Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

457 results about "Phosphorus doped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for depositing a phosphorus doped silicon arsenide film and related semiconductor device structures

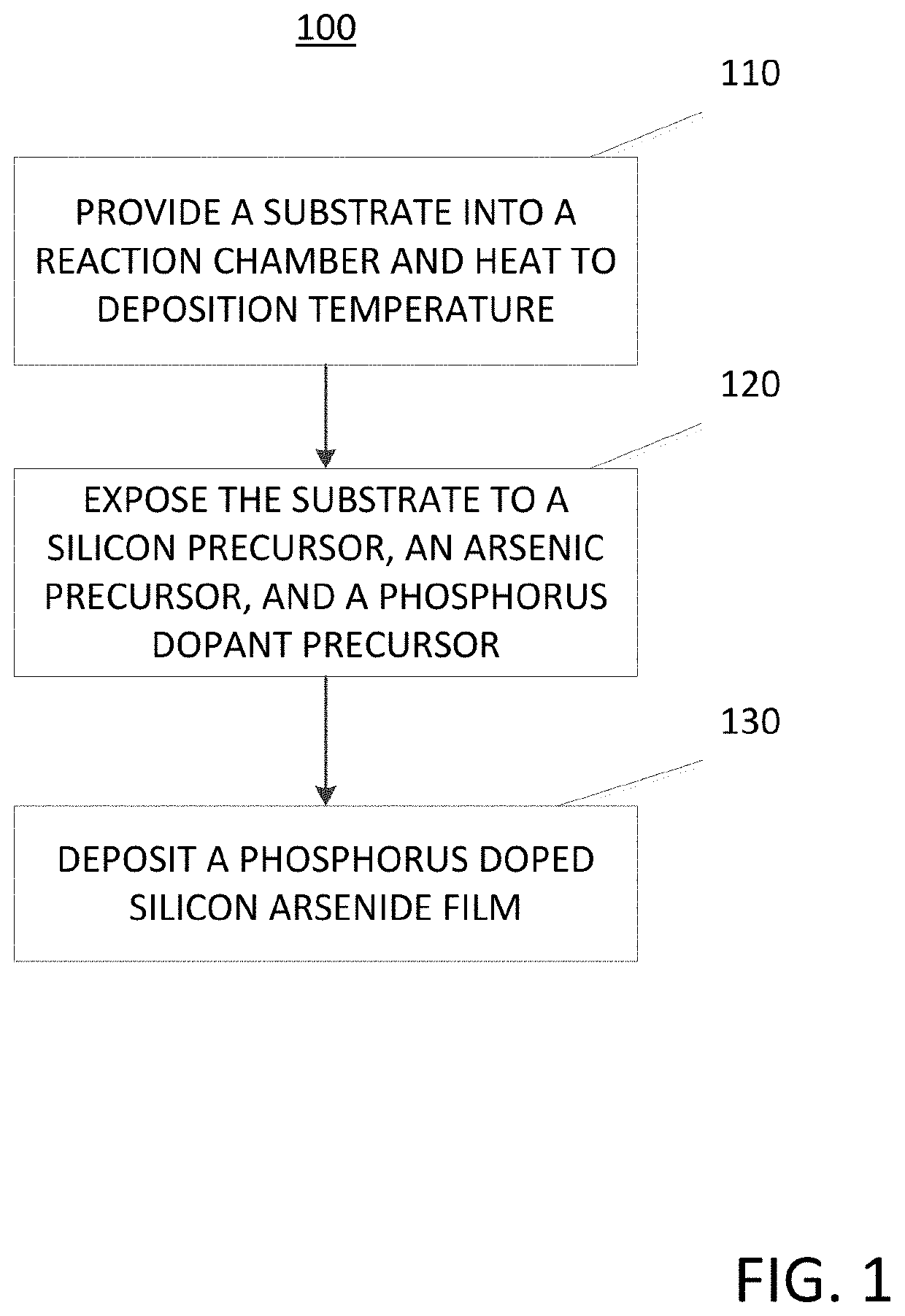

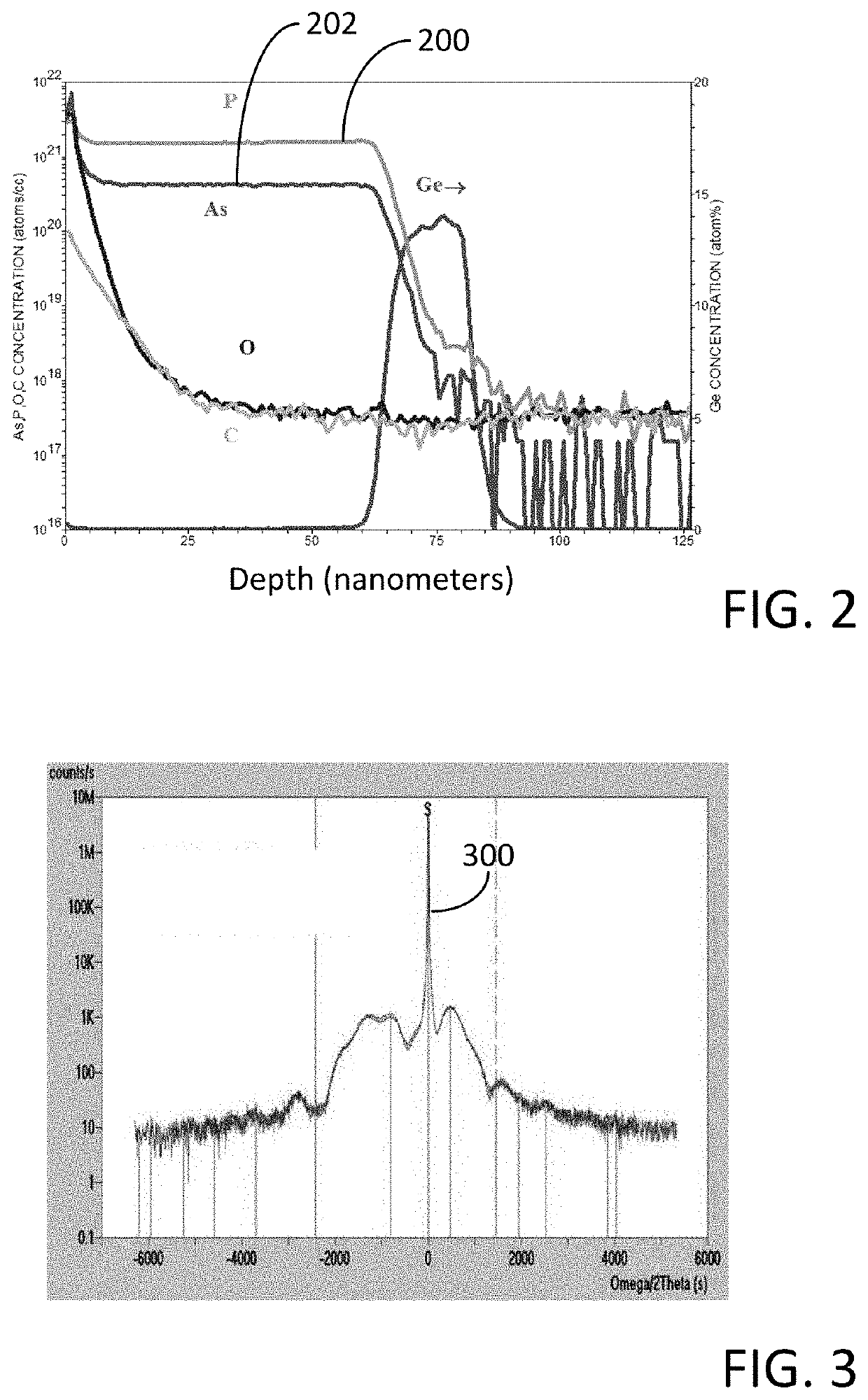

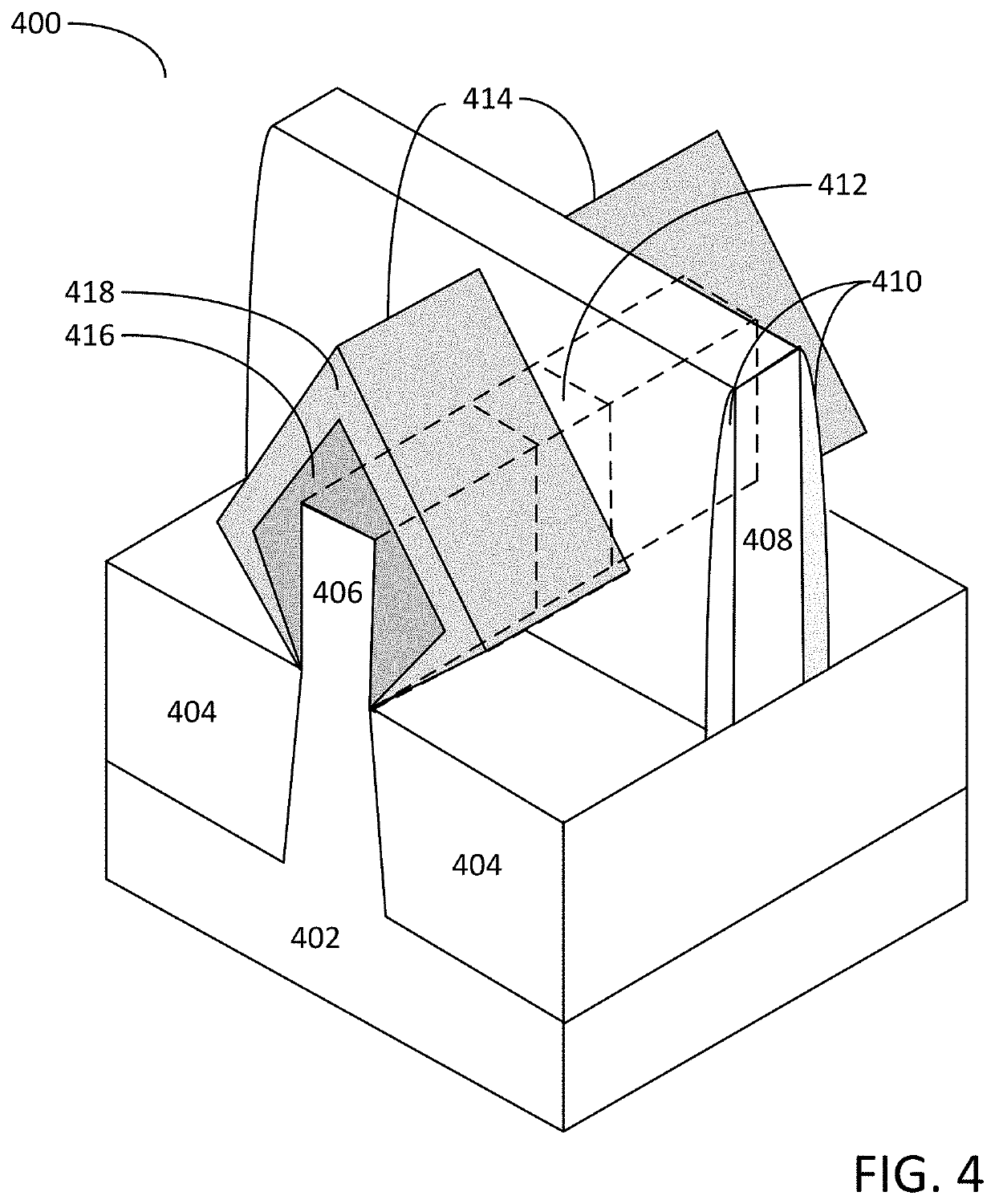

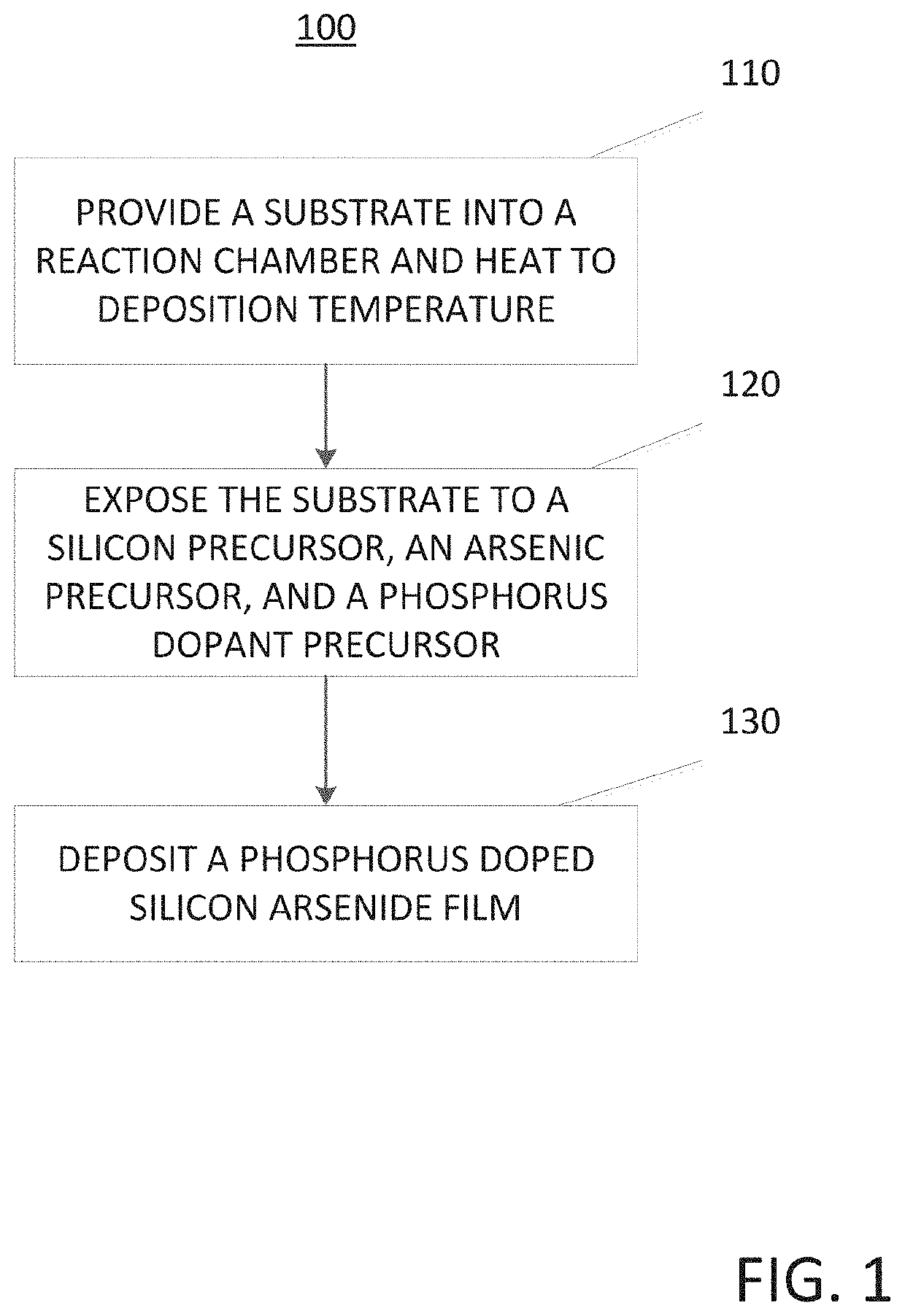

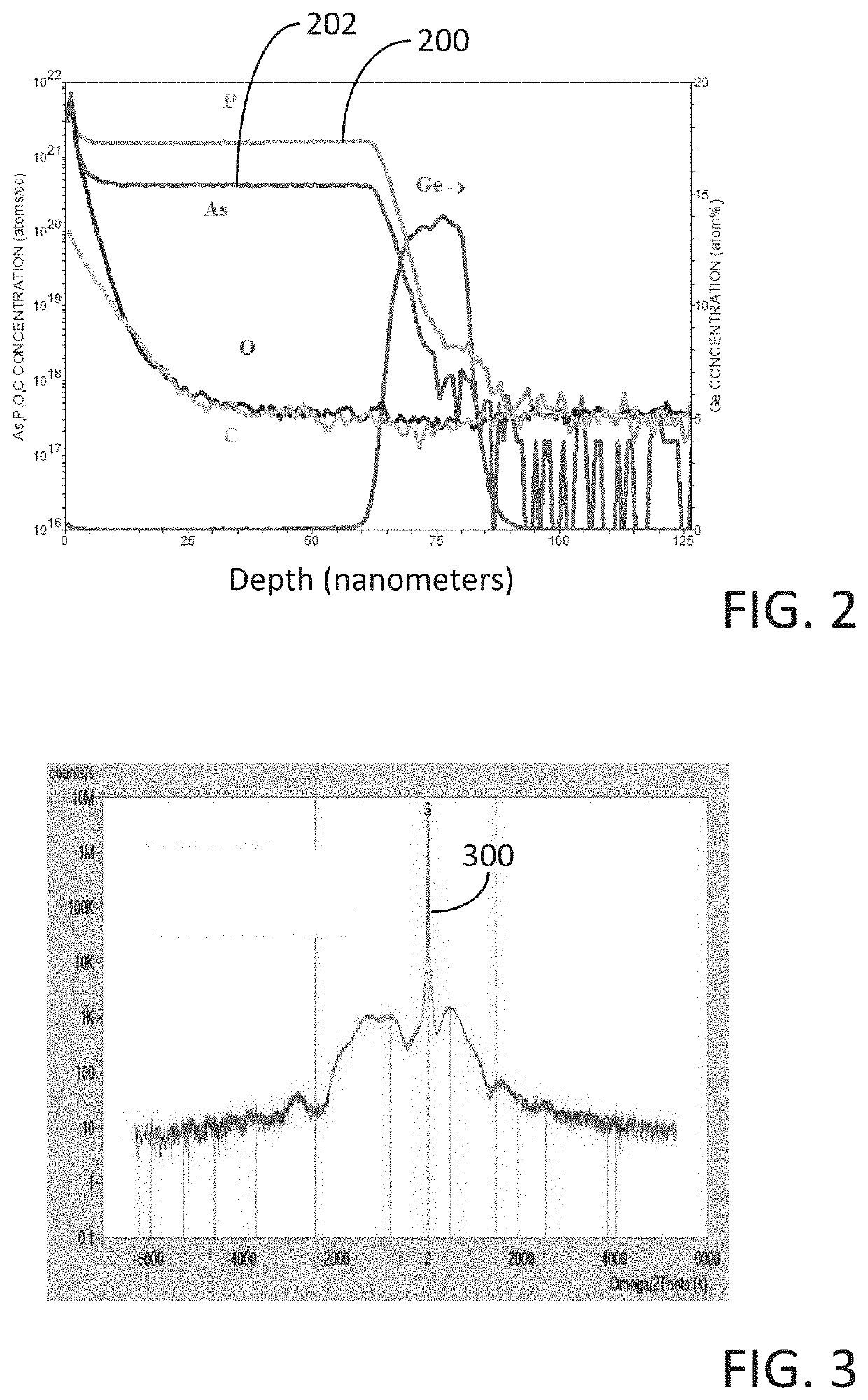

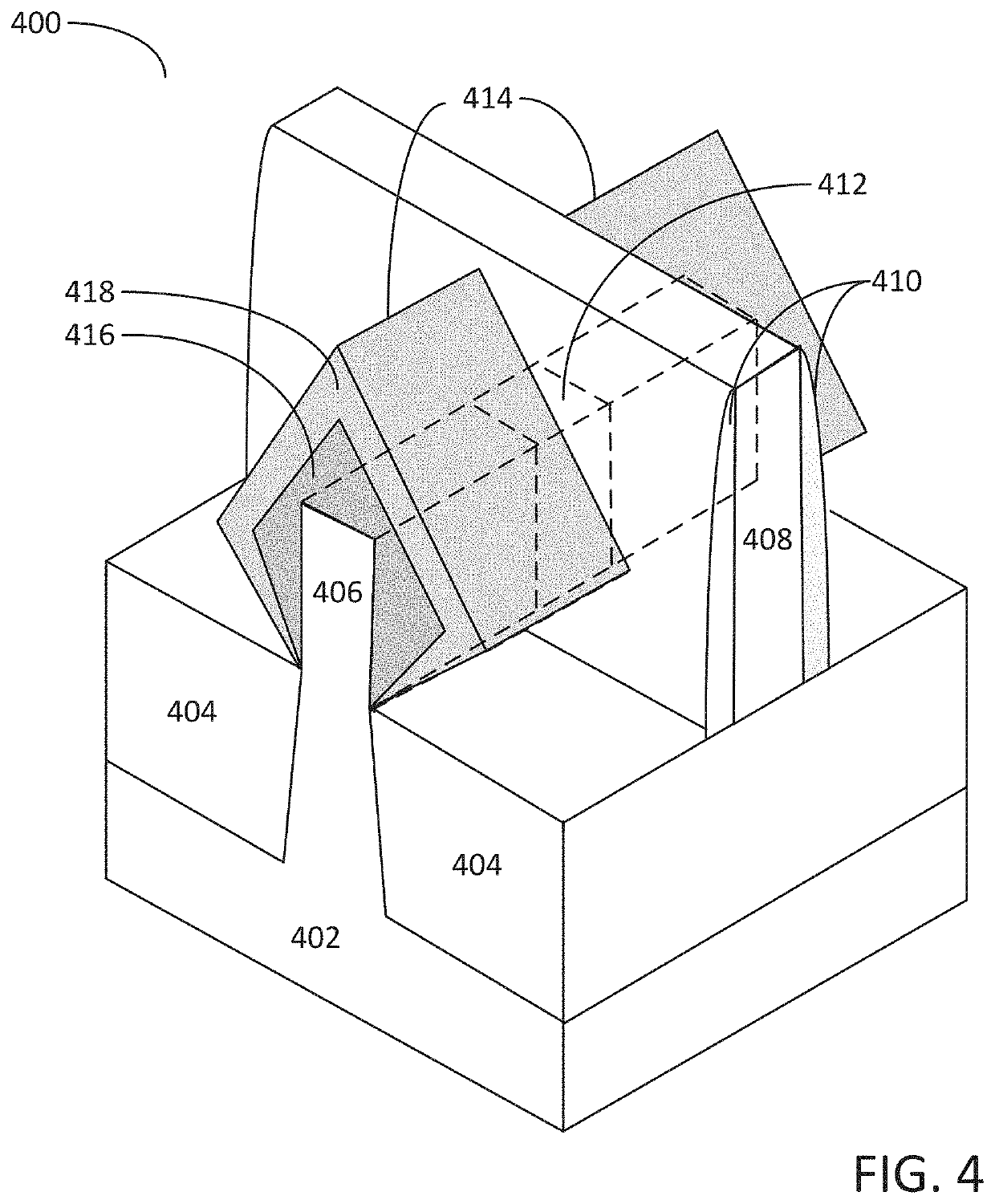

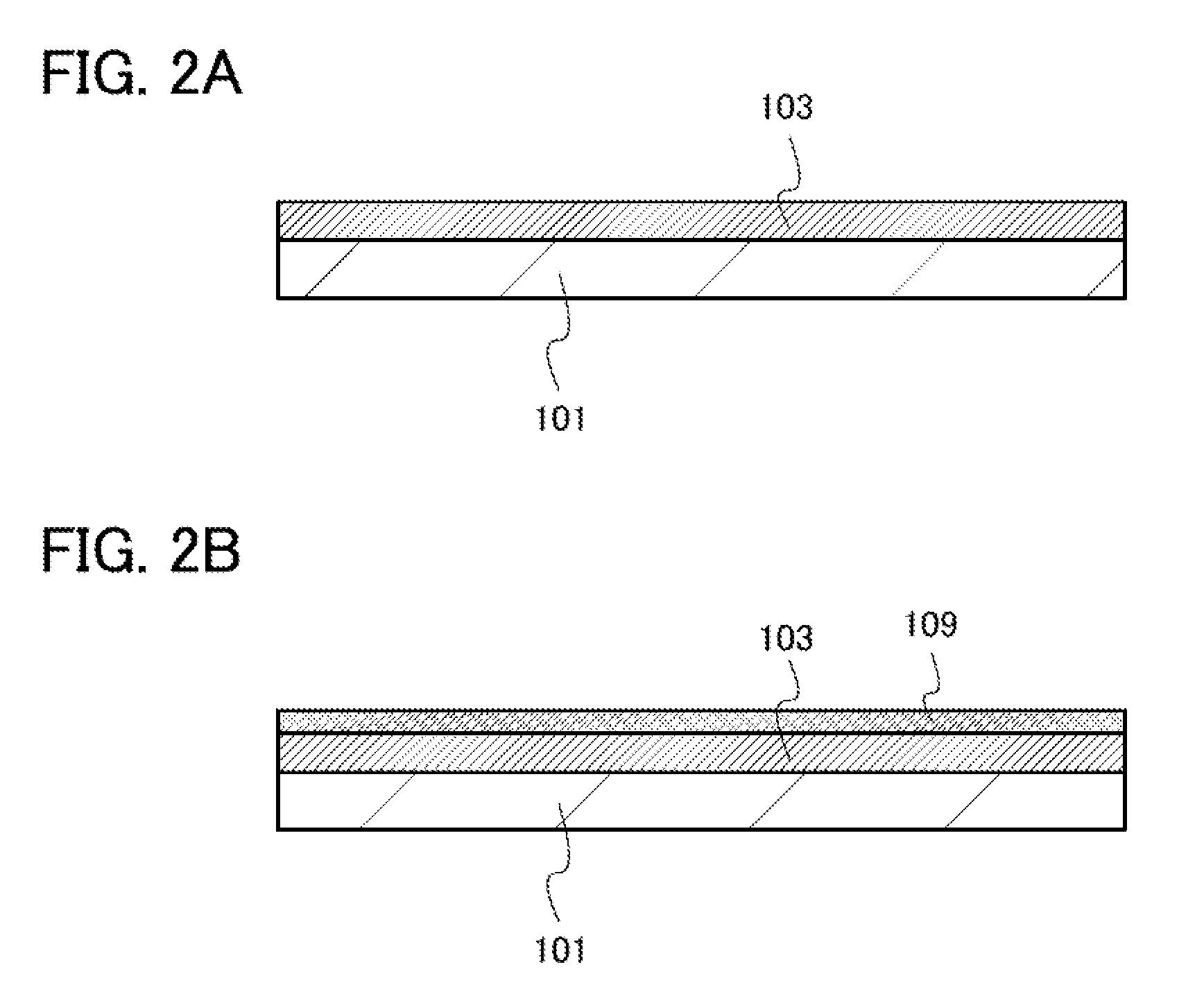

ActiveUS20190393308A1Inhibited DiffusionTransistorPolycrystalline material growthDopantDeposition temperature

A method for depositing a phosphorus doped silicon arsenide film is disclosed. The method may include, providing a substrate within a reaction chamber, heating the substrate to a deposition temperature, exposing the substrate to a silicon precursor, an arsenic precursor, and a phosphorus dopant precursor, and depositing the phosphorus doped silicon arsenide film over a surface of the substrate. Semiconductor device structures including a phosphorus doped silicon arsenide film deposited by the methods of the disclosure are also provided.

Owner:ASM IP HLDG BV

Method for depositing a phosphorus doped silicon arsenide film and related semiconductor device structures

ActiveUS20200395444A1Inhibited DiffusionTransistorPolycrystalline material growthDevice materialSilicon thin film

