-voltage live working robotsHigh control precisionProgramme-controlled manipulatorHydraulic machineryHigh pressure

The invention relates to a master-slave hydraulic mechanical arm system of a high-voltage hot-line operation robot, which comprises a hydraulic oil source, mechanical arm bodies, hydraulic servo drivers, optical fibers, master arm controllers, master arms, handheld terminals and the like. The mechanical arm bodies are connected with the hydraulic servo drivers and the hydraulic oil source respectively. The hydraulic servo drivers are connected with the master arm controllers which are connected with the master arms. The master arms are connected with the handheld terminals. The hydraulic servo drivers and the master arm controllers are respectively connected with a power source. The master-slave hydraulic mechanical arm system is fast in processing speed, low in cost and stable and reliable in performance.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

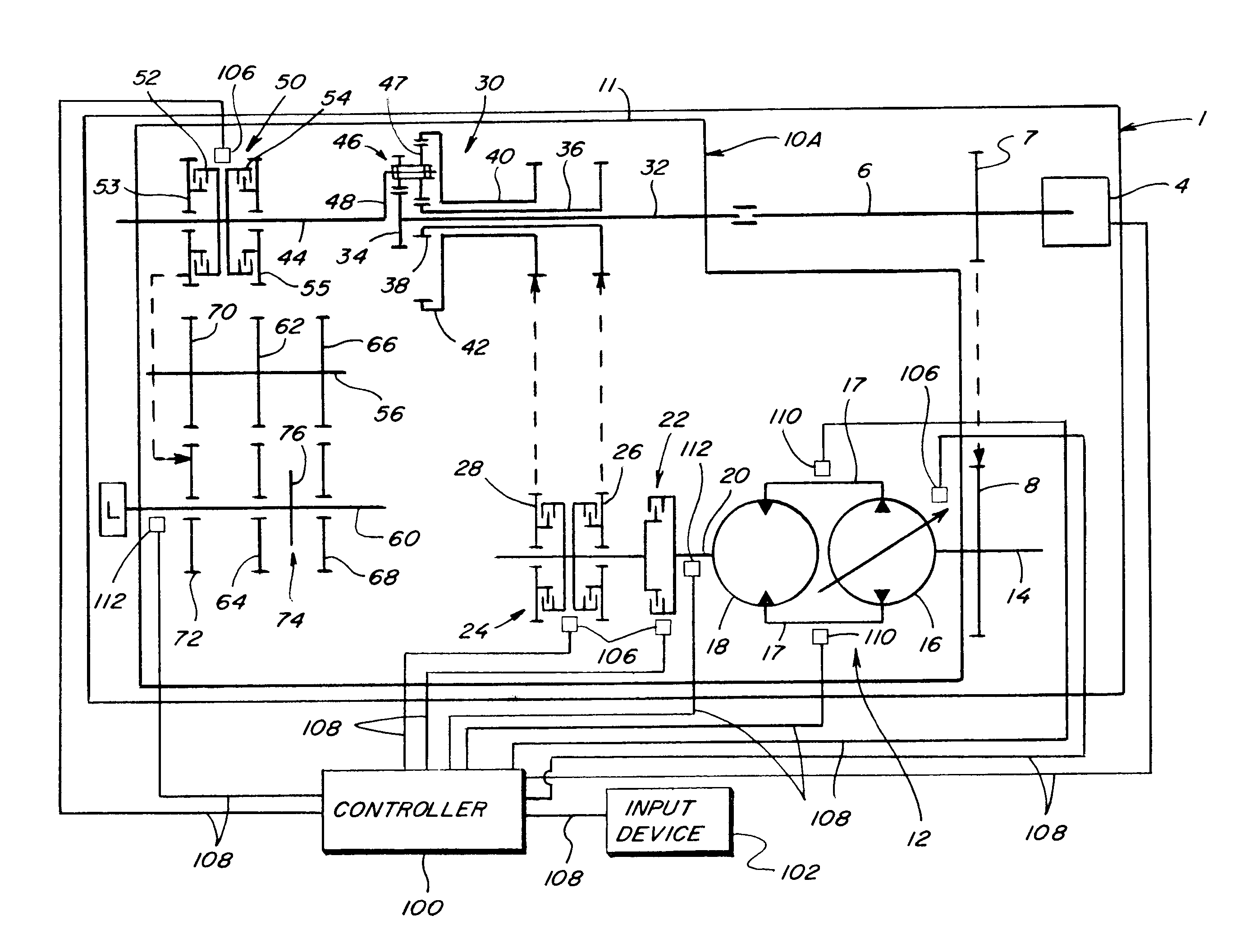

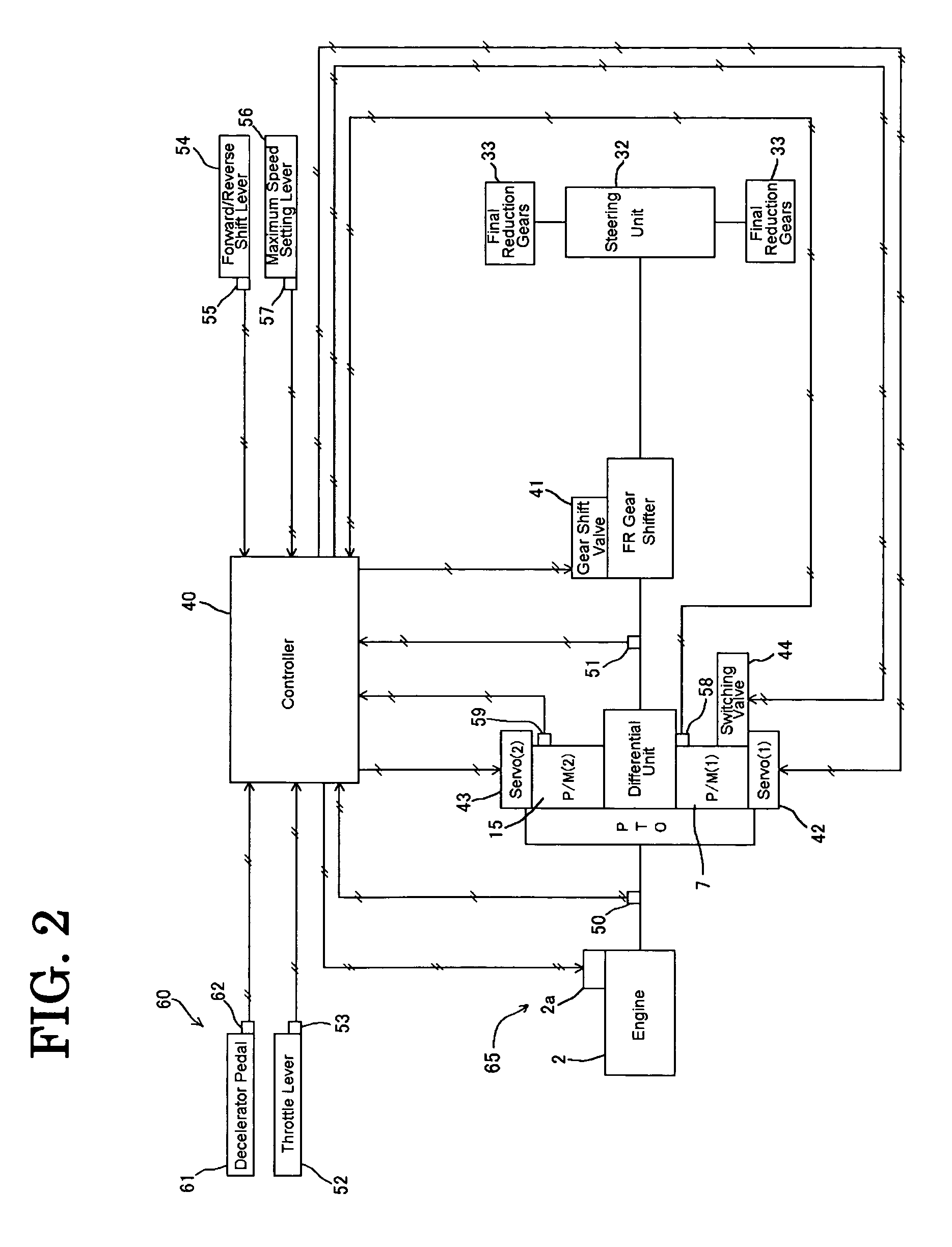

Vehicle control system

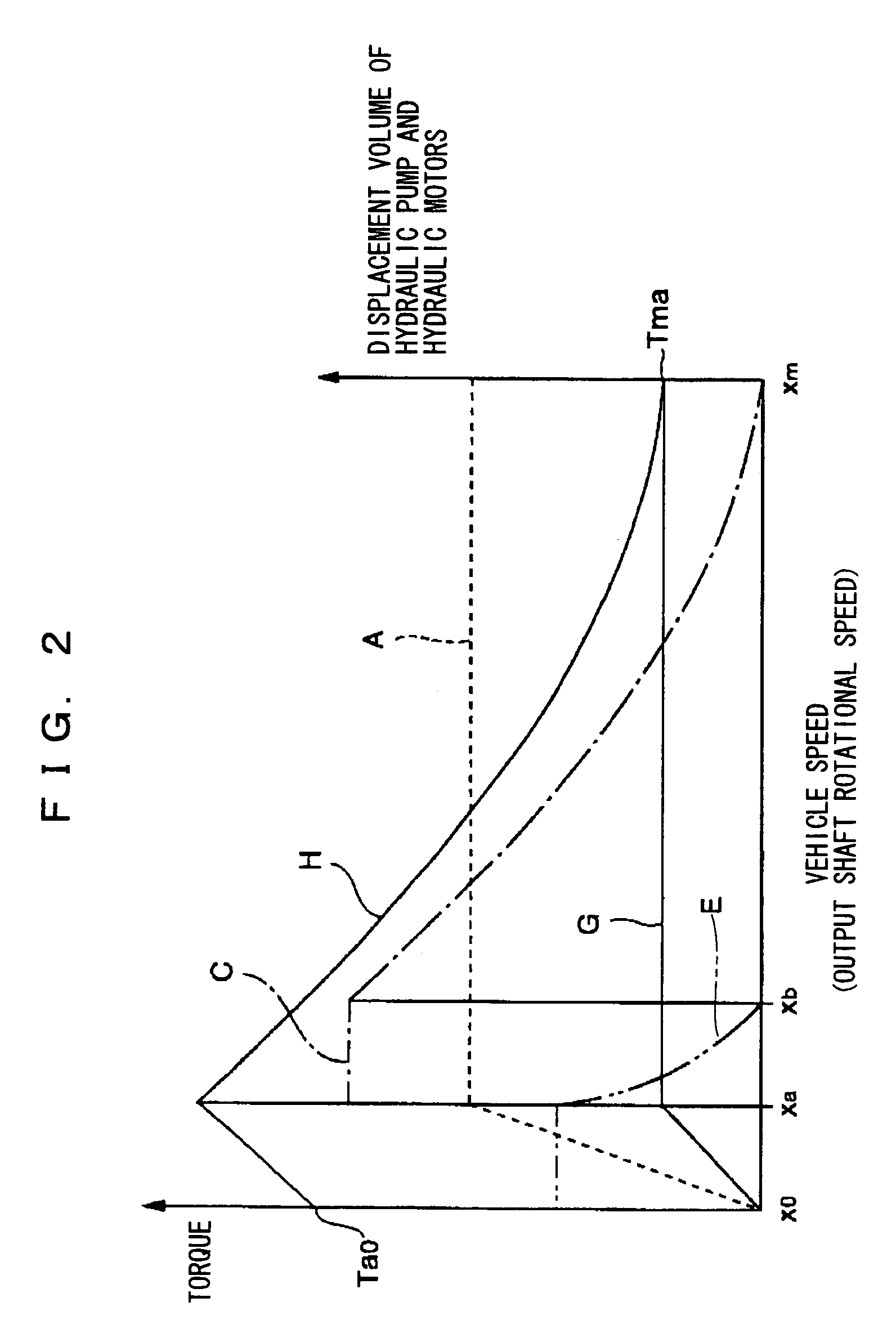

A vehicle control system which is capable of performing a quick decelerating operation in all vehicle speed regions and setting a direct region where power from an engine is transmitted through a mechanical transmission unit only in a hydro-mechanical transmission. The vehicle control system includes an engine and a hydro-mechanical transmission and is designed to set a tractive force-vehicle speed characteristic corresponding to the direct region where power transmission from the input shaft to the intermediate output shaft of the hydro-mechanical transmission is done by the mechanical transmission unit alone in a specified engine speed region. An engine control system controls the engine and a decelerator outputs a deceleration command according to an operating amount thereof. The engine control system controls the engine to reduce engine output torque corresponding to a specified engine speed region in response to the deceleration command.

