Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

619results about How to "Easy to achieve large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

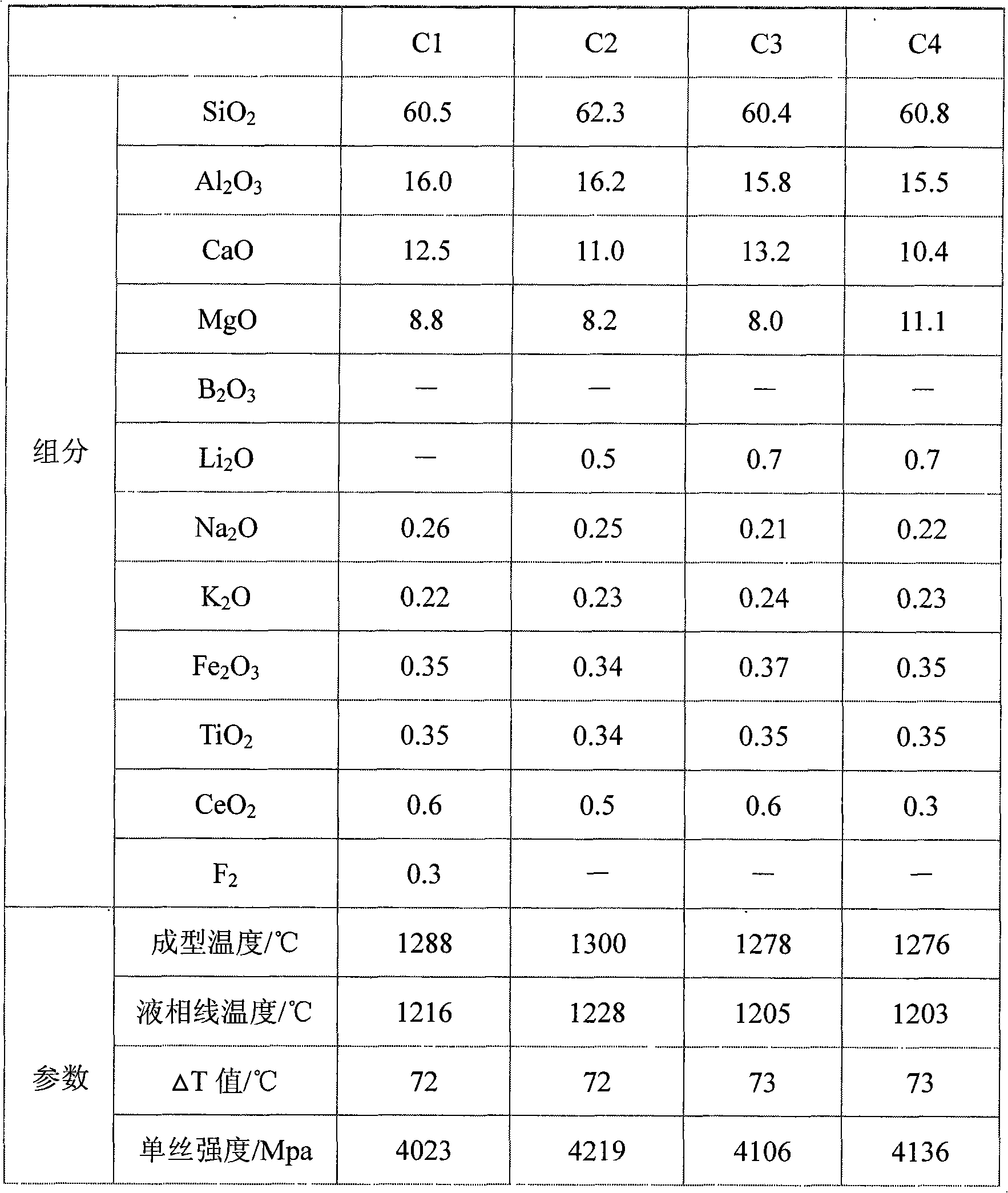

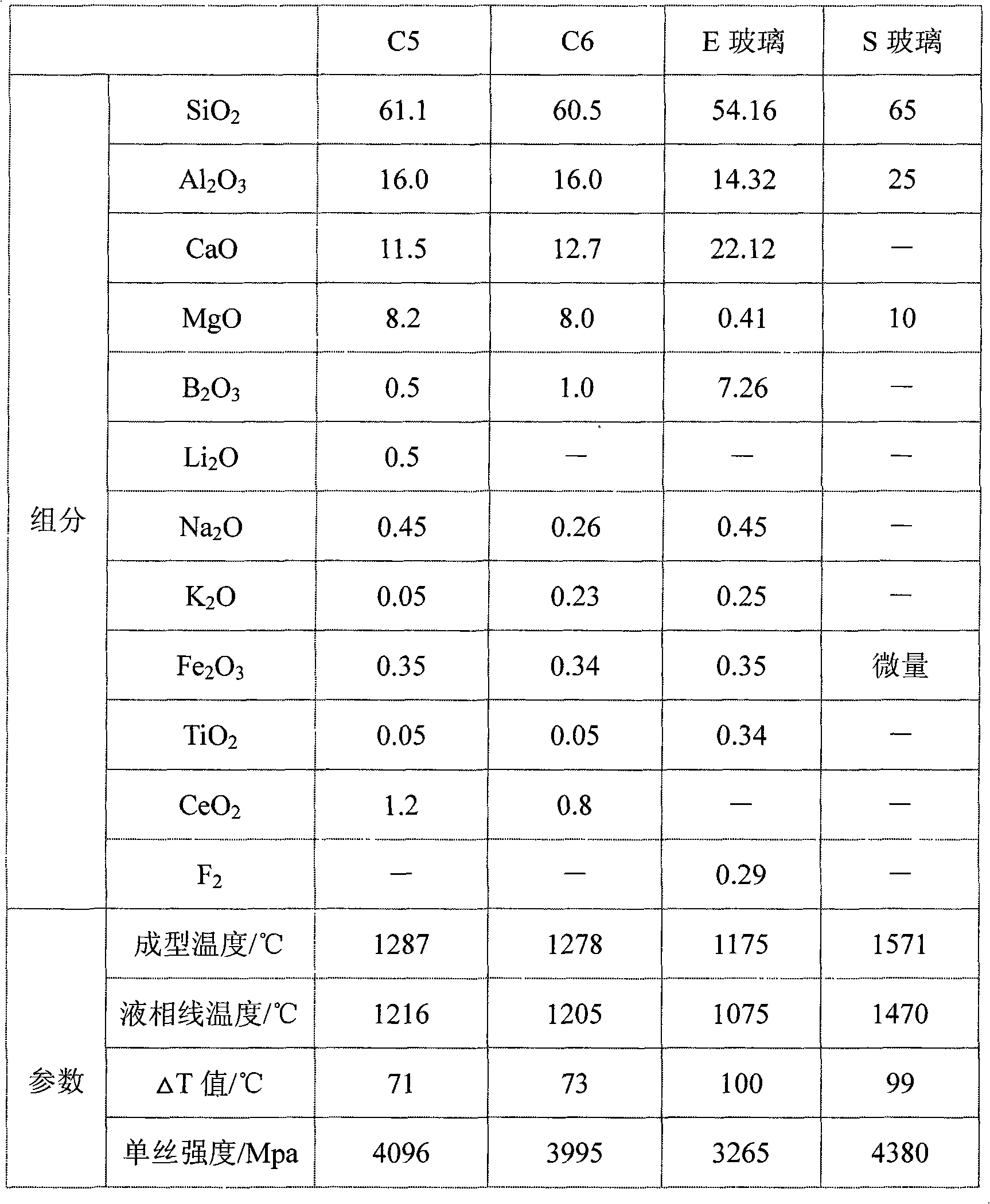

High strength glass fiber composition

The invention discloses a high strength glass fiber composition which comprises the components with the weight percentage: 58-65% of SiO2, 14-20% of Al2O3, 15-25% of CaO+MgO, 0.05-1% of K2O+Na2O, 0.05-1% of Fe2O3 and 0.1-2% of CeO2; wherein, the proportional relation of the components is that CaO / MgO is more than 0.7 and less than 2.2. By preference and combination of the components, the high strength glass fiber composition not only can fully utilize rich raw mineral materials of China, but also can reduce mold temperature, liquidus temperature and clarification temperature and has lower total cost and easy large scale commercial process under the premise of ensuring the high strength of glass fiber.

Owner:JUSHI GRP CO

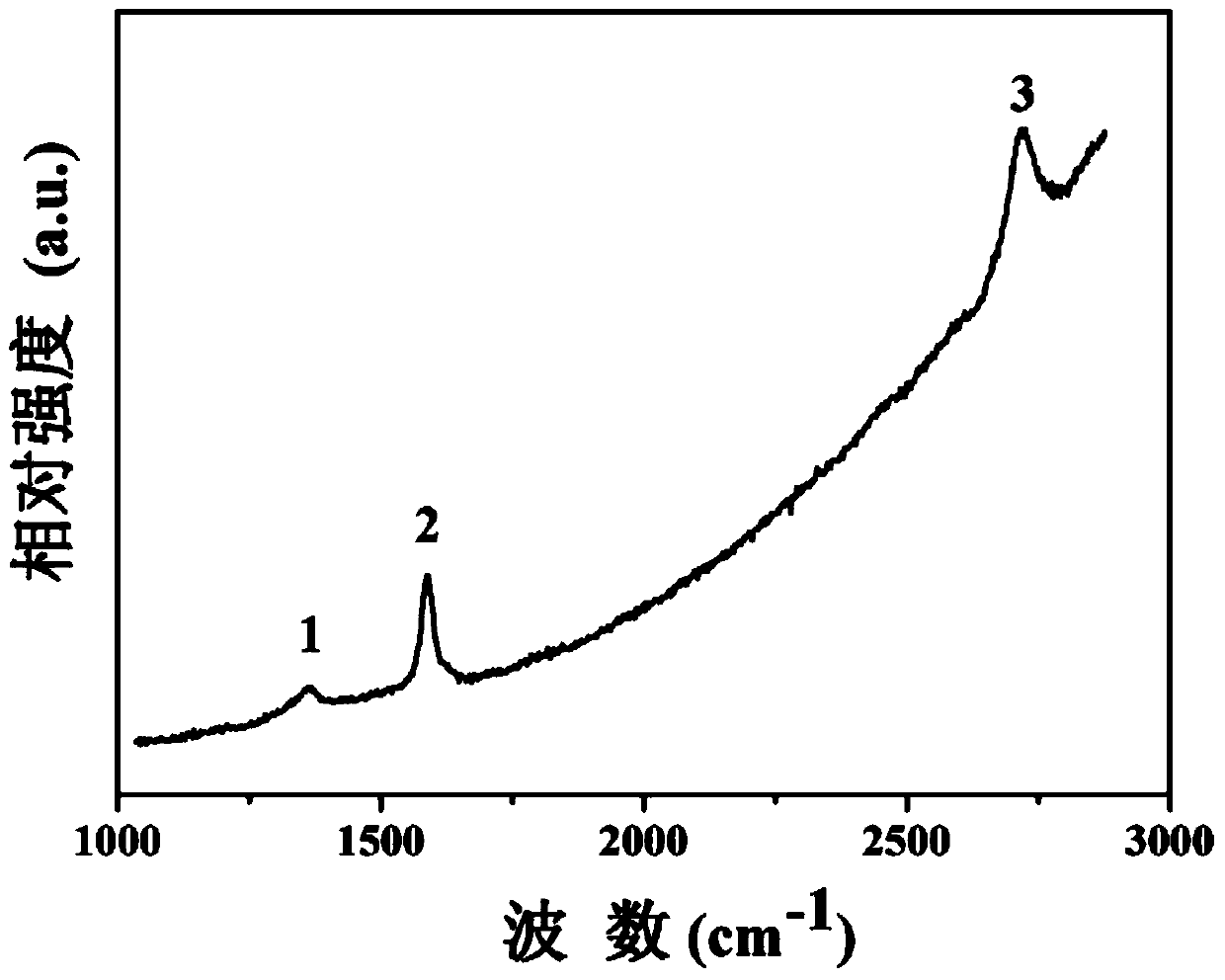

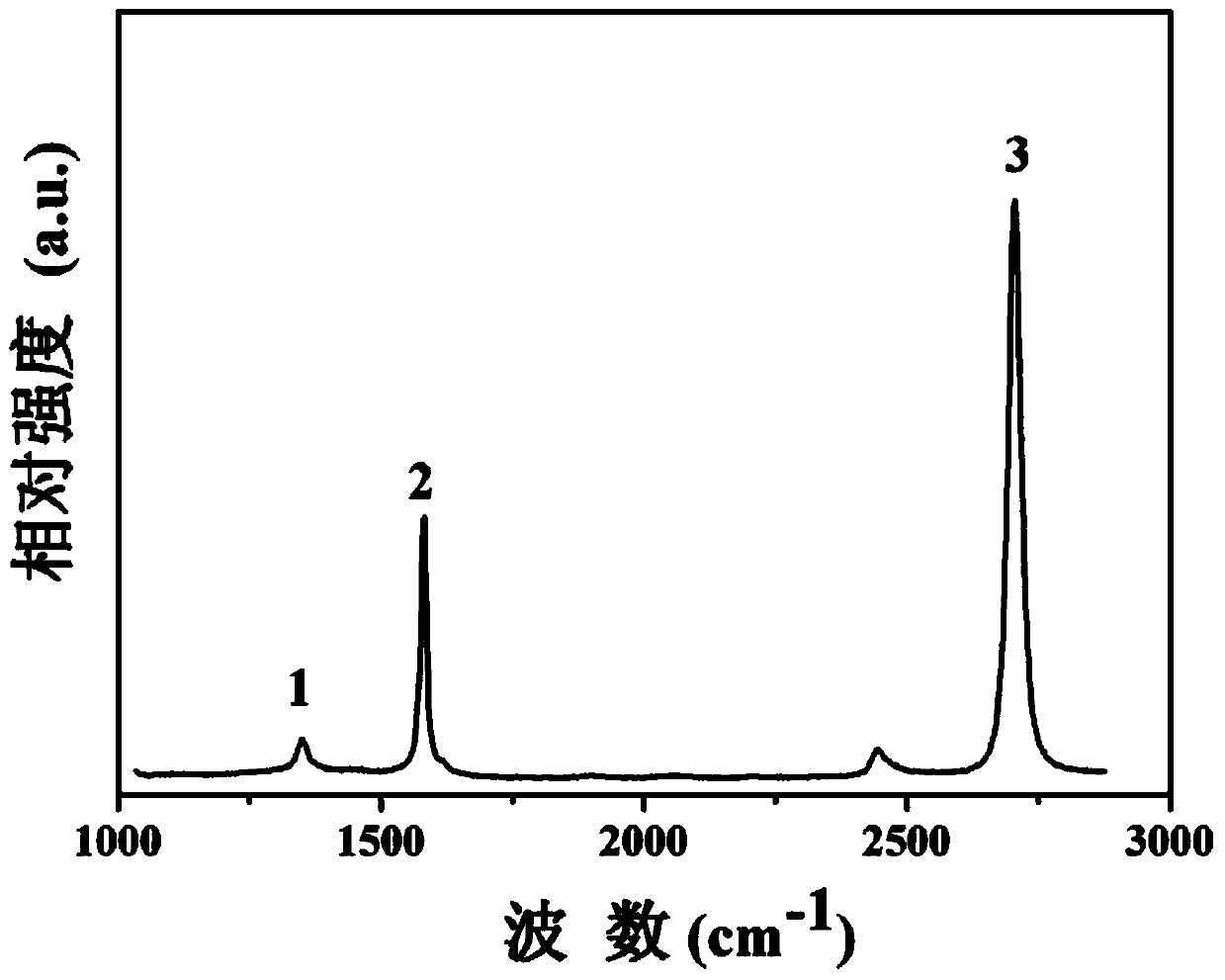

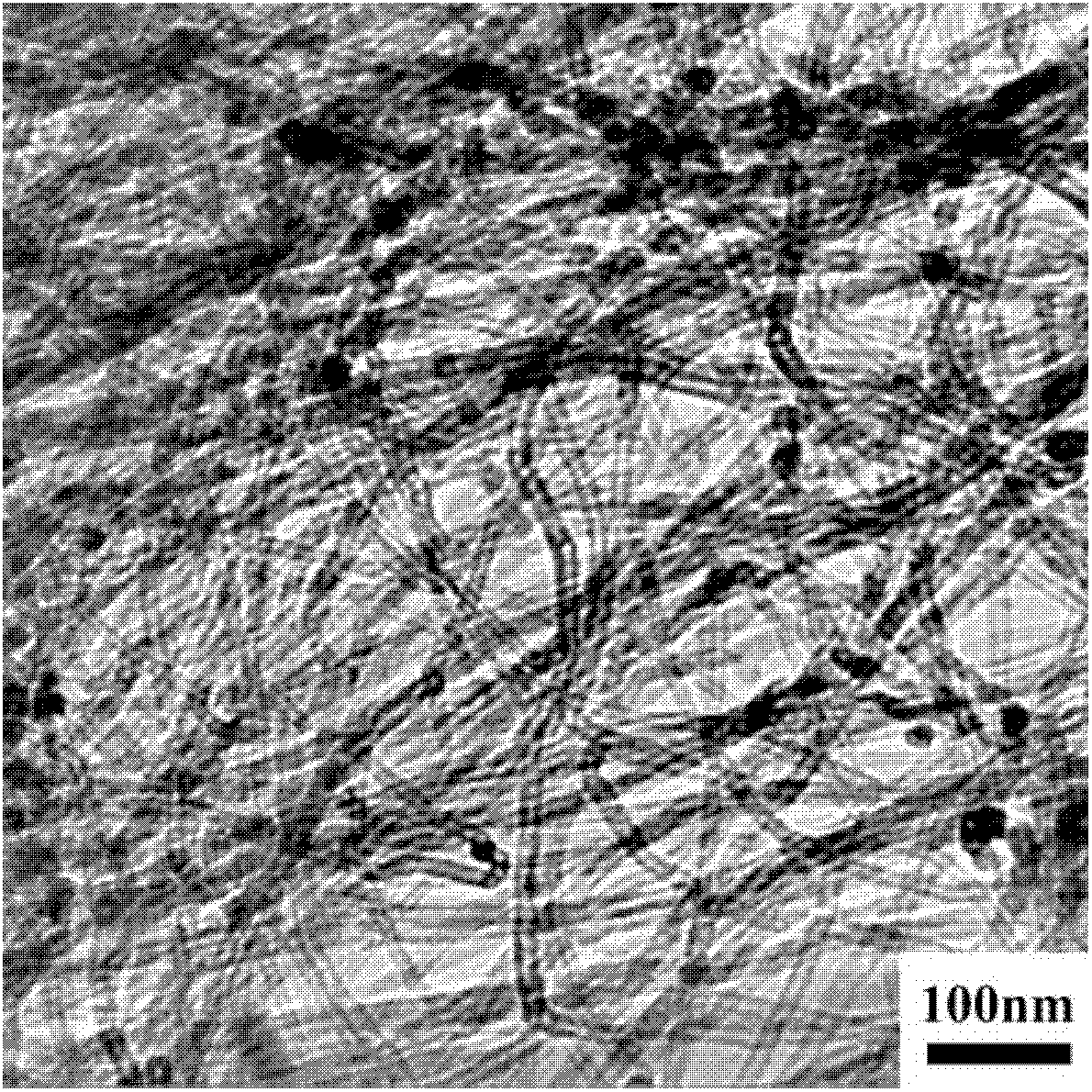

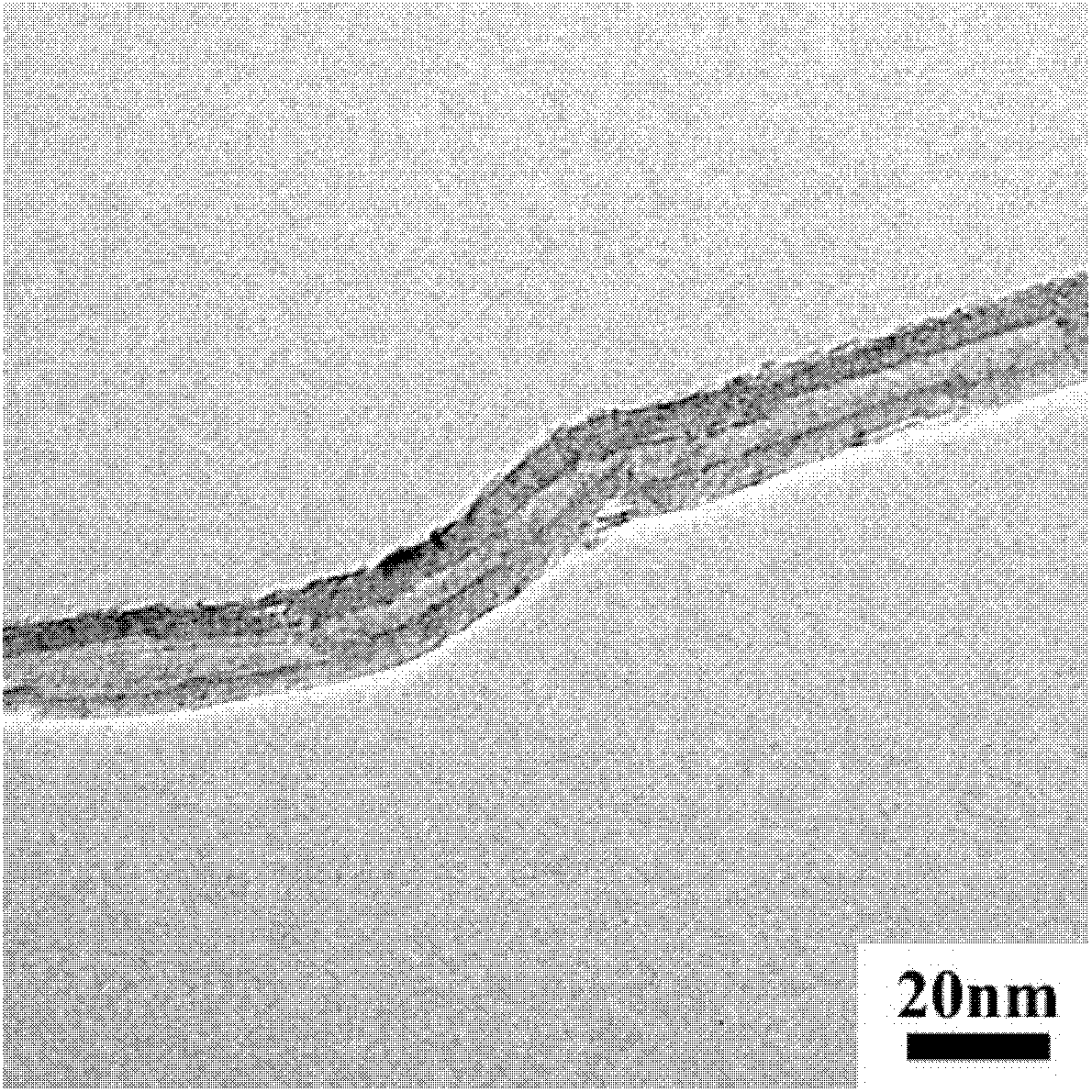

Efficient in-situ preparation method of graphene reinforced copper-based composite material

The invention discloses an efficient in-situ preparation method of a graphene reinforced copper-based composite material, and relates to a method for preparing a graphene reinforced copper-based composite material and the method can be used for solving the problems of poor uniform dispersion, poor structure integrity of grapheme and complex process in the existing preparation method of the graphene reinforced copper-based composite material. The efficient in-situ preparation method of the graphene reinforced copper-based composite material comprises the following steps: putting copper powder in a plasma reinforced chemical vapor deposition vacuum device, introducing hydrogen, preserving heat at high temperature, then introducing argon and carbon source gas, depositing, stopping introducing the carbon source gas after ending the deposition, and finally, cooling below the room temperature to obtain grapheme / copper composite powder, and then primarily pressing, sintering and secondarily pressing the grapheme / copper composite powder to obtain the graphene reinforced copper-based composite material. The method is an efficient in-situ preparation method of a graphene reinforced copper-based composite material.