A method for depositing a phosphorus doped silicon arsenide film is disclosed. The method may include, providing a substrate within a reaction chamber, heating the substrate to a deposition temperature, exposing the substrate to a silicon precursor, an arsenic precursor, and a phosphorus dopant precursor, and depositing the phosphorus doped silicon arsenide film over a surface of the substrate. Semiconductor device structures including a phosphorus doped silicon arsenide film deposited by the methods of the disclosure are also provided.

Owner:ASM IP HLDG BV

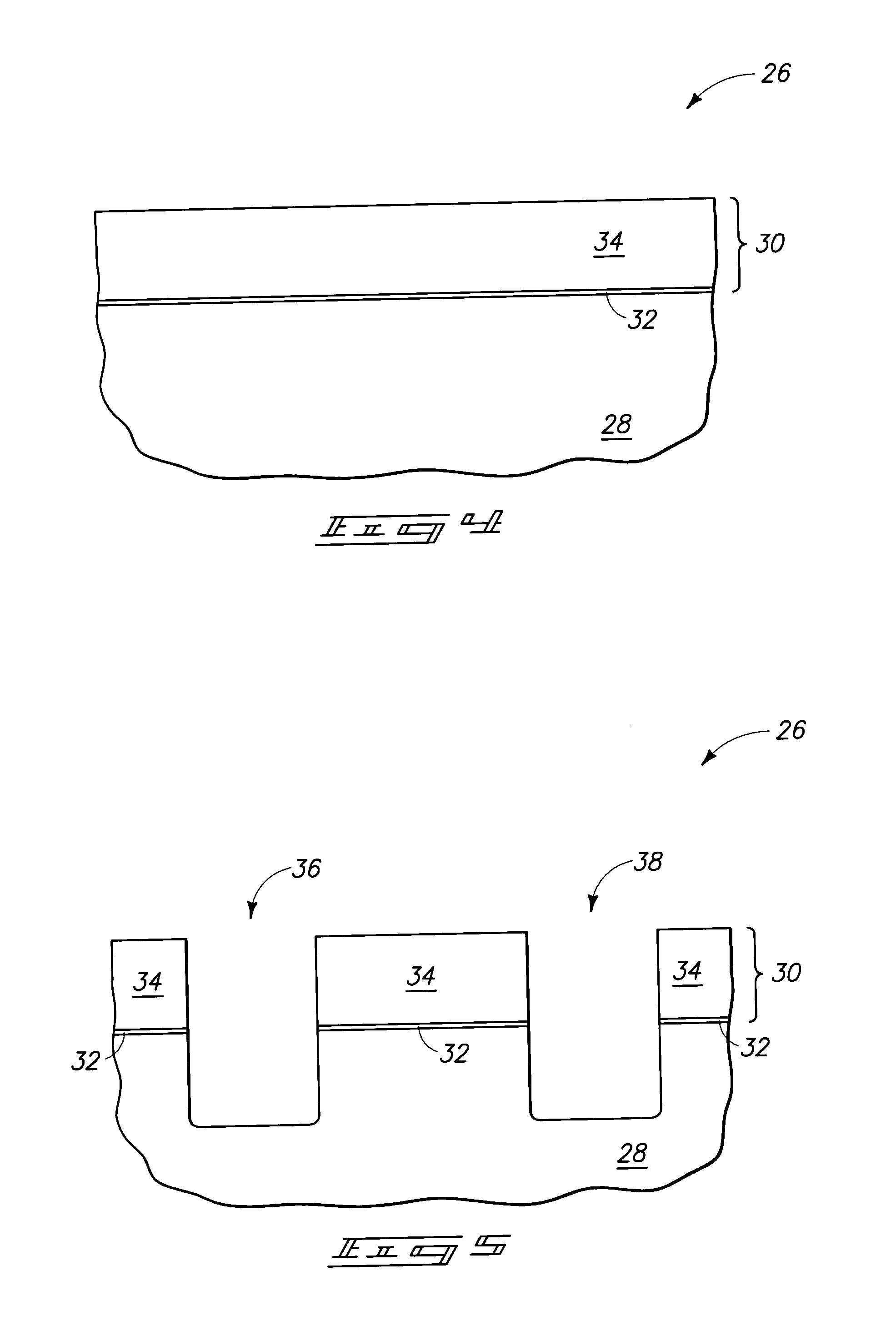

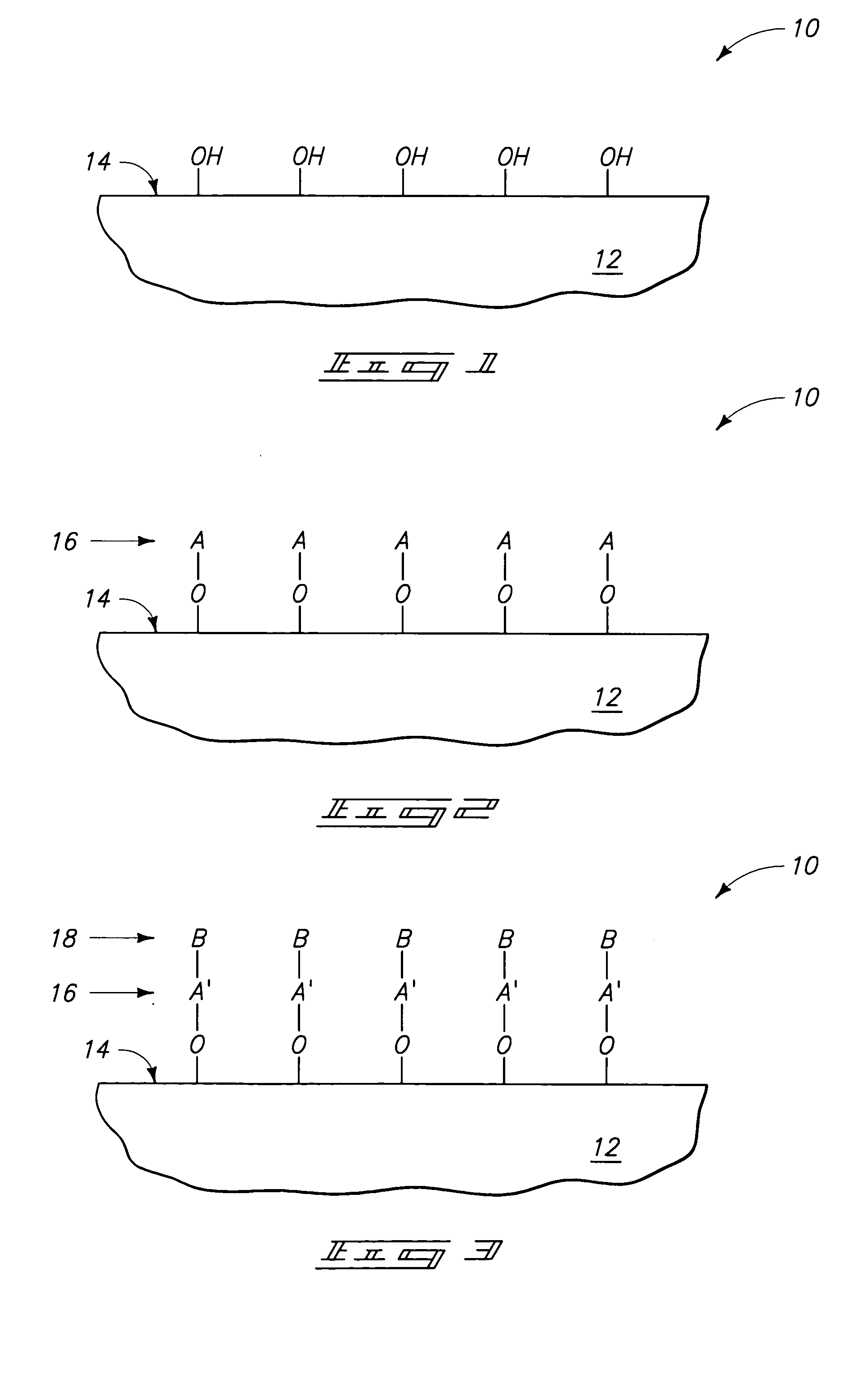

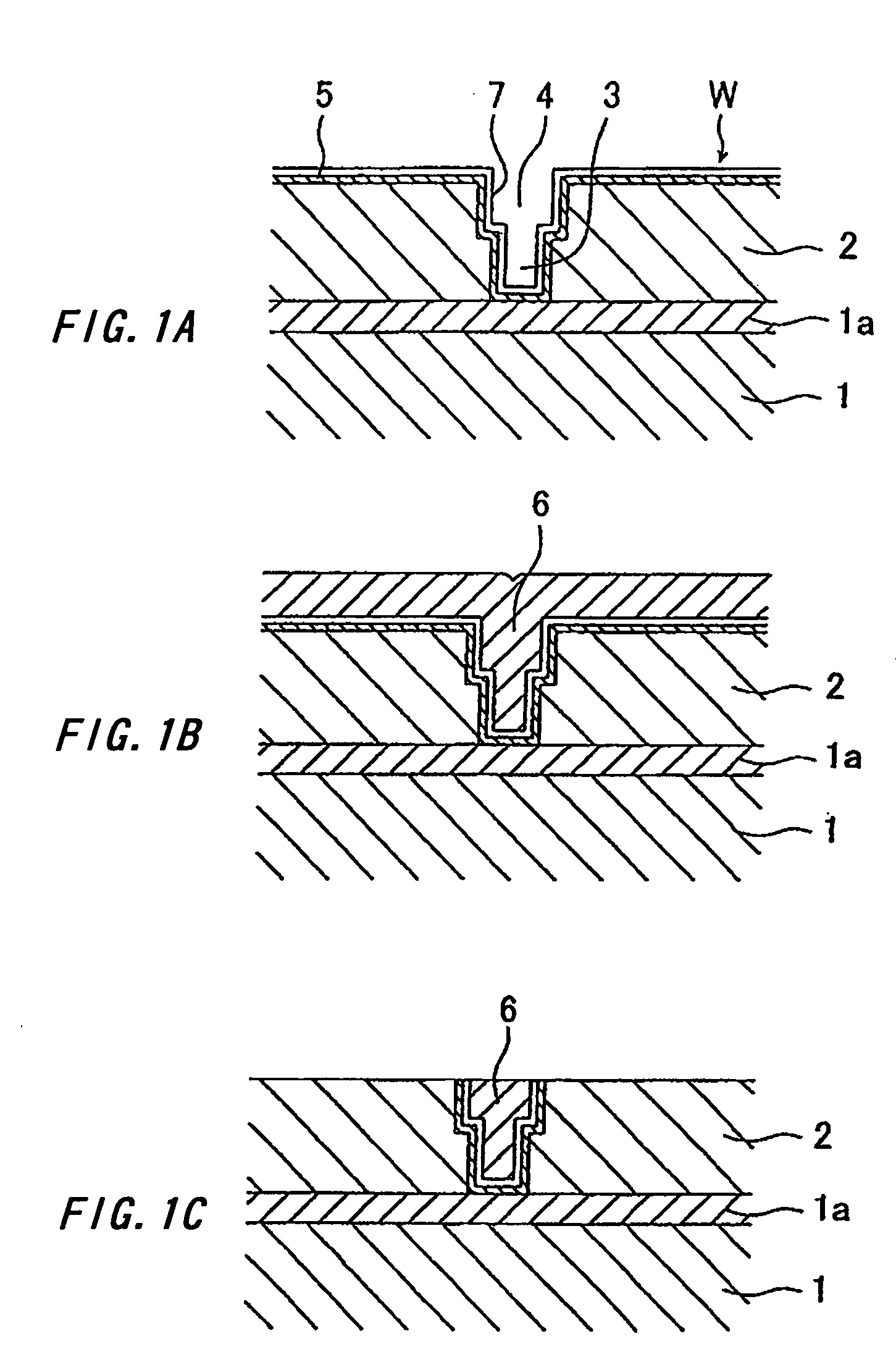

Methods of forming a phosphorus doped silicon dioxide comprising layer, and methods of forming trench isolation in the fabrication of integrated circuitry

ActiveUS20050009368A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilicon dioxide

This invention includes methods of forming a phosphorus doped silicon dioxide comprising layers, and methods of forming trench isolation in the fabrication of integrated circuitry. In one implementation, a method of forming a phosphorus doped silicon dioxide comprising layer includes positioning a substrate within a deposition chamber. First and second vapor phase reactants are introduced in alternate and temporally separated pulses to the substrate within the chamber in a plurality of deposition cycles under conditions effective to deposit a phosphorus doped silicon dioxide comprising layer on the substrate. One of the first and second vapor phase reactants is PO(OR)3 where R is hydrocarbyl, and an other of the first and second vapor phase reactants is Si(OR)3OH where R is hydrocarbyl.