Owner:KOMATSU LTD

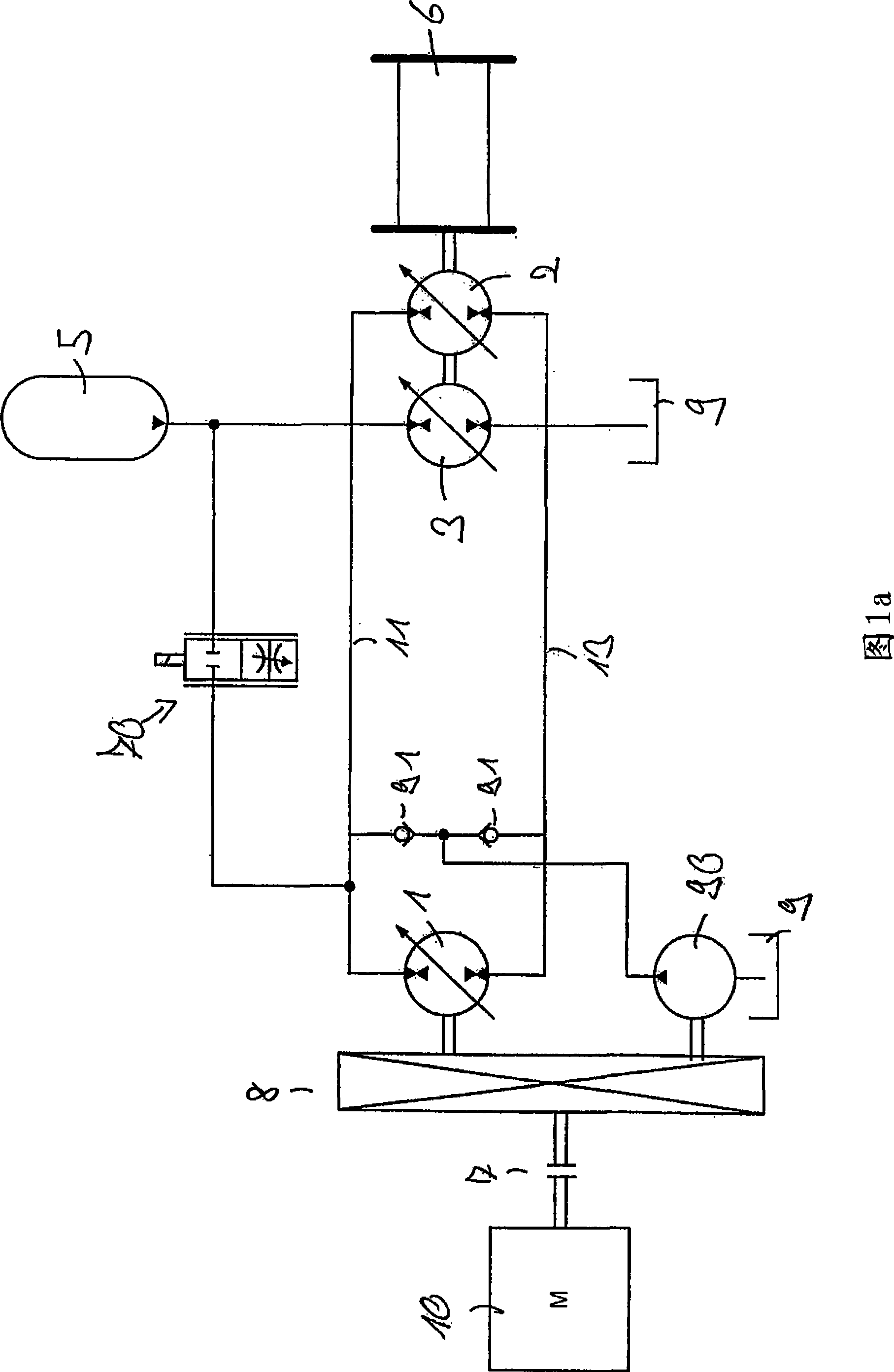

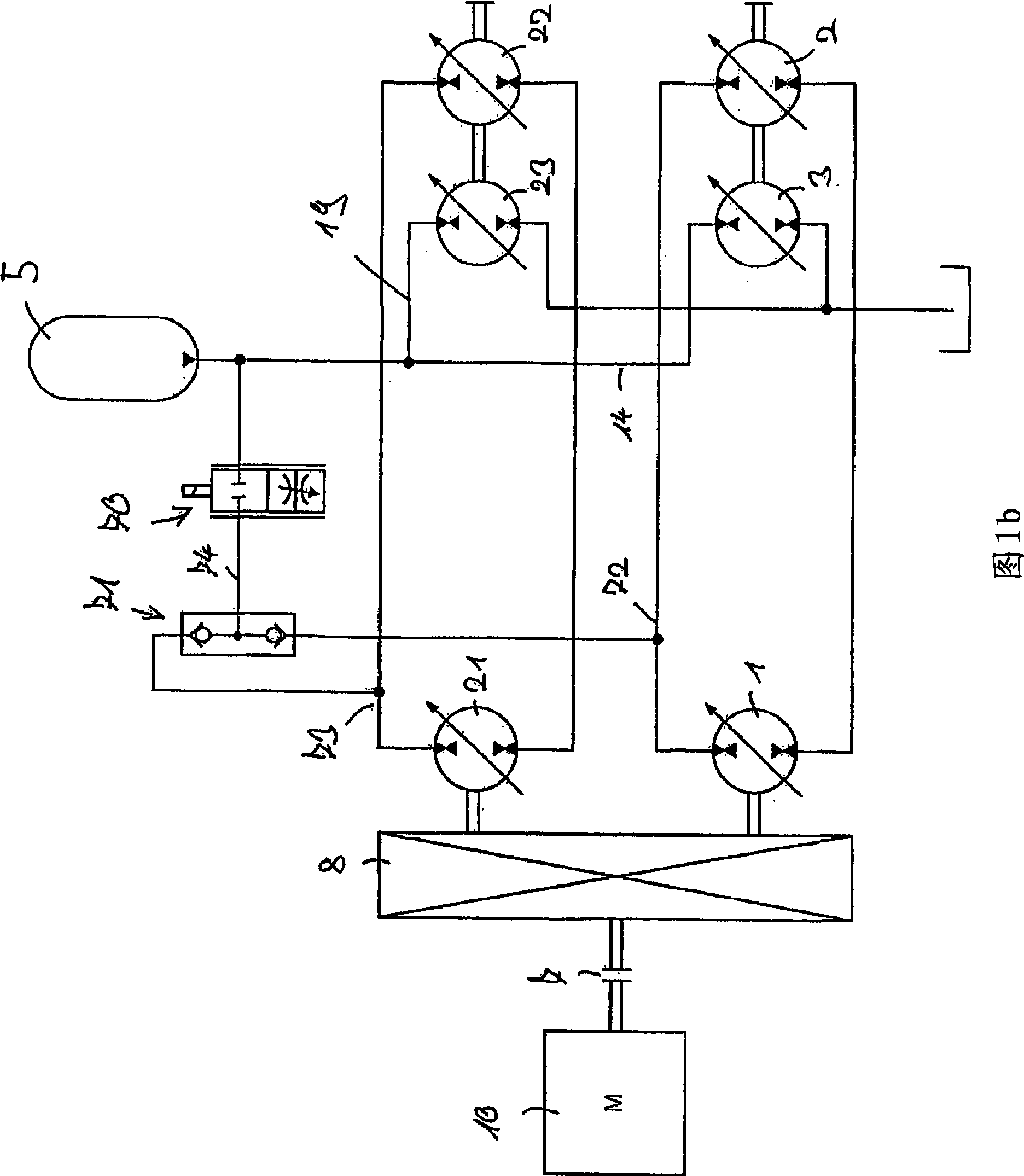

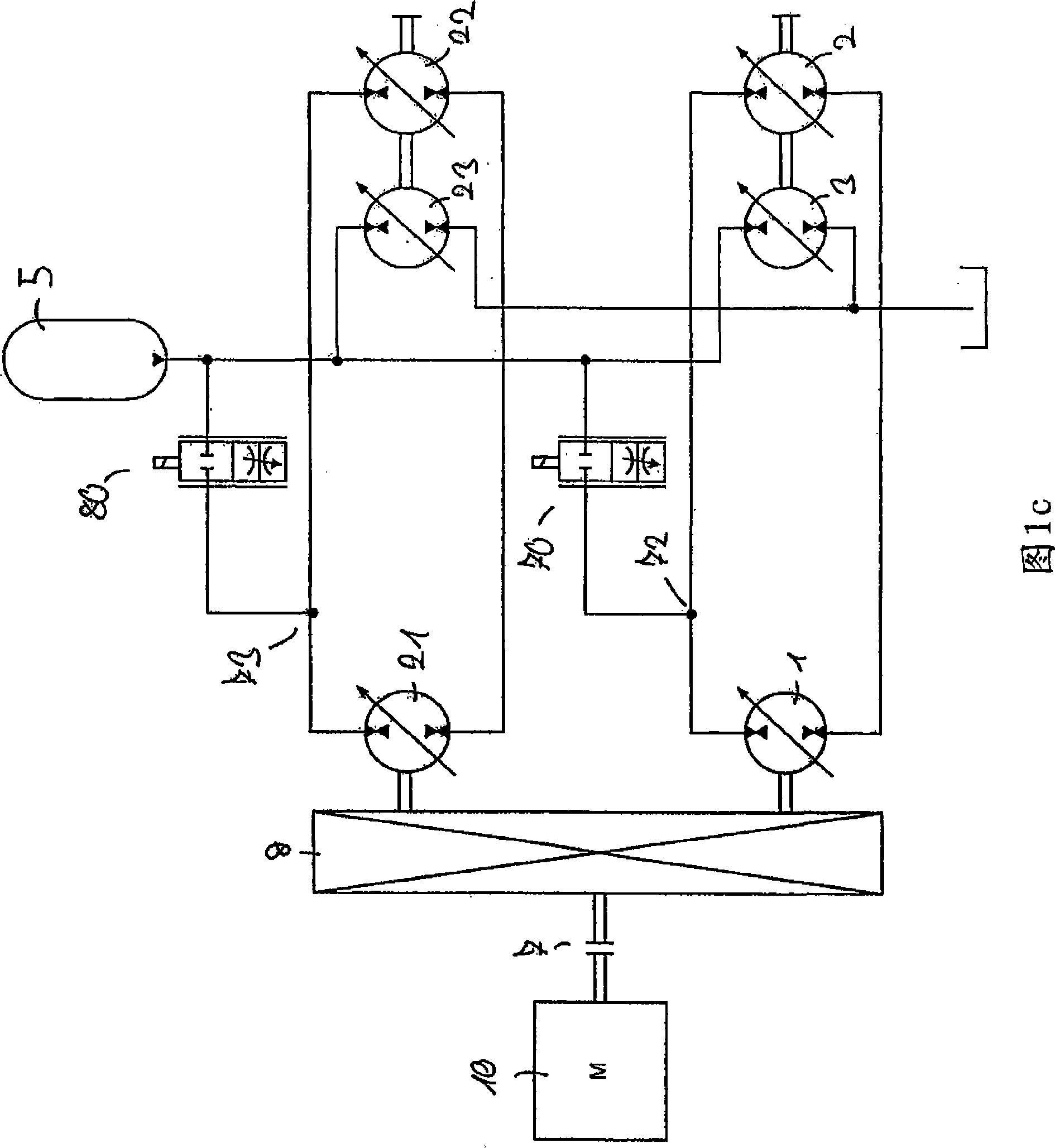

Hydraulic drive system with energy recuperation

ActiveCN101398017AImprove efficiencyEasy to startAccumulator installationsServomotorsHydraulic machineryMechanical energy

The present invention relates to a hydraulic drive system for driving an apparatus, with a drive unit, a first and a second hydraulic displacement machine, with which the drive unit is connectable or connected for transmitting mechanical energy, and a third and a fourth hydraulic displacement machine, which are connectable o r connected with the apparatus for transmitting mechanical energy, wherein the first hydraulic displacement machine is hydraulically connected or connectable wit h the third hydraulic displacement machine, and wherein a high-pressure accumulator is provided, which is hydraulically connected or connectable with the second and the fourth hydraulic displacement machine.

