Phosphorus-doped nickel cobaltate/foam nickel electrode, preparation method and applications thereof

A technology of nickel foam and nickel cobaltate, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the problems of limited application, low stability, low reserve, etc., and achieve reduced consumption, good stability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of phosphorus-doped nickel cobaltate / foam nickel electrode, comprising the following steps:

[0030] (1) Preparation of foamed nickel: Cut the foamed nickel into a rectangle with a size of 1cm×1.5cm, soak the foamed nickel in 3M HCl, acetone, absolute ethanol and deionized water in sequence for ultrasonic cleaning, each time for 10 minutes;

[0031] (2) Add 232.84mgCo(NO 3 ) 2 ·6H 2 O, 116.3mgNi(NO 3 ) 2 ·6H 2 O, 72mg urea and 30mL deionized water were mixed, and after stirring for 30 min, a hydrothermal solution was obtained.

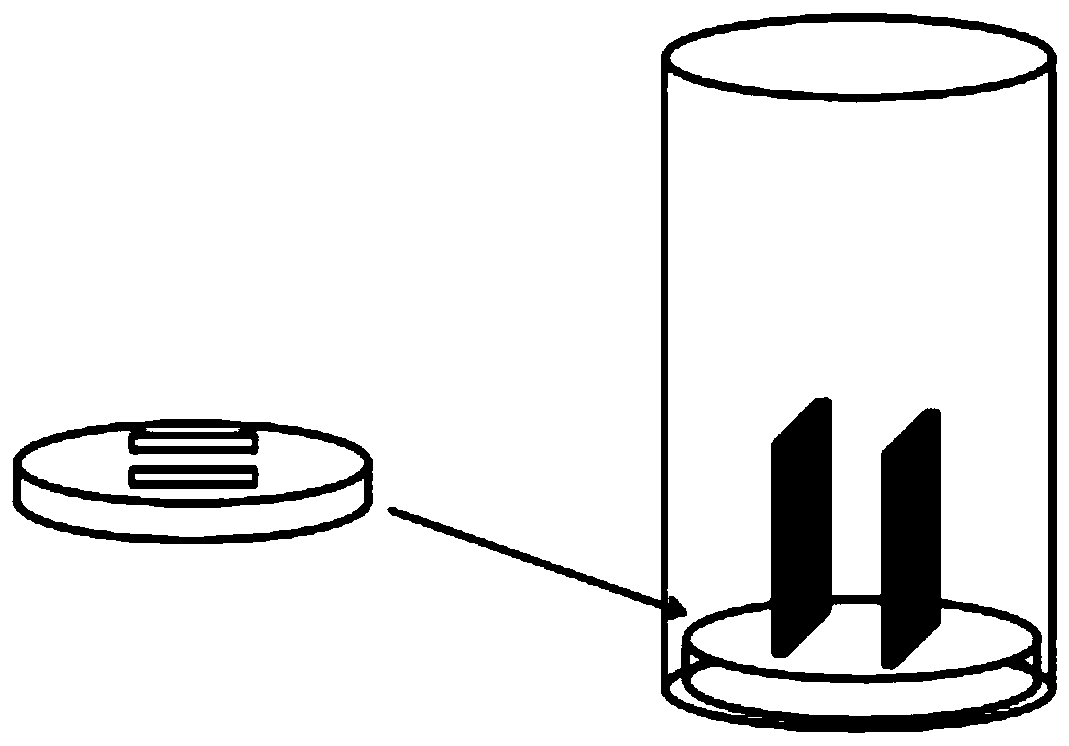

[0032] (3) Add the dried nickel foam and the prepared hydrothermal solution into a 50ml reactor, keep it warm at 120°C for 8 hours, pour the prepared hydrothermal solution into the high-pressure reactor, and fix the nickel foam vertically in the high-pressure reactor. At the bottom of the reactor, after fastening the autoclave, place the autoclave in a blast drying oven. After the heat preservation is over, cool to ro...

Embodiment 2

[0037] A preparation method of phosphorus-doped nickel cobaltate / foam nickel electrode, comprising the following steps:

[0038] (1) Preparation of foamed nickel: Cut the foamed nickel into a rectangle with a size of 1cm×1.5cm, soak the foamed nickel in 3M HCl, acetone, absolute ethanol and deionized water in sequence for ultrasonic cleaning, each time for 12 minutes;

[0039] (2) Add 200mgCo(NO 3 ) 2 ·6H 2 O, 100mgNi(NO 3 ) 2 ·6H 2 O. 50mg urea and 25mL deionized water were mixed, and after stirring for 25 min, the hydrothermal solution was obtained.

[0040] (3) Add the dried nickel foam and the prepared hydrothermal solution into a 50ml autoclave, keep it warm at 120°C for 8 hours, pour the prepared hydrothermal solution into the autoclave, and fix the foam nickel vertically on the The bottom of the autoclave (such as figure 1 shown), after fastening the autoclave, place the autoclave in a blast drying oven. After the heat preservation is over, cool to room temperat...

Embodiment 3

[0044] A preparation method of phosphorus-doped nickel cobaltate / foam nickel electrode, comprising the following steps:

[0045] (1) Preparation of foamed nickel: Cut the foamed nickel into a rectangle with a size of 1cm×1.5cm, soak the foamed nickel in 3M HCl, acetone, absolute ethanol and deionized water in sequence for ultrasonic cleaning, each time for 10 minutes;

[0046] (2) 300mgCo(NO 3 ) 2 ·6H 2 O, 200mgNi(NO 3 ) 2 ·6H 2 0, 100mg urea and 30mL deionized water were mixed, and the hydrothermal solution was obtained after stirring for 30 min.

[0047] (3) Add the dried nickel foam and the prepared hydrothermal solution into a 50ml reaction kettle, keep it warm at 120°C for 8 hours, pour the prepared hydrothermal solution into the high-pressure reaction kettle, and fix the nickel foam vertically in the reaction kettle Bottom of kettle (such as figure 1 shown), after fastening the autoclave, place the autoclave in a blast drying oven. After the heat preservation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com