Owner:MICRON TECH INC

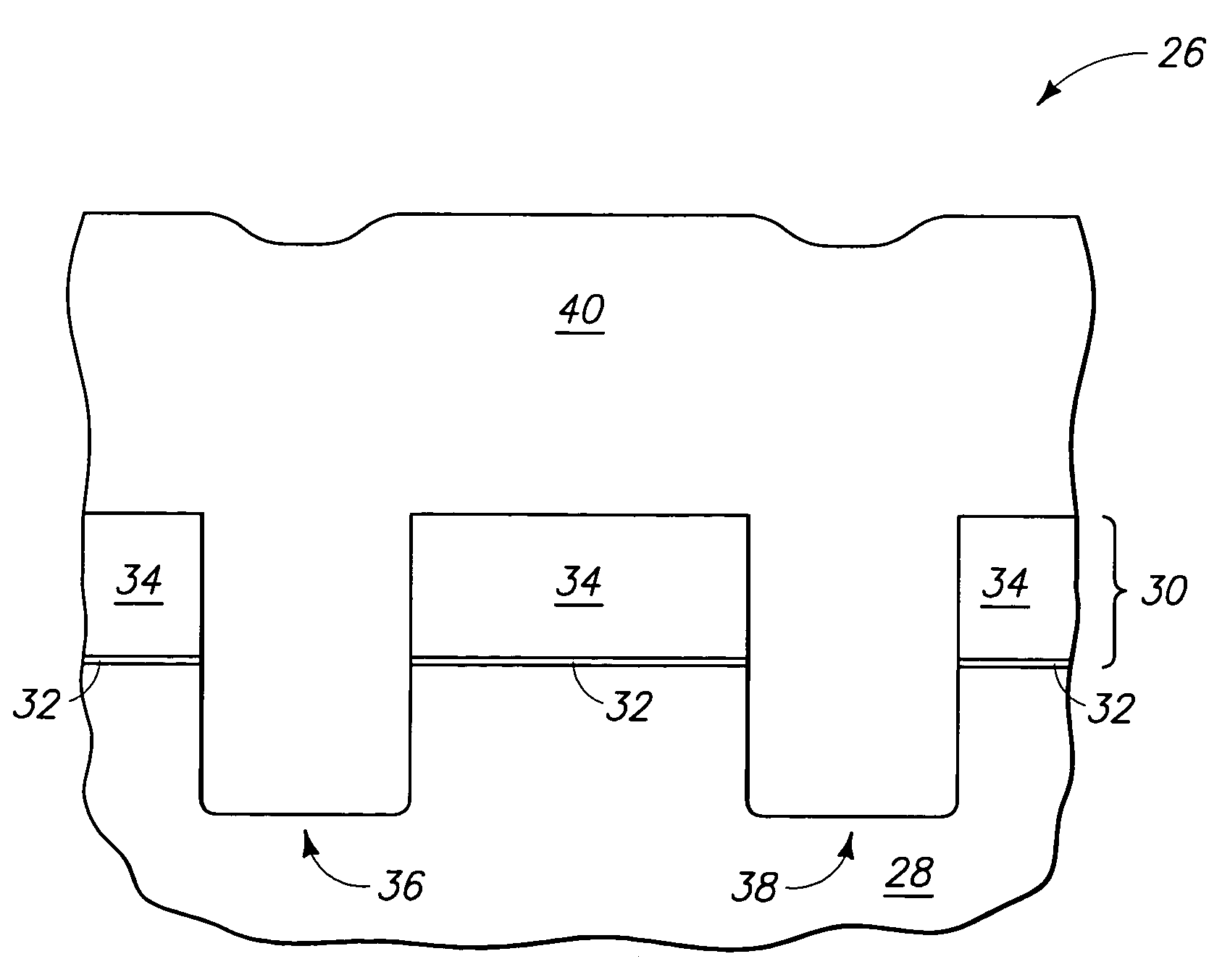

Method of forming trench isolation in the fabrication of integrated circuitry

InactiveUS20050124171A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilicon dioxide

This invention includes methods of forming a phosphorus doped silicon dioxide comprising layers, and methods of forming trench isolation in the fabrication of integrated circuitry. In one implementation, a method of forming a phosphorus doped silicon dioxide comprising layer includes positioning a substrate within a deposition chamber. First and second vapor phase reactants are introduced in alternate and temporally separated pulses to the substrate within the chamber in a plurality of deposition cycles under conditions effective to deposit a phosphorus doped silicon dioxide comprising layer on the substrate. One of the first and second vapor phase reactants is PO(OR)3 where R is hydrocarbyl, and an other of the first and second vapor phase reactants is Si(OR)3OH where R is hydrocarbyl.

Owner:MICRON TECH INC

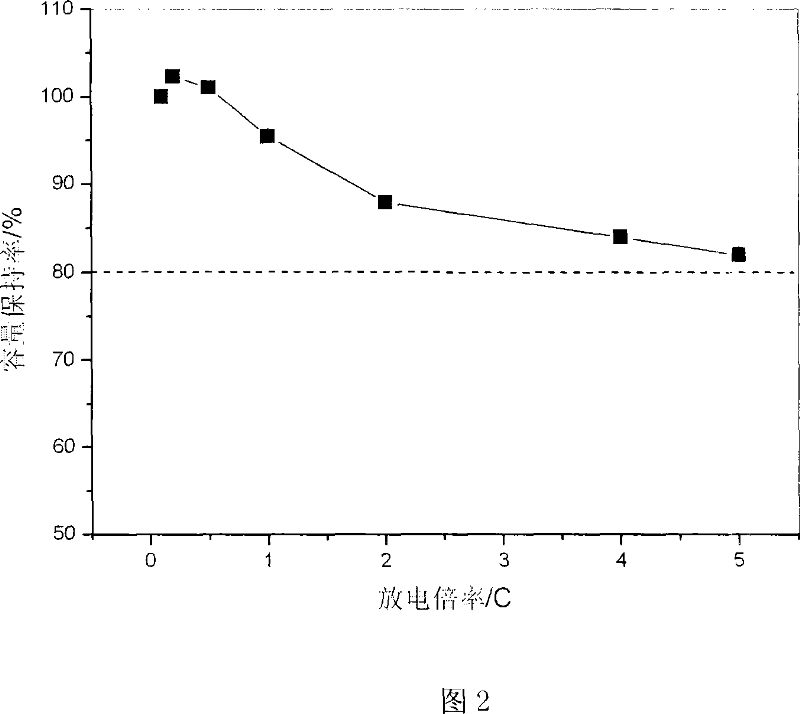

Negative electrode material, making method, lithium ion secondary battery, and electrochemical capacitor

InactiveUS20100009261A1Improved in rate and cycle propertySimple preparation processElectrode thermal treatmentHybrid capacitor electrodesSilicon oxideSilicon dioxide

Particles of a silicon oxide of formula: SiOx wherein x is 0.5 to 1.6, a silicon composite comprising silicon dispersed in silicon dioxide and having a molar ratio Si / O from 1:0.5 to 1:1.6, or a mixture thereof are doped with 50-100,000 ppm of phosphorus. A negative electrode material comprising the phosphorus-doped particles is suited for use in non-aqueous electrolyte secondary batteries. A lithium ion secondary battery having satisfactory cycle and rate properties is obtainable.

Owner:SHIN ETSU CHEM IND CO LTD

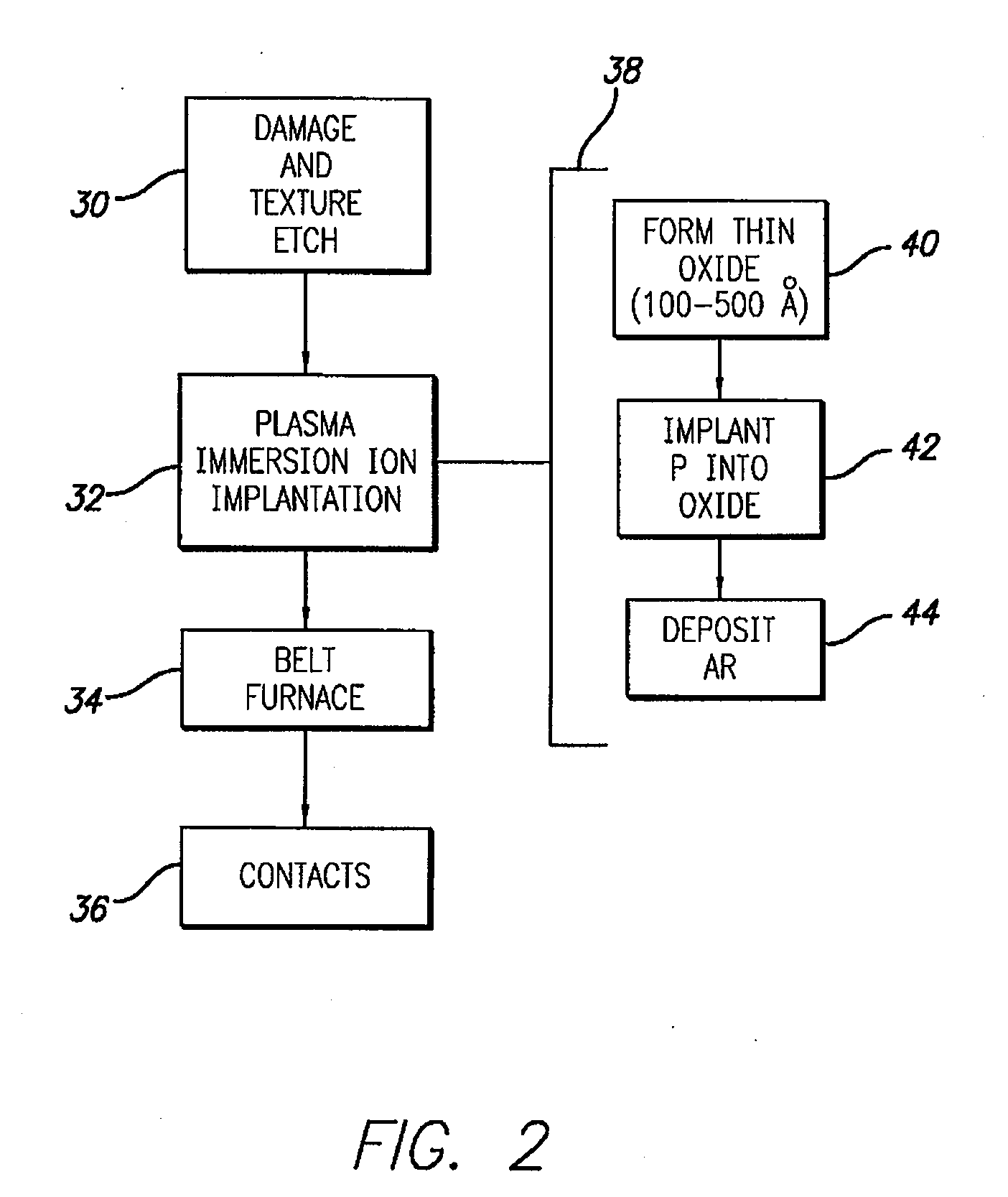

Method of making an improved selective emitter for silicon solar cells

InactiveUS20090142875A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationPlasma-immersion ion implantationSilicon solar cell

A method for forming a selective emitter on a silicon solar cell is provided including forming an oxide layer on a surface of the P-type silicon substrate, implanting phosphorus doping atoms into the oxide layer on the substrate using plasma immersion ion implantation, patterning the oxide layer, annealing the substrate to provide heavily doped regions in the patterned regions and a lightly doped region between the patterned regions, and providing metal contacts to the heavily doped regions.

Owner:APPLIED MATERIALS INC

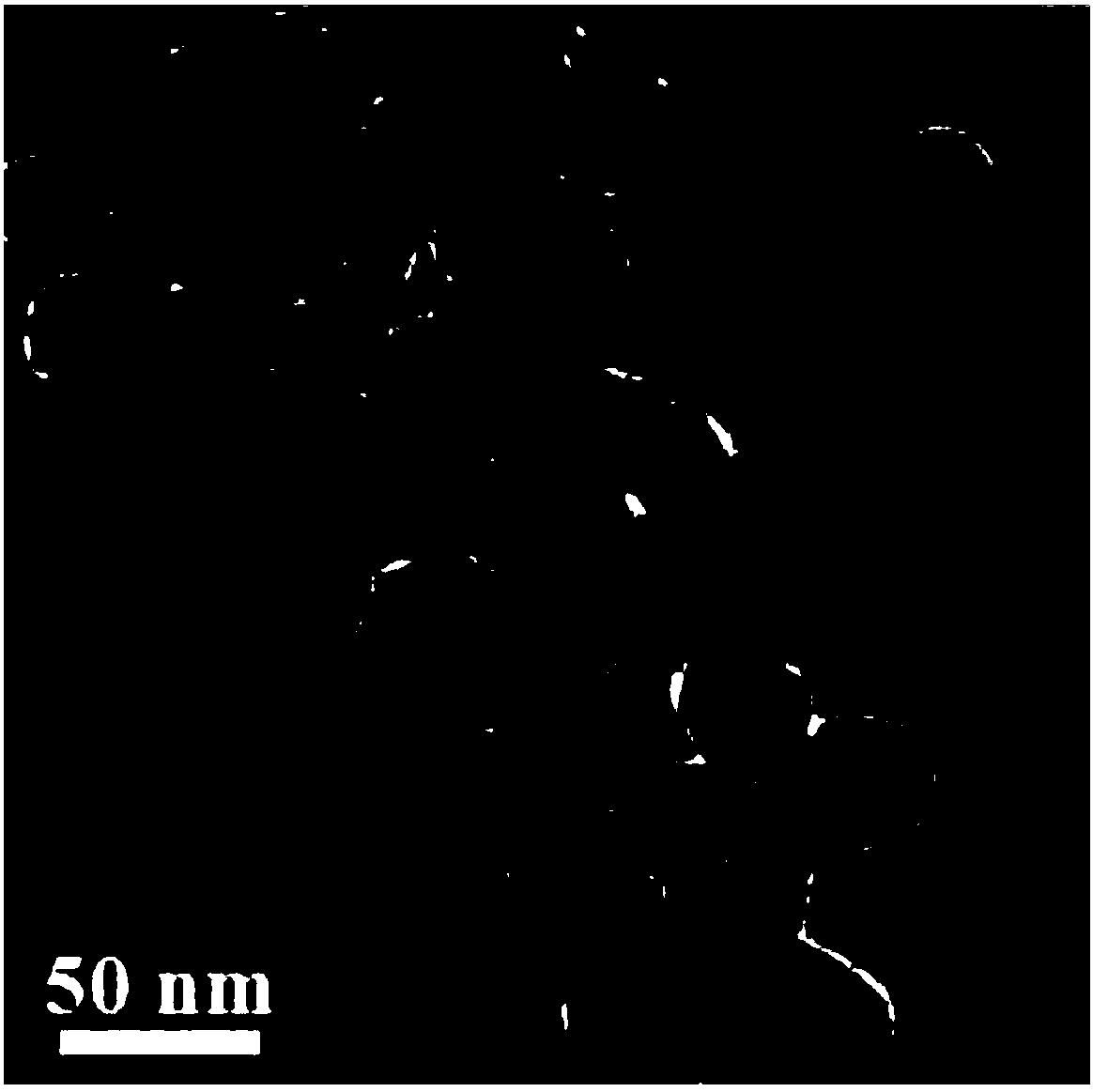

Phosphorus-doped nickel cobalt sulfide/carbon nanotube-carbon nanofiber composite material and preparation method thereof

InactiveCN106076377AEasy to makeEasy to operatePhysical/chemical process catalystsElectrodesFiberNew energy

The invention belongs to the technical field of transitional-metal sulfide-carbon materials, and concretely relates to a phosphorus-doped nickel cobalt sulfide / carbon nanotube-carbon nanofiber composite material and a preparation method thereof. The preparation method comprises preparing carbon nanotube-doped carbon nanofiber through electrostatic spinning and high-temperature carbonization, then growing nickel cobalt sulfide nanorod in situ through a hydrothermal process, and finally calcining a phosphorus-containing precursor at a high temperature in an atmosphere of an inert gas, so as to prepare the phosphorus-doped composite material. The prepared carbon nanofiber possesses relatively large specific surface area, and the electric conductivity is effectively enhanced by doping carbon nanotube. By taking the carbon naofiber as a substrate, nickel cobalt sulfide nanorod uniformly densely grows on the surface of the composite fiber, and the synergistic effect of various substances is fully displayed. By doping phosphorus, the electrochemical activity of the composite material is further improved. The prepared phosphorus-doped nickel cobalt sulfide / carbon nanotube-carbon nanofiber composite material is applicable as a high-performance electro-catalytic material and an electrode material of lithium ion battery, solar cells and other new-energy-source devices.

