Explosive-handling robot

A technology of explosive-discharge robots and manipulators, which is applied to manipulators, motor vehicles, tracked vehicles, etc., and can solve problems such as high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

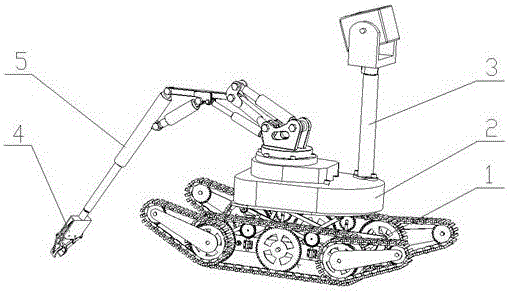

[0019] Such as figure 1 As shown, an EOD robot includes a chassis 1, a box body 2, a detection unit 3, a manipulator 4, and a hydraulic mechanical arm 5; the box body 2 is fixed on the chassis 1, and the detection unit 3 is installed on the box body 2 Above, the hydraulic mechanical arm 5 is fixed on the box body 2 , and the manipulator 4 is fixedly connected with the hydraulic mechanical arm 5 .

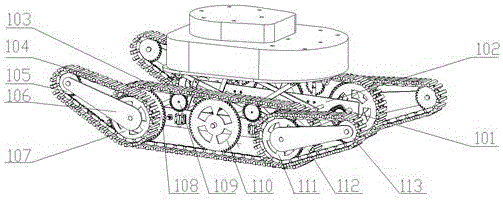

[0020] Such as figure 2 As shown, the chassis 1 adopts a swing arm crawler obstacle surmounting structure, including a DC motor 101, a steel frame 102, a driving crawler 103, a swing arm crawler 104, a driven swing arm small sprocket 105, a swing arm 106, and a driven swing Arm large sprocket 107, driven sprocket 108, pinch wheel 109, intermediate sprocket 110, active swing arm large sprocket 111, driving sprocket 112, active swing arm small sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com