Owner:LIEBHERR WERK NENZING

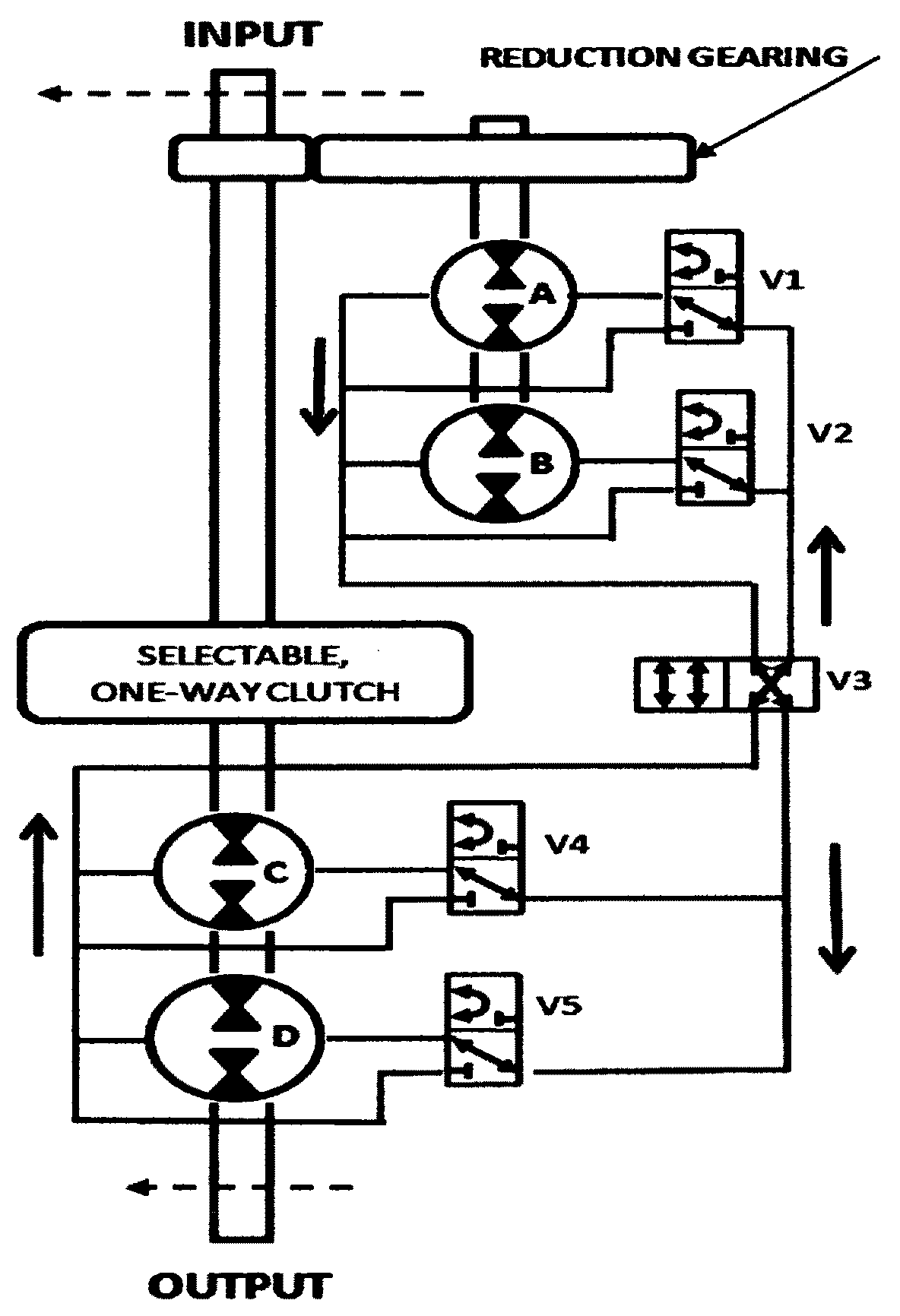

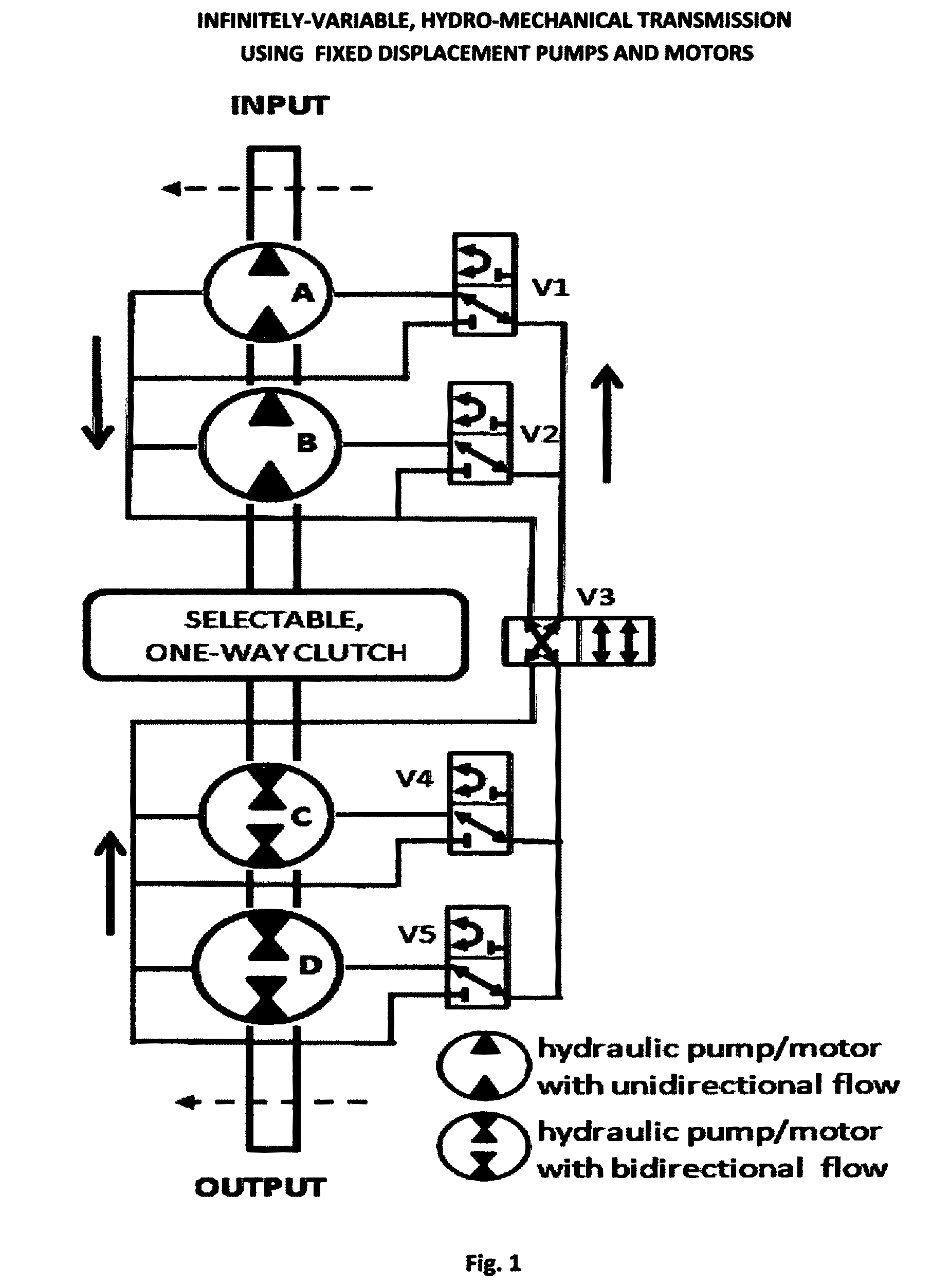

Infinitely-variable, hydro-mechanical transmission using fixed displacement pumps and motors

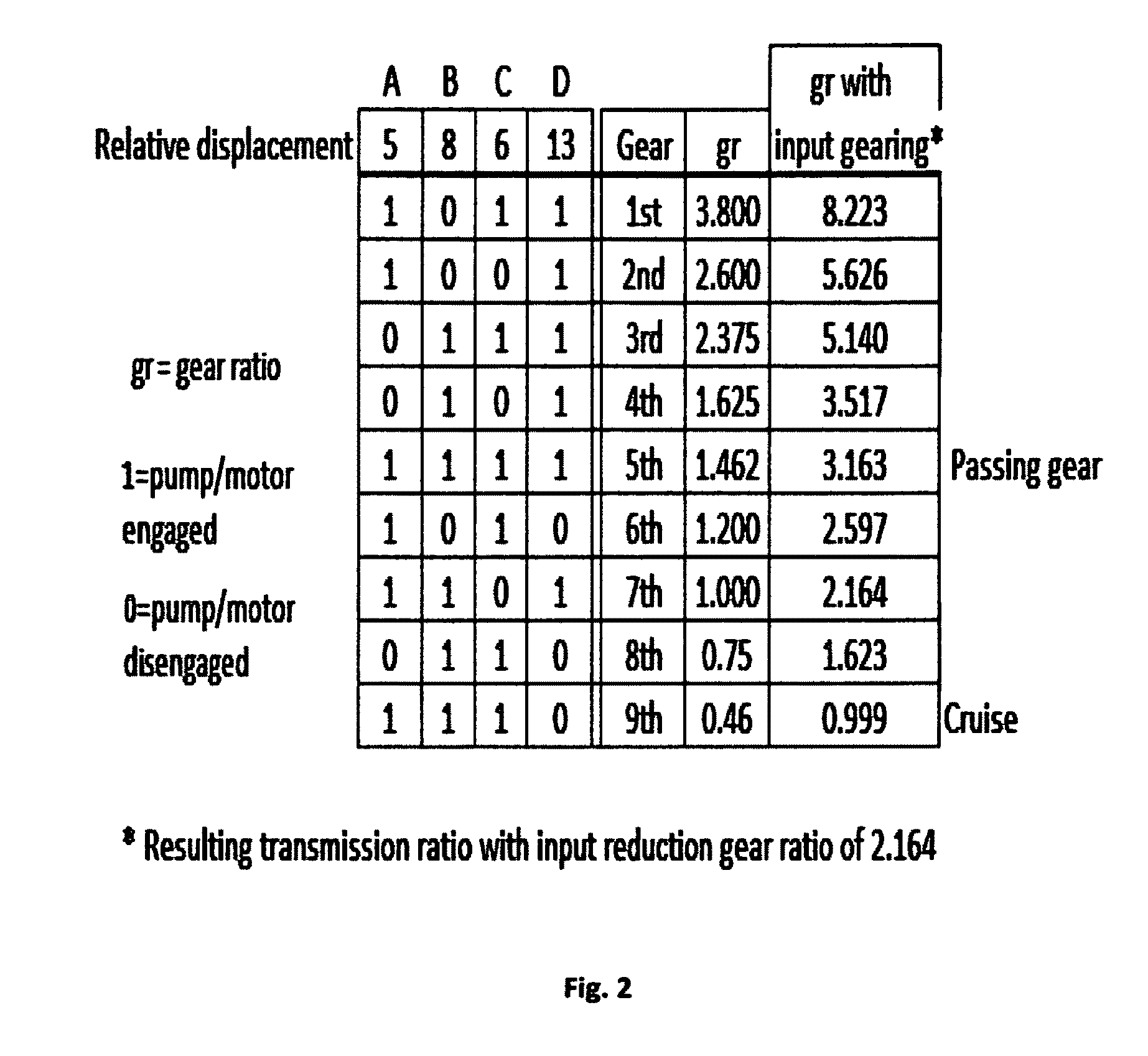

This invention consists of two or more fixed displacement hydraulic pump / motors mounted on a common input shaft hydraulically connected to two or more fixed hydraulic pump / motors mounted on a common output shaft. The relative displacements of the pump / motors are chosen such that by selectively activating the individual pump / motors, the transmission ratio can be changed in the case when the input devices and acting as pumps driving the output devices as motors (conversely when driving the vehicle in reverse). Further, a hydraulic accumulator and reservoir are attached in a manner that allows the pressurized fluid to augment the flow produce by the input pumps in order to increase the transmission ratio. Similarly, the transmission ratio can also be reduced by causing the input pumps to pump fluid into the accumulator at the same time they are pumping fluid through the output motors. The transmission also contains a single speed all mechanical by-pass for use when cruising and an input reduction gear to increase the torque and power capacity of the transmission.A further feature of the transmission is a valve arrangement that allows the transmission to generate a continuously variable braking torque when the transmission is used to supply braking force to the vehicle.In addition, the transmission includes a selectable, one-way clutch that connects the input directly to the output. When engaged, this clutch provides an all mechanical by-pass to the hydraulic transmission for use when cruising in order to improve the efficiency.