Owner:HARBIN INST OF TECH

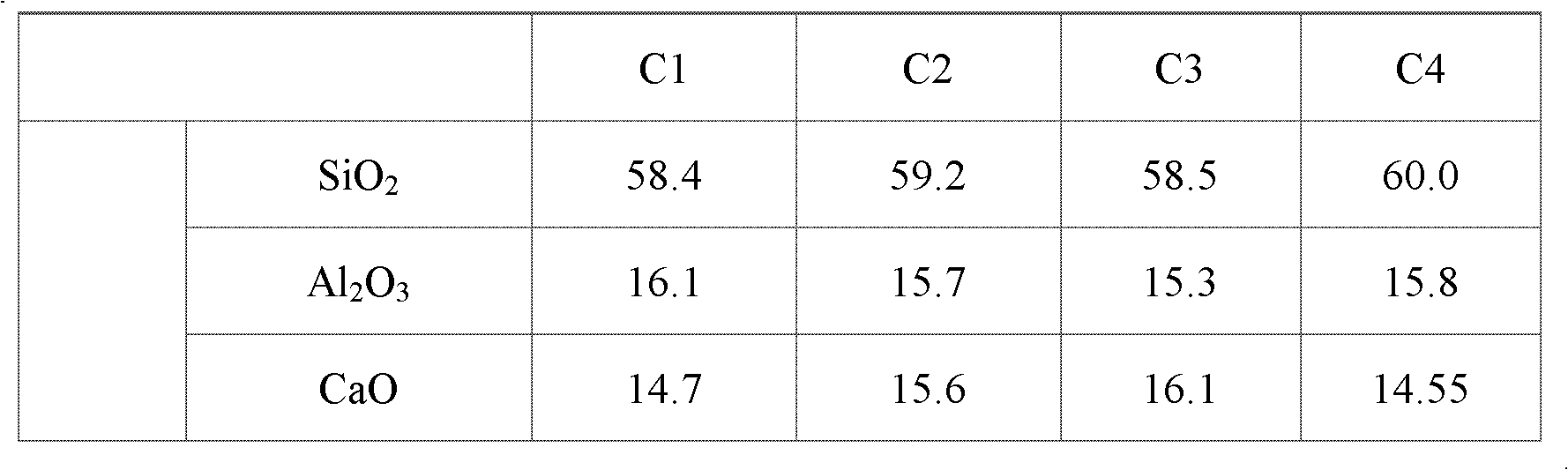

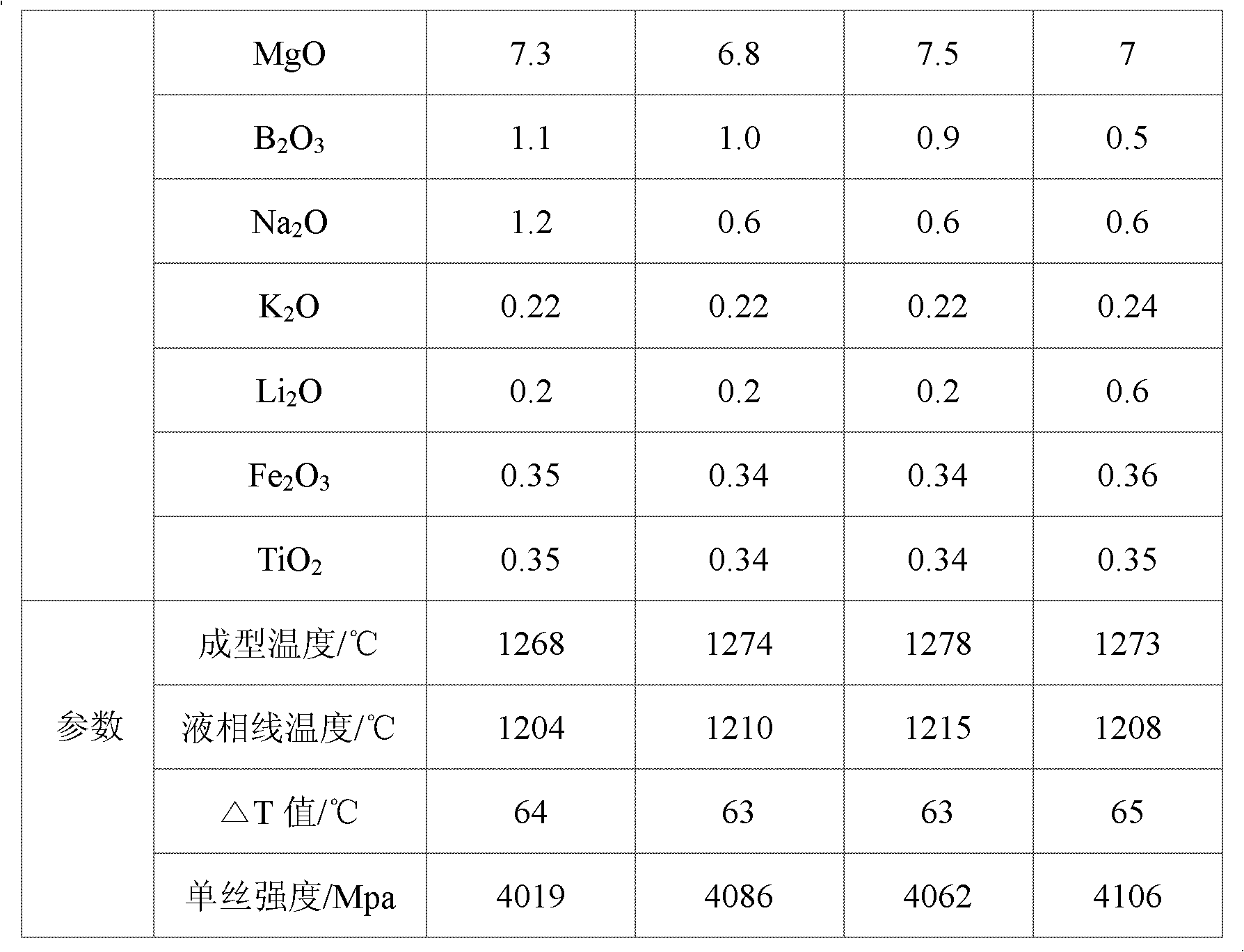

Composition for preparing high-performance glass fiber by tank furnace production

ActiveCN101838110AImprove mechanical propertiesEasy to achieve large-scale industrial productionGlass fiberFiber

The invention discloses a composition for preparing high-performance glass fiber by tank furnace production. The composition contains the following components in percentage by weight: 57.5 to 62.5 percent of SiO2, 14.5 to 17.5 percent of Al2O3, 13.5 to 17.5 percent of CaO, 16.5 to 8.5 percent of MgO, 0.05 to 0.6 percent of Li2O, 0.1 to 2 percent of B2O3, 0.1 to 2 percent of TiO2, 0.1 to 2 percent of Na2O, 0.1 to 1 percent of K2O, and 0.1 to 1 percent of Fe2O3, wherein the ratio of (CaO+MgO) to the MgO is more than 3, and the content of at least one of Li2O, B2O3 and TiO2 is over 0.5 percent. The composition for preparing the high-performance glass fiber makes the melting, clarification and fiber forming performance of the glass close to boron-free E glass on the basis of maintaining high mechanical properties of the glass fiber; and the composition is easy for large-scale industrialized production of tank furnace method, and has the manufacturing cost close to that of the E glass.

Owner:JUSHI GRP CO

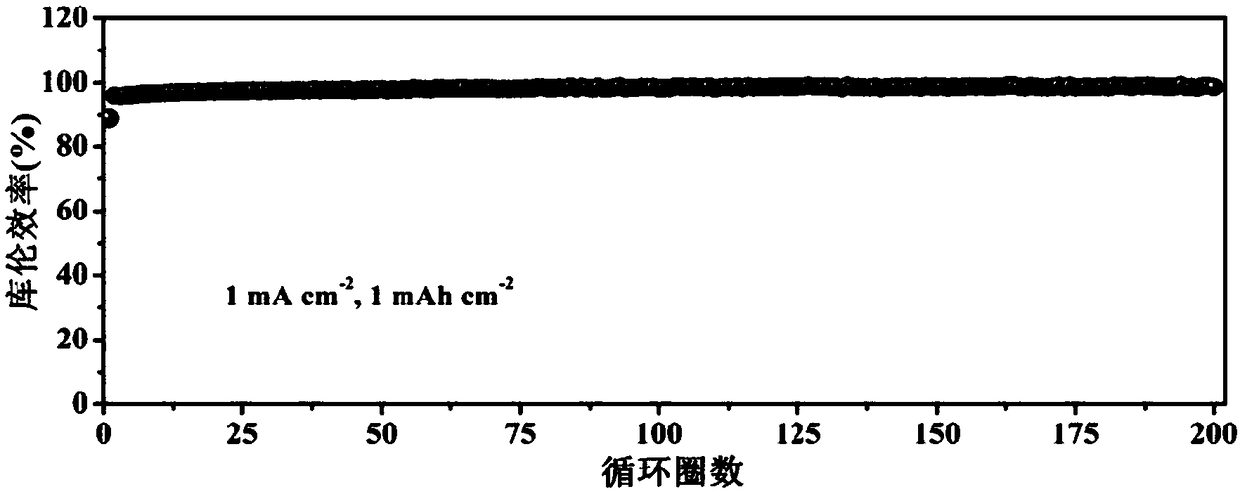

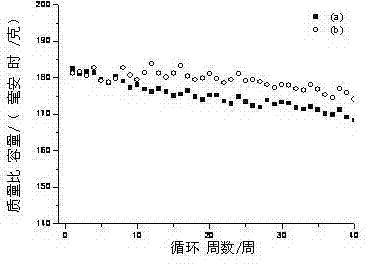

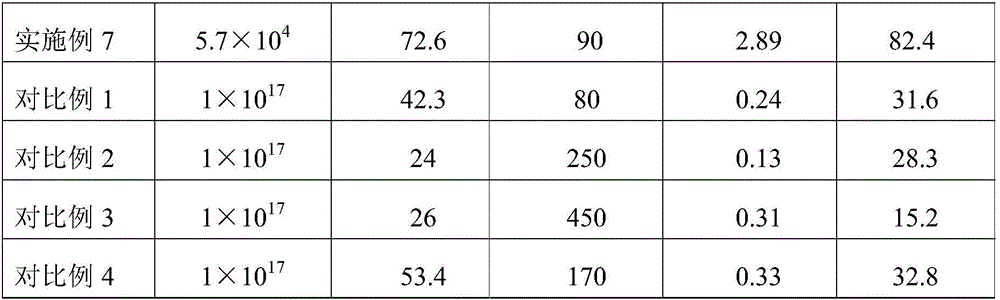

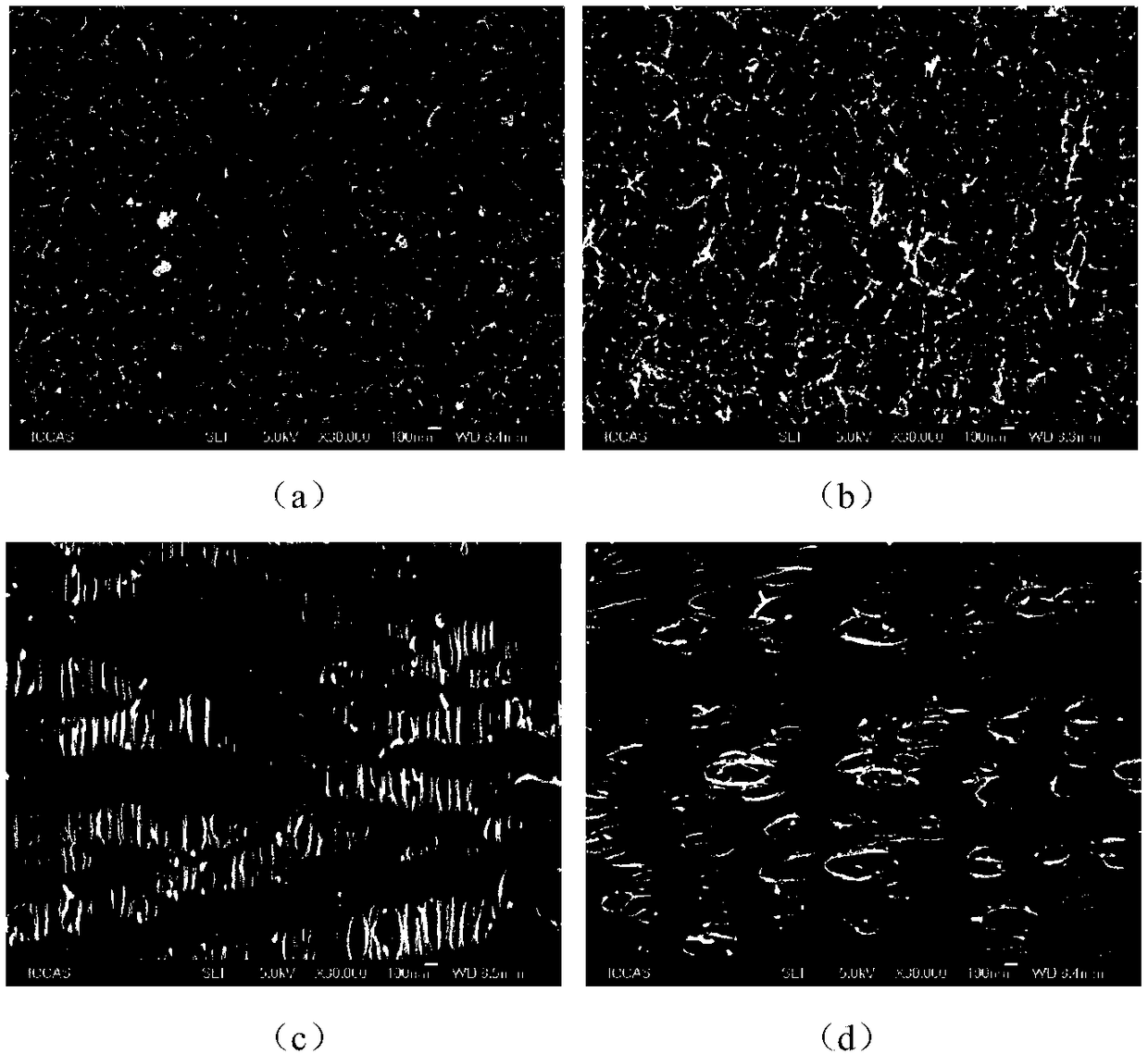

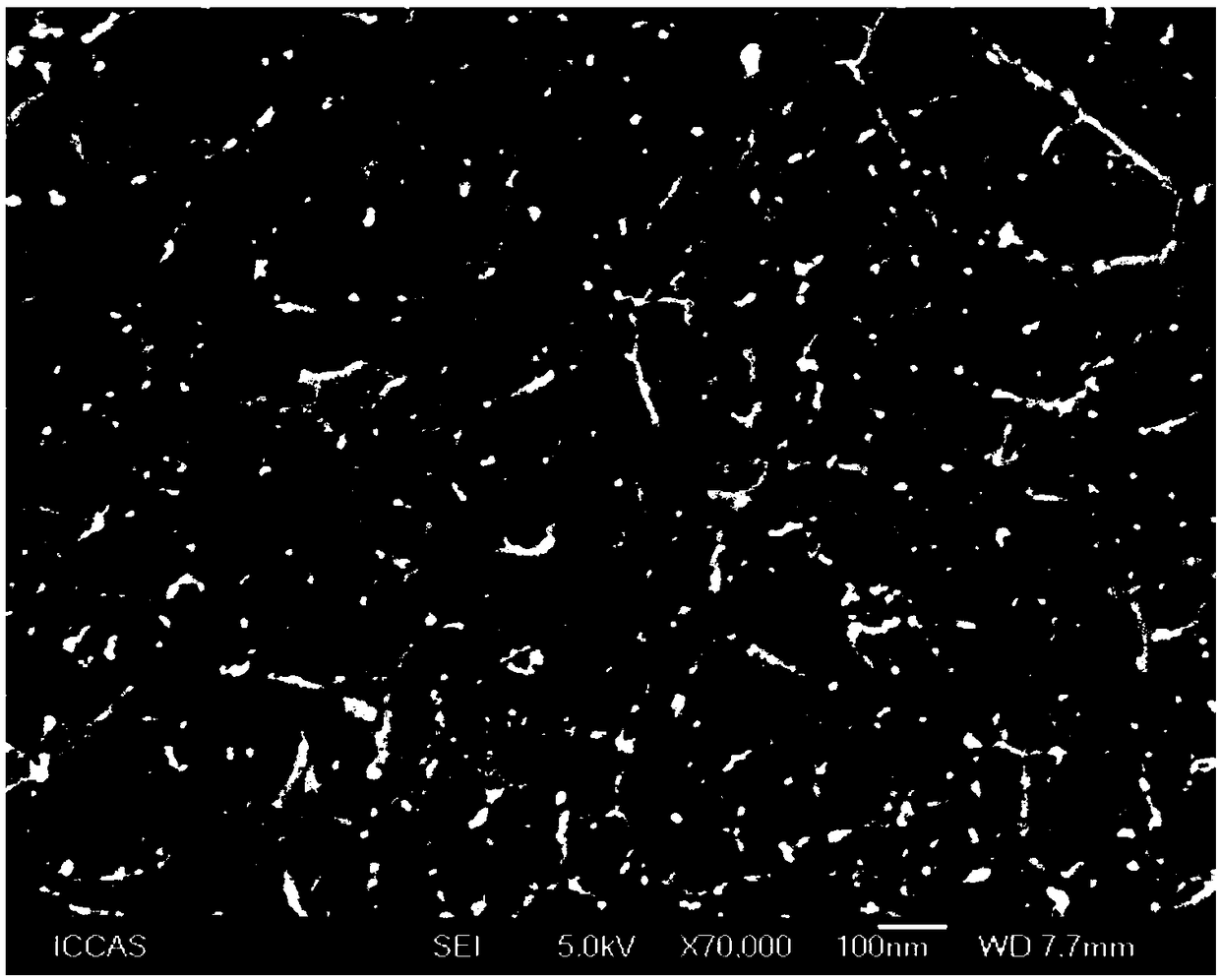

Lithium metal battery lithium negative electrode surface modification method, and lithium metal battery

