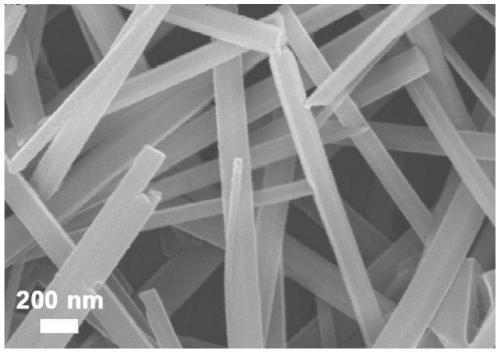

Phosphorus-doped cobalt nitride nanowire electrocatalyst as well as preparation method and application thereof

A cobalt nitride sodium and phosphorus doping technology, which is applied in the field of electrocatalysis, can solve the problems of further improvement in catalytic activity and stability, and achieve the effects of improving catalytic activity and stability, good conductivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the synthesis of P-CoN / CC nanowire catalyst

[0030] 1) Sonicate the carbon cloth in nitric acid, acetone, absolute ethanol, and deionized water for 30 minutes to remove impurities on the surface of the carbon cloth substrate, then wash it with a large amount of deionized water, and finally dry it in vacuum at 60°C for later use. ;

[0031] 2) Weigh 356mg of cobalt chloride hexahydrate, add 450mg of urea into 40mL of distilled water, and ultrasonically disperse it for 30 minutes to obtain a solution with a concentration of 37.5mmol / L;

[0032] 3) Put the solution obtained in step 2) and the pretreated carbon cloth in step 1) together into a hydrothermal kettle for hydrothermal reaction at 100°C for 12 hours. After cooling to room temperature, take out the carbon cloth, and then use distilled water and ethanol respectively Each was washed 3 times, and then placed in a vacuum drying oven at 60°C for vacuum drying to obtain a cobalt hydroxide precursor catal...

Embodiment 2

[0038] Embodiment 2: Synthesis of CoN / CC nanowire catalyst

[0039] 1) Sonicate the carbon cloth in nitric acid, acetone, absolute ethanol, and deionized water for 30 minutes to remove impurities on the surface of the carbon cloth substrate. Then wash it with a large amount of deionized water, and finally, dry it under vacuum at 60°C, and set it aside;

[0040] 2) Weigh 476mg of cobalt chloride hexahydrate, add 600mg of urea into 80mL of distilled water, and ultrasonically disperse it for 30 minutes to obtain a solution with a concentration of 25mmol / L;

[0041] 3) Put the solution obtained in step 2) together with the pretreated carbon cloth into a hydrothermal kettle for hydrothermal reaction at 120°C for 8 hours, take out the carbon cloth after cooling to room temperature, and wash with distilled water and ethanol for 3 Then, place it in a vacuum drying oven and dry it under vacuum at 60°C to obtain the cobalt hydroxide precursor catalyst Co(OH) grown in situ on the carbon...

Embodiment 3

[0045] Example 3: Co(OH) 2 Synthesis of / CC nanowire catalysts

[0046] 1) Sonicate the carbon cloth in nitric acid, acetone, absolute ethanol, and deionized water for 30 minutes to remove impurities on the surface of the carbon cloth substrate. Then wash it with a large amount of deionized water, and finally, dry it under vacuum at 60°C for later use.

[0047] 2) Weigh 238mg of cobalt chloride and 300mg of urea into 40mL of distilled water, and ultrasonically disperse them evenly for 30 minutes to obtain a solution with a concentration of 25mmol / L;

[0048] 3) Put the solution obtained in step 2) together with the pretreated carbon cloth into a hydrothermal kettle for a hydrothermal reaction at 140°C for 10 hours. After cooling to room temperature, take out the carbon cloth, and then wash with distilled water and ethanol for 3 Once again, place it in a vacuum drying oven at 60°C and dry it under vacuum to obtain the cobalt hydroxide catalyst Co(OH) grown on the carbon cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com