Owner:LLOYDCO

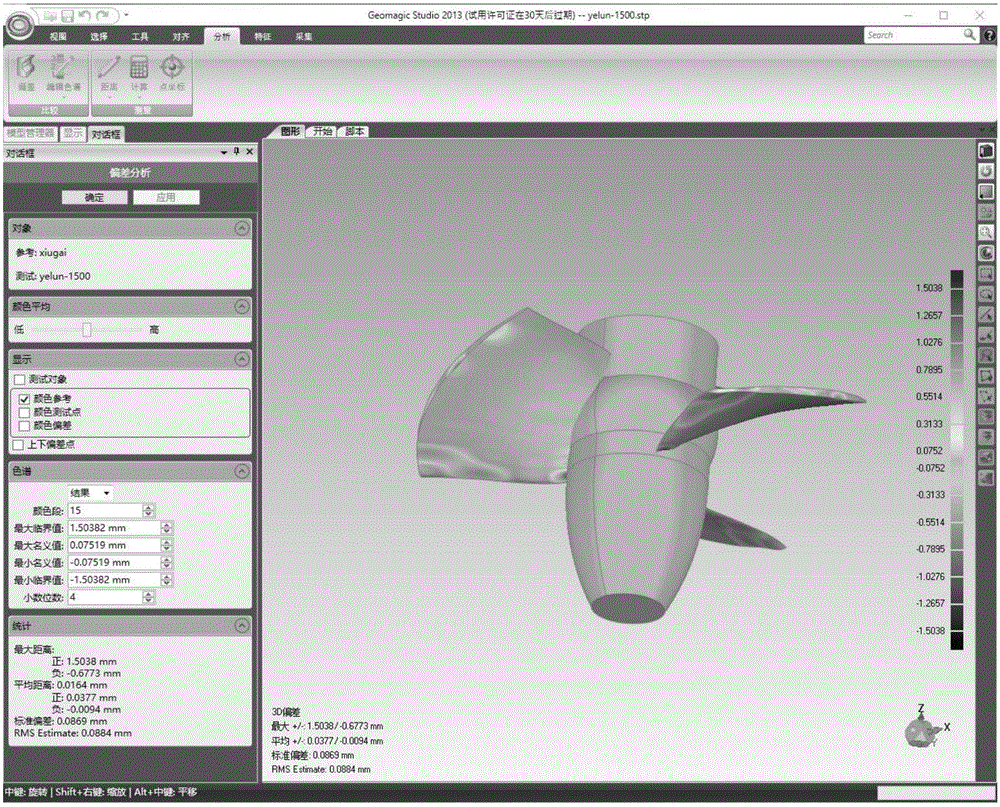

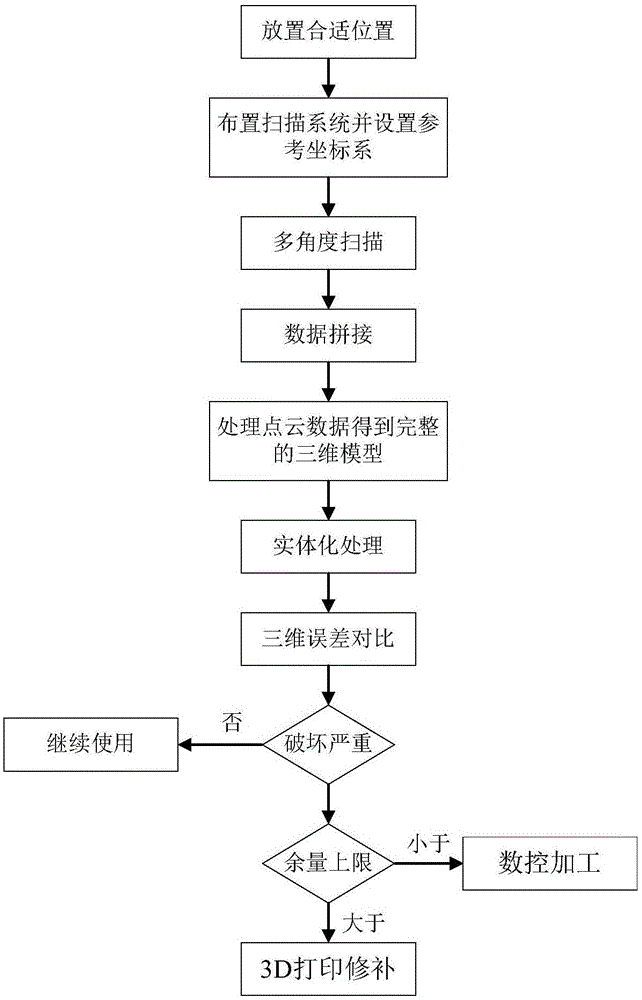

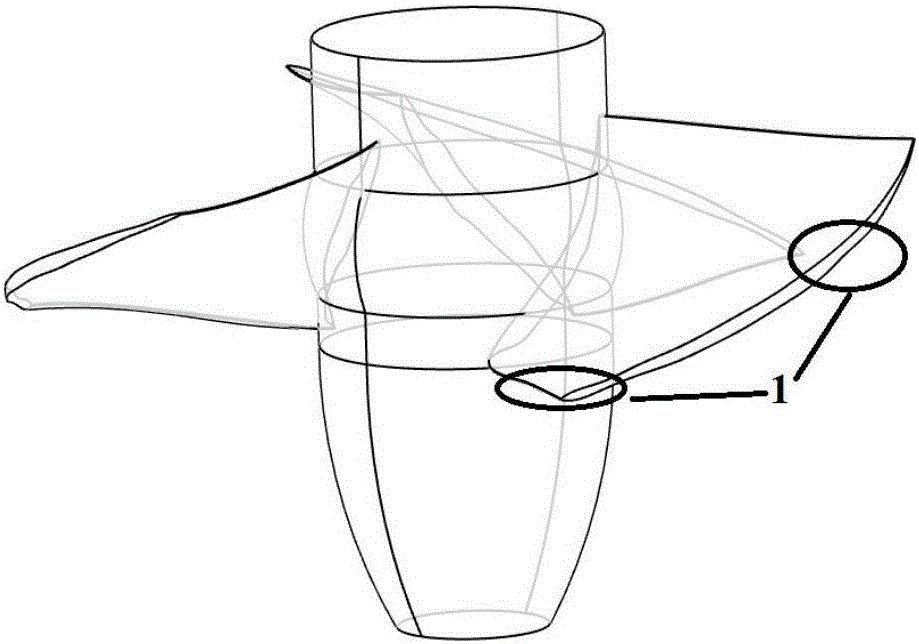

Hydraulic machinery blade surface detecting method and device

InactiveCN106767524AOvercome speedOvercome incomplete construction of surface informationUsing optical meansMechanical measuring arrangementsNumerical controlPoint cloud

The invention discloses a hydraulic machinery blade surface detecting method and device. The method and device use a composite three-dimensional non-contact measurement technology which is combined with a structural light technology, a phase measurement technology and a computer vision technology to detect the blade surface. The method comprises the steps of part fixing, multi-angle scanning, data stitching, point cloud data processing, materialization, error analysis, 3D printing numerical control repair and the like. According to the invention, the hydraulic machinery blade surface detecting method and device have the advantages of high detection precision, convenient device installation and quick inspection speed; components to be detected are not dismantled; and a detection result can be directly used for subsequent digital processing or 3D printing repair.

Owner:JIANGSU UNIV

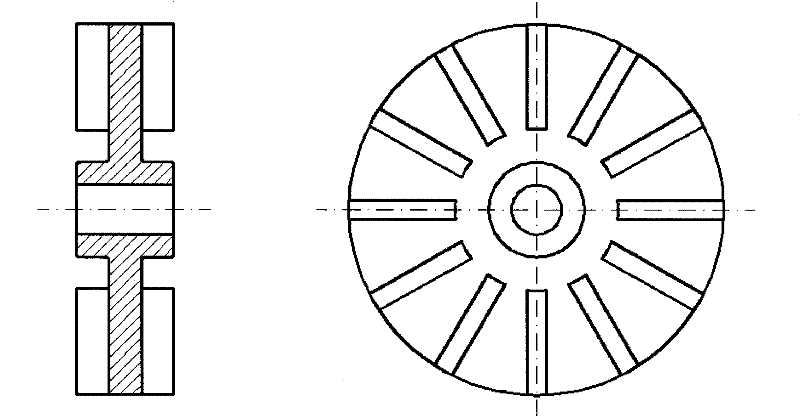

Impeller type magneto rheological fluid brake for vehicle

InactiveCN102401046ARealize integrated controlContinuous braking processLiquid resistance brakesBrake actuating mechanismsDrive wheelRoad surface

The invention discloses an impeller magneto rheological fluid brake for a vehicle. The fluid brake consists of a shell, a braking impeller, an electromagnetic device, a bearing shaft, a conical roller bearing, a sealing ring, an end cover and an auxiliary electromagnetic clutch, wherein the electromagnetic device comprises a magnet exciting coil and a magnet insulating copper sleeve; a half shaft on a driving wheel or a steering joint on a non-driving wheel can be taken as the bearing shaft; blades with rectangular sections are distributed on the peripheries of both sides of a disk of the braking impeller; the auxiliary electromagnetic clutch consists of a driving disk, a driven disk and a middle disk which consists of two branch disks transversely crossing the brake shell; the two branch disks are connected through a guide shaft, and form a conjugate friction pair together with the driving and driven disks of the clutch; and the closing and opening states of the conjugate friction pair are controlled by using the resultant force of the pre-tightening force of pre-tightening spring groups on both sides of the shell and the electromagnetic force of the clutch, so that zero-field loss of a magneto rheological fluid can be effectively avoided by using the brake during normal running of the vehicle, the real-time, active and continuous ABS (Antilock Brake System) braking process of the vehicle can be realized during braking, and a braking control process with higher performance than that of a hydraulic mechanical braking system is realized on a low-adhesion road surface.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