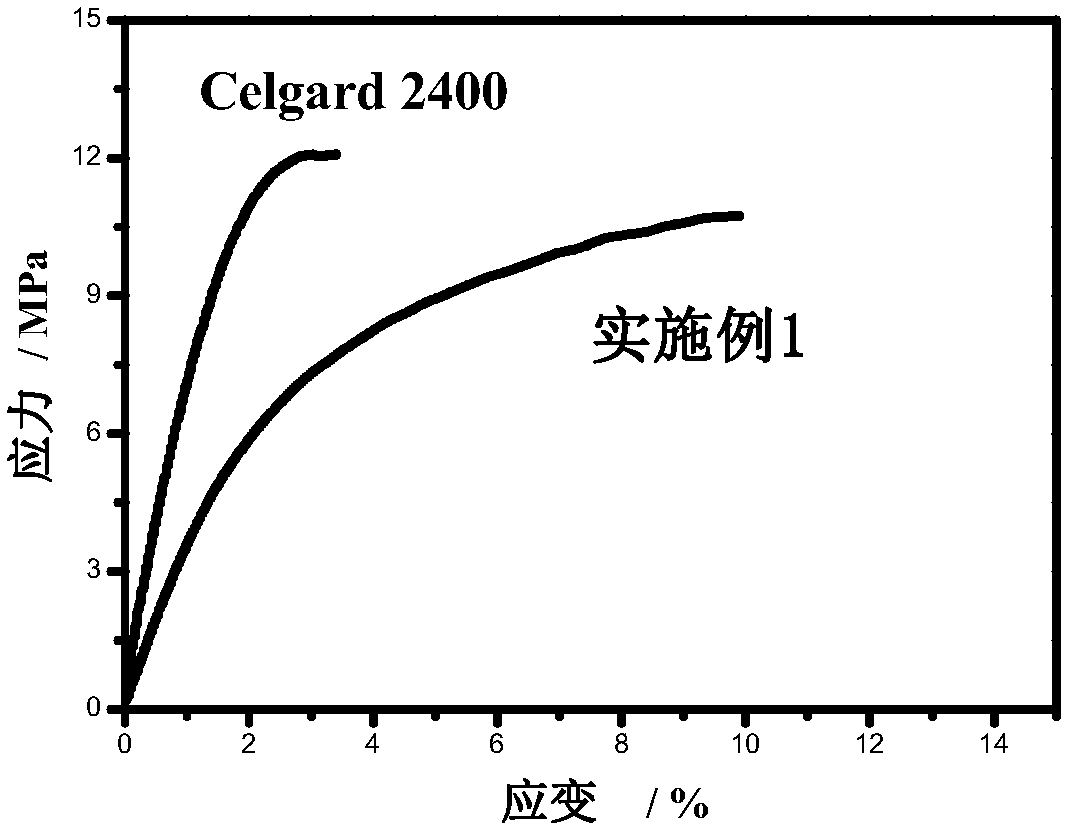

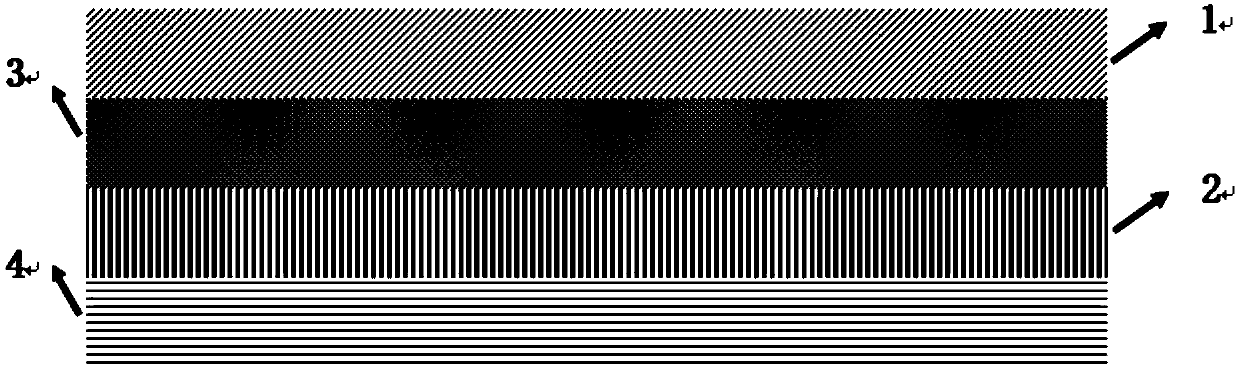

ActiveCN108448058ASimple processEasy to operateElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersHigh energyShielding gas

The invention discloses a lithium metal battery lithium negative electrode surface modification method, and a lithium metal battery. The modification method comprises the following steps: a lithium metal negative electrode is impregnated in or coated with a fluorine-containing ionic liquid in a dry protection gas atmosphere, is fluorinated, and is taken out to make a protection layer rich in lithium fluoride formed on the surface of the metal lithium negative electrode in order to obtain a lithium fluoride coated metal lithium negative electrode. The lithium fluoride protection layer obtainedby surface fluorination is very uniform and dense, and can reduce the consumption of lithium metal and an electrolyte and inhibit the formation of lithium dendrites in order to make the metal lithiumnegative electrode have a high specific discharge capacity, a long cycle life and a good safety, so the stability and the high efficiency of the lithium metal battery in a long cycle process are achieved, use requirements of a high-energy and high-power power battery are met, the industrialization process of the lithium metal battery is facilitated, and lithium metal battery has a wide applicationprospect.

Owner:SOUTH CHINA UNIV OF TECH

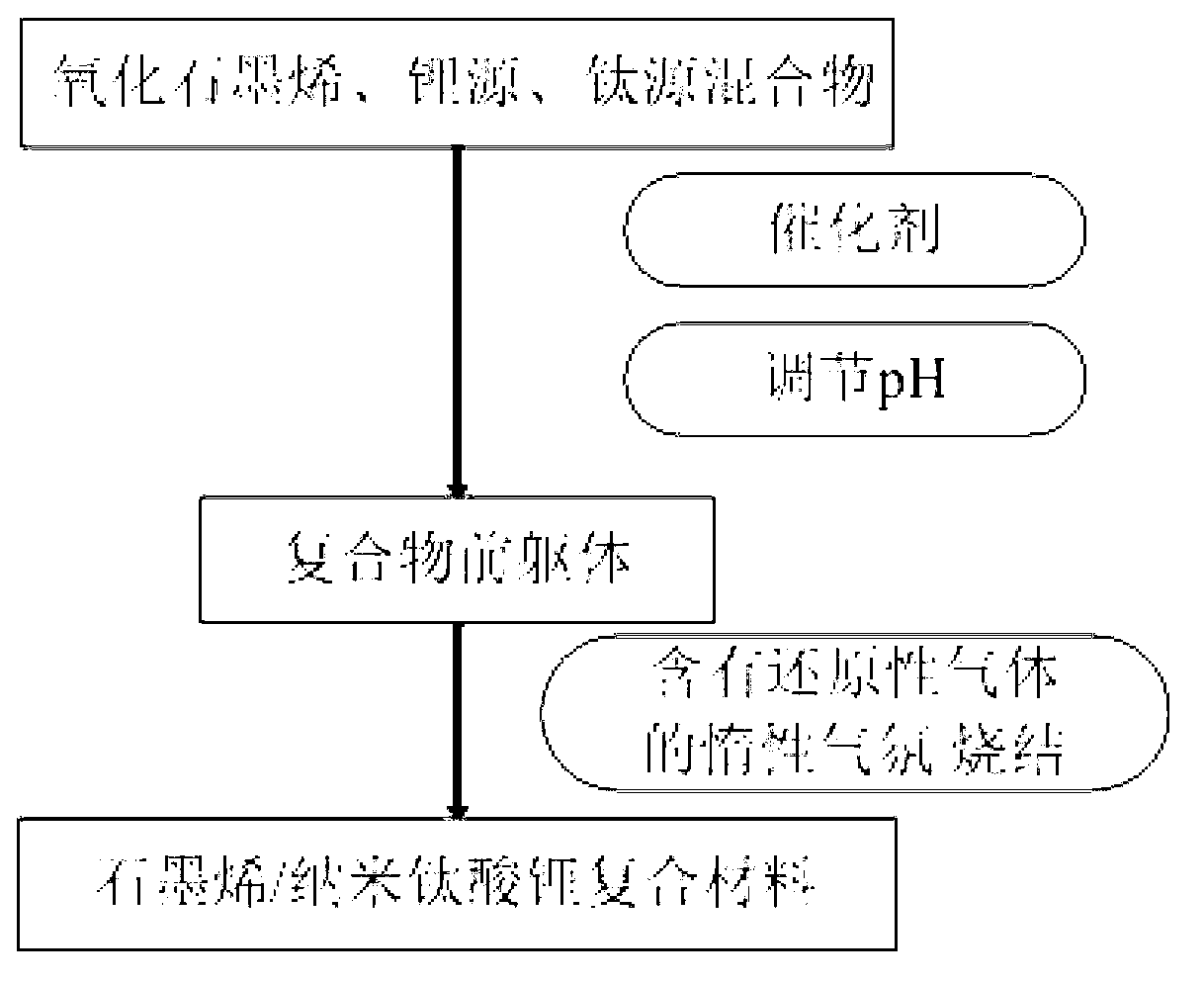

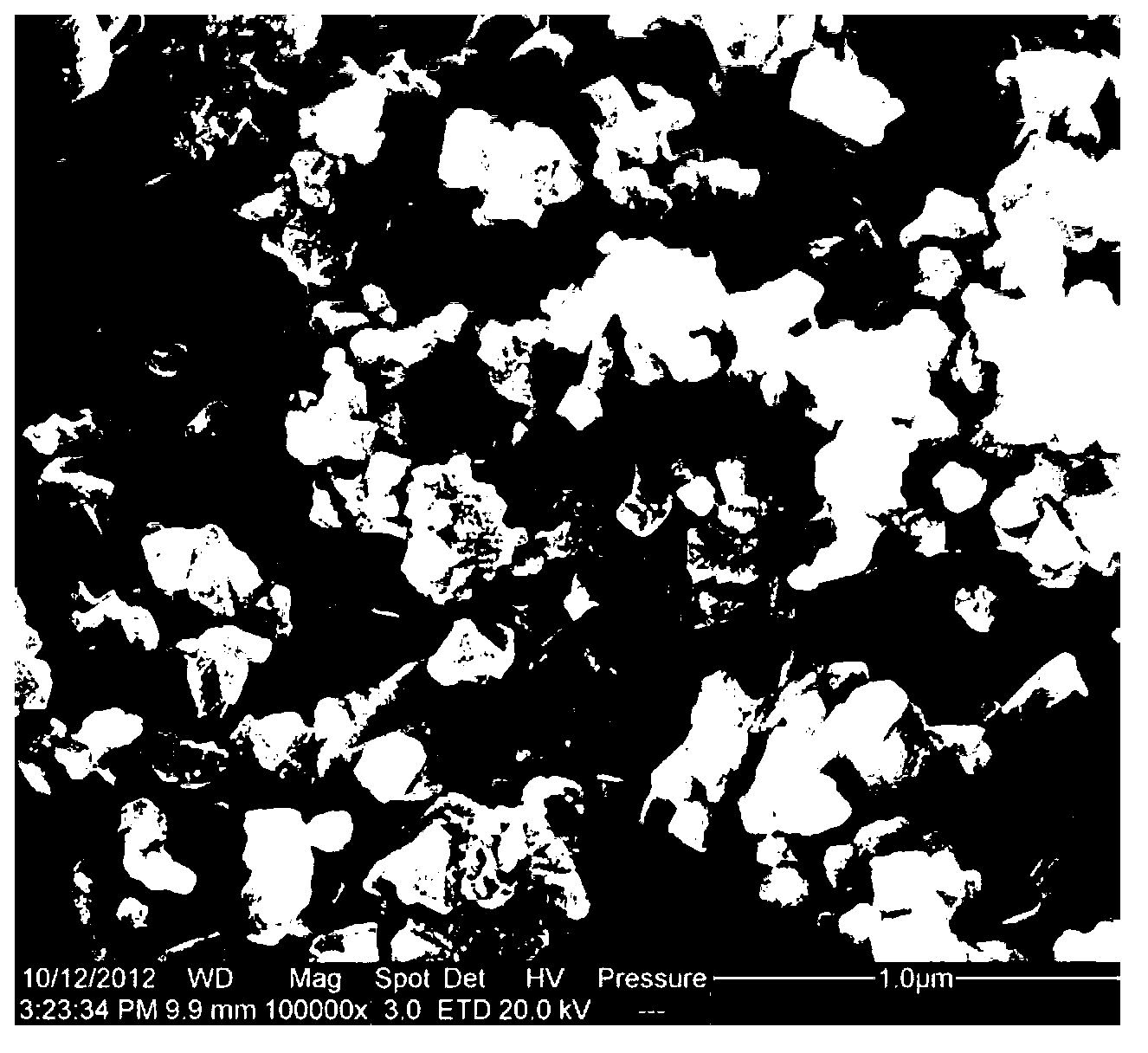

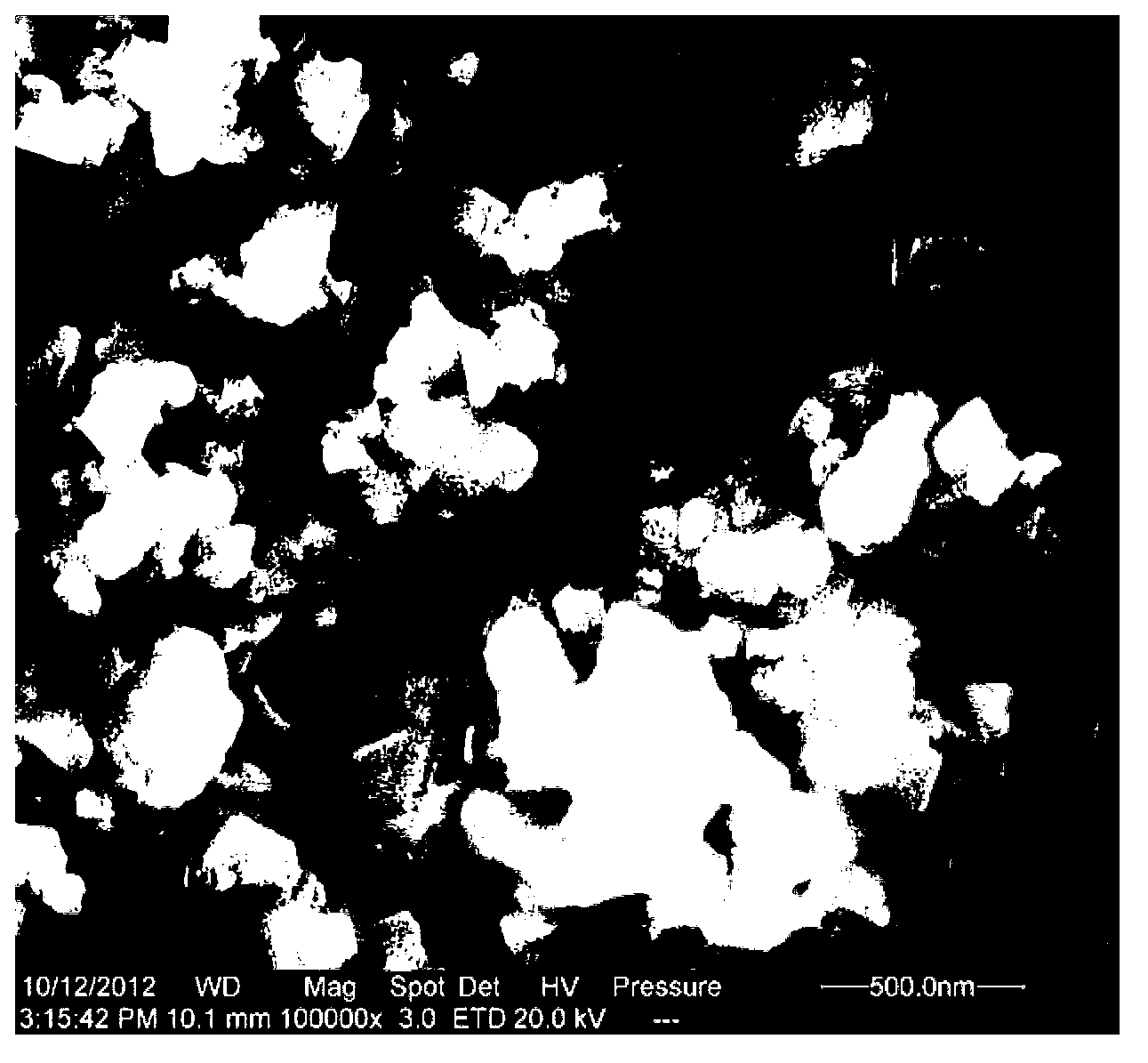

Preparation method of graphene/lithium titanate composite anode material

ActiveCN103022459AImprove electrochemical performanceGood magnificationCell electrodesHybrid/EDL manufactureActivated carbonSupercapacitor

The invention discloses a preparation method of a graphene / lithium titanate composite anode material, which comprises the following steps: compounding compounds serving as a lithium source and a titanium source and graphene oxide through a liquid-phase method and reducing graphene oxide of the compound in inert gas mixed with reducing gas into graphene so as to obtain the graphene / lithium titanate composite anode material. The method has the characteristic of realizing uniform distribution of graphene in lithium titanate through an in-situ compounding technique. Under the same conditions, the discharge time of a hybrid capacitor which respectively takes the graphene / lithium titanate composite anode material and activated carbon as the anode and cathode is obviously greater than that of an electric double-layer capacitor which takes activated carbon as an electrode and that of a hybrid capacitor which respectively takes lithium titanate and activated carbon as the anode and cathode. The lithium titanate phase purity of a hybrid supercapacitor and lithium ion battery composite anode materials prepared by the method disclosed by the invention is higher. Furthermore, the preparation method further has the characteristic of easily realizing the large-scale industrial production.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI +1

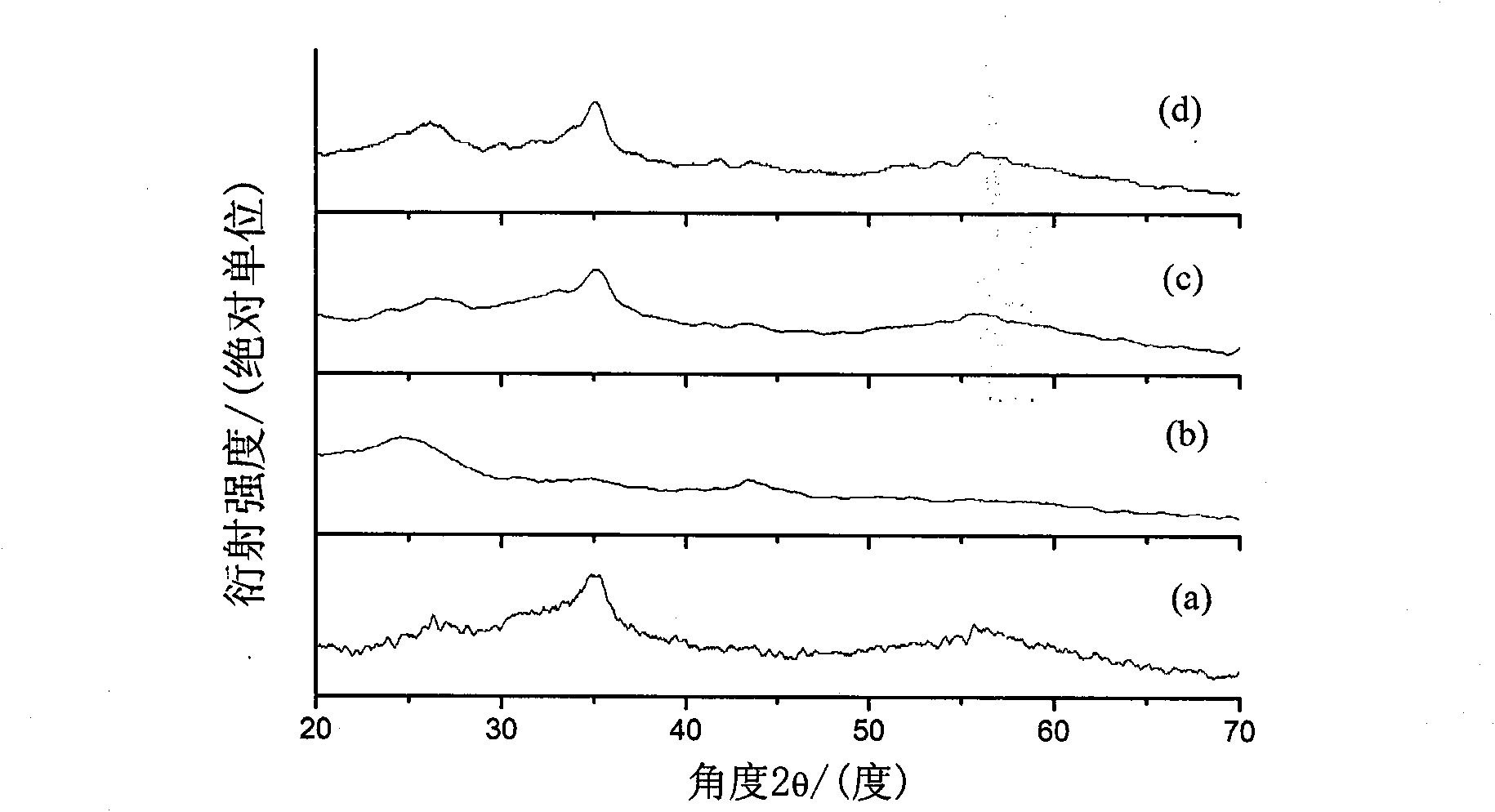

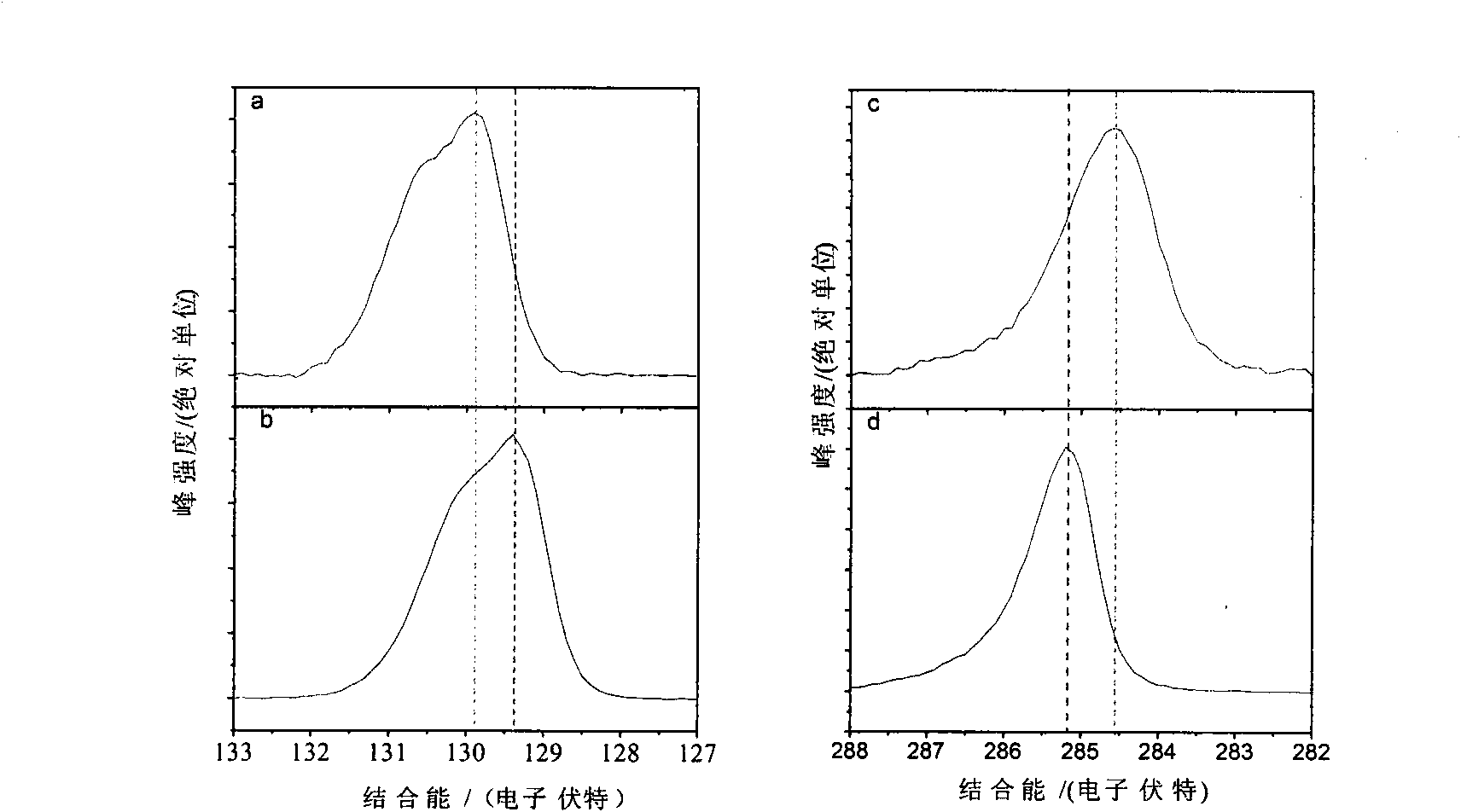

Phosphorus doped graphene and preparation method thereof

The invention provides a preparation method for phosphorus doped graphene. The preparation method comprises the following steps: uniformly mixing graphite oxide and phosphorus pentoxide in a mass ratio of 1: 0.5-3 and placing an obtained mixture in a reactor; introducing protective gas into the reactor, wherein introduction flow velocity of the protective gas is 200 to 400 ml / min; heating the interior of the reactor to a temperature of 800 to 900 DEG C at a heating speed of 15 to 20 DEG C / min and maintaining the temperature for 30 min to 2 h; and cooling the reactor to room temperature in the protective gas with flow velocity of 200 to 400 ml / min so as to prepare the phosphorus doped graphene. According to the method, phosphorus pentoxide is used as a phosphorus source, the maximum doping amount of elemental phosphorus can approach 10%, so the adjustable range of phosphorus is wide; and the method has the advantages of simple process, convenient operation, no special requirements on equipment and easy realization of large scale industrial production. The invention further provides the phosphorus doped graphene prepared by using the preparation method.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Carbon porous electrode preparing method