Owner:FUDAN UNIV

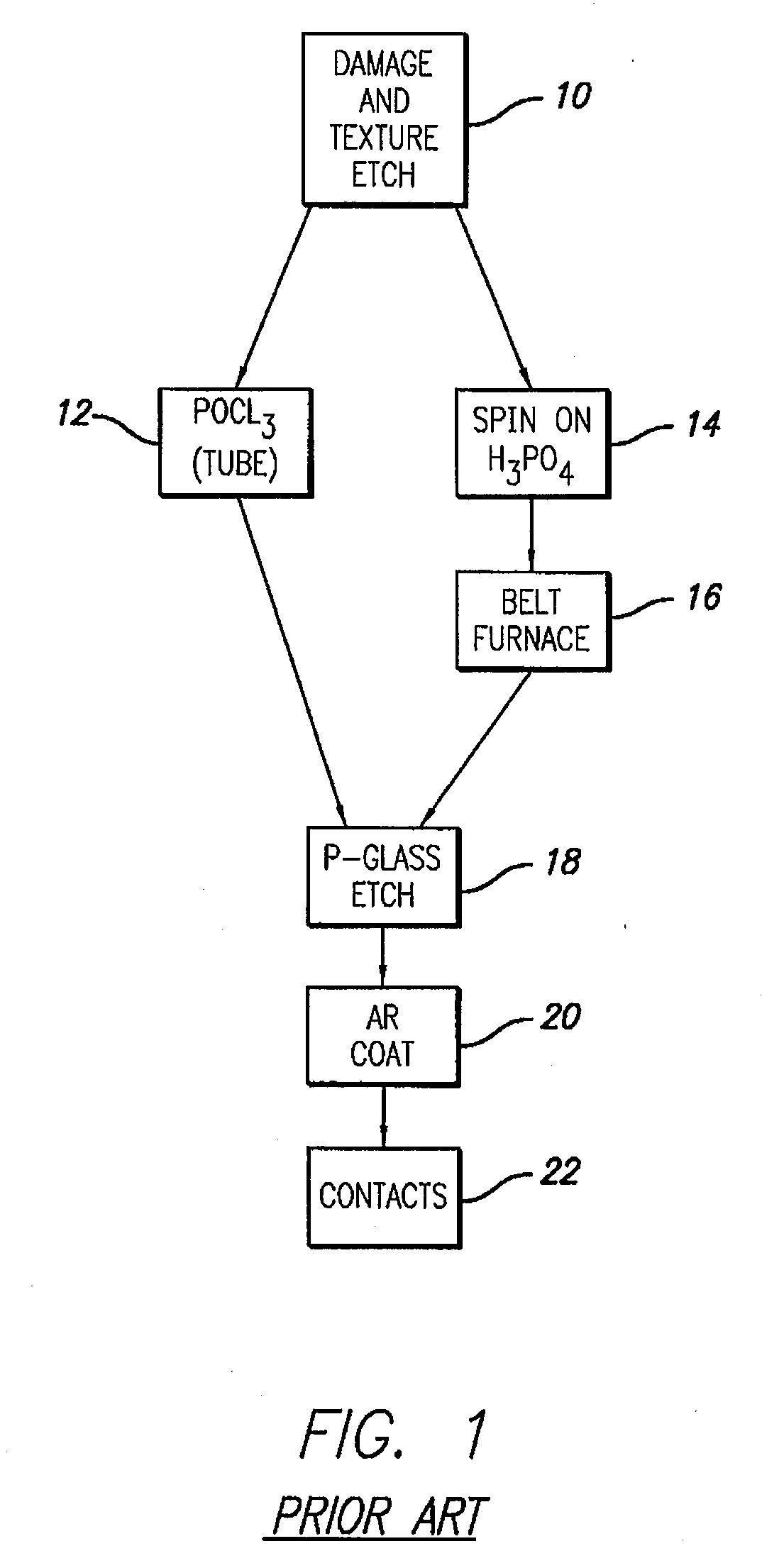

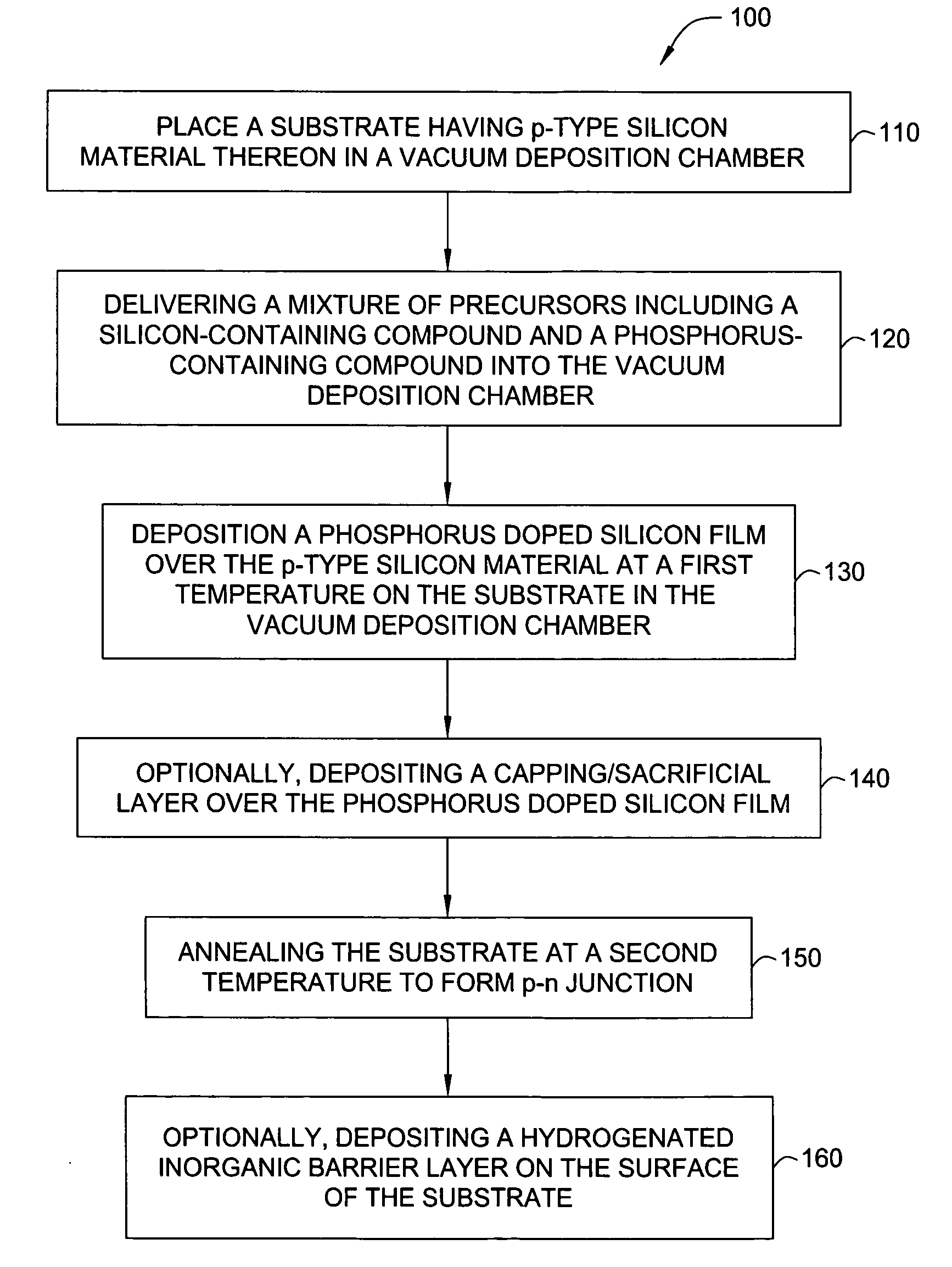

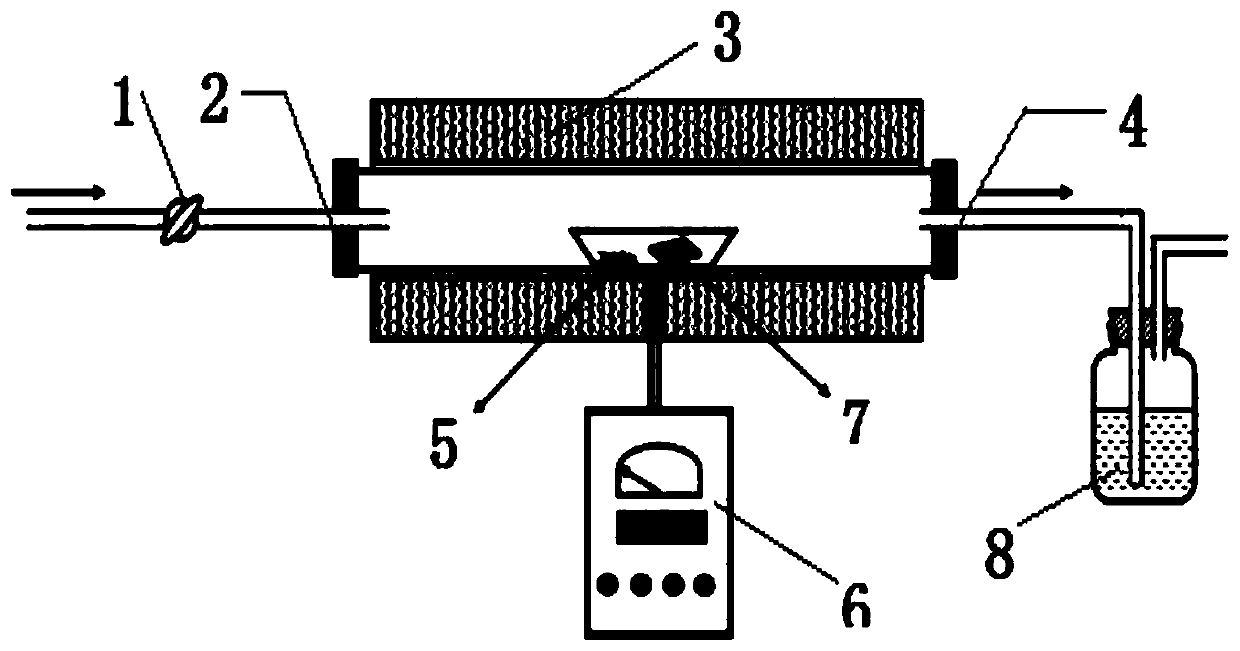

Silicon photovoltaic cell junction formed from thin film doping source

A method and apparatus for fabricating a solar cell and forming a p-n junction is disclosed. Solar cell p-n junction is formed by depositing a thin film of n-type phosphorus doped silicon material on a sheet from a mixture of precursors and annealing the sheet to obtain the p-n junction at a desired depth. In one embodiment, a plasma enhanced chemical vapor deposition chambers is used to deposit a phosphorus doped amorphous silicon film on a sheet surface by using precursors including a silicon-containing gas, a hydrogen-containing precursor, and a phosphorus-containing gas. In another embodiment, annealing furnace and / or rapid thermal processing chambers are used to anneal the sheet having the phosphorus doped amorphous silicon film deposited thereon.

Owner:APPLIED MATERIALS INC

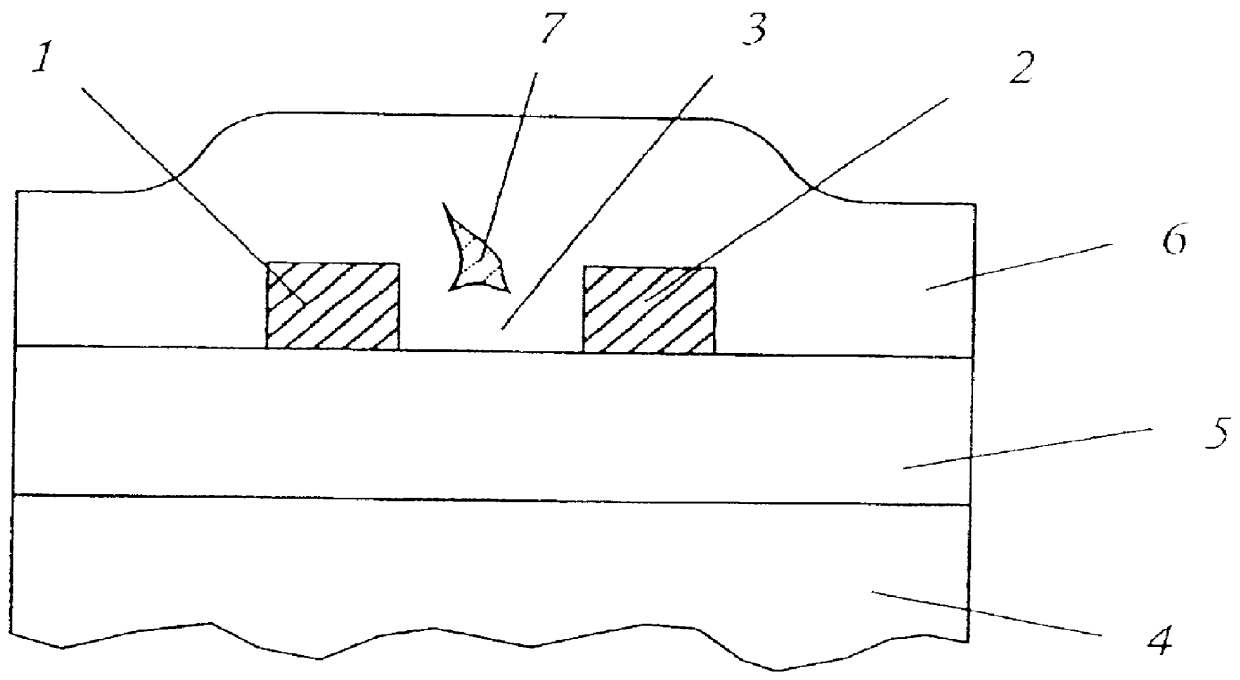

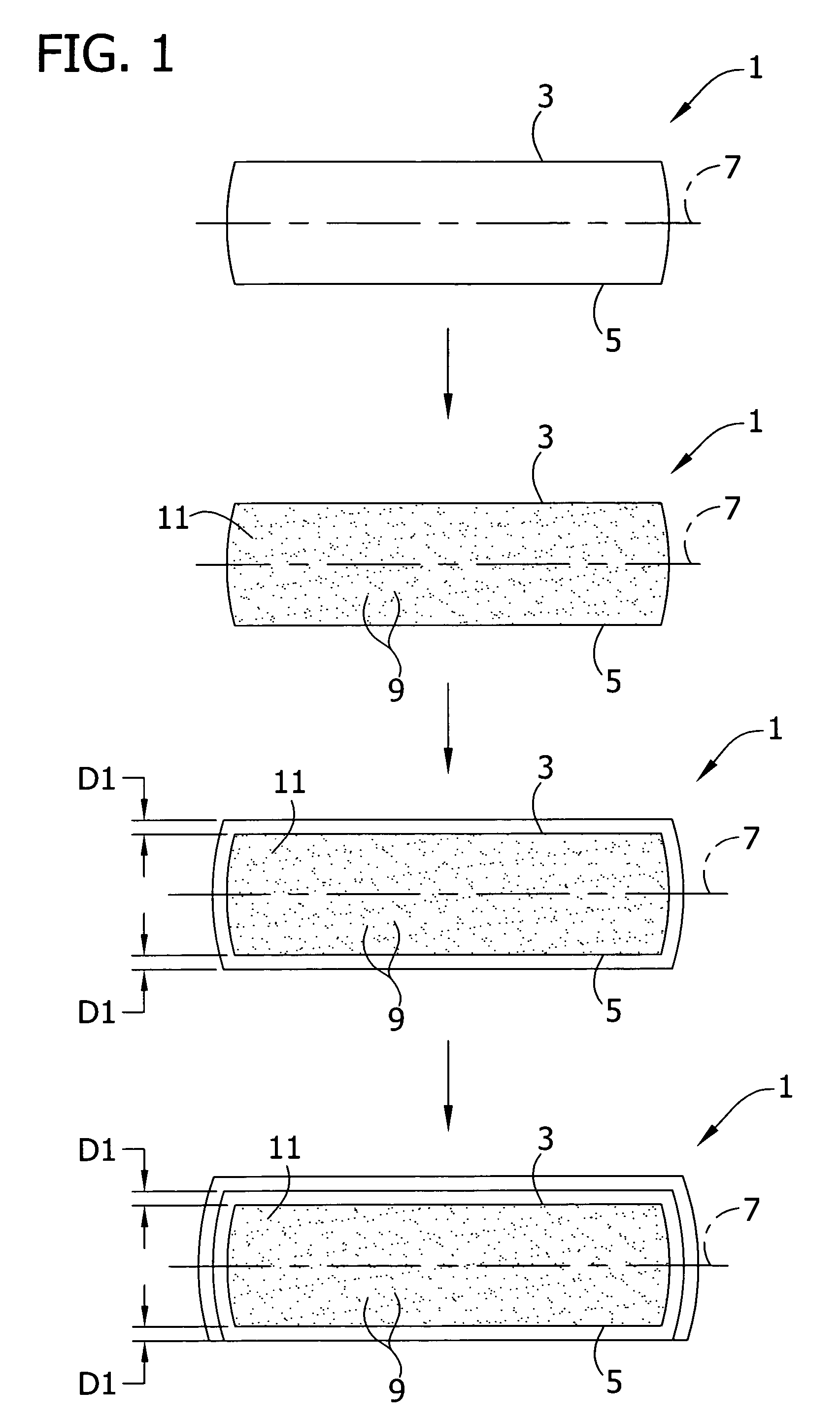

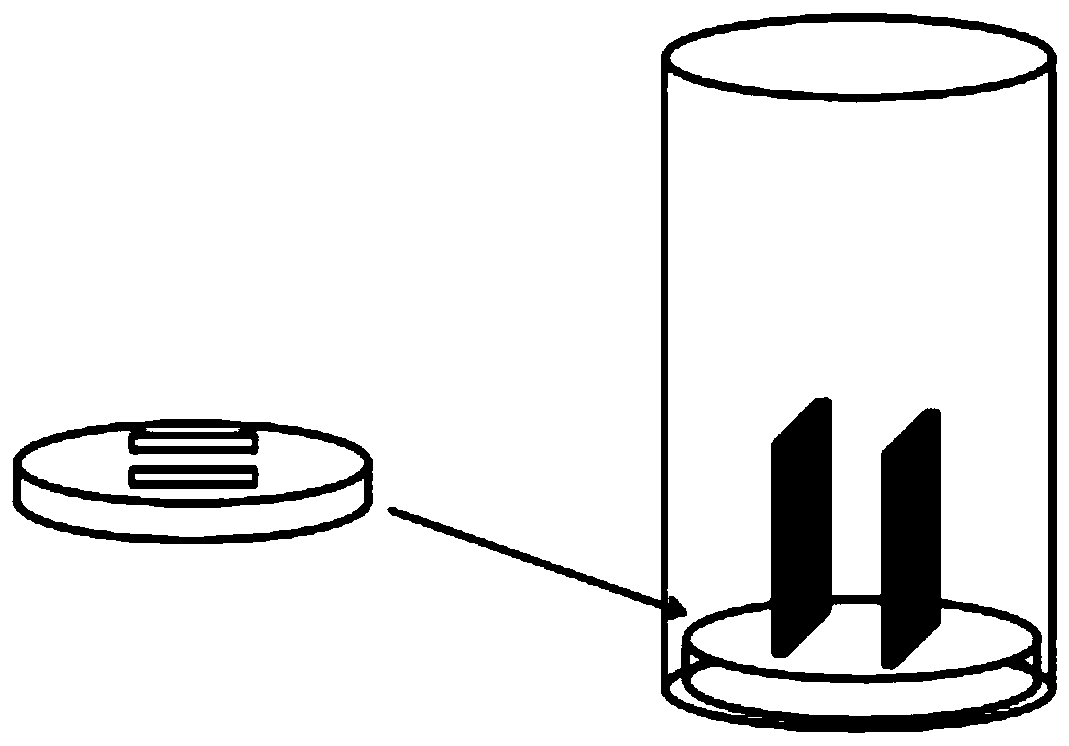

Waveguide pair with cladding

PCT No. PCT / GB97 / 00040 Sec. 371 Date Apr. 12, 1999 Sec. 102(e) Date Apr. 12, 1999 PCT Filed Jan. 8, 1997 PCT Pub. No. WO97 / 25636 PCT Pub. Date Jul. 17, 1997A planar waveguide structure has, supported on a lower refractive index buffer layer (5), a pair of optical cores (1, 2) that, over at least a portion of their length, are closely spaced. These cores are covered with a layer (6) of cladding material comprising boron and phosphorus doped silica glass deposited by PECVD as a succession of individually annealed layers in order to minimize the incidence of voids in the deposit between the cores.

Owner:NORTEL NETWORKS UK +1

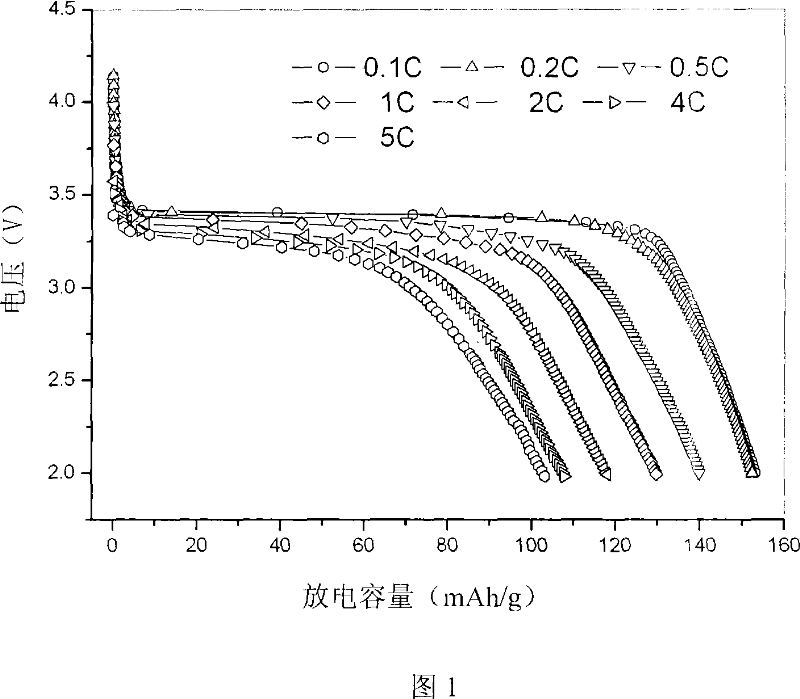

LiFePO4 cathode material based on P site doped and preparation method thereof

InactiveCN101037195AImprove rate discharge performanceImprove discharge capacityCell electrodesPhosphorus compoundsPhosphateFiltration

Disclosed is a phosphorus-doped lithium iron phosphate positive electrode material and a preparation method of the same, which relates to a positive electrode materials of lithium ion batteries. The present invention provides a phosphorus-doped lithium iron phosphate positive electrode material of lithium ion batteries with higher charge-discharge capacity, excellent multiplying power performance and cycle performance, and a preparation method of the same. The positive electrode material has a formula of LiyFe(P1-xMx)O4, wherein M is doping element of Ge, Sn, Se, Te or Bi. The preparation method comprises the steps of mixing the ferrite and phosphate with dopant; adding at least one of the water, alcohol, acetone serving as ball mill solvent; scrubbing and filtrating after ball milling; vacuum drying the filtration product to obtain the intermediate product which is mixed with lithium salt; adding ball mill solvent to ball mill again; drying the product and then heating calcining in the presence of inert gas or reducing atmosphere to obtain doping type lithium iron phosphate LiyFe(P1-xMx)O4 powder.