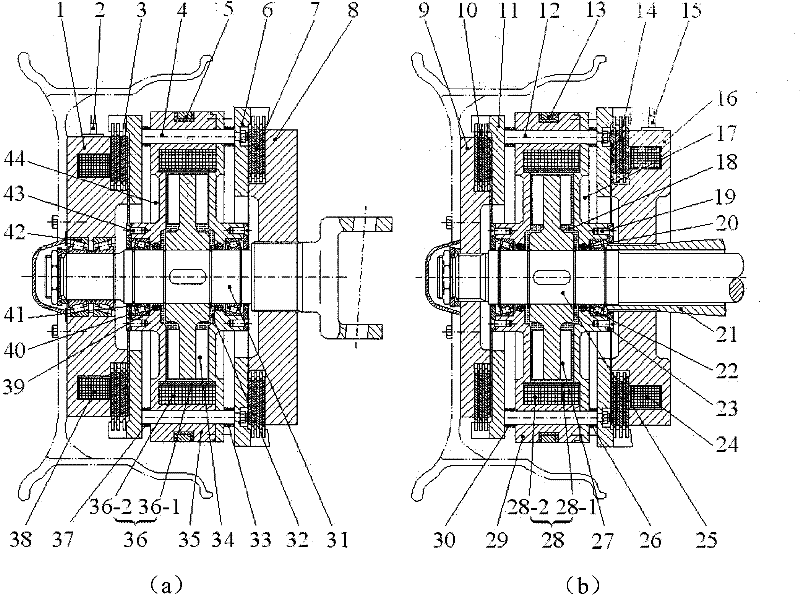

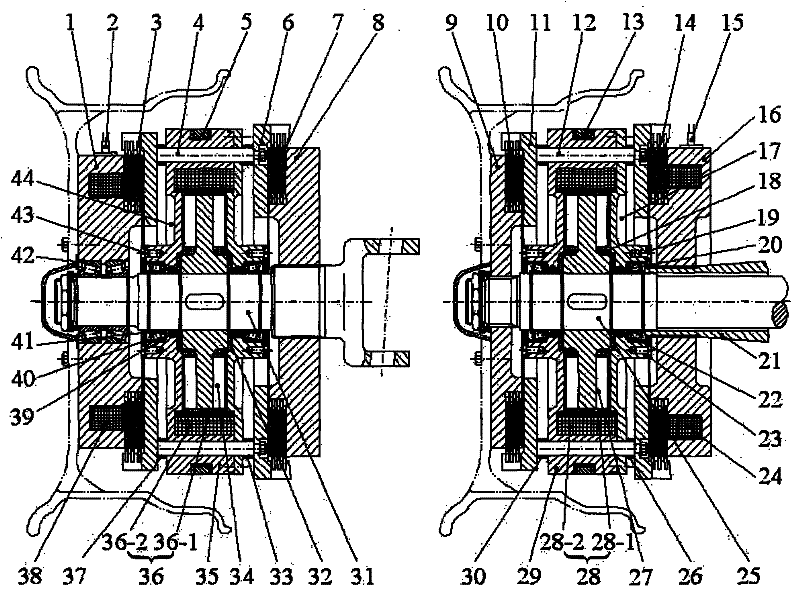

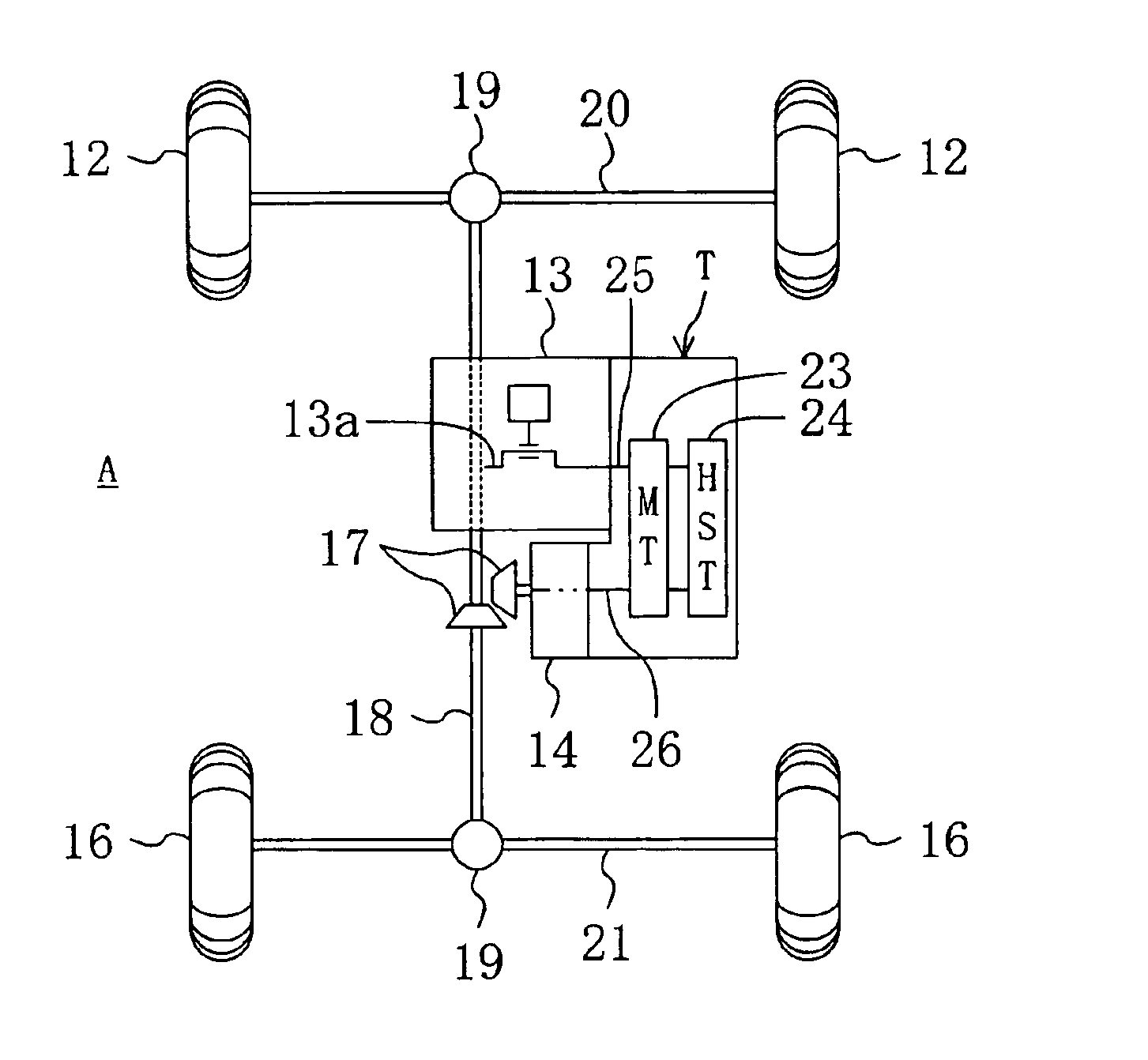

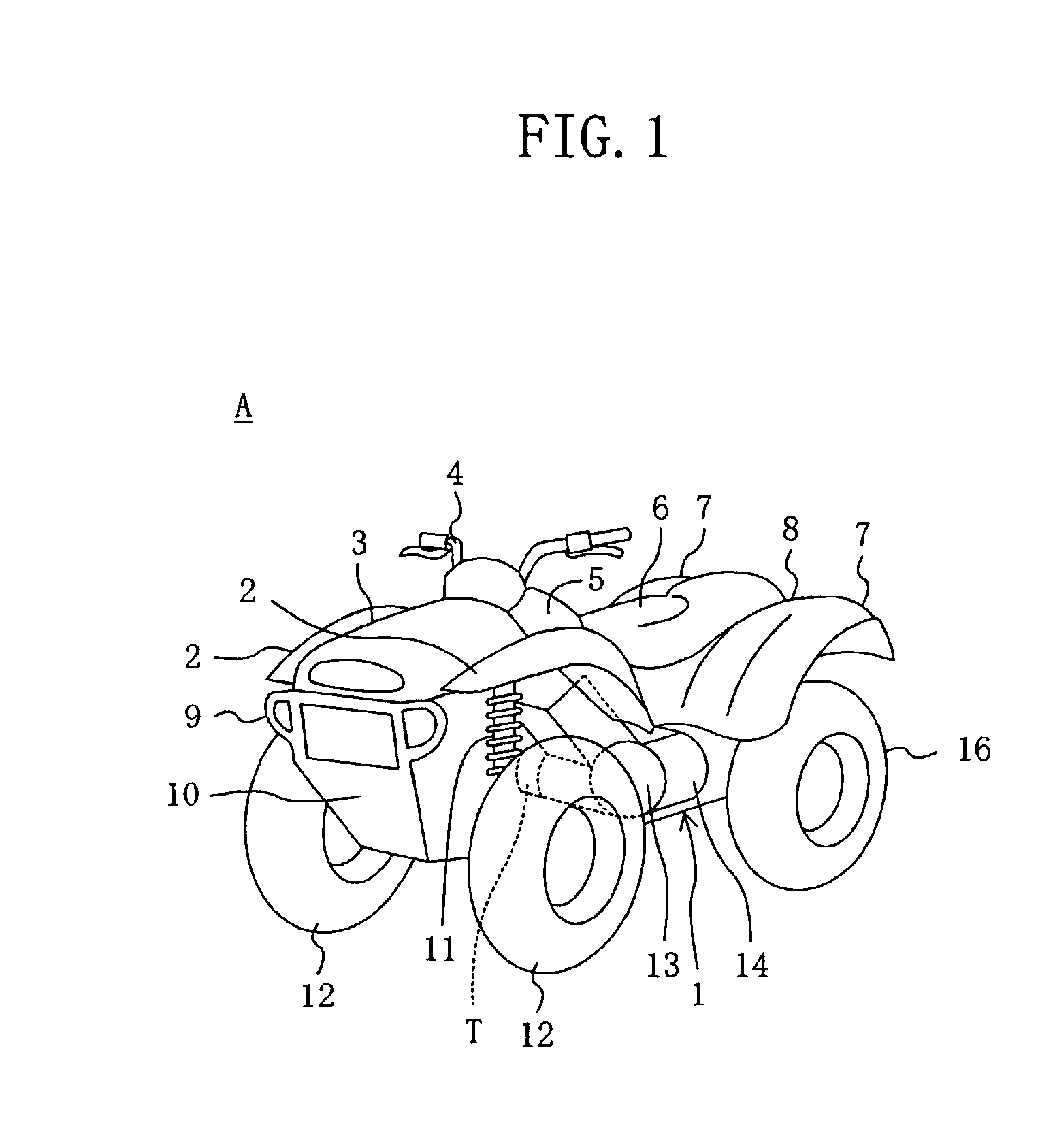

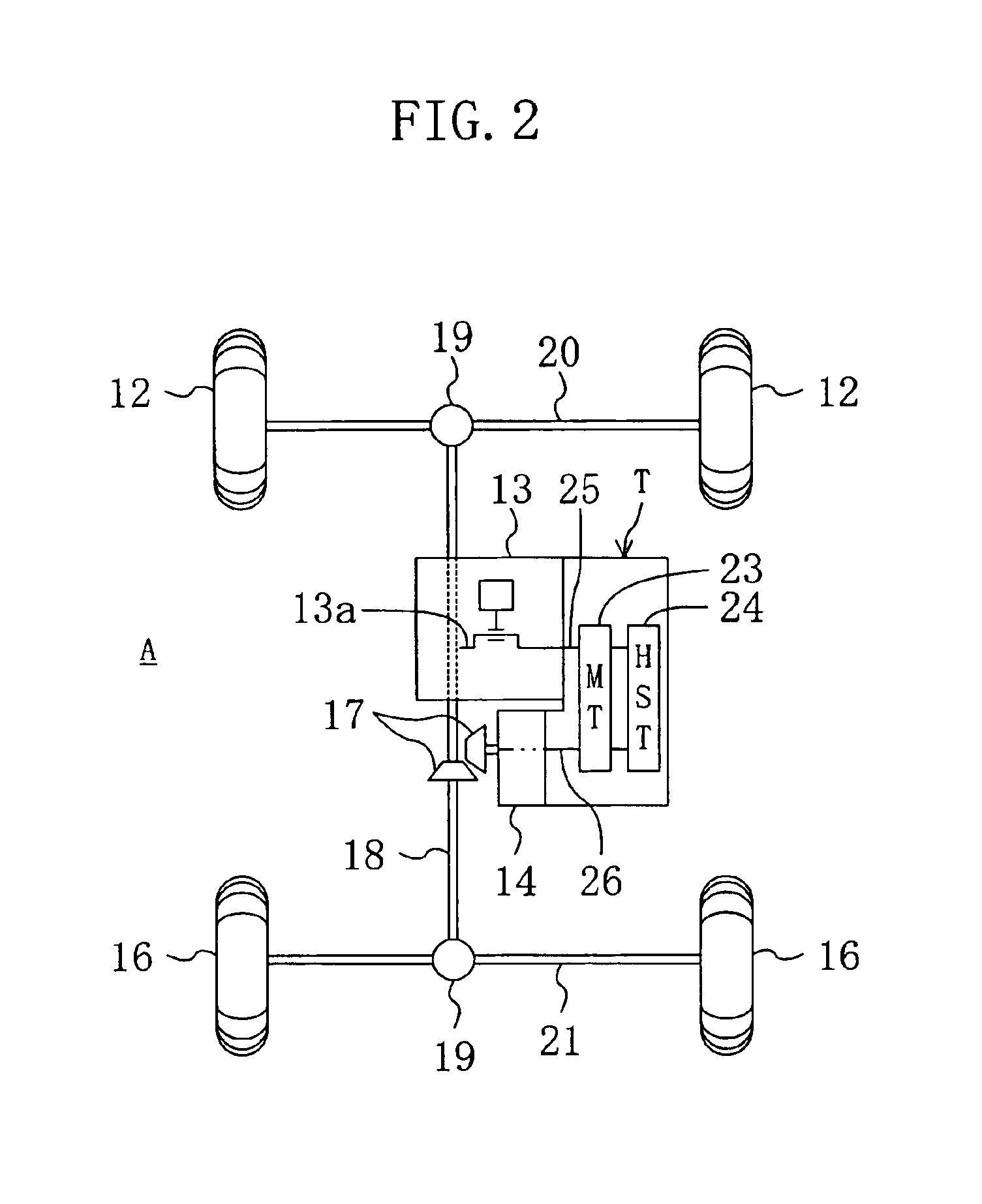

Hydromechanical speedchange device and vehicle having speed change device mounted thereon

InactiveUS6848530B2Improve cooling effectEasy maintenanceGearboxesElectric propulsion mountingBody right sideHydraulic machinery

An HMT apparatus (T) is mounted on a vehicle (A). In the HMT apparatus (T), input rotational force from an engine (13) is once divided into two systems which are then transmitted by an MT device (23) and by an HST device (24) respectively and are re-synthesized for transfer toward wheels (12) and (16). The HMT apparatus (T) is disposed on the vehicle-body right side of the engine (13) which is sideways-mounted on a vehicle body (1), and its input and output shafts (25) and (26) are disposed in parallel with a crank shaft (13a) of the engine (13) and are disposed to run parallel with each other. The input shaft (25) is coupled directly to the crank shaft (13a) and an input gear (27) of the MT device (23) is mounted on the input shaft (25), and a hydraulic piston pump (30) of the HST device (24) is connected to the right side end of the input shaft (25). A planetary gear mechanism (28) of the MT device (23) is connected to the right side end of the output shaft (26), and a hydraulic piston motor (31) of the HST device (24) is connected to the right side of the planetary gear mechanism (28). By virtue of such arrangement, it is possible to improve the degree of freedom of the layout of each component of the HMT apparatus (T), to reduce axial dimensions, and further to provide improvement in the cooling property and maintenance property of the section of the HST device (24).

Owner:DANFOSS PAUER SOLYUSHENS APS

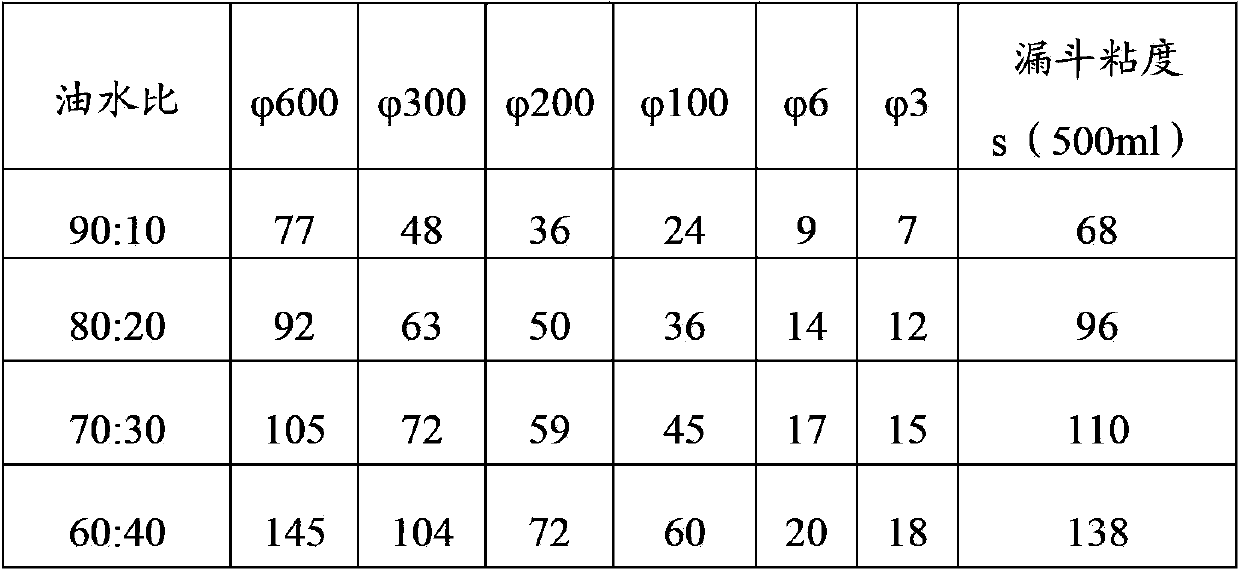

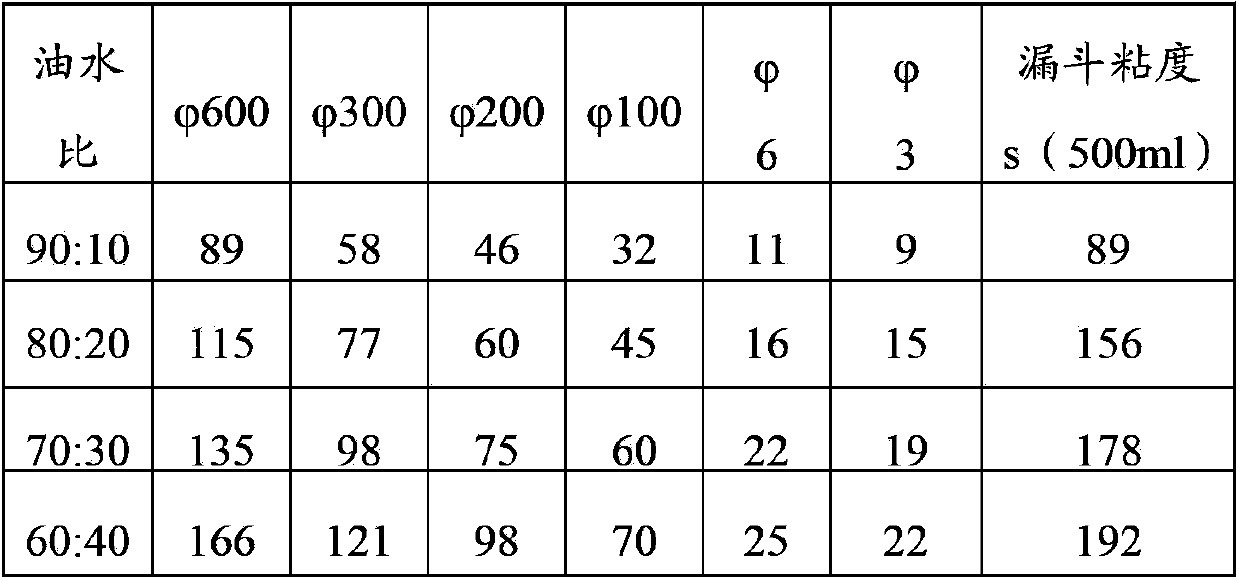

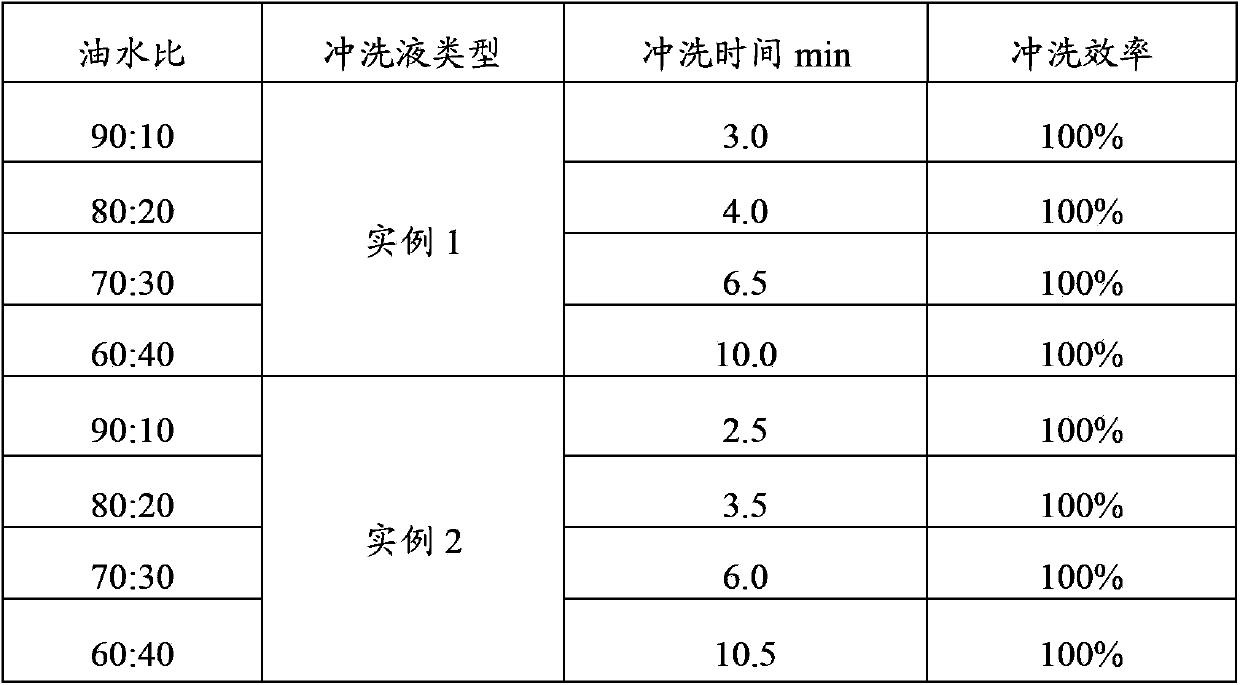

Flushing fluid for cementing of horizontal shale gas well

ActiveCN103965845AWide adaptabilityEasy to cleanDrilling compositionWell cementingHydraulic machinery