ActiveCN103943380AMinimize or avoid adverse problemsEasy to achieve large-scale industrial productionElectrode manufacturing processesHybrid/EDL manufactureCurrent collectorClark electrode

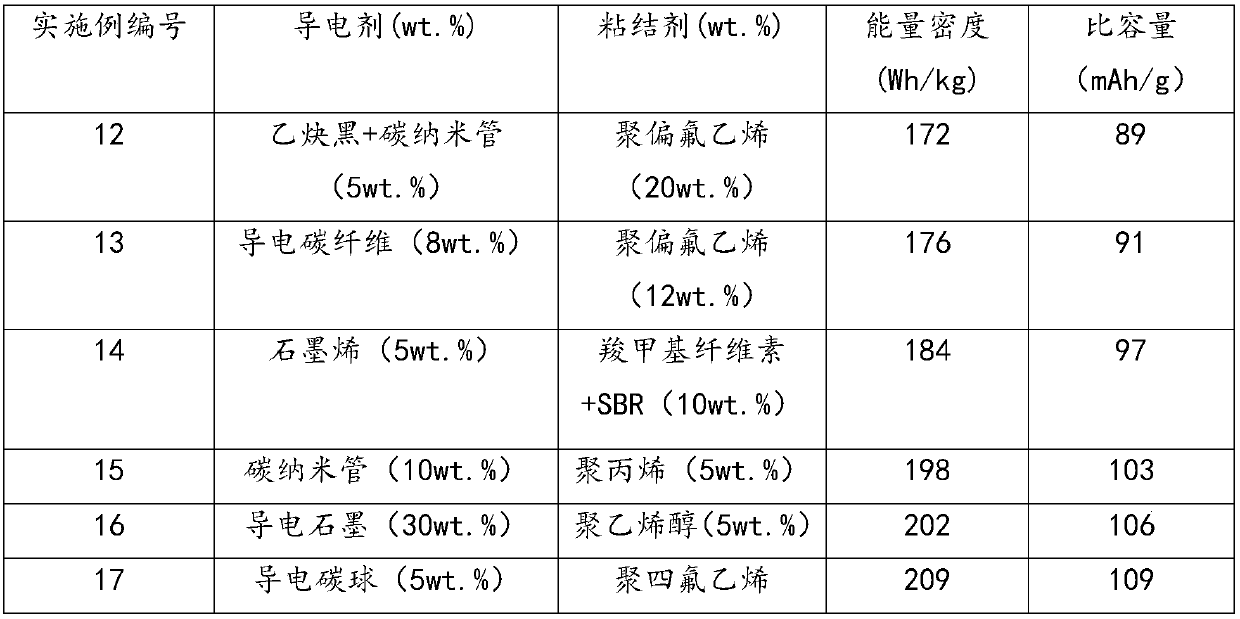

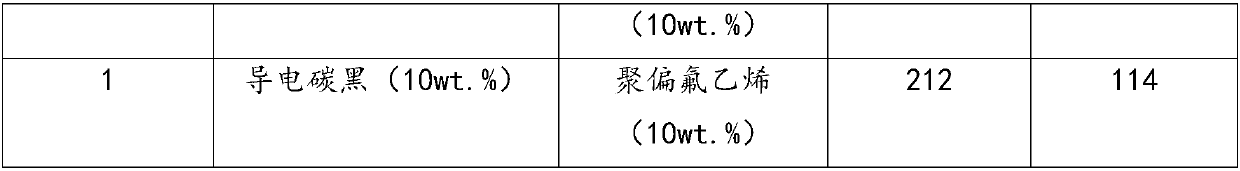

The invention provides a novel carbon porous electrode preparing method. According to the method, a simple preparing technology is realized while the excellent performance of a carbon porous electrode is guaranteed. The carbon porous electrode preparing method comprises the steps that the surface of a current collector is coated with an electrode material containing carbon materials, binders and conductive agents, drying is conducted, and then an electrode plate in a specified thickness is formed; carbonizing treatment is conducted on the electrode plate at a temperature higher than or equal to 400 DEG C in an inert atmosphere, and then the carbon porous electrode is formed. By the adoption of the method, the obtained carbon porous electrode is better is conductive performance, resistance among carbon granules is reduced, ohmic drop on the carbon electrode in usage is reduced, actual working performance of the electrode is improved, the structural strength of the obtained carbon porous electrode is high, and the effective reaction area of the carbon electrode material is increased.

Owner:陆艾珍

Composite metallic-oxide-cladded lithium nickel cobalt manganese oxide anode material and preparation method thereof

InactiveCN102244260AImprove electrochemical cycle performanceImprove discharge specific capacityCell electrodesHydrotalciteManganese oxide

The invention discloses a composite metallic-oxide-cladded lithium nickel cobalt manganese oxide anode material and a preparation method thereof. One metallic element in the composite metallic oxide in the anode material is Al of which the mass is 0.02%-0.92% of that of the lithium nickel cobalt manganese oxide; and the other metallic element in the composite metallic oxide in the anode material is one selected from transition metal Co or Zn, and the mass of the other metallic element is 0.2%-4.0% of that of the lithium nickel cobalt manganese oxide. The composite metallic-oxide-cladded lithium nickel cobalt manganese oxide anode material can be used to exert the respective advantages of the two metallic oxides and the synergy effect between the two metallic oxides sufficiently, thus improving the electrochemical cycle performance and the specific discharge capacity of the anode material under the condition of higher charge cut-off voltage obviously. The preparation method comprises the following steps: forming a hydrotalcite precursor layer on the surface of the lithium nickel cobalt manganese oxide firstly; and roasting to obtain the composite metallic-oxide-cladded lithium nickel cobalt manganese oxide anode material, thus ensuring the uniform distribution of two kinds of metallic ions in the hydrotalcite precursor and the oxide cladding layer of the final product, thereby exerting the best cladding effect.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

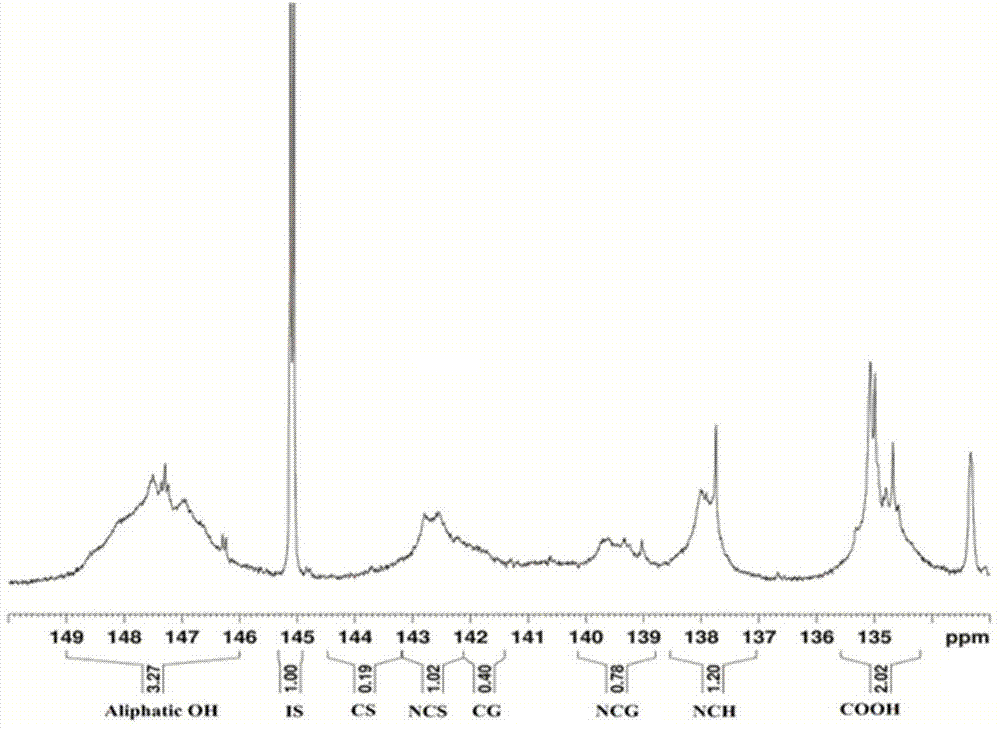

Method for preparing lignin-based environment-friendly phenolic resin adhesive

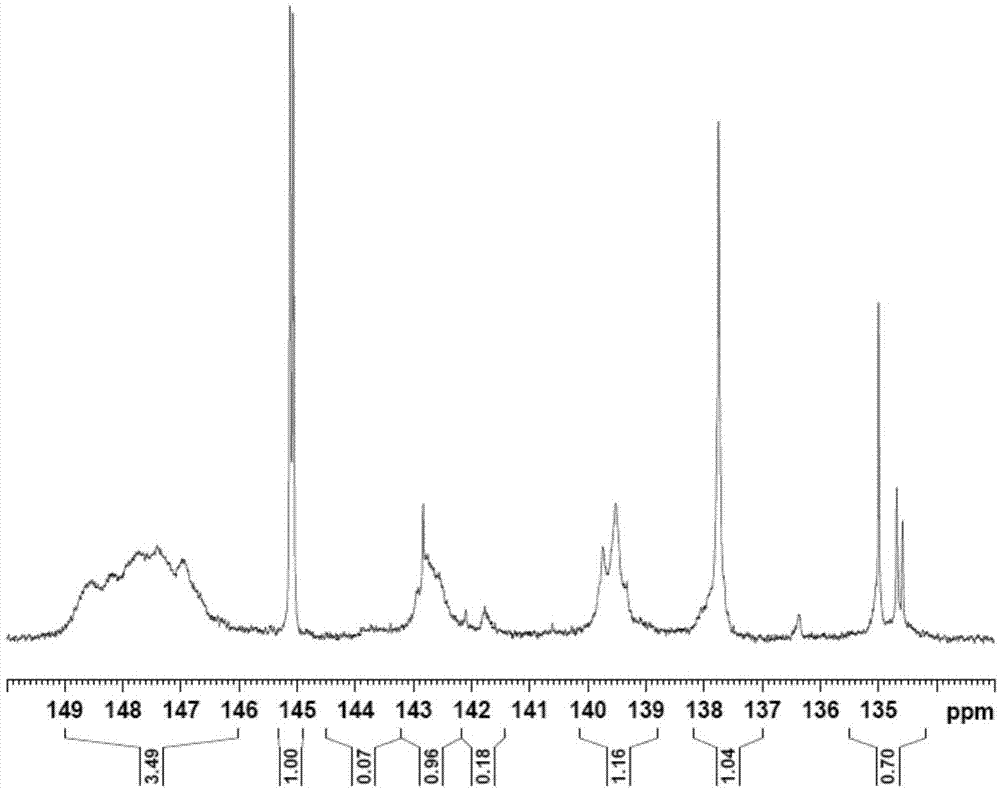

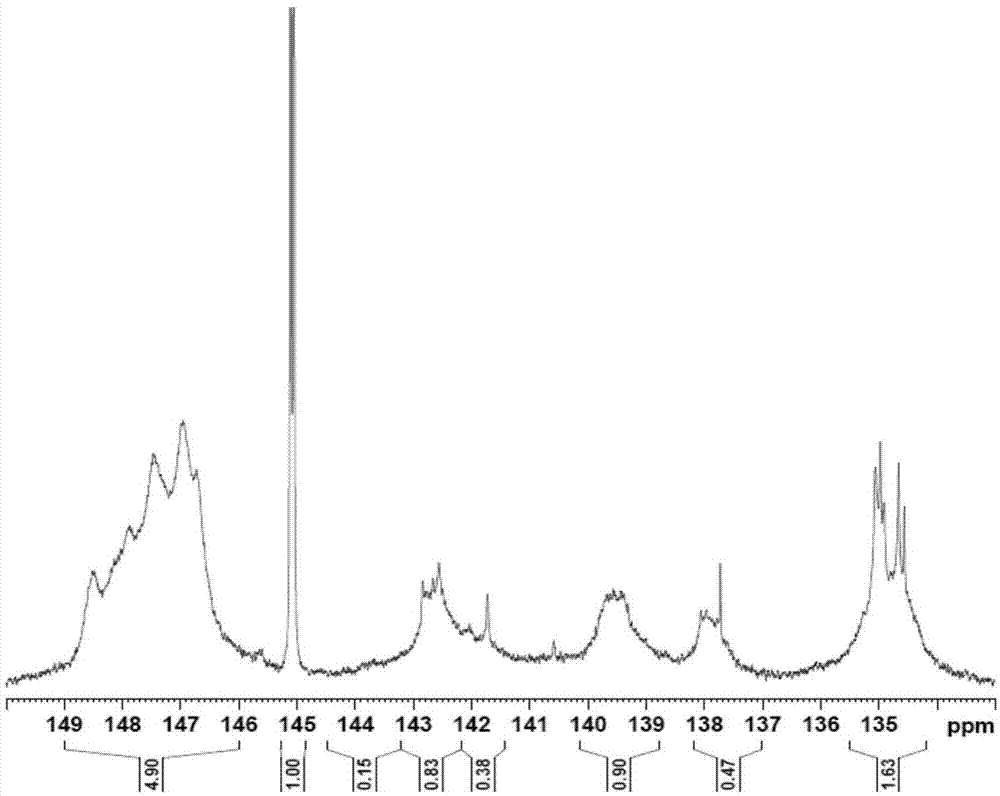

ActiveCN103804618AAvoid excessive releaseAdaptableAldehyde/ketone condensation polymer adhesivesAlcoholNMR - Nuclear magnetic resonance

The invention discloses a method for preparing a lignin-based environment-friendly phenolic resin adhesive. The method comprises the following steps: 1, carrying out quantitative analysis on hydroxyl of a lignin material by using a quantitative phosphorus spectrum of nuclear magnetic resonance technology, and obtaining the quantity of active site points in unit mass of lignin material when reacting with formaldehyde by calculating the quantity of phenolic hydroxyl groups and alcoholic hydroxyl groups; 2, mixing the lignin material with phenol to form a material mixture, wherein the mass ratio of the lignin material to the phenol is (1:9)-(8:2) in the mixing process; 3, calculating the gross of formaldehyde; 4, mixing the material mixture obtained in the step 2 with formaldehyde and aqueous alkali for reaction, so as to prepare the lignin-based environment-friendly phenolic resin adhesive. The biomass refined by-product lignin is utilized at high value on the basis that the problems of expensive product and formaldehyde pollution of the traditional lignin-based phenolic resin adhesive are solved, and the method has great economic significance and social significance.

Owner:HUNAN FORESTECH NEW MATERIALS CO LTD

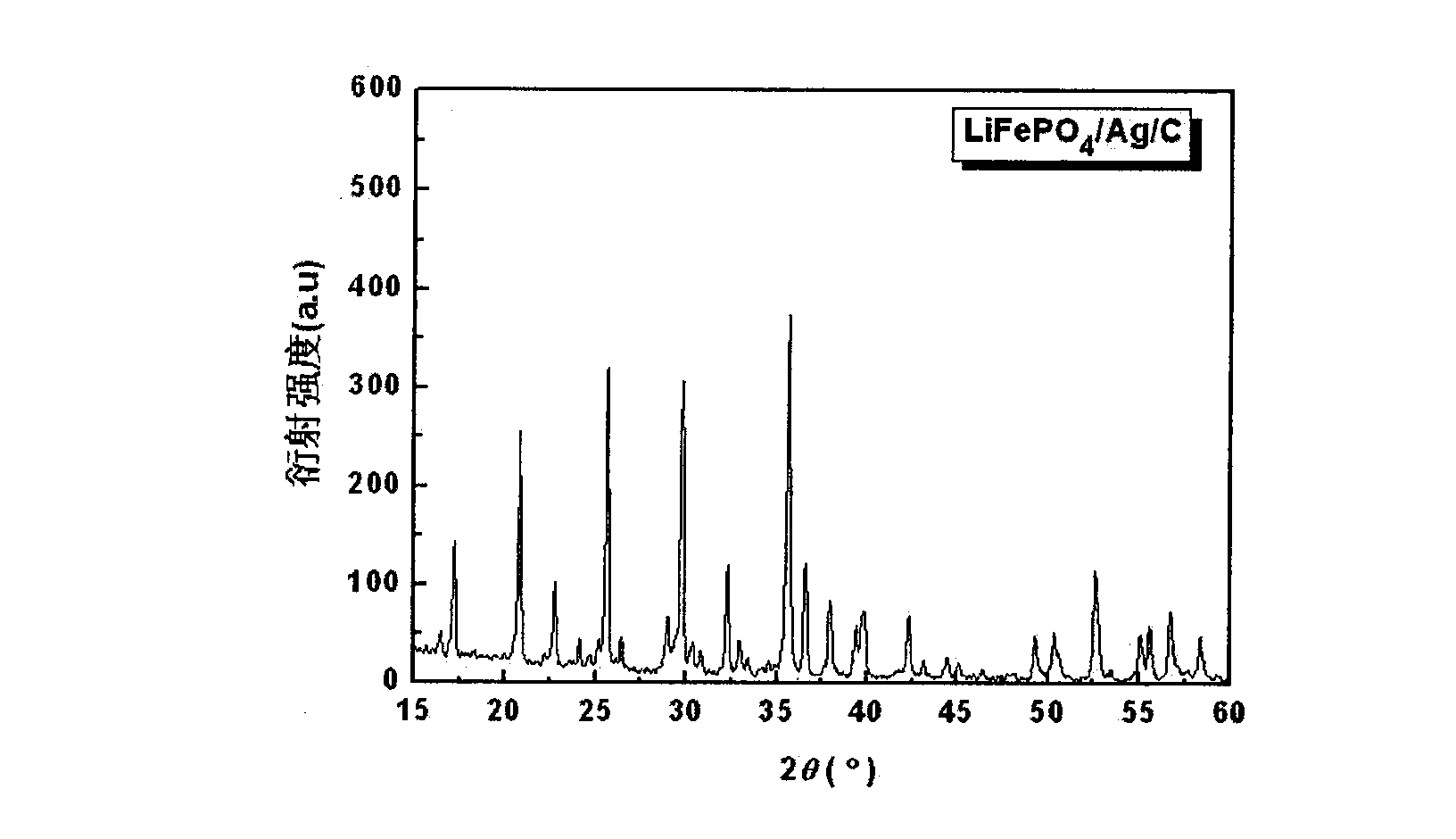

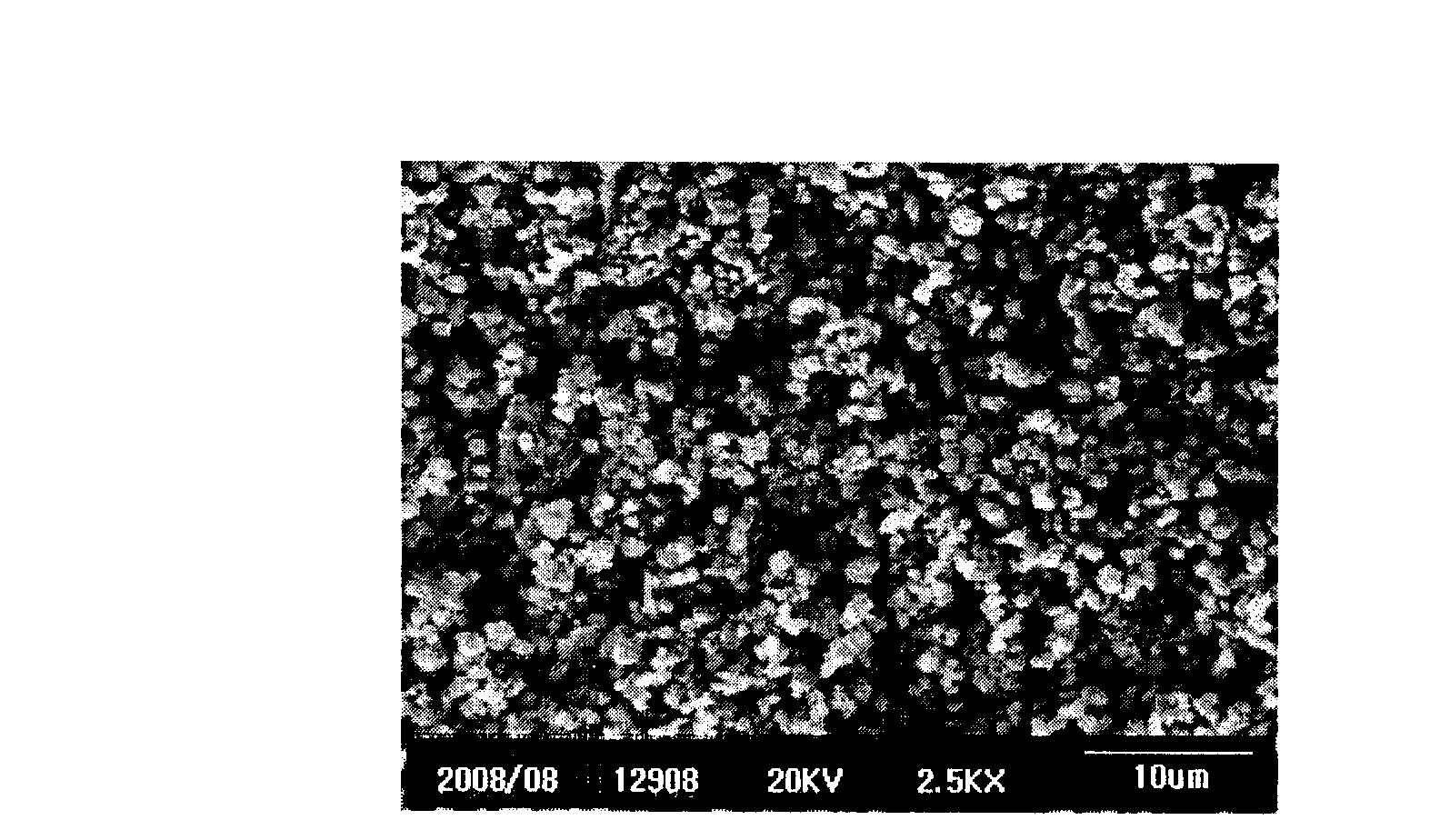

Method for preparing metal-silver-doped carbon-covering lithium iron phosphate of lithium-ion battery cathode material