Owner:XIAMEN UNIV

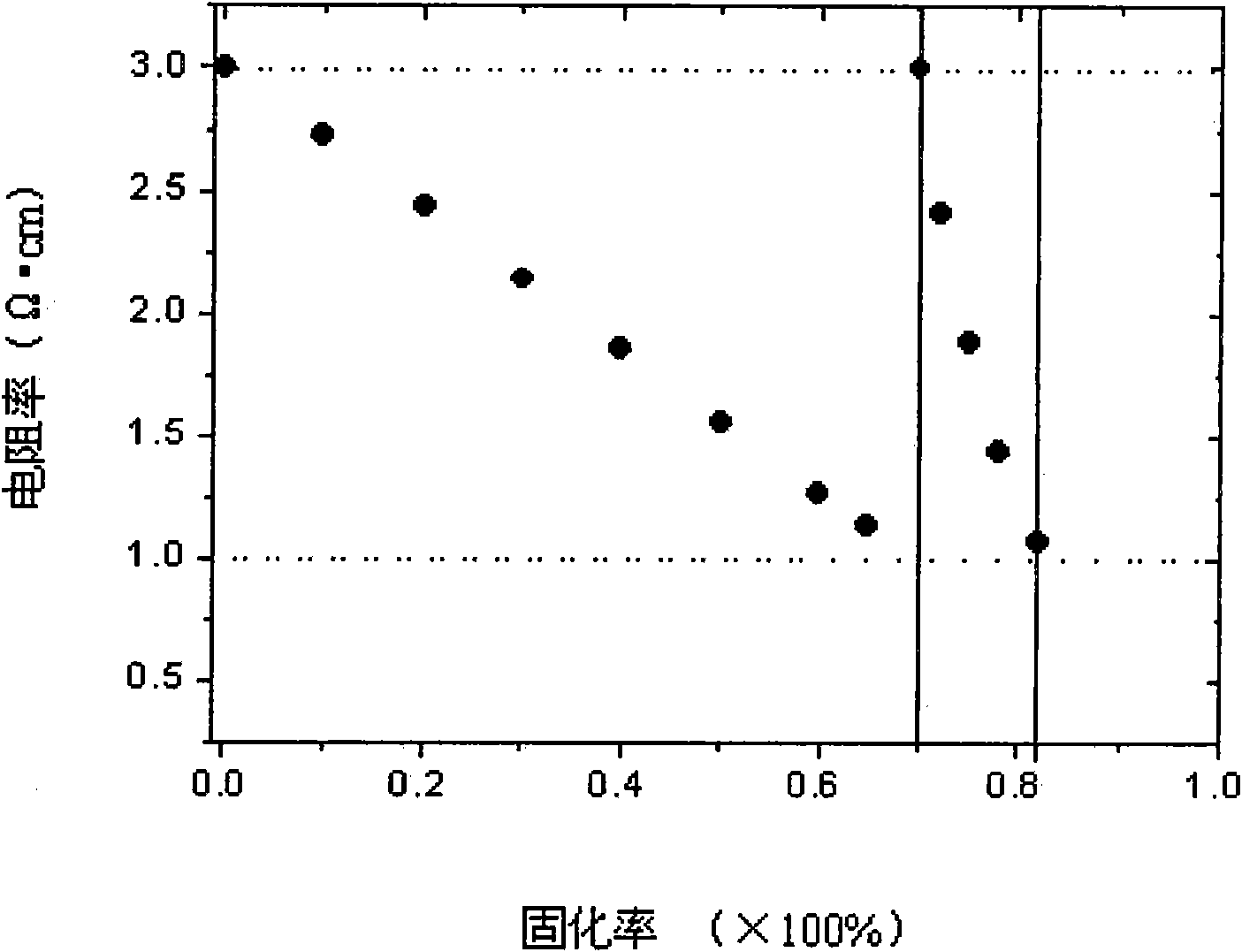

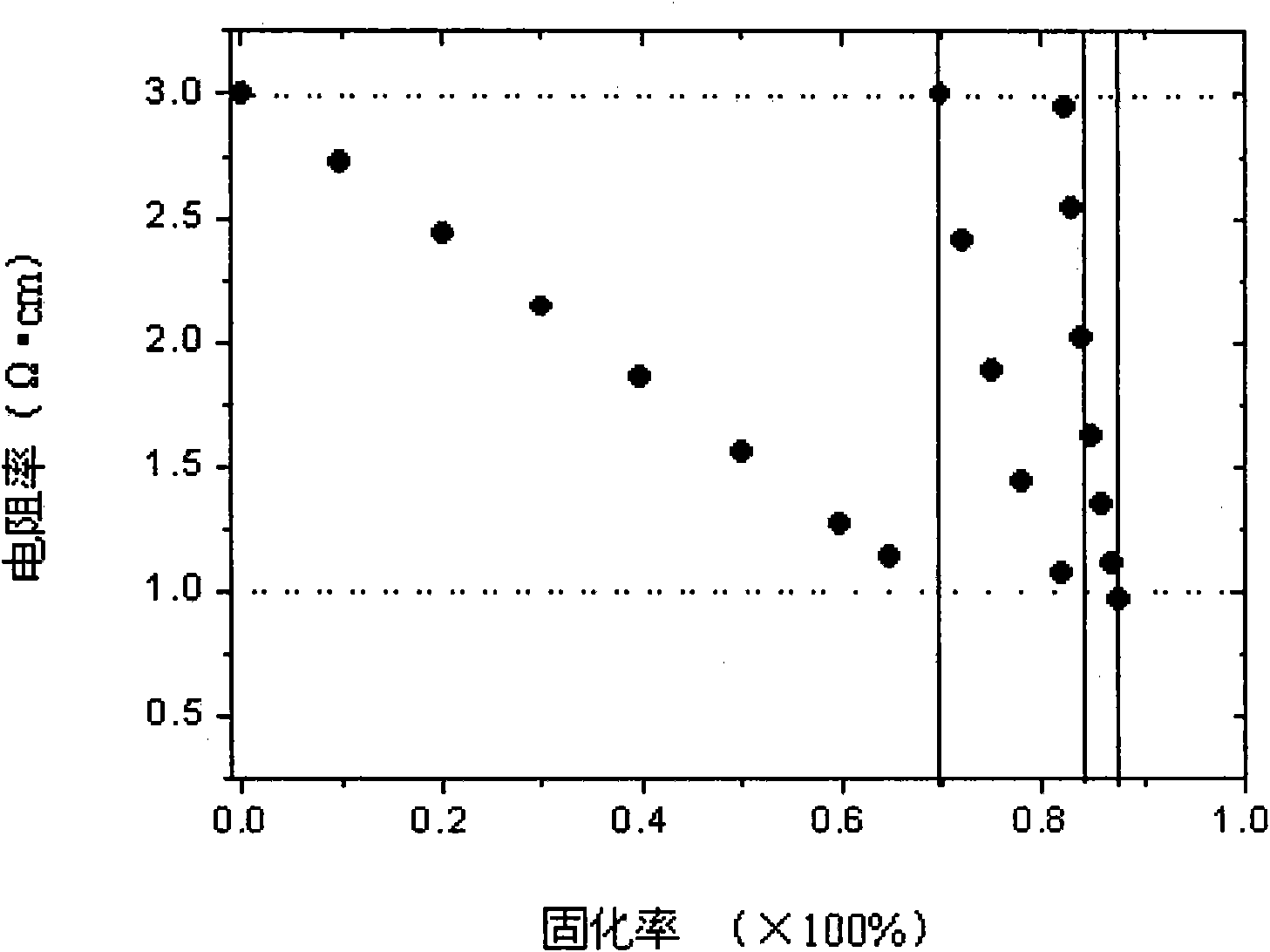

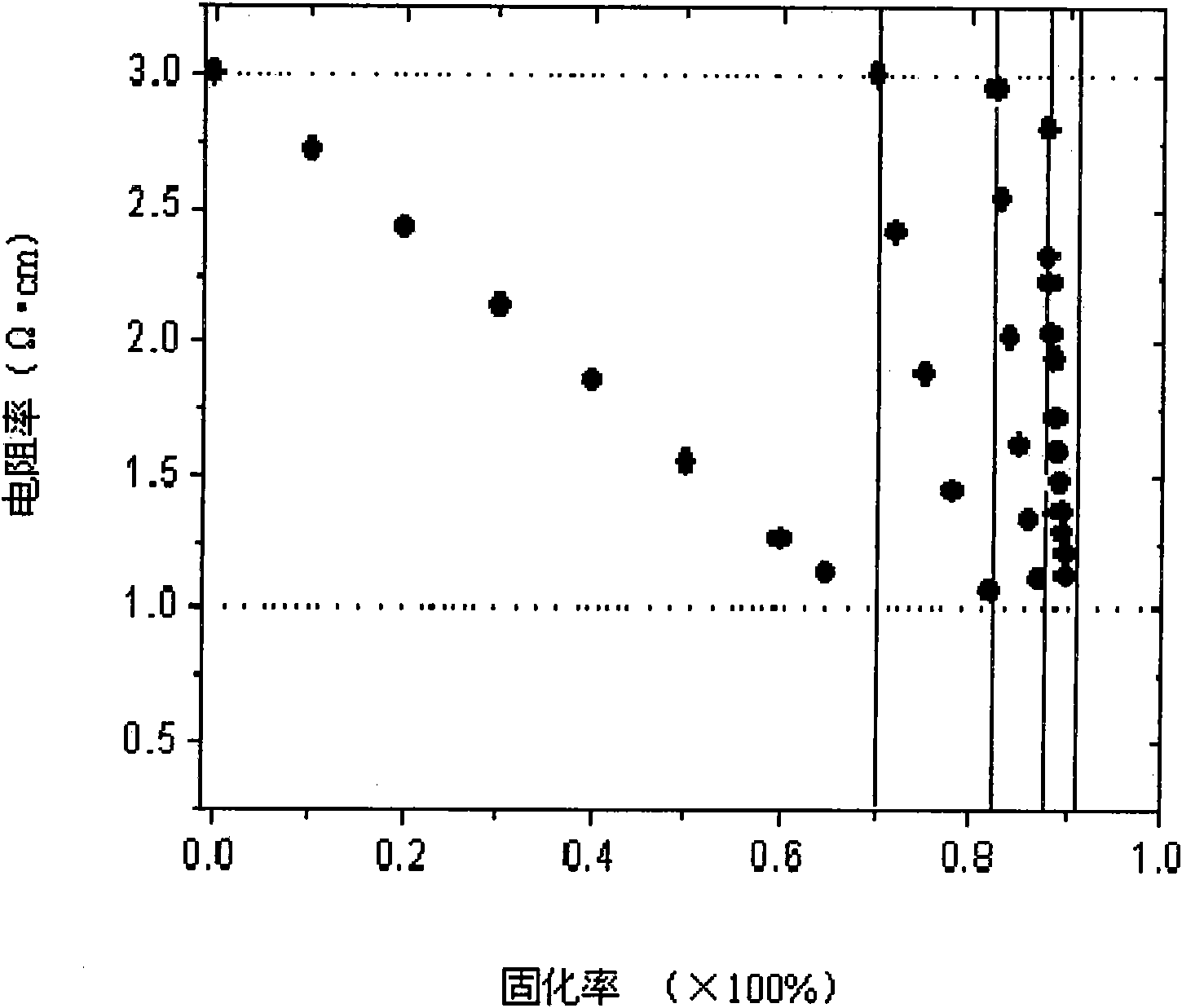

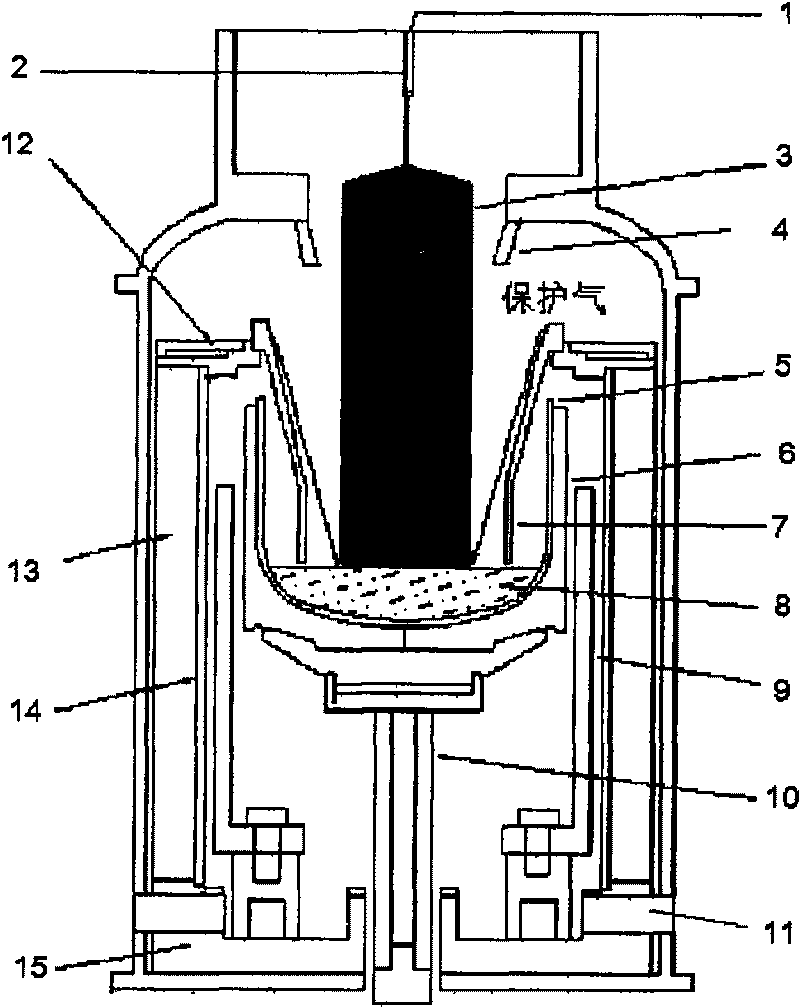

Method for controlling specific resistance of gallium-doped Czochralski silicon in crystal growth process

InactiveCN101654804AIncrease profitReduce manufacturing costBy pulling from meltDopantPhotovoltaic industry

The invention discloses a method for controlling the specific resistance of gallium-doping Czochralski silicon in the crystal growth process, which comprises the following steps: melting multi-crystalsilicon in vacuum or under the protection of argon, melting gallium in the silicon solution to form a gallium-doping silicon solution, and growing the single crystal of the Czochralski silicon; in the crystal growth process, when the specific resistance of the crystal is 1.2-1.0 omega cm, doping the n type dopant-phosphorus with certain concentration in the residual gallium-doping silicon solution to form a phosphorus and gallium-doped silicon solution for continuously growing, and enabling the specific resistance of the crystal to be regulated to 3.0 omega cm again; and when the curing ratioof the crystal reaches 80-90%, stopping the growth. The phosphorus doping process in the residual gallium-doped silicon solution can be carried out many times. The invention can control the specificresistance of the back half part of the single crystal of the gallium-doped Czochralski silicon in the range of 1-3 omega cm to be favorable for increasing the utilization ratio of silicon materials in the process of preparing high-efficiency solar batteries, thus the manufacturing cost of the high-efficiency batteries is greatly reduced, and the method has simple operation and can be easily applied to the photovoltaic industry in a large scale.

Owner:ZHEJIANG UNIV

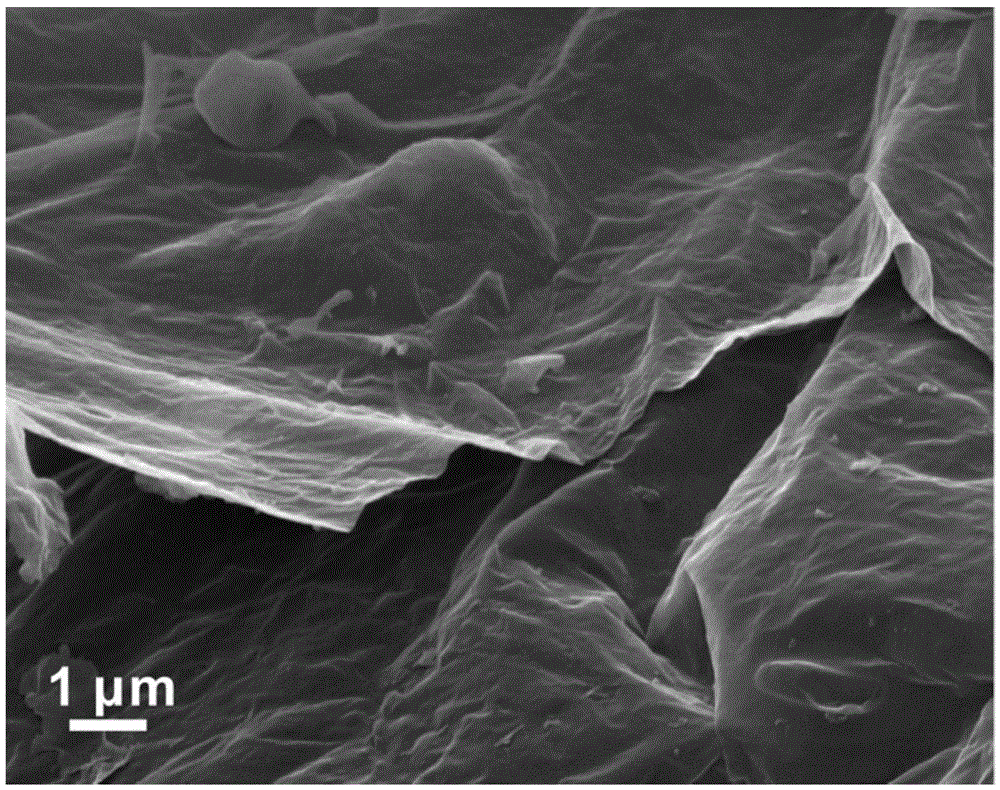

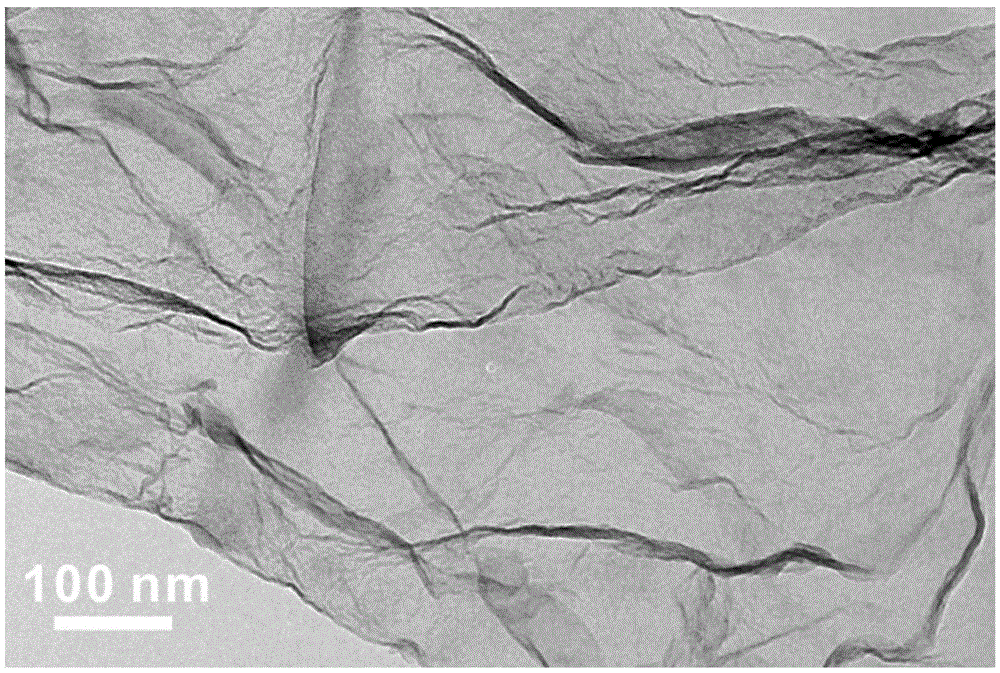

Method for preparing nitrogen and phosphorus codoped porous graphene material

The invention belongs to the field of preparation of nanometer materials, and provides a method for preparing a nitrogen and phosphorus codoped porous graphene material. The nitrogen and phosphorus codoped porous graphene material is prepared by taking phosphorus-containing polyion liquid microgel as a novel soft ball template and phosphorus-doped precursor, and ammonium hydroxide as a nitrogen source and another pore-forming agent. The prepared porous graphene material has a thin pore wall, large specific surface area and pore diameter, uniform and stable properties, and has potential application prospect in fields such as supercapacitors, security check and catalysis. According to the method, the source of raw materials is wide; the method is simple and easy to operate, is beneficial for mass production in large scale, and has good industrial production basis and wide application prospect.