The invention provides a high-efficiency flushing fluid applicable to cementing of a horizontal shale gas well. The flushing fluid has certain shearing force and viscosity, exerts a dragging effect on oil slurry and an oil film under the action of hydraulic machinery and achieves the purposes of effective cleaning of the oil film and replacement of a viscous oil-based drilling fluid. The flushing fluid is mainly composed of a nonionic surfactant, an anionic surfactant, organic acid and a viscosity and shearing force improving agent, and comprises, by weight, 2 to 10 parts of the nonionic surfactant, 2 to 7 parts of the anionic surfactant, 2 to 4 parts of organic acid, 0.5 to 5.0 parts of the viscosity and shearing force improving agent and 72 to 100 parts of clear water. The flushing fluid provided by the invention has a high efficiency flushing effect on drilling fluids with high viscosity and shearing force and with a wide range of the oil-water ratio, e.g., from 60 / 40 (v / v) to 90 / 10(v / v).

Owner:CHINA PETROLEUM & CHEM CORP +1

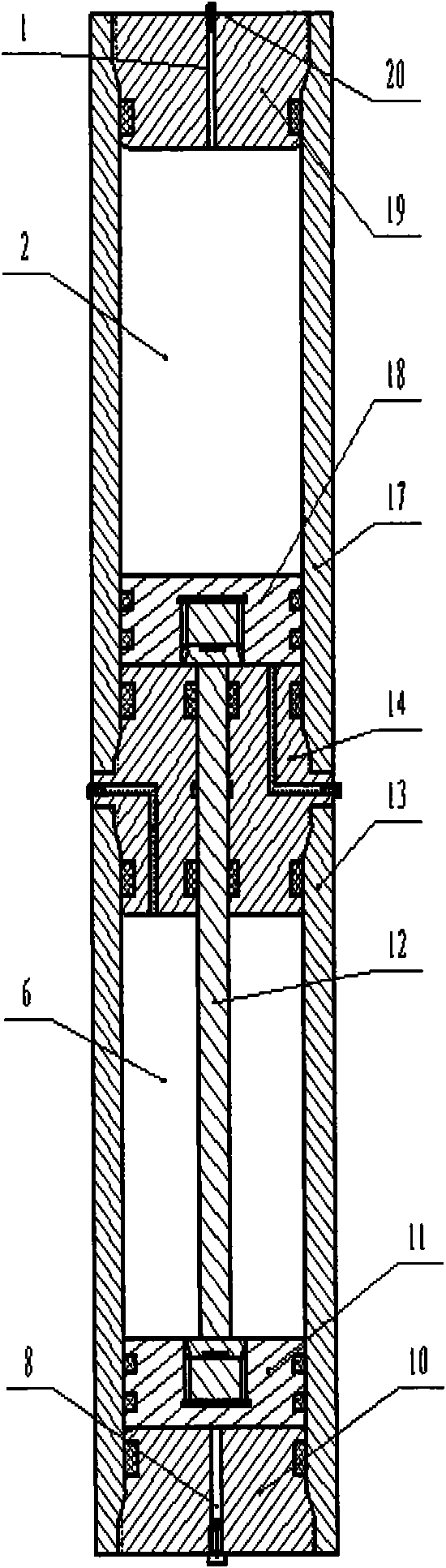

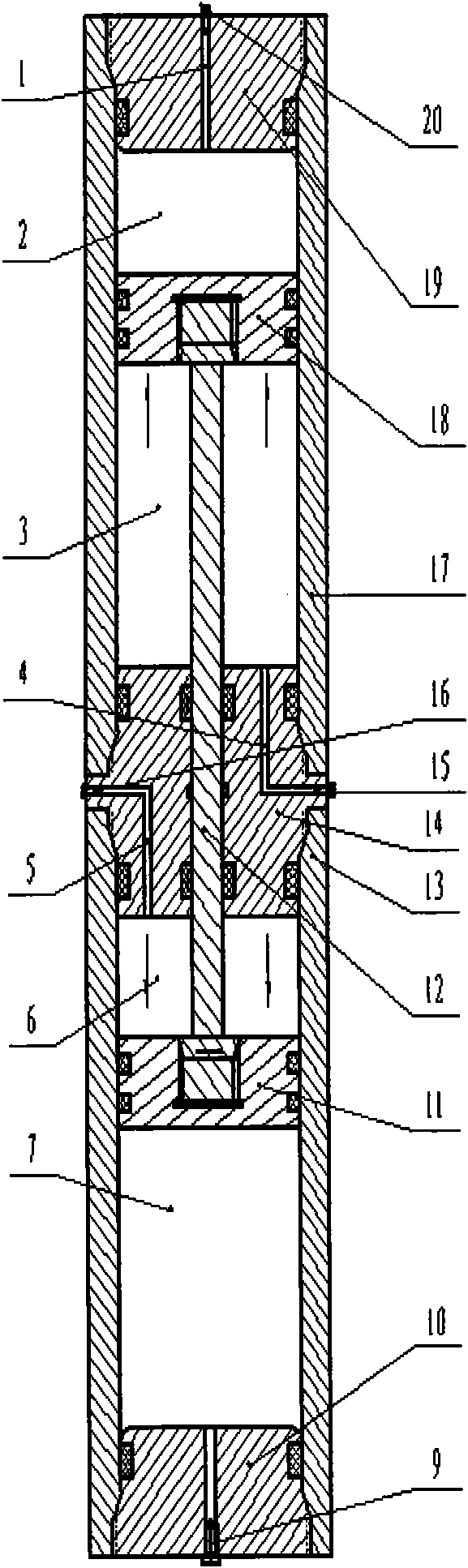

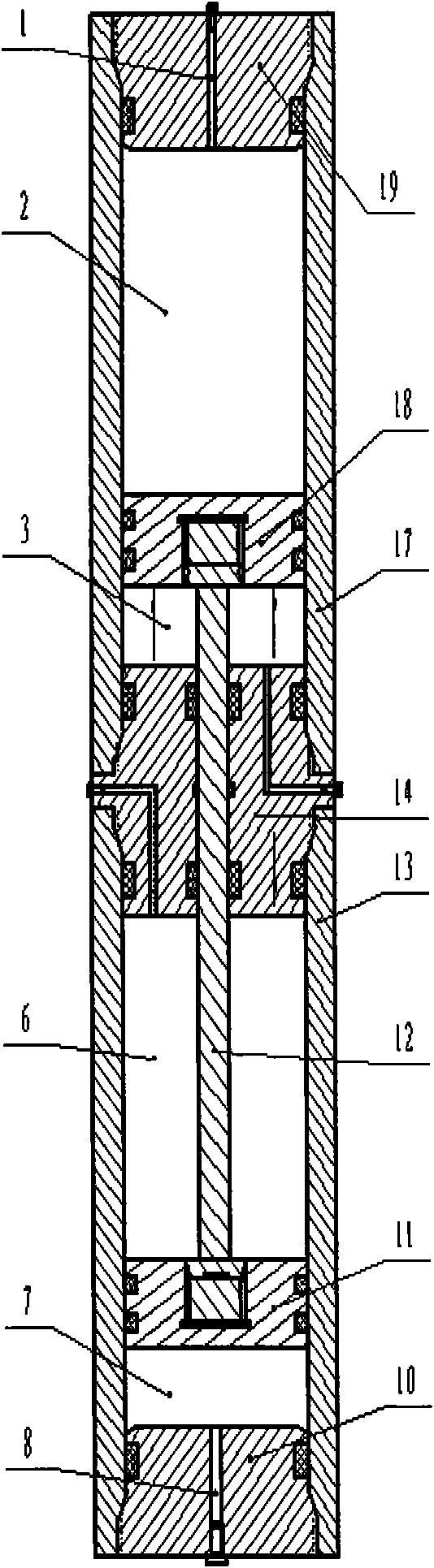

Piston-type deep sea water pressure compensation energy accumulator

ActiveCN101832303AReduce frictionAvoid deformationMechanical apparatusManufacturing cost reductionHydraulic machinery

The invention relates to a deep sea water pressure compensation energy accumulator which is mainly applied to accumulate energy for the deep sea petroleum drilling hydraulic machinery. A cylindrical upper shell and a cylindrical lower shell are respectively fixed by screws at the two ends of a cylindrical connection baffle plate, a piston rod is arranged inside a centre hole of the connection baffle plate, the two ends of the piston rod are respectively connected with an upper piston and a lower piston. The upper piston, the lower piston and the connection baffle plate divide the energy accumulator into 4 cavities; hydrostatic pressure of sea water is delicately utilized to prevent the energy accumulator from being affected when working in the deep sea, effective liquid amount discharge of the energy accumulator is improved, so that a small number of energy accumulators can be employed to provide sufficient energy for underwater hydraulic sets and machines and tools, reduce weight of the underwater devices and effectively use space and reduce manufacturing cost.

Owner:河北华北石油荣盛机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com