The invention discloses a method for preparing metal-silver-doped carbon-covering lithium iron phosphate of lithium-ion battery cathode material, comprising steps: A. mixing lithium compound, phosphate and silver compound together according to the mole ratio of Li: P: Ag, and dissolving by water; sequentially adding citric acid and glycol, and stirring to prepare collosol; B. adding organic sugar with the molar weight of 1-2 times of that of silver salt into the collosol, adding iron compound with the mole number being the same as that of lithium salt and carbon reducing agent with the equal molar weight based on pure carbon, and evenly mixing, vacuum drying and ball-milling the mixture; then, pressing the mixture powder to be molded after ball-milling, and preparing precursor of synthesized lithium iron phosphate; C. putting the obtained precursor into a vacuum reaction furnace to have reaction under the condition of certain vacuum degree, and ball-milling to obtain the metal-silver-doped carbon-covering lithium iron phosphate LiFePO4 / Ag / C cathode material. The method has the advantages of simple technique, easy amplification, good electric conduction performance, excellent high-rate discharge performance, high specific capacity and electrochemistry efficiency, small particle size distribution range and high tap density.

Owner:广州云通锂电池股份有限公司 +1

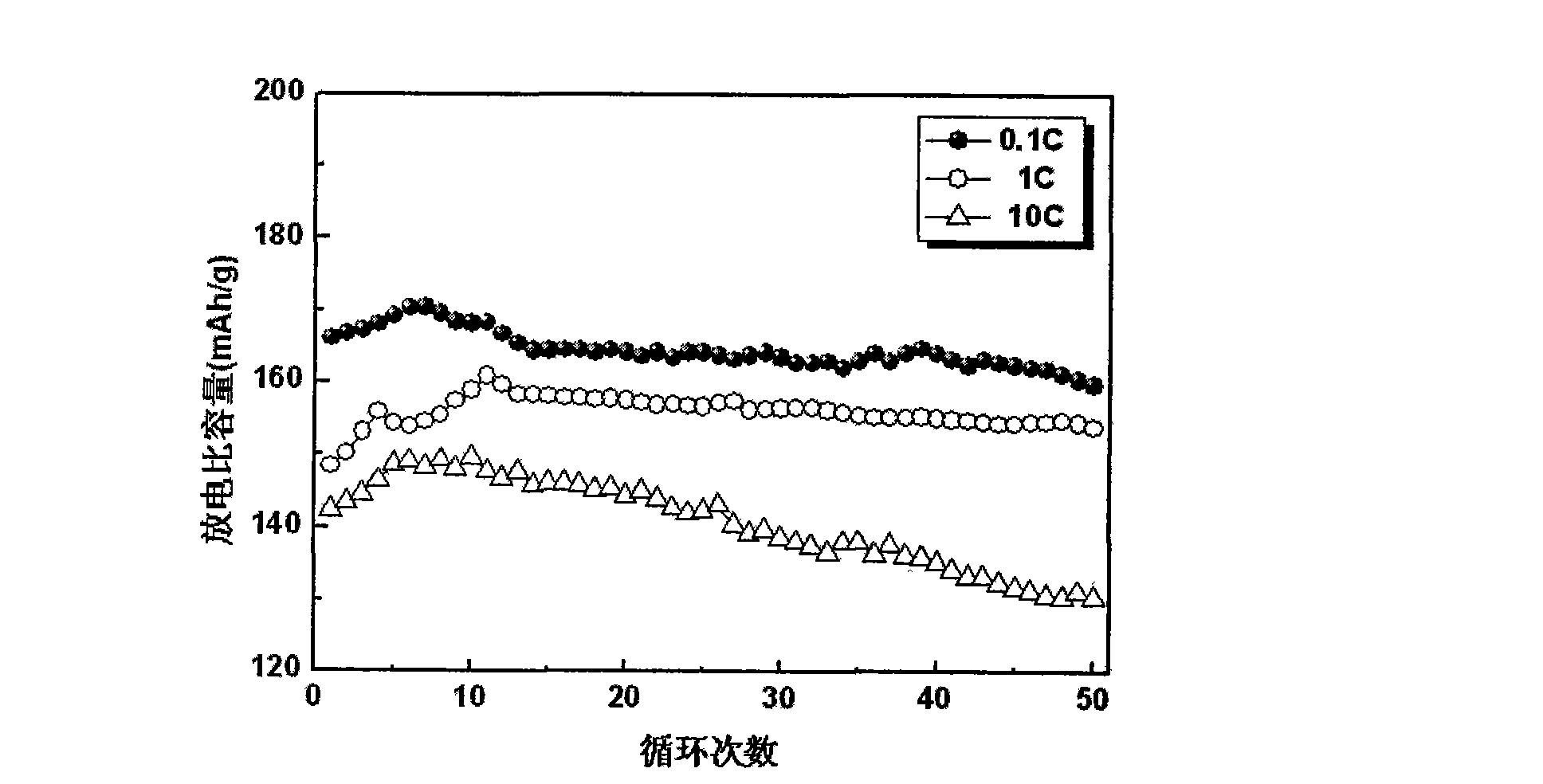

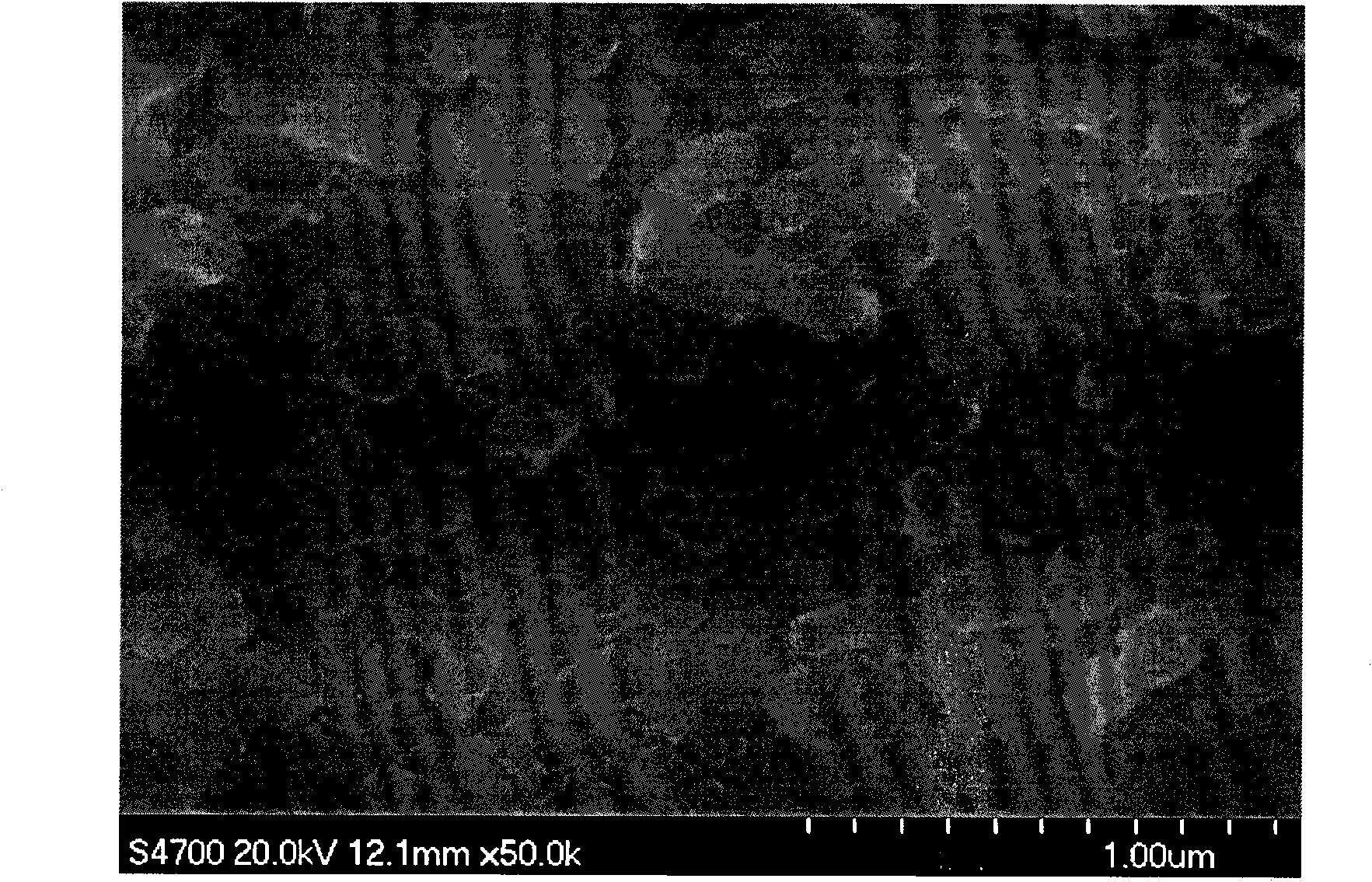

Phosphorus/carbon composite negative electrode material of lithium ion battery and preparation method thereof

InactiveCN101604752AHigh reversible specific capacityGood electrochemical cycle stabilityElectrode manufacturing processesSource materialCarbon source

The invention discloses a phosphorus / carbon composite negative electrode material of a lithium ion battery and a preparation method thereof, which belong to the technical field of electrode materials of the lithium ion batteries and preparation thereof. In the composite material, the mass ratio of P to C is 8 / 2-4 / 6, and the composite material has an amorphous structure containing P-C chemical bonds. A phosphorus source material and a carbon source material are mixed according to the mass ratio of the P to the C of 8 / 2-4 / 6; then the mixed material is added into a stainless steel tank; stainless steel balls are added into the mixed material according to the mass ratio of the mixed material and the stainless steel balls of 1:20-1:80; and the ball milling is performed for 5 to 30 hours under the protection of nitrogen to obtain the phosphorus / carbon composite material. The phosphorus / carbon composite material has higher reversible specific capacity and good electrochemical cycle stability; and the material has simple process and convenient operation, and is easy to realize mass industrial production.

Owner:BEIJING UNIV OF CHEM TECH

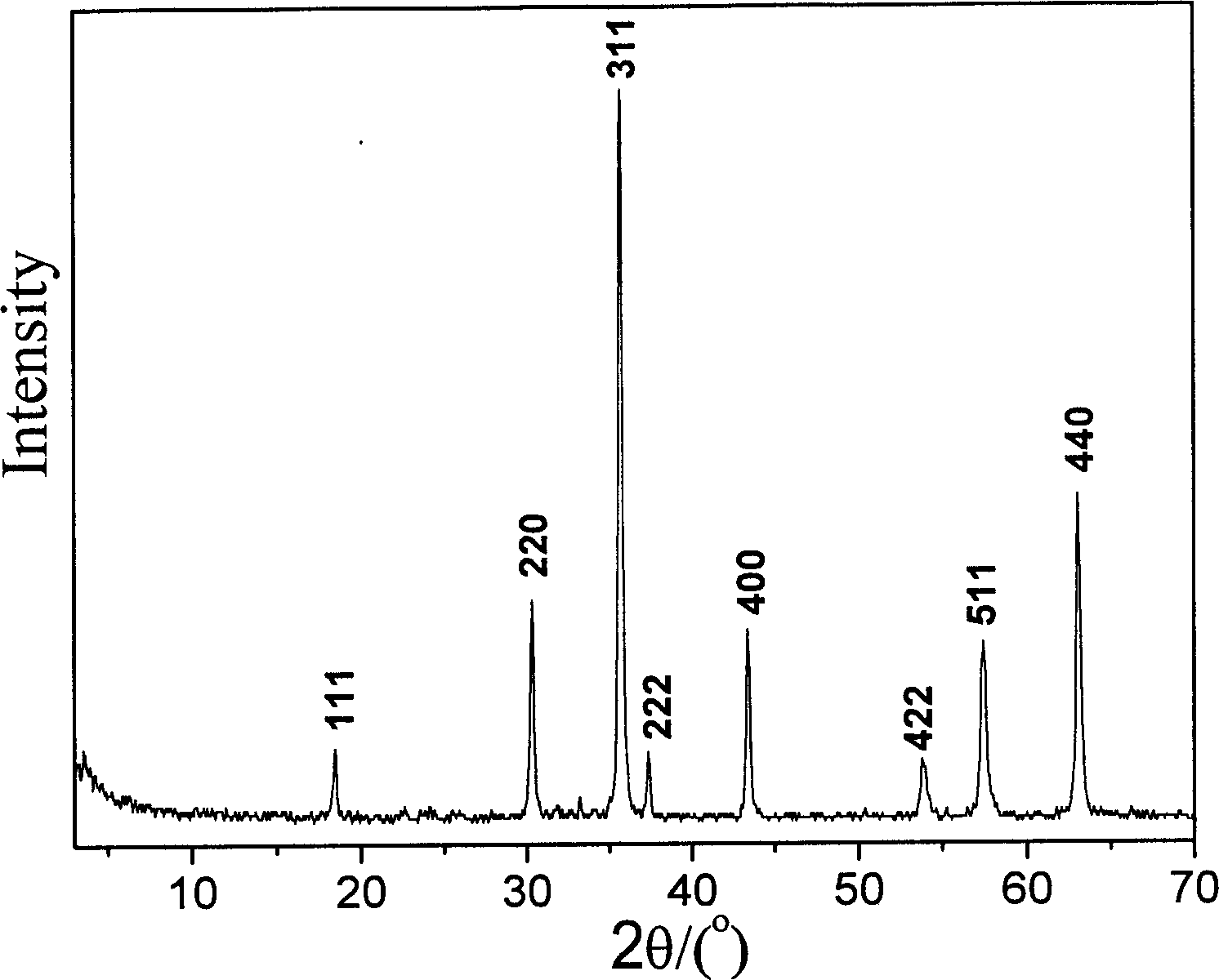

Spinel type composite metal oxide electrode material and preparing process thereof

InactiveCN1719642AHigh specific capacitanceGood electrochemical cycle performanceElectrode manufacturing processesFinal product manufactureSolid phasesMetal oxide electrode

This invention provides a spinel compound metal oxide electrode material and its preparation method, in which, the composition of the electrode material is Mfe204, M is one element or composition of any two elements in Co, Ni Cu and Fe of +2 valence transition metal elements. Taking compound metal oxide M-Fe2+-Fe3+|-LDHs as the precursor and M is one element or composition of any two elements in Co, Ni, Cu, Fe elements, the electrode material is got by baking them under a certain temperature, compared with carbon materials, said electrode material has higher mass ratio capacity and volume ratio capacity.

Owner:BEIJING UNIV OF CHEM TECH

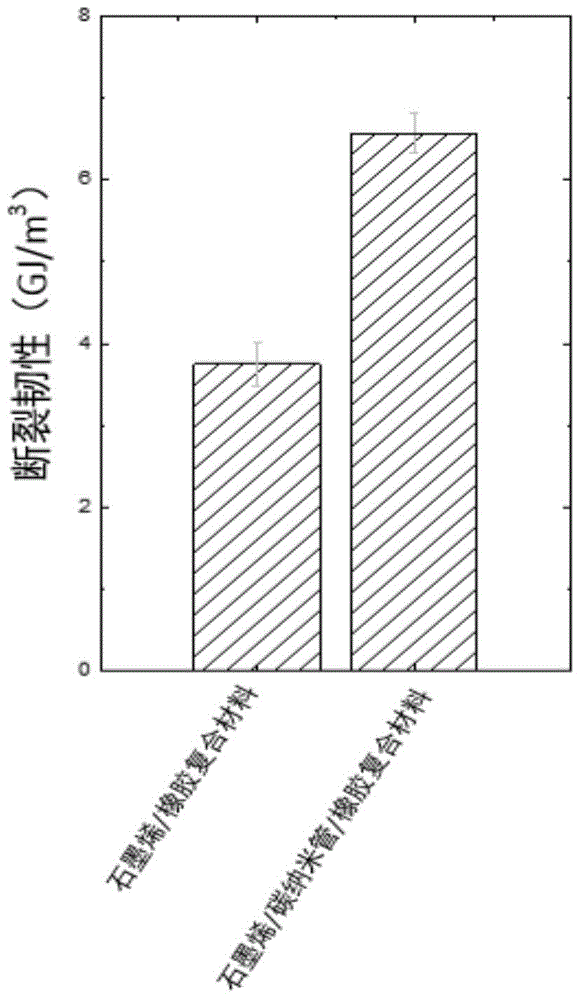

Graphene/carbon nano tube hybridized filler network enhanced rubber material and preparation method thereof

ActiveCN105131359AGood mechanical propertiesImprove fatigue resistanceRubber materialCarbon nanotube

The invention discloses a graphene / carbon nano tube hybridized filler network enhanced rubber material and a preparation method thereof. According to the rubber material, graphene and carbon nano tubes are taken as filler, a hybridized filler network is formed in a rubber material matrix, wherein 100 parts by mass of the rubber material matrix are adopted, and 0.1-20 parts by mass of graphene and the carbon nano tubes are adopted. The rubber material is prepared according to steps as follows: oxidized graphene and the carbon nano tubes are added to water, and a hybridized suspension liquid is prepared; the prepared hybridized suspension liquid is added to an emulsion of the rubber material matrix and mixed, a demulsifier is added for demulsification, an oxidized graphene / carbon nano tube / rubber particle suspension liquid is prepared, then, a reducing agent is added for a reduction reaction, solid-liquid separation is performed after sufficient reaction, an obtained solid phase is washed and dried, and the rubber material is prepared. The graphene and the carbon nano tubes form the hybridized filler network in the rubber material and have an energy dissipation function, so that the rubber material has excellent mechanical property, fatigue resistance, crack growth resistance and conductive property.

Owner:SICHUAN UNIV

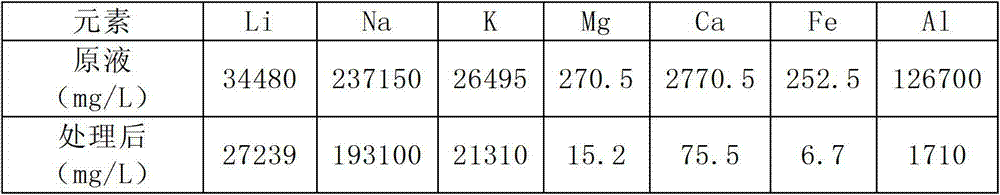

Method for extracting lithium from primary lithium-extraction solution of lithium ores

ActiveCN103114211AAbundant reserves of raw material resourcesThe process is simple and reasonableProcess efficiency improvementNanofiltrationInorganic salts

The invention relates to a method for extracting lithium from a primary lithium-extraction solution of lithium ores. The method comprises the following steps: (a) mixing inorganic salt with the primary lithium-extraction solution, removing the precipitates to obtain secondary lithium-extraction solution; (b) carrying out nanofiltration treatment on the secondary lithium-extraction solution, separating mono-valent cation salt solution from multi-valent cation salt solution; and (c) extracting lithium salt from the mono-valent cation salt solution. Other mono-valent and multi-valent salt separation solutions can be concentrated, crystallized or precipitated to obtain the corresponding salts. The invention provides a novel technology which is used for effectively recycling lithium from the lithium ores; the material resource storage capacity is abundant, the process flow is simple and reasonable, the operation is reliable and the energy consumption is low, so that the purpose of reducing the cost and the energy consumption is achieved.

Owner:宁波圣岛新材料有限公司

Lithium battery hard carbon microsphere cathode material with core-shell structure and preparation method thereof

The invention provides a lithium battery hard carbon microsphere cathode material with core-shell structure and a preparation method thereof. The lithium battery hard carbon microsphere cathode material with core-shell structure is formed by starch and a graphitized layer as coating. The surface of the material is subjected to catalytic graphitization treatment to form the graphitized layer, and the inside of the material maintains the hard carbon structure. The product is made by preparing a starch-based hard carbon microsphere and performing catalytic graphitization treatment. Owing to the highly-graphitized coating layer, the first charge / discharge efficiency of the prepared carbon microsphere with core-shell structure is higher than the conventional hard carbon-based materials; and owing to the hard carbon inner structure, the capacity is higher and the magnification property is excellent.