Owner:FUDAN UNIV

Phosphorus doped graphene and preparation method thereof

The invention provides a preparation method for phosphorus doped graphene. The preparation method comprises the following steps: uniformly mixing graphite oxide and phosphorus pentoxide in a mass ratio of 1: 0.5-3 and placing an obtained mixture in a reactor; introducing protective gas into the reactor, wherein introduction flow velocity of the protective gas is 200 to 400 ml / min; heating the interior of the reactor to a temperature of 800 to 900 DEG C at a heating speed of 15 to 20 DEG C / min and maintaining the temperature for 30 min to 2 h; and cooling the reactor to room temperature in the protective gas with flow velocity of 200 to 400 ml / min so as to prepare the phosphorus doped graphene. According to the method, phosphorus pentoxide is used as a phosphorus source, the maximum doping amount of elemental phosphorus can approach 10%, so the adjustable range of phosphorus is wide; and the method has the advantages of simple process, convenient operation, no special requirements on equipment and easy realization of large scale industrial production. The invention further provides the phosphorus doped graphene prepared by using the preparation method.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

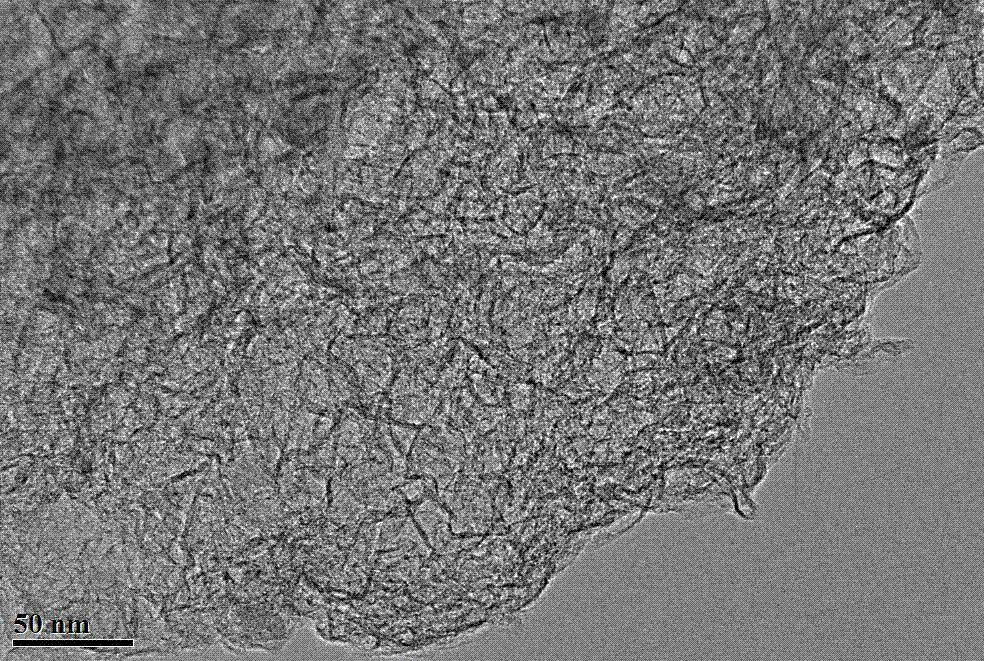

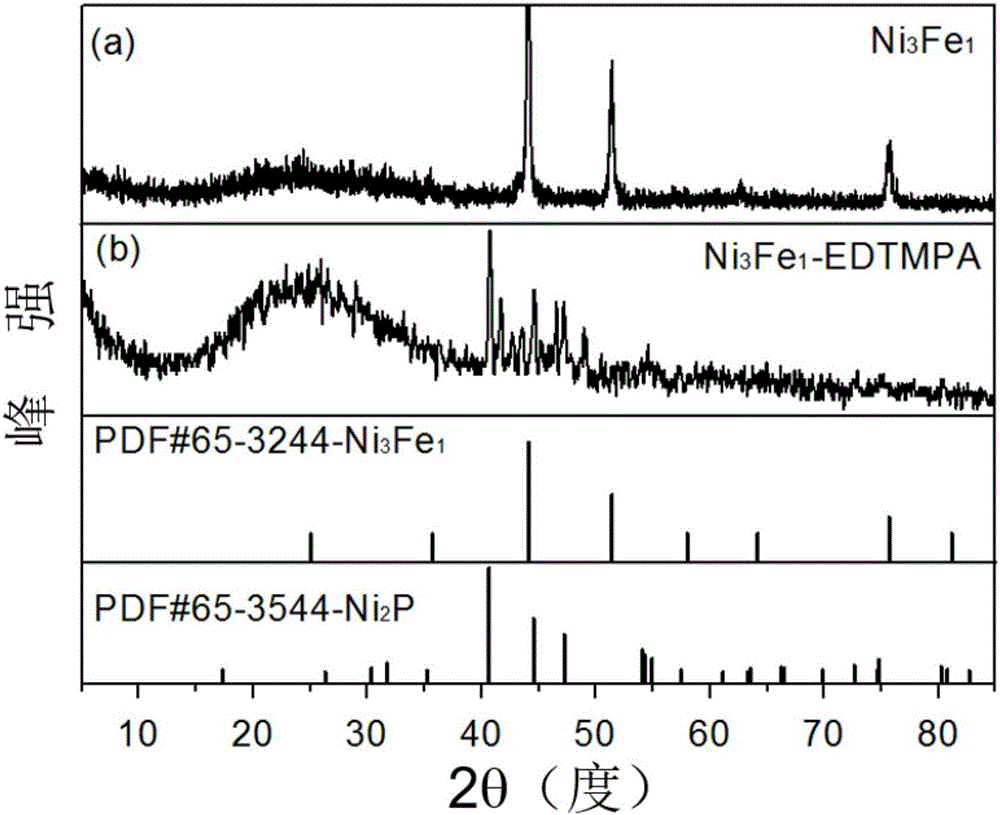

Transition metal embedded porous nitrogen-phosphorus-doped carbon material and preparation method and application thereof

ActiveCN106807427ALarge specific surface areaFully contactedPhysical/chemical process catalystsCell electrodesPhosphoric acidMetal particle

The invention provides a transition metal embedded porous nitrogen-phosphorus-doped carbon material, employing agar as a carbon source, metal ions as a fixing agent, and EDTMPA (ethylene diamine tetramethylene phosphoric acid) as a nitrogen and phosphorus source; the porous nitrogen-phosphorus-doped carbon material prepared has co-existing microscopic and mesoscopic structures and metal particles evenly distributed in a carbon carrier. Compared with the prior art, the preparation method according to the invention is simple, the cost of raw materials is low, nitrogen and phosphorus doping efficiency can be improved effectively, the specific surface area of the catalyst nanoparticles can be enlarged effectively, and the prepared porous nitrogen-phosphorus-doped carbon material has high surface active area and high graphitizing degree, is capable of increasing current intensity when the catalyst engages in catalytic reaction, and has excellent electrocatalytic activity and fast dynamical progress.

Owner:NANJING NORMAL UNIVERSITY

Preparation method of solar cell

InactiveCN101937945AOvercome defilementOvercome defectsFinal product manufactureSemiconductor devicesScreen printingSilicon oxide

The invention discloses a preparation method of a solar cell. The method comprises the following steps: providing a plurality of polycrystalline silicon wafers for texturization; overlapping the textured silicon wafers, depositing a silicon nitride or silicon oxide masking film on the periphery of the silicon wafers, then diffusing a phosphorus doping layer on the front surface of the to-be-prepared positive electrode of the silicon wafers to form a PN junction, wherein the periphery of the silicon wafers can not form the diffusion PN junction owning to the existence of the masking film; removing the peripheral masking film and the surface phosphosilicate glass; preparing a passivation layer and an antireflection layer; and performing screen printing and sintering to form a back Ag electrode, a back Al-back surface and a front Ag electrode. In the preparation method of the solar cell provided by the invention, the masking film is formed before the impurity source diffusion used for preparing the PN junction; owning to the existence of the masking film, the periphery of the silicon wafers can not form the PN junction; and the silicon wafers after diffusion is washed with acid to remove the masking film on the periphery of the silicon wafers and the phosphosilicate glass on the diffusion surface, thus achieving the aim of replacing the etching step.

Owner:百力达太阳能股份有限公司

Anion modified mercury-free catalyst for ethyne hydrochlorination reaction, and preparation method thereof

InactiveCN103272619AHarm reductionAvoid inactivationPhysical/chemical process catalystsPreparation by halogen halide additionPhosphatePyrophosphate

The invention discloses an anion modified mercury-free catalyst for an ethyne hydrochlorination reaction, and a preparation method thereof. The catalyst comprises a catalyst carrier and an active component, wherein the catalyst carrier is active carbon, the active component is a sulfate, a chloride, a phosphate or a pyrophosphate of copper or tin, and the carrier is acid-washed active carbon or phosphorus doped active carbon. The preparation method comprises preparing an active component impregnating solution, adding a catalyst carrier to carry out equivalent volume impregnation, drying, baking and other process steps. According to the present invention, acetylene and hydrogen chloride are mixed and then are subjected to a reaction in the catalyst system, wherein the catalysis system of the present invention has characteristics of environmental protection and safety compared with the current mercury catalyst in the industry; and the catalyst prepared by the preparation method has characteristics of high activity, high selectivity, good stability, and longer service life, and is more suitable for ethyne hydrochlorination reactions for producing vinyl chloride through a calcium carbide method compared with the general mercury-free catalyst.

Owner:TIANJIN UNIV

Power storage device

ActiveUS20120141866A1Charge-discharge efficiency can be improvedShorten charging timeNon-aqueous electrolyte accumulatorsHybrid capacitor electrodesLithiumAmorphous silicon

A power storage device which has improved performance such as higher discharge capacity and in which deterioration due to peeling or the like of an active material layer is less likely to be caused is provided. In an electrode for the power storage device, phosphorus-doped amorphous silicon is used for the active material layer over a current collector as a material that can be alloyed with lithium, and niobium oxide is deposited over the active material layer as a layer containing niobium. Accordingly, the capacity of the power storage device can be increased and the cycle characteristics and the charge-discharge efficiency can be improved.

Owner:SEMICON ENERGY LAB CO LTD

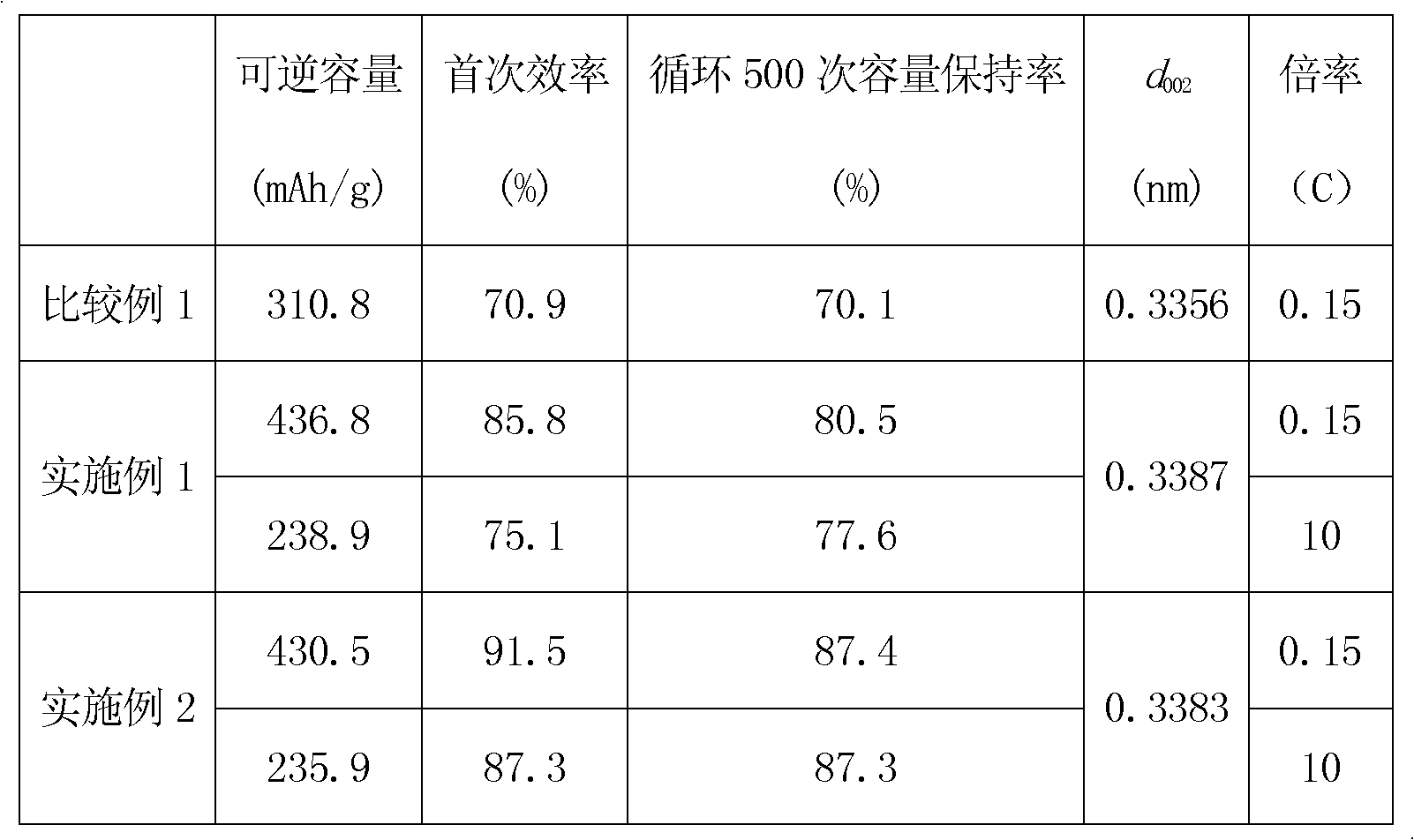

Carbon cladding layer expansion graphite composite material used for lithium ion batteries and preparation method thereof

InactiveCN101841019AImprove lithium intercalation spaceHigh reversible specific capacityCell electrodesPhosphatePhosphoric acid

The invention provides a carbon cladding layer expansion graphite composite material used for lithium ion batteries and a preparation method thereof. The carbon cladding layer expansion graphite composite material has a shell-kernel structure, wherein, the inner kernel is phosphorus-doped layer expansion graphite, and the layer spacing is 0.3360-0.3390nm; the outer shell is a pyrolysis product of phenolic resin; the carbon cladding layer expansion graphite composite material is prepared by the processes of raw material pretreatment, oxidized intercalation, cladding and layer removing; phosphoric acid dissolved with organic acid or a phosphate-nitrate system is adopted as oxidized intercalator. Lithium ion battery cathode prepared by the carbon cladding layer expansion graphite composite material of the invention has the characteristics of high capacity, high power and long service life. The preparation method of the invention has the characteristics of simple and easily operated process, and moderate and practical conditions and the like.

Owner:HUNAN UNIV

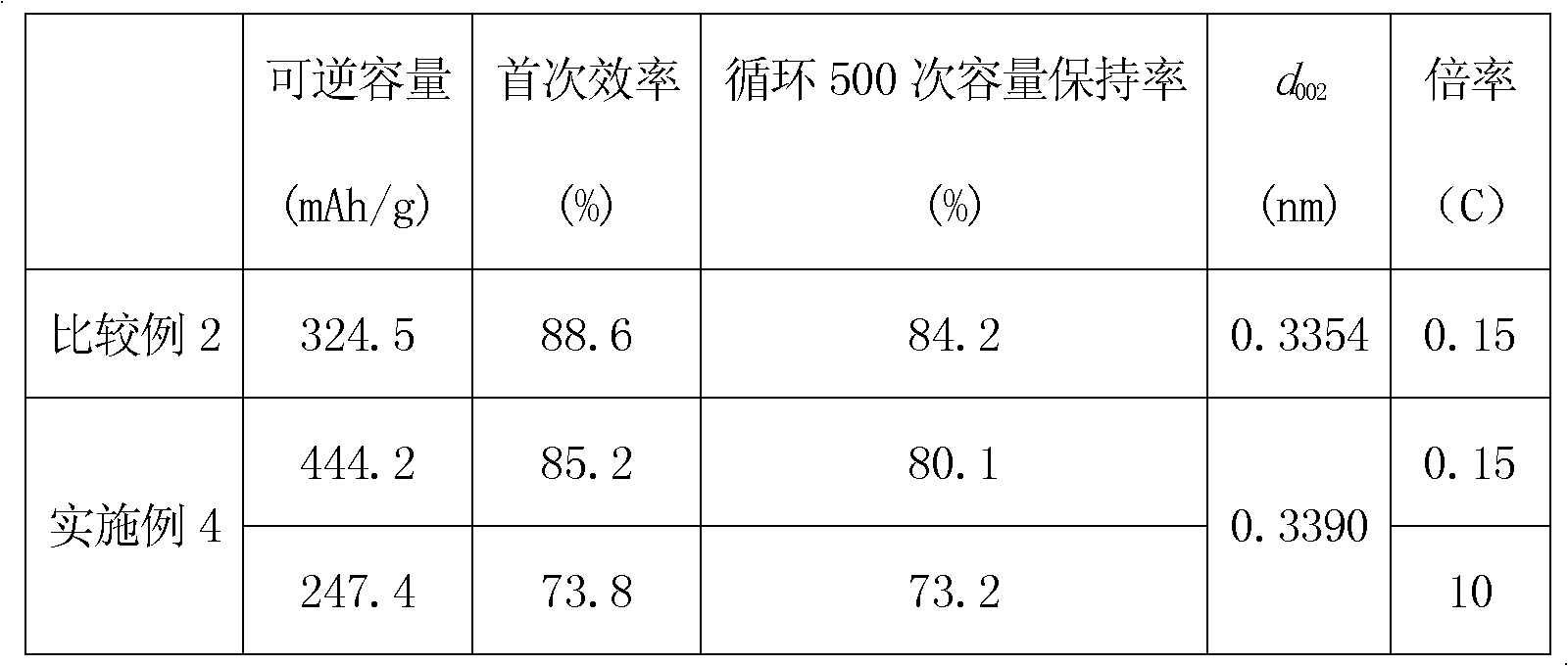

Method for batch green synthesis of nitrogen and phosphorus doped fluorescent carbon dots

ActiveCN106381143ALow costEasy to realize batchMaterial nanotechnologyNano-carbonQuantum yieldReaction temperature

The invention provides a method for batch green synthesis of nitrogen and phosphorus doped fluorescent carbon dots, wherein the method comprises the following steps: a first step, adopting a high-boiling-point polar organic solvent as a reaction medium, wherein the boiling point of the high-boiling-point polar organic solvent is greater than 180 DEG C; a second step, adopting organic small molecules as a carbon dot precursor, and adopting an auxiliary combination synthesis reagent; a third step, by a solvothermal reaction, mixing and dissolving the carbon dot precursor, phosphoric acid and the auxiliary combination synthesis reagent in the high-boiling-point polar organic solvent, controlling the reaction temperature and the reaction time, and preparing nitrogen and phosphorus doped fluorescent carbon dots; and a fourth step, purifying the mixed solution after the reaction of the third step, to obtain the high-purity fluorescent carbon dots. The water-soluble carbon dots with high fluorescence quantum yield can be further prepared in batch, and the fluorescent emission wavelength of the fluorescent carbon dots is controlled by controlling the reaction temperature and the reaction material ratio; the preparation process is green and pollution-free, has no need of special equipment, has the cost reduced, and is prone to realization of batching and scaling production.

Owner:SHANGHAI JIAO TONG UNIV

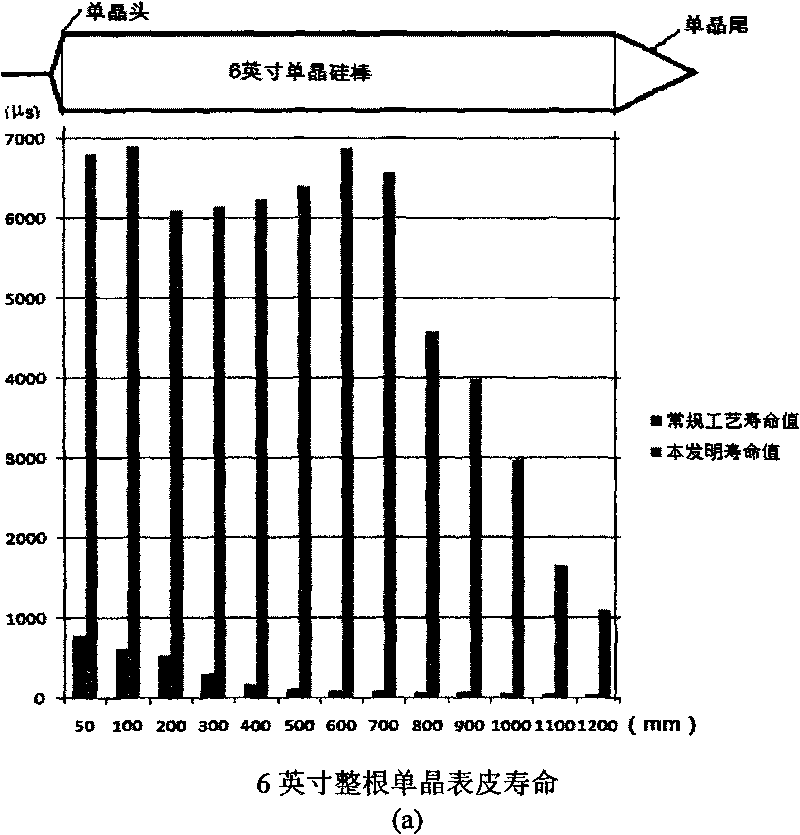

Growth process for N-type solar energy silicon single crystal with minority carrier service life of larger than or equal to 1,000 microseconds

InactiveCN101724899ASolve the problem of low lifespanPractical growing methodPolycrystalline material growthBy pulling from meltCrystal orientationSingle crystal

The invention relates to a growth process for N-type solar energy silicon single crystal with minority carrier service life of larger than or equal to 1,000 microseconds. The appearance is in 6-8 inches, the (100) crystal orientation resistivity range is between 1 omega.cm and 20 omega.cm, the minority carrier service life of the surface and the section is larger than or equal to 1,000 microseconds, the clearance oxygen content [Oi] is smaller than or equal to 17.5ppma, and the substituted carbon content [Cs] is smaller than or equal to 0.5ppma. Phosphorus-doped block-shaped polycrystalline silicon is used as a raw material to prepare the N-type solar energy silicon single crystal. The process comprises the steps of: charging, heating, leading diameter, maintaining equal diameter, collecting, cooling, heating by a program, stably heating and melting the material; after a thermal field in melting silicon is stable, leading the thin diameter, lifting the tail part of a single crystal to the upper edge of a guide cylinder with the cooling time of not larger than three hours. The crystal growth process is practical, has high efficiency and low cost, can prepare the N-type single crystal silicon which is completely larger than or equal to 1,000 microseconds from the head part to the tail part by a CZ method, and creates an industrialized foundation for efficiency improvement of an efficient solar battery.

Owner:任丙彦 +1

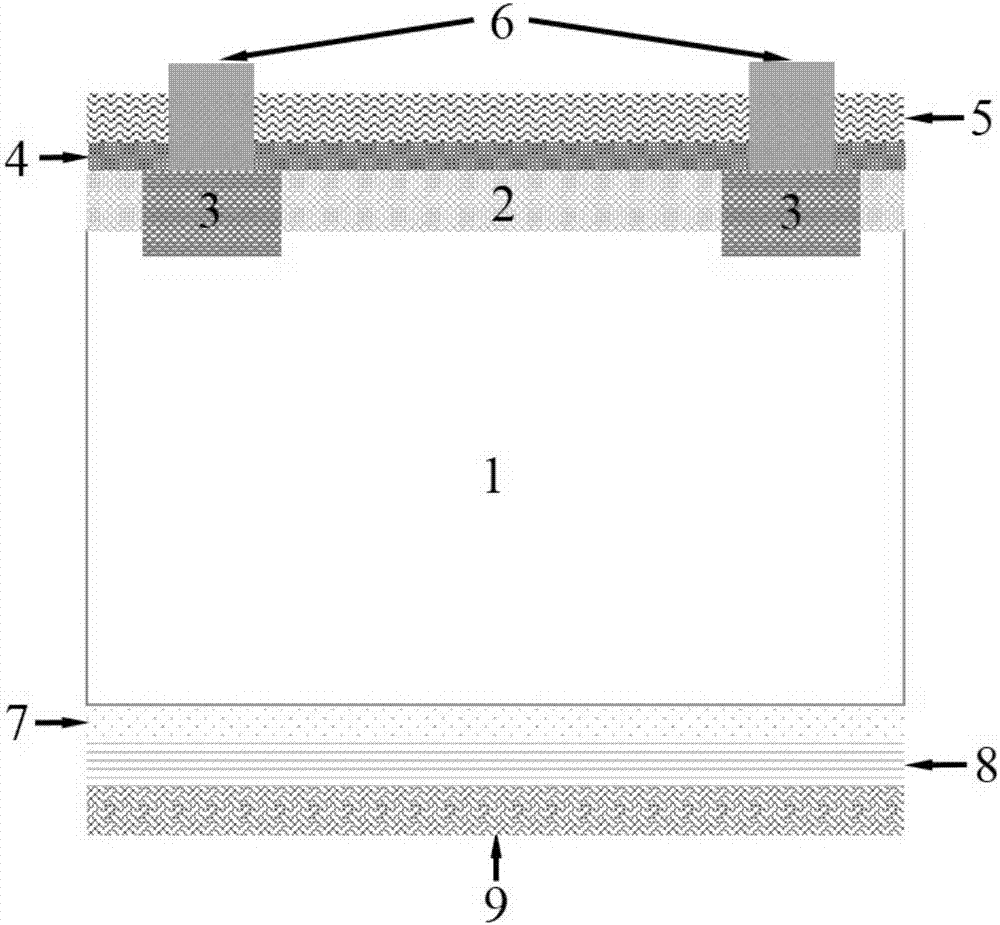

Selective emitter junction and tunneling oxide efficient N-type battery preparation method

InactiveCN107482079ASimple structureImprove composite speedFinal product manufacturePhotovoltaic energy generationOhmic contactSlurry

The invention relates to a selective emitter junction and tunneling oxide efficient N-type battery preparation method. The method comprises the steps of: performing texturing after removing a damaged layer of a silicon wafer, forming a boron-doped P+ emitter junction on the front surface, forming a local heavily doped region by means of laser treatment, growing an ultra-thin tunneling oxide layer and a phosphorus-doped silicon thin film on the back surface of the silicon wafer, depositing an aluminium oxide layer on the surface of the P+ emitter junction, growing a hydrogenated silicon nitride passivation antireflection layer on the front surface of the silicon wafer, and finally printing an Ag / Al slurry on the front surface of the silicon wafer. According to the selective emitter junction and tunneling oxide efficient N-type battery preparation method, a metalized ohmic contact structure of Ag or Al is formed on the back surface through metallization, low-temperature annealing is carried out by means of a drying oven, and the contact performance of electrodes is improved. Compared with the prior art, the selective emitter junction and tunneling oxide efficient N-type battery preparation method adopts the selective emitter junction on the front surface as well as the ultra-thin tunneling oxide layer (<4 nm) and the phosphorus-doped silicon thin film on the back surface, thus can significantly reduce the metal-semiconductor surface recombination on the front surface and the back surface, and has the most obvious advantage of being capable of greatly increasing electrical performance parameters on the basis of being compatible with the traditional battery manufacturing process.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

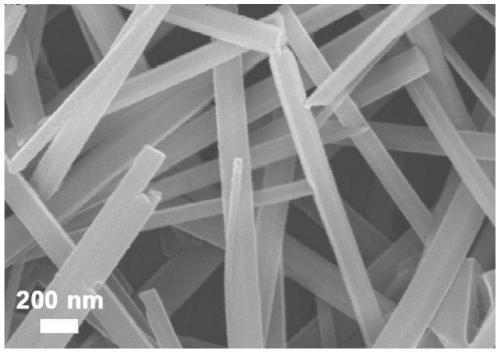

Phosphorus-doped cobalt nitride nanowire electrocatalyst as well as preparation method and application thereof

InactiveCN110433846AImprove conductivityIncrease surface areaPhysical/chemical process catalystsElectrodesNanowireSolvent

The invention relates to a phosphorus-doped cobalt nitride nanowire electrocatalyst as well as a preparation method and application thereof, and belongs to the technical field of electrocatalysis. Thepreparation method comprises the following steps: a cobalt metal salt and urea are used as raw materials, water is used as a solvent, a carbon cloth is used as a substrate, and a cobalt hydroxide nanowire precursor array is grown in situ on the surface of the carbon cloth substrate by a hydrothermal process; and the precursor array is placed in an ammonia gas atmosphere, high-temperature calcination is performed, the calcination product is placed in a tube furnace with a phosphorus source, calcination is performed for doping phosphorus, and finally the phosphorus-doped cobalt nitride nanowirecatalyst is obtained. According to the method provided by the invention, the catalyst obtained by the method has a material with nanowire morphology grown in situ, the nanowire structure has a largersurface area, the carbon cloth as a substrate has good electrical conductivity, so that the catalyst has superior performance in an electrocatalytic oxygen evolution reaction and an electrocatalytichydrogen evolution reaction; and at the same time, the process is simple to operate, and the catalyst is a non-precious metal, has low preparation costs and high stability, and has good application prospects in the oxygen evolution reaction and the hydrogen evolution reaction.

Owner:ZHEJIANG UNIV OF TECH

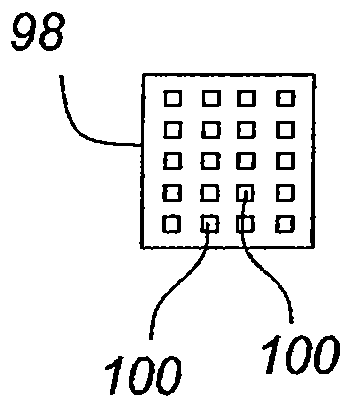

Arsenic and phosphorus doped silicon wafer substrates having intrinsic gettering

ActiveUS7485928B2Improve uniformityLow resistivityPolycrystalline material growthAfter-treatment detailsWaferingPhysical chemistry

Owner:GLOBALWAFERS CO LTD

Arsenic and phosphorus doped silicon wafer substrates having intrinsic gettering

ActiveUS20070105279A1Great wafer-to-wafer uniformityLow resistivityPolycrystalline material growthAfter-treatment detailsManufacturing technologyOxygen precipitates

Owner:GLOBALWAFERS CO LTD

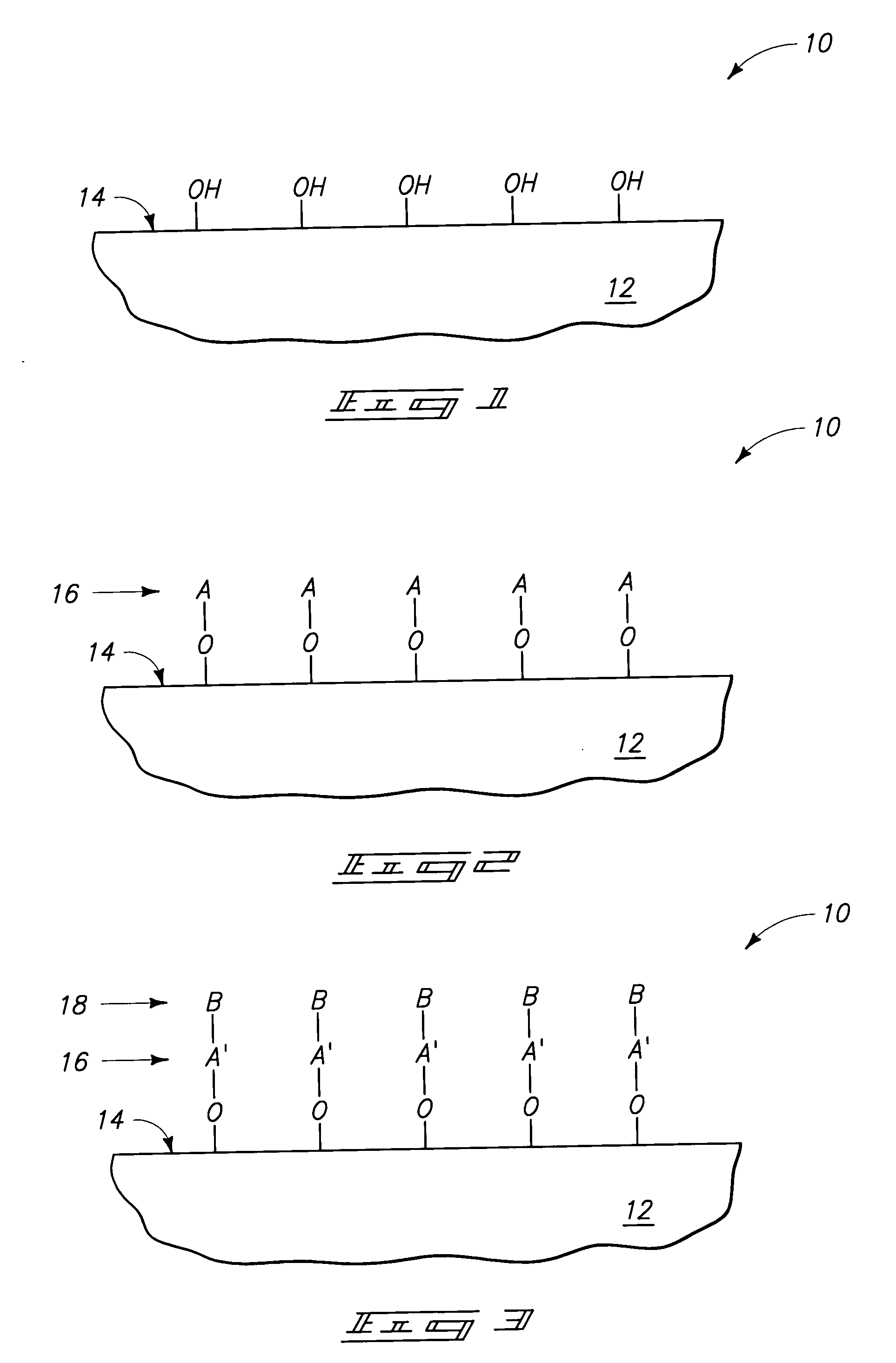

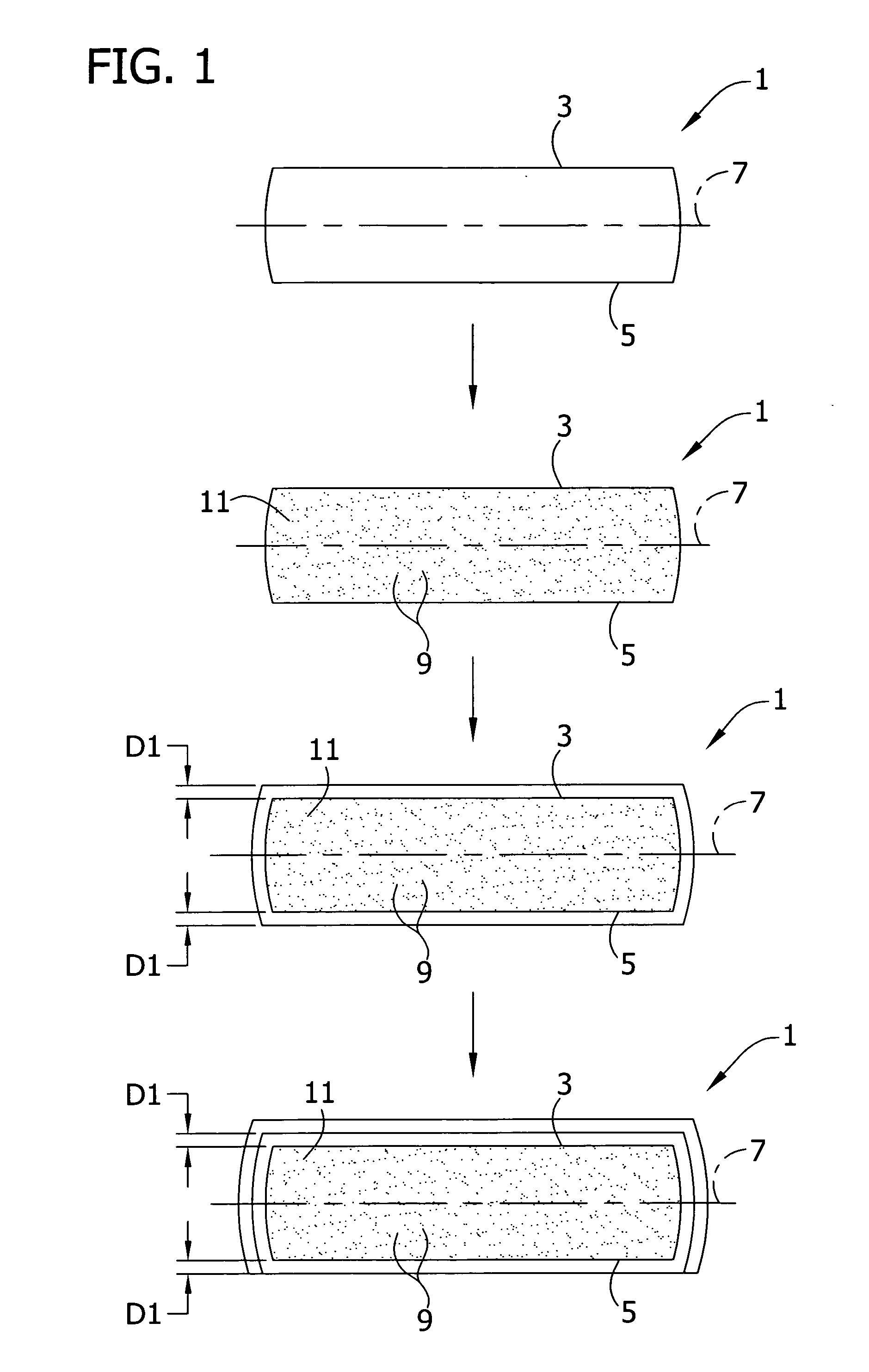

Nanowire device with improved epitaxy

InactiveUS9318553B1Improved epitaxyTransistorSemiconductor/solid-state device manufacturingNanowirePhosphorus doped

As disclosed herein, a method for fabricating a nanowire device with improved epitaxy, includes forming a nanowire stack on a substrate, the nanowire stack having one or more sacrificial layers, where the substrate includes a bulk substrate, an oxide layer, and an extremely thin silicon (ETSOI) layer, removing the sacrificial layers, depositing and patterning a gate material over the nanowire stack, the gate material having sidewalls, covering the sidewalls of the gate material with a spacer layer, and epitaxially growing an in-situ doped layer comprised of doped silicon from the ETSOI layer. The ETSOI may have a (100) crystallographic orientation. A pFET source / drain may be epitaxially grown by including an in-situ doped layer of boron doped SiGe. An nFET source / drain may be epitaxially grown by including an in-situ doped layer of phosphorus doped Si:C. A device corresponding to the method is also disclosed herein.

Owner:IBM CORP

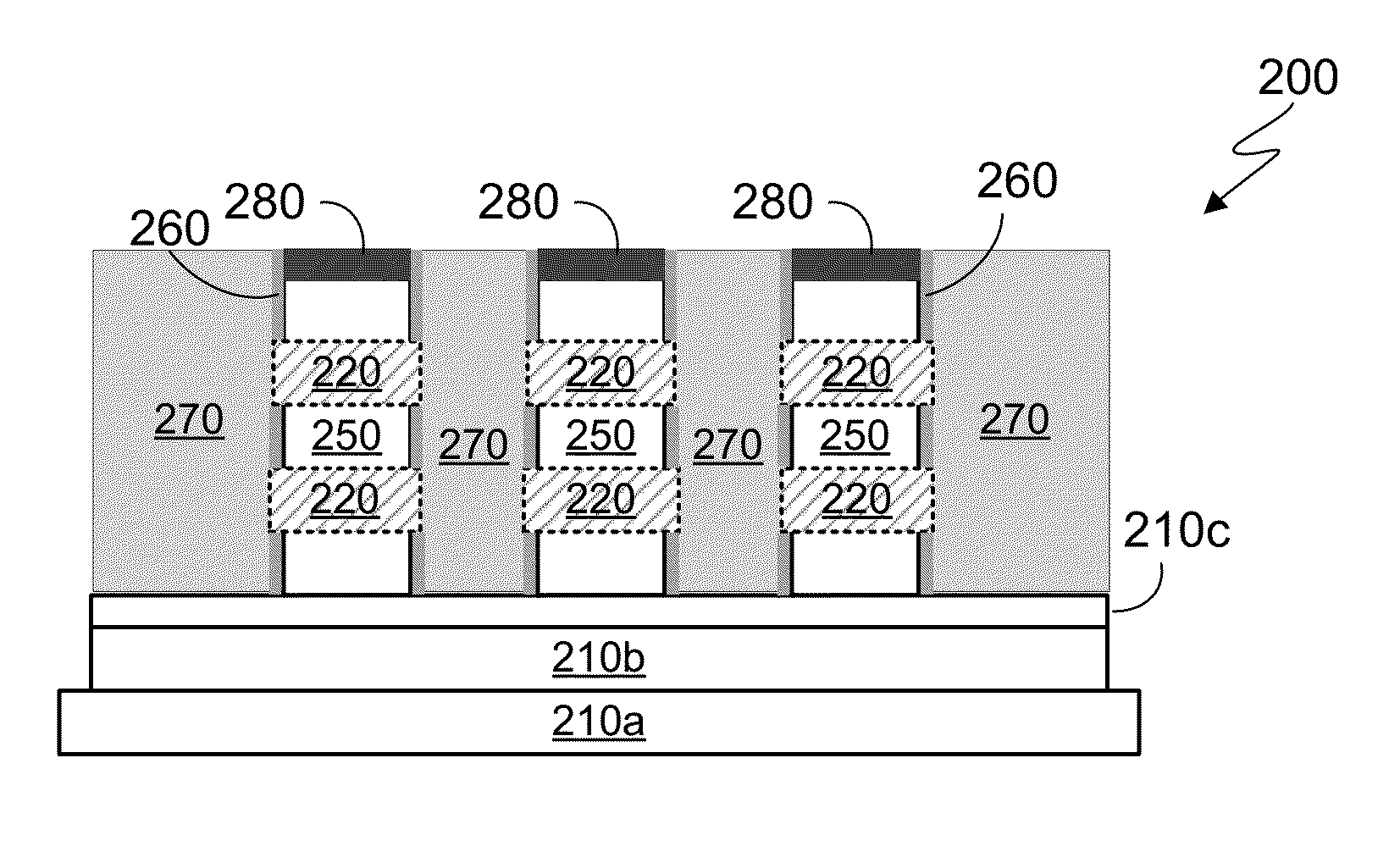

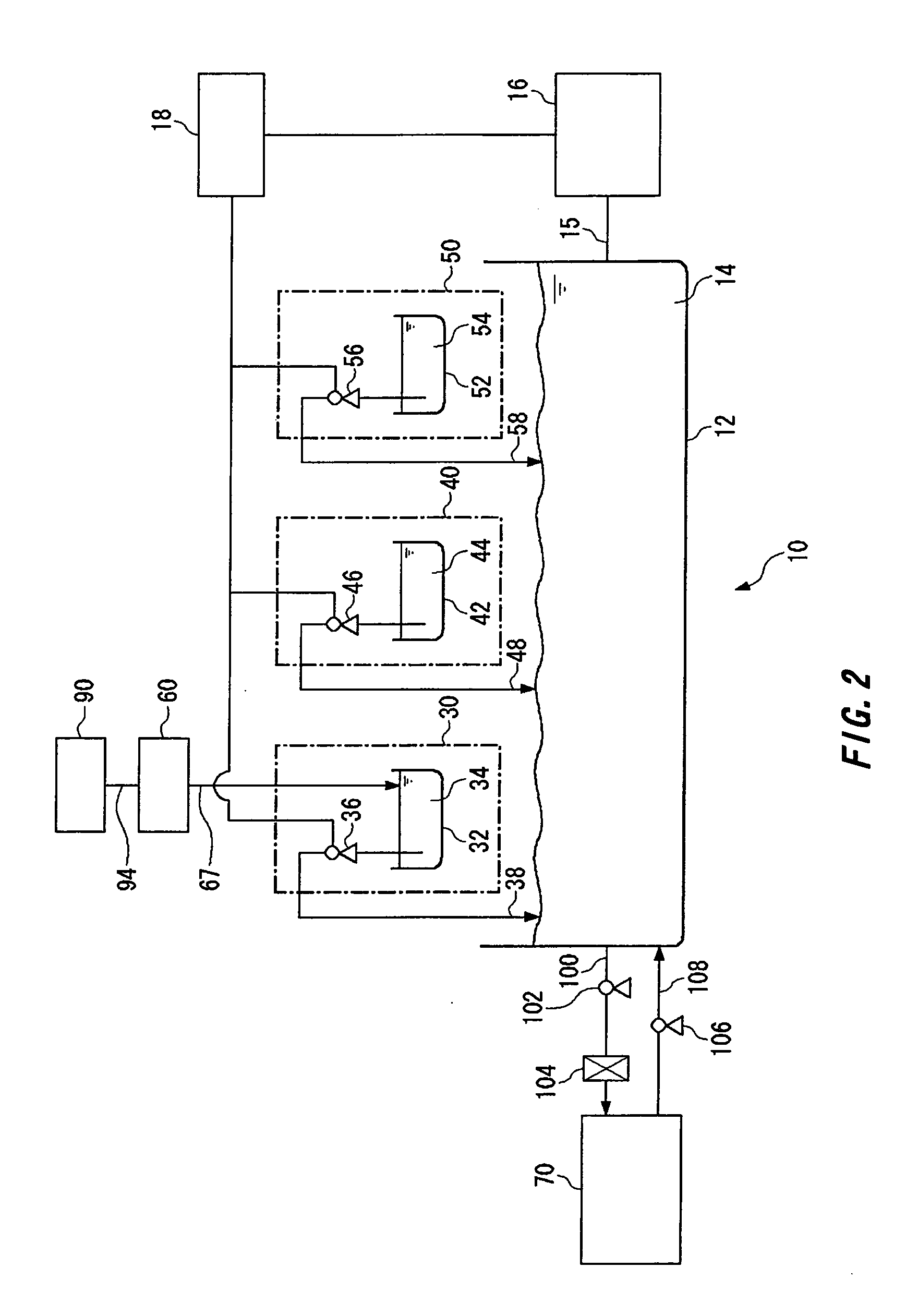

Plating method, plating apparatus and a method of forming fine circuit wiring

InactiveUS20050126919A1Reduce the amount requiredPossibility of deteriorationCellsPrinted element electric connection formationIon contentElectrical resistance and conductance

A copper plating film has a lower chlorine ion content. Circuit wiring of high electromigration resistance is formed by electroplating. In a method of copper plating using a leveler containing a nitrogen-containing high molecular compound, the leveler is dechlorinated prior to its use for plating. A plating apparatus has a tank for preparing a plating solution, a device for dechlorinating a leveler, a leveler supply station for supplying the dechlorinated leveler to the tank and a plating station. A method of forming fine circuit wiring includes forming a circuit with a phosphorus-doped copper plating layer on a substrate for an electronic circuit having a fine circuit pattern, a barrier layer and any necessary seed layer formed thereon.

Owner:EBARA CORP +1

Phosphorus-doped nickel cobaltate/foam nickel electrode, preparation method and applications thereof

InactiveCN110195235AIncrease transfer rateExcellent electrocatalytic oxygen evolutionElectrode shape/formsElectrolysisNickel electrode

The invention belongs to the field of electrode materials, and particularly relates to a phosphorus-doped nickel cobaltate / foam nickel electrode, a preparation method and applications thereof. The preparation method comprises: sequentially carrying out cutting treatment, ultrasonic cleaning treatment and drying treatment on foam nickel so as to be spare; dissolving Co(NO3)2.6H2O, Ni(NO3)2.6H2O andurea in deionized water, and uniformly stirring to obtain a hydrothermal solution; inserting the foam nickel into a polytetrafluoroethylene mold base, wherein the foam nickel is maintained in a vertical state; maintaining the 120 DEG C for 5-8 h, cooling to a room temperature, washing, drying, calcining, and cooling to a room temperature to obtain a nickel cobaltate / foam nickel electrode; and placing the nickel cobaltate / foam nickel electrode and NaH2PO2.2H2O in a quartz boat, placing the quartz boat in a tubular furnace, and phosphating to obtain the phosphorus-doped nickel cobaltate / foam nickel electrode. According to the present invention, the obtained phosphorus-doped nickel cobaltate / foam nickel electrode can be used as the cathode for hydrogen evolution in water electrolysis, can further be used as the anode for oxygen evolution, is a dual-function electrode, and has good economy and environmental protection.

Owner:YANCHENG INST OF TECH

Preparation method of phosphorus-doped two-dimensional carbon material and application thereof in sodium-ion battery

ActiveCN105609777ASimple manufacturing methodConditions are easy to controlNon-aqueous electrolyte accumulatorsCell electrodesElectricityPhosphate

The invention discloses a preparation method of a phosphorus-doped two-dimensional carbon material and application thereof in a sodium-ion battery. The method comprises the step of putting the mixture of carbon quantum dots and phosphate in an inert atmosphere for high-temperature calcination to obtain the phosphorus-doped two-dimensional carbon material. The method is simple and convenient in operation, short in period and high in yield, and is beneficial for industrial production; and the obtained phosphorus-doped two-dimensional carbon material as an electrode material can be used for preparing the sodium-ion battery with excellent electrical performance.

Owner:CENT SOUTH UNIV

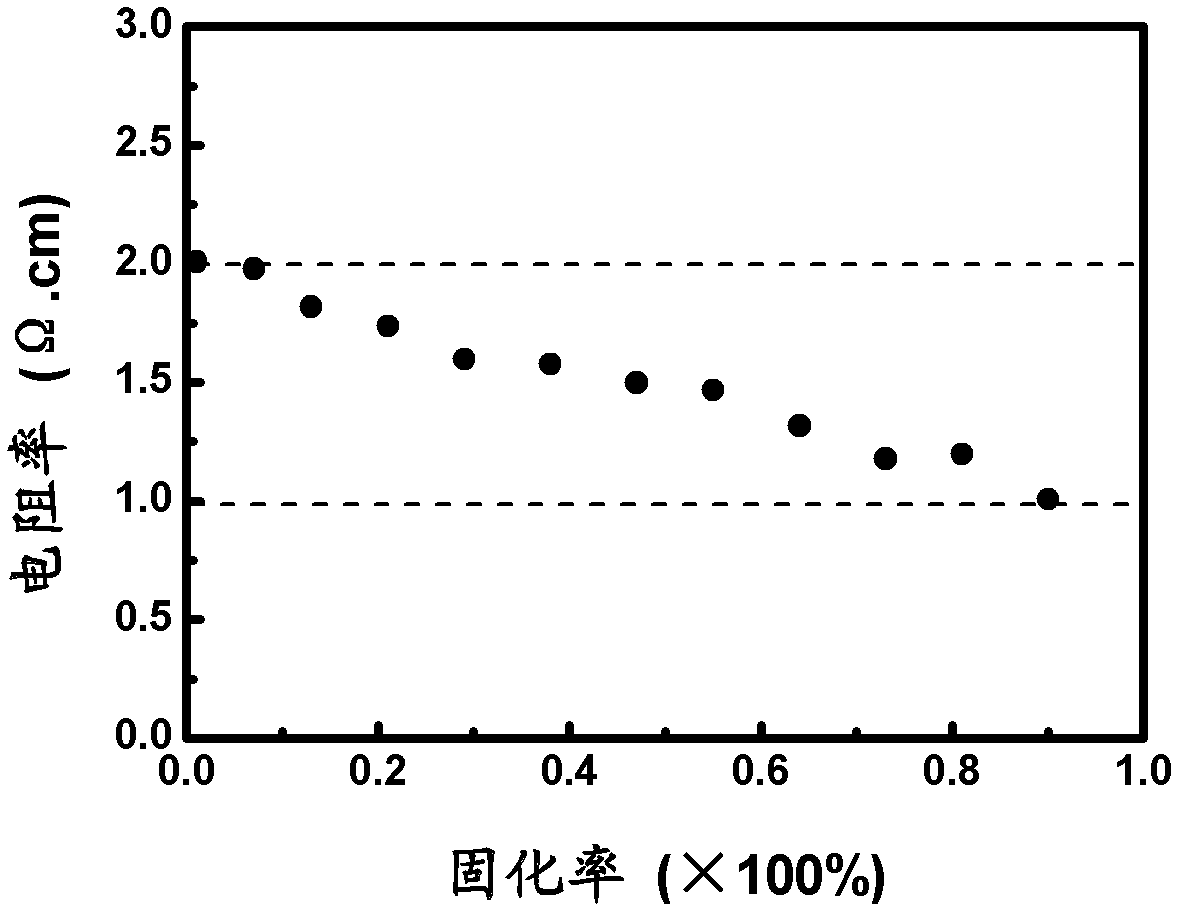

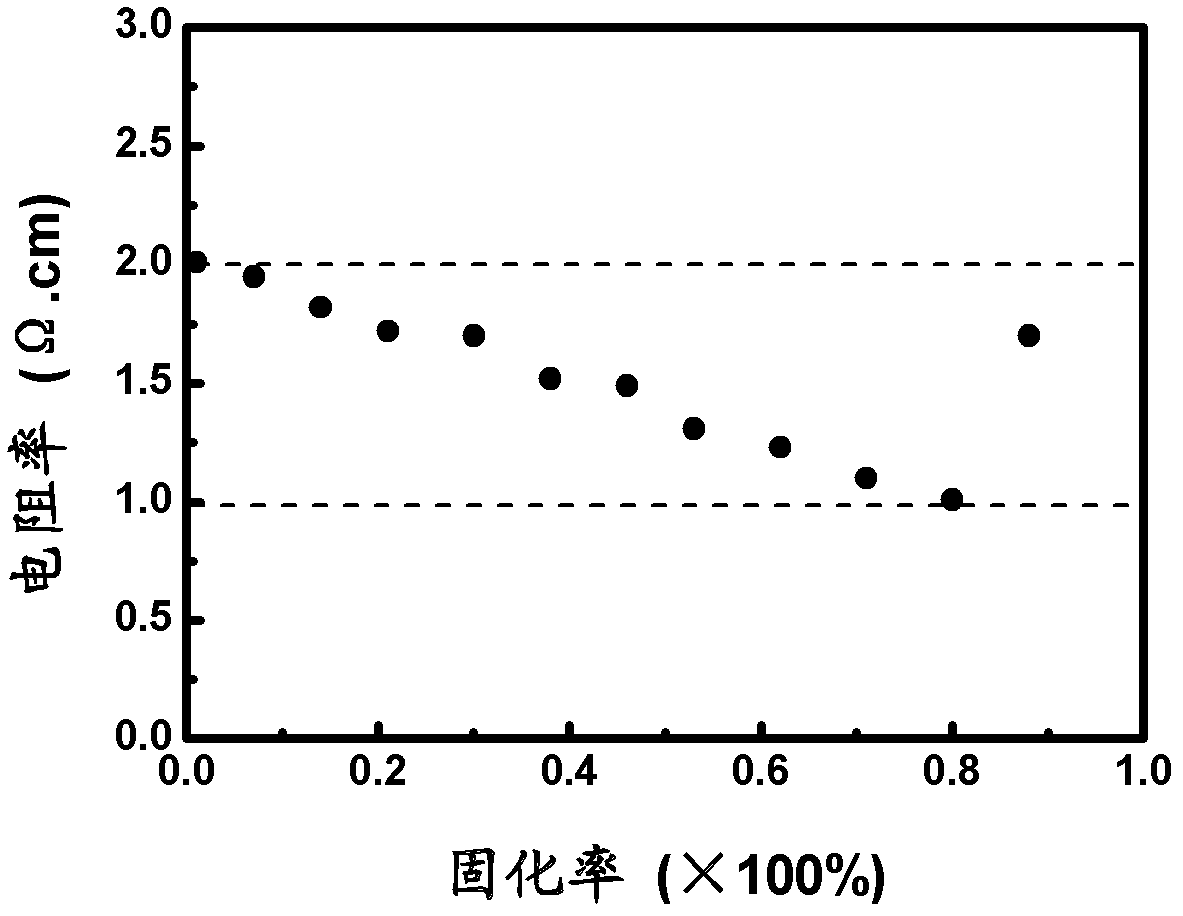

N-type casting policrystalline silicon with uniform doping resistivity and preparation method thereof

ActiveCN102560641AIncrease profitReduce manufacturing costPolycrystalline material growthSingle crystal growth detailsPhotovoltaic industryIngot

The invention discloses an N-type casting policrystalline silicon with a uniform doping resistivity and a preparation method thereof. The preparation method comprises the following steps of: mixing a polycrystalline silicon material, a phosphorus doping agent and gallium; then fusing; and growing a polycrystalline silicon body by using a casting method. According to the N-type casting policrystalline silicon with the uniform doping resistivity, the resistivity of about 90% N-type phosphorus doping phosphorus doping cast ingots can be controlled in the range of 1.0-2.0 omega.cm, therefore, the utilization rate of the N-type polycrystalline silicon crystal in the process of manufacturing an efficient solar cell is beneficially improved, the manufacturing cost of the efficient solar cell is remarkably lowered, the preparation method is simple to operate and easy to popularize and use in the photovoltaic industry.

Owner:ZHEJIANG UNIV

Phosphorus-doped cadmium zinc sulfide solid solution catalyst, photocatalytic system and method for producing hydrogen through water decomposition

ActiveCN107790160AEnhanced light absorptionVisible light catalytic activity is highPhysical/chemical process catalystsHydrogen productionHydrogenDecomposition

The invention discloses a phosphorus-doped cadmium zinc sulfide solid solution catalyst. The phosphorus-doped cadmium zinc sulfide solid solution catalyst adopts a chemical formula of P-ZnxCd1-xS, wherein x is greater than or equal to 0 and smaller than or equal to 1. The invention further discloses a preparation method of the phosphorus-doped cadmium zinc sulfide solid solution catalyst. The preparation method comprises the following steps: uniformly mixing a cadmium zinc sulfide solid solution and a phosphorus source, and performing a phosphorization reaction to obtain the phosphorus-doped cadmium zinc sulfide solid solution catalyst. By the preparation method, raw materials have few types and are cheap and easy to obtain, a reaction condition is mild, and operation is easy. The invention further discloses a comprises a photocatalytic system comprising the phosphorus-doped cadmium zinc sulfide solid solution catalyst. Any cocatalyst and any electronic sacrificial agent are required to be added in the photocatalytic system, a reaction system is simple, and the water decomposition is catalyzed under a pure water condition, so that practical application is more facilitated.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com