Owner:DONGFANG ELECTRIC CORP LTD

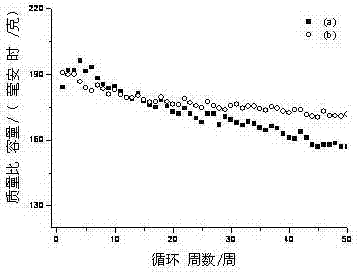

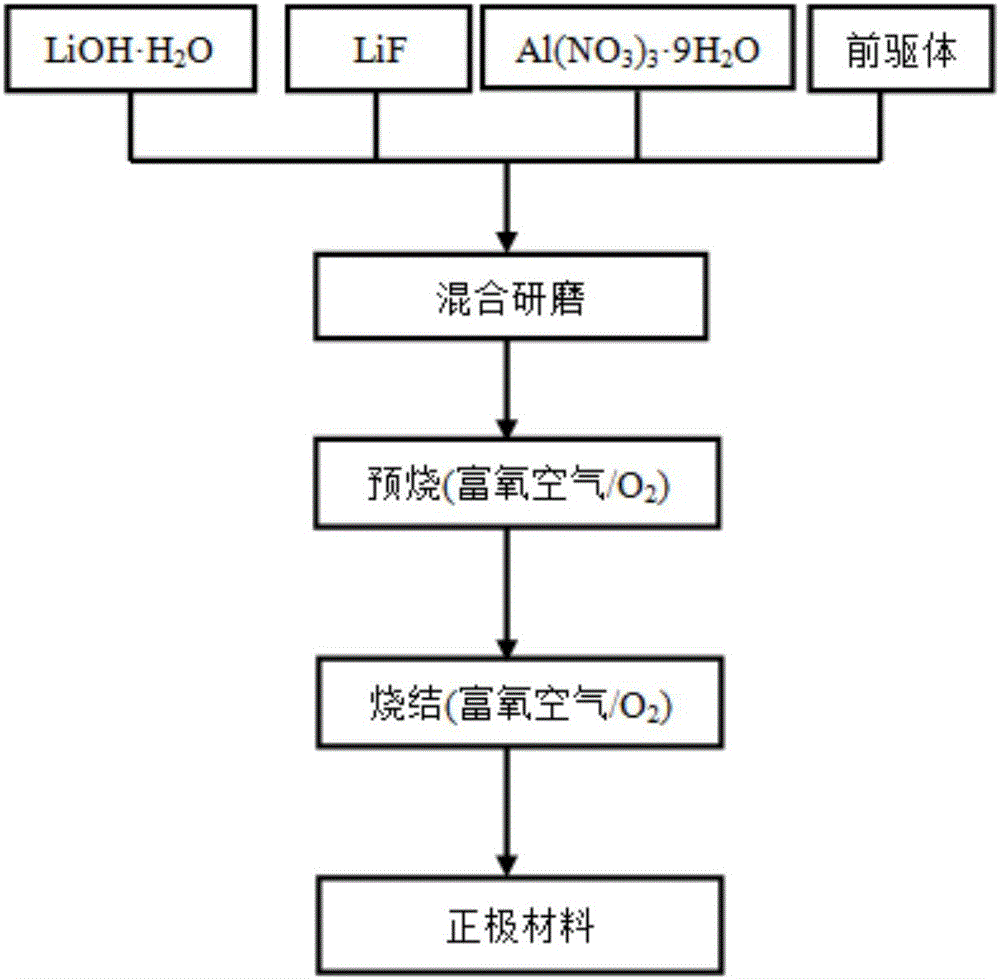

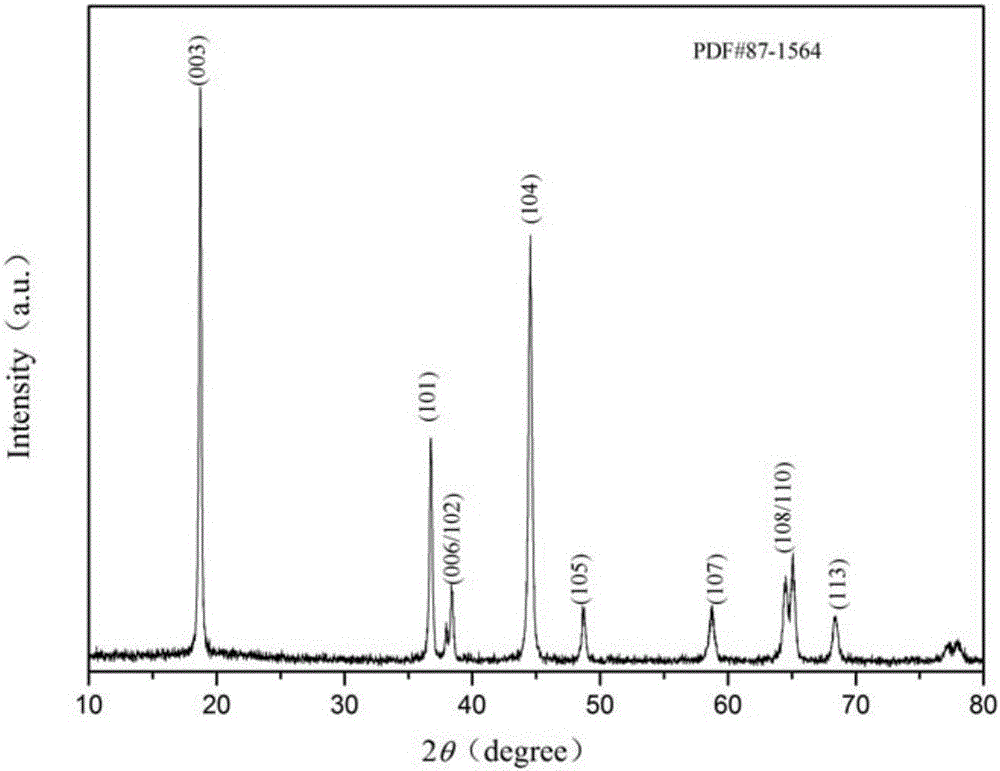

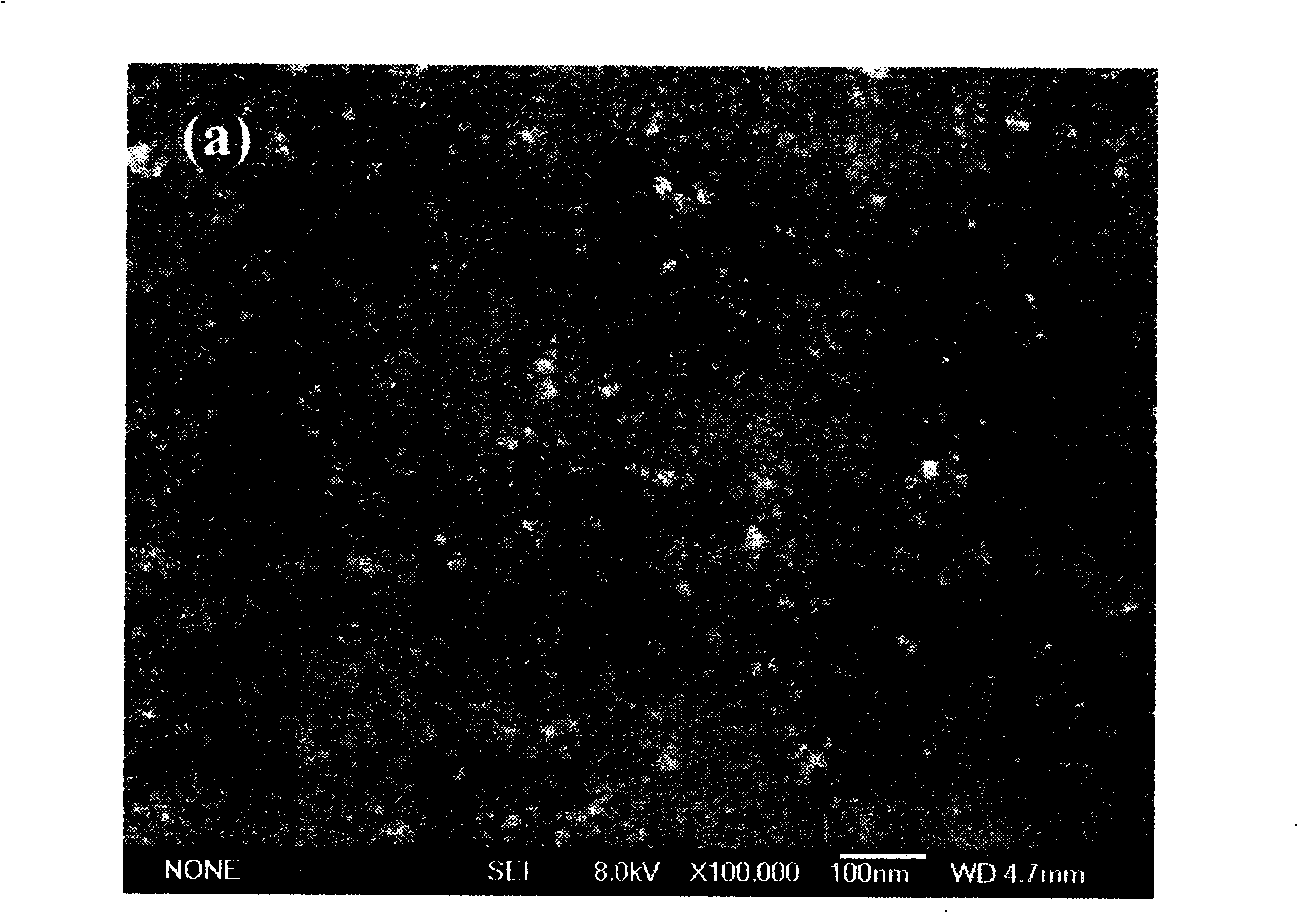

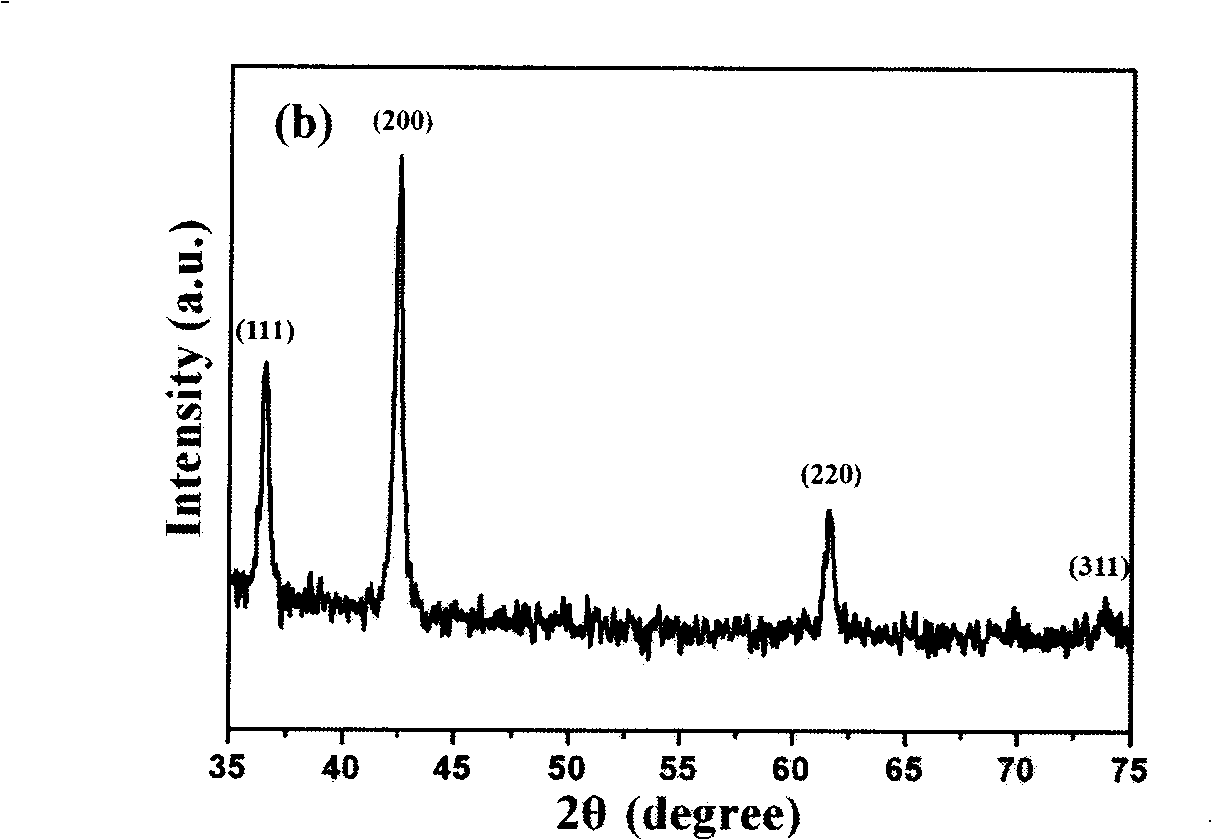

LiNi0.6-xCo0.2Mn0.2AlxO2-yFy positive electrode material for lithium ion cell and preparation method thereof

ActiveCN105990577AImprove structural stabilityHigh discharge specific capacityCell electrodesSecondary cellsAluminiumSpecific discharge

The invention belongs to the field of lithium ion cell and specifically relates to a LiNi0.6-xCo0.2Mn0.2AlxO2-yFy positive electrode material for the lithium ion cell and a preparation method thereof. X is more than 0 and y is less than or equal to 0.05. The positive electrode material is used for overcoming the defect of poor electrochemical performance of the Ni-Co lithium manganate ternary positive electrode material. According to the invention, a minute quantity of aluminum and fluorine are doped, so that the positive electrode material for the lithium ion cell has higher specific discharge capacity and excellent cycle performance; under a room temperature environment, when the voltage scope is 2.7-4.3V and the constant current charge-discharge multiplying power is 0.5C, the specific discharge capacity of the material at the first time can reach 187.9mAh g<-1>, and after circulation for 20 times, the specific discharge capacity still can reach 192.1mAh g1 and the capacity retention ratio reaches up to 102.2%; when the voltage scope is increased to 2.7-4.5V and the constant current charge-discharge multiplying power is 0.5C, the initial specific discharge capacity of the material can reach 225.8mAh g<-1>, and after circulation for 20 times, the specific discharge capacity still can reach 190.2mAh g<-1> and the capacity retention ratio reaches up to 84.2%. The preparation technique of the material is simple and controllable, the product purity is high, the chemical uniformity is high, the crystal quality is high, the product grain is small and the size distribution is uniform.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Graphene composite copper thick film conductive slurry and preparation method thereof

InactiveCN104021842AImprove conductivityGraphene with excellent conductivity improvesNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesion forceConductive polymer

The invention discloses graphene composite copper thick film conductive slurry. The graphene composite copper thick film conductive slurry comprises the following components in percentage by mass: 60%-80% of conductive phase, 0.5%-5% of glass phase, 15%-39.5% of organic carrier, totaling 100%. The preparation method comprises the steps of mixing the components, heating to 35-40 DEG C, and uniformly stirring. According to the graphene composite copper thick film conductive slurry disclosed by the invention, by adding graphene with an excellent conductive property, the conductive property of the slurry is improved; by bismuth oxide low-melting glass, the conductive thick film slurry has excellent electrical properties and adhesion force even when being sintered at a low temperature. The slurry has the advantages of good conductivity and small printing thickness, can be effectively applied to production of a conductive material for various products, has the advantages of simple preparation process, convenience in operation, good conductivity, uniform distribution of particle sizes and easiness in coating, and is suitable for mass production of enterprises.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Orientational alignment carbon nano-tube and carbon coating cobalt nano-particle complex and preparation thereof

InactiveCN101348936AAdjust densitySimplify the experimental stepsPolycrystalline material growthNanostructure manufactureGas phaseCarbon nanotube

The invention relates to a carbon nano tube in an oriented array, a carbon-coated cobalt nano particle compound and a preparation method thereof. The preparation method comprises the following steps: firstly, a Co membrane is deposited on a Si substrate by means of magnetron sputtering; secondly, the Co membrane is oxidized during heating up plasma-enhanced chemical vapor deposition equipment so as to form small cobalt oxide nano particles; thirdly, working gas H2+CH4 is fed in so as to carry out deposition growth; and finally, the carbon nano tube in the oriented array and the carbon-coated cobalt nano particle composite material are obtained. The compound carbon nano tube is directionally perpendicular to the Si substrate, and the carbon-coated cobalt nano particle is adhered to the top surface of the carbon nano tube in the oriented array, wherein the carbon nano tube is a multi-wall carbon nano tube; moreover, the cobalt particle is monocrystal cobalt. The preparation method is simple and has the advantages of one-step finishing, easy control and convenient industrial production; moreover, the prepared composite material has an enormous application prospect in fields such as high-density magnetic recording material, wave absorption, biological medicine, electromagnetic screen, sensor and catalytic materials.

Owner:JILIN UNIV

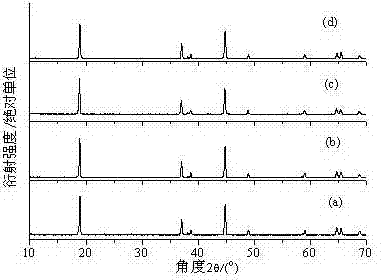

Preparation method of modified spinel lithium manganese oxide cathode material

ActiveCN103474647APromote circulationImprove high temperature performanceCell electrodesManganates/permanganatesManganeseSpinel

The invention discloses a preparation method of modified spinel lithium manganese oxide, an cathode material for a lithium ion cell. The preparation method comprises the following steps of metering one or more than two manganese compounds selected from MnO2, Mn3O4, Mn(OH)2 and Mn2O3, a lithium compound selected from Li2CO3 and LiOH and one or more doping agents selected from oxides or hydroxides of Cr, La, Ce, Zr, Ni, Mg, Ti, Al, Ca, V and B according to a chemical formula Li(1+X)Mn(2-X-Y)MYO4 (M is a doping modifier, X is not less than 0 and not more than 0.20 and Y is not less than 0 and not more than 0.25), mixing the materials uniformly, then carrying out sintering and surface treatment, reducing the alkali content of the sintered substance through surface treatment, controlling the alkali content in a certain range and then carrying out smashing, dispersing and grading and sieving, thus obtaining the uniformly doped lithium manganese oxide cathode material. The method is simple, the preparation processes are easy to operate and control, the production cost is low and the product performances are excellent.

Owner:NANTONG RESHINE NEW MATERIAL

Method for preparing lithium manganate used as lithium ion battery anode material by using trimanganese tetroxide

ActiveCN102336441AReduce bring inUniform compositionCell electrodesManganates/permanganatesPhysical chemistryManganate

The invention discloses a method for preparing lithium manganate used as a lithium ion battery anode material by using trimanganese tetroxide, comprising the following steps of: firstly, preparing the trimanganese tetroxide and the lithium salt according to the molar ratio of lithium to manganese 0.5-0.6, uniformly mixing the trimanganese tetroxide and the lithium salt to get the precursor, and then, pre-sintering the precursor; executing ball milling and spray drying after pre-sintering, and then, executing secondary sintering; finally, executing isostatic cool pressing on the products of the secondary sintering process, and crashing and classifying the products to get the lithium manganate used as the lithium ion battery anode material. The method has the advantages of being simple and practical in technical steps, low in cost, easy to realize mass industrial production, excellent in product performance, and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

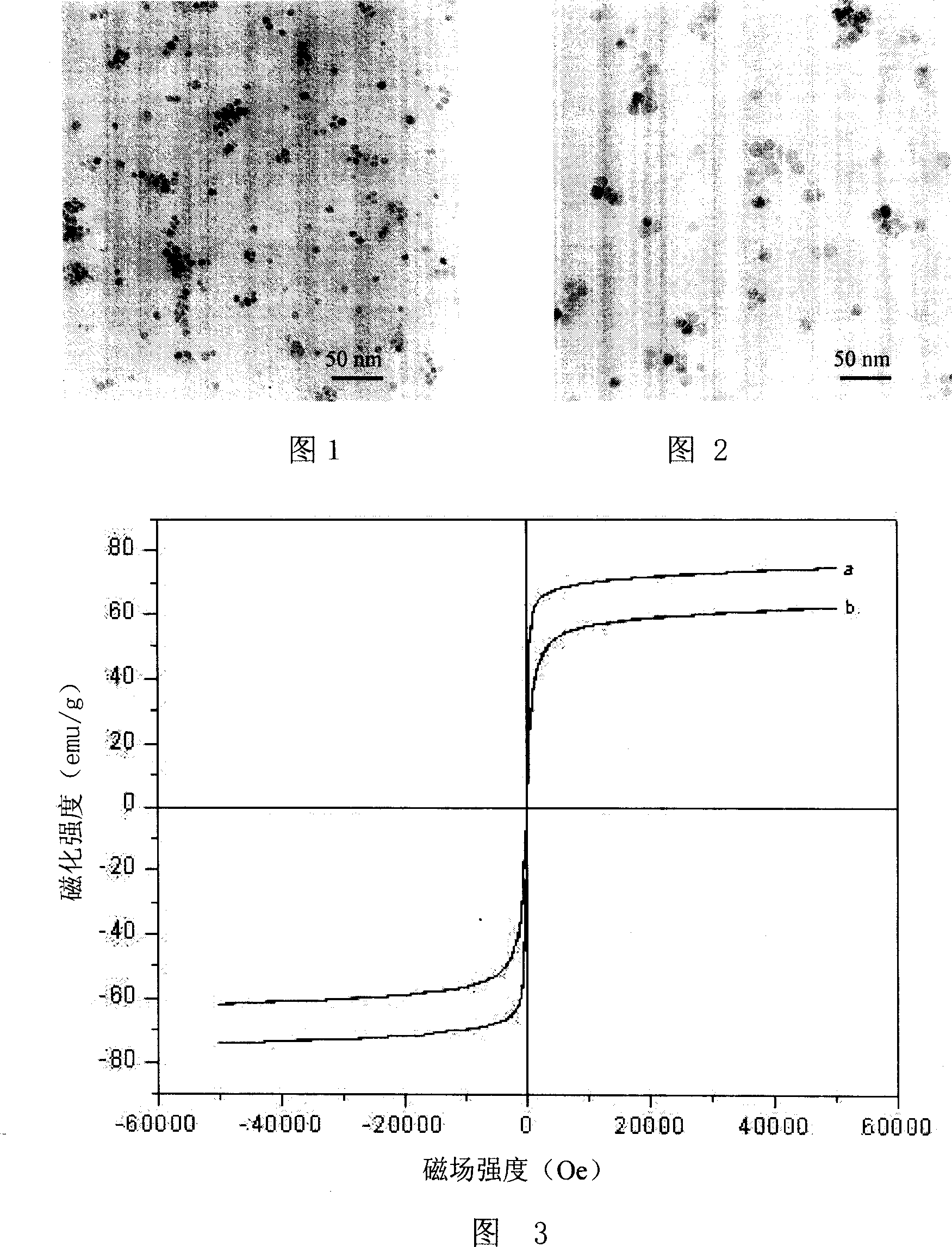

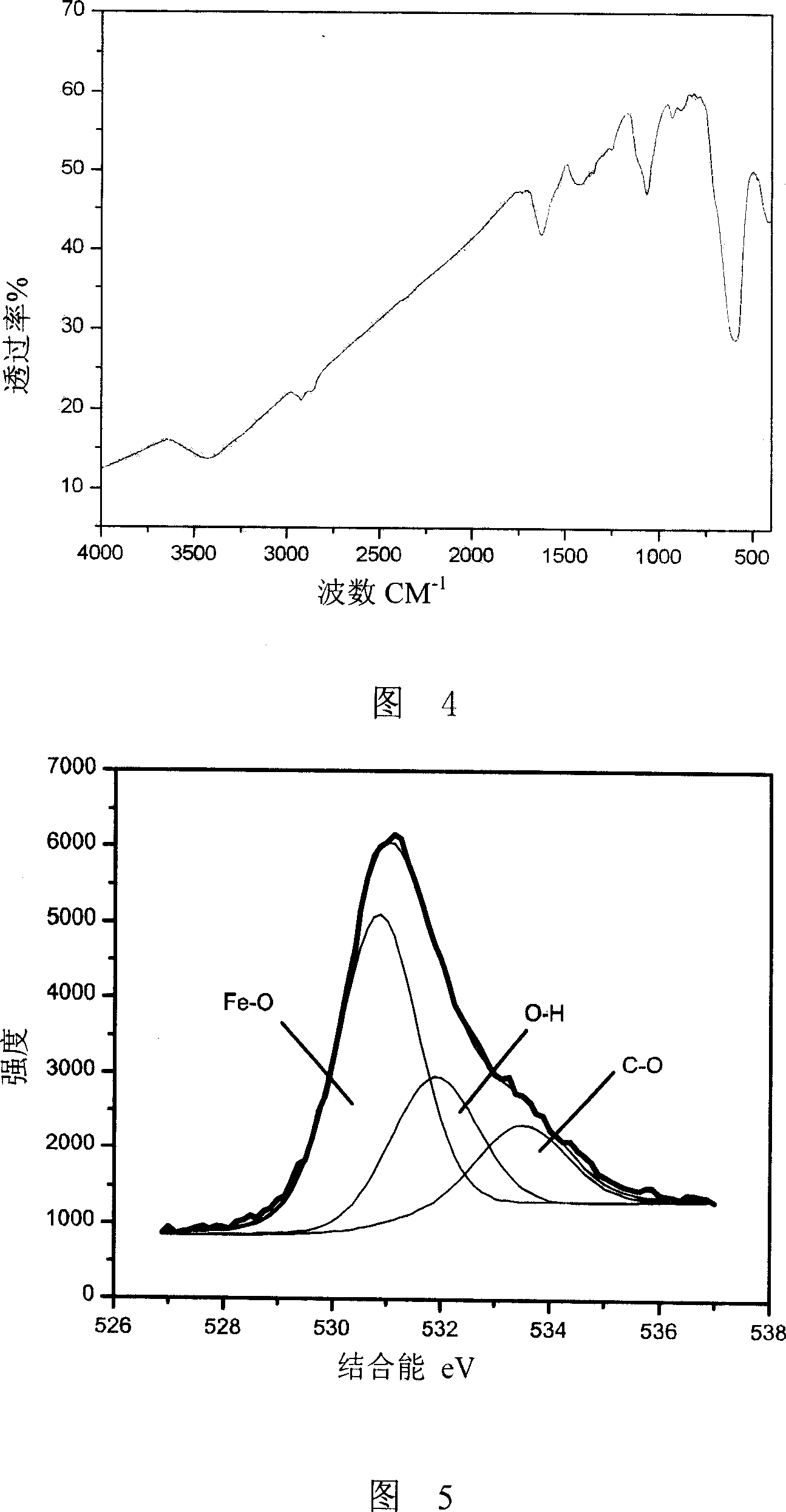

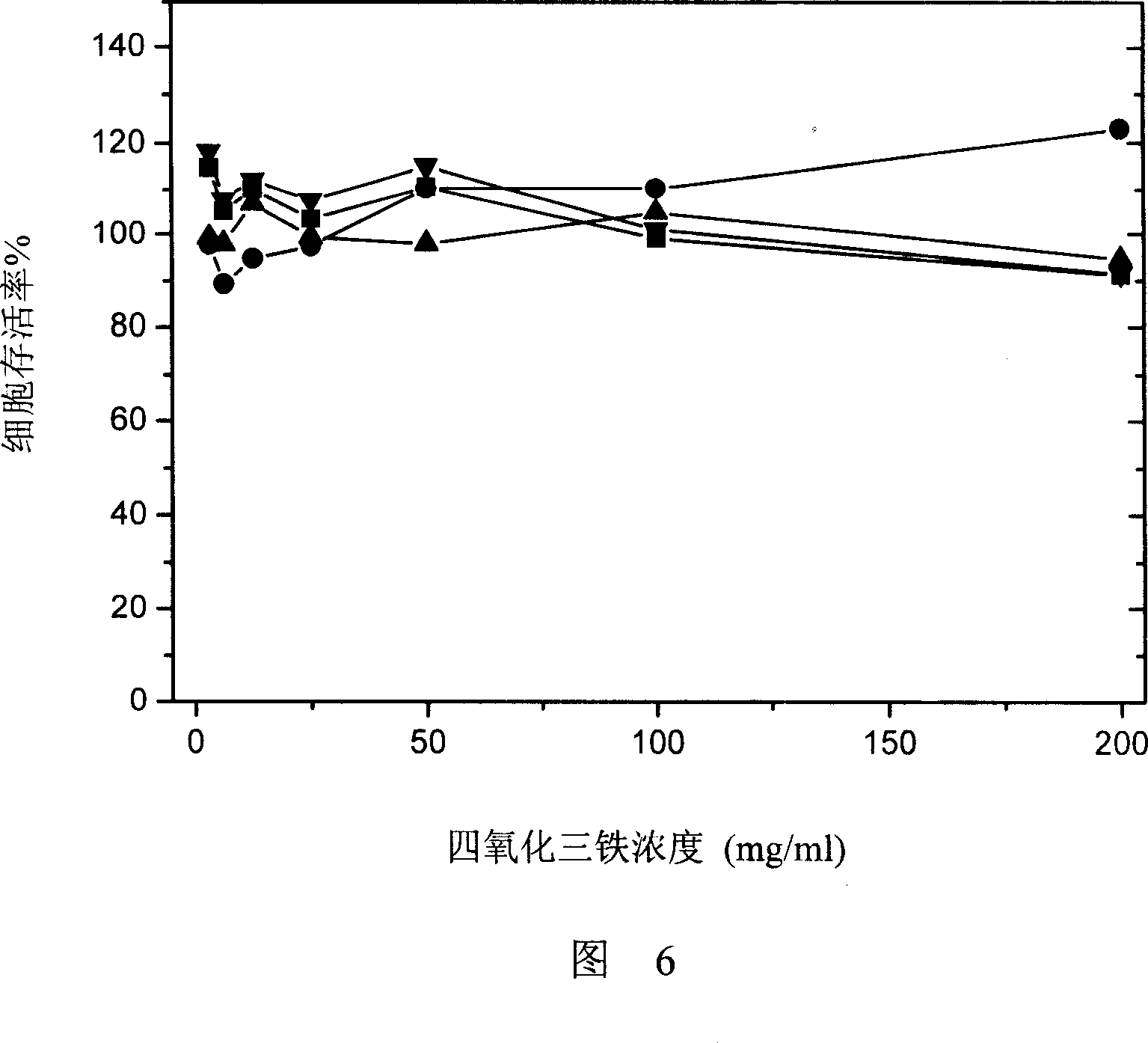

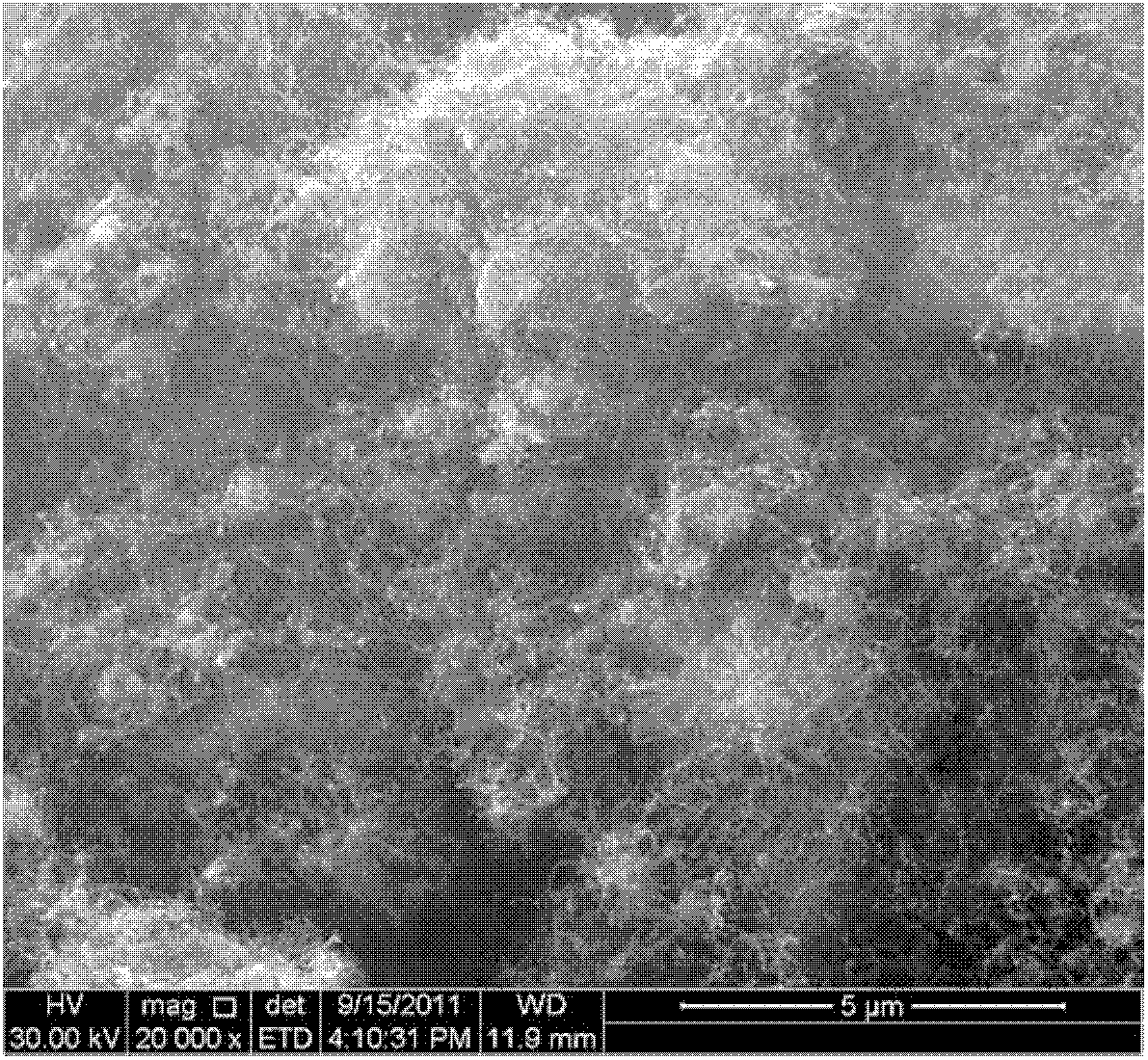

Superparamagnetism magnetic resonance contrast medium, and its preparing method

InactiveCN101002951AHigh crystallinityHigh saturation magnetizationEmulsion deliveryIn-vivo testing preparationsPolyolResonance

A superparamagnetic MRI contrast medium is a Fe3O4 nanoparticl coated by polyol moleculae. Its preparing process includes such steps as high-temp reaction of Fe contained compound in polyol solution, cooling, depositing, separating, dispersing it in water, filtering, and sterilizing. It has high crystalline level, high saturated magnetic intensity and high imaging effect.

Owner:HARBIN INST OF TECH

Method for preparing carbon nano tube enhanced titanium-base compound material by in-suit reaction

The invention relates to a method for preparing a carbon nano tube enhanced titanium-base compound material by in-suit reaction in order to solve the problems of low uniform dispersion and low structural completeness of a carbon nano tube in the conventional method for preparing the carbon nano tube enhanced titanium-base compound material and pollution to the titanium-base material caused by reaction of a carbon group and a titanium base body. The method comprises the following steps of: adding nickel nitrate hexahydrate and TiH2 powder into an ethanol solution, stirring and evaporating to obtain Ni-TiH2 compound powder; paving the Ni-TiH2 compound powder in a quartz boat, putting the quartz boat into deposition equipment, feeding H2, raising temperature, feeding CH4, and after the deposition is finished, stopping feeding the CH4 so as to obtain carbon nano tube / TiH2 compound power; pressing the carbon nano tube / TiH2 compound power into a block body, sintering, and re-pressing to obtain the carbon nano tube enhanced titanium-base compound material. Carbon nano tubes in the compound material are uniform to disperse and cannot be aggregated; the compound material is high in purity and has a complete structure; and reaction between the titanium and the defected carbon nano tube can be avoided.

Owner:HARBIN INST OF TECH

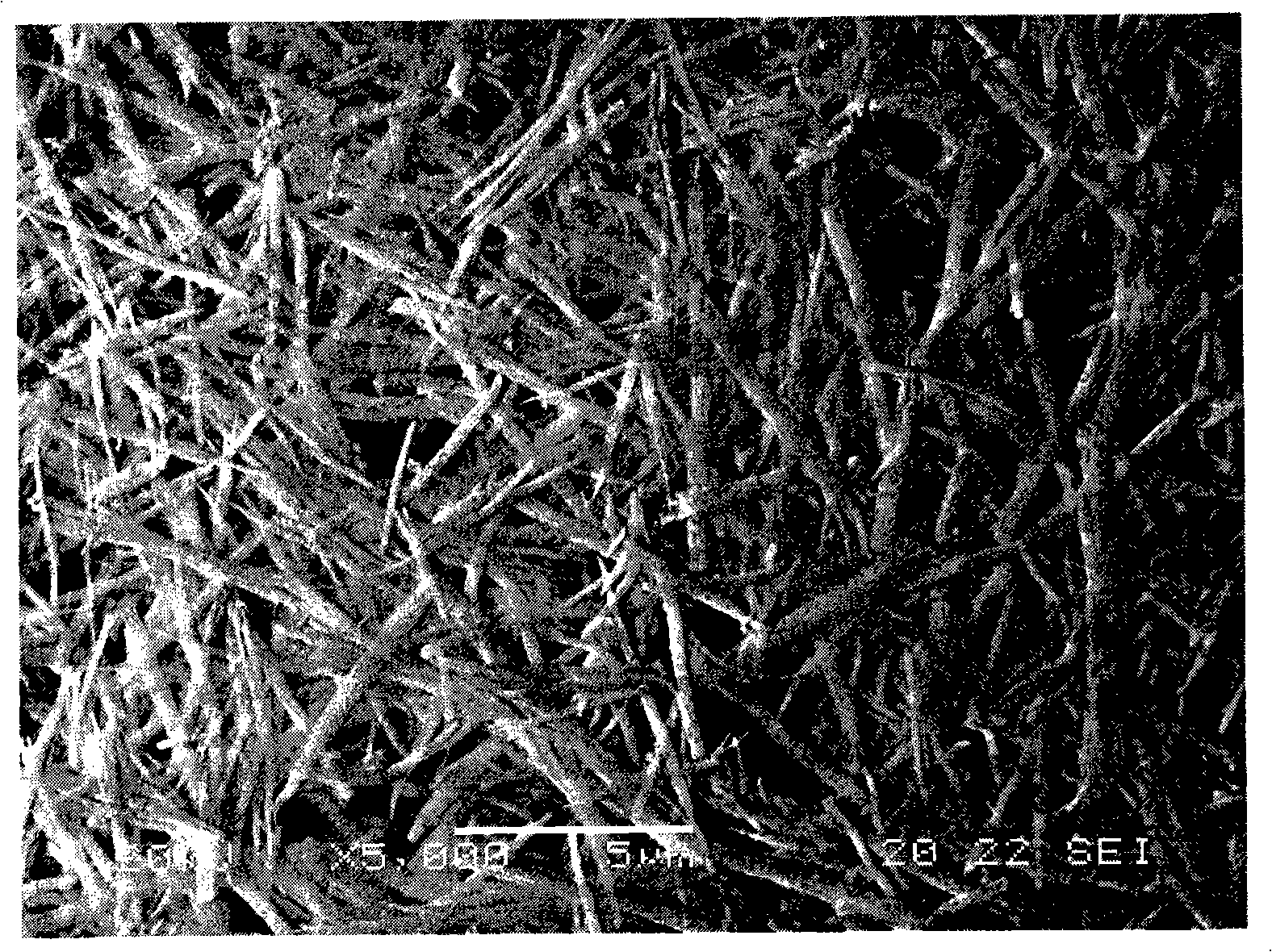

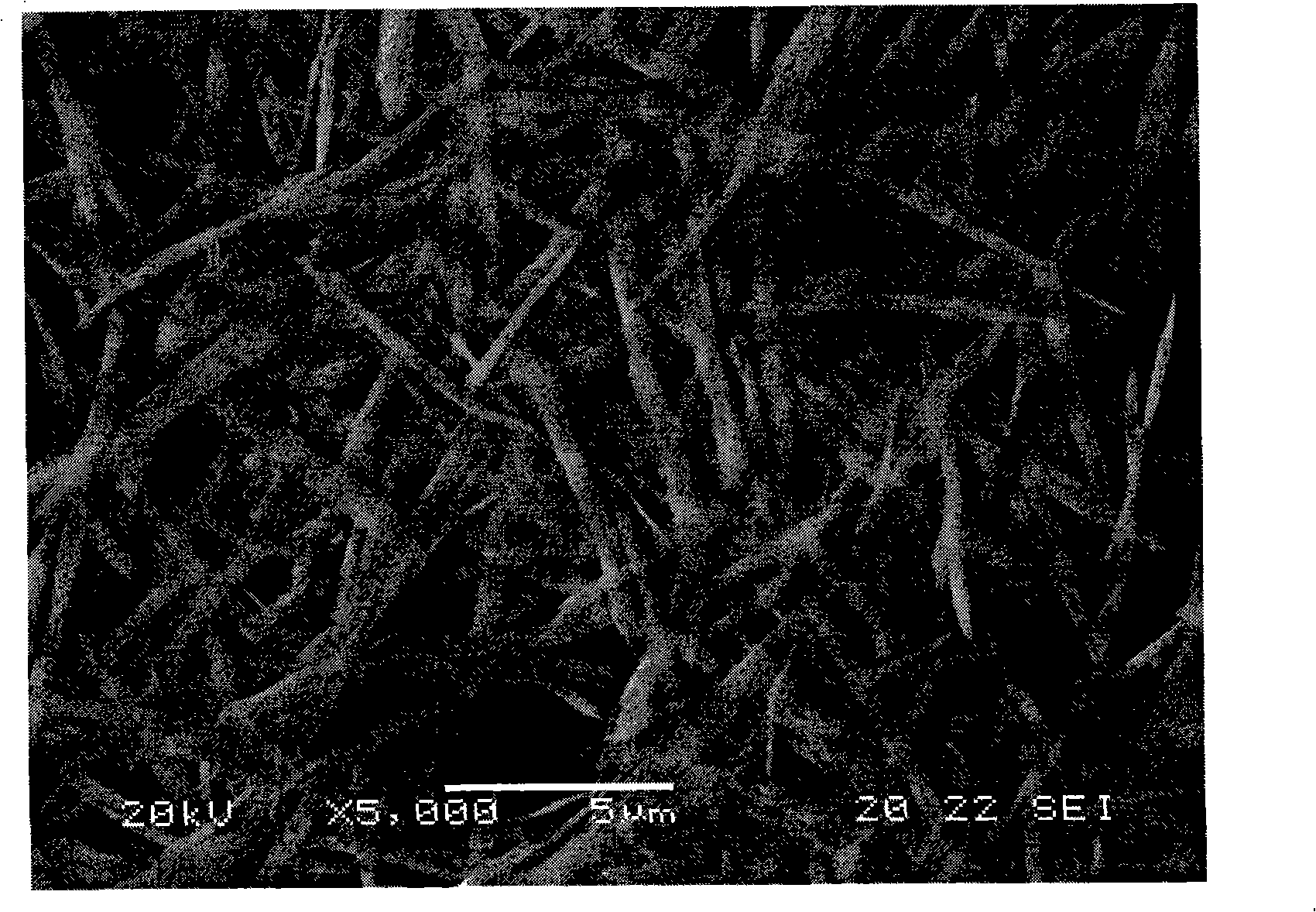

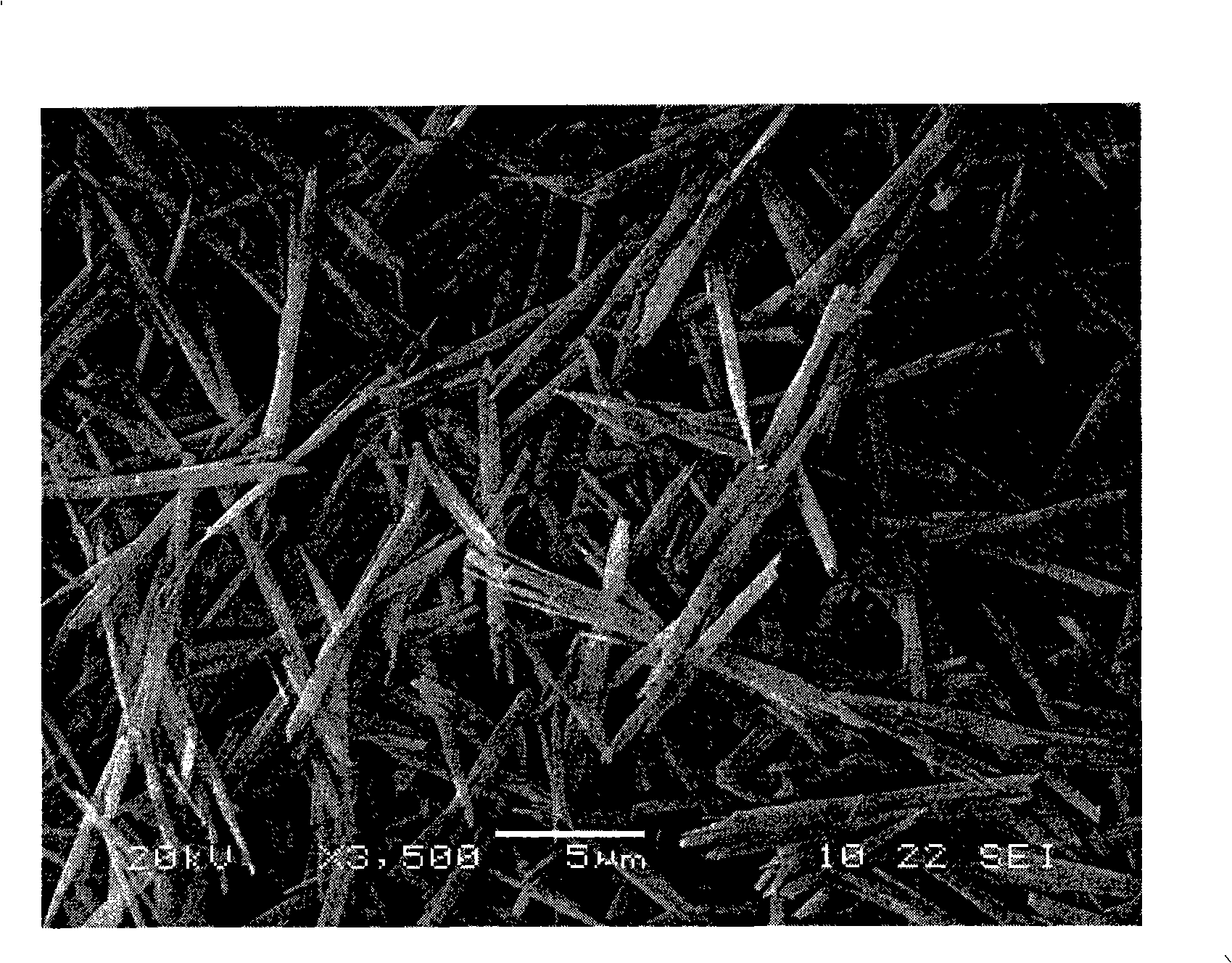

Hydrothermal preparation method for aluminum oxide whiskers at low temperature

InactiveCN101338448AImprove qualityHigh purityPolycrystalline material growthFrom normal temperature solutionsX-rayDistilled water

The invention provides a preparation method of aluminum oxide whisker in the hydrothermal under low temperature. The preparation method comprises the procedures as follows: aluminum nitrate is dissolved in distilled water to prepare the solution with the concentration of 0.5 to 1.5mol / L; urea with the molar weight that is 2 to 10 times more than the aluminum nitrate is added into the aluminum nitrate solution and the solution is stirred until transparent clarified collosol is made; the collosol is placed in a reaction kettle for 6 to 12h under the temperature of 90 DEG C to 120 DEG C to obtain white deposit of the precursor of the alumina whisker; and the white deposit is washed by the distilled water and roasted for 2 to 12h under the temperature of 1100 DEG C to 1300 DEG C and the alumina whisker is made. The alumina whisker prepared by the invention is identified to be pure phase by x-ray diffraction. The average diameter of the alumina whisker is 0.5mum and the length of the alumina whisker is 5 to 10mum. The alumina whisker can be used as an additive for ceramic materials, function materials and metal materials, and the like, and well improve the mechanical property and the heat-resistant property of the materials.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Three-dimensional graphene modification-based plastic composite material and preparation thereof

The invention relates to the technical field of materials, and in particular disclosesa three-dimensional graphene modification-based plastic composite material. The three-dimensional graphene modification-based plastic composite material is prepared from 95 percent to 99.9 percent by weight of a plastic base material and 0.1 percent to 5 percent by weight of three-dimensional graphene. The three-dimensional graphene is a three-dimensional structure assembling body of a two-dimensional graphene sheet, has excellent electrical conductivity, heat conductivity and mechanical properties of graphene, also has unique properties, such as flexibility, porosity, highly active surface area and the like, and can tightly contact with abase material, so that the three-dimensional graphene can be uniformly distributed in the plastic base material, and the electrical conductivity, the heat conductivity and the mechanical properties of plastic products are enhanced.

Owner:GUANGDONG NANOLUTION SCI & TECH CO LTD

Cellulose based gel polymer electrolyte and preparation method thereof, and lithium ion battery containing electrolyte

ActiveCN108063279AUniform nanoporous structureImprove mechanical propertiesSecondary cellsElectrolyte immobilisation/gelificationCellulosePolymer electrolytes

The invention discloses a cellulose based gel polymer electrolyte and a preparation method thereof, and a lithium ion battery containing the electrolyte. The gel polymer electrolyte is obtained by absorbing an organic electrolyte solution with a cellulose porous membrane or a cellulose composite porous membrane with a nanopore structure and then gelating. The cellulose porous membrane or cellulosecomposite porous membrane is obtained by a dissolving and regeneration method, the thickness is 20-200 [mu]m, the average pore size is less than 50 nm, the porosity is 30-98%, the tensile strength is3-80 MPa, and the dimensional thermal stability is good; the cellulose based gel polymer electrolyte obtained by adsorbing the organic electrolyte solution and gelating has the advantages of high ionic conductivity, wide electrochemical stability window and the like and is suitable for lithium ion batteries with high performance and high safety.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Organogel polymer electrolytic solution, preparation method, application, sodium-based dual-ion battery and preparation method thereof

ActiveCN109638344AGuaranteed electrochemical performanceImprove securityFinal product manufactureSecondary cellsElectrochemistrySodium salt

The invention belongs to the technical field of energy storage devices and relates to an organogel polymer electrolytic solution, a preparation method, application, a sodium-based dual-ion battery anda preparation method thereof. The organogel polymer electrolytic solution of the present invention comprises a solid polymer substrate and an organic electrolytic solution; wherein the solid polymersubstrate comprises an organic polymer and an inorganic additive; and the organic electrolytic solution comprises sodium salt and an organic solvent. The liquid electrolytic solution and the diaphragmin a traditional battery are replaced by the rigid-flexible organogel polymer electrolytic solution where the organic and inorganic materials coexist, thereby improving the safety of the battery under the premise of ensuring the electrochemical performance of the battery, broadening the application field of dual-ion batteries, bringing new design opportunities for energy storage devices in the field of wearable electronic devices in the future, achieving low-cost batteries without using the diaphragm and a protection circuit.

Owner:SHENZHEN INST OF ADVANCED TECH

Preparation method for copper foil current collector and application

InactiveCN103579631ASimple preparation processLow costElectrode carriers/collectorsCvd grapheneElectrical battery

The invention provides a preparation method for a copper foil current collector. The method comprises the steps of: providing a clean copper foil, placing it in chemical vapor deposition equipment, and conducting sealing; introducing a protective gas into the equipment, exhausting air, then starting heating to a temperature of 800-1000DEG C, then starting plasma equipment, introducing a carbon-containing gas, keeping the status for 100-300min, at the end of reaction, stopping heating, turning off the plasma equipment, stopping introducing the carbon-containing gas, and performing cooling to room temperature in a protective gas atmosphere, thus obtaining the copper foil current collector with graphene growing on the surface. The preparation method for the copper foil current collector provided by the invention has a simple preparation process. The contact internal resistance between the prepared copper foil current collector with graphene growing on the surface and a battery active material is greatly reduced, so that the total internal resistance of the battery is reduced, and the power density of the battery is enhanced.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

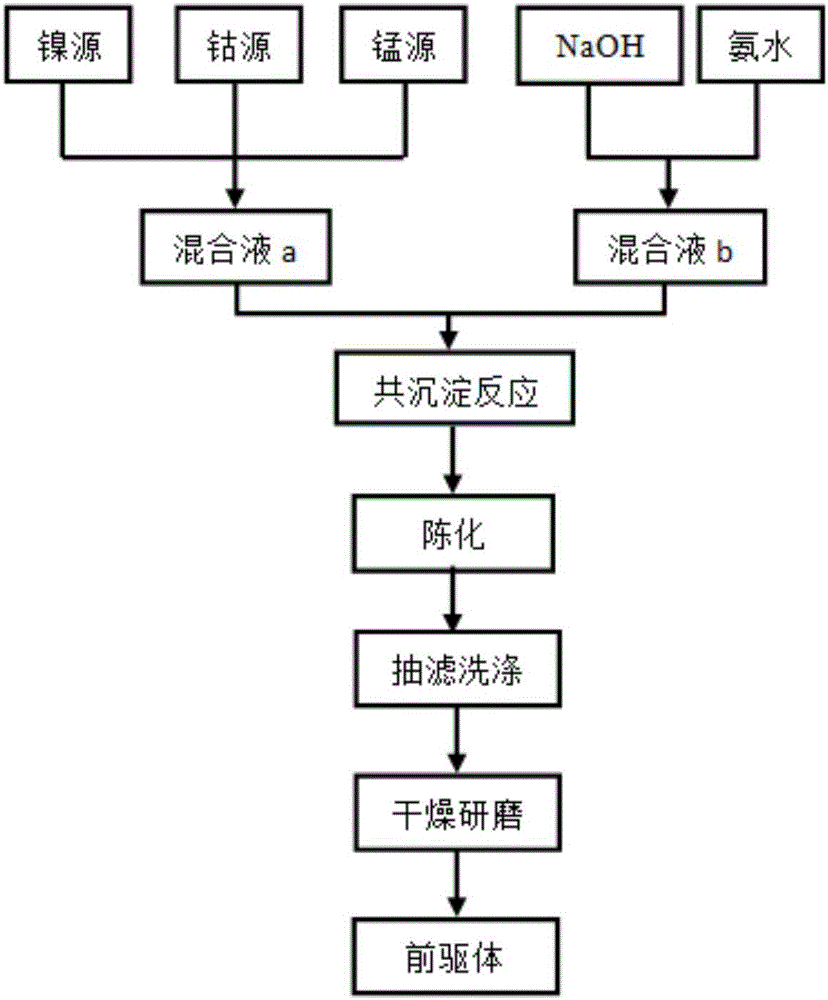

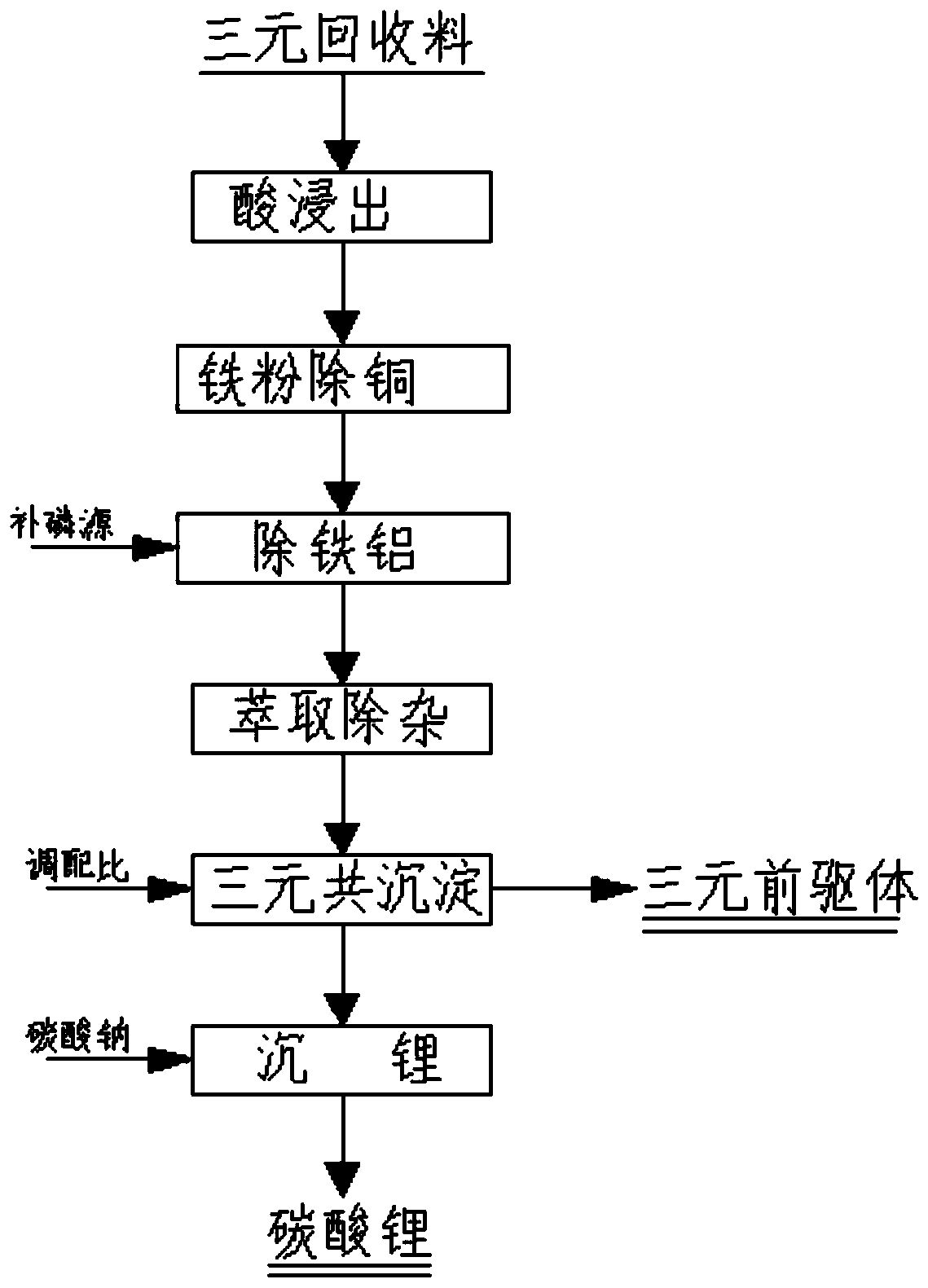

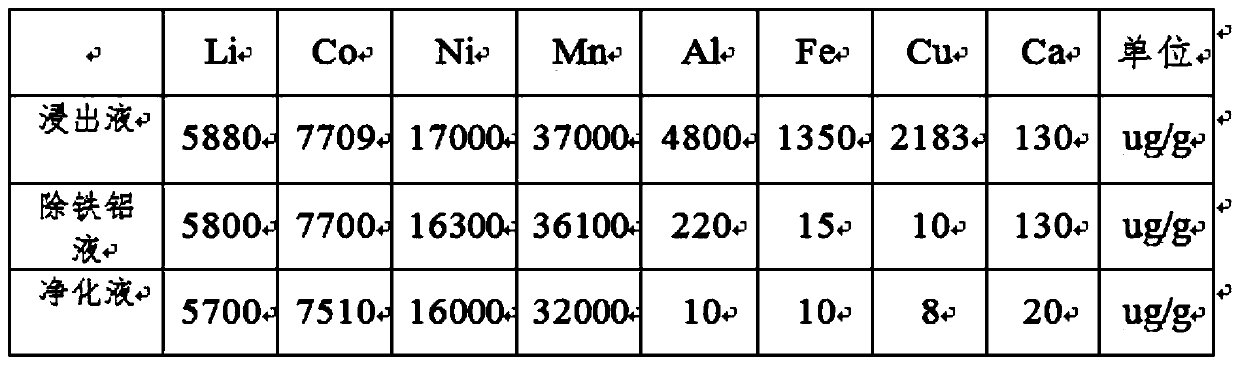

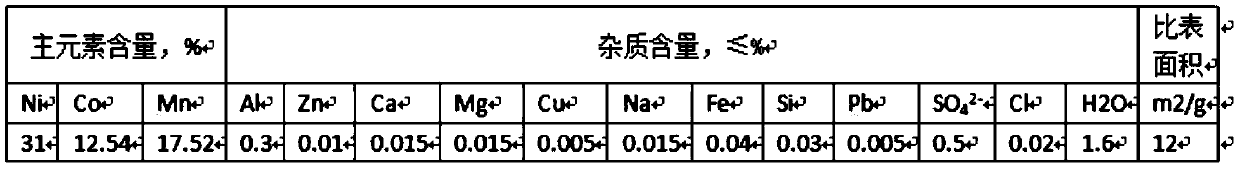

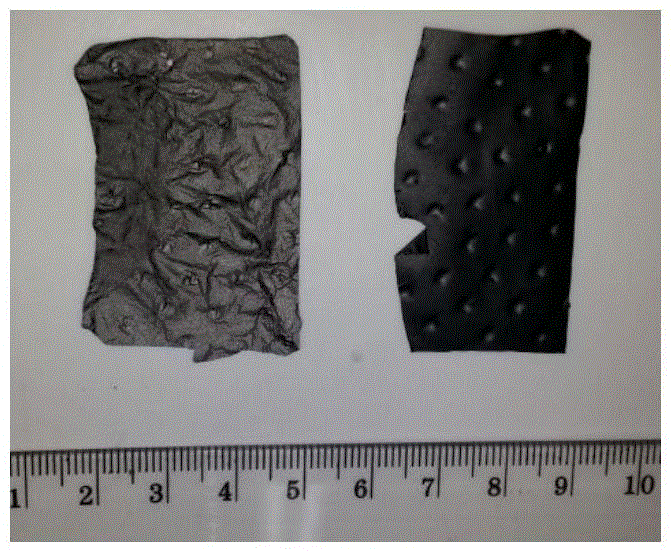

Recycling method of waste nickel cobalt manganese lithium ternary battery positive electrode material

PendingCN111082043AImprove filtering effectEasy to achieve large-scale industrial productionCell electrodesWaste accumulators reclaimingPregnant leach solutionO-Phosphoric Acid

The invention discloses a recycling method of a waste nickel cobalt manganese lithium ternary battery positive electrode material. The method comprises the following steps that: 1) acid leaching is performed, specifically, a powder material containing a ternary positive electrode material, negative electrode powder, copper-aluminum powder, iron and other elements is added into dilute acid, and a reducing agent is also added into the dilute acid, and agitation leaching is performed, so that a leachate containing nickel, cobalt, manganese, aluminum, lithium, copper and iron can be obtained; 2) copper removal is performed, specifically, iron powder is added into the leachate, the iron powder reacts with the leachate at a certain temperature, and filtering is performed, so that a copper-removed liquid is obtained; 3) iron and aluminum removal is performed, specifically, a phosphoric acid compound is added into the copper-removed liquid, dilute alkali is added into the copper-removed liquidat the same time, so that the pH value of the liquid can be adjusted to 2.5-3.5, and iron and aluminum can be removed; 4) P204 extraction and impurity removal is performed; 5) a nickel-cobalt-manganese ternary precursor is prepared; and 6) a lithium-containing liquid is added to a saturated sodium carbonate solution, so that evaporation and concentration are performed, so that lithium carbonate powder can be obtained. The recovery rate of nickel, cobalt, manganese and lithium is higher than 95%; the purity of the obtained nickel, cobalt, manganese ternary precursor and the lithium carbonate is high; and the nickel, cobalt, manganese ternary precursor and lithium carbonate can be directly used for preparing ternary battery materials, and resource recycling is truly achieved.

Owner:宁夏百川新材料有限公司

Preparation method of high-conductivity graphene membrane

The invention belongs to the technical field of preparation of graphene materials, and particularly relates to a preparation method of a high-conductivity graphene membrane. The preparation method comprises the following steps: preparing graphene oxide through an improved Hummer method in the presence of phosphoric acid protective agent, filtering through a polyester fiber filter membrane to obtain a graphene oxide membrane, and reducing the obtained graphene oxide membrane in a hydriodic acid-ethanol mixed solution to obtain the graphene membrane. The preparation method is simple and convenient to operate, has simple requirements for equipment and technology, and is cheap in raw materials and low in cost; and the prepared graphene membrane has few defects and high conductivity. The preparation method is easy to realize large-scale industrial production.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method for aluminum foil current collector and application

InactiveCN103579630ASimple preparation processLow costElectrode carriers/collectorsInternal resistanceRoom temperature

The invention provides a preparation method for an aluminum foil current collector. The method comprises the steps of: providing a clean aluminum foil, placing it in chemical vapor deposition equipment, and performing sealing; introducing a protective gas into the equipment, at the same time turning on a vacuum system, starting heating when the air pressure is 1-100Pa, then turning on plasma equipment when heated to 500-600DEG C, introducing a carbon-containing gas, maintaining the status for 100-300min, at the end of reaction, stopping heating, turning off the plasma equipment, stopping introducing the carbon-containing gas, and carrying out cooling to room temperature in a protective gas atmosphere, thus obtaining aluminum foil current collector with grapheme growing on the surface. The preparation method for the aluminum foil current collector provided by the invention has a simple preparation process, the contact internal resistance between the prepared aluminum foil current collector with grapheme growing on the surface and a battery active material is greatly reduced, and the phenomenon of embedding lithium ions into the aluminum foil can be prevented, so that the cyclic stability and service life of the lithium ion battery